Two-stage machine tool gearing, in particular spindle gearing

A technology of machine tool transmission and transmission mechanism, which is applied in transmission devices, gear transmission devices, mechanical equipment, etc., can solve the problems of friction power, diameter and speed increase, and achieve the effects of improving efficiency, reducing rotational inertia, and improving running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

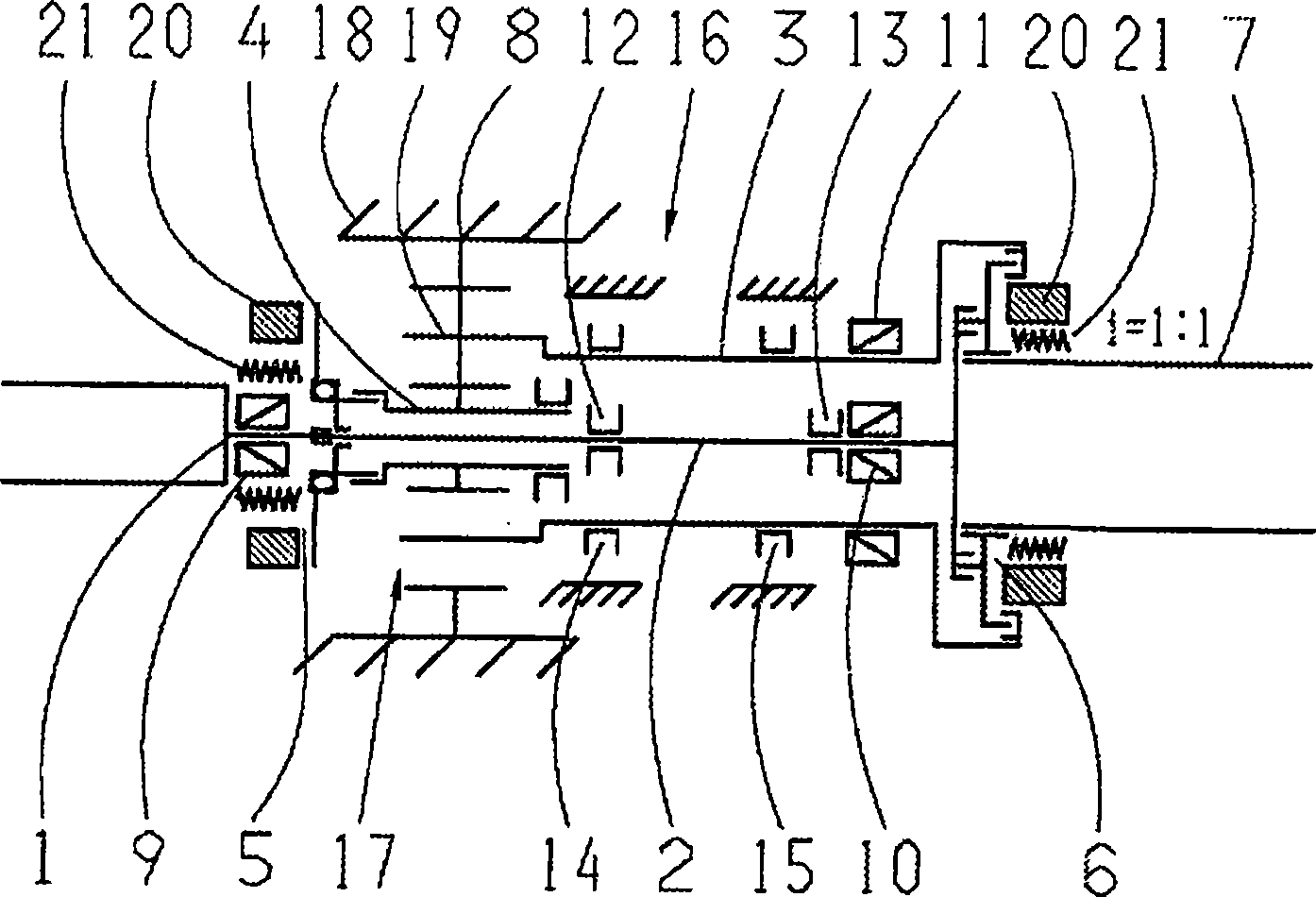

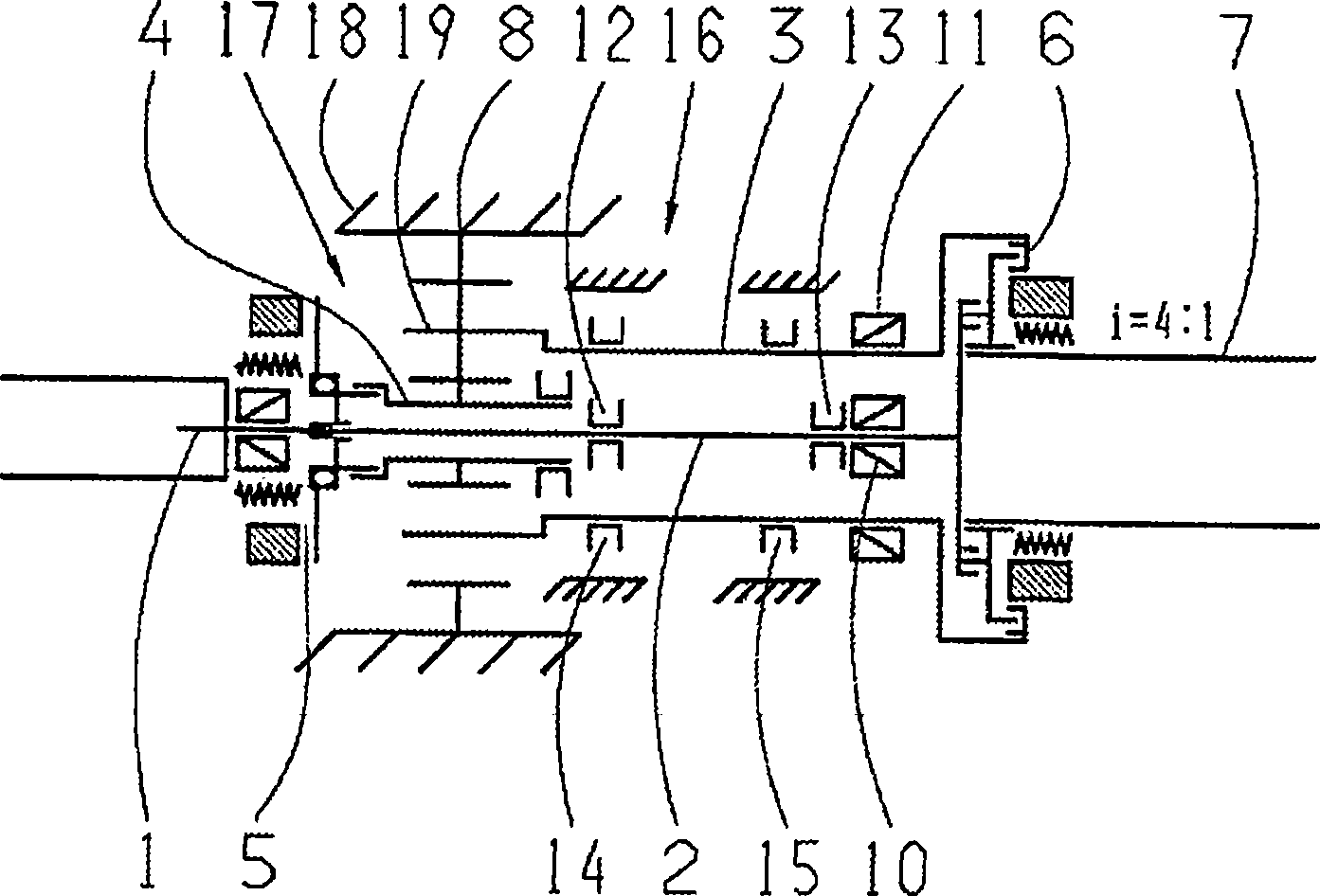

