Patents

Literature

41results about How to "The production process is reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

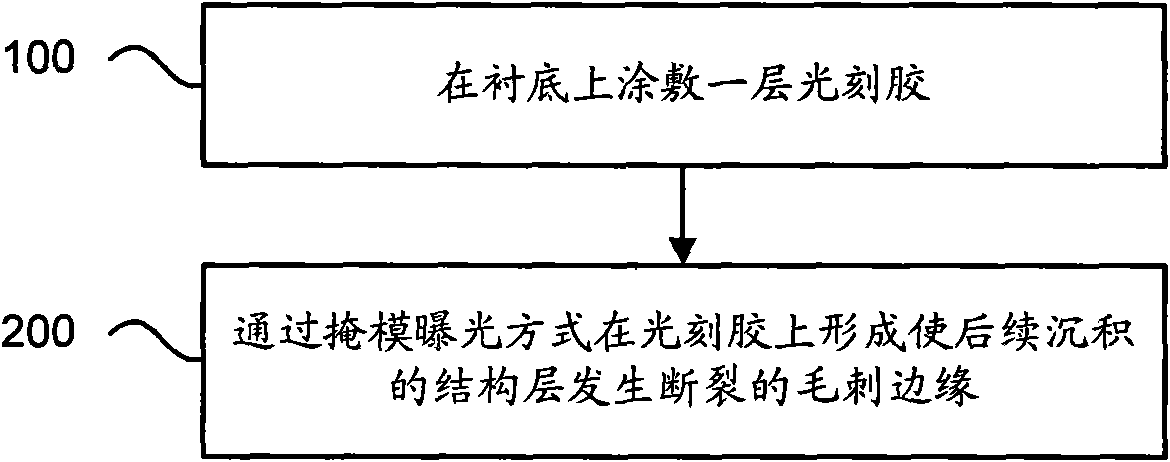

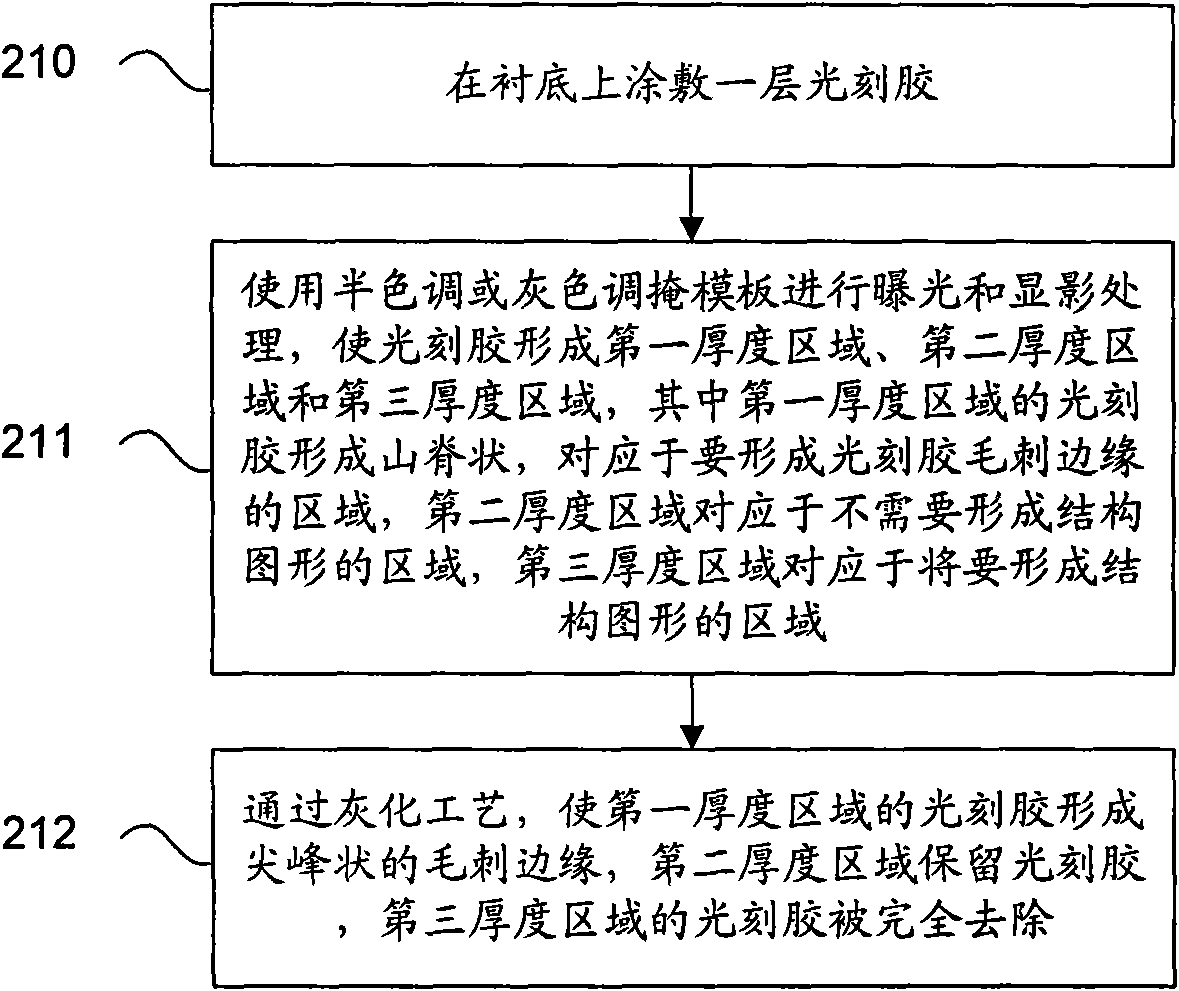

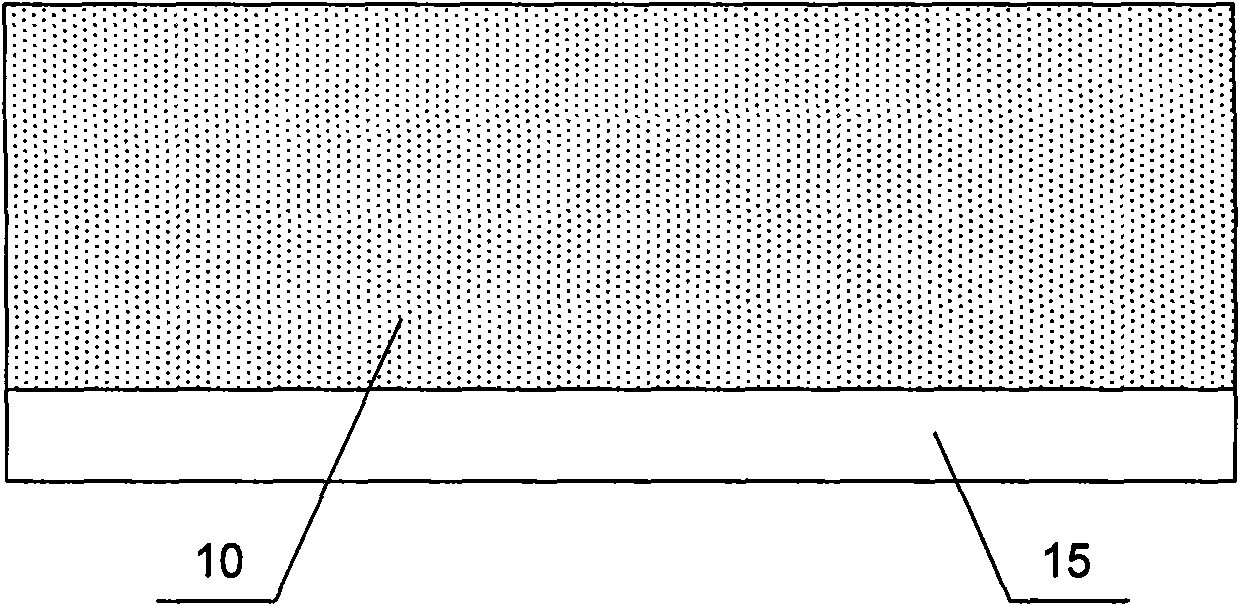

Photoresist burr edge-forming method and TFT-LCD array substrate-manufacturing method

InactiveCN101630640AGuarantee the quality of the lift-off processWide applicabilitySemiconductor/solid-state device detailsSolid-state devicesPhotoresistMaterials science

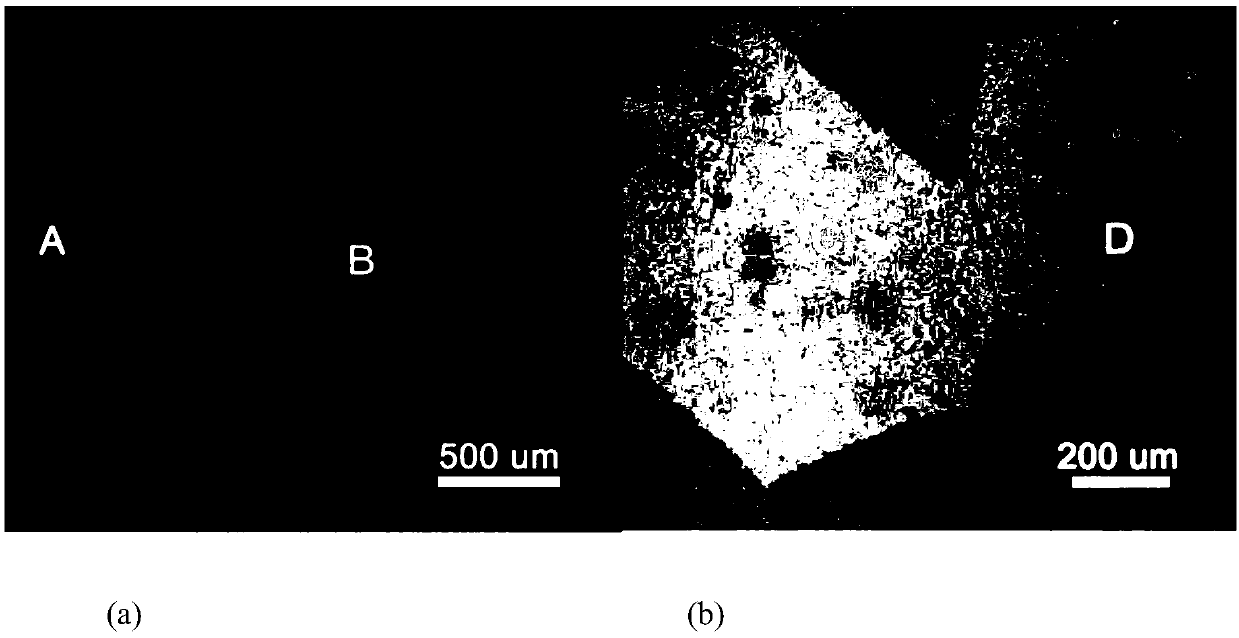

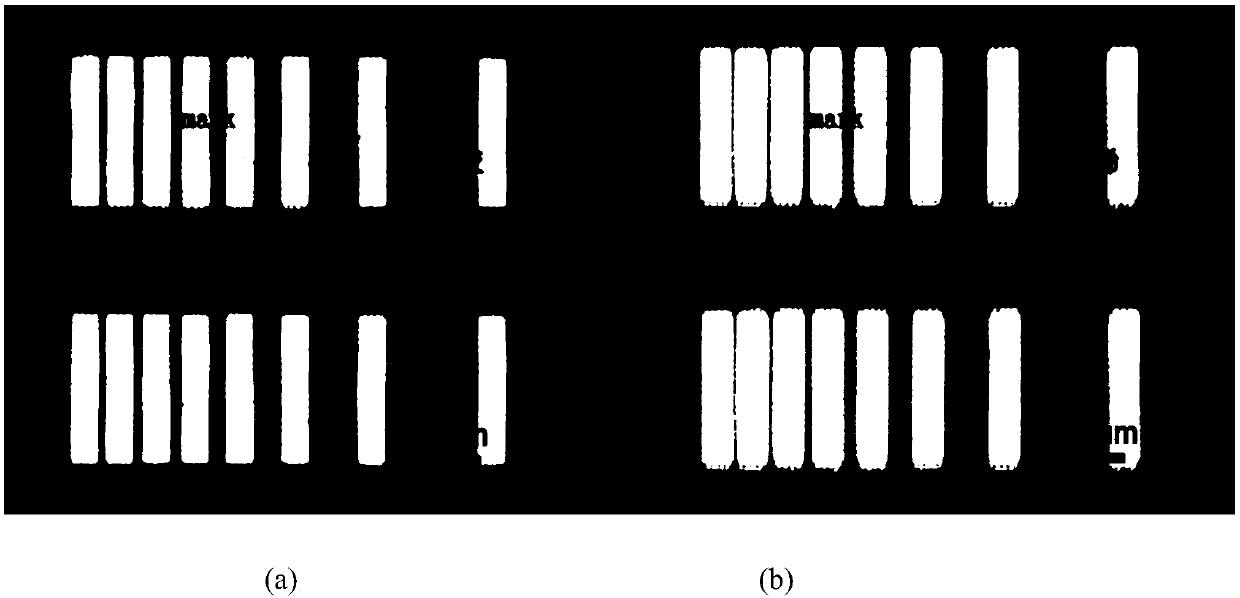

The invention relates to a photoresist burr edge-forming method and a TFT-LCD array substrate-manufacturing method. The TFT-LCD array substrate-manufacturing method comprises: forming a gate line and a gate electrode graph on a substrate; forming a data wire, a source electrode, a drain electrode and a TFT channel region, reserving photoresist, depositing a passivation layer and removing the photoresist together with the passivation layer on the photoresist through a lift-off stripping process; and smearing the photoresist, forming peak-shaped burr edges on the photoresist, depositing a transparent conductive film, forming a pixel electrode graph through the lift-off stripping process and directly connecting a pixel electrode with the drain electrode. The invention forms the photoresist burr edges through a third composition process and breaks the deposited transparent conductive film on the burr edges so as to effectively guarantee the quality of the lift-off stripping process, and has the advantages of simple reliable manufacturing process, easy implementation in practical production and broad application prospects.

