Patents

Literature

32results about How to "Small rotational inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

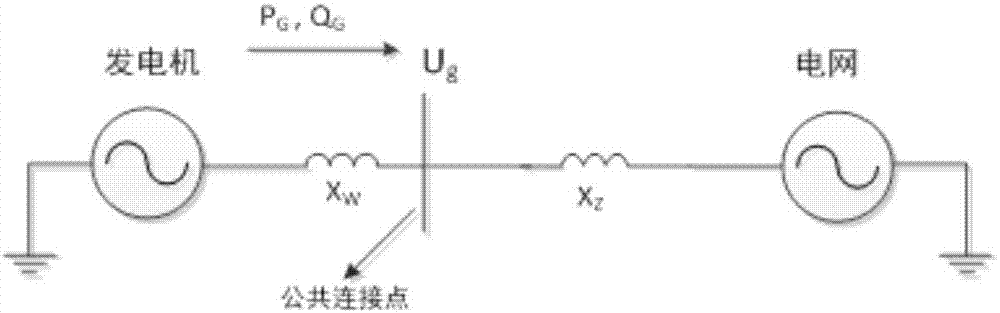

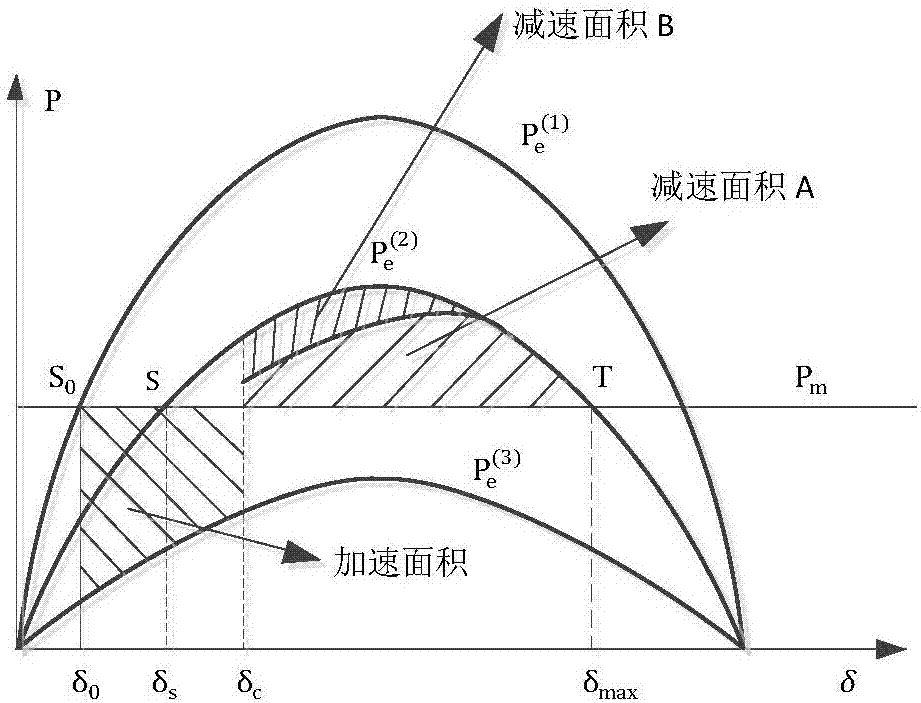

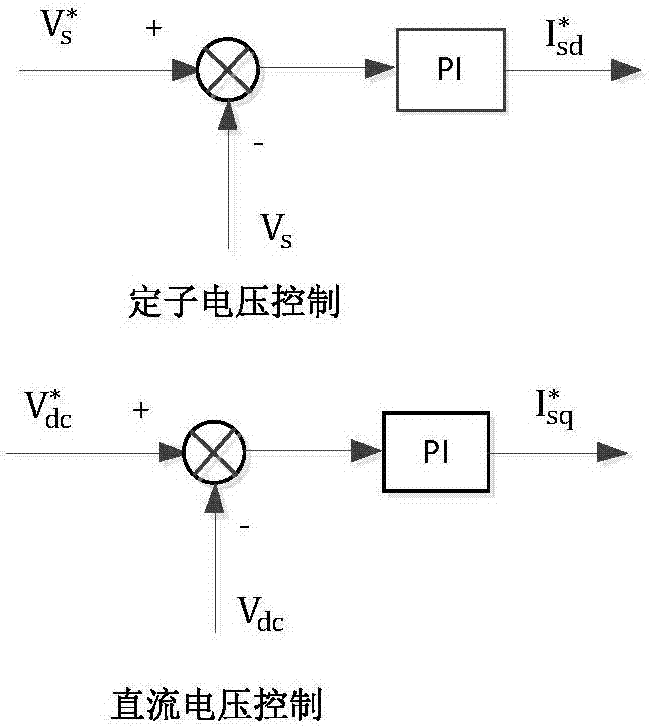

Wind farm reactive-power control strategy for promoting transient stability of weak power grid integrated with wind power

PendingCN107994588AIncrease deceleration areaSmall rotational inertiaSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationElectric power systemEngineering

The invention discloses a wind farm reactive-power control strategy for promoting the transient stability of a large-scale weak power grid integrated with wind power. The strategy is divided into twoaspects of turbines and a wind farm, wherein in the turbine aspect, reactive-power priority control is adopted; in the wind farm aspect, based on a transient energy method, a transient unbalanced energy prediction value is calculated, a transient voltage stability margin is calculated, reactive power output of the different direct-drive wind turbines is adjusted, and a reactive power adjusting instruction is transmitted to each turbine. A strategy overall used by a controller is that according to interaction of the wind farm and an electric system in a system, reactive power control to the wind farm is decomposed into additional control to each draught fan. The control strategy needs no any additional hardware, the communication ability of a centralized control system of the wind farm andthe control strategy of direct drive wind turbines themselves are made full use of, the unreasonable fluctuation of overall reactive power voltage of the wind farm is avoided, and the transient stability performance of the weak power grid integrated with the wind farm can be effectively improved.

Owner:WIND POWER TECH CENT OF GANSU ELECTRIC POWER +2

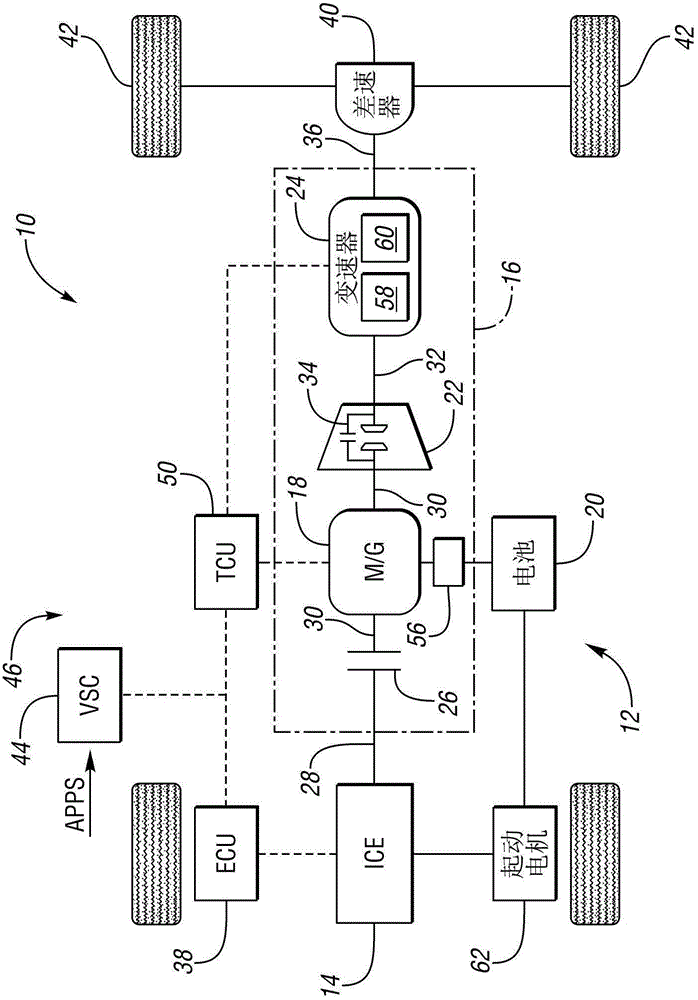

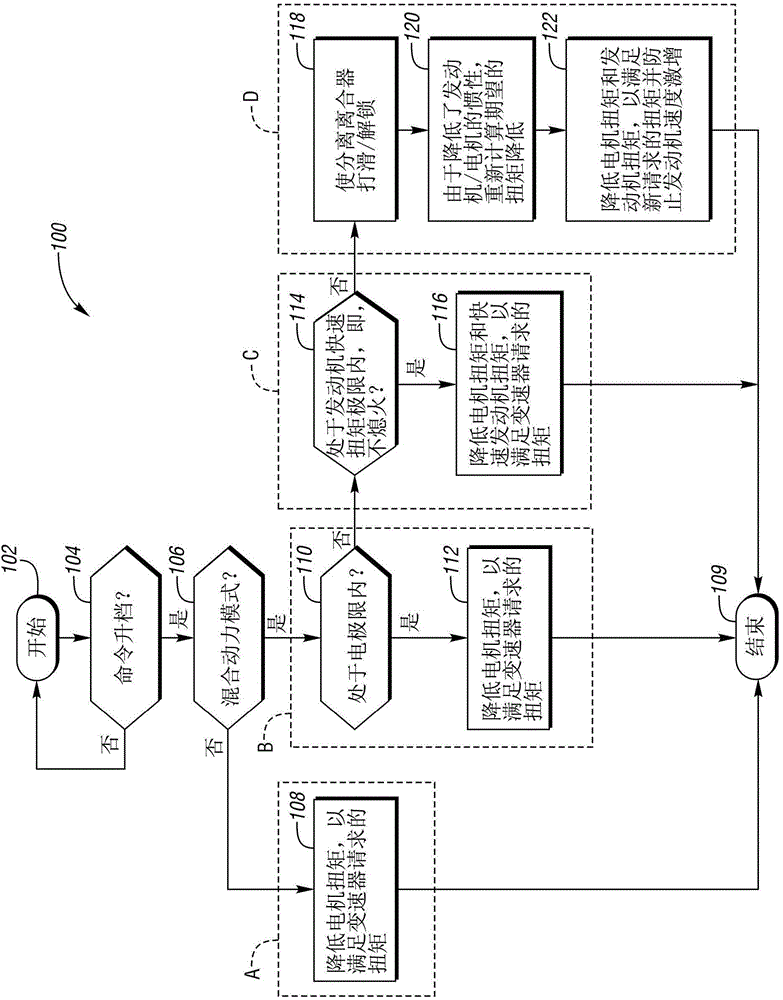

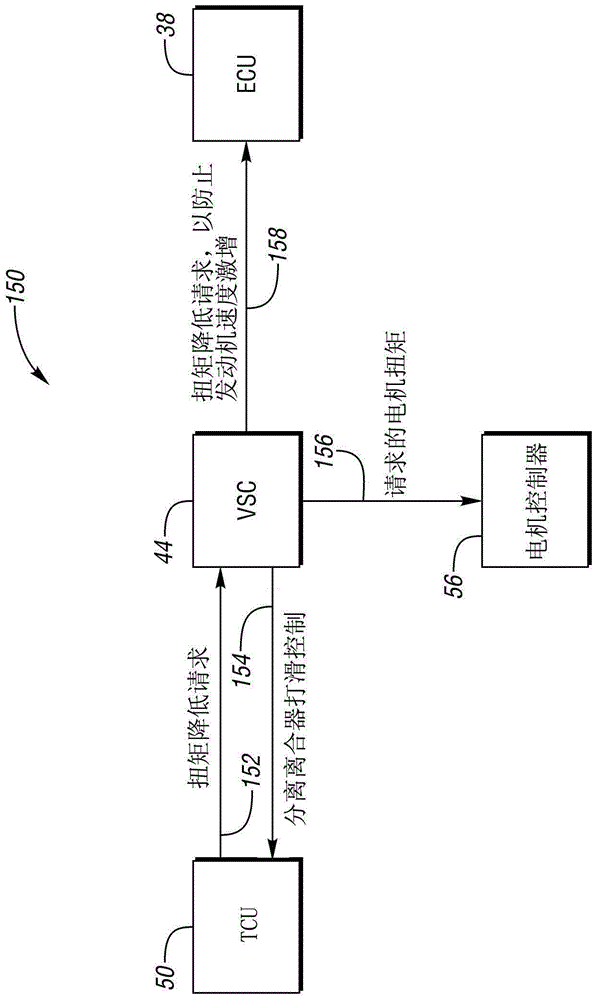

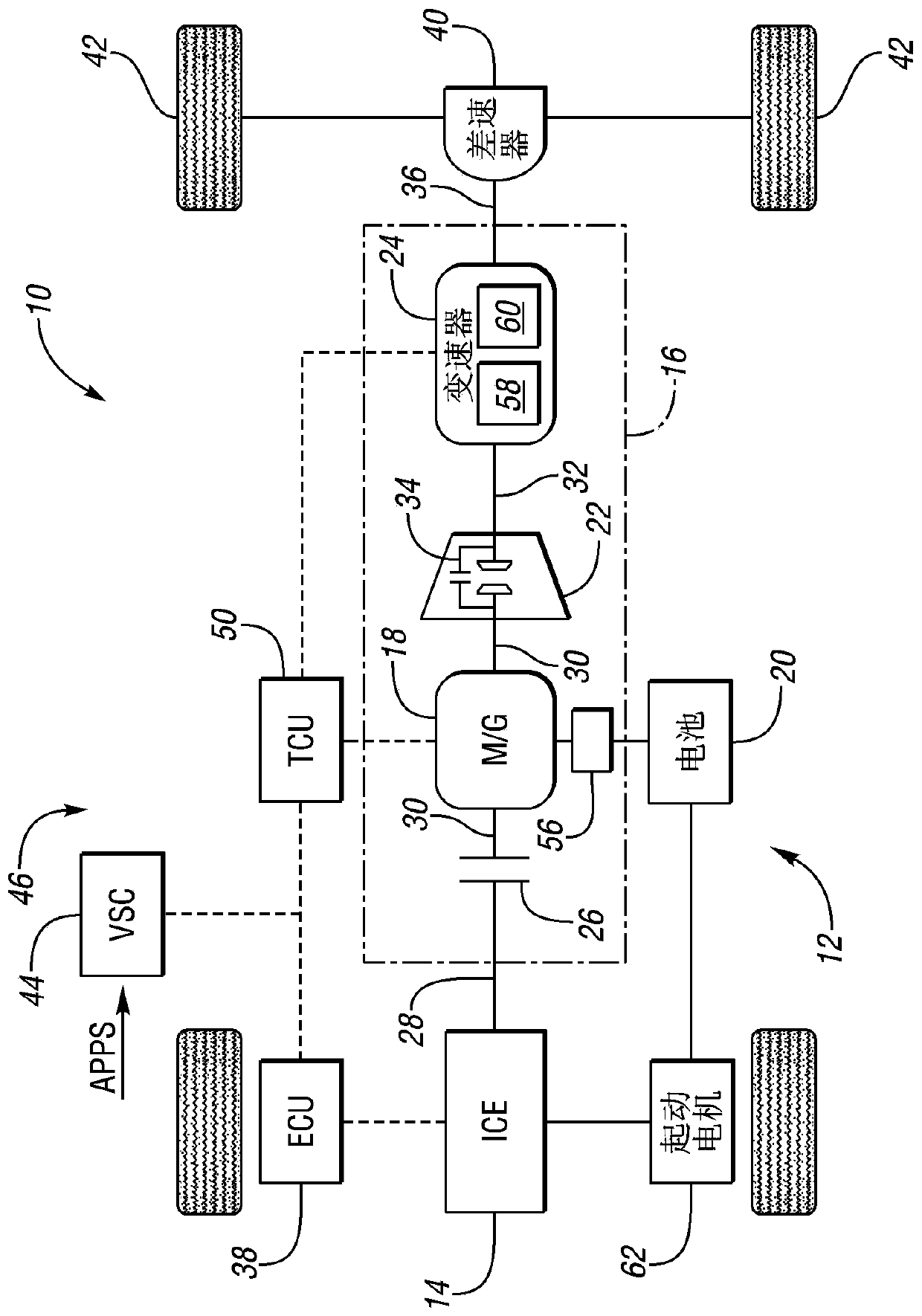

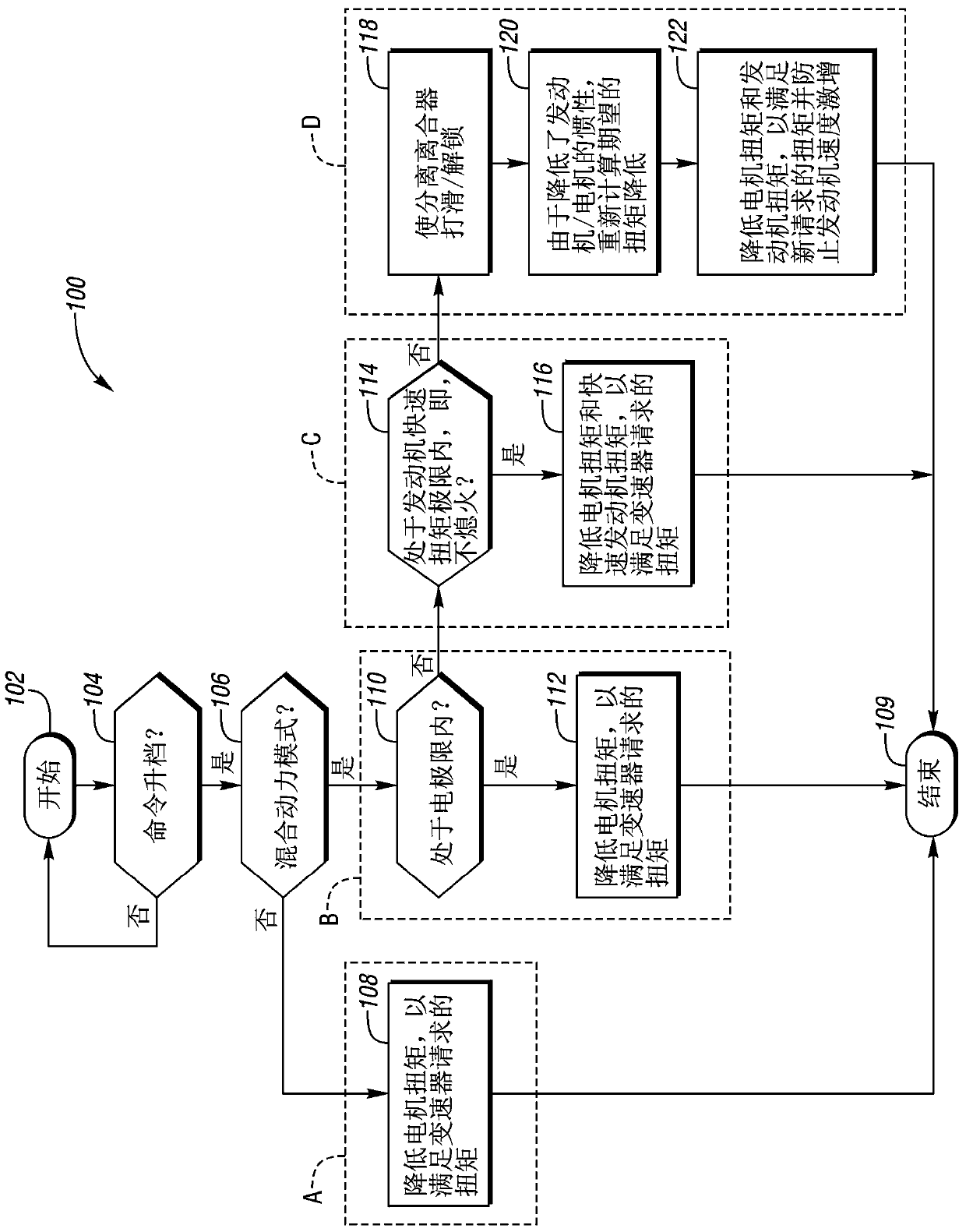

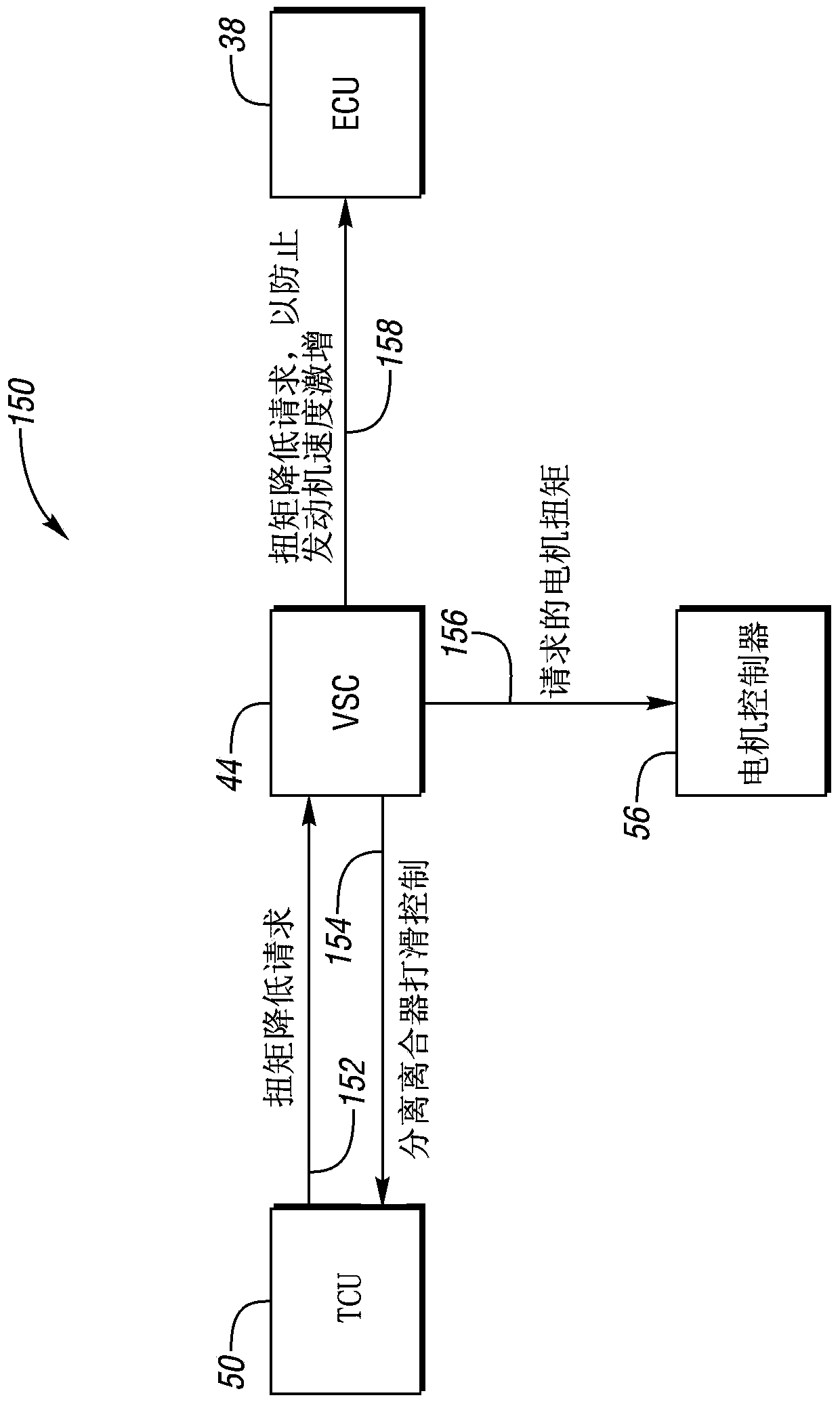

Hybrid vehicle

ActiveCN104627183ASmall rotational inertiaReduce input torqueHybrid vehiclesSpeed controllerElectricityElectric machine

A hybrid vehicle has an engine, an electric machine connected to the engine by an upstream clutch, a transmission gearbox connected to the electric machine by a downstream clutch, and a controller. The controller is configured to, in response to a commanded upshift of the gearbox, modulate a pressure of the upstream clutch. A method for controlling a vehicle includes, in response to a commanded upshift of a gearbox, controlling an upstream clutch to a first nonzero speed differential corresponding to a first inertia connected to and upstream of the gearbox to reduce inertia torque during the upshift. A method for controlling a vehicle includes, in response to a commanded upshift of a gearbox when the vehicle is beyond an electrical limit and a fast path torque reduction limit, slipping an upstream clutch and reducing torque outputs of an engine and an electric machine.