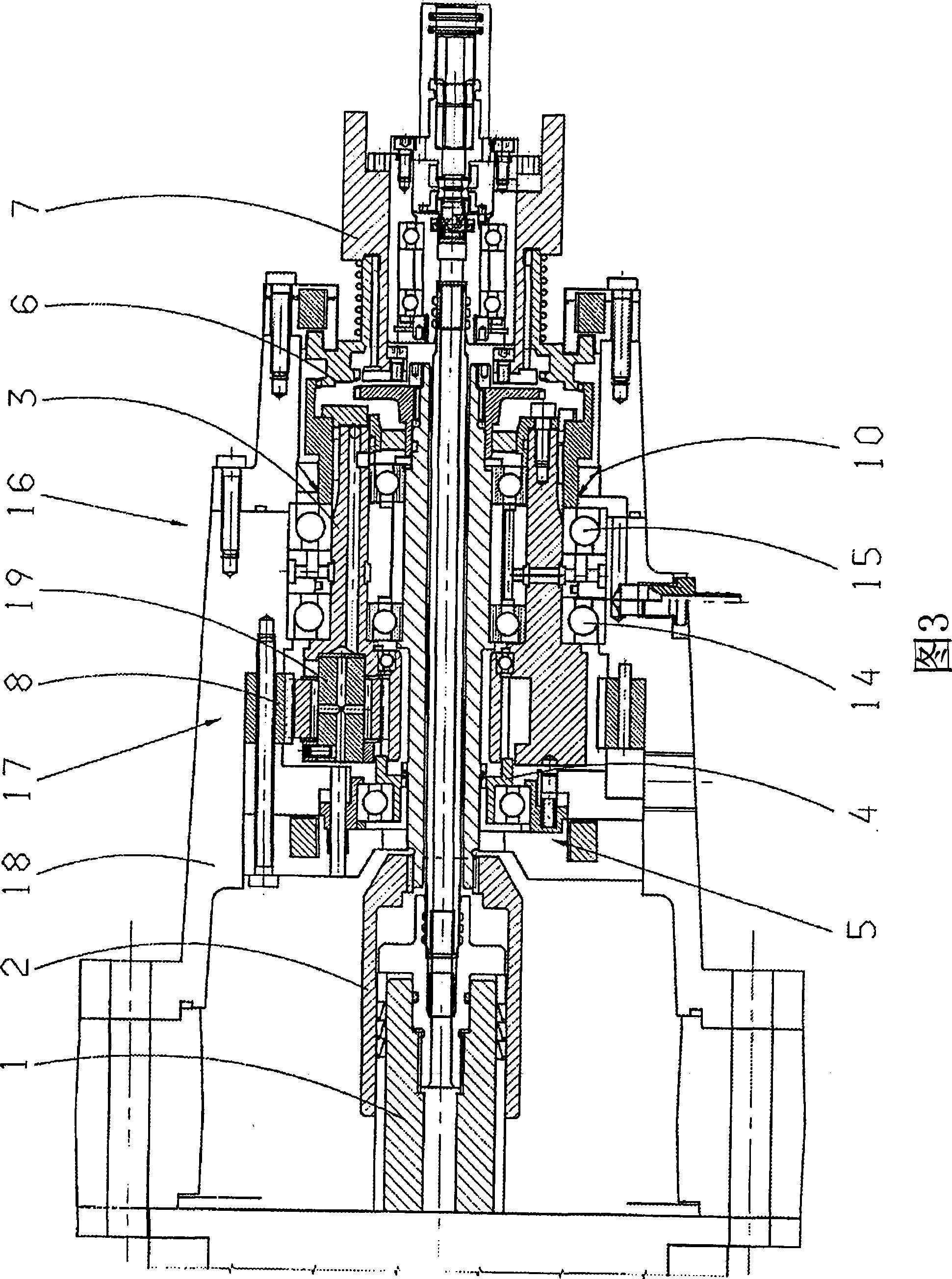

[0026] refer to figure 1 , according to the invention the machine tool transmission 16 comprises a planetary gear set 17, a drive shaft (motor shaft) 1, a first driven shaft 2, which is connected to the drive shaft 1 in a rotationally fixed manner and can be connected to the planetary gear set The center wheel 4 of 17 is detachably connected via the first switching element 5 . Furthermore, a second driven shaft 3 is provided, which is connected in a rotationally fixed manner to the spacer 19 of the planetary gear set 17 , and a second switching element 6 is provided, which establishes the connection between the main shaft 7 or the main shaft insert and the optional second A detachable connection between one or the second drive shaft 2 or 3.

[0027] According to the present invention, by allowing the first driven shaft 2 and the main shaft 7 to be connected through the second switching element 6 to form a direct drive movement (second transmission stage) under the condition t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com