Owner:BOE TECH GRP CO LTD +1

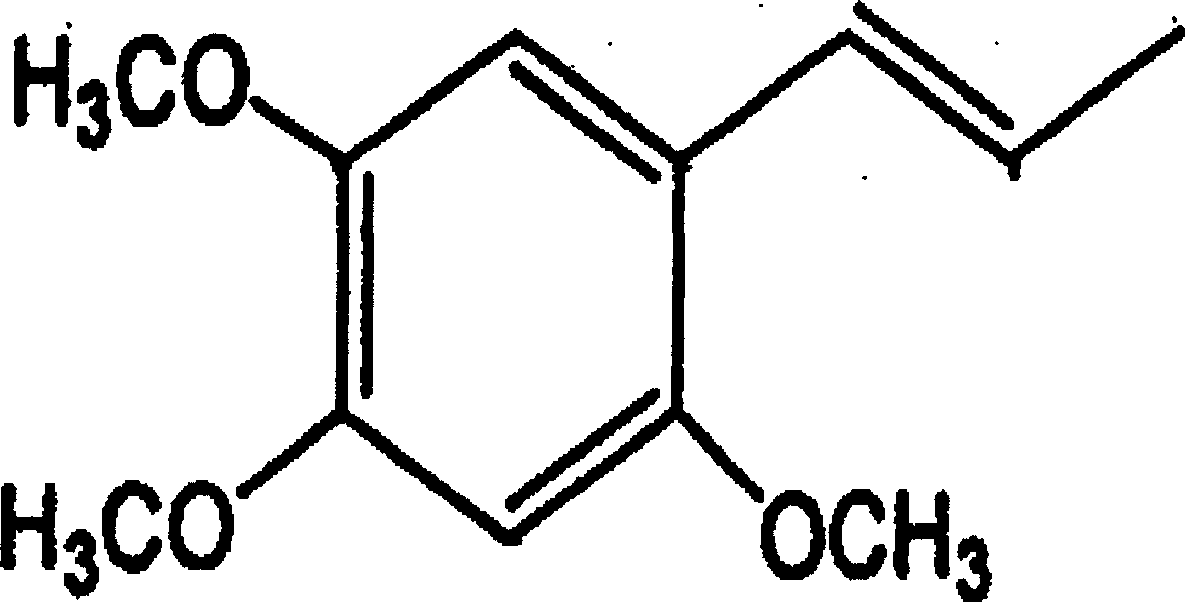

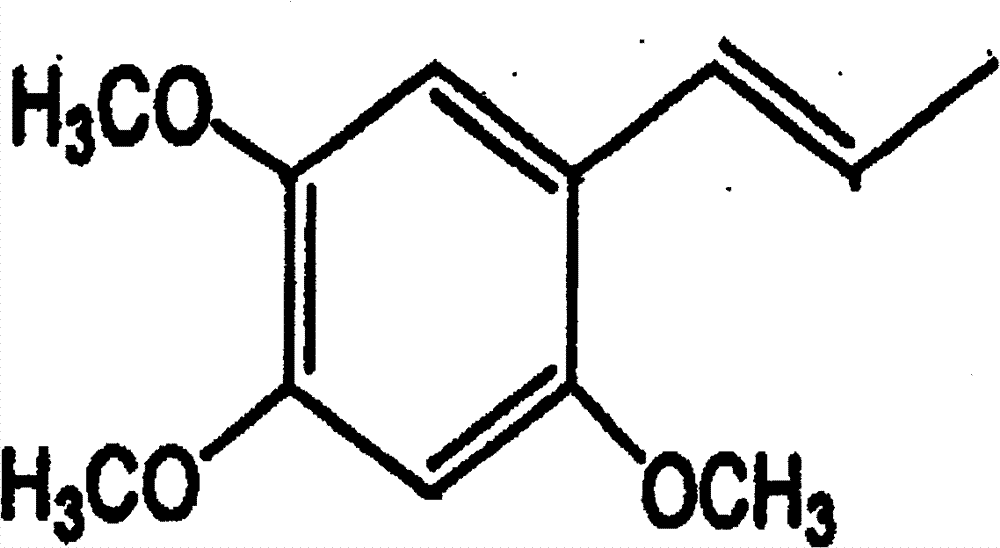

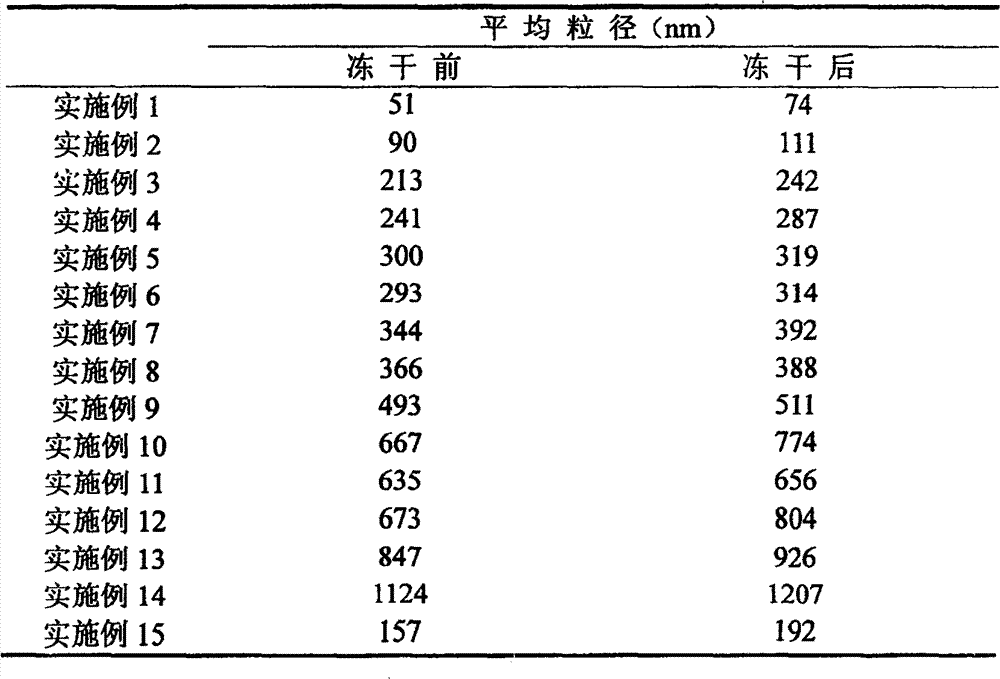

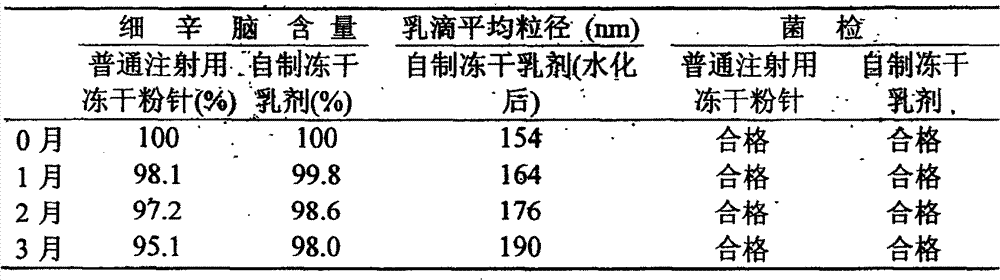

Dry asarol emulsion and its prepn and application

InactiveCN101088499AImprove stabilityGood curative effectOrganic active ingredientsNervous disorderDiseaseEmulsion

The present invention discloses one kind of dry AAA emulsion and its preparation and application, and the dry AAA emulsion has asarol as effective component, emulsifier and other supplementary material. The dry AAA emulsion has mature technological process, easy industrial production, high stability, high curative effect and other advantages. It is applied mainly in clinical treatment of bronchitis, lung infection, asthma and other diseases.

Owner:陈云生 +1

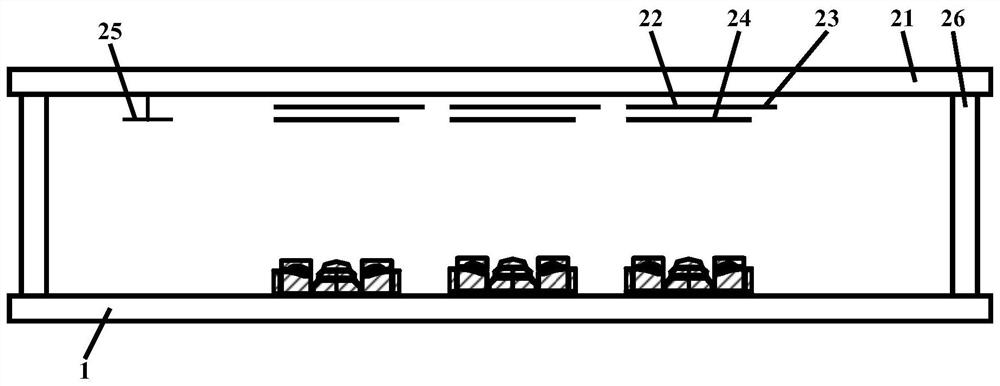

Graphene-metal heterojunction-based gas sensor array and preparation method thereof

PendingCN109632906AHigh sensitivityQuick responseMaterial electrochemical variablesHeterojunctionSensor array

The invention discloses a grapheme-metal heterojunction-based gas sensor array and a preparation method thereof. The grapheme-metal heterojunction-based gas sensor array is capable of detecting the types of gases and the concentration of the corresponding gases and has a fast response rate and a high recognition rate. The gas sensor array includes a substrate and a plurality of sets of grapheme-metal heterojunction-based resistive gas sensors formed on the substrate. The preparation method of the gas sensor array includes the following steps that: S1, a metal electrode array and conductive leads are processed on the substrate; S2, graphene is transferred to the substrate on which the metal electrode array is formed; S3, plasma etching is utilized to etch away excess graphene on the substrate, so that resistive gas sensors are formed; and S4, magnetron sputtering coating is adopted to process a cover layer at the top layer of the gas sensor. The grapheme-metal heterojunction-based gas sensor array and the preparation method thereof have good application prospects in mine operation, food safety detection, environmental monitoring, robot electronic nose and the like.

Owner:GUANGXI NORMAL UNIV

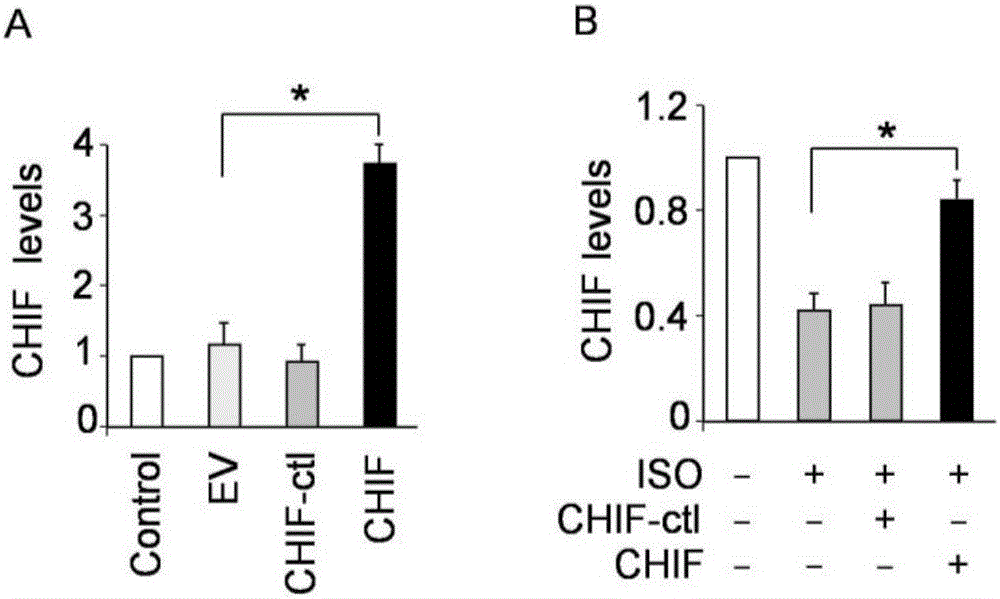

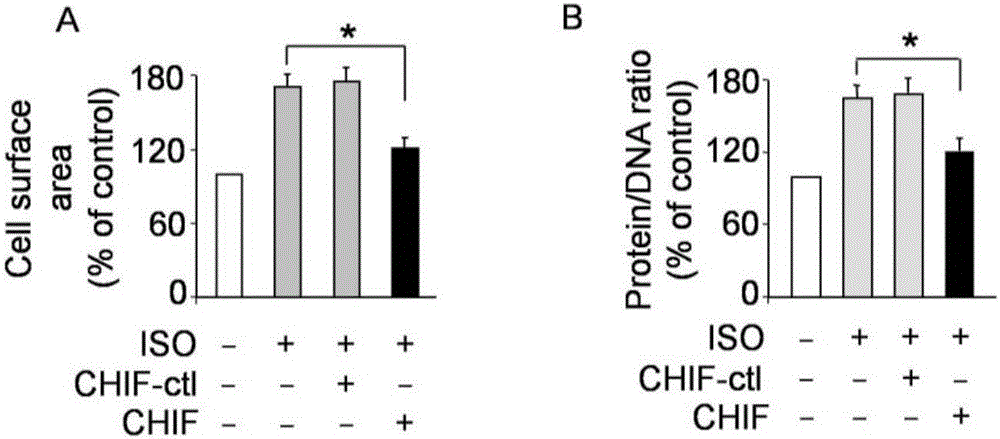

CircRNA CHIF nucleotide and pharmaceutical composition comprising such nucleotide and application thereof

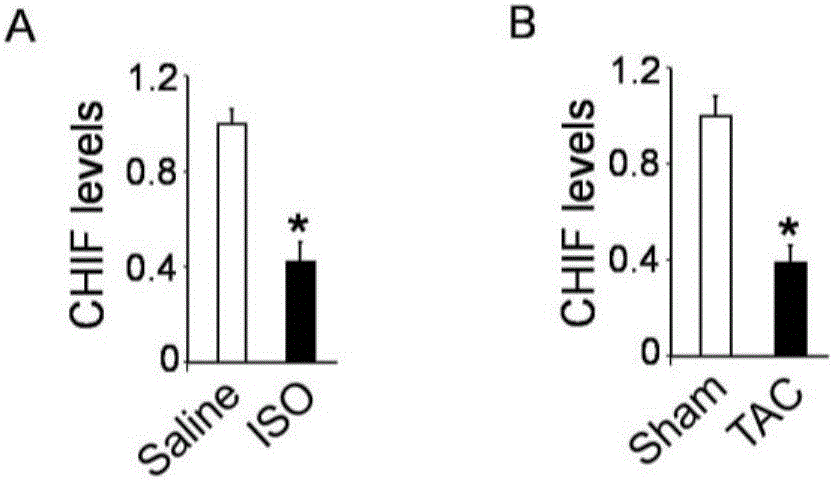

ActiveCN106222174AReasonable formulaPharmacologically reliableOrganic active ingredientsCardiovascular disorderCardiac fibrosisCholesterol

The invention discloses circRNA CHIF nucleotide and a pharmaceutical composition comprising the circRNA CHIF nucleotide. The pharmaceutical composition comprises the circRNA CHIF nucleotide, an auxiliary, and a viral vector or an embedding vector, the embedding vector is cholesterol, nanoparticles or lipidosome, preferably lipidosome, the viral vector is one or more of adenovirus vector, lentiviral vector and retroviral vector, preferably adenovirus vector, and the auxiliary is one or more of mannitol, phosphate buffer solution and normal saline, preferably phosphate buffer solution, the circRNA MNCR viral vector is 1016 PFU in infectivity titer, and a mass ratio of the circRNA CHIF nucleotide to the lipidosome is 1:1.25; a mass ratio of the viral vector or embedding vector to the auxiliaries is 1:200. The pharmaceutical composition is used for preventing and treating cardiac hypertrophy, cardiac fibrosis, coronary heart disease and heart failure, has reasonable formula, is simple to manufacture, has significant therapeutic effect, is widely applicable and is friendly to service environments.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

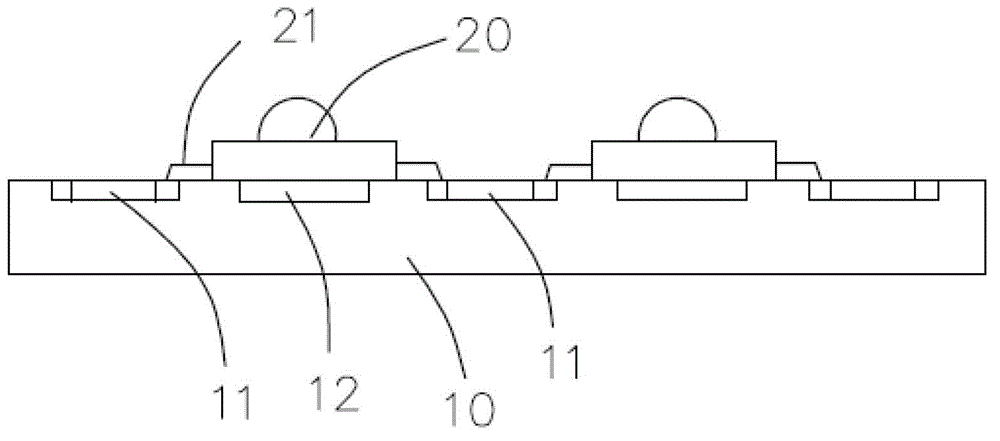

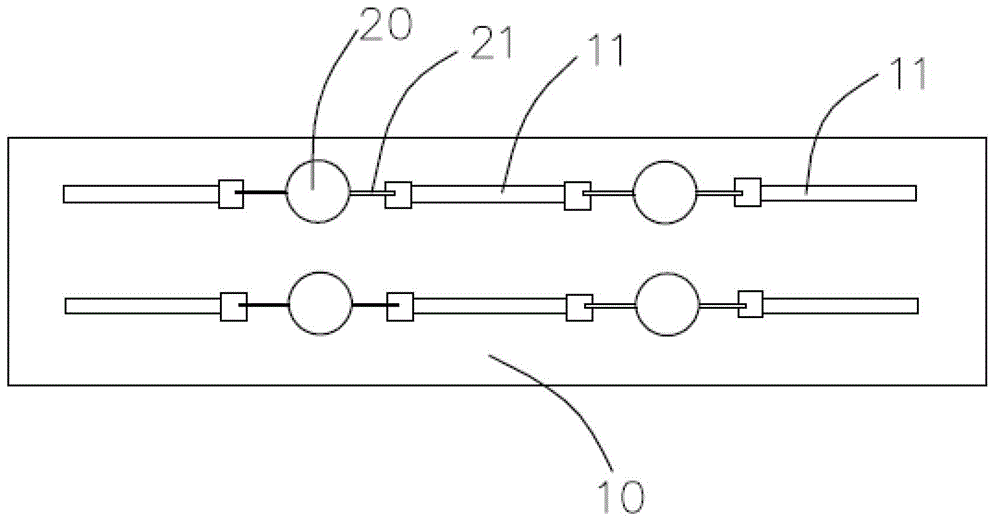

Substrate-free LED (Light-Emitting Diode) lamp and preparation method thereof

ActiveCN102980066AReasonable structural designSimple structural designPlanar light sourcesPoint-like light sourceLaser etchingChemical plating

The invention discloses a substrate-free LED (Light-Emitting Diode) lamp and a preparation method thereof. The substrate-free LED lamp comprises a base and a plurality of LED lamp beads arranged on a the base, wherein the base is provided with a metal plating a and a metal plating b; a circuit layer is formed on the metal plating a; a heat conducting layer is formed on the metal plating b; pins of the LED lamp beads are welded on the metal plating a; the LED lamp beads and the metal plating a construct a conducting circuit; and the bottoms of the LED lamp beads are tightly attached to the metal plating b, so that heat of the LED lamp beads is convenient to conduct. The substrate-free LED lamp has the advantages of simple structure and good radiating effect; the preparation method is simple and convenient; and the circuit layer and the heat conducting layer are formed on the base by adopting laser etching and electric chemical plating methods, so that the manufacturing cost is low.