Owner:FORD GLOBAL TECH LLC

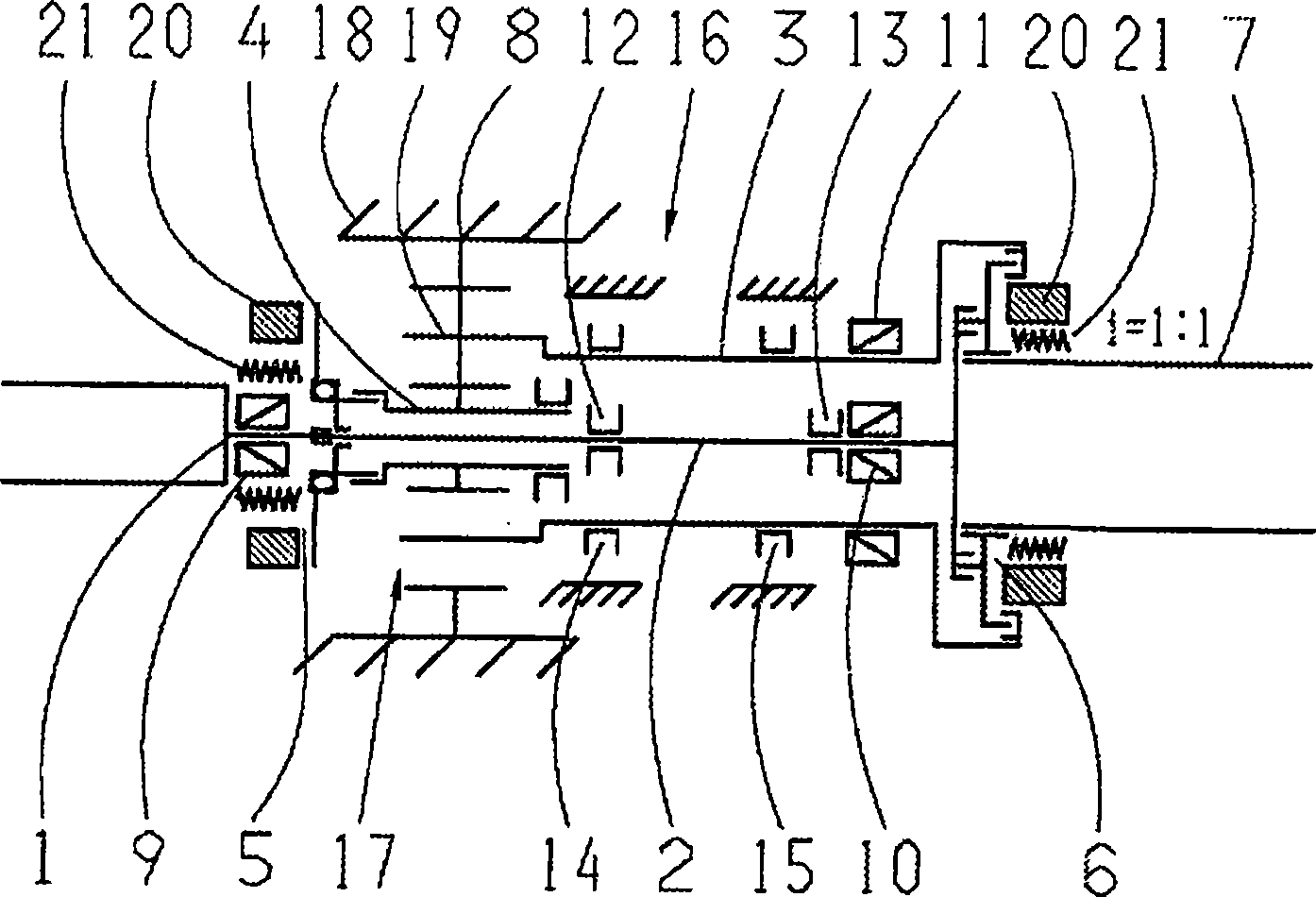

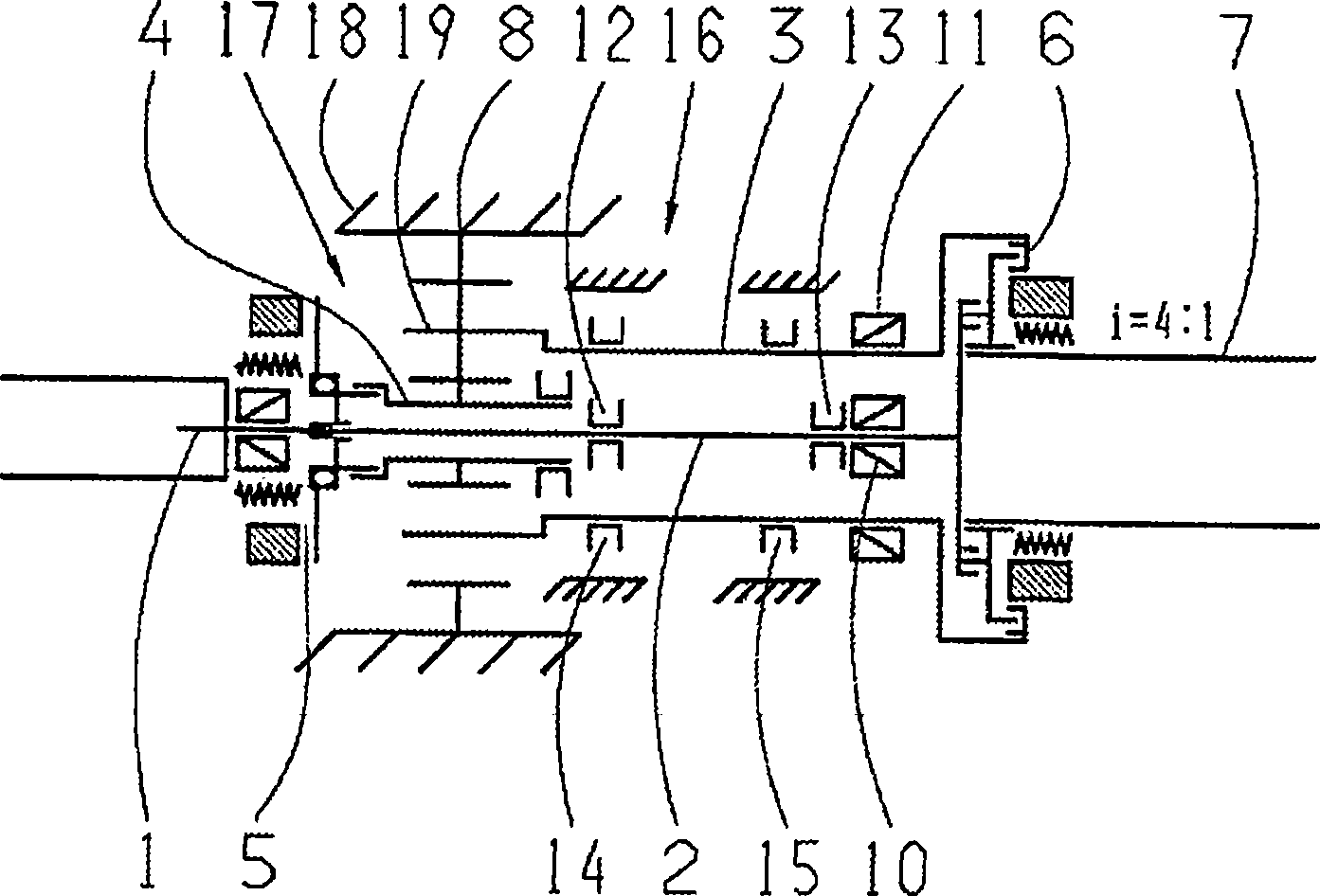

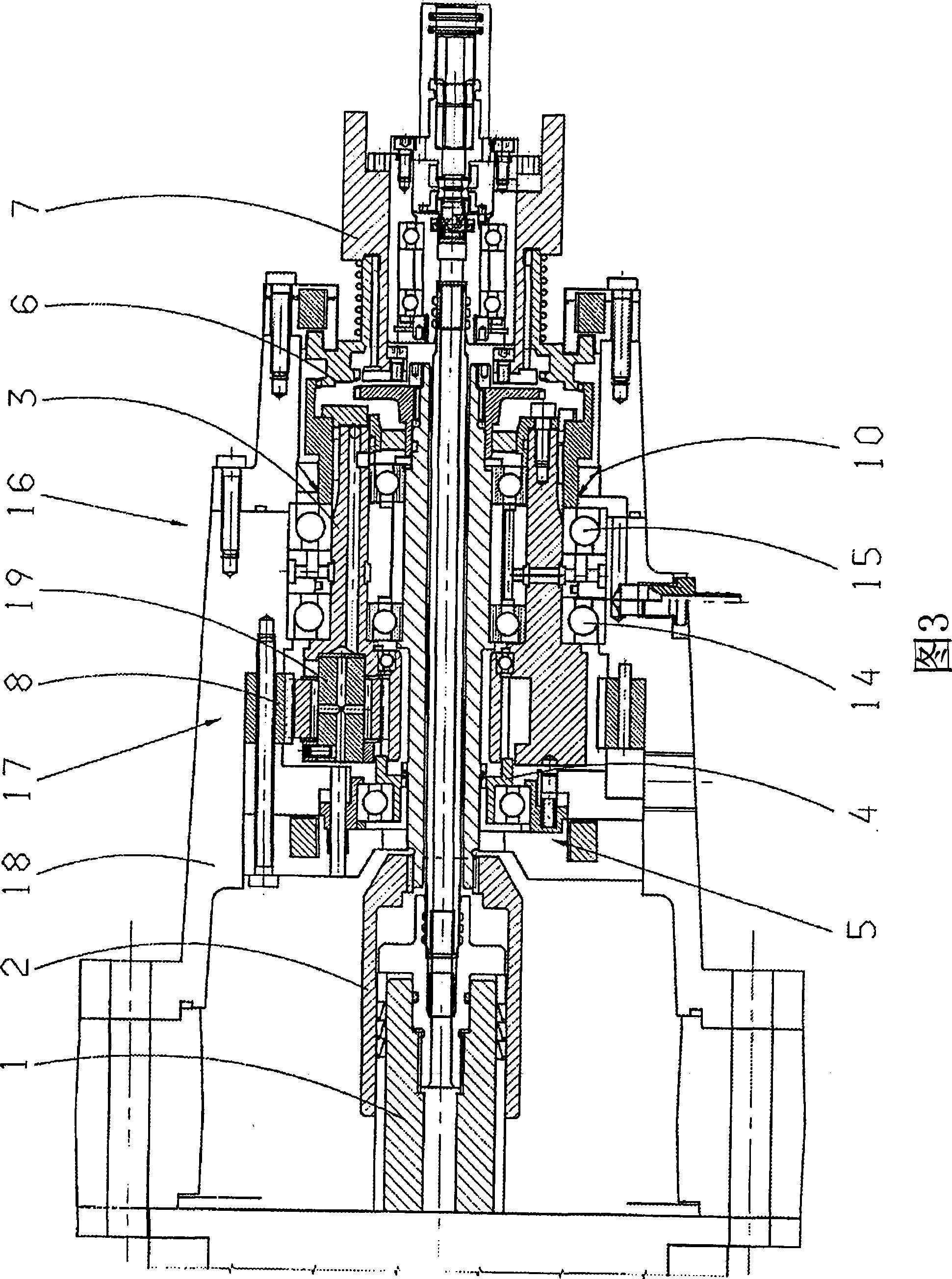

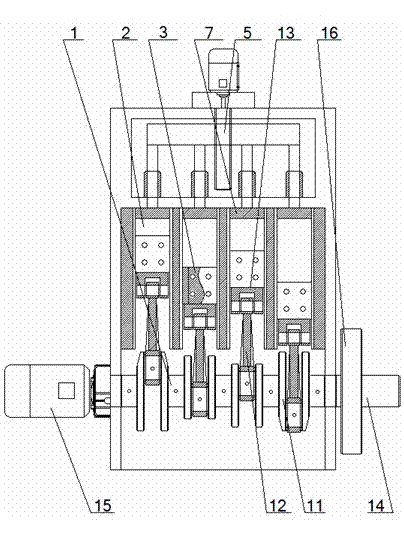

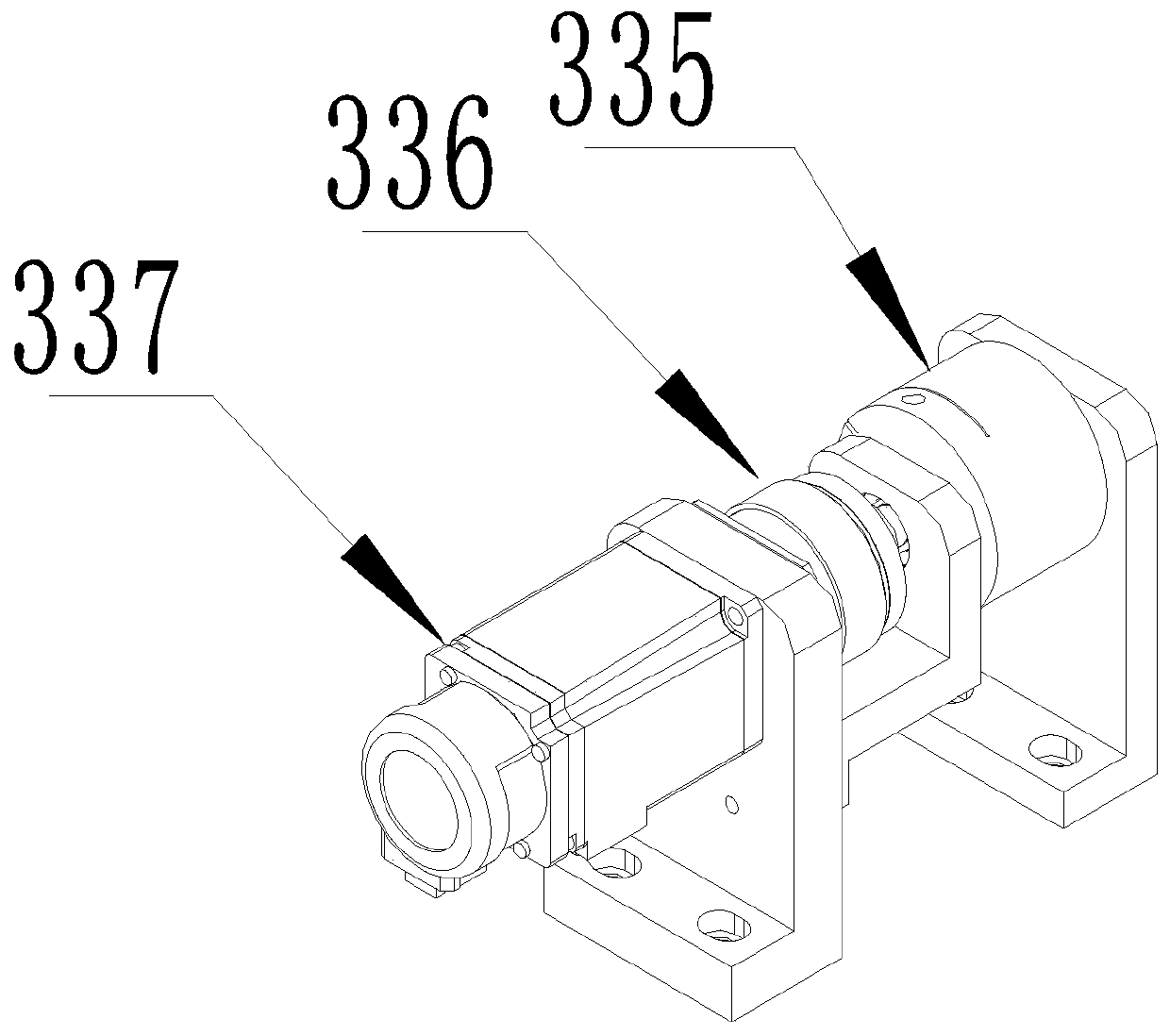

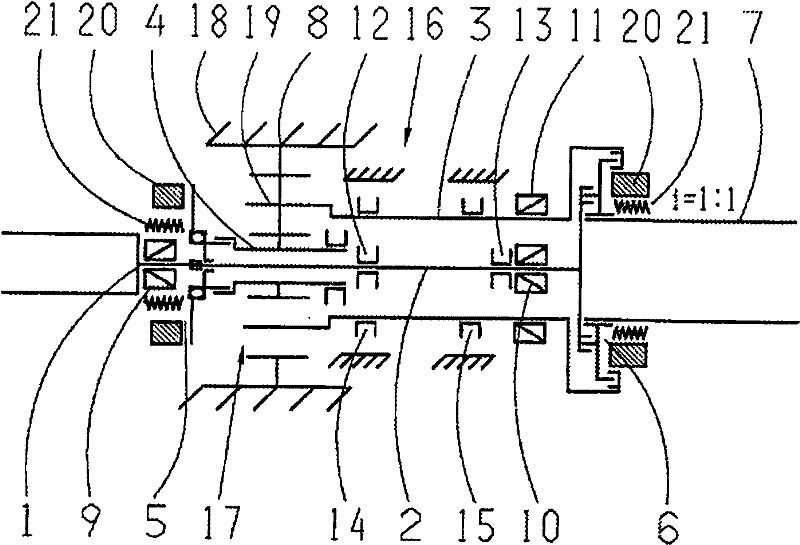

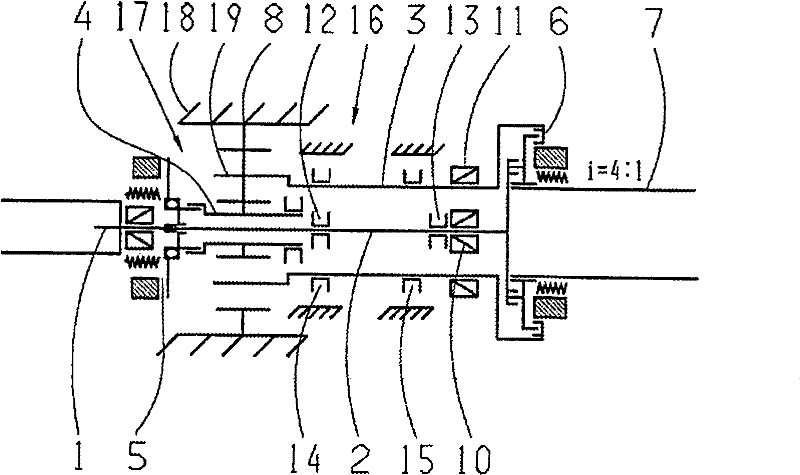

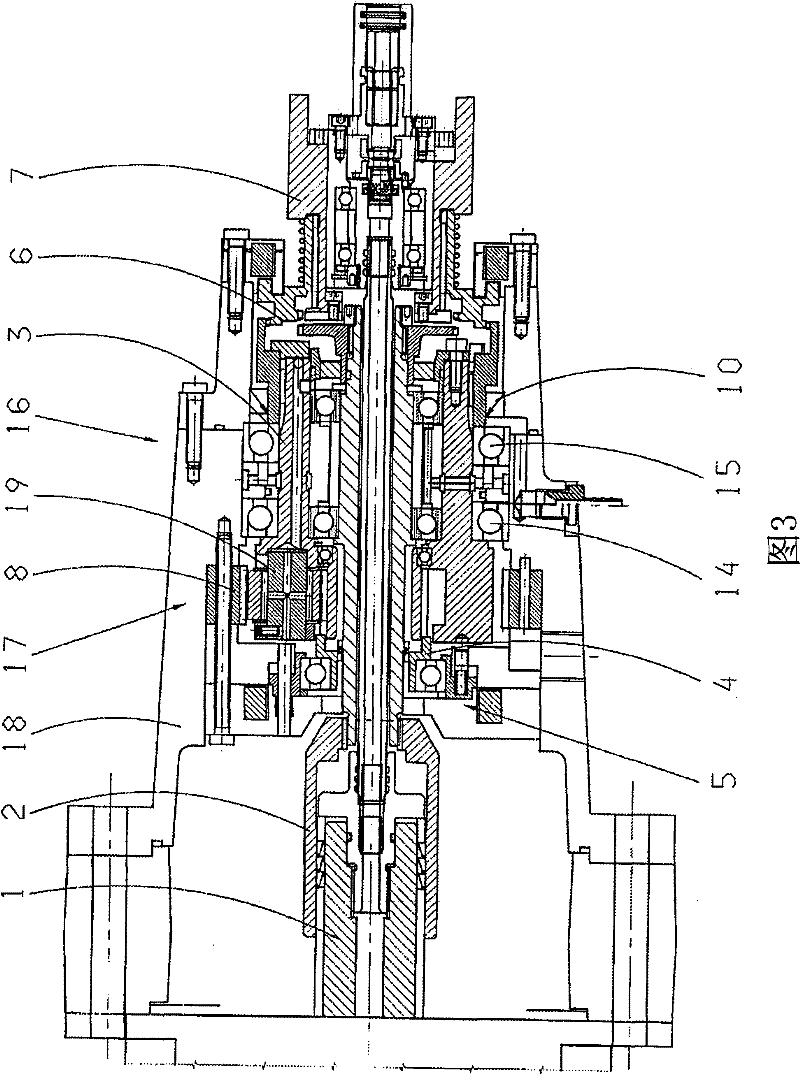

Two-stage machine tool gearing, in particular spindle gearing

InactiveCN101389884ATransmission motion accelerationSmall rotational inertiaToothed gearingsGear wheelEngineering

Owner:ZF FRIEDRICHSHAFEN AG

Magnetomotive device and using method thereof

The invention relates to a magnetomotive device, which comprises a crankshaft, a main motor and at least two magnetomotive units, wherein an output shaft of the main motor is connected with a power output shaft sequentially through the camshaft and a flywheel; a sliding permanent magnet in each magnetomotive unit is connected with a rod journal on the crankshaft through a crankshaft connecting rod; a back permanent magnet which corresponds to each sliding permanent magnet is arranged right behind a leading channel where each sliding permanent magnet is located; and a top permanent magnet is correspondingly arranged above each sliding permanent magnet. When the magnetomotive device is used, the repulsive force exists between the sliding permanent magnets and the back permanent magnets to facilitate the sliding permanent magnets to drive the crankshaft to rotate in an accelerative manner through the crankshaft connecting rod. The magnetomotive device disclosed by the invention has the advantages of sufficient magnetomotive power, large output power, uniform and coherent power output and high stability.

