Turbocharger

A turbocharger and turbine technology, which is applied to machines/engines, engine components, internal combustion piston engines, etc., can solve problems such as damage to supercharger parts, poor acceleration performance, and wheel speed reduction, to avoid knocking, The effect of prolonging the service life and not reducing the wheel speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

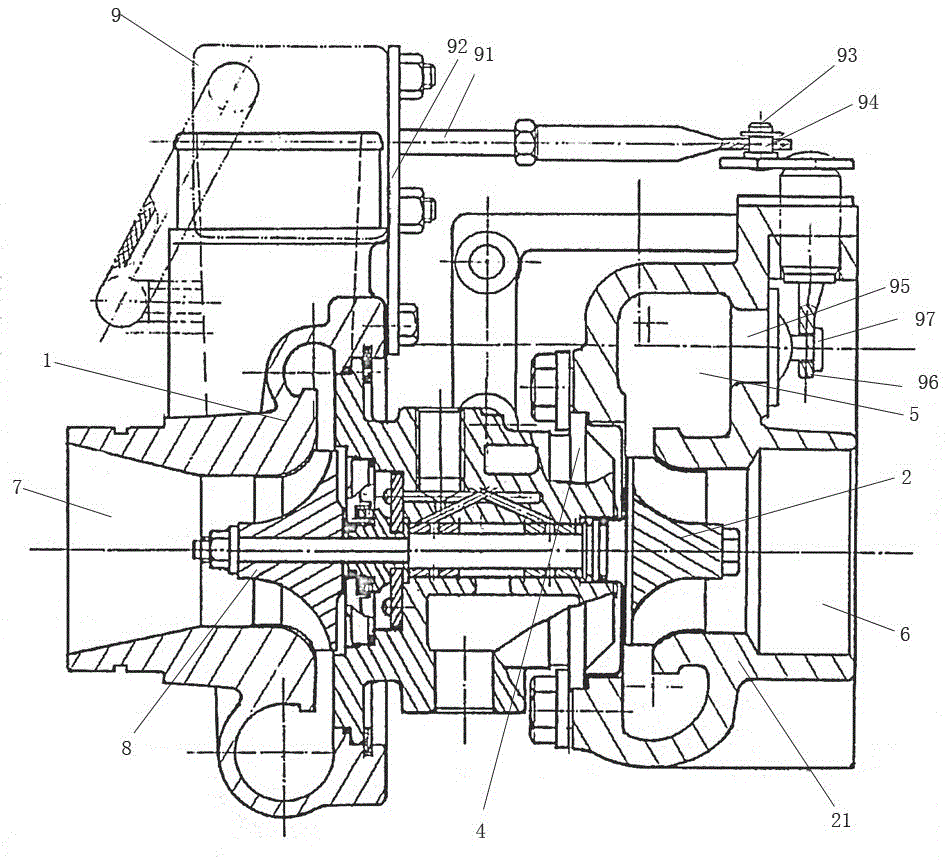

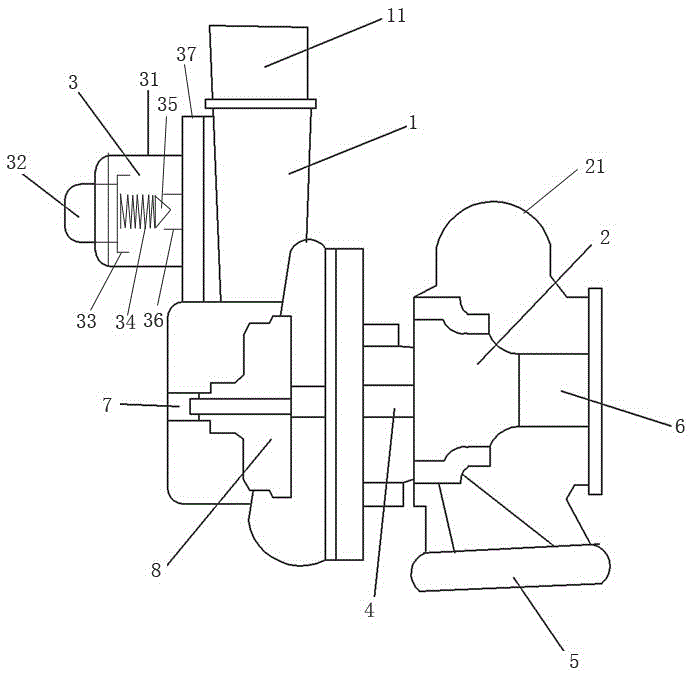

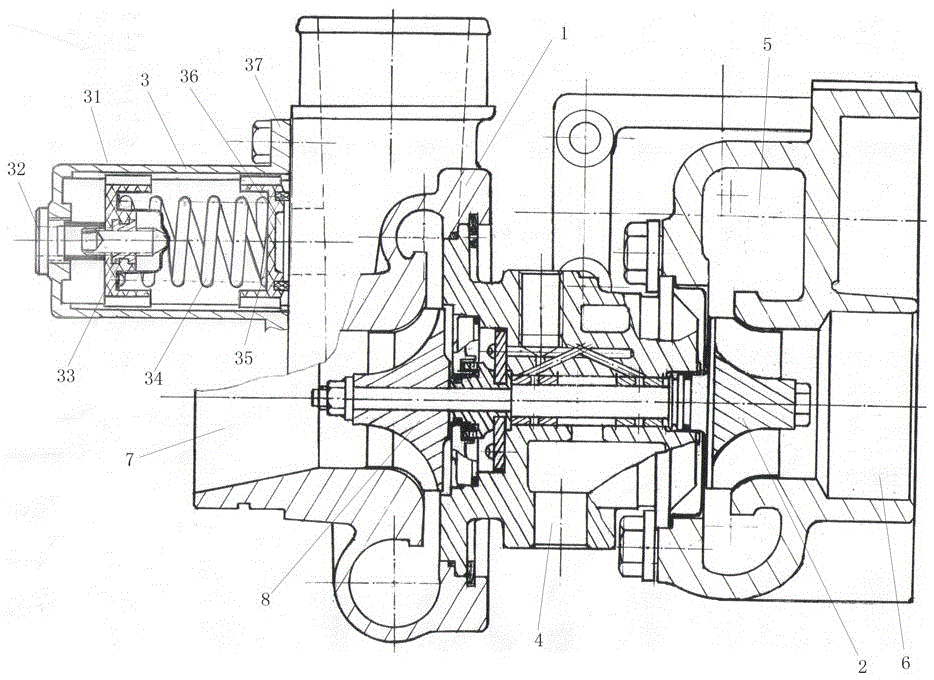

[0018] Such as figure 2 , 3 As shown, the turbocharger of the present invention includes an intermediate body 4, the two ends of the intermediate body are axially connected to the impeller 8 and the turbine 2 respectively, the impeller is covered with an air compressor shell 1, the air compressor shell and the impeller form a compressor, and the air compressor shell outlet 11 A shock absorber 3 is installed on the side of the turbine, a turbine casing 21 is provided on the outside of the turbine, an air inlet 7 is provided on one side of the impeller, and a turbine inlet 5 and an exhaust gas outlet 6 are provided on the turbine.

[0019] Described shock absorber comprises: adjusting screw 32, spring seat 33, stage clip 34, spool 35 and casing 31, and casing is provided with exhaust hole, and the bottom of casing is provided with connecting plate 37, and connecting plate There is an air release hole in the middle. The shock absorber is installed on the compressed air shell th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com