Owner:SINOPLAST NEW MATERIAL

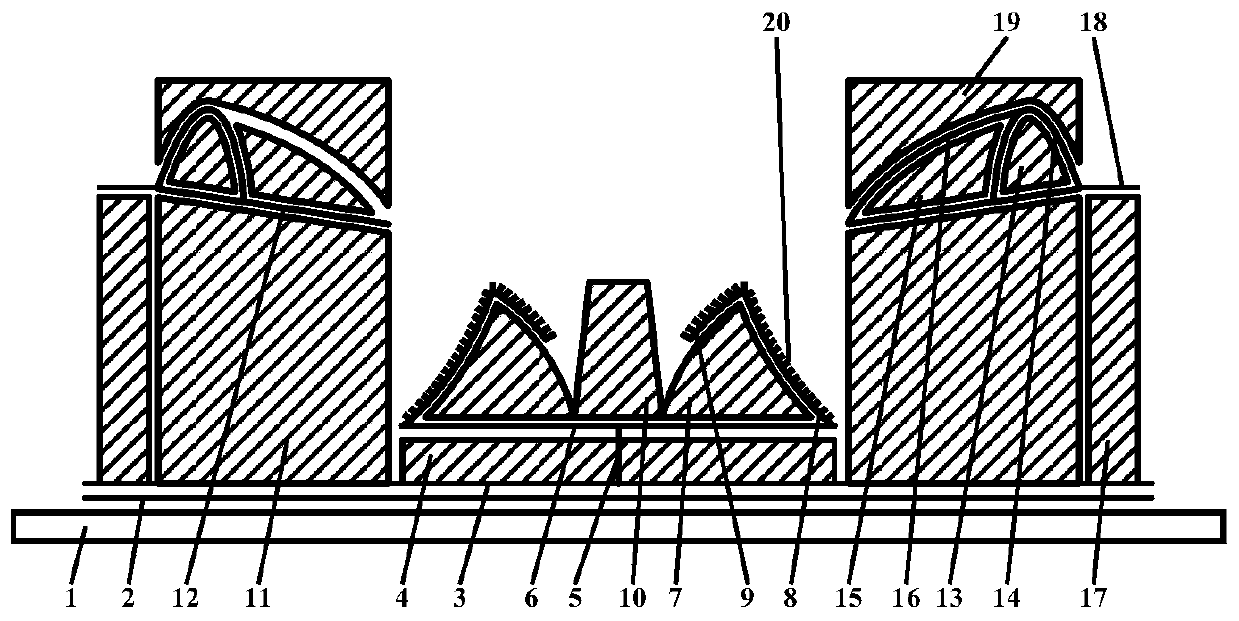

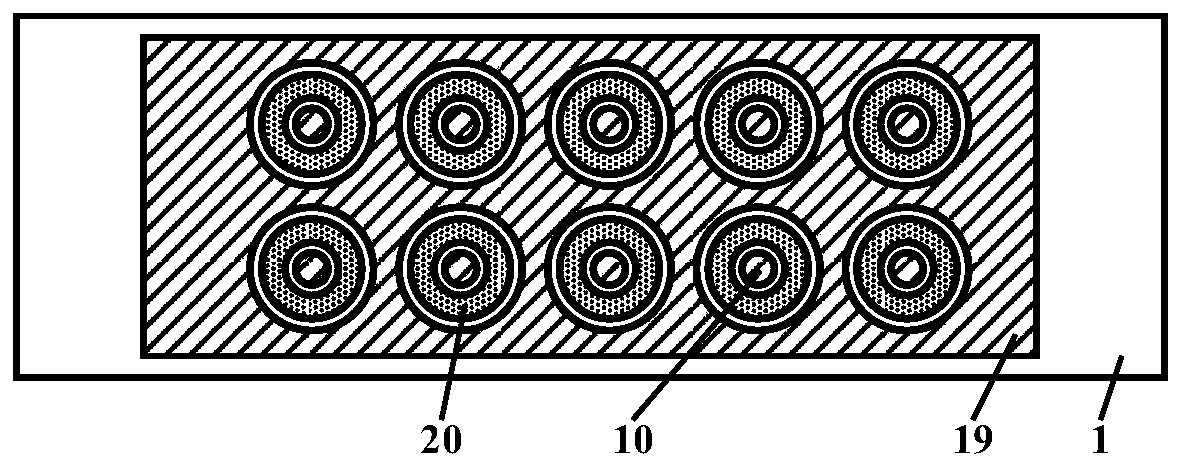

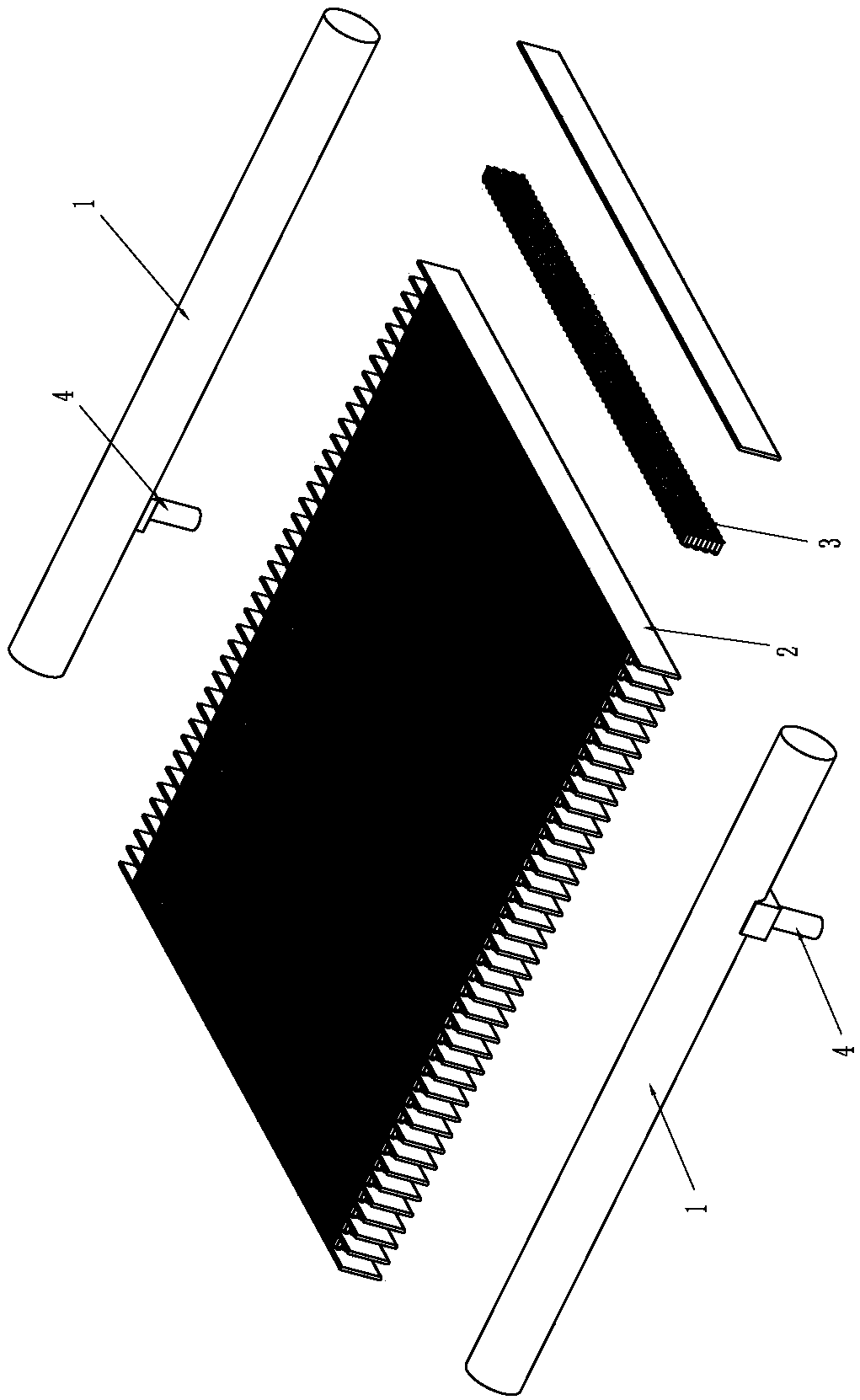

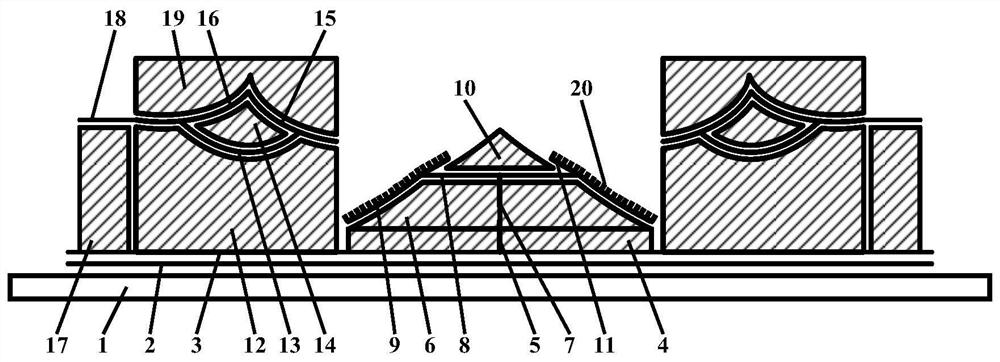

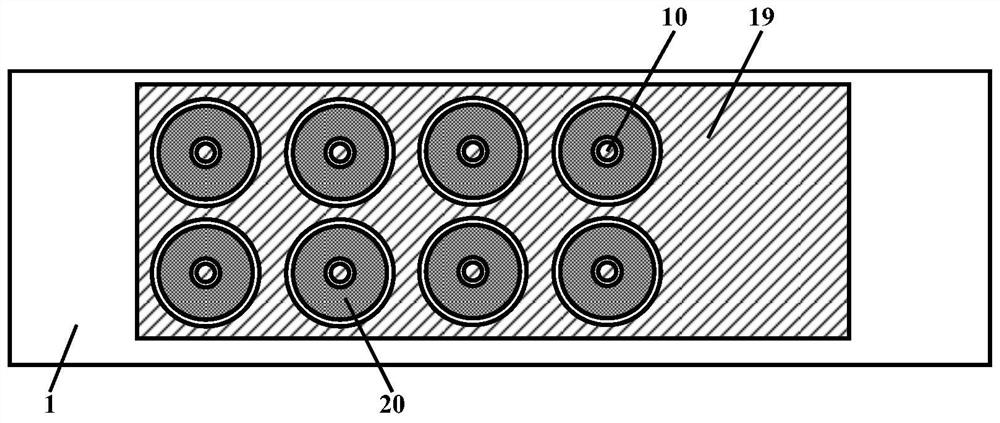

Light-emitting backlight source with annular column convex-concave connecting surface cathode double-same-side arc gating structure

InactiveCN110828264AIncrease surface areaLarge product areaCathode ray tubes/electron beam tubesSolid cathode detailsGlass sheetMaterials science

The invention discloses a light-emitting backlight source with an annular column convex-concave connecting surface cathode double-same-side arc gating structure. The light-emitting backlight source comprises a vacuum sealing body and a getter accessory element located in the vacuum sealing body, wherein the vacuum sealing body is composed of a front hard transparent glass plate, a rear hard transparent glass plate and glass narrow frame strips; the front hard transparent glass plate is provided with an anode square power transmission layer, an anode tortuous line silver layer and a thin light-emitting layer, the anode square power transmission layer is connected with the anode tortuous line silver layer, and the thin light-emitting layer is manufactured on the anode square power transmission layer; and the rear hard transparent glass plate is provided with an annular column convex-concave connecting surface cathode double-same-side arc gating structure. The light-emitting backlight source has the advantages of reliable manufacturing structure and high light-emitting brightness.

Owner:JINLING INST OF TECH

Preserved rehmanniae and manufacture method

The invention relates to preserved rehmanniae and a preparation method thereof.The preserved rehmanniae takes rehmanniae as material and is made by adding with compound material. The preserved rehmanniae contains 50-100 shares of fresh rehmanniae, 40-70 shares of sucrose, 2-5 shares of salt, 0.1-0.2 shares of citric acid, and 0.08-0.15 shares of alum. The manufacturing method of the invention includes the process: the material is selected, washed, with peel removed, cut, dipped in salt solution, rinsed in clean water and desalted; the material is heated in boiling water containing alum, taken out, cooled in cold water, and then drained; sugar and the citric acid are added for preservation; the material is added with sugar and is boiled for twice; then the rehmanniae blocks are taken out, with sugar solution dropped, and are dried and packed, thus obtaining the invention. The manufacture process is reliable and the preserved rehmanniae can be produced by using the current production condition of the preserved fruit.The preserved rehmanniae made by the invention is sweet and delicious in taste without foreign flavor. Besides, the preserved rehmanniae keeps rich mannitol, rehmannin, vitamin A and a plurality of amino acids in rehmanniae. The invention has the function of nourishing essential fluid, reinforcing kidney, improving the five viscera, invigorating vital energy and energy, etc.After long-term drinking, the invention can prolong life, prevent hairs from graying, and improve health.

Owner:TIANJIN POLYTECHNIC UNIV

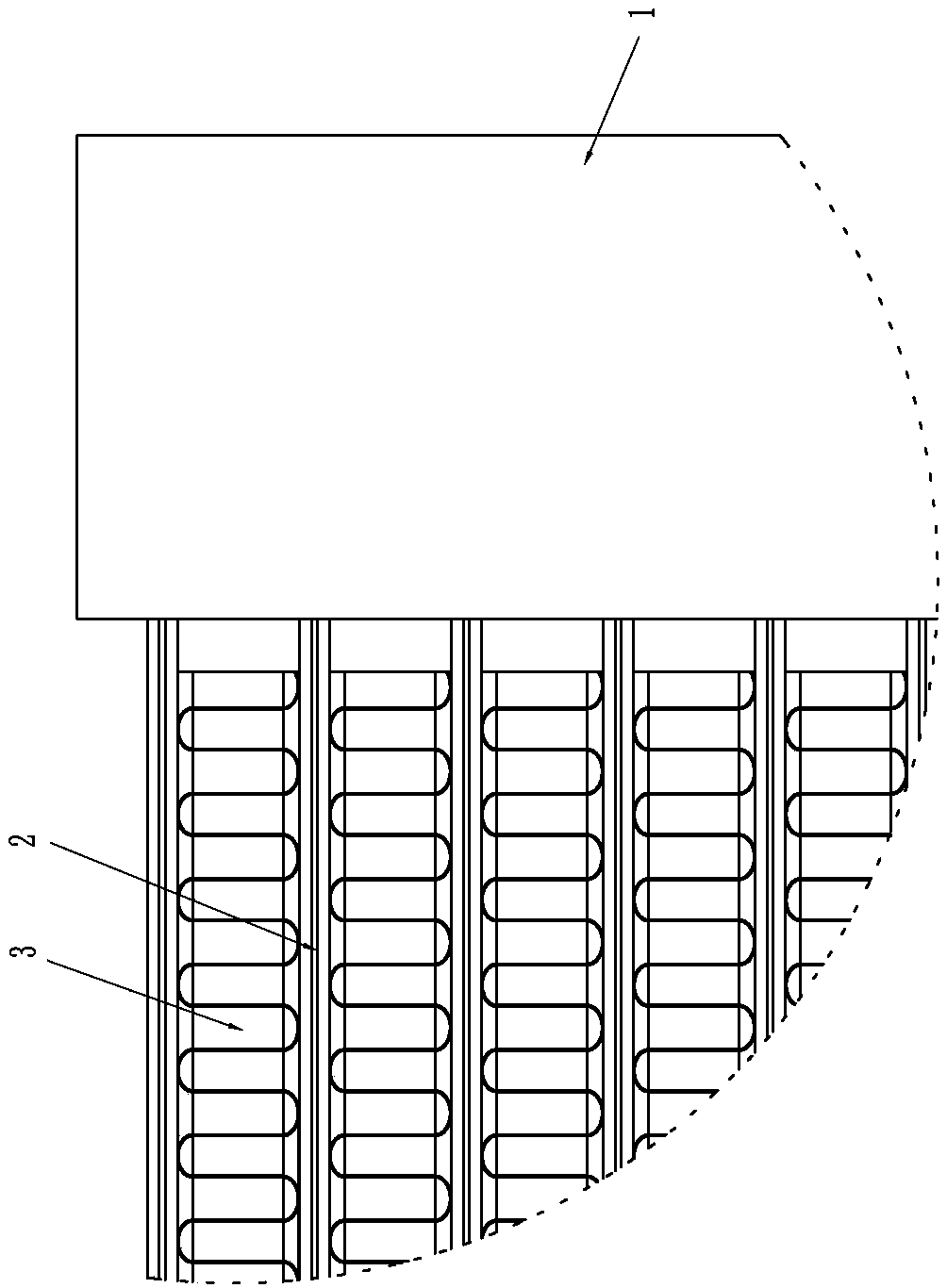

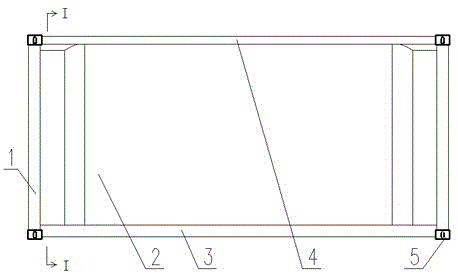

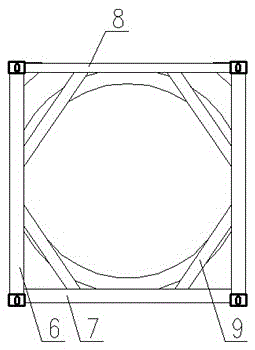

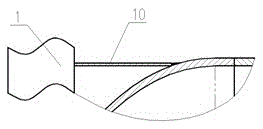

Inclined fin type parallel flow heat exchanger and production process thereof

PendingCN107726884AReduce air resistanceNot easy to gather and freezeStationary conduit assembliesLaminated elementsWork in processEngineering

The invention discloses an inclined fin type parallel flow heat exchanger and a production process thereof. The inclined fin type parallel flow heat exchanger includes a pair of collecting pipes parallel to each other and separated from each other, multiple flat pipes, partition pieces and inclined fins, wherein the two ends of the flat pipes communicate with inner cavities of the two collecting pipes, and the flat pipes are installed in sequence and in parallel in a left and right spaced mode; and the partition pieces are installed in the collecting pipes, and the inclined fins are installedbetween the every two adjacent flat pipes. In the production process, the collecting pipes, the partition pieces, an end cover, the flat pipes and the inclined fins are produced separately firstly; then the flat pipes are installed between the two collecting pipes; the inclined fins are placed between the adjacent flat pipes to form a semi-finished product entirety; after the semi-finished productentirety is packed, the partition pieces and the end cover are sealed; the inclined fins are fixed in the semi-finished product entirety through brazing; and at last, quality inspection and packing are conducted. So the inclined fin type parallel flow heat exchanger has multiple advantages that air resistance is low, condensate water is not easily accumulated and frozen, heat resistance is low, and heat exchange efficiency is high. Meanwhile, the production process of the inclined fin type parallel flow heat exchanger is stable and reliable, and production quality is improved.

Owner:DONGGUAN FENGRUIDE TEMPERATURE CONTROL TECH CO LTD

Preserved carrot and manufacture method

The invention relates to preserved carrot and a preparation method thereof. The preserved carrot takes carrot as material and contains 70-150 shares of carrots, 50-80 shares of sucrose, 5-10 shares of sodium hydroxide, 0.2-0.4 shares of sodium sulfite, and 0.1-0.2 shares of citric acid. During manufacturing, the material is selected, washed, dipped in clean water, and washed with flowing water; then the material is placed in sodium hydroxide solution, taken out, washed in clean water, slightly stirred, with peel removed, and is cut into chips or blocks; the material is dipped in sodium sulfite solution, rinsed clean in water, and taken out, with water dropped; then the material is preserved in sugar and boiled in sugar for twice; the carrot is taken out, with sugar solution dropped, and is dried and packed, thus obtaining the preserved carrot. The invention is reliable in manufacturing process and has the function of invigorating vital energy, restoring consciousness, invigorating liver, improving eyesight, reducing fever, relieving inflammation, detoxifying, maintaining skin and beautifying features.