Owner:SUIZHOU SHUANGYI LONGJI MACHINERY TECH

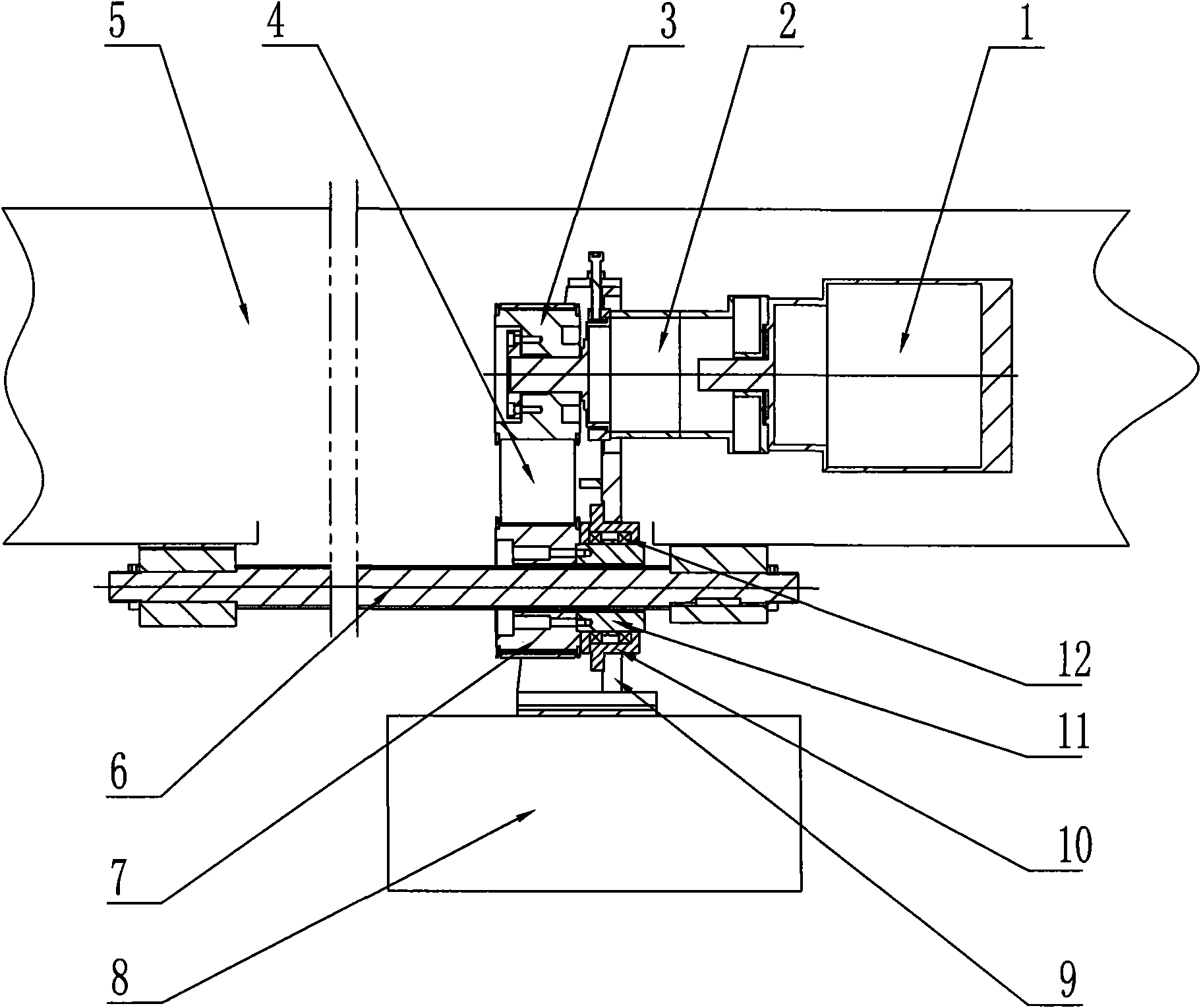

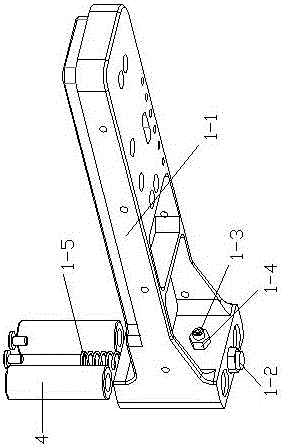

Crossbeam driving mechanism of long-stroke numerical control laser cutting machine

InactiveCN101596686AEasy to installHigh transmission precisionFeeding apparatusLaser beam welding apparatusNumerical controlEngineering

The invention discloses a cutting head driving mechanism of a long-stroke numerical control laser cutting machine, belonging to the field of laser cutting machines. The cutting head driving mechanism comprises a stand, a moving crossbeam, a guide screw, a nut and a servo motor, wherein the guide screw is meshed with the nut, a shaft tip of the servo motor is connected with a driving pulley through a reduction box in a transmission way, the reduction box is fixed with the moving crossbeam by a connecting seat, the guide screw is fixedly arranged on the stand along the X axial direction, the nut is arranged in a bearing seat by a bearing, the bearing seat is fixed on the connecting seat, a shaft tip of the nut is connected with a driven pulley which is concentric with the nut, and the driving pulley and the driven pulley are connected in a transmission way by a synchronous belt. The cutting head driving mechanism has the advantages of low inertia and noise, high rigidity, simple and convenient installation, and the like and is suitable for being used in a long-stroke numerical control laser cutting machine.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

Preparation method of woven carpet without gumming process

ActiveCN108411460AEnhanced shape retention and dimensional stabilityOmit the adhesive processHeating/cooling textile fabricsWoven fabricsCopolyesterWeft yarn

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber-formed filament or a staple fibre yarn, a first coating layer is apolyester fiber filament or a staple fibre yarn, the second coating layer accounts for 20%-50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass ofthe composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt copolyester fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt copolyester fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, the pile and weft yarns as well as the weftyarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpet are enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

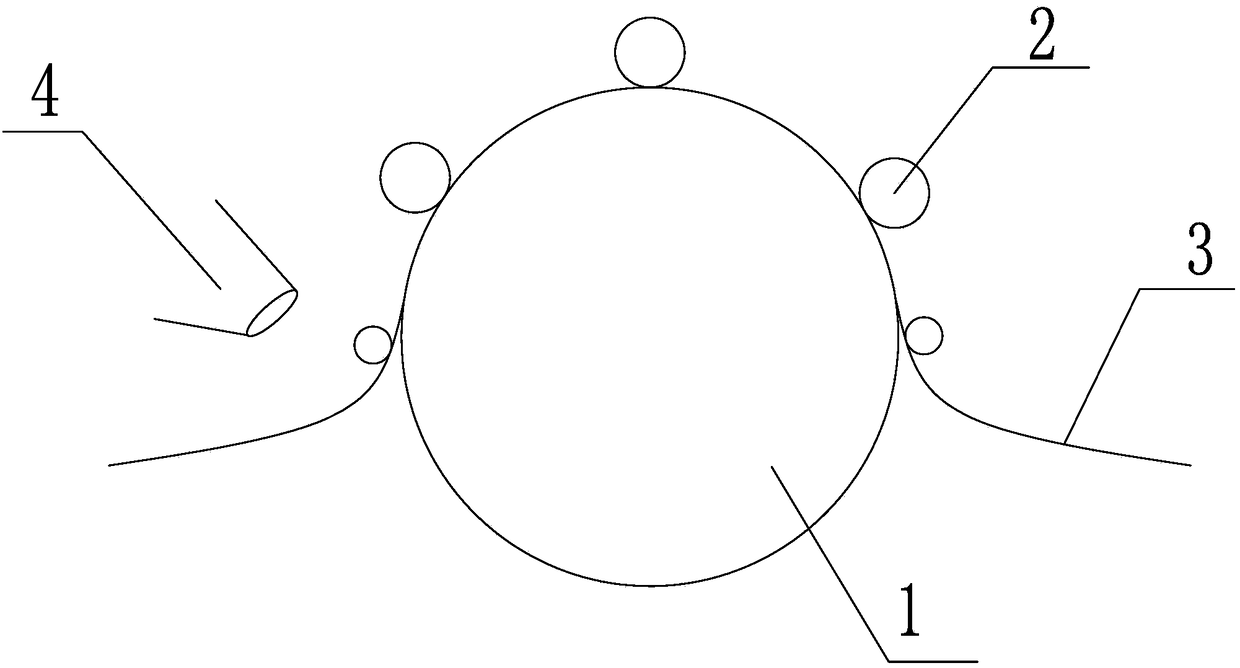

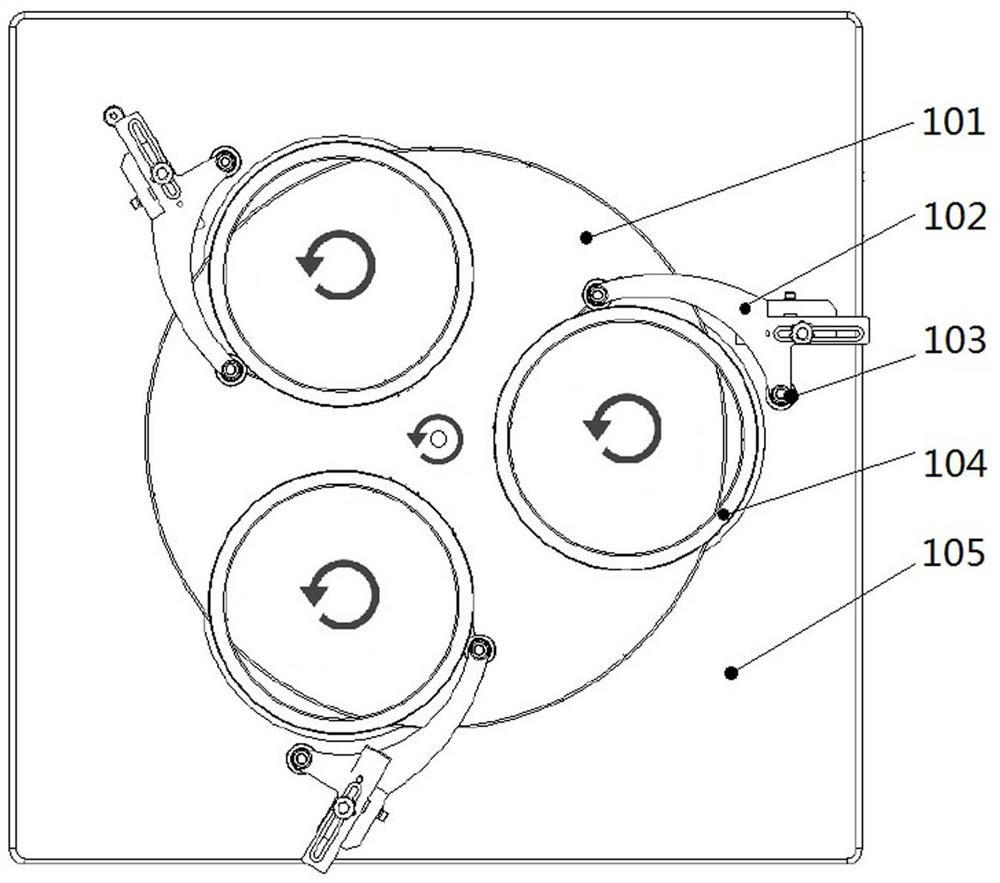

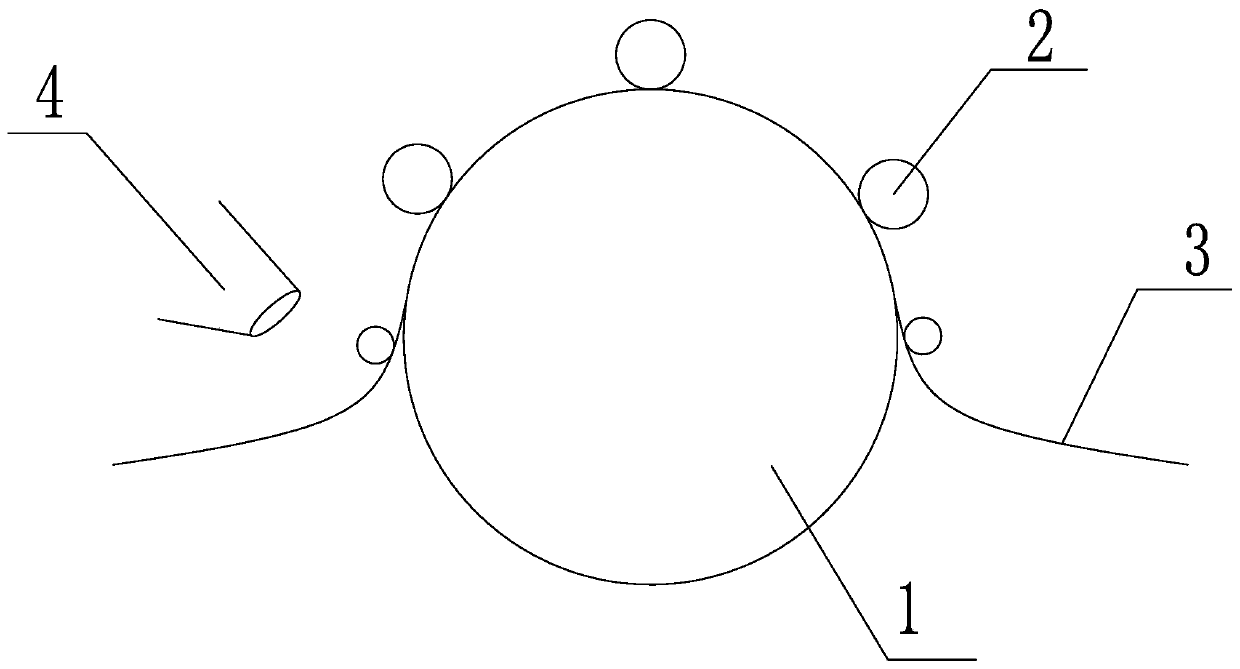

Screen printing machine

PendingCN111452488ASimple designSave installation spaceScreen printersPrinting press partsScreen printingRotary stage

The invention discloses a screen printing machine. The screen printing machine comprises a bottom plate. The bottom plate is sequentially provided with an inlet slice conveying mechanism, a rotating platform group and an outlet slice conveying mechanism. The rotating platform group comprises a rotating frame and a rotation drive mechanism driving the rotating frame to do rotating movement. A plurality of silicon wafer placement conveying platforms are arranged on the rotating platform in the circumferential direction. An inlet slice detection positioning mechanism, a screen printing device andan outlet slice detection mechanism are arranged on the circumferential side of the rotating frame, the silicon wafer placement conveying platforms sequentially move to the positions below the detection positioning mechanism, the screen printing device and the outlet slice detection mechanism in the rotating process. The rotating platform assembly design is simplified, the rotating platform and the silicon wafer placement conveying platforms are integrally designed, the assembly installation space is reduced, the total weight is reduced, the assembly weight is drawn close to the center of therotating platform so that the rotation inertia can be reduced, the printing precision is improved, the silicon wafer placement conveying platforms carry out conveying in a non-contact manner, the conveying power is stable, and the precision is good.

Owner:LIANCHENG KEKESI TECH CO LTD

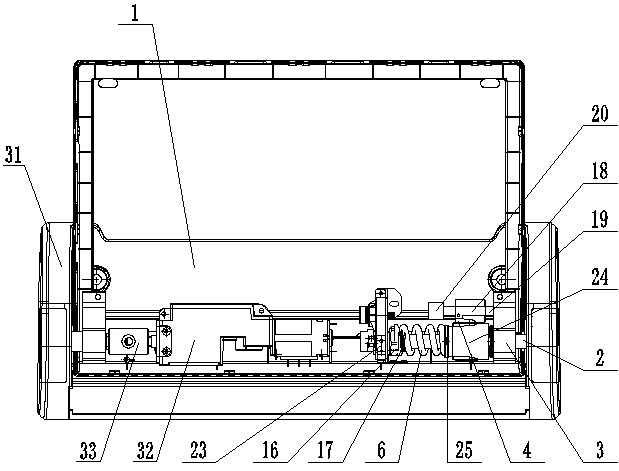

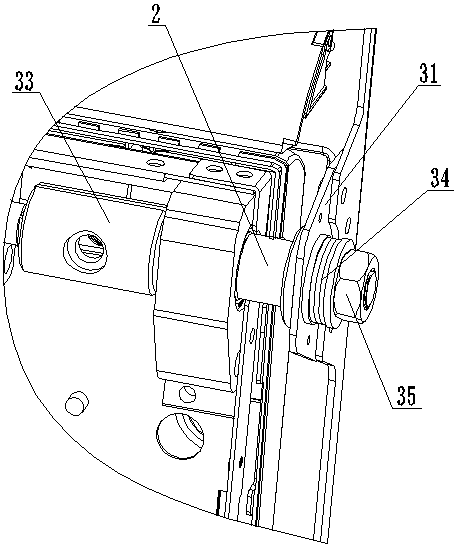

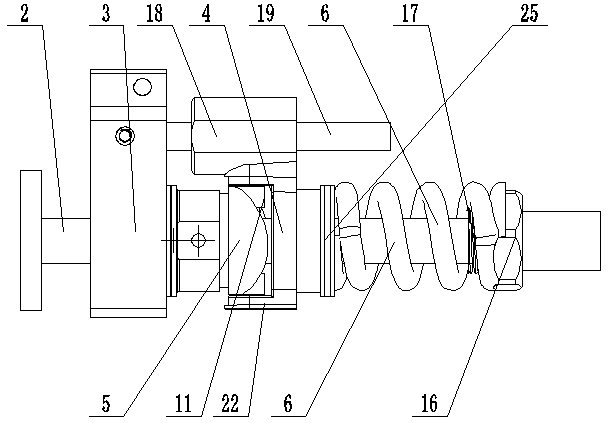

Vehicle display

PendingCN110371038ASmall rotational inertiaReduce shakingVehicle componentsInternal combustion piston enginesEngineeringGravitation

The invention discloses a vehicle display, and aims at solving the defects that a large part of a mechanism of an existing vehicle display is arranged at one end far away from a rotating shaft, so that the center of gravity of the whole mechanism is closer to the middle position of the display, and during a using process of the vehicle display, shaking of the display can be caused by a slight acceleration change of a vehicle, and a larger elastic mechanism is needed for supporting the display. The vehicle display comprises a mounting bracket, rotating shafts, a display bracket, a balancer anda turnover driving device, wherein the turnover driving device, the balancer and other components are all arranged on a connecting line of the two rotating shafts, so that the rotating inertia of thewhole device is reduced, and meanwhile, the shaking of the display, which is caused by the acceleration and vibration of the vehicle, is also reduced.

