Device for precisely boring lug hole of hinge beam

A hinge and fine boring technology, applied in the direction of positioning device, boring/drilling, boring bar, etc., can solve the problems of locking of the boring bar and the support hole, low production efficiency, prolonged processing time, etc., to ensure the processing accuracy , Improve production efficiency, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

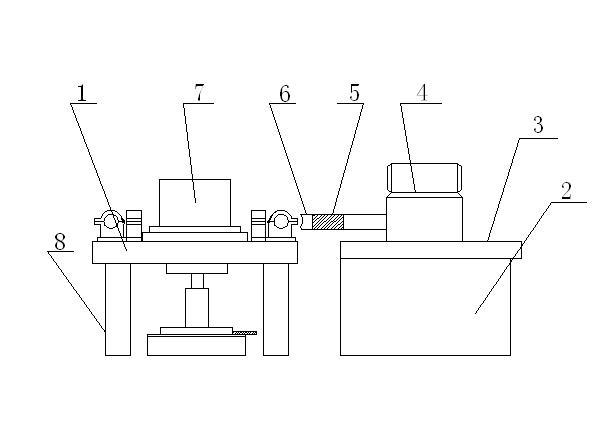

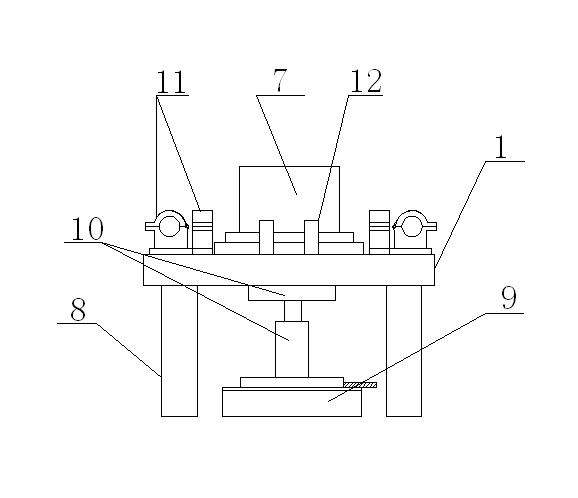

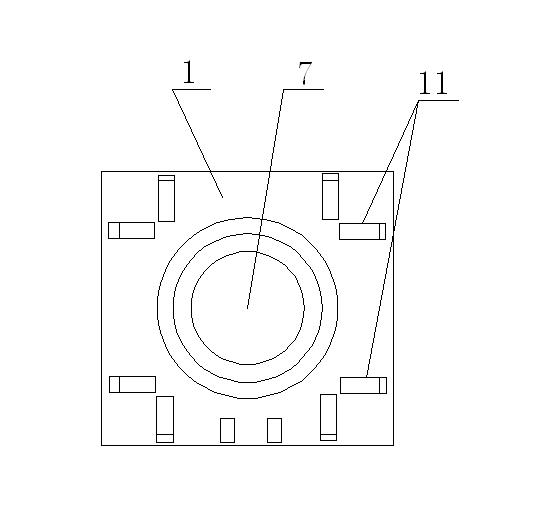

[0025] As shown in the figure, a device for finely boring the ear hole of the hinge beam is mainly composed of a boring frame 1 for fixing the hinge beam, a machine bed 2, a power unit 4 and a boring bar 6. One end of the boring bar 6 passes through the The knuckle coupling 5 is connected with the output shaft of the power unit 4, and the power slide 3 is set on the machine bed 2, the power unit 4 is set on the power slide 3, and the boring frame 1 is supported by four supporting columns 8. Support, a lifting and rotating mechanism 10 is provided at the bottom of the boring mold frame 1, and the lifting and rotating mechanism 10 is arranged on a fixed support seat 9, and a central positioning sleeve 7 and a clamping mechanism 12 are fixed on the upper part of the boring mold frame 1 for The positioning and fixed clamping of the hinge beam cylinder body, the upper surface of the boring mold frame 1 is provided with a boring bar support 11, which is used to support the boring bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com