Rechargeable textile cleaning twisting gun

A rechargeable and clean technology, applied in the direction of textiles and papermaking, etc., can solve the problems of easy falling out of the fixed position by external force, no axial positioning of the rolling needle, and many hidden troubles, so as to achieve convenient and fast start-stop operation switching and improve operation The effect of stability and guaranteed rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

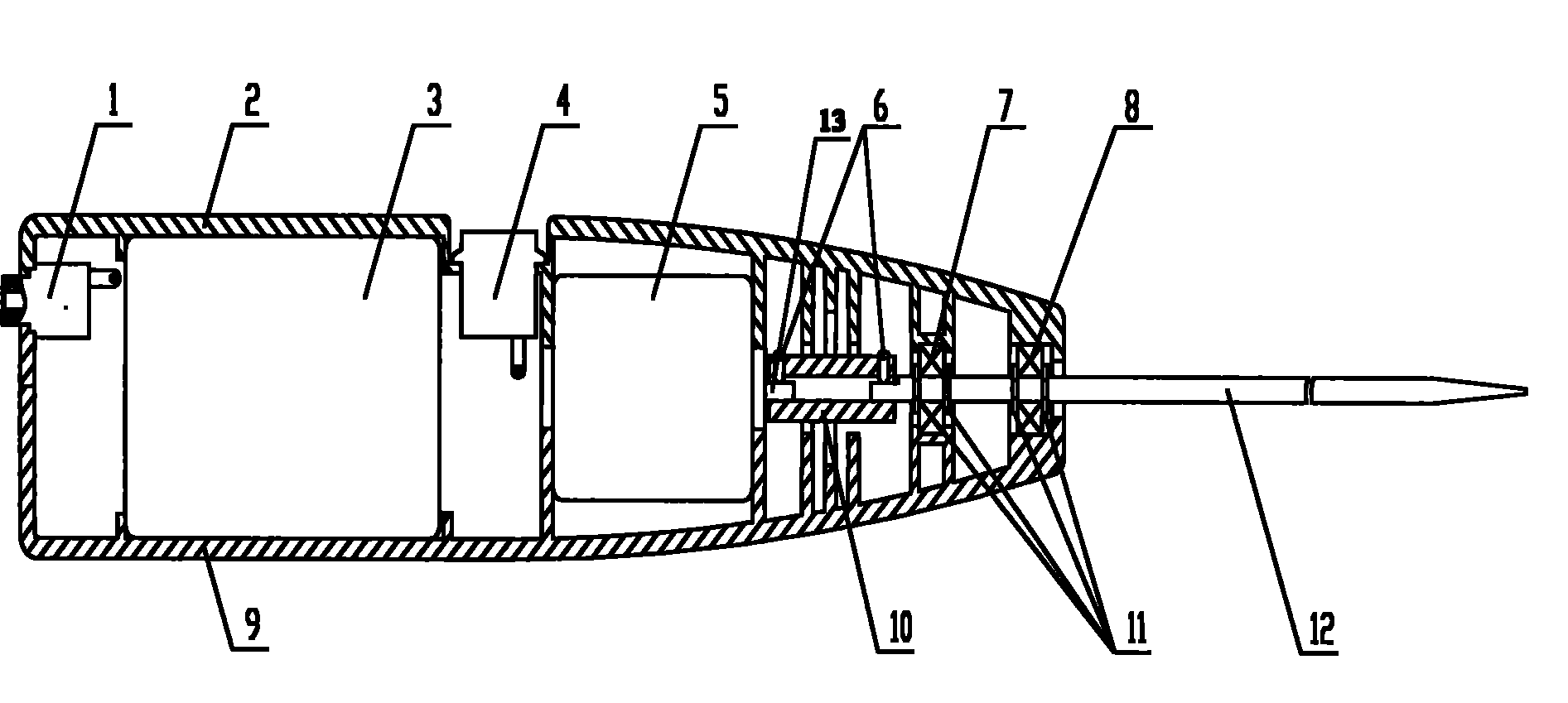

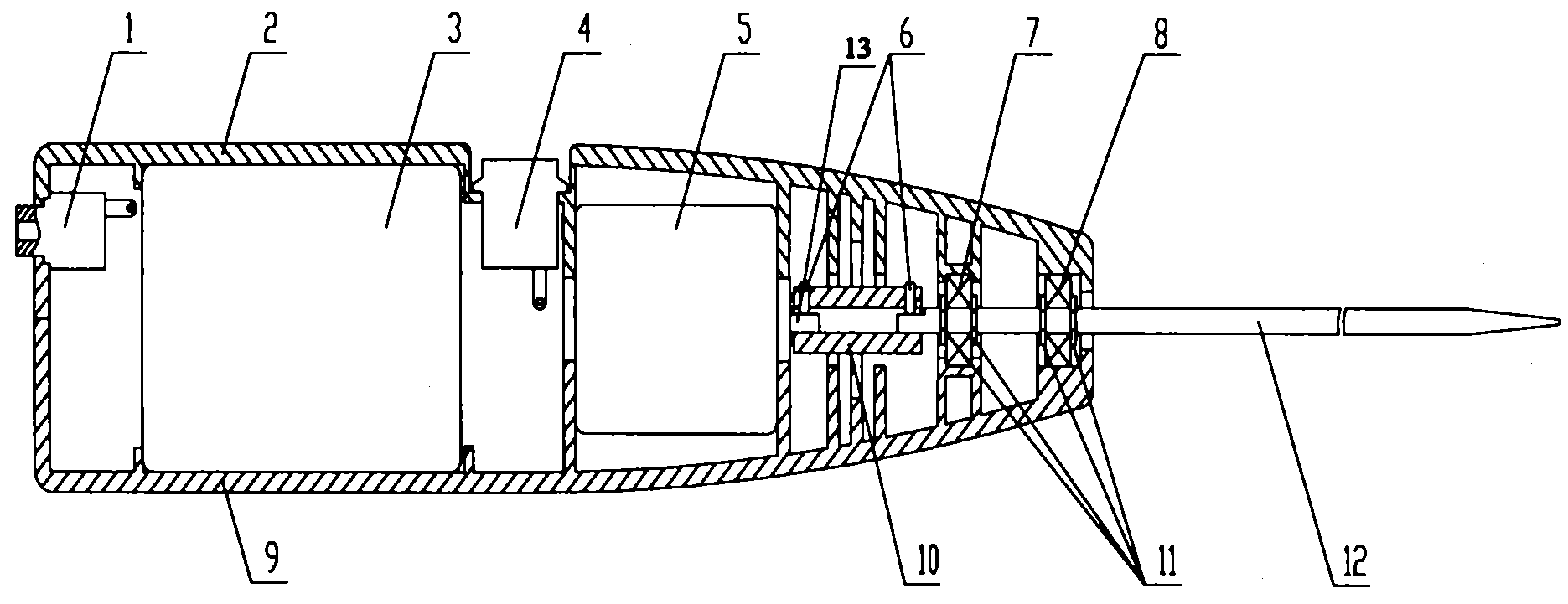

[0015] This embodiment proposes a charging type textile cleaning twist gun, including a housing, the housing is preferably composed of an upper housing 2 and a lower housing 9, and the accommodation space formed by the cooperation of the upper housing 2 and the lower housing 9 accommodates electrical connections The battery 3 and the motor 5, the end of the housing is provided with the charging interface 1 of the battery 3, the middle part of the housing is provided with a motor switch 4, the rotating shaft 13 of the motor 5 is connected to the winding needle 12 by transmission, preferably, the rotating shaft 13 of the motor 5 passes through the connecting sleeve 10. Drive and connect the coil needle 12. The connecting sleeve 10 is preferably made of copper. Specifically, the part where the rotating shaft 13 is inserted into the connecting sleeve 10 has a flat section. To locate the rotating shaft 13; the part where the rolling needle 12 is inserted into the connecting sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com