Owner:TIANJIN POLYTECHNIC UNIV

Preserved yam and manufacture method

InactiveCN101204190AThe production process is reliableRefreshingDigestive systemConfectioneryForest yamDietary fiber

The invention relates to preserved Chinese yam and a preparation method thereof. The preserved Chinese yam takes Chinese yam as material and contains 70-150 shares of Chinese yam, 50-80 shares of sucrose, 0.15-0.3 shares of sodium sulfite, and 0.1-0.2 shares of citric acid. During manufacturing, the material is selected, washed, and cut; then the material is processed with sulfate, heated in hot water, taken out, and cooled, with water dropped; the sucrose solution is added with the citric acid, and the material is preserved in sugar and then is boiled in sugar for twice; the Chinese yam is taken out, with sugar solution dropped, and is dried, and packed, thus obtaining the preserved Chinese yam. The manufacture process is reliable and the preserved rehmanniae can be produced by using the current production condition of the preserved fruit. The preserved Chinese yam made by the invention is sweet and delicious in taste. At the same time, the food keeps a plurality of dietary fibers, vitamins and amino acids in Chinese yam. The preserve Chinese yam has the function of invigorating vital energy, restoring consciousness, invigorating liver, improving eyesight, nourishing essential fluid, and reinforcing kidney.

Owner:TIANJIN POLYTECHNIC UNIV

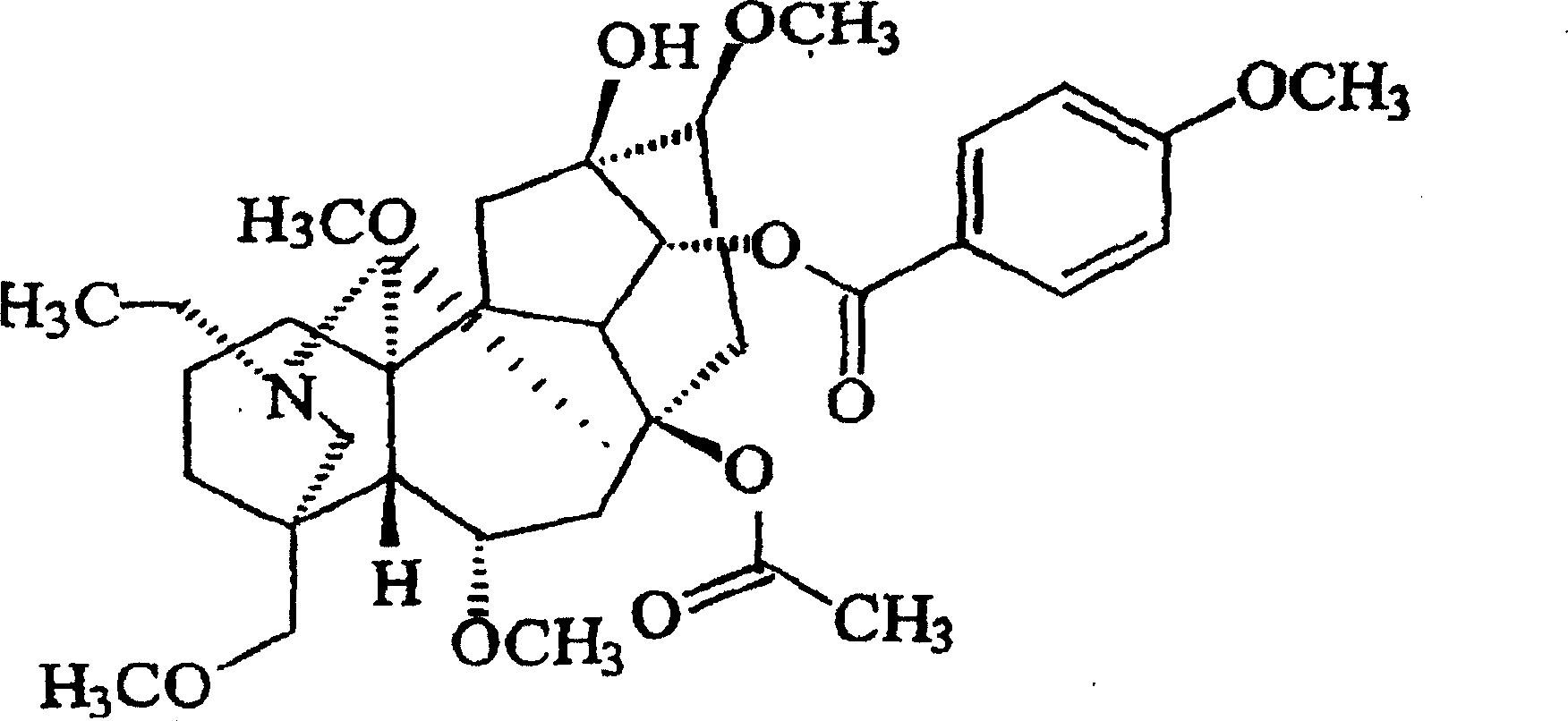

Bulleyaconitin A dry emulsion and its preparation method and application

InactiveCN101057845AImprove stabilityGood curative effectOrganic active ingredientsAntipyreticDiseaseDrug content

The invention discloses a medicine preparation form, especially discloses a Bulleyaconitin A dry emulsion and the preparing method and application. It takes Bulleyaconitin A in the dry emulsion as effective component, and also comprises oil phase, emulsifying agent and other findings. The dry emulsion is characterized by mature preparation process, easy industrialization, good stability, easy transportation and storage, controllable medicine content and good effect. The invention is used for local anesthesia, reducing fever, relieving pain, treating rheumatism and atrophic arthritis, scapulohumeral periarthritis, sprain of waist and limbs joints, herpes zoster, cold and dentalgia and other infections or pains.

Owner:陈云生 +1

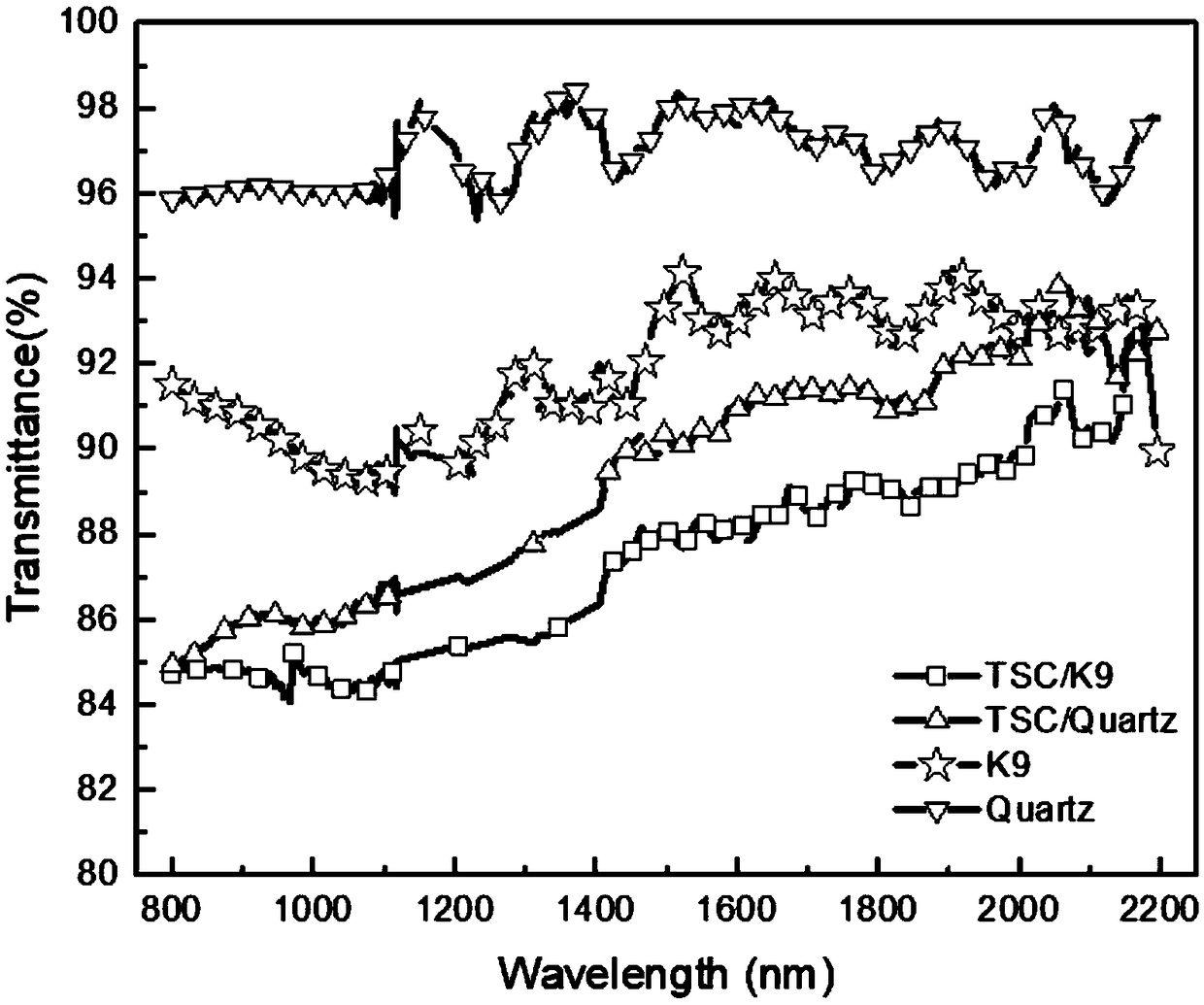

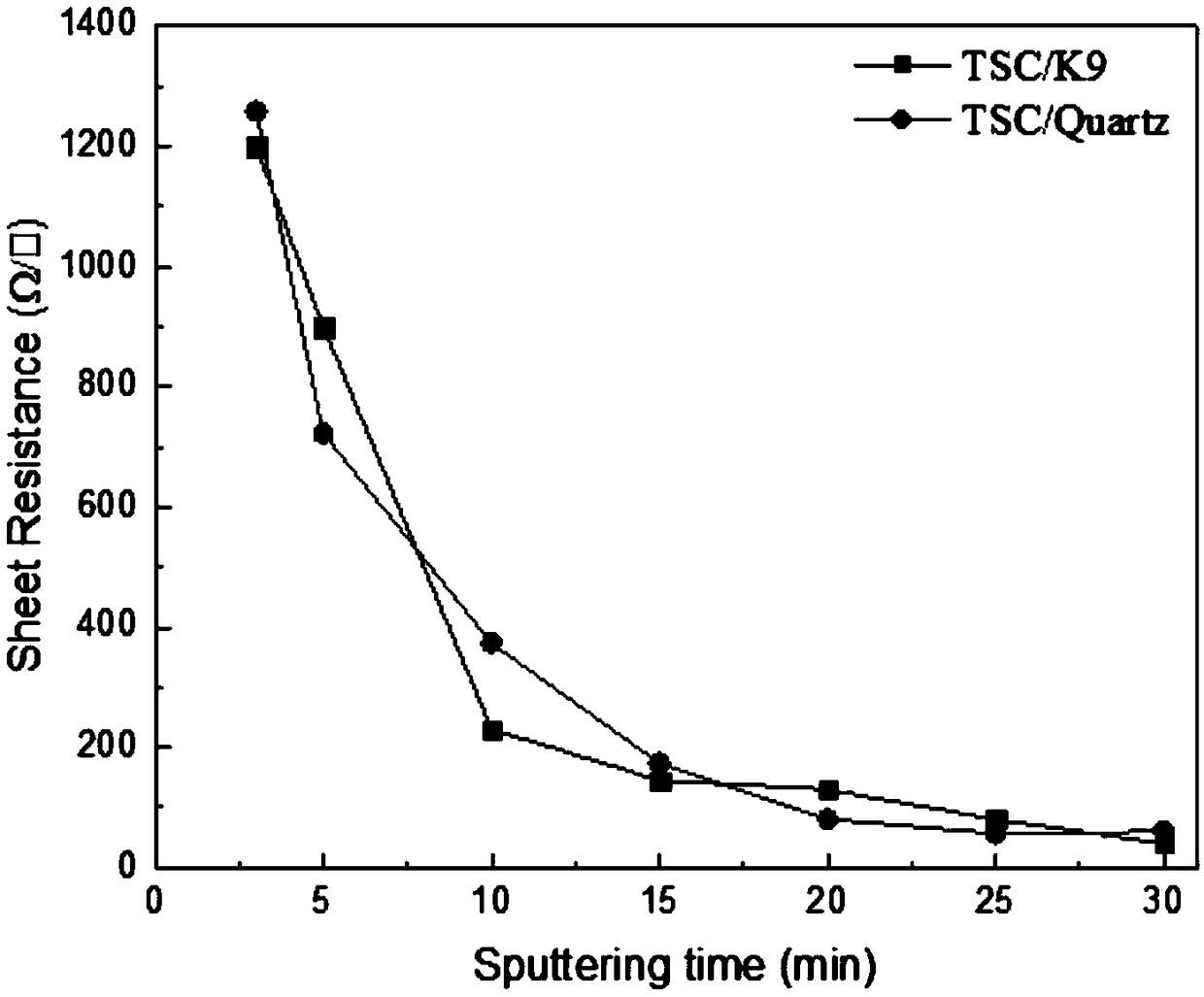

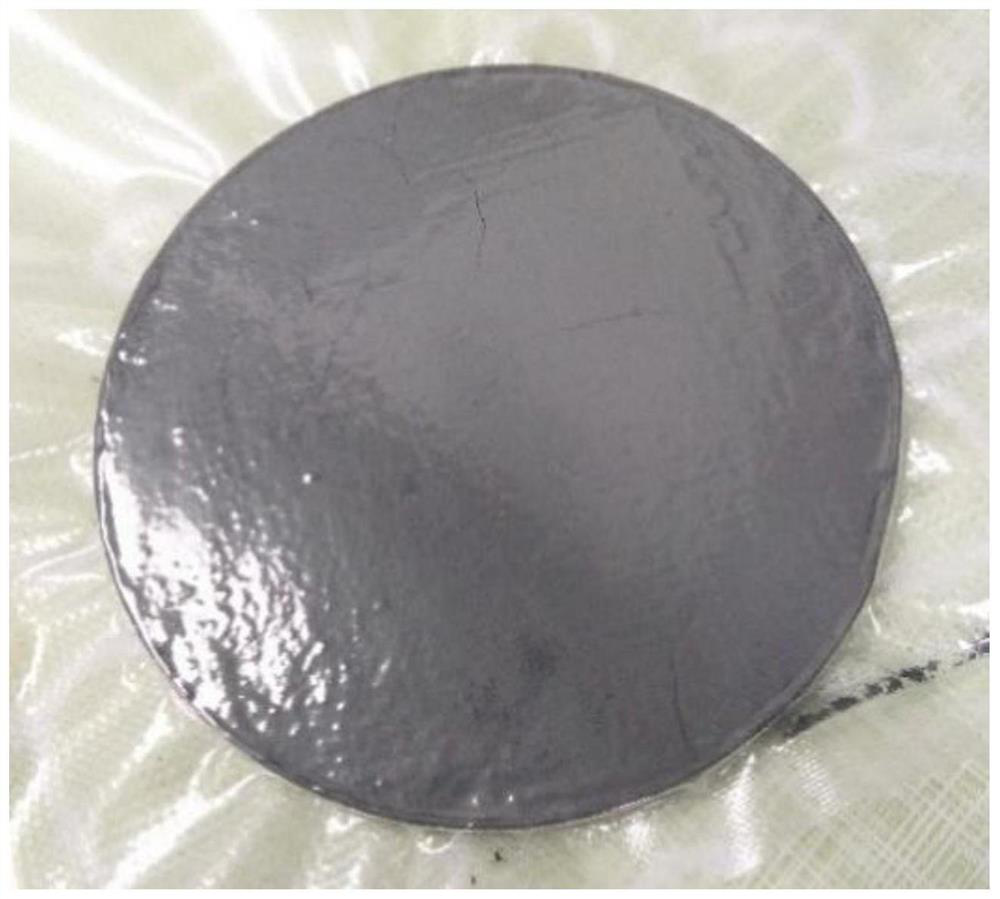

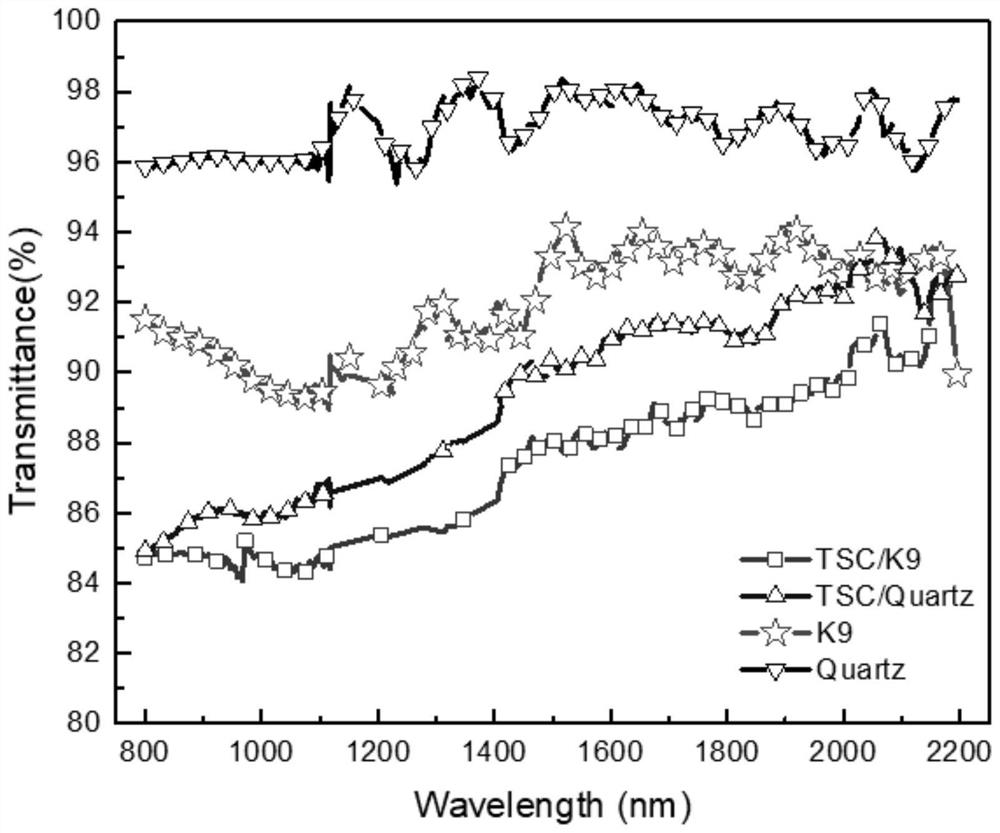

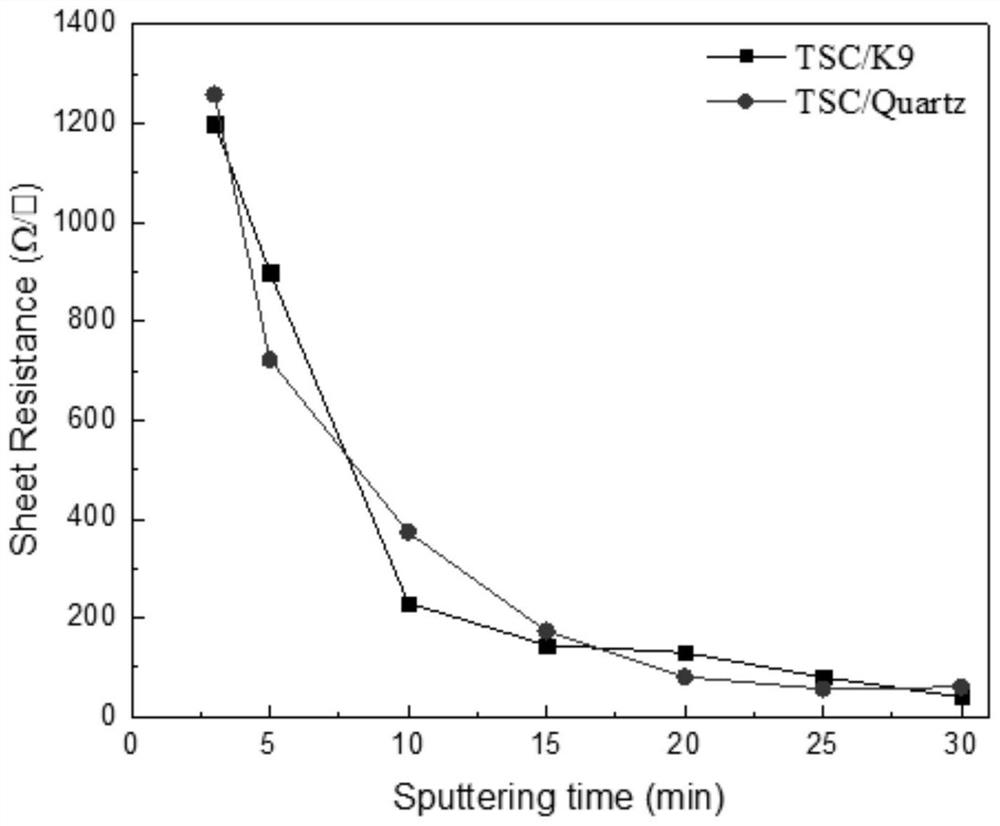

TSC ceramic film, and preparation method and application thereof

ActiveCN108930019AImprove mechanical propertiesImprove friction and wear propertiesVacuum evaporation coatingSputtering coatingGas phaseTransmittance

