layered fuel distributor

A fuel distributor, layered technology, applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of limited number of oil outlets, high precision and high price, and inability to flexibly control the pressure, so as to reduce the The possibility of mutual seizure, the improvement of reliability, and the effect of expanding the power and application range of matching machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following combined with the attachment is further explained to the present invention.

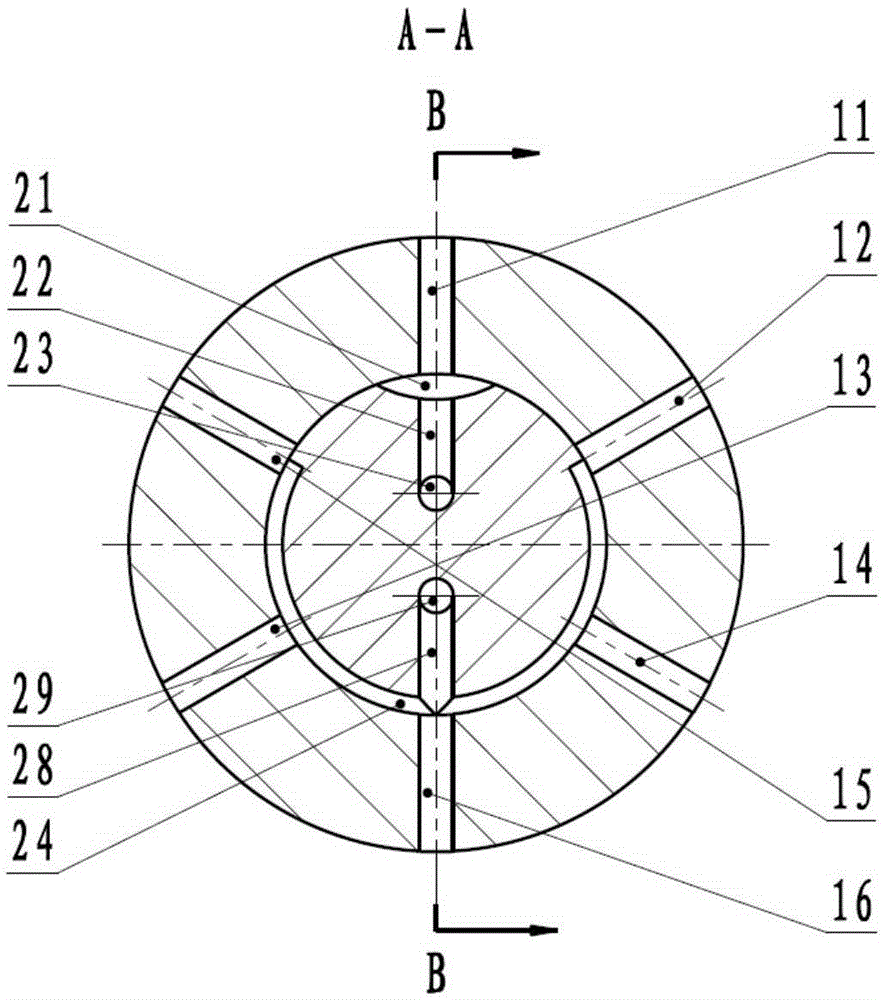

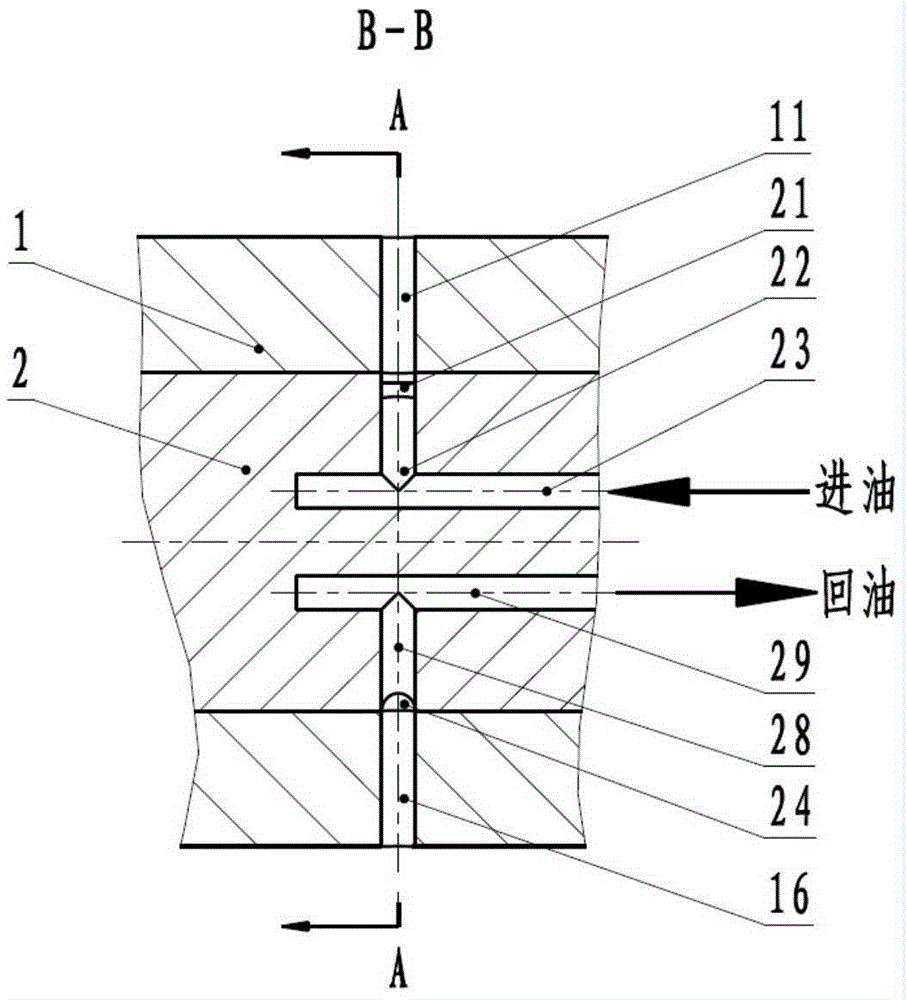

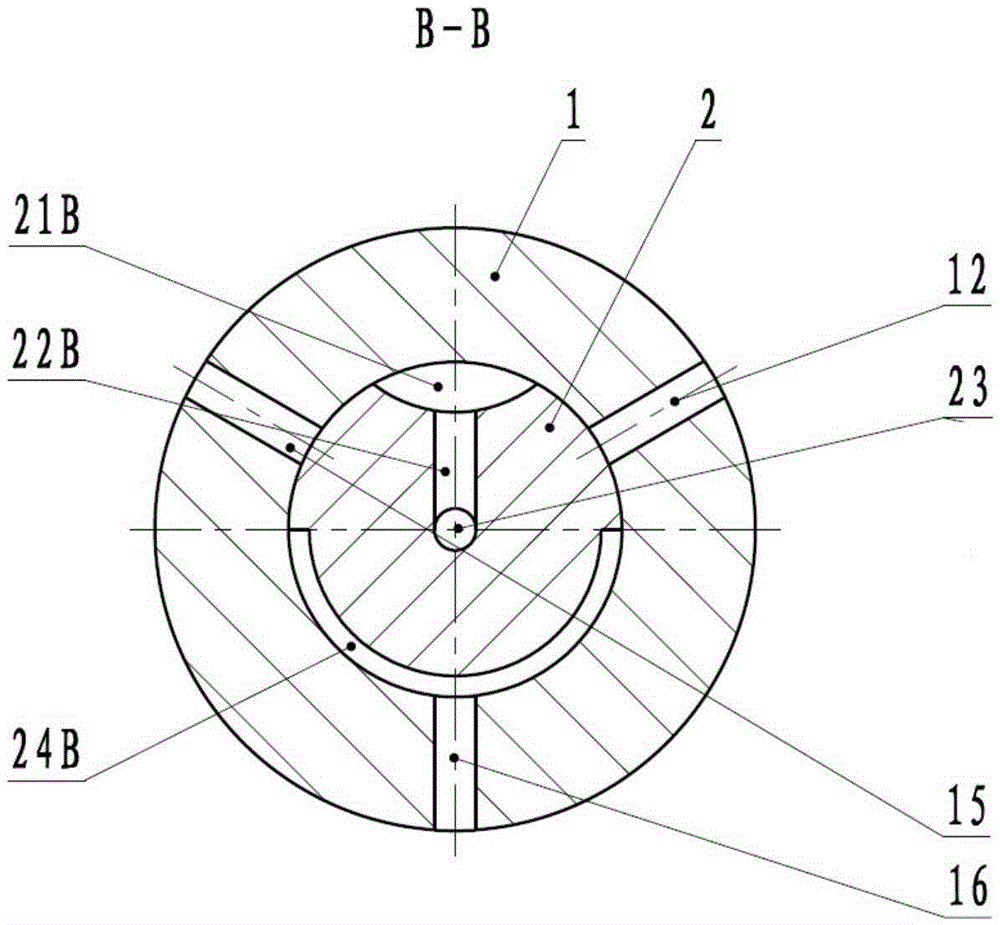

[0057] The core of the invention announced a layered fuel distributor is that the allocation of the stator out of the oil pores are divided into multi -layer layout according to the number of cylinders, and the allocation of the rotor out of the oil holes for pairing design.

[0058] First introduce the working principle of the existing distribution device, and then introduce the specific details of the layered fuel distributor proposed by the present invention.

[0059] Figure 1A and Figure 1B The 6 -cylinder engine is displayed with an existing distribution of an existing distribution in the principle of layering.It can be seen that the figure shows that when the distribution of the allocation rotor in the assignment rotor 23 The fuel passing the fuel pores 22 to the distribution of the rotor out of the oil cavity is distributed into the allocation of the allocation of stator 1 ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com