Large-size high-speed invisible flying saucer

A flying saucer and disc-shaped technology, applied in aircraft, aircraft control, aircraft parts, etc., can solve the problems of invisibility, poor vertical maneuverability, and inability to load loads, etc., to achieve mature manufacturing technology, improve vertical maneuverability, and increase speed and mobility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

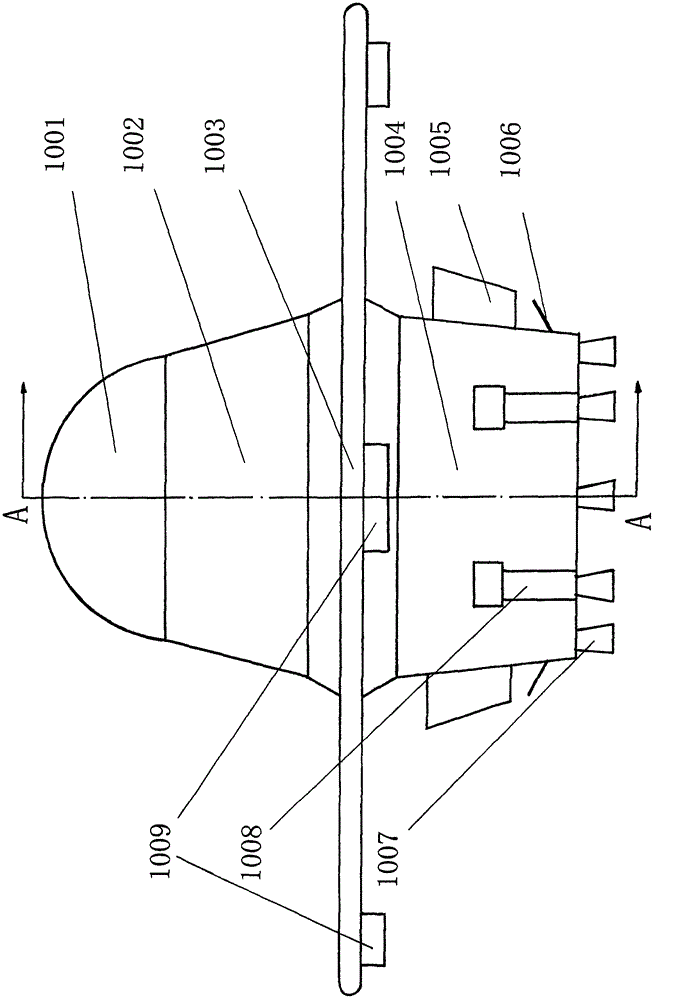

[0054] figure 1 It is the front view of the flying saucer of the present invention, as shown in the figure, the flying saucer is composed of cockpit 1001, passenger compartment 1002, disc-shaped wing 1003, equipment compartment 1004, fixed wing surface 1005, infrared emitter 1006, vector engine 1007, landing gear 1008, rotary motor 1009, etc. constitute.