Owner:HANGZHOU HANGZHENG ELECTRONICS TECH

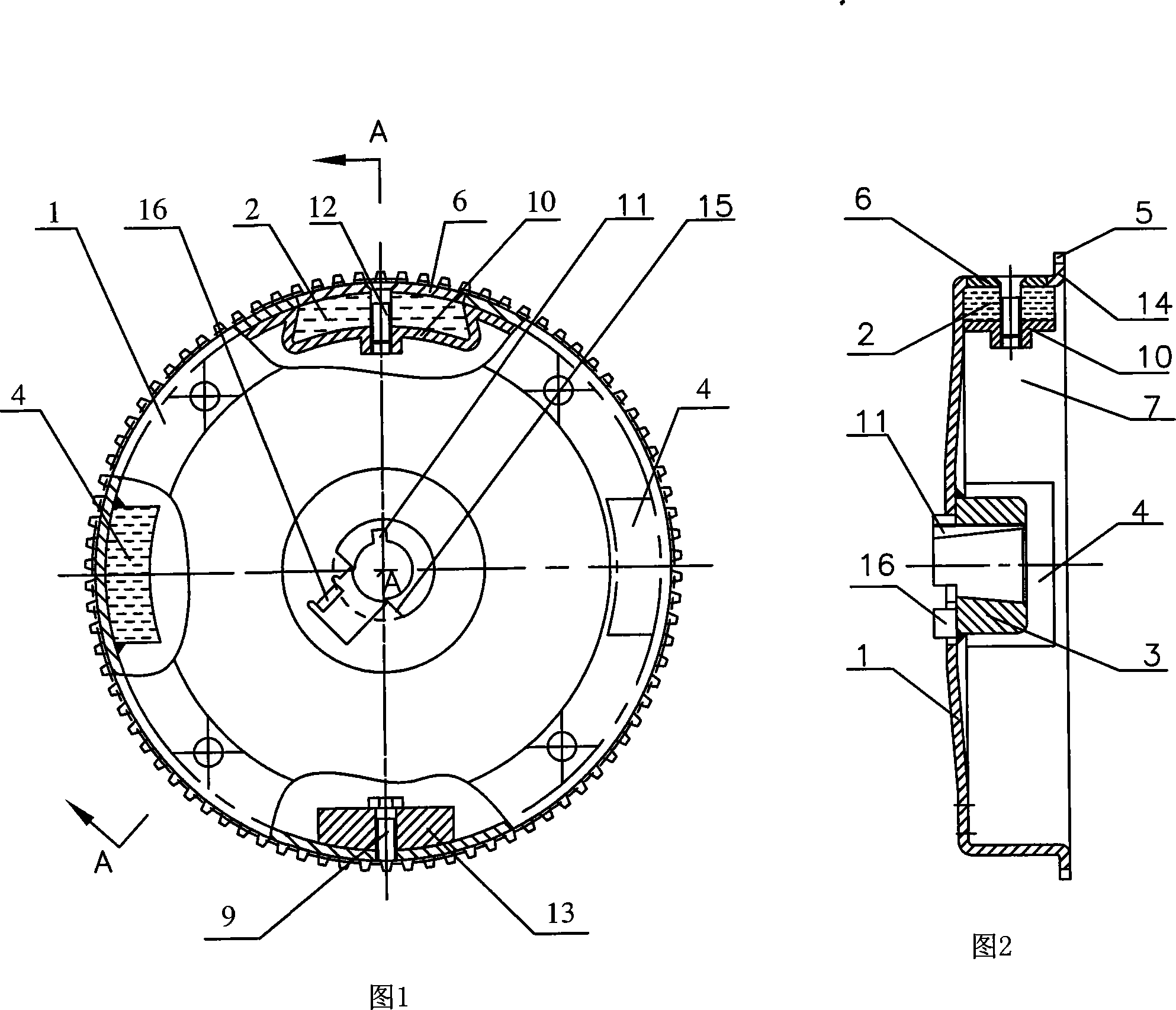

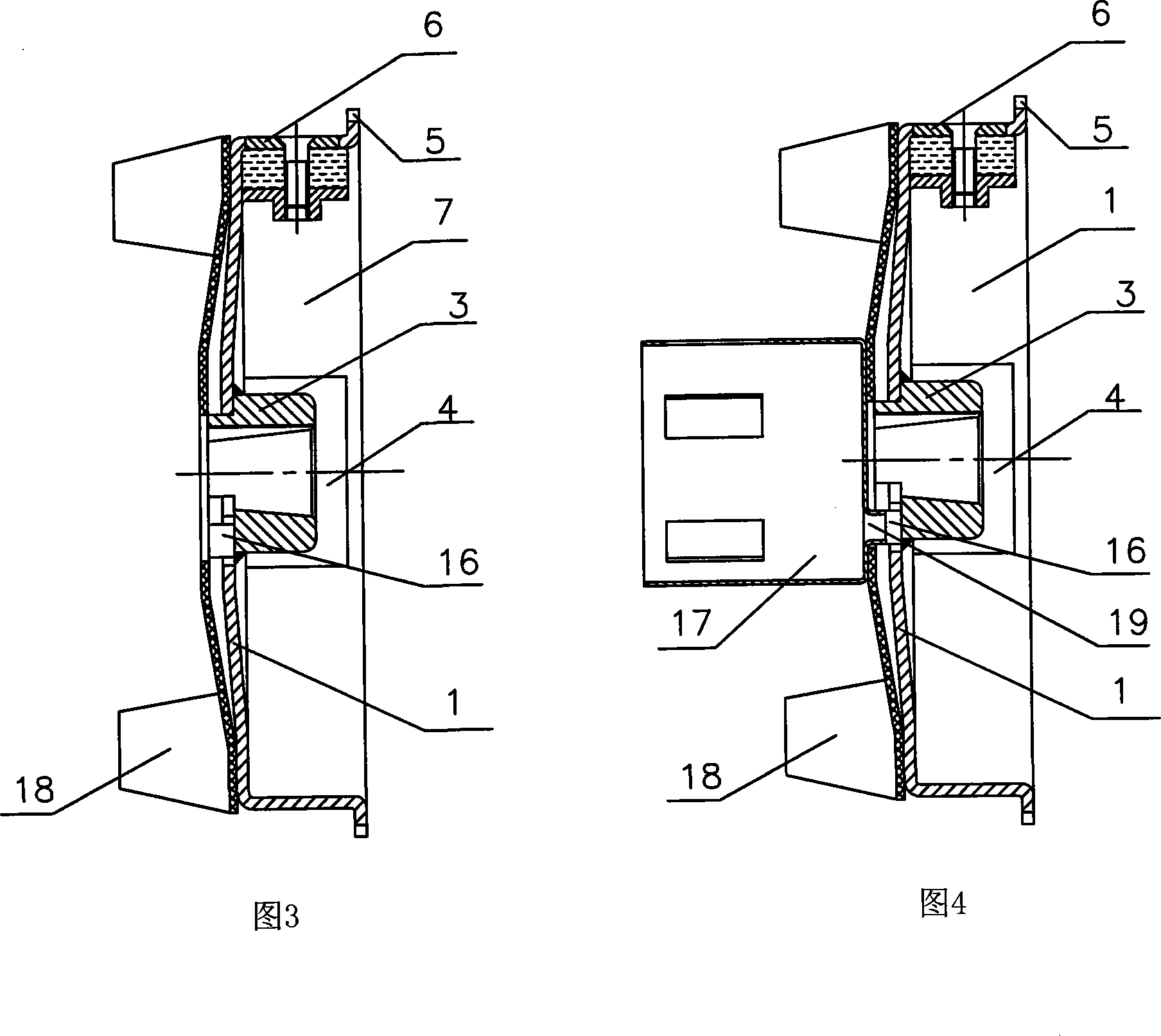

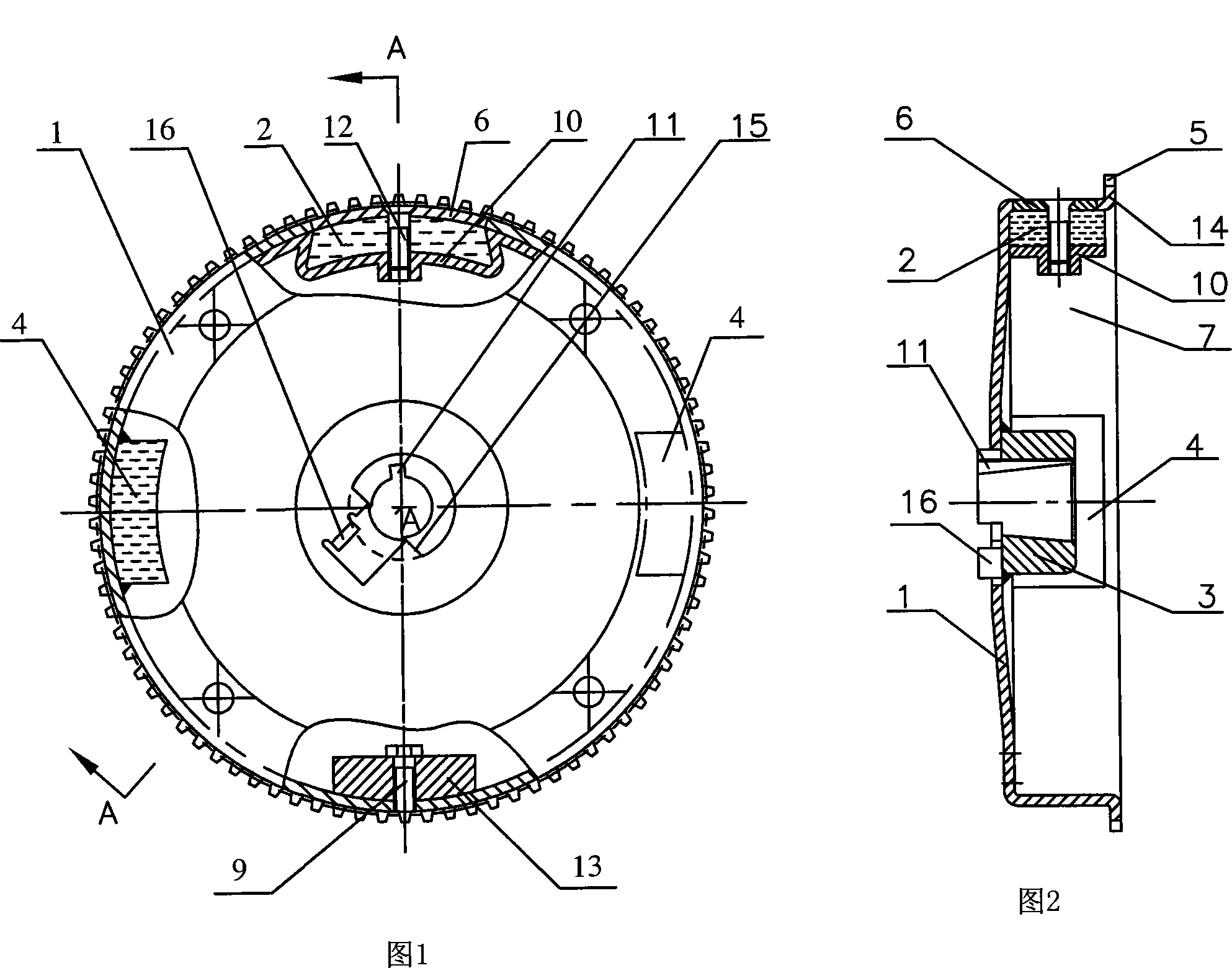

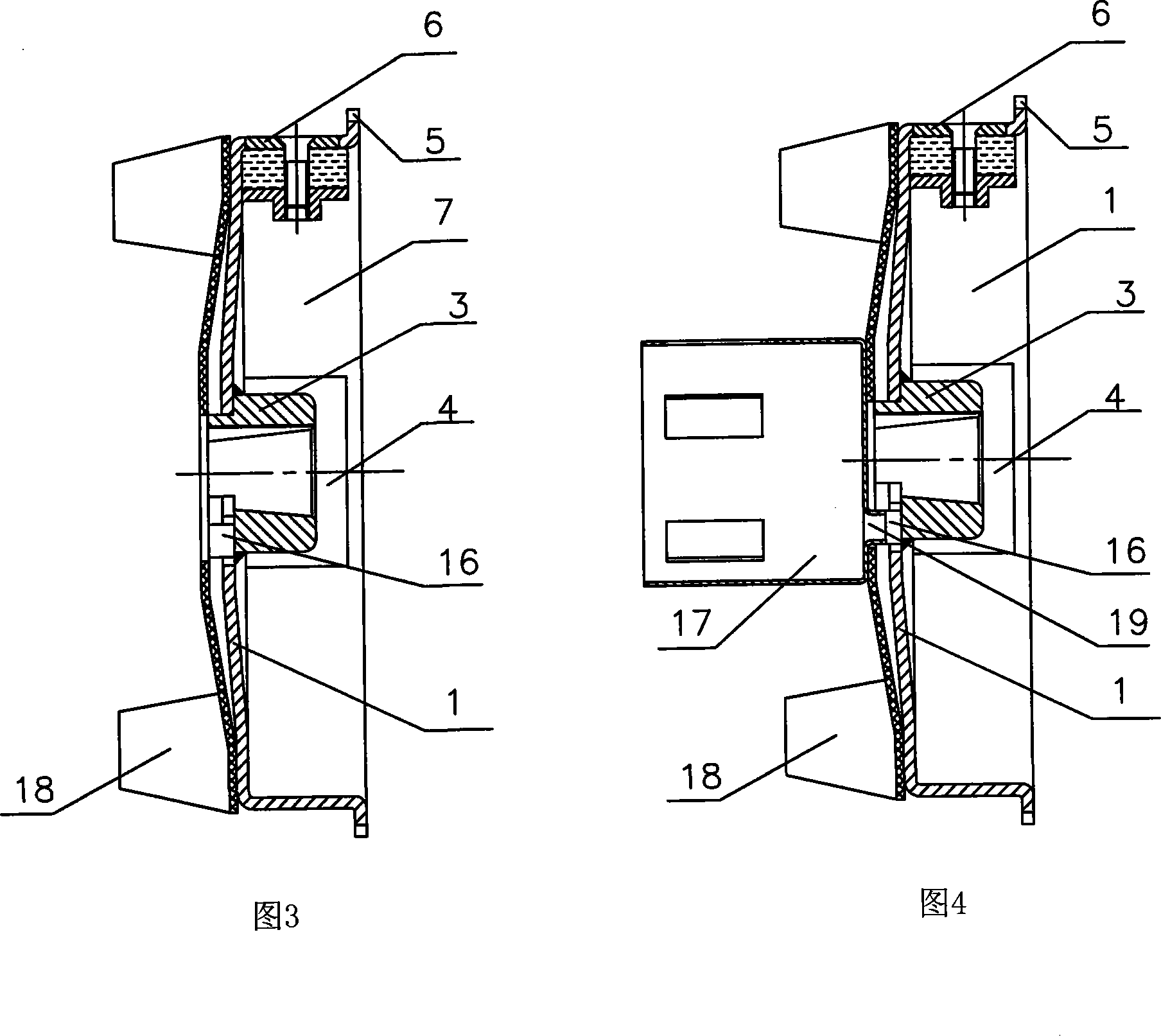

Gasoline engine electric-starting flywheel

InactiveCN101169092AReduce weightSmall rotational inertiaPower operated startersElectric motor startersElectrical stabilityFlywheel

The invention discloses an electric starter flywheel of a gasoline engine, which comprises a flywheel disc, inner and outer magnetic steel fixed on the flywheel disc and a balance weight. Start the flywheel of the driven teeth. The driven teeth are located on the folded edge of the ring flywheel that is turned and extended from the mouth of the cavity of the flywheel. The folded edge and the flywheel are integrally structured. It not only reduces the weight of the flywheel, but also reduces the rotational inertia of the flywheel, and can completely stop the rotation within 3 seconds when braking. It can also ensure the stability and reliability of the torque transmitted by the driven gear of the electric starter, and prolong the service life of the flywheel. .

Owner:LONCIN MOTOR

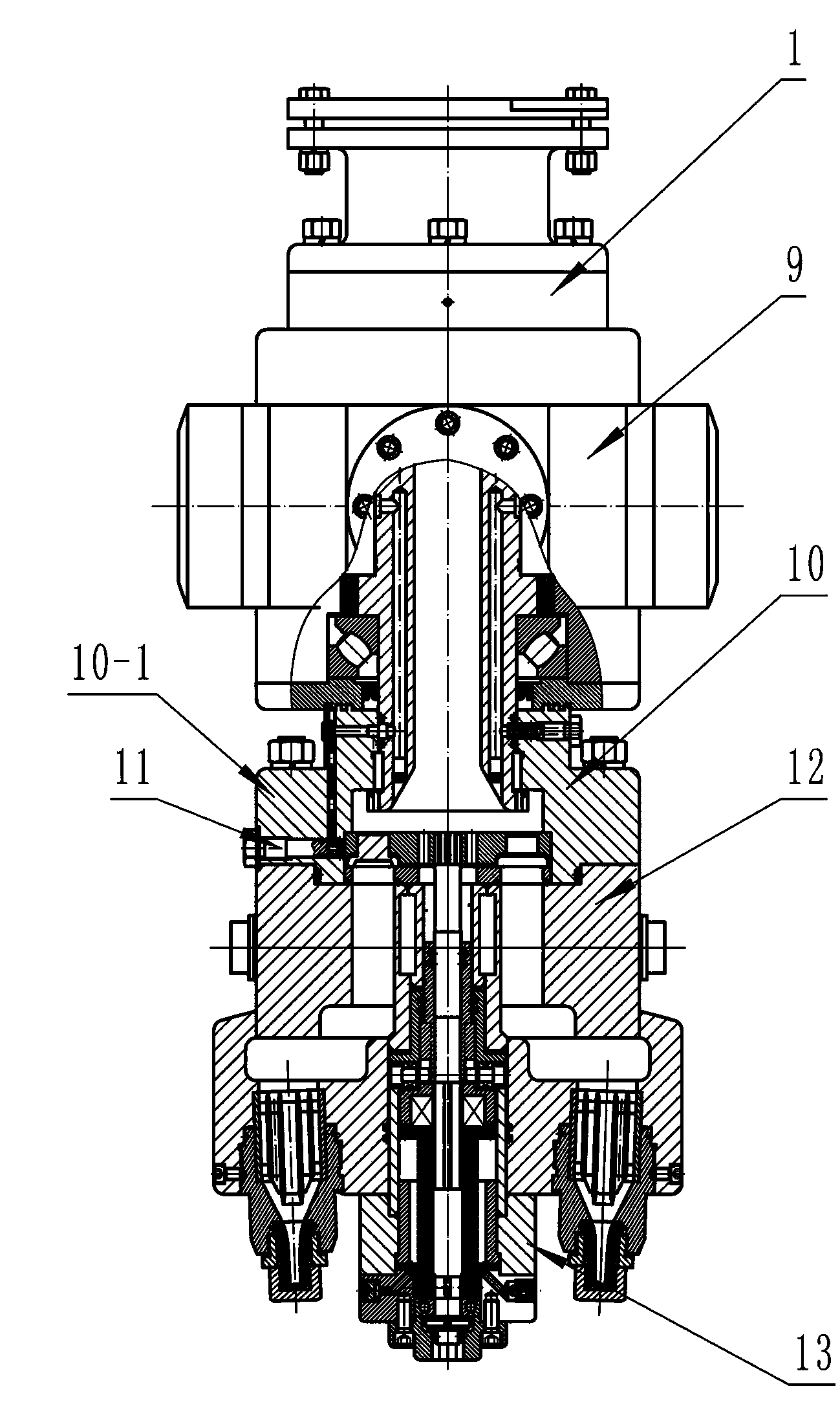

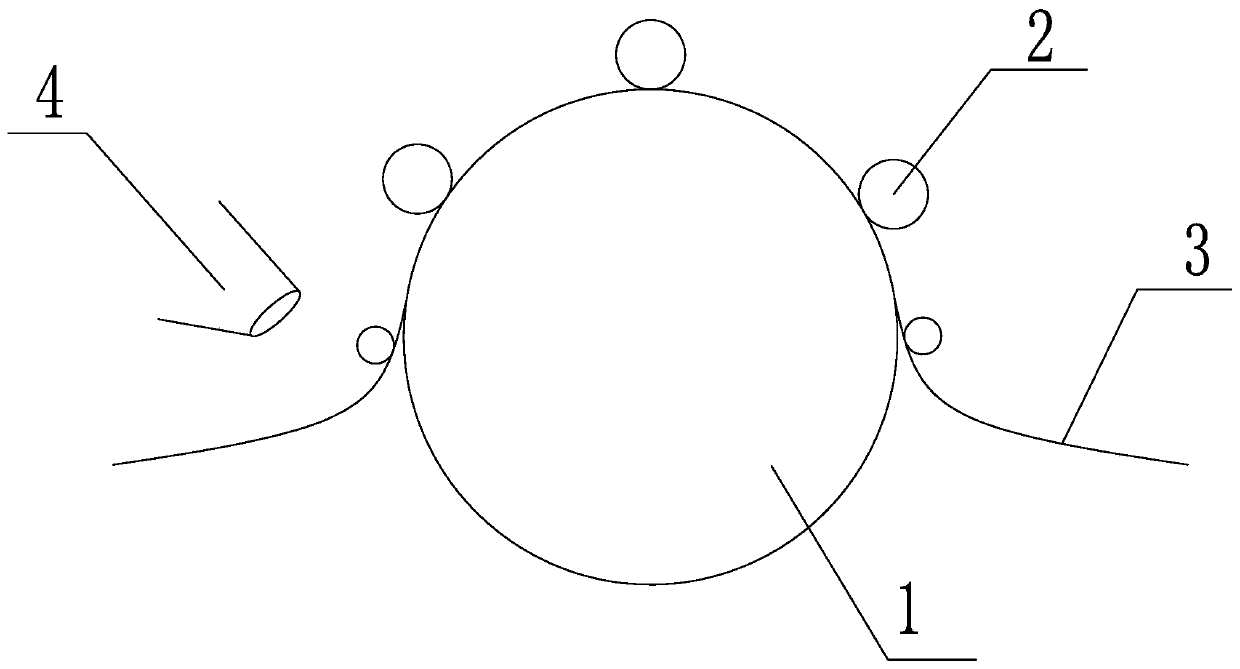

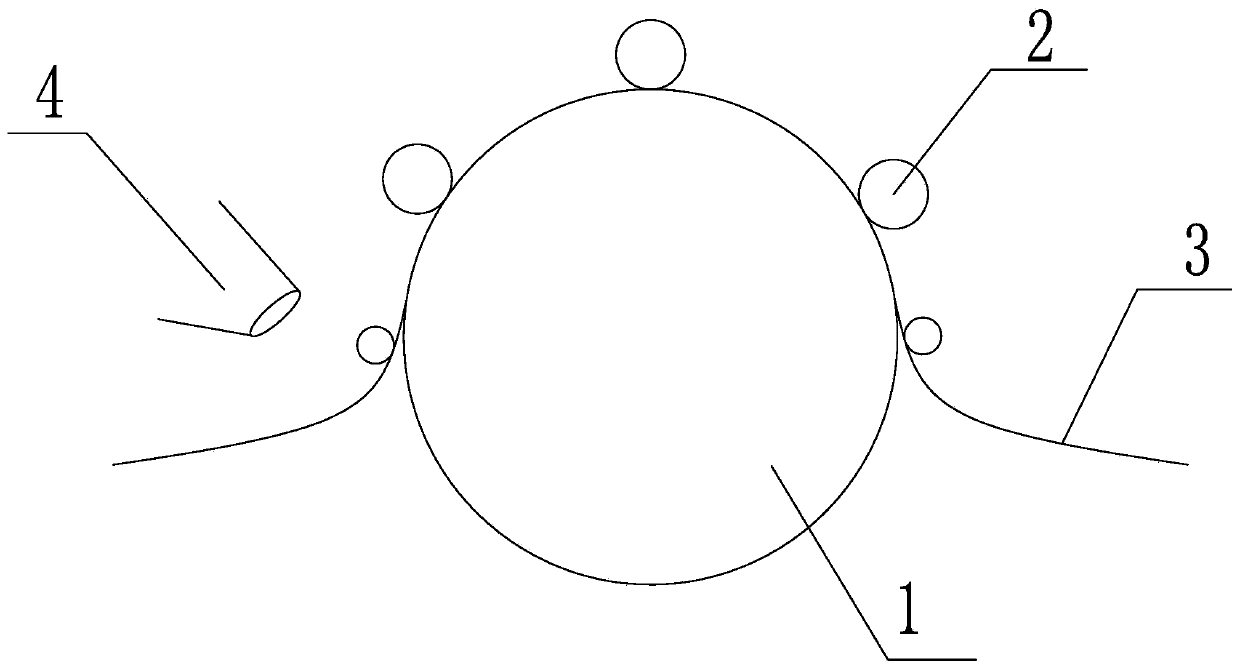

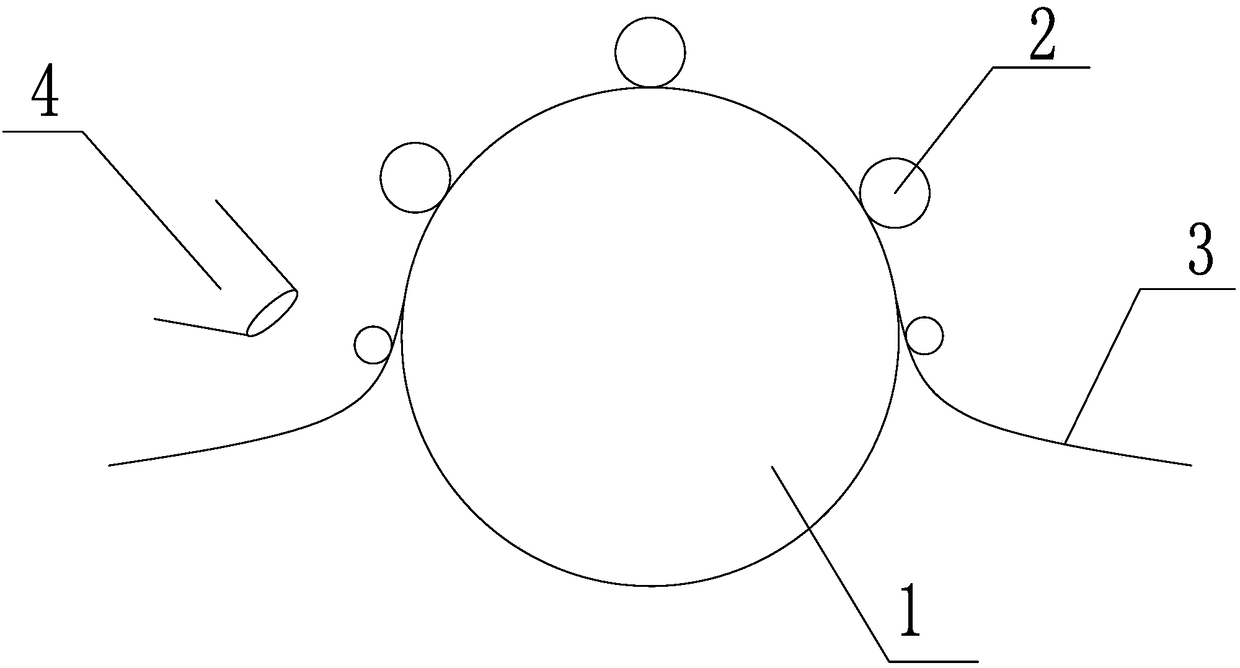

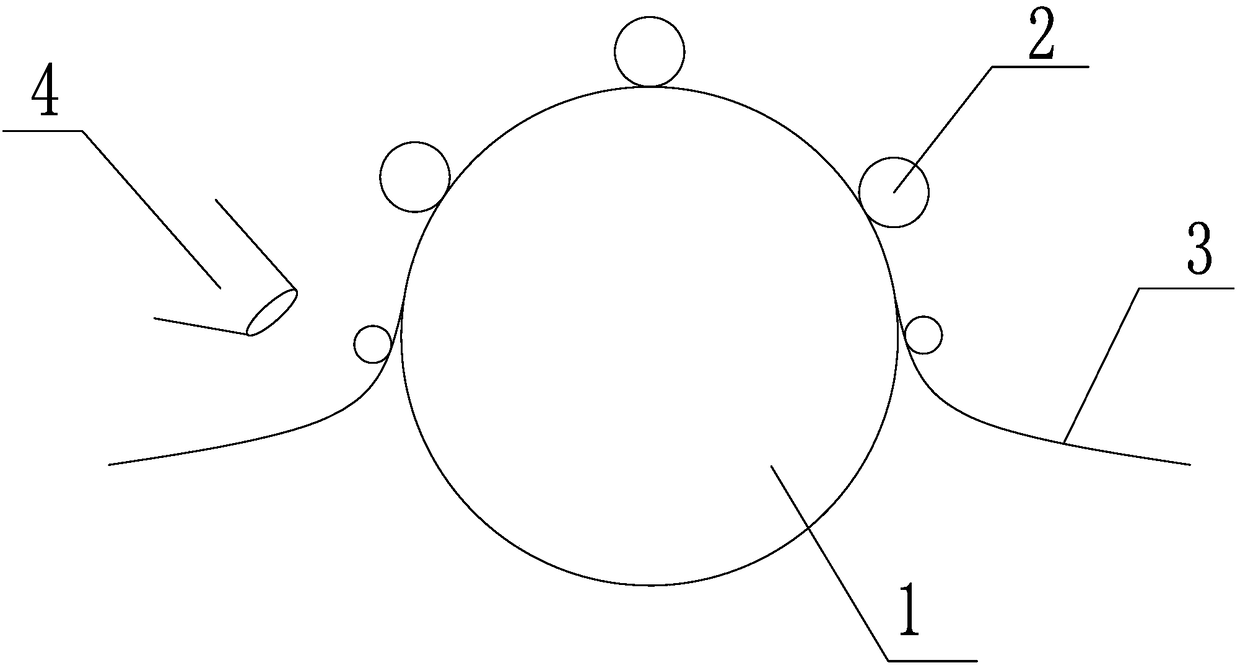

Automatic rotation type coke cutter

InactiveCN103540327ASmall rotational inertiaQuality improvementThermal non-catalytic crackingEnergy inputWater flowCoke