The invention discloses a TSC ceramic film, and a preparation method and an application thereof, and belongs to the technical field of photoelectric materials. The semiconductor film with a micro-nanothickness is prepared in traditional physical vapor deposition (PVD) coating manner by using a Ti3SiC2 powder material as a target material. The preparation method has the advantages of simplicity, reliability and low cost, and the prepared film keeps the good mechanical performances and friction wearing performance of the Ti3SiC2 material, and also has dual performances of near-infrared lights and moderate conductivity. The Ti3SiC2 ceramic film obtained by the method has a transmittance of 80% or above and a conductivity of 50- 2000 omega / square in a spectral range of 800-2200 nm, so the application range of the Ti3SiC2 material can be broadened to the technical field of photoelectricity based on the above properties, and the Ti3SiC2 material provides a theoretical basis for packaging ofinfrared band photoelectric devices as a window material. The ceramic film of the invention has good engineering application prospects in the field of photoelectricity.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

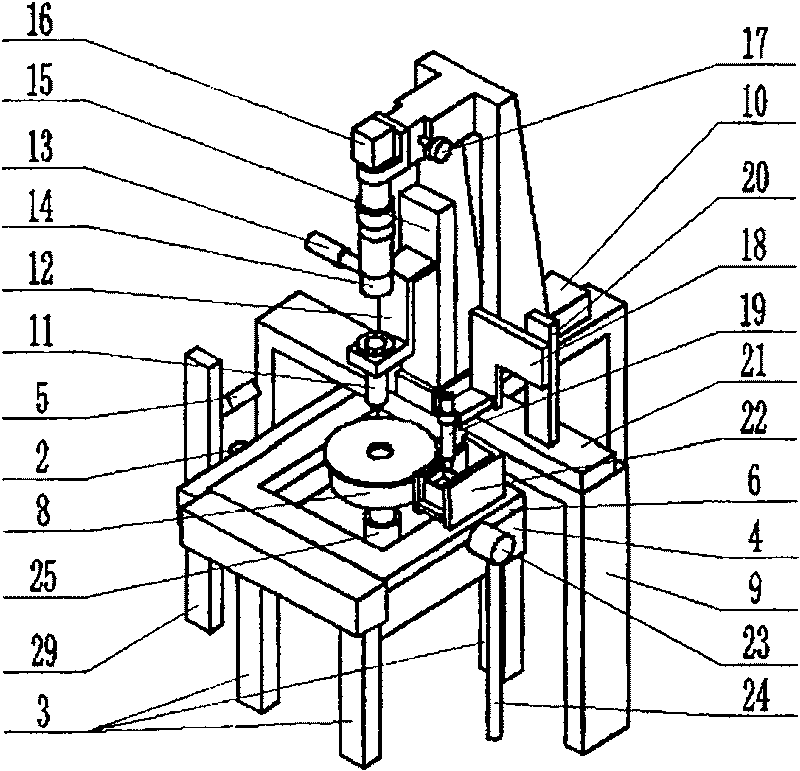

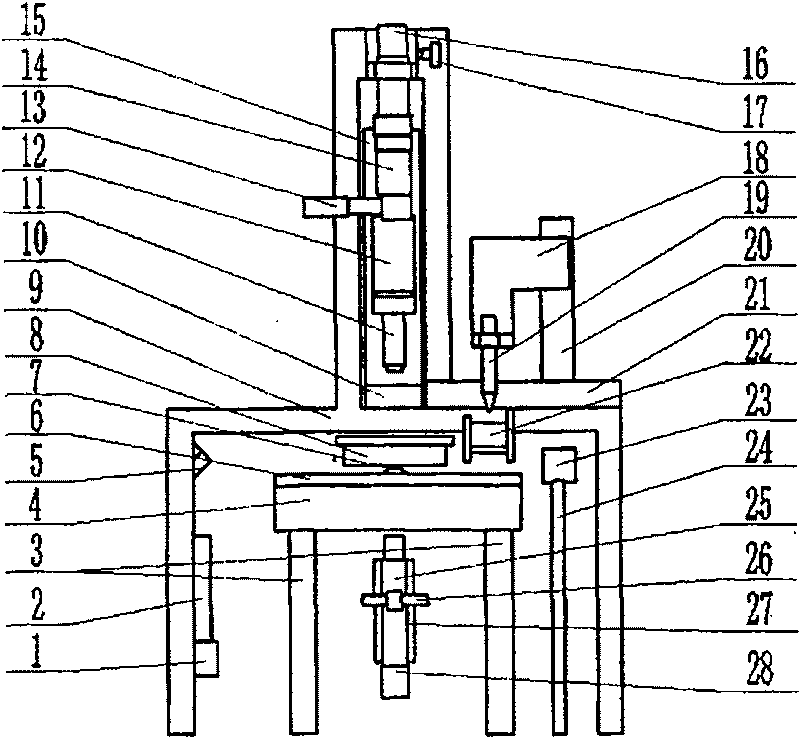

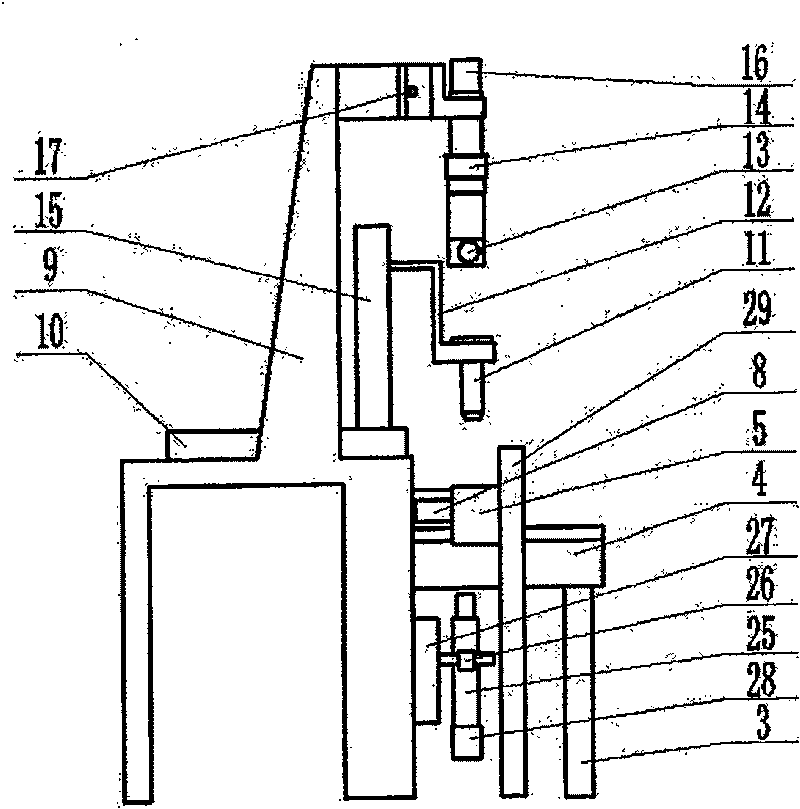

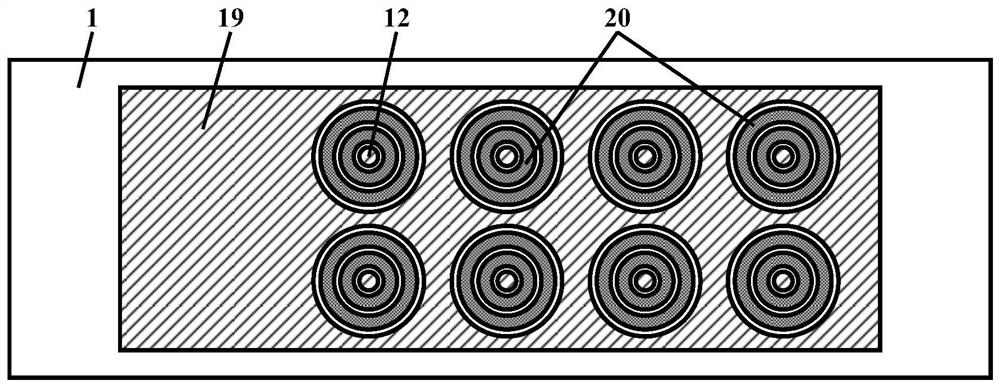

Apparatus for manufacturing aspherical microlens array

The invention relates to a non-sphere micro-lens array manufacturing device, which solves the problem that during the manufacture of the prior micro-lens and array devices thereof, the surface shape of the micro-lens is beyond control and real-time detection of optical performance of the surface of the micro-lens is impossible. The device comprises a main support, an injector, an upper electrode,a transverse detection optical circuit, a longitudinal detection optical circuit, an annular, an ultraviolet source and so on, wherein a liquid box is arranged under the injector, and one side of theinjector is provided with the upper electrode and a specimen stage. An undersurface of the specimen stage and an upper surface of the upper electrode are provided with tin indium oxide coatings to form a parallel-plate capacitor type electric field. The injector injects a liquid drop between the specimen stage and the upper electrode, the electric filed controls the surface shape of the liquid lens, the transverse detection optical circuit carries out real time detection of the surface shape of the liquid lens, the longitudinal detection optical circuit detects a focused spot, aberration analysis is carried out according to the surface shape and an image of the focused spot and the annual ultraviolet source solidifies the liquid lens when proper surface shape and focused spot are proper, so a solid non-sphere micro-lens with excellent optical performance is obtained. The device has the advantages of simple process, high repetitiveness and low cost.

Owner:UNIV OF SCI & TECH OF CHINA

Preserved potato and manufacture method

InactiveCN101204189AThe production process is reliableBeautyConfectionerySweetmeatsSucroseDietary fiber

The invention relates to preserved potato and a preparation method thereof. The preserved potato takes potato as material and contains 70-150 shares of potato, 50-70 shares of sucrose, 0.75-1.25 shares of sodium hydrogen sulfite, and 0.05-0.1 shares of citric acid. During manufacturing, the material is selected, washed, with peel removed, and cut with color protected; the material is taken out, rinsed in clean water, and processed by sulfur; then the material is boiled in boiling water to eighty percent cooked and is cooled with water dropped; after that, the material is preserved, boiled and dipped in sugar, dried and packed, thus obtaining the preserved potato. The manufacture process is reliable and the preserved rehmanniae can be produced by using the current production condition of the preserved fruit. The preserved potato made by the invention is sweet and delicious in taste. At the same time, the food keeps a plurality of dietary fibers, vitamins and amino acids in potato. The invention has the function of protecting stomach, keeping health, maintaining skin and beautifying features.