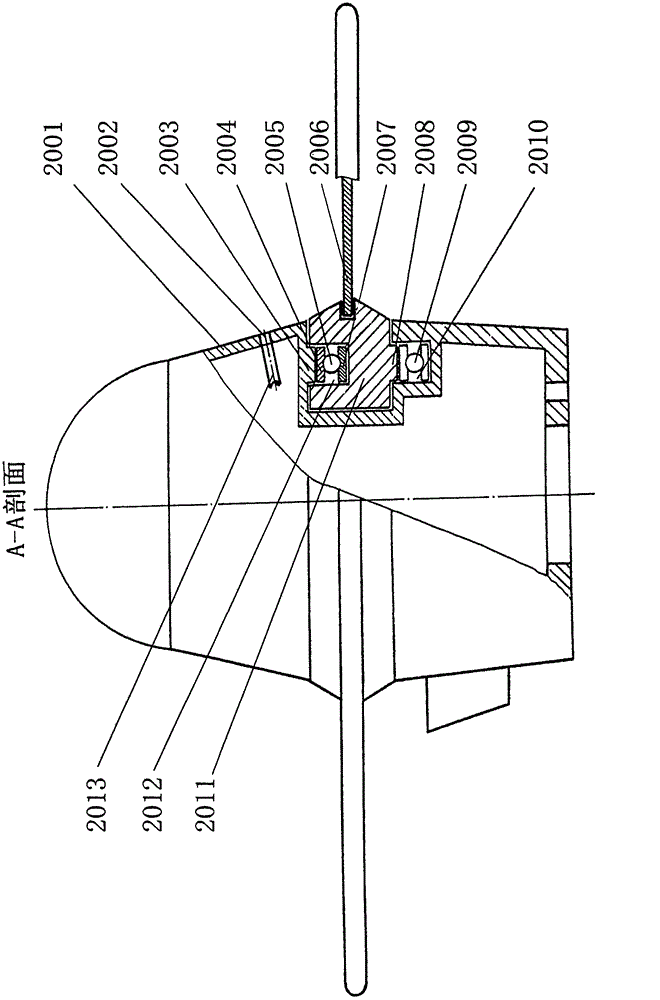

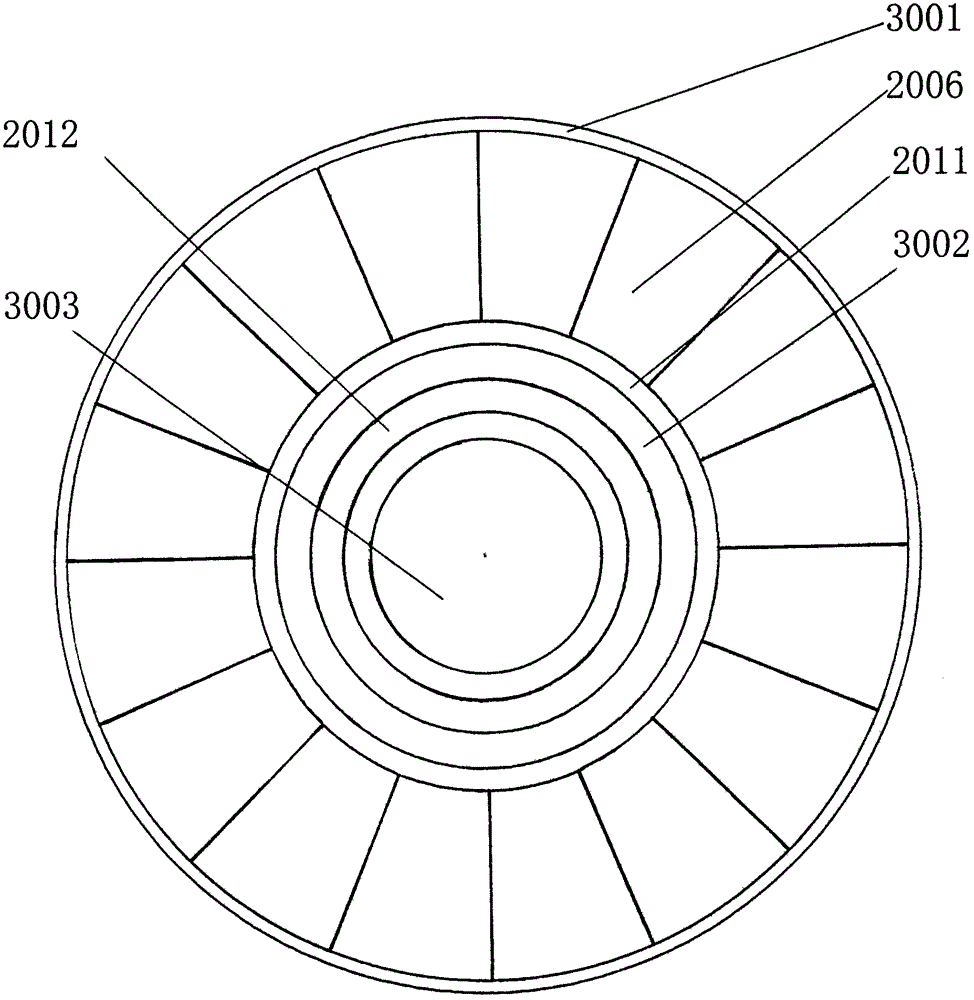

[0055] figure 2 It is a schematic view of the partial structure of the vertical section of the embodiment of the present invention, showing the internal conditions of the rolling contact between the nacelle and the disc-shaped wing through thrust ball bearings. Thrust ball bearing upper ring 2004, thrust ball bearing steel ball 2005, blade 2006, thrust ball bearing lower ring 2007, wheel hub annular flange 2008, lower thrust ball bearing 2009, equipment cabin annular groove 2010, wheel hub 2011, wheel hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com