Owner:XIANGYANG HANGSHENG PETRO CHEM ENVIRONMENTAL PROTECTION EQUIP

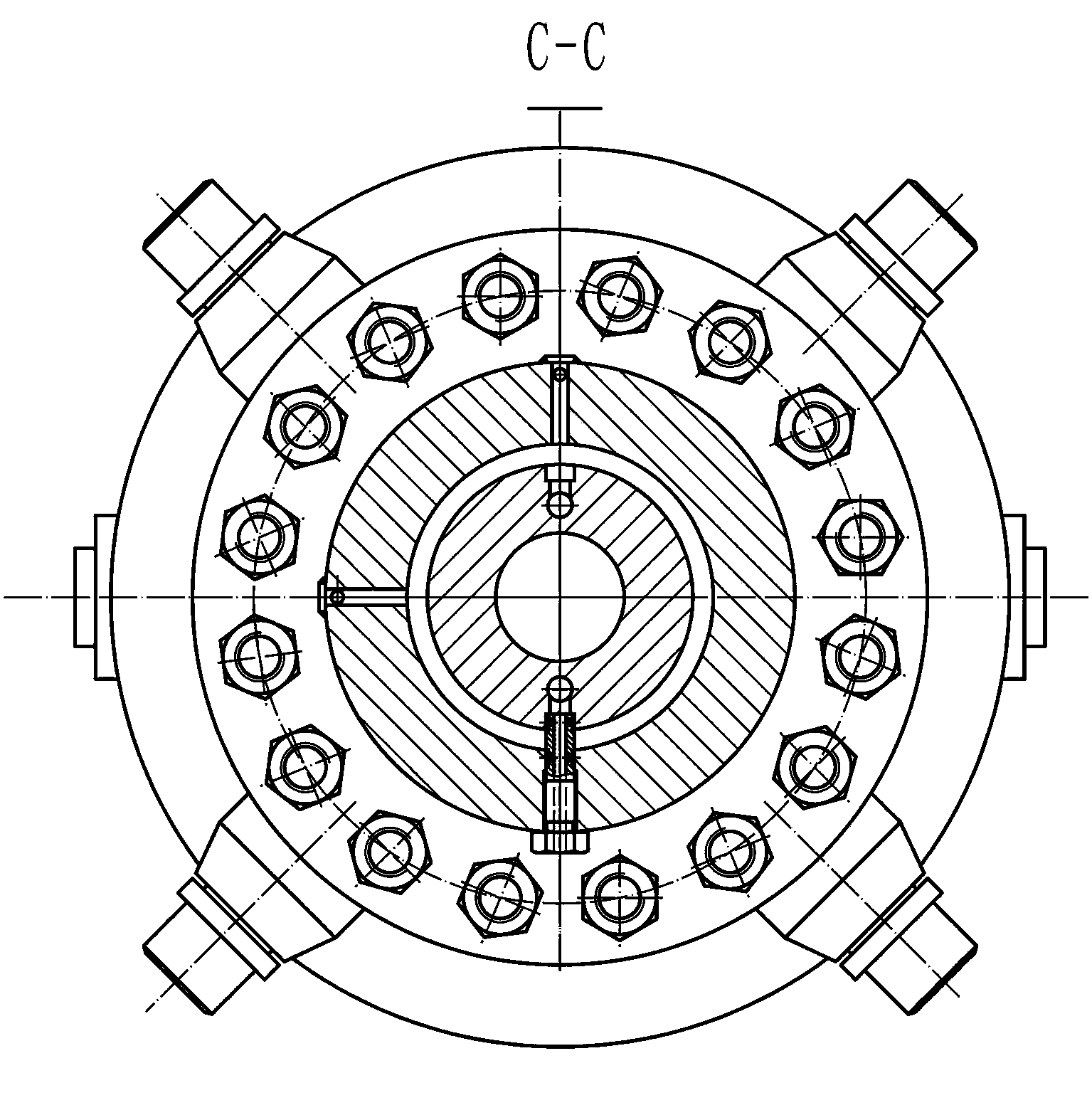

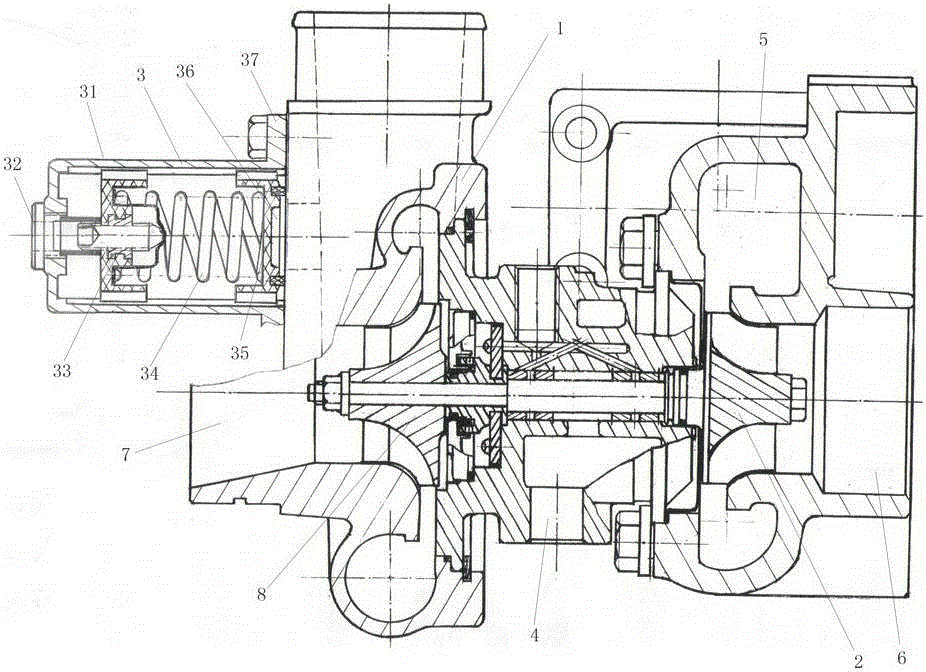

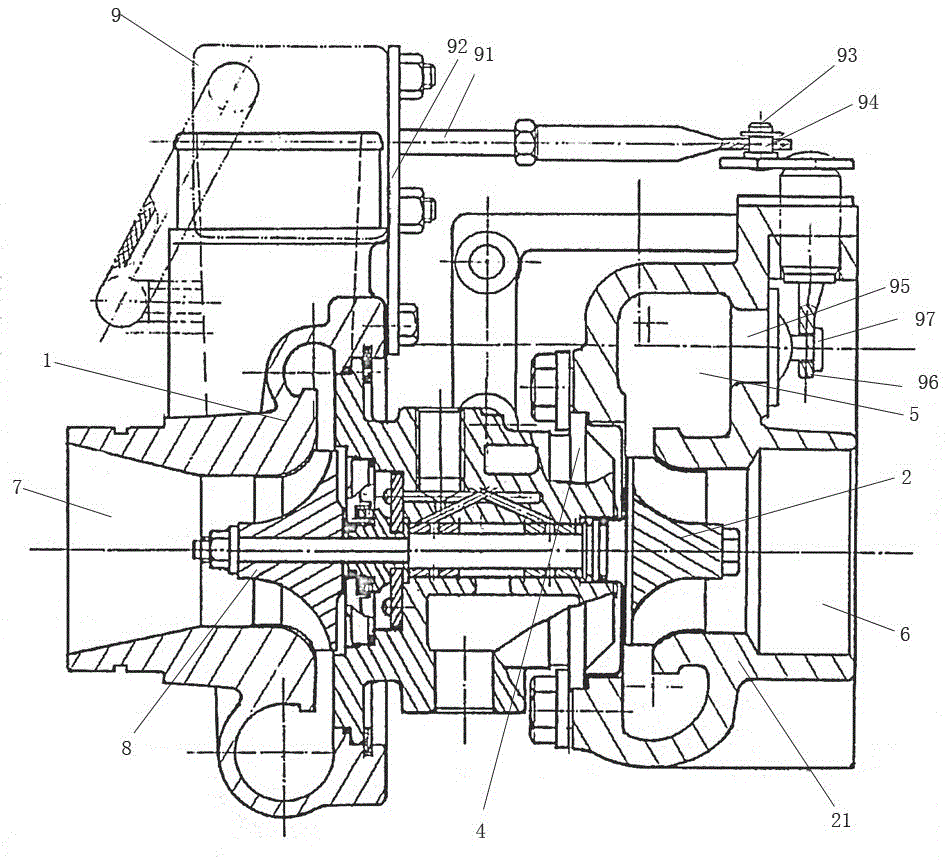

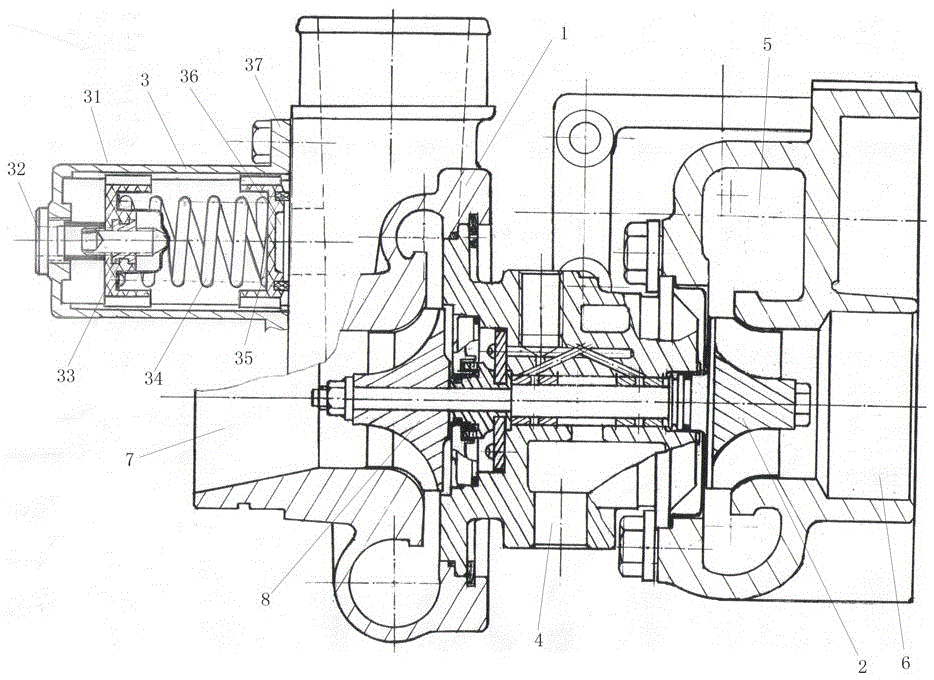

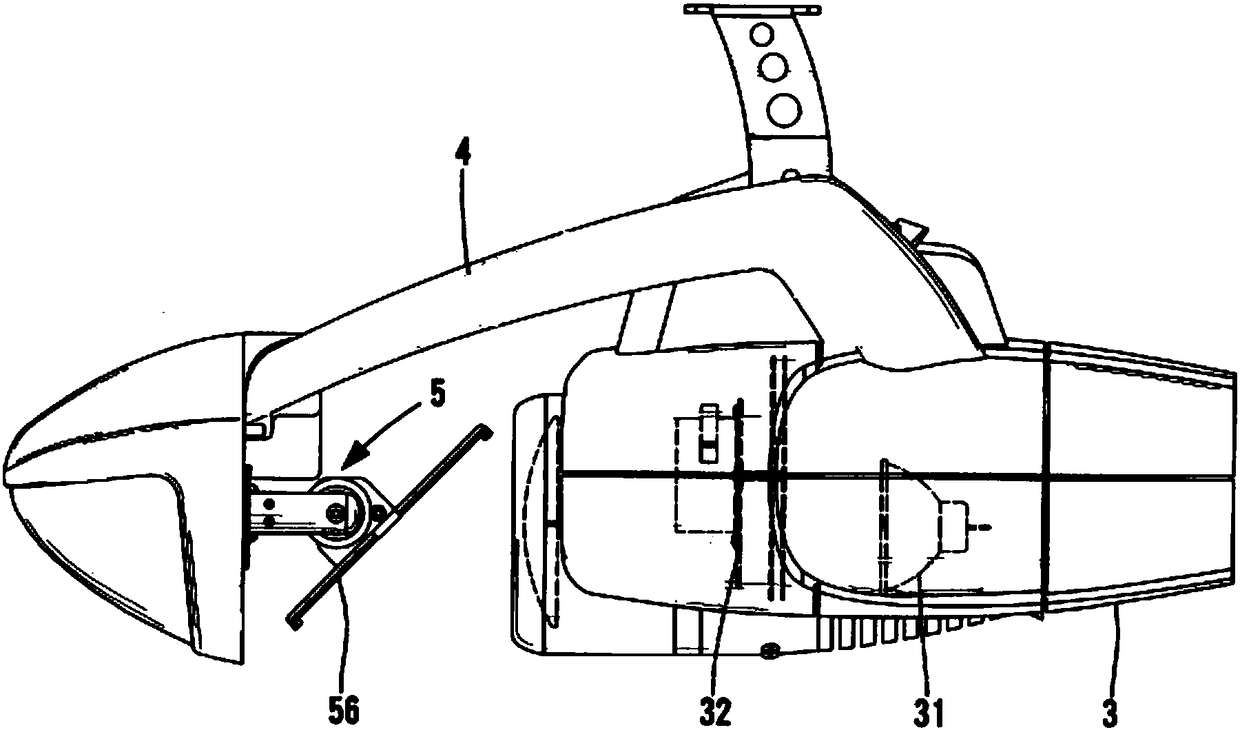

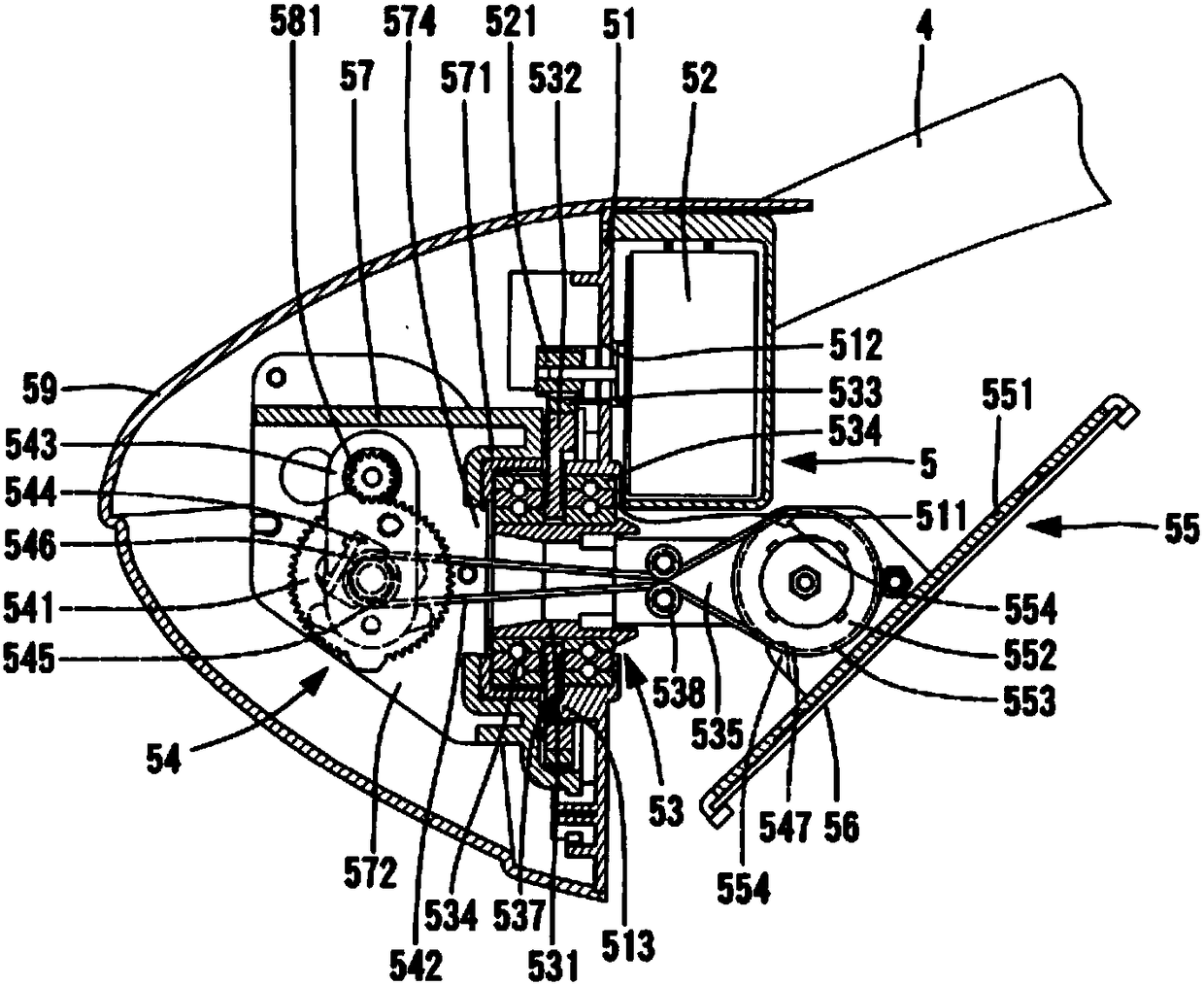

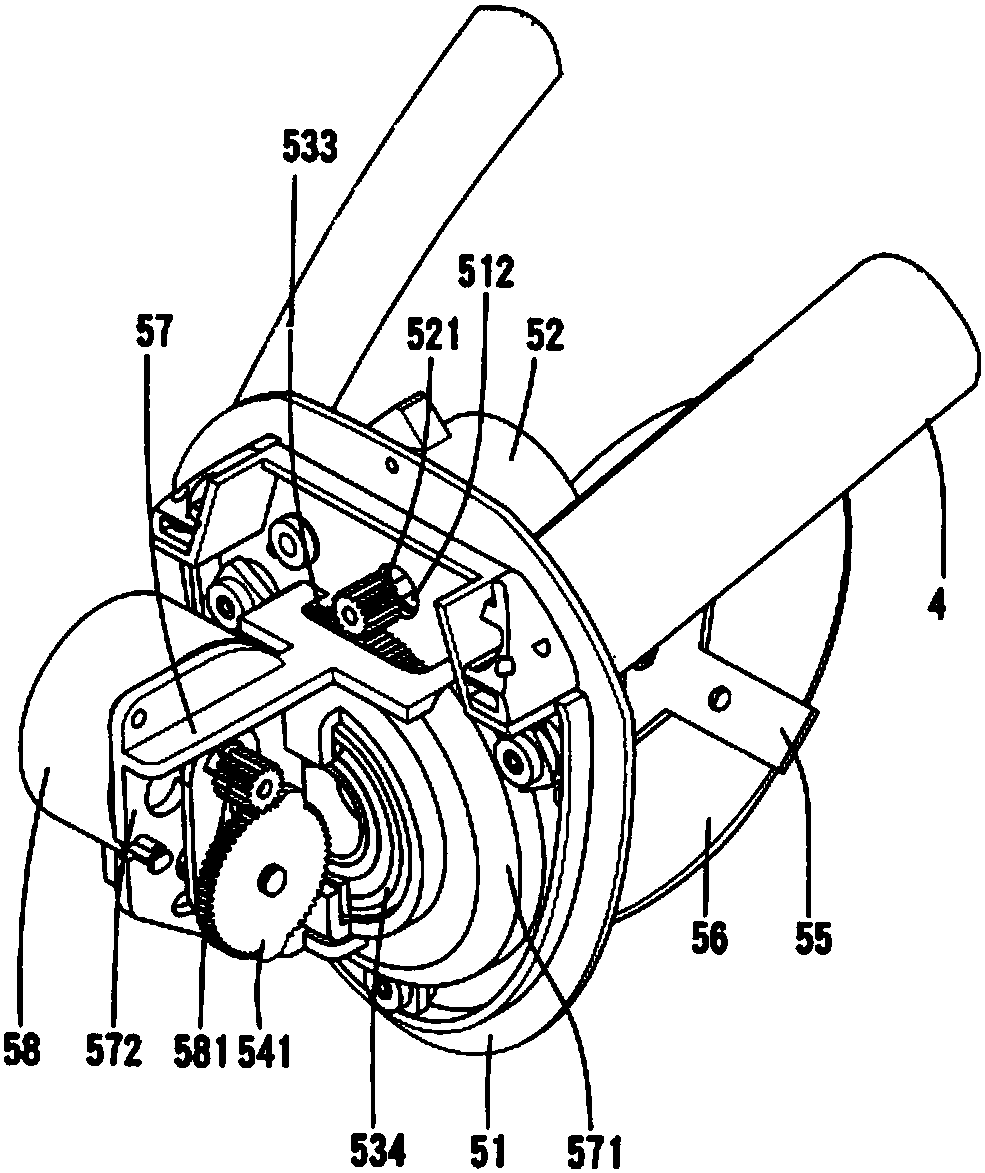

Turbocharger

InactiveCN105240113AExtended service lifeAvoid knockingInternal combustion piston enginesEngine componentsAir compressionImpeller

The invention relates to a turbocharger which comprises an intermediate body. The two ends of the intermediate body are connected with an impeller and a turbine through shafts respectively. The impeller is covered with an air compression shell. A shock absorber is installed on the side face of an outlet of the air compression shell. An air inlet is formed in one side of the impeller. A turbine air inlet and an exhaust gas outlet are formed in the turbine. A turbine shell of the turbocharger is provided with the shock absorber instead of a bypass vent valve so that knocking and surging can be avoided. The pressure is adjusted through a precision spring of the shock absorber, so that the turbocharger is flexible, reliable and convenient to install, adjust and repair. When the turbocharger and an engine are matched and adjusted, adjustment is performed through an adjusting spring, operation is easy, accurate and reliable, and technicians of an engine factory assembly production line and automobile repair technicians can install and adjust the turbocharger to meet the ideal standard according to the power, the displacement and the number of turns of the engine.

Owner:成军

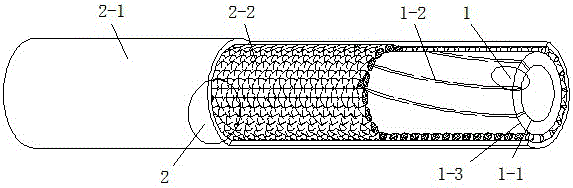

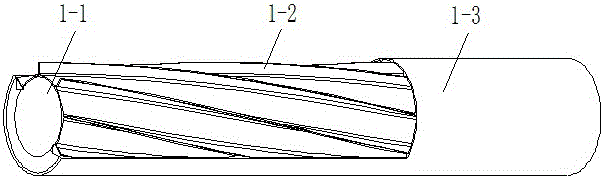

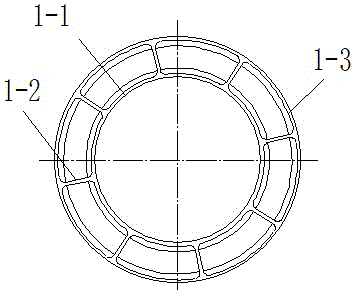

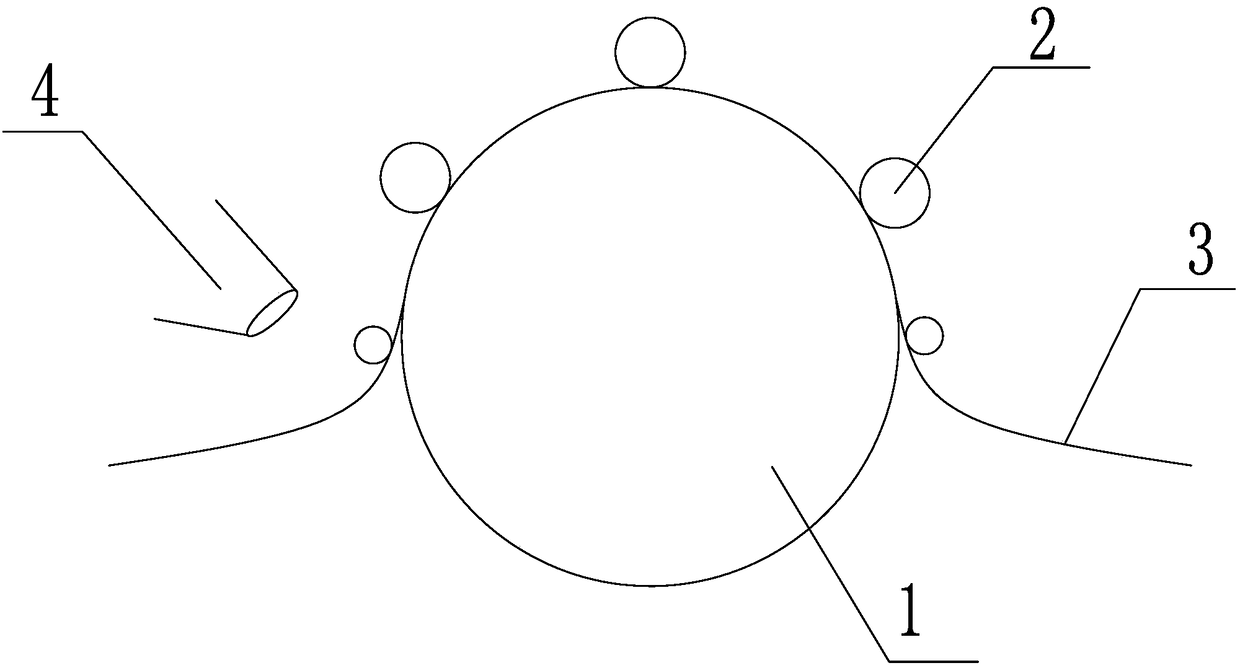

Backing roll fiber-braided composite layer

PendingCN106743981AIncreasing the thicknessInhibit sheddingFilament handlingRotary inertiaBraided composite

The invention discloses a backing roll fiber-braided composite layer and belongs to a backing roll. The composite layer comprises a fiber-braided structure reinforcement layer and a pouring layer; the outside of the fiber-braided structure reinforcement layer is wrapped by the pouring layer; the fiber-braided structure reinforcement layer is a sleeve-mesh-shaped braided fabric formed by braiding a composite in a braiding machine and is single-layer or multilayer; the pouring layer is formed by wrapping an external cylinder of the fiber-braided structure reinforcement layer by using various materials through a pouring process; and the pouring layer is made of resin, rubber or polyurethane. The composite layer disclosed by the invention is braided in a reciprocated way by using the braiding machine, so that the thickness of an outer layer is increased, and the drop of the fiber-braided structure reinforcement layer is avoided; the outer cylinder is formed by pouring a special high-strength material for the backing roll; and the backing roll fiber-braided composite layer is light in weight, high in tensile strength, free of breakage at the outer layer, small in rotary inertia, high in outer cylinder precision, free of deformation, free of mechanical waves on the formed backing roll, antistatic, corrosion-resistant, high-temperature-resistant and long in life, so that the product quality is improved, and the productivity is increased.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