Owner:TIANJIN POLYTECHNIC UNIV

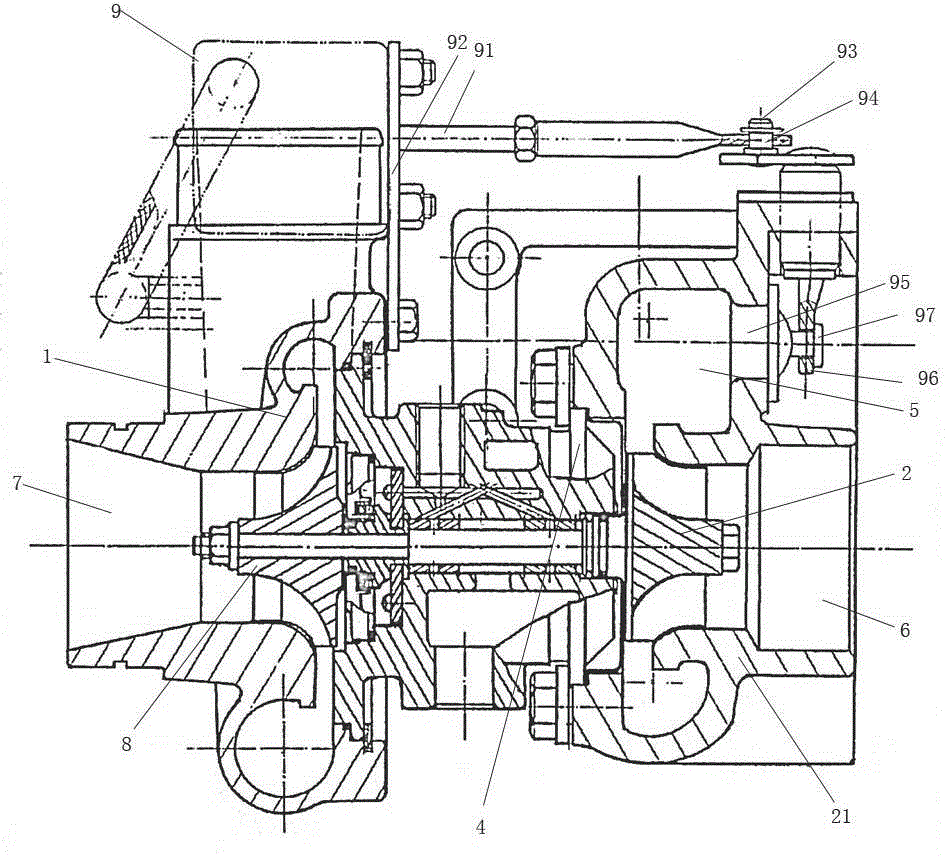

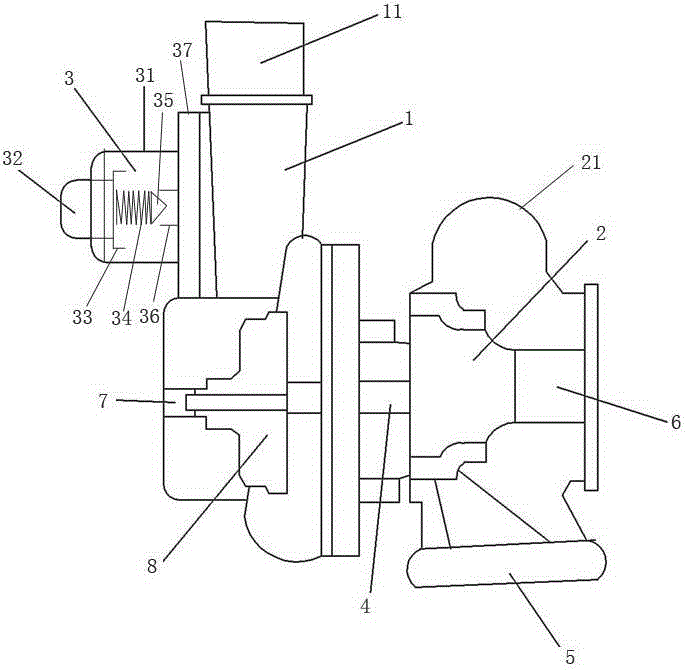

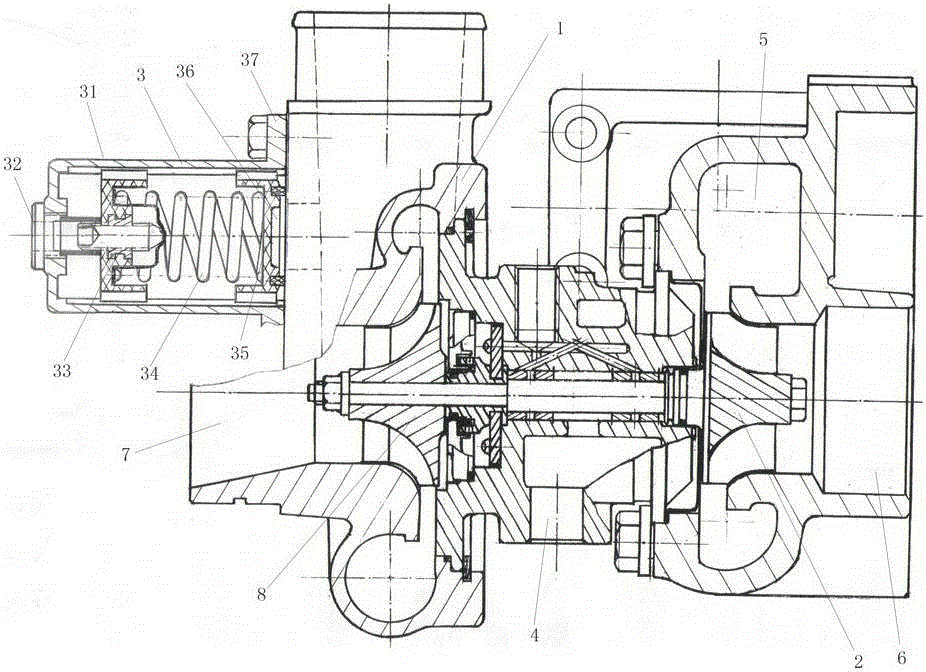

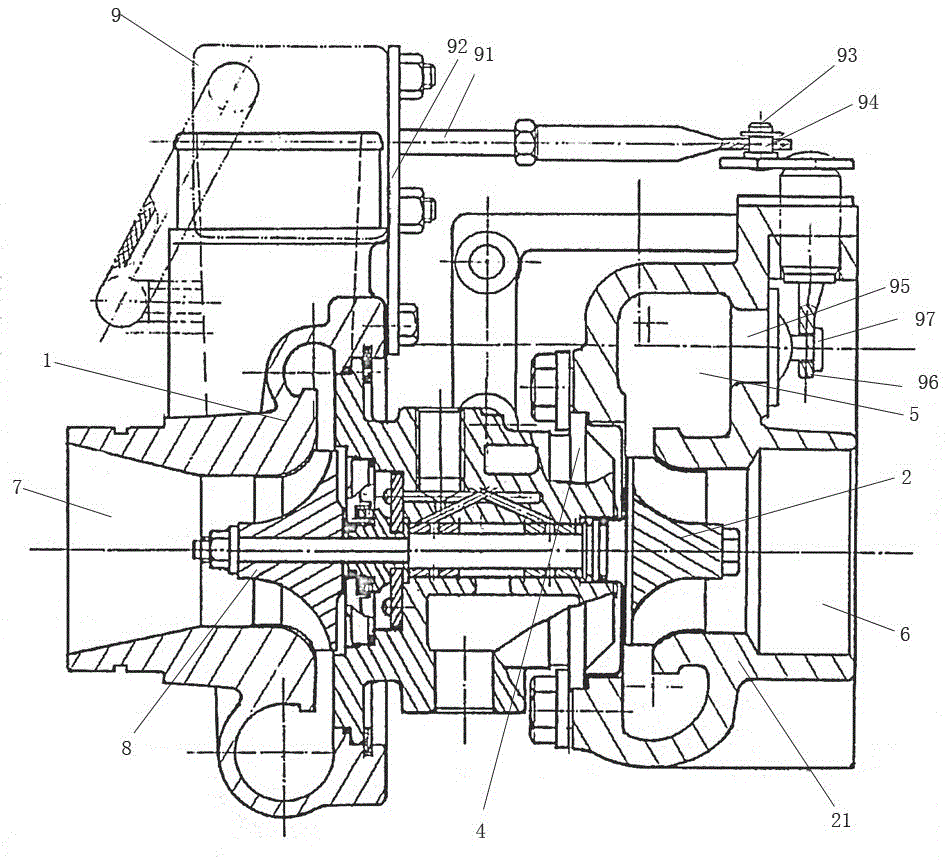

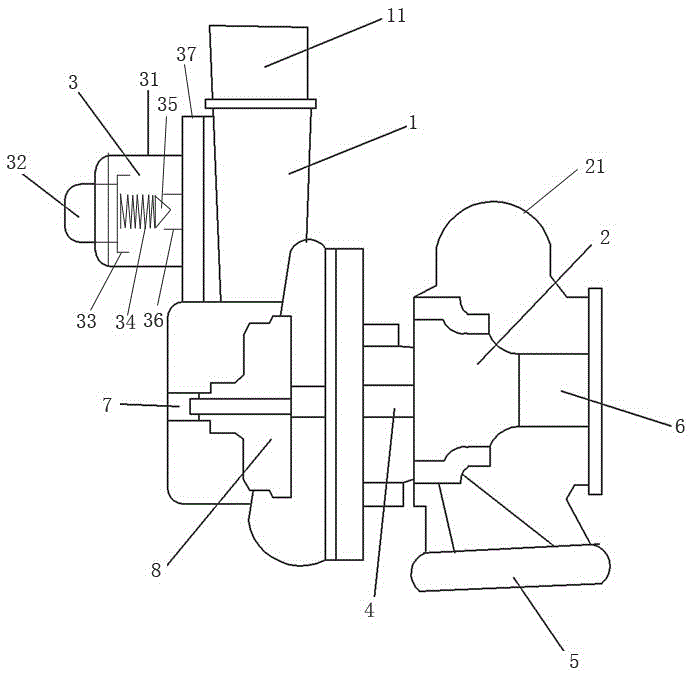

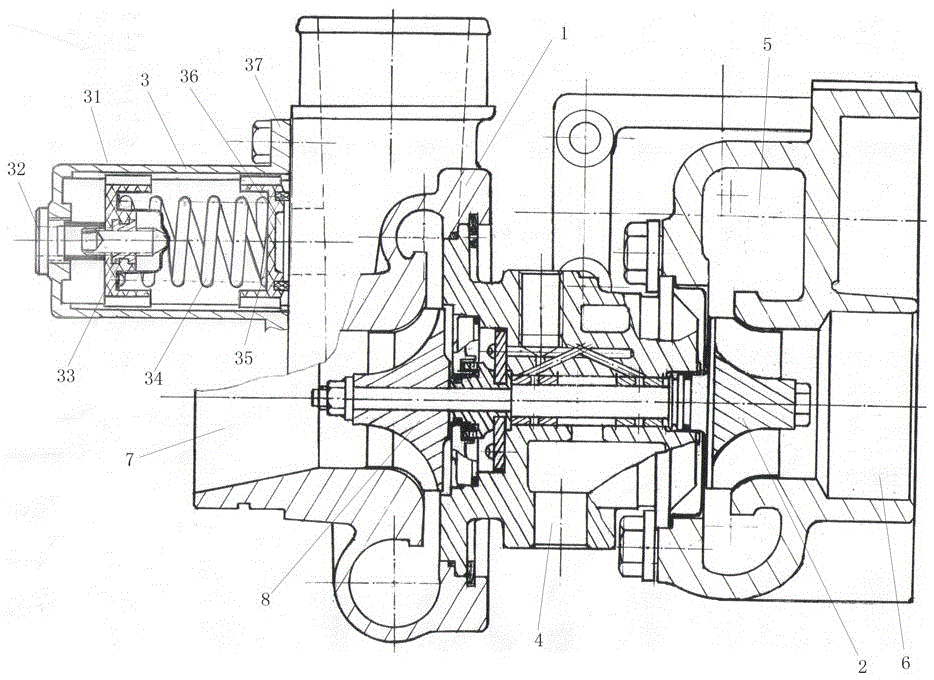

Turbocharger

InactiveCN105240113AExtended service lifeAvoid knockingInternal combustion piston enginesEngine componentsAir compressionImpeller

The invention relates to a turbocharger which comprises an intermediate body. The two ends of the intermediate body are connected with an impeller and a turbine through shafts respectively. The impeller is covered with an air compression shell. A shock absorber is installed on the side face of an outlet of the air compression shell. An air inlet is formed in one side of the impeller. A turbine air inlet and an exhaust gas outlet are formed in the turbine. A turbine shell of the turbocharger is provided with the shock absorber instead of a bypass vent valve so that knocking and surging can be avoided. The pressure is adjusted through a precision spring of the shock absorber, so that the turbocharger is flexible, reliable and convenient to install, adjust and repair. When the turbocharger and an engine are matched and adjusted, adjustment is performed through an adjusting spring, operation is easy, accurate and reliable, and technicians of an engine factory assembly production line and automobile repair technicians can install and adjust the turbocharger to meet the ideal standard according to the power, the displacement and the number of turns of the engine.

Owner:成军

Method for processing fish bone snack food

The invention provides a method for processing a fish bone snack food. The method comprises the following steps: (a) pretreating fish bones, namely firstly removing fish scraps on fish bones and washing the fish bones in clear water, then, boiling the fish bones in a pot for 10-20 minutes to cure the fish bones and remove grease on the surfaces of the fish bones, picking out the fish bones, and performing drying for later use; (b) performing enzymolysis, namely performing soaking and enzymolysis on the fish bones in an endopeptidase aqueous solution at 40-60 DEG C for 2-4 hours; and (c) performing soaking with a seasoning spice liquid, namely soaking the enzymolytic fish bones in the seasoning spice liquid at the temperature of 25-35 DEG C for 0.5-2 hours.

Owner:ZHEJIANG OCEAN UNIV

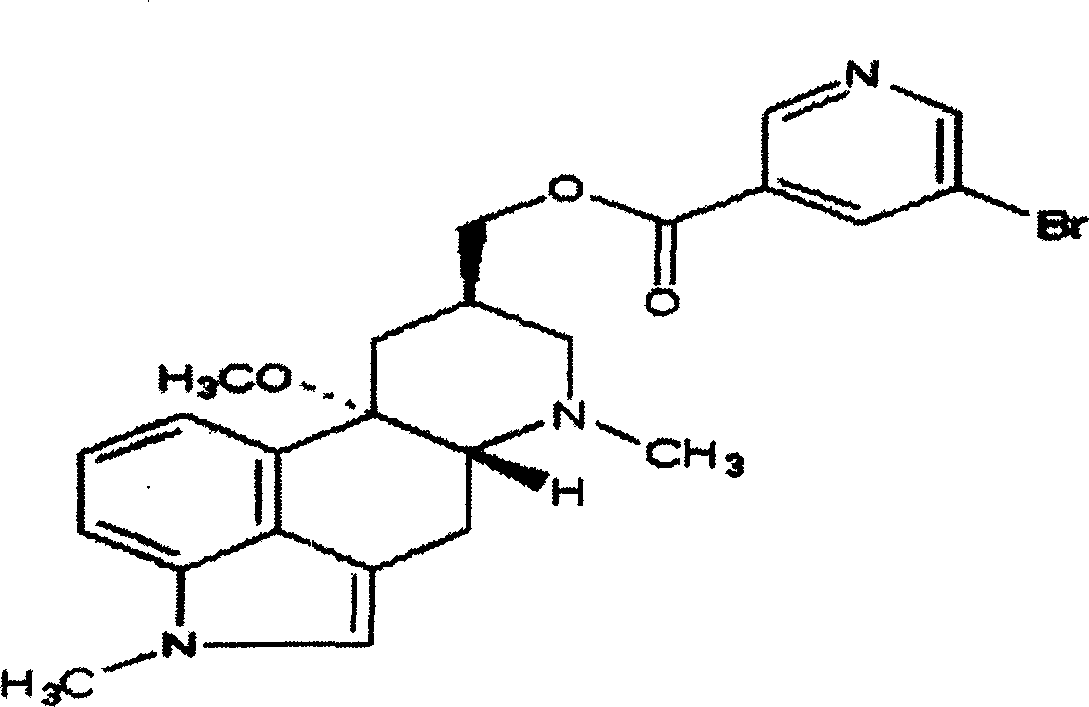

Nicergoline dry emulsion and its preparation method and application

InactiveCN101057848AImprove stabilityGood curative effectNervous disorderEmulsion deliveryOil phaseAcute urine retention

The invention discloses a medicine preparation form, especially discloses a nicergoline dry emulsion and the preparing method and application. It takes nicergoline in the dry emulsion as effective component, and also comprises oil phase, emulsifying agent and other findings. The dry emulsion is characterized by mature preparation process, easy industrialization, good stability, easy transportation and storage, controllable medicine content and good effect. The invention is used for improving cerebral arteriosclerosis and affective disorder caused by cerebral apoplexy after-effect, acute and chronic circulatory disturbance and acute urine retention resulted from blood vessel dementia and prostate gland proliferation.

Owner:陈云生 +1

Preparation method of direct methanol fuel cell negative support material

InactiveCN110350216AImprove performanceReduce manufacturing costFinal product manufactureSealing/support meansButylphthalideTert butyl

The invention relates to a preparation method of a direct methanol fuel cell negative support material. According to the technical scheme, the preparation method mainly comprises the following steps:taking divinylbenzene containing tert-butyl catechol as a stabilizer and tin oxide as raw materials; coating the surface of the tin oxide with polydivinylbenzene by adopting a dispersion polymerization method; and then performing pyrolysis to prepare the direct methanol fuel cell negative support material with tin particles uniformly dispersed in a carbon matrix. The preparation method has the beneficial effects that the preparation cost can be greatly reduced; the cost performance is relatively high; the material has relatively strong market competitiveness compared with products at home andabroad; the direct methanol fuel cell negative support material product can be manufactured through the method; and a negative support body manufactured from the negative support material has the characteristics of being low in shrinkage rate, small in deformation, high in graphitization degree, high in conductivity, good in mechanical property and the like.

Owner:郭峰

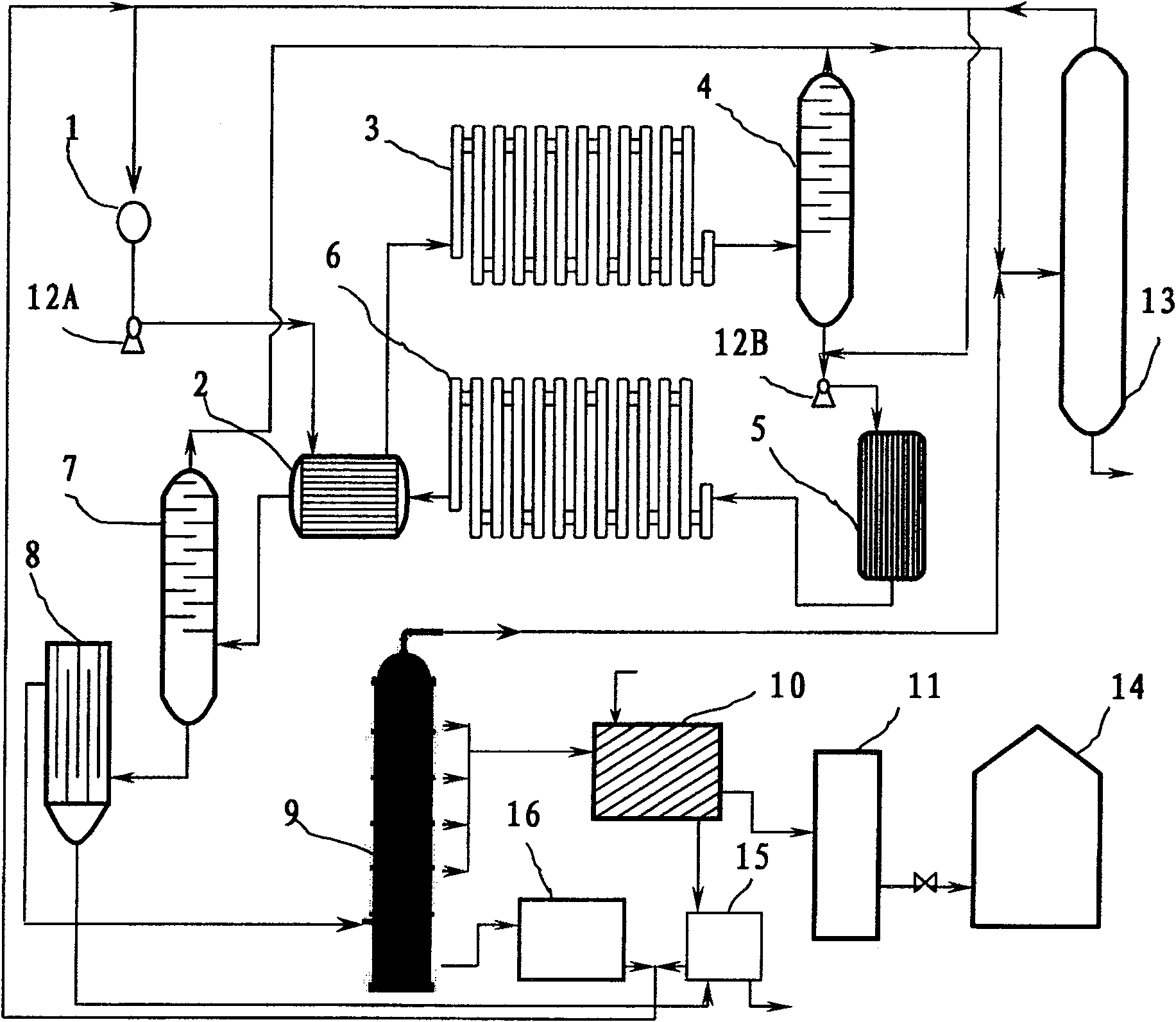

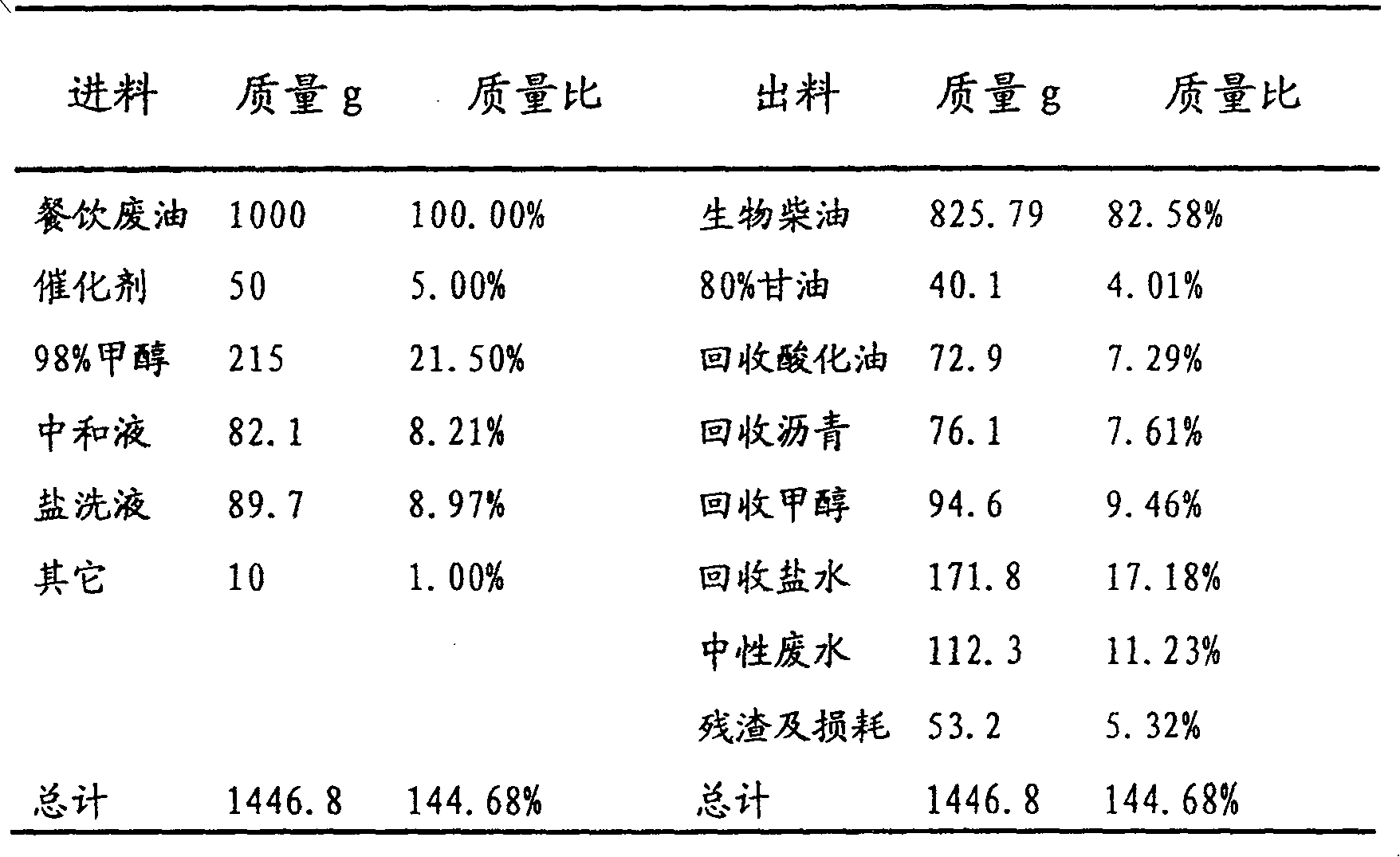

Apparatus for producing biodiesel for vehicle and its preparing method

InactiveCN100552002CLow costAchieve serializationBiofuelsLiquid hydrocarbon mixture productionBiodieselDistillation

