Numerical control machine tool spindle box system with embedded braking mechanism

A braking mechanism and technology of numerically controlled machine tools, which are applied in the directions of driving devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of fast wear of friction plates, reduced machining accuracy of machine tools, and short service life, etc., and achieve slow friction and wear, The effect of short braking time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

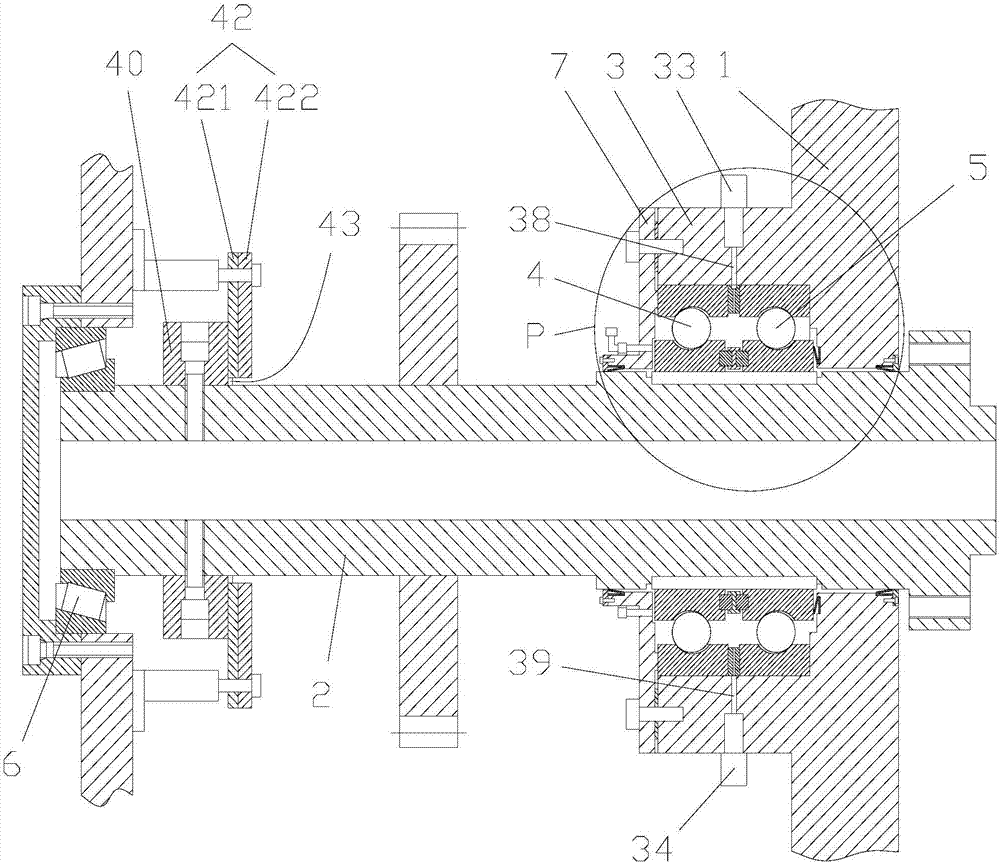

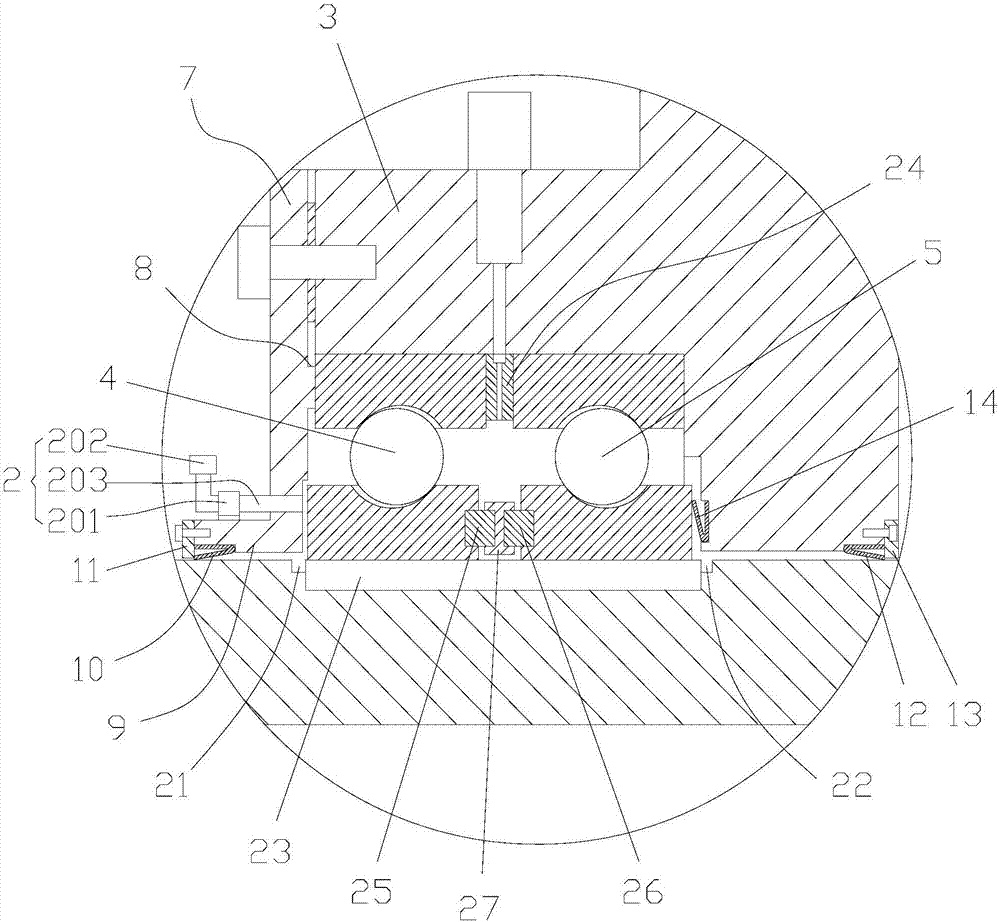

[0030]As shown in the figure, the CNC machine tool spindle box system with embedded braking mechanism in this embodiment includes a box body 1 and a main shaft 2; a bearing seat 3 is formed on the inner side of the box body, and the front end of the main shaft passes through two One deep groove ball bearing is installed on the bearing housing inside the box, the first deep groove ball bearing 4 of the two deep groove ball bearings is close to the middle of the box, and the second deep groove ball bearing 5 is close to the outside of the box; The rear end of said main shaft is installed on the casing by angular contact bearing 6.

[0031] The headstock system of this embodiment also includes a main shaft brake, the main shaft brake includes a brake ring 40 fixed on the main shaft by screws, and the brake ring is close to the angular contact bearing. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com