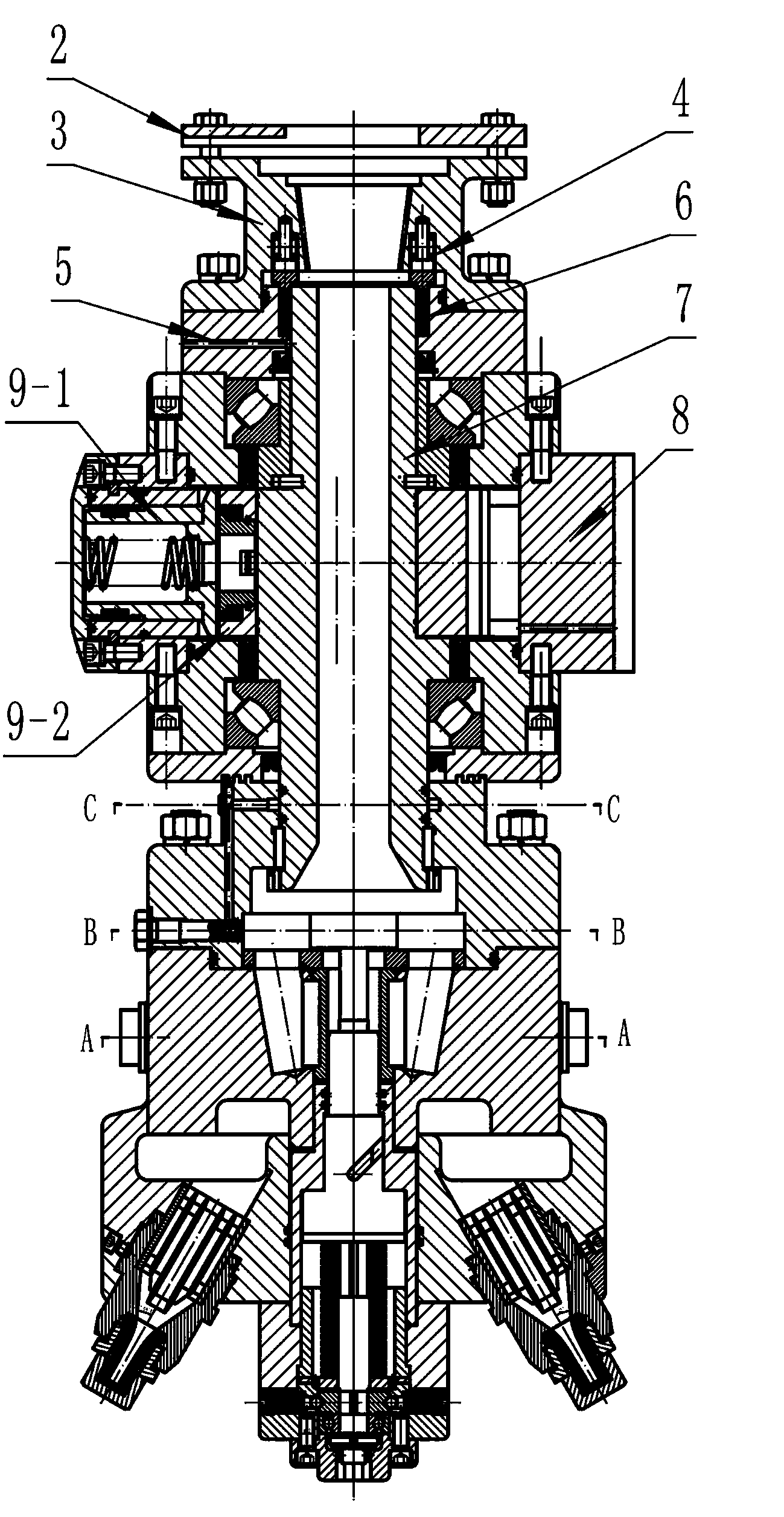

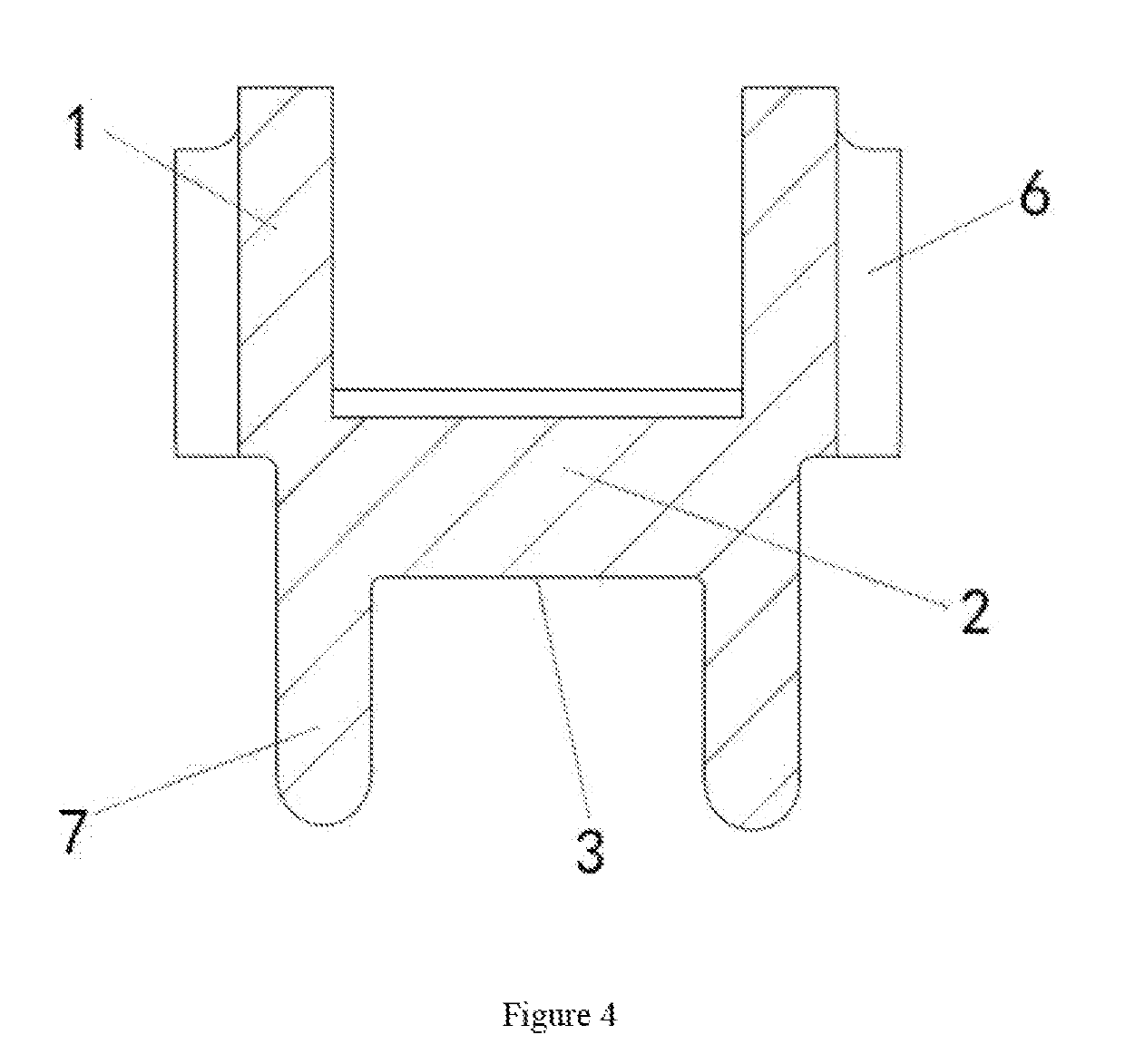

Two-stage machine tool gearing, in particular spindle gearing

InactiveCN101389884BWith transmission ratioSmall rotational inertiaToothed gearingsControl theoryMachine tool

Proposed is a two-stage machine tool gearing, in particular spindle gearing, comprising a planetary gear set (16), in which the spindle (7) or a spindle insert can be connected in a form-fitting or force-fitting manner to the drive output (2, 3) of the gearing (17), which gearing (17) has a first drive output shaft (2) and a second drive output shaft (3), wherein the first drive output shaft (2) is rotationally fixedly connected to the drive input shaft (1) and can be detachably connected by means of a first switching element (5) to the sun gear (4) of the planetary gear set (17), wherein the second drive output shaft (3) is rotationally fixedly connected to the planetary carrier (19) of the planetary gear set (17) and the ring gear (8) of the planetary gear set (17) is rotationally fixedly connected to the housing (18) of the gearing, and wherein a second switching element (6) is provided which produces a detachable connection between the spindle (7) or a spindle insert and, selectively, the first or the second drive output shaft (2) or (3).

Owner:ZF FRIEDRICHSHAFEN AG

A kind of preparation method of latex-free machine-woven carpet

ActiveCN108396397BGuaranteed pull-out forceReduce dosageCarpetsWoven fabricsPolymer scienceLatex rubber

The invention discloses a method for preparing a latex-free woven carpet. The second coating layer is filament or spun yarn formed of hot-melt fibers, and the first coating layer is fiber long yarn formed of nylon 6 or nylon 66. Silk or spun yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn. Pile weft. When hot-melt copolyamide fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of nylon or wool fibers, when the hot-melt copolyamide fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the carpet pile and The shape retention and dimensional stability of the carpet, thereby omitting the back glue process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:BINZHOU COC CARPET

A kind of preparation method of machine-woven carpet without back glue process

ActiveCN108411460BGuaranteed pull-out forceReduce dosageHeating/cooling textile fabricsWoven fabricsFiberPolymer science

The invention discloses a preparation method of a machine-woven carpet without adhesive backing process. The second coating layer is filament or staple fiber yarn formed by hot-melt fibers, and the first coating layer is polyester fiber filament or staple yarn. Fiber yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn . When hot-melt copolyester fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt copolyester fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the pile and the carpet Excellent shape retention and dimensional stability, thereby omitting the back glue process in the carpet preparation process, making the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

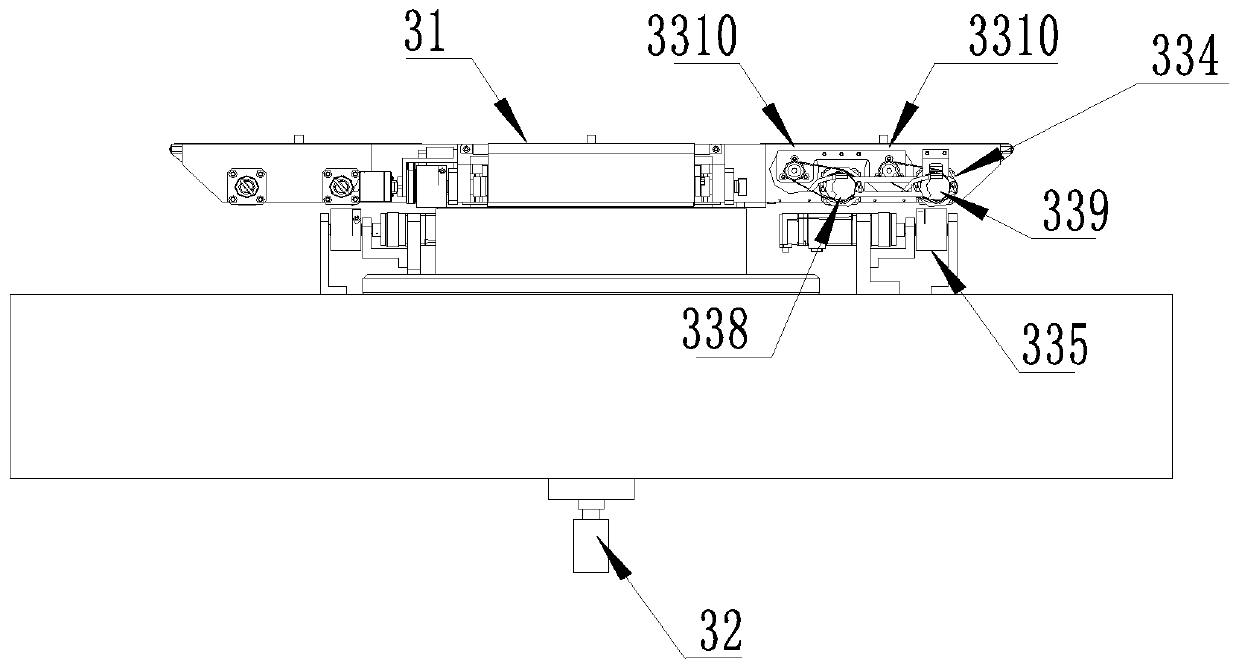

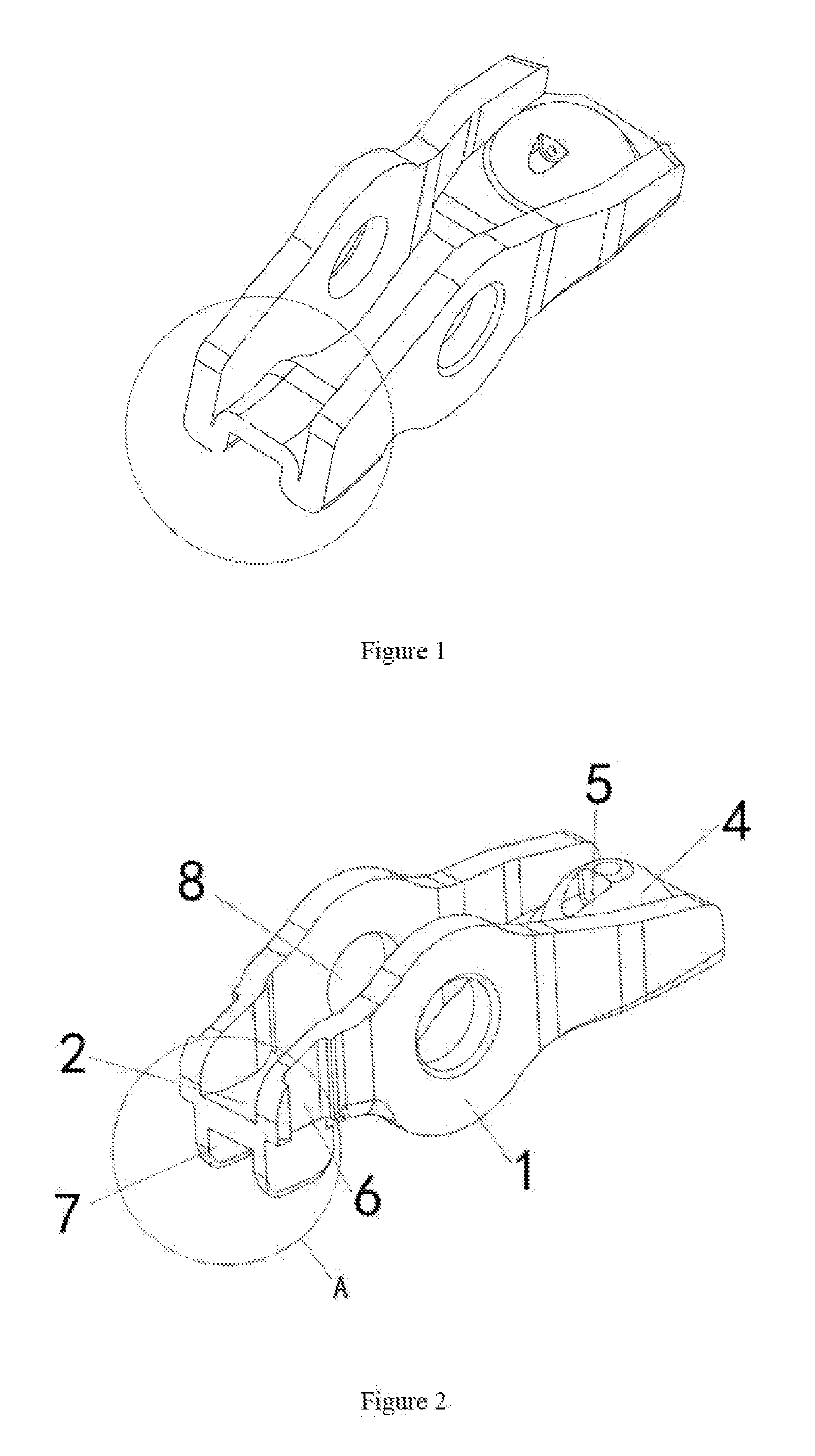

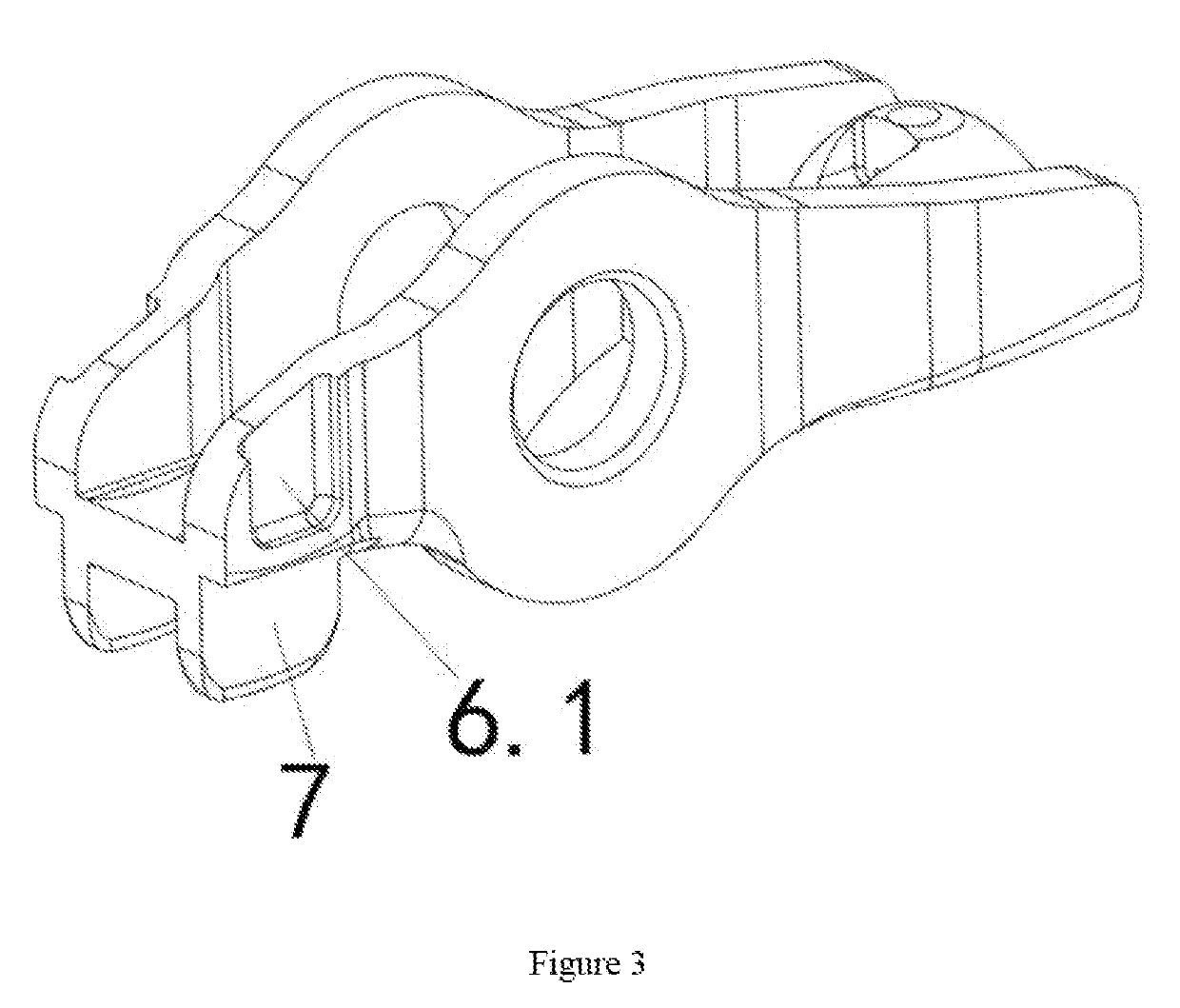

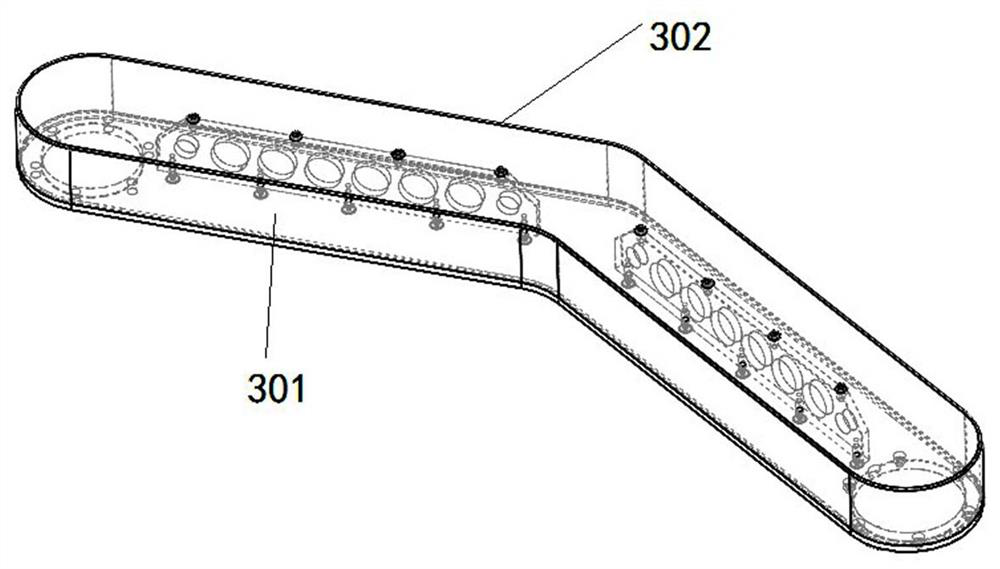

A rack and pinion driven cable stripping and rotating parallel crimping mechanism

ActiveCN104218426BImprove crimp qualityLight structureConnection formation by deformationMechanical engineeringRack and pinion

The invention discloses a gear-rack-driven cable peeling and rotating parallel crimping mechanism which comprises a swing arm unit, a pneumatic gripper unit and a gear-rack driving unit. The swing arm unit is connected with the pneumatic gripper unit through a linear bearing, the gear-rack driving unit is in screw fastening with the swing arm unit. The gear-rack-driven cable peeling and rotating parallel crimping mechanism is simple and light in integral structure, convenient to operate, small in rotating inertia, capable of realizing parallel crimping, high in cable crimping quality and low in integral power consumption.

Owner:HEBI HAICHANG SPECIAL EQUIP

Turbocharger

InactiveCN105587402AExtended service lifeAvoid knockingInternal combustion piston enginesEngine componentsImpellerProduction line

Owner:成军

Reflection device of stage lamp

InactiveCN108278529ASmooth rotationSmall rotational inertiaLighting applicationsMechanical apparatusLight beamEngineering

The invention discloses a reflection device of a stage lamp. The reflection device of the stage lamp comprises a base mounted on a unit body, a support arranged on the base in a combined mode, a firstmotor mounted on the base, a second motor mounted on the support, a first transmission mechanism driven by the first motor, a second transmission mechanism driven by the second motor, a mirror holderis pivoted on a rotary shaft of the first transmission mechanism, and a reflection mirror arranged on the mirror holder in a combined mode. The second transmission mechanism is hung on a pivoting part of the mirror holder through a rope ring so that the reflection mirror can be driven by the first motor and the second motor to rotate by variable angles around the light projection direction or around the direction intersecting with the light projection direction so as to reflect a light beam projected by a light source, and the first motor and the second motor can drive the reflection mirror to smoothly rotate with small power.