This invention relates to a production device and its manufacturing method for bio-diesel oil with super-low sulphur used in car, in which, the device includes a first section tubular reactor, a second section tubular reactor, a first flash column, a heater, a heat exchanger, a second flash column, a sedimentation separator, a reduced pressure distillation tower, a neutralization washing tower and a desulfurizer. The method includes feeding raw materials into two sectional pressure tubular reactors into two sectional pressure tubular reactors continuously for reaction putting, the outgoing material of the tubular reactor into the sedimentation separator for separation, feeding the separator into the reduced pressure distillation tower, cutting a cut fraction in a certain temperature sphere to be neutralized, washed and desulfurized to get bio-diesel oil continuously.

Owner:亚洲生物燃油(BVI)有限公司

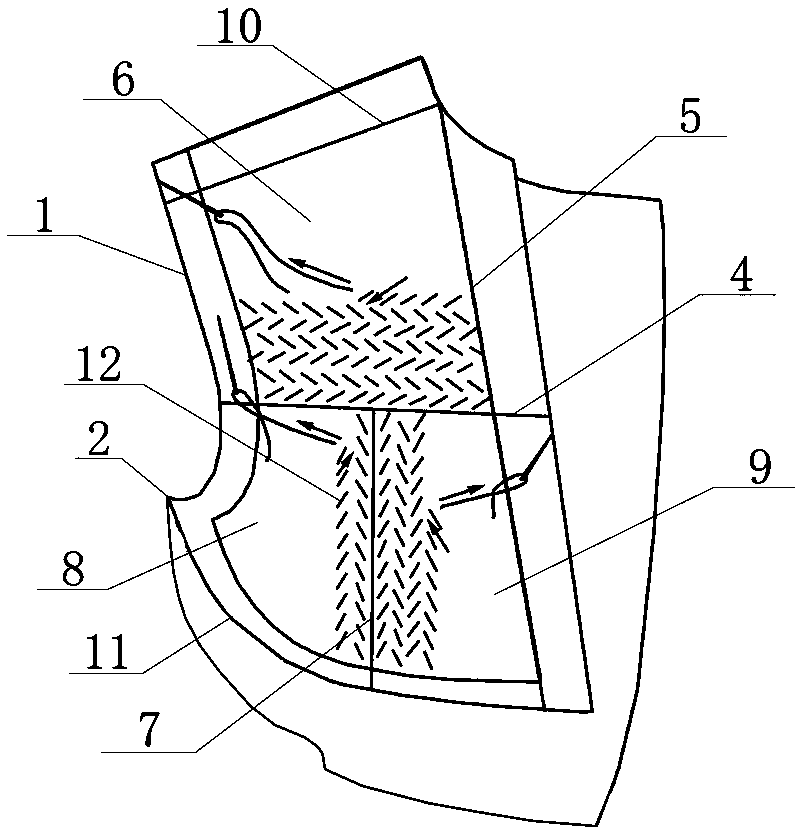

A kind of hand-sewing method of front chest lining for high-grade suits or coats

ActiveCN106072959BFit closelySimple preparation processClothes making applicancesEngineeringRight chest

Owner:老合兴洋服(杭州)有限公司

Turbocharger

InactiveCN105587402AExtended service lifeAvoid knockingInternal combustion piston enginesEngine componentsImpellerProduction line

Owner:成军

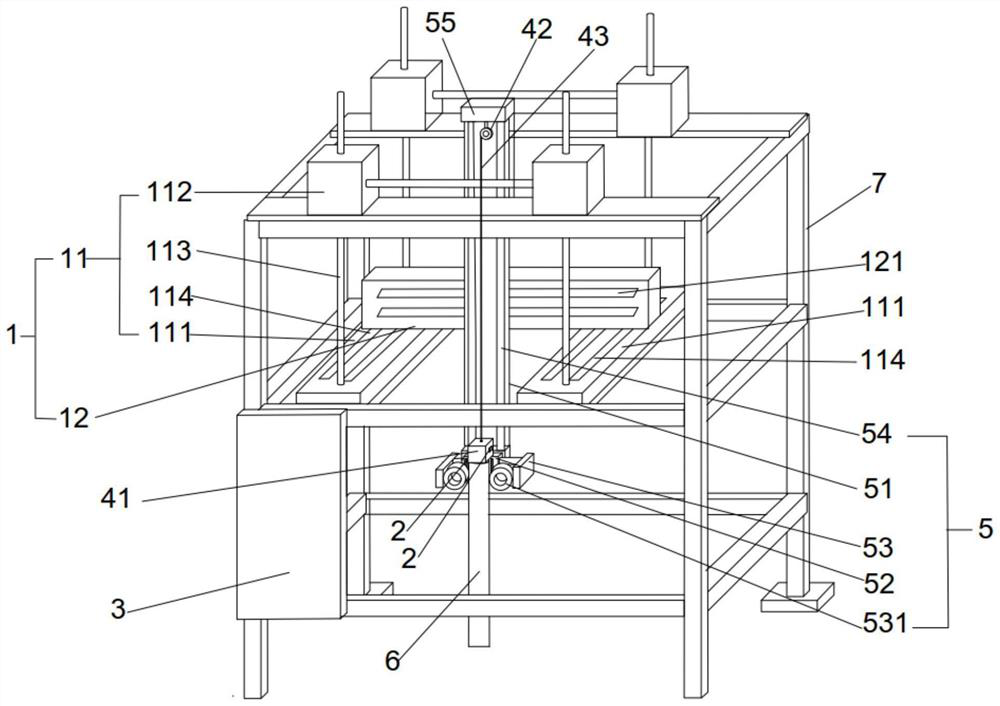

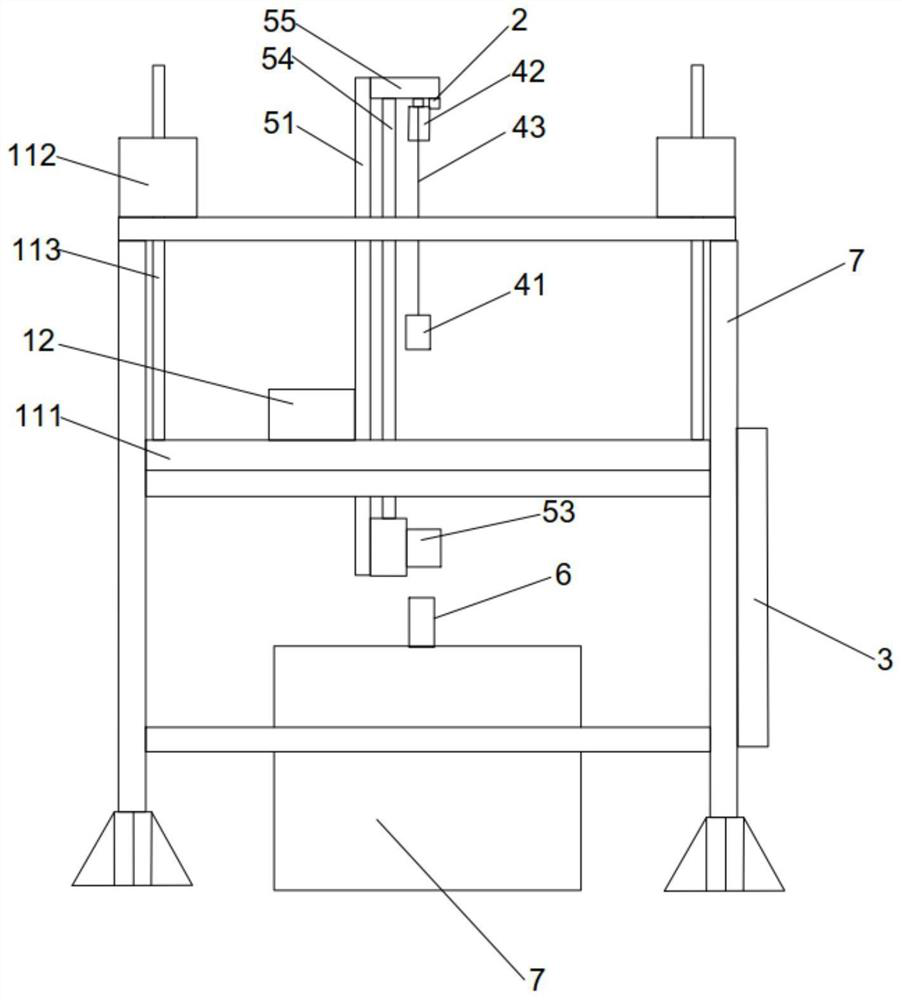

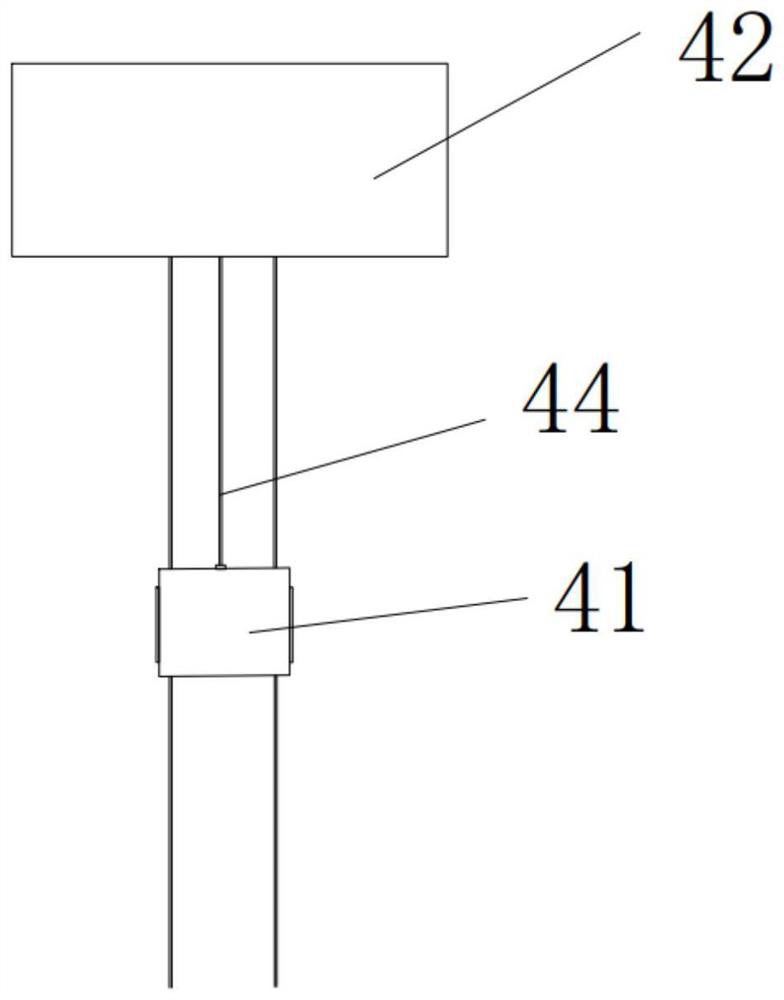

Transplanting type automatic pile driver testing device and using method thereof

PendingCN114878195ASimple preparation processThe production process is reliableNuclear energy generationStructural/machines measurementControl systemStructural engineering

A transplanting type automatic pile driver testing device disclosed by the present invention comprises a frame, the frame is provided with a moving system, a positioning system, a control system, a pile hammer device and a pipe grabbing cylinder system, the moving system comprises a vertical lifting module and a transverse moving module, and a pipe grabbing cylinder sleeves the transverse moving module. The transverse moving module is connected to the vertical lifting module in a sleeved mode, the transverse moving module controls the pipe grabbing air cylinder system to move in the horizontal direction, the vertical lifting module controls the pipe grabbing air cylinder system and the transverse moving module to move in the vertical direction, the pipe grabbing air cylinder system pneumatically clamps and controls a test pile, and the pile hammer device is detachably arranged at the position of the pipe grabbing air cylinder system. The moving system, the positioning system and the pipe grabbing air cylinder system are all controlled by the control system. The device can accurately position the piling position.

Owner:WENZHOU UNIVERSITY

A kind of preparation method of TSC ceramic thin film and its product and application

ActiveCN108930019BImprove mechanical propertiesImprove friction and wear propertiesVacuum evaporation coatingSputtering coatingTransmittanceThin membrane

The invention relates to a preparation method of a TSC ceramic thin film and its product and application, belonging to the technical field of photoelectric materials. The present invention proposes to adopt the traditional physical vapor deposition (PVD) coating method, utilize Ti 3 SiC 2 The powder material is used as the target material to prepare a semiconductor thin film with a micronano thickness. The manufacturing process is simple, reliable and low in cost. 3 SiC 2 In addition to good mechanical and friction and wear properties, the material has dual properties of near-infrared light penetration and moderate electrical conductivity. Utilize the Ti that the inventive method makes 3 SiC 2 The transmittance of the ceramic thin film in the 800-2200nm spectral range is not less than 80%, and the conductivity is 50Ω / □-2000Ω / □. Based on the above properties, the present invention uses Ti 3 SiC 2 The scope of application of the material is extended to the field of optoelectronic technology, and it provides a theoretical basis for its use as a window material for the packaging of infrared band optoelectronic devices. The ceramic film of the invention has good engineering application prospects in the field of optoelectronics.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Tank-type container tank box tank body and frame connecting structure

InactiveCN105600207ACompact and lightweightImprove effective transport capacityLarge containersStructural engineeringMechanical engineering

Owner:江西制氧机有限公司

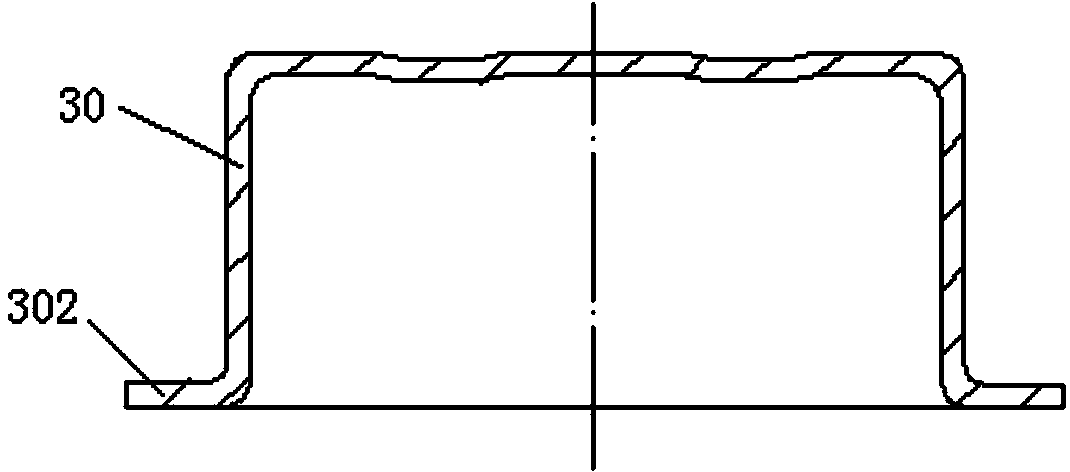

Impeller manufacturing process and lateral blade cut punching-bending forming die

The invention provides an impeller manufacturing process and a lateral blade cut punching-bending forming die. The manufacturing process includes the steps of a, blanking and drawing, to be more specific, blanking and drawing a metal plate to form a drawn part with a flange, wherein the drawn part comprises a cup-shaped body, and the flange is disposed at the bottom of the cup-shaped body; b, punching top surface, to be more specific, punching a shaft hole in the center of the top surface of the drawn part; c, punching the flange, to be more specific, evenly punching a plurality of positioning process holes along the periphery of the flange of the drawn part; d, performing lateral blade cut punching-bending forming, to be more specific, using the lateral blade cut punching-bending forming die to punch all blade grooves; e, cutting the flange of the drawn part. Compared with the prior art, the manufacturing process has the advantages that the impeller manufactured by the process is of an integral metal structure and good in rigidity and strength, equal division precision and consistence of the blades are high, balancing indexes can be satisfied, and long-term stable operation of a fan can be guaranteed.