Owner:广州歌斯达舞台灯光设备有限公司

Production method of woven carpet with no latex

InactiveCN108396441AGood shape retentionGood dimensional stabilityCarpetsWoven fabricsLow-density polyethyleneViscous flow

The invention discloses a production method of a woven carpet with no latex. A second covering layer is made with hot-melt fiber filaments or staple yarns; a first covering layer is made with high-density polyethylene fiber filaments or staple yarns; the second covering layer accounts for 20-50% of total mass of composite yarn; the first covering layer accounts for 10-15% of the total mass of thecomposite yarn; the balance is core yarns; pile wefts are therefore produced. During the production of a no-gum carpet with hot-melt low-density polyethylene fiber as an adhesive material, pile yarnsare made in conjunction with nylon fiber or wool; the hot-melt low-density polyethylene fiber melts down when heated to above its melting point in a hot pressing step, and fiber macromolecular chain conformation varies; segmer transition allows the whole macromolecular chain to slide, a viscous flow occurs, piles, wefts and warps are effectively fixed after solidifying, pull-out strength of the piles is enhanced, and shape-maintaining property and dimensional stability are enhanced for the carpet; therefore, the gumming step in the carpet production process is omitted, so that the carpet produced is more environmentally friendly.

Owner:QINGDAO UNIV

Preparation method of latex-free woven carpet

InactiveCN108411459ASolve the problem of impermeabilityOmit the adhesive processCarpetsWoven fabricsViscous flowEngineering

The invention discloses a preparation method of a latex-free woven carpet. A second wrapping layer is made of filaments or short fiber yarn formed by hot melt fiber, and a first wrapping layer is madeof polyester fiber filaments or short fiber yarn. Composite yarn comprises, by mass, 20-25% of second wrapping layer, 10-15% of first wrapping layer and the balance pile weft prepared from core yarn.When the latex-free carpet is produced from hot-melt copolyester fiber serving as an adhesive material and pile yarn prepared from nylon fiber or wool, the hot-melt copolyester fiber is melted when heated to be higher than the melting point in the hot pressing procedure, and a fiber macromolecular chain conformation changes; through transition of a chain segment, the whole macromolecular chain slides, viscous flow is generated, cured piles and the weft are effectively solidified, and the weft and warp are effectively solidified, so that the drawing strength of the piles and the shape preservation and size stability of the carpet are enhanced, then the gumming procedure in the carpet preparation process is omitted, and the prepared carpet is more environmentally friendly.

Owner:QINGDAO UNIV

Lightweight rocker arm frame and curved crown part forming process thereof

ActiveUS20190093522A1Simple molding processSmall rotational inertiaValve arrangementsMachines/enginesEngineeringBearing surface

This invention provides a novel lightweight rocker arm frame and a forming process of a curved crown part thereof, including two sidewalls and two bottom plates. The two sidewalls are connected through the bottom plates respectively located at two ends. A ball socket protruded upwards and an, oil hole are arranged at a bottom plate at one end, and a bottom surface of a bottom plate at the other end is a bearing surface. A pin shaft hole is formed in the middle of each sidewall without the bottom plates. According to the rocker arm frame disclosed by the invention, the strength of the structure can be ensured while light weight is realized. The production efficiency of the rocker arm frame is effectively improved, and the structure of the valve rod supporting position is improved.

Owner:HANGZHOU XZB TECH

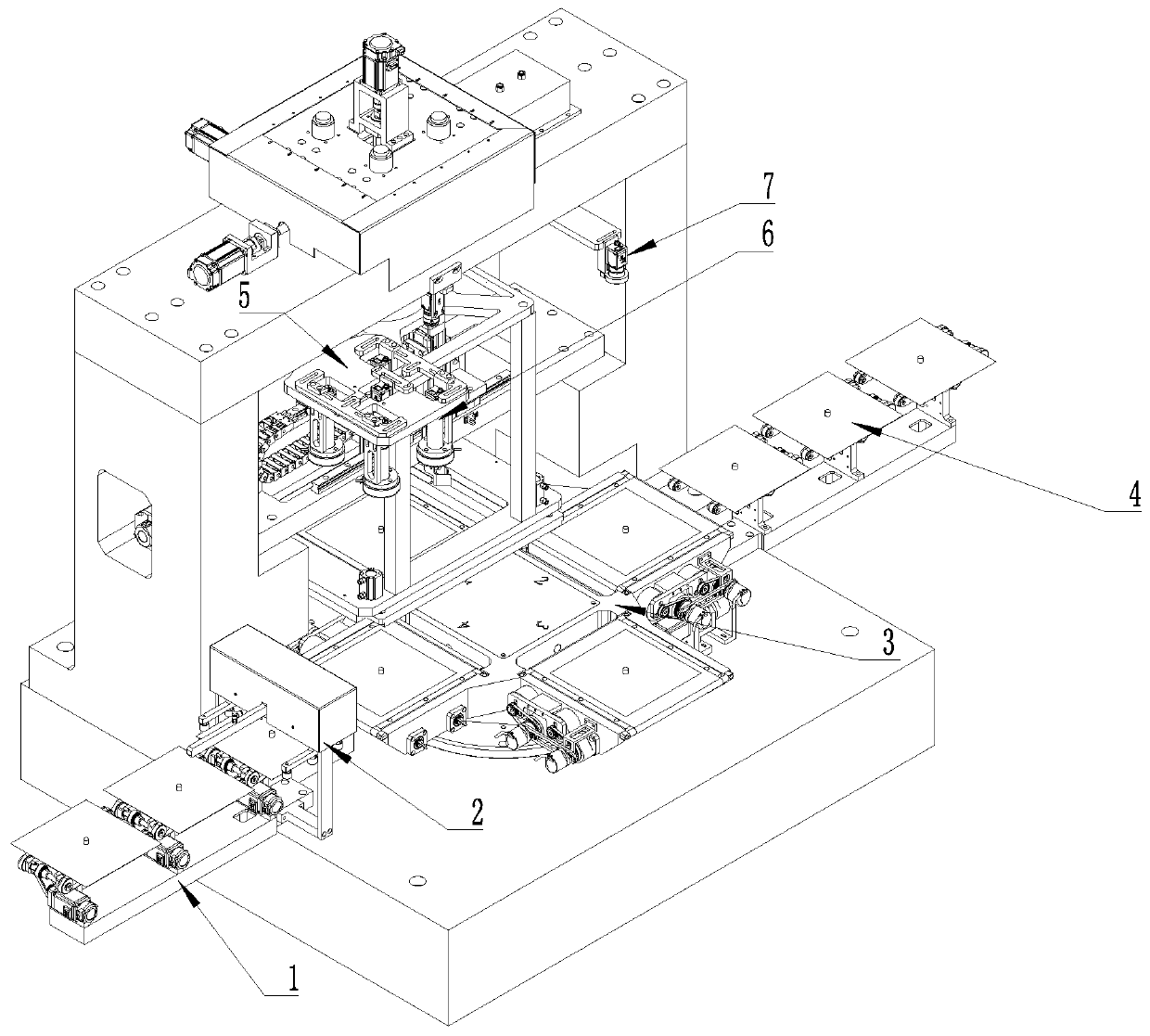

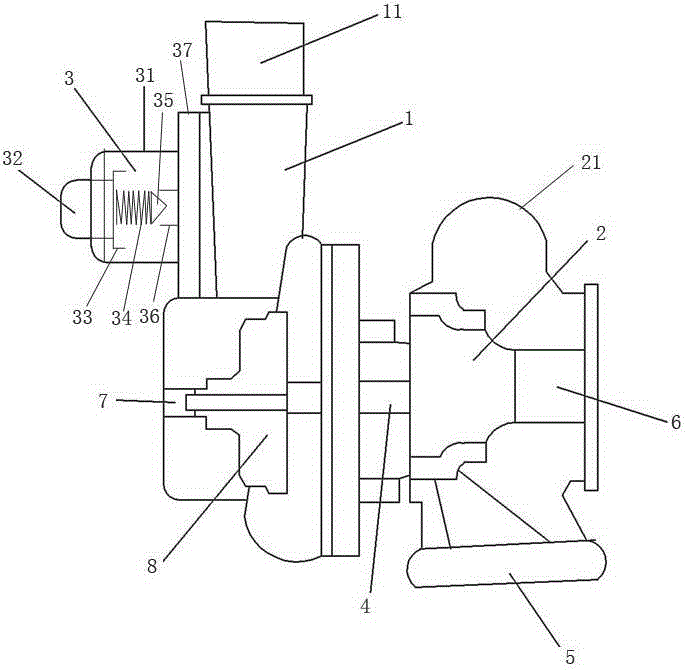

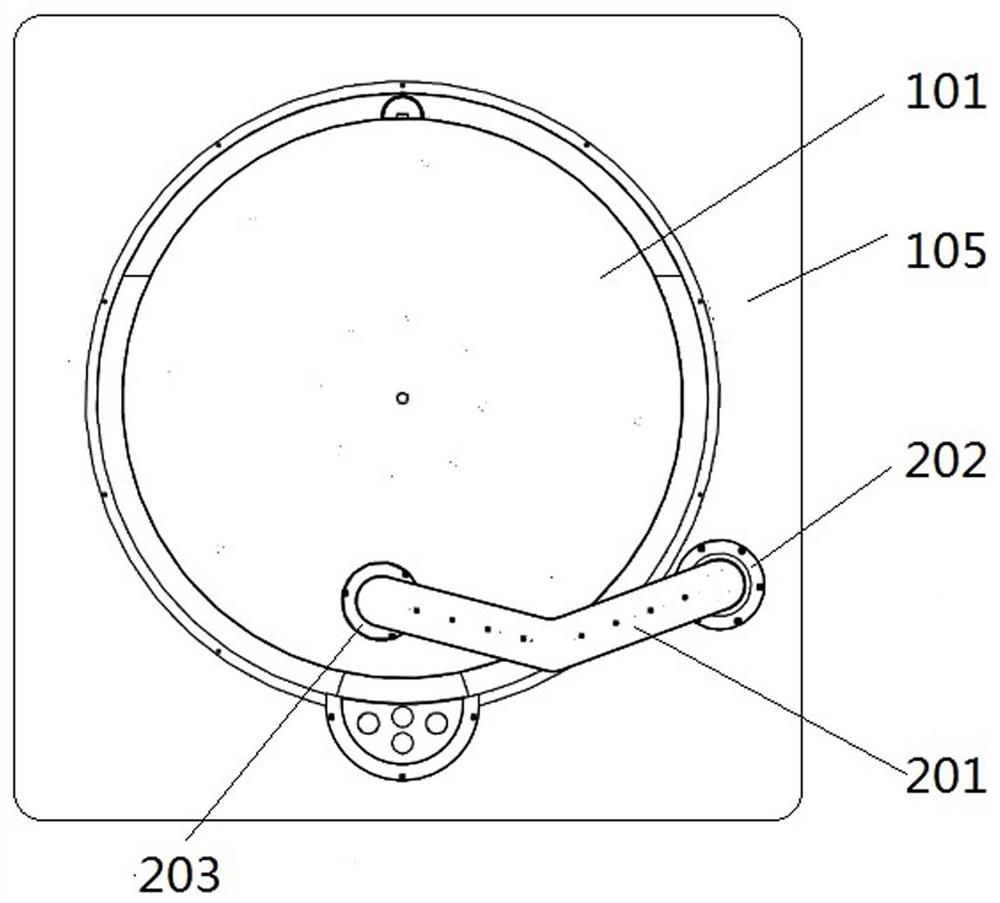

Polishing disk trimming device of polishing machine

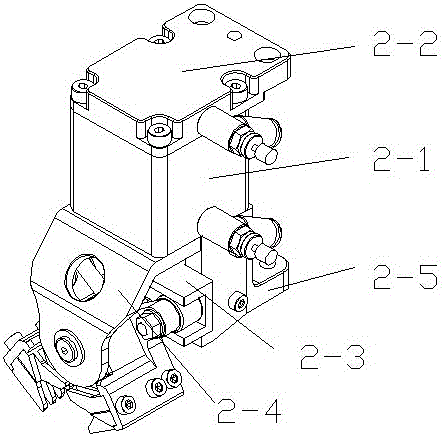

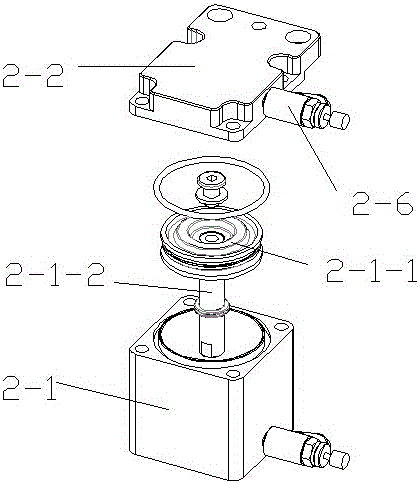

PendingCN114193326AReduce loadSmall rotational inertiaAbrasive surface conditioning devicesPolishingEngineering

The invention discloses a polishing disk trimming device of a polishing machine, and belongs to the technical field of polishing equipment. A polishing disk trimming device of a polishing machine is composed of a rotating arm assembly (201), a driving assembly (202) and a disk trimming main shaft assembly (203). The driving assembly (202) is fixed to a workbench on the outer side of a polishing disk of the polishing machine through screws evenly distributed on the circumference, one end of the rotating arm assembly (201) is fixed to the driving assembly through screws evenly distributed on the circumference, and the disk repairing main shaft assembly (203) is fixed to the other end of the rotating arm assembly through screws evenly distributed on the circumference. According to the polishing disc finishing device, the finishing force of the polishing disc can be changed without manually replacing the finishing wheel, the maintenance time is shortened, the whole finishing mechanism is light in weight, the rotating inertia of the polishing disc is effectively reduced, and the polishing process is more stable.

Owner:莱玛特·沃尔特斯(沈阳)精密机械有限公司

A kind of preparation method of woven carpet without back glue process

ActiveCN108411458BSolve the problem of impermeabilityImprove bindingHeating/cooling textile fabricsCarpetsPolyesterFiber

The invention discloses a method for preparing a woven carpet without a backing process. The second coating layer is hot-melt fiber filament or spun yarn, and the first coating layer is polypropylene fiber filament or spun yarn. , the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn. When hot-melt ethylene-vinyl acetate copolymer fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt ethylene-vinyl acetate copolymer fibers are heated to Melting occurs when the melting point is above the melting point, and the conformation of the fiber macromolecular chain changes. Through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. The pull-out strength of the head and the shape retention and dimensional stability of the carpet, thereby omitting the adhesive backing process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

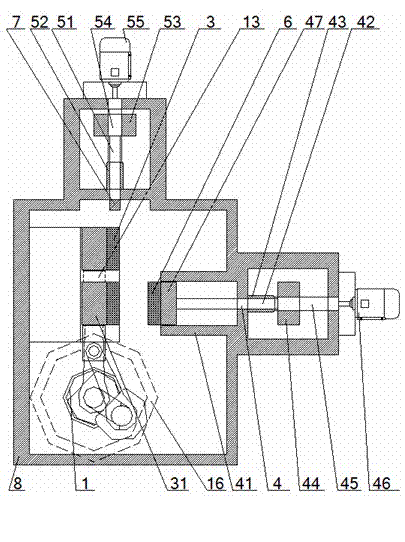

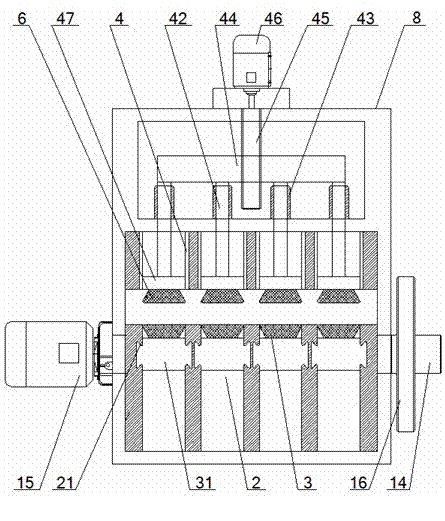

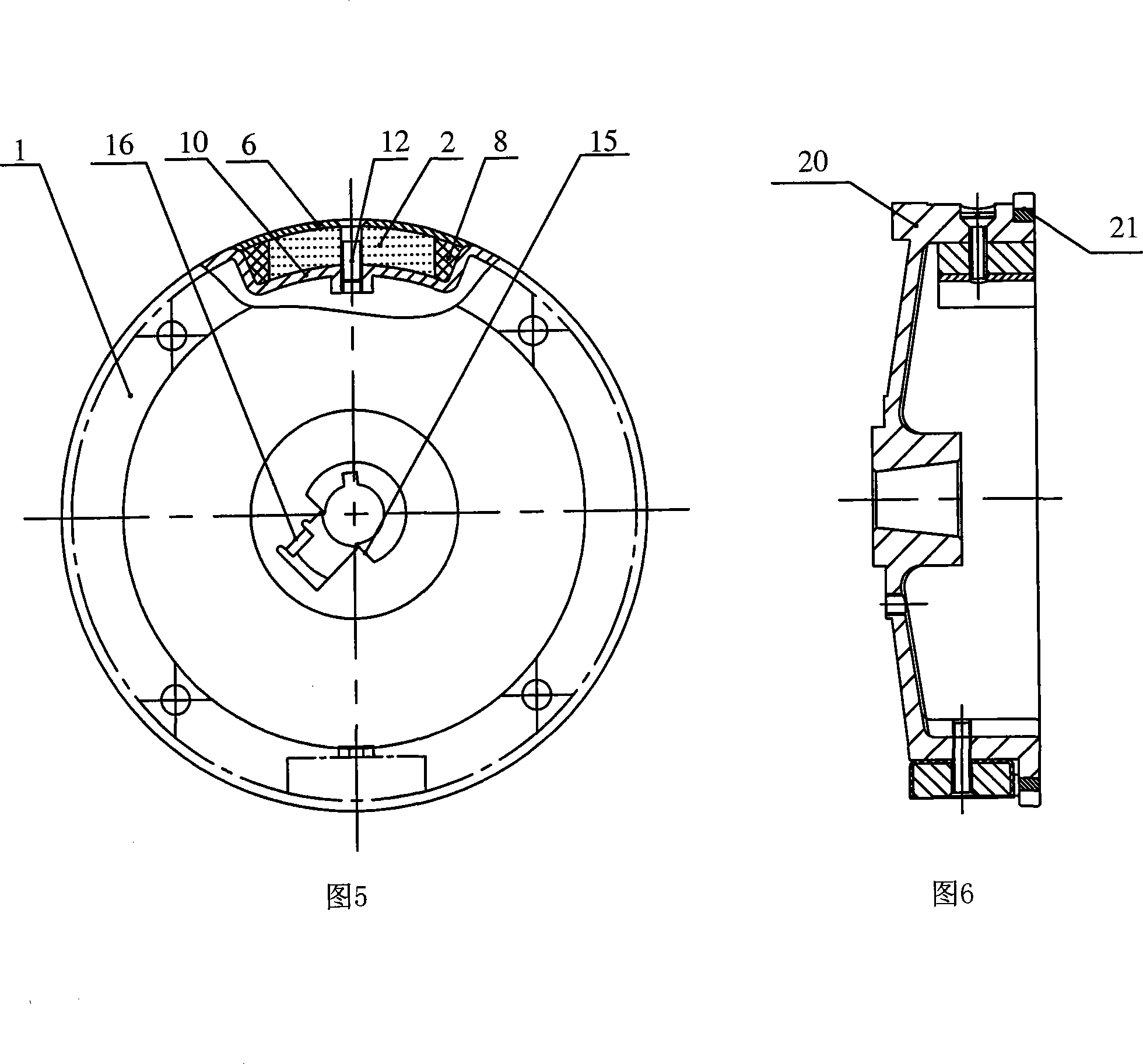

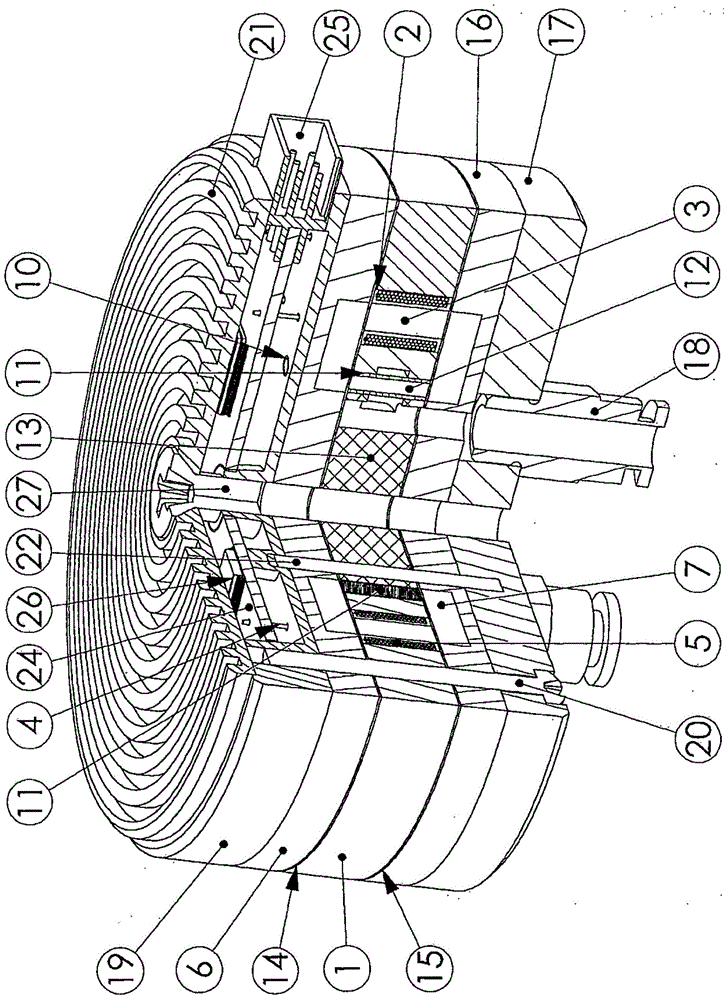

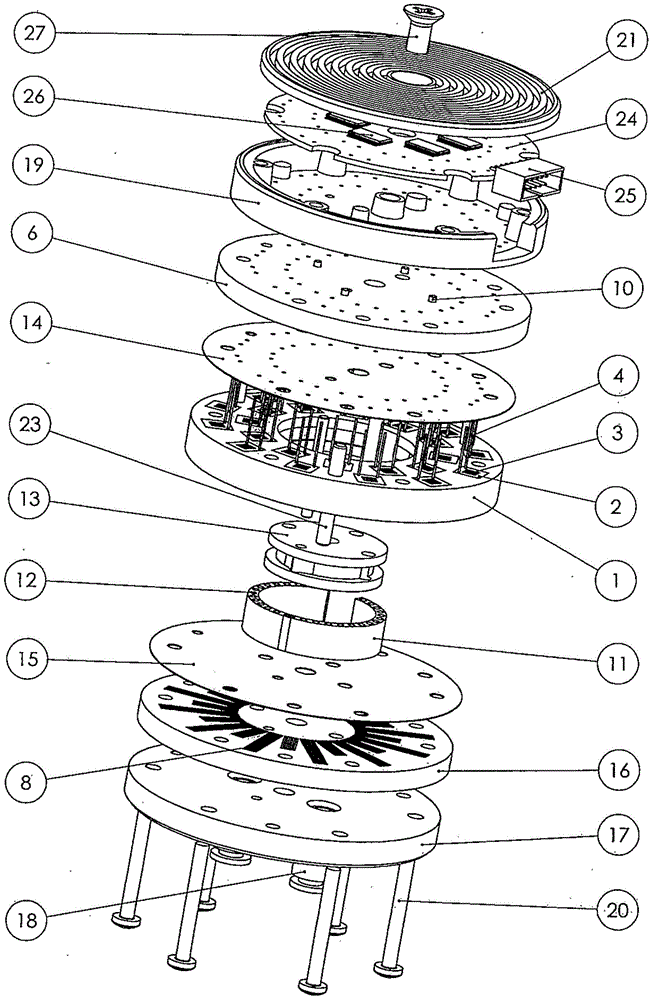

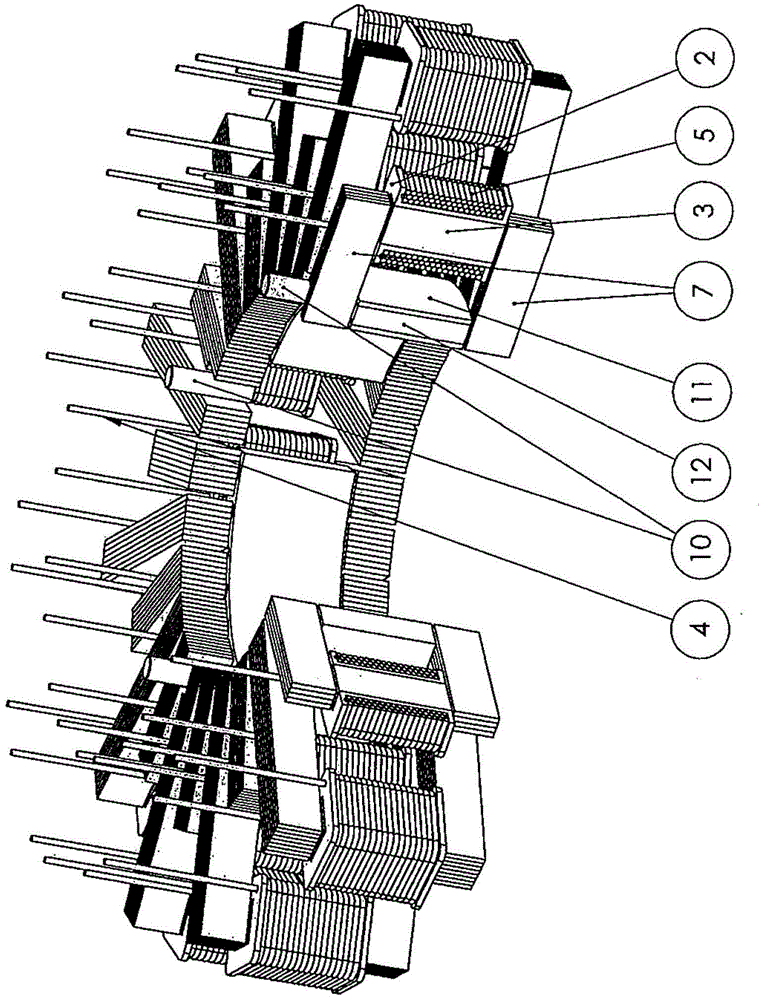

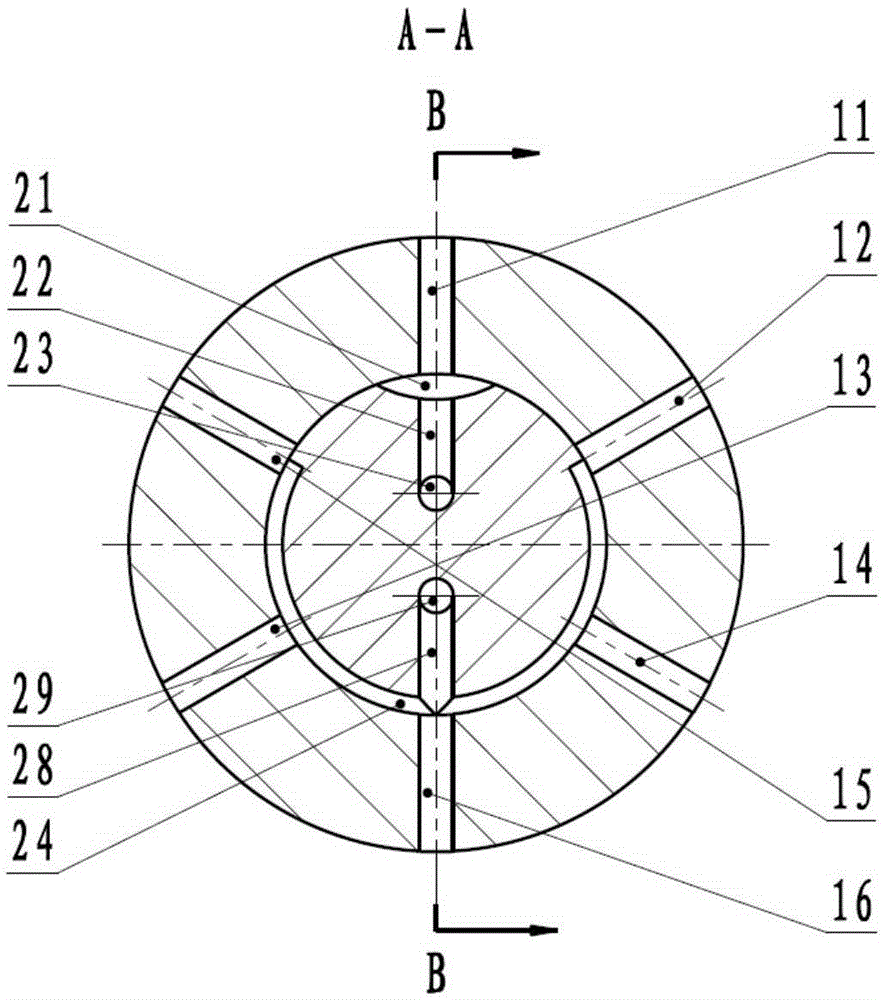

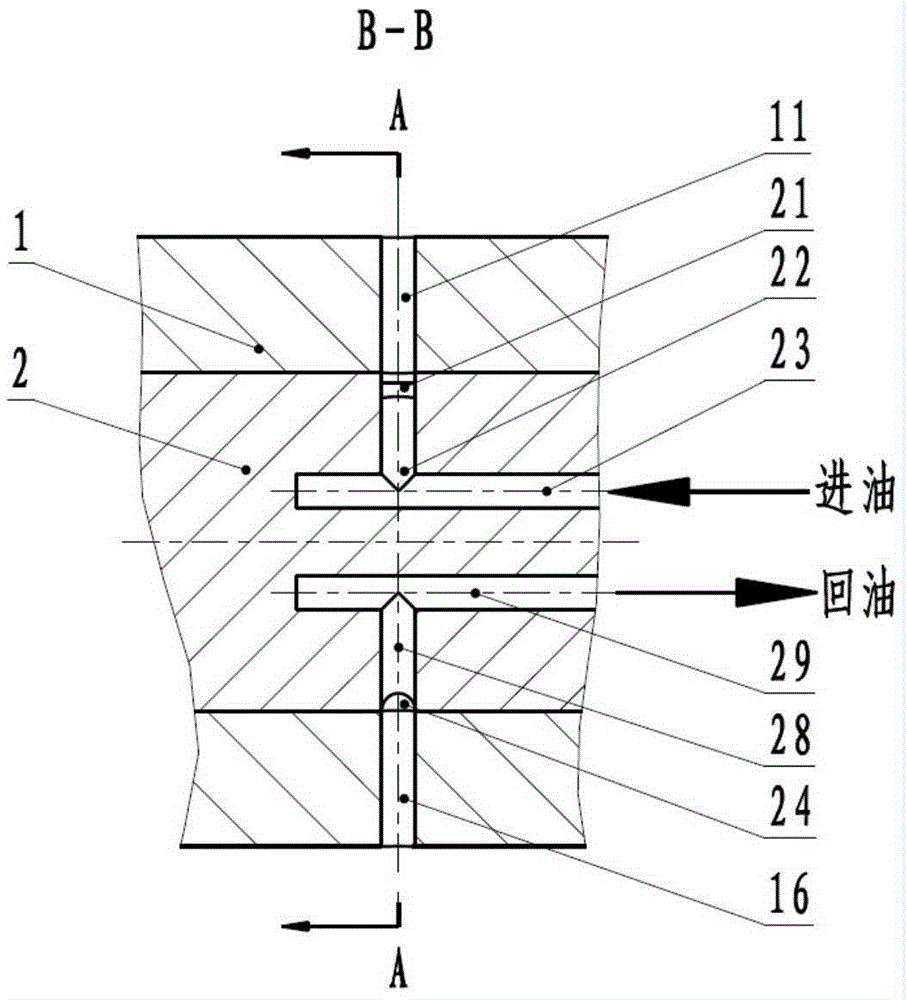

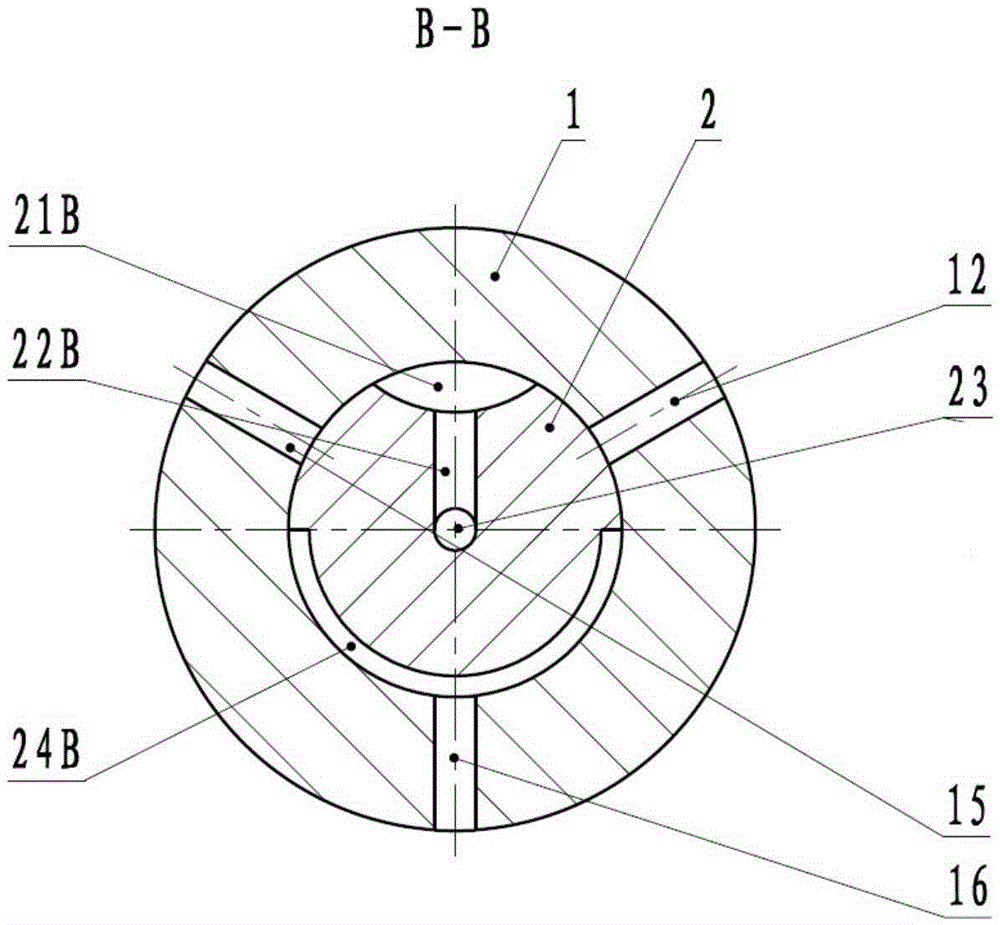

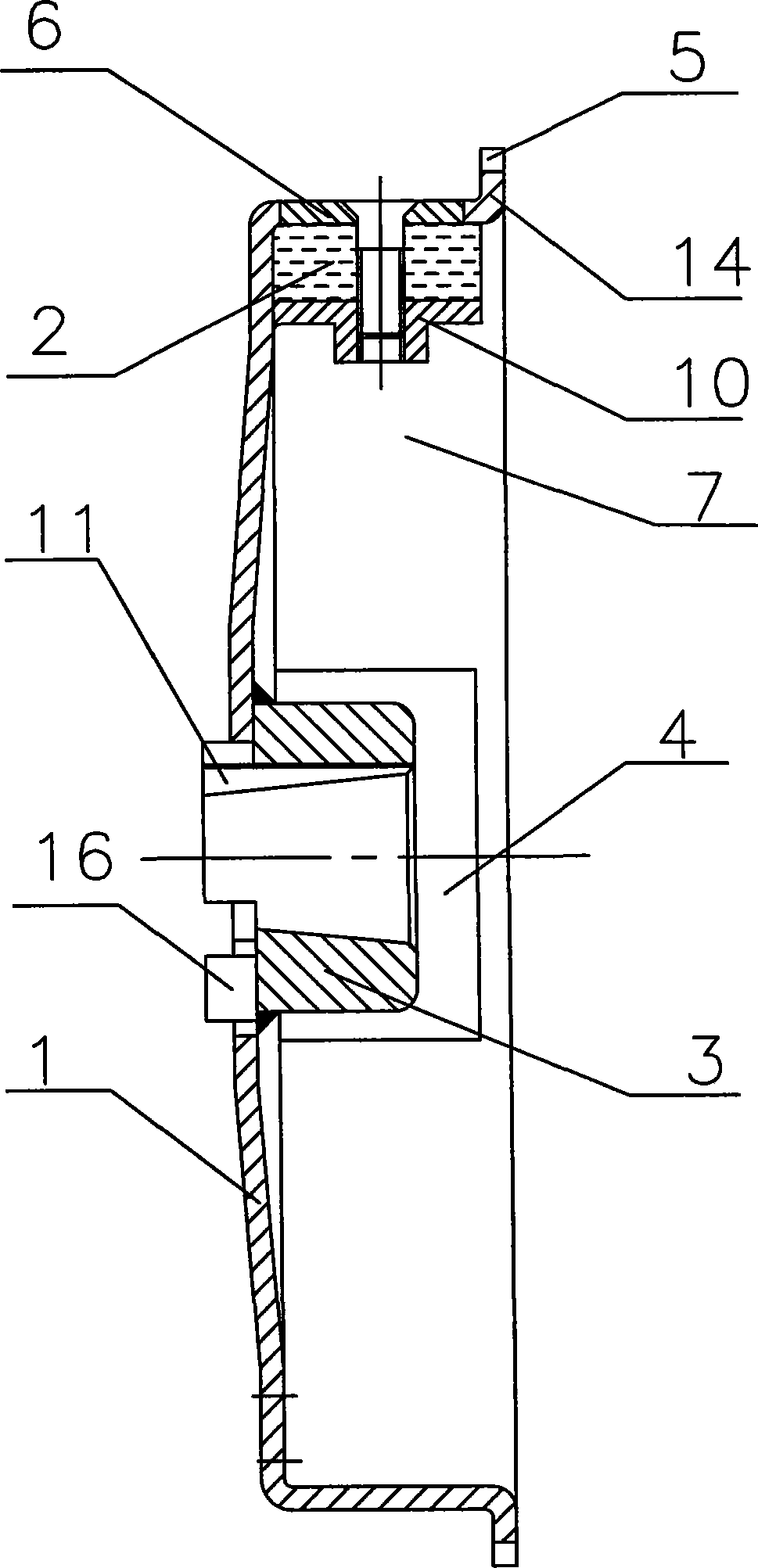

Electric machine - fluid machine stanchev aggregation set

ActiveCN104838090AIncrease powerWeight increaseRotary piston pumpsRotary piston liquid enginesElectric machineComputer module

Electrical machine - Fluid Machine stanchev aggregation set comprising Stator / Body Unit, Rotor / Piston Units and Power Supply and Control Module. The stator / body unit (1) shapes volume of rotation in which there are two segment-type rotor / piston units (11). Two channels (30) in the walls, shaping the volume of rotation, are in contact with two external areas from and to which fluid is fed and let out. The permanent magnets (12) are fixed in the rotor / piston units (11). Electromagnets frame the permanent magnets with their magnetic yokes (3) and (7) and coils (5). The poles of the electromagnets (7) face the trajectory of the poles of the magnetic yokes (7) of the permanent magnets (12). The terminal ends of the coils (5) of the electromagnets are connected to the electronic control module (24). Position sensors (10) fixed in the stator / body unit (1). Control module (24) secures control of the electromagnets.

Owner:西门·斯坦切夫·西梅奥诺夫

Composite-forming ultra-light floor roller

The invention discloses a composite-forming ultra-light floor roller. The composite-forming ultra-light floor roller comprises a shaft core and a fiber-woven composite layer. An outer cylinder of the shaft core is covered with the structural-fiber-woven composite layer; the shaft core comprises an outer barrel, an inner barrel and supports; the inner barrel and the outer barrel are homocentric, and the multiple supports are arranged between the inner barrel and the outer barrel and evenly distributed between the inner barrel and the outer barrel in a spiral mode; a composite layer comprises a fiber-woven-structure enhancement layer and a pouring layer; the fiber-woven-structure enhancement layer is covered with the pouring layer, is a sleeve mesh-shaped woven fabric woven with composite materials in a weaving machine and comprises a single or multiple players. The composite-forming ultra-light floor roller has the advantages that the mass is light, the strength is high, the rotational inertia is small, the accuracy of the outer cylinder and the extension strength are high, the floor roller is not deformable and not straightened, the outer layer is not fractured, and the formed floor roller is free of mechanical wave, resistant to static electricity, corrosion and high temperature and long in service life; the making processes are reduced, energy is saved, consumption is reduced, the manufacturing cost and the maintaining cost are low, the parking time is short, and the product quality and the production yield are increased.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

Preparation method of woven carpet without gumming process

ActiveCN108411458AImprove stabilityOmit the adhesive processHeating/cooling textile fabricsCarpetsViscous flowHot melt

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber filament or a staple fibre yarn, a first coating layer is a polypropylene fiber filament or a staple fibre yarn, the second coating layer accounts for 20%- 50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass of the composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt ethylene-vinyl acetate copolymer fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt ethylene-vinyl acetate copolymer fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, thepile and weft yarns as well as the weft yarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpetare enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

A kind of preparation method of latex-free woven carpet

ActiveCN108396440BDimensionally stableSolve the problem of impermeabilityCarpetsWoven fabricsPolymer scienceHigh density

The invention discloses a method for preparing a latex-free woven carpet. The second coating layer is hot-melt fiber filament or staple yarn, and the first coating layer is high-density polyethylene fiber filament or staple fiber. yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the hanging pile weft yarn. When using hot-melt ethylene-vinyl acetate copolymer fibers as bonding materials to produce adhesive-free carpets, and with pile yarns made of nylon fibers or wool, when hot-melt ethylene-vinyl acetate copolymer fibers are used in the heat-pressing process When it is heated above its melting point, it melts, and the conformation of the fiber macromolecular chain changes. Through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. The pull-out strength of the pile and the shape retention and dimensional stability of the carpet are improved, thereby omitting the adhesive backing process in the carpet preparation process, and making the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

hybrid vehicle

ActiveCN104627183BReduce inertiaReduce torqueHybrid vehiclesSpeed controllerElectric machineHybrid vehicle

A hybrid vehicle having an engine, an electric machine connected to the engine by an upstream clutch, a transmission gearbox connected to the electric machine by a downstream clutch, and a controller. The controller is configured to adjust pressure of the upstream clutch in response to a commanded upshift of the gearbox. A method for controlling a vehicle includes, in response to a commanded upshift of a gearbox, controlling an upstream clutch to a first non-zero speed differential to reduce inertial torque during the upshift, the first non-zero speed differential being in contact with a gear The box is associated with a first inertial counterpart located upstream of the gearbox. A method for controlling a vehicle includes slipping an upstream clutch and reducing output torque of an engine and an electric machine in response to a commanded upshift of a gearbox when the vehicle is outside an electric limit and a fast path torque reduction limit.

Owner:FORD GLOBAL TECH LLC

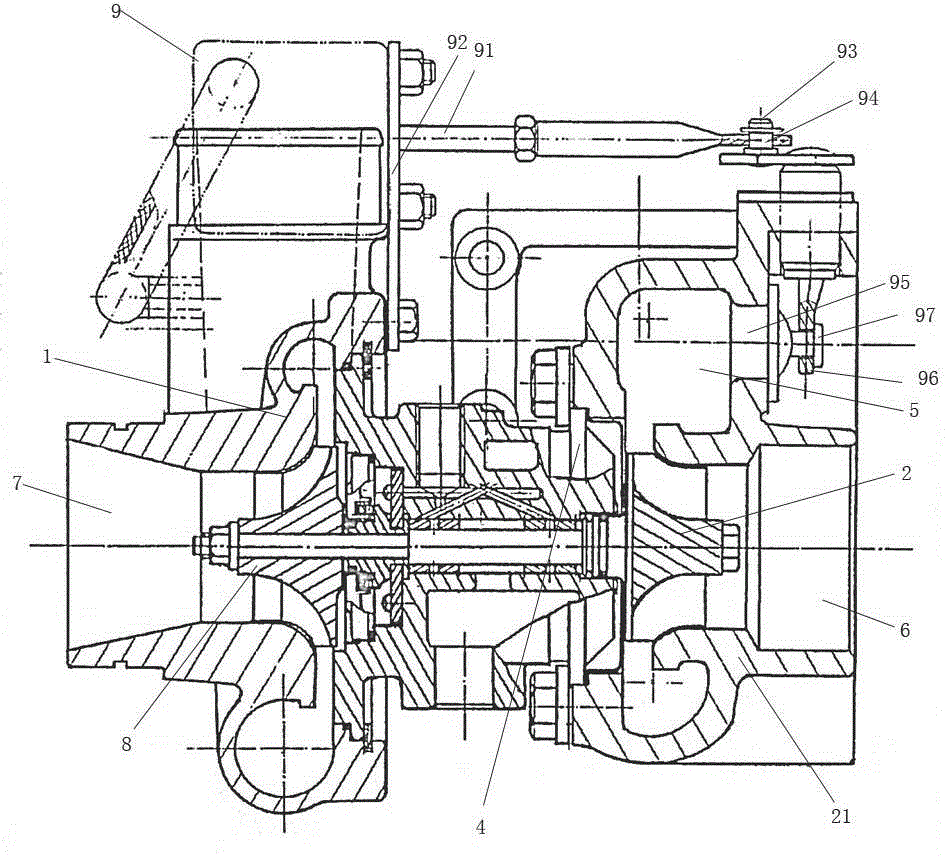

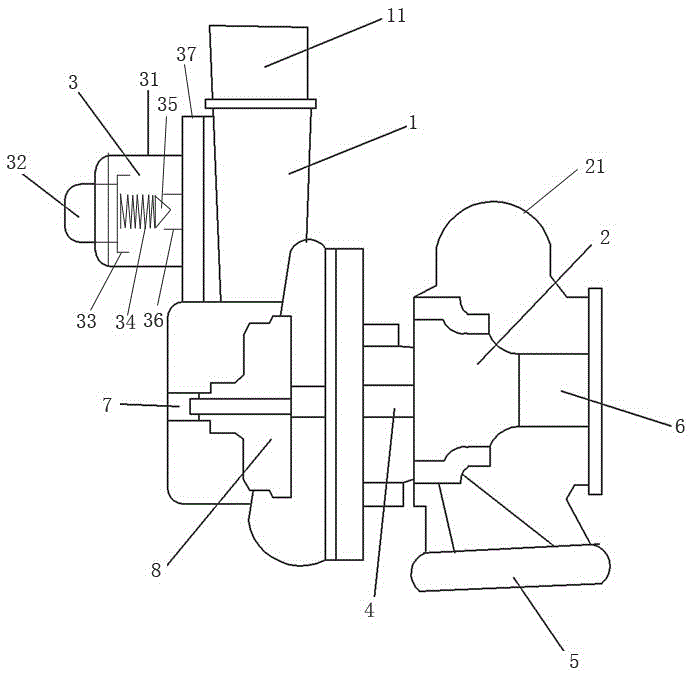

layered fuel distributor

ActiveCN103644054BPhase Requirements ExtendedSmall diameterFuel injection apparatusMachines/enginesFuel distributionEngineering

The invention discloses a layered fuel distributor, which includes a distribution rotor, a distribution stator and a casing. The distribution rotor rotates in the distribution stator, and the oil outlet holes of the distribution stator are divided into multiple layers, and the distribution rotor has the same number of radial distribution rotor oil outlet holes as the number of layers of the distribution stator; The number is the same, the number of layers matches the number of cylinders of the engine, and the number of cylinders is an integer multiple of the number of layers; the oil inlet channel of the distribution rotor is also used as the oil return channel, that is, the oil supply and oil return of the layered fuel distributor are Shared oil passage and can be continuous. The layered fuel distributor has doubled the available phases of oil supply and oil return. The increase of the oil supply phase broadens the power range, and the increase of the oil return phase prolongs the available oil return time to provide support for emission compliance.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

Gasoline engine electric-starting flywheel

InactiveCN101169092BReduce weightSmall rotational inertiaPower operated startersElectric motor startersFreewheelElectricity

The invention discloses an electric starting flywheel of a gasoline engine, which includes a flywheel disc, an inner alnico and an outer alnico fixed on the flywheel disc, and a balancing weight. The flywheel disc which is strike molded by steel plate has a concave cavity and an electric starting driven gear. The driven gear is arranged on the hem around the flywheel disc, the opening part of theconcave cavity of the flywheel disc bends and extends outwards to form the hem, and the hem and the flywheel are integrated. The invention reduces the weight of the flywheel, lessens the rotation inertia of the flywheel, can stop the rotation completely in three seconds when braking, can ensure the stability and the reliability of the torque transmitting by the electric starting driven gear during, and can prolong the service life of the flywheel.

Owner:LONCIN MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com