Owner:SUZHOU INST OF INDAL TECH

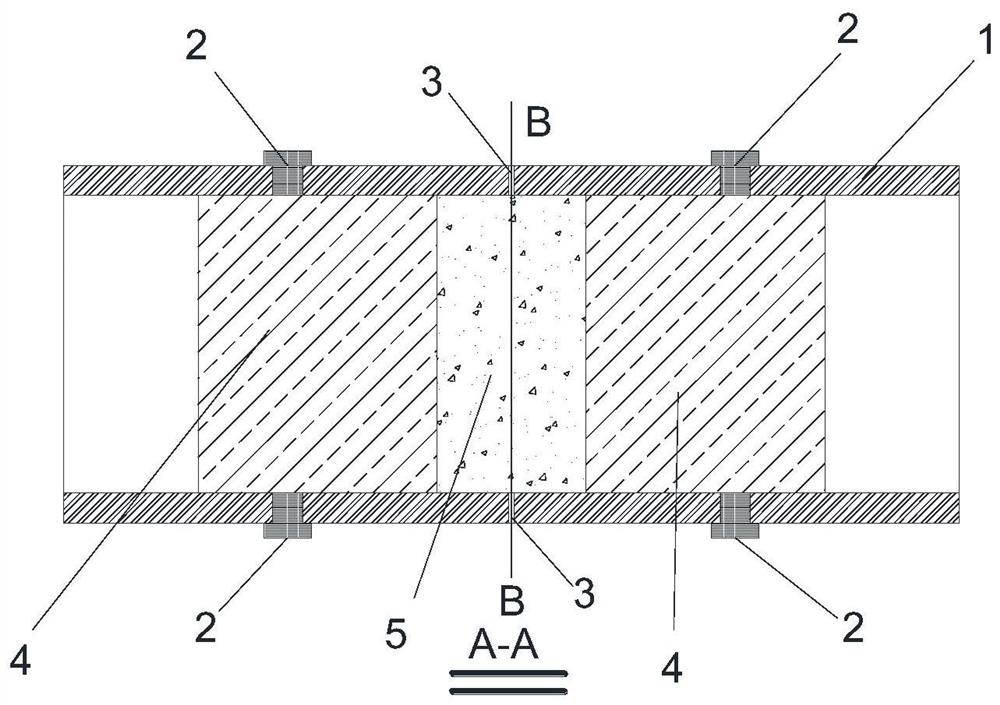

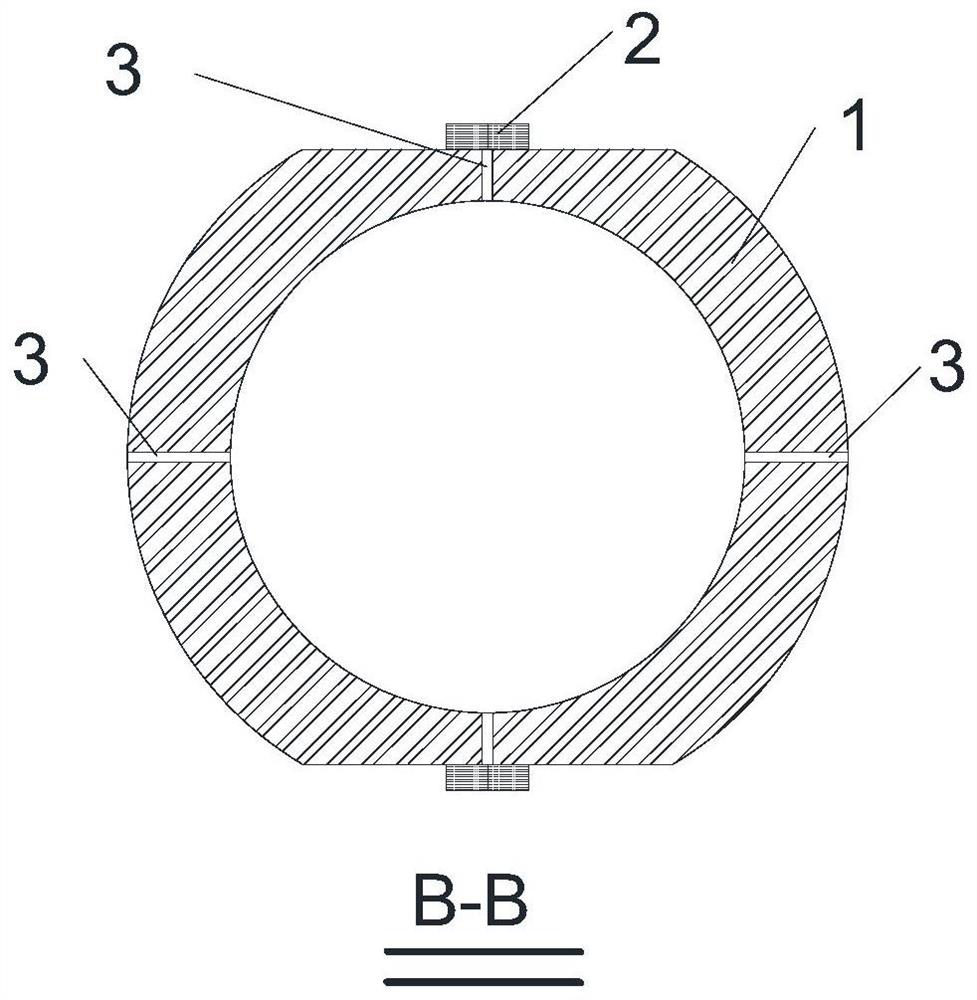

A separate Hopkinson rod impact test device

ActiveCN109883814BSolve the situation that cannot be dischargedBig errorMaterial strength using single impulsive forceSoft materialsMechanical engineering

The invention discloses a separate Hopkinson bar impact test device, which is suitable for the Hopkinson bar impact test of bulk / soft materials, comprising a casing (1) and a nut (2) for fixing a sample pad , exhaust components, sample pads (4) and casing supporting parts, the sample pads (4) are respectively located on the left and right sides of the inside of the casing (1), between the two sample pads (4) It is a sample chamber, and the nuts (2) for fixing the sample pad are distributed on the wall of the casing (1); the exhaust part is an exhaust hole (3) or an exhaust groove (9); the device mainly It solves the problem that the bulk / soft material cannot be fixed in the separated Hopkinson rod impact test, and the air in the casing cannot be discharged when the sample in the casing is impacted at high speed, which affects the test result. At the same time, it can display the sample during the test State, and the production process is simple, reliable, easy to use, easy to operate.

Owner:SOUTHEAST UNIV

Dry asarol emulsion and its prepn and application

InactiveCN101088499BImprove stabilityGood curative effectOrganic active ingredientsNervous disorderDiseaseEmulsion

The present invention discloses one kind of dry AAA emulsion and its preparation and application, and the dry AAA emulsion has asarol as effective component, emulsifier and other supplementary material. The dry AAA emulsion has mature technological process, easy industrial production, high stability, high curative effect and other advantages. It is applied mainly in clinical treatment of bronchitis, lung infection, asthma and other diseases.

Owner:陈云生 +1

Preserved honeydewmelon and manufacture method

InactiveCN101204192AThe production process is reliableWith buckConfectionerySweetmeatsSucroseSulfite salt

The invention relates to preserved honeydew melon and a preparation method thereof.The preserved honey dew melon takes honey dew melon as material and contains 75-150 shares of honey dew melon, 60-80 shares of sucrose, 0.1-0.2 shares of sodium sulfite, and 0.05-0.1 shares of citric acid, 1-5 shares of lime, and 0.1-0.2 shares of alum.During manufacturing, the material is washed, with peel and seeds removed, and is cut into slices or blocks; then the material is dipped in lime solution, rinsed in clean water for deliming, and placed in sodium sulfite solution for sulfur process; the melon slices through sulfur process is heated in hot water, during which 0.1 per cent of alum is added; then the processed honey dew melon is placed in cans, with sucrose added in; heat sugar solution and the citric acid are prepared, and the material is dipped in the original sugar solution and is boiled in sugar for twice; then the honey dew melon is taken out, with sugar solution dropped, and is dried and packed, thus obtaining the preserved honey dew melon. The invention is reliable in manufacture process and sweet and delicious in taste.The invention has the function of reducing hypertension, invigorating vital energy, regulating mind, and reducing fat.

Owner:TIANJIN POLYTECHNIC UNIV

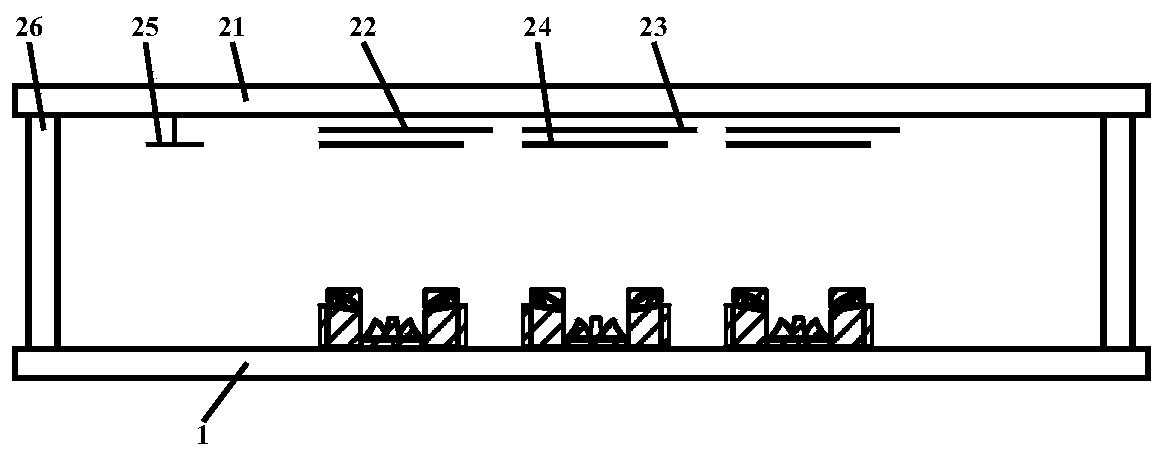

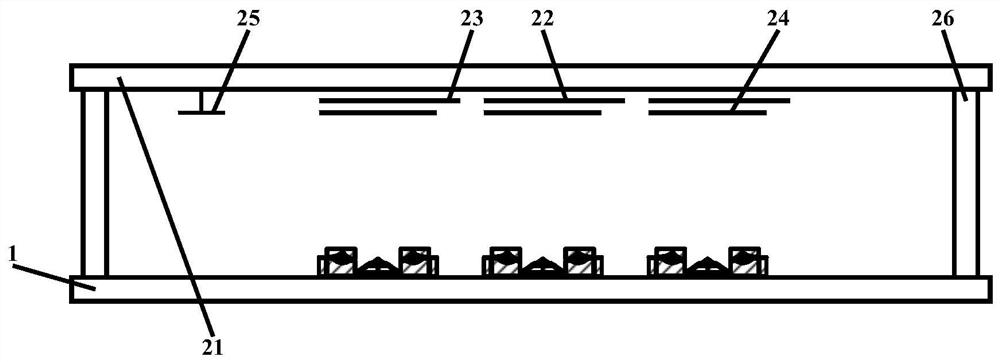

Light-emitting backlight source of micro-sinking continuous curved surface cathode low sail concave arc gating structure

InactiveCN111696840ASimple structureThe production process is reliableTube/lamp screens manufactureNon-emitting electrodes manufactureEngineeringGlass sheet

The invention discloses a light-emitting backlight source of a micro-sinking continuous curved surface cathode low sail concave arc gating structure. The backlight source comprises a vacuum sealing body and a getter accessory element positioned in the vacuum sealing body, and is characterized in that the vacuum sealing body consists of a front hard transparent glass plate, a rear hard transparentglass plate and a glass narrow frame strip; the front hard transparent glass plate is provided with an anode leveling film guide layer, an anode chain-continuing silver wire layer and a thin light-emitting layer, the anode leveling film guide layer is connected with the anode chain-continuing silver wire layer, and the thin light-emitting layer is manufactured on the anode leveling film guide layer; and a micro-sinking continuous curved surface cathode low sail concave arc gating structure is arranged on the rear hard transparent glass plate. The light-emitting backlight source has the advantage of being excellent in light-emitting gray scale adjustable performance.

Owner:JINLING INST OF TECH

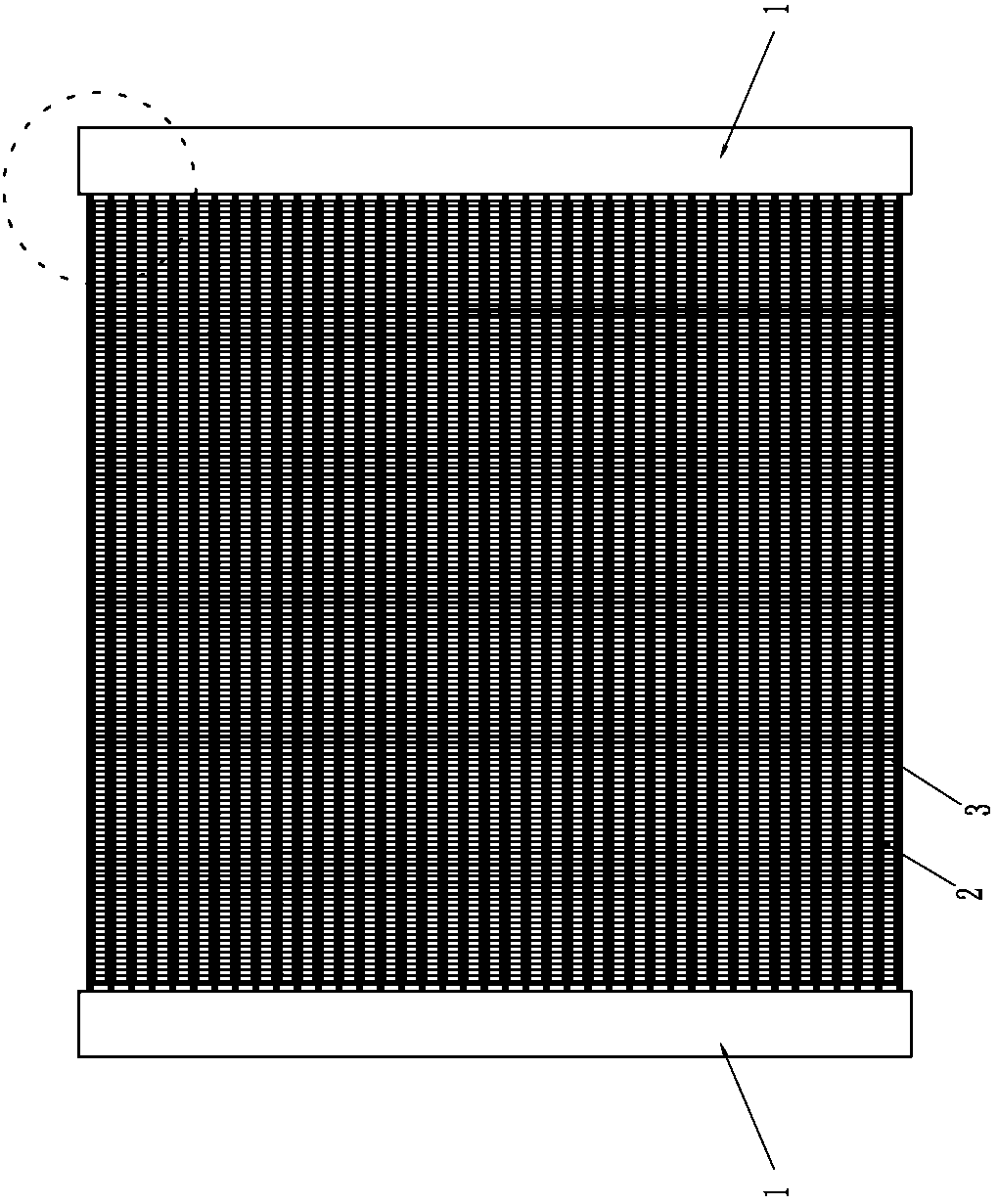

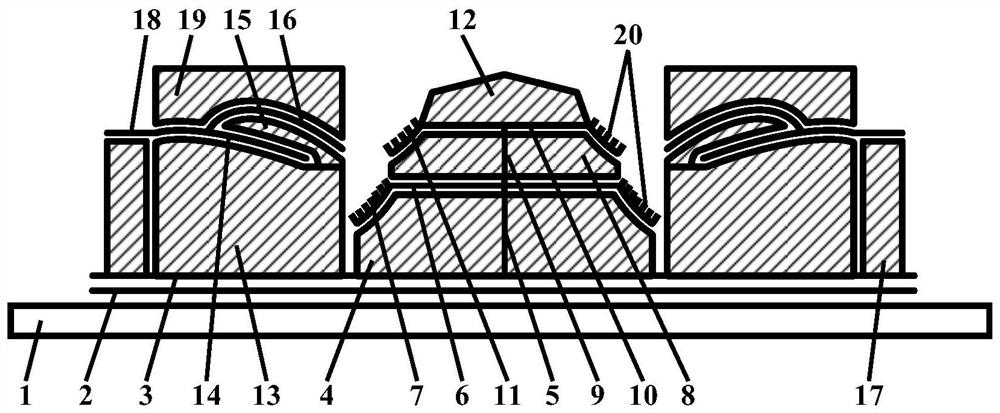

Light-emitting backlight source of double-probe curved gating structure of cathode with different vertical separation degree and same concave surface

InactiveCN111627784ASignificant progressIncrease electrode surface areaTube/lamp screens manufactureNon-emitting electrodes manufactureLuminous intensityFilm base

The invention discloses a light-emitting backlight source of a double-probe curved gating structure of a cathode with different vertical separation degree and the same concave surface. The light-emitting backlight source comprises a vacuum sealing body and a getter accessory element positioned in the vacuum sealing body, and is characterized in that the vacuum sealing body consists of a front hardtransparent glass plate, a rear hard transparent glass plate and a narrow glass frame strip; the front hard transparent glass plate is provided with an anode material film base flat layer, an anode extension system silver bent layer and a thin light-emitting layer, the anode material film base flat layer is connected with the anode extension system silver bent layer, and the thin light-emitting layer is manufactured on the anode material film base flat layer; and the rear hard transparent glass plate is provided with a double-probe curved gating structure of the cathode with the same concavesurface and different vertical separation degrees. The light-emitting backlight source has the advantage of being excellent in light-emitting intensity uniformity.

Owner:JINLING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com