TSC ceramic film, and preparation method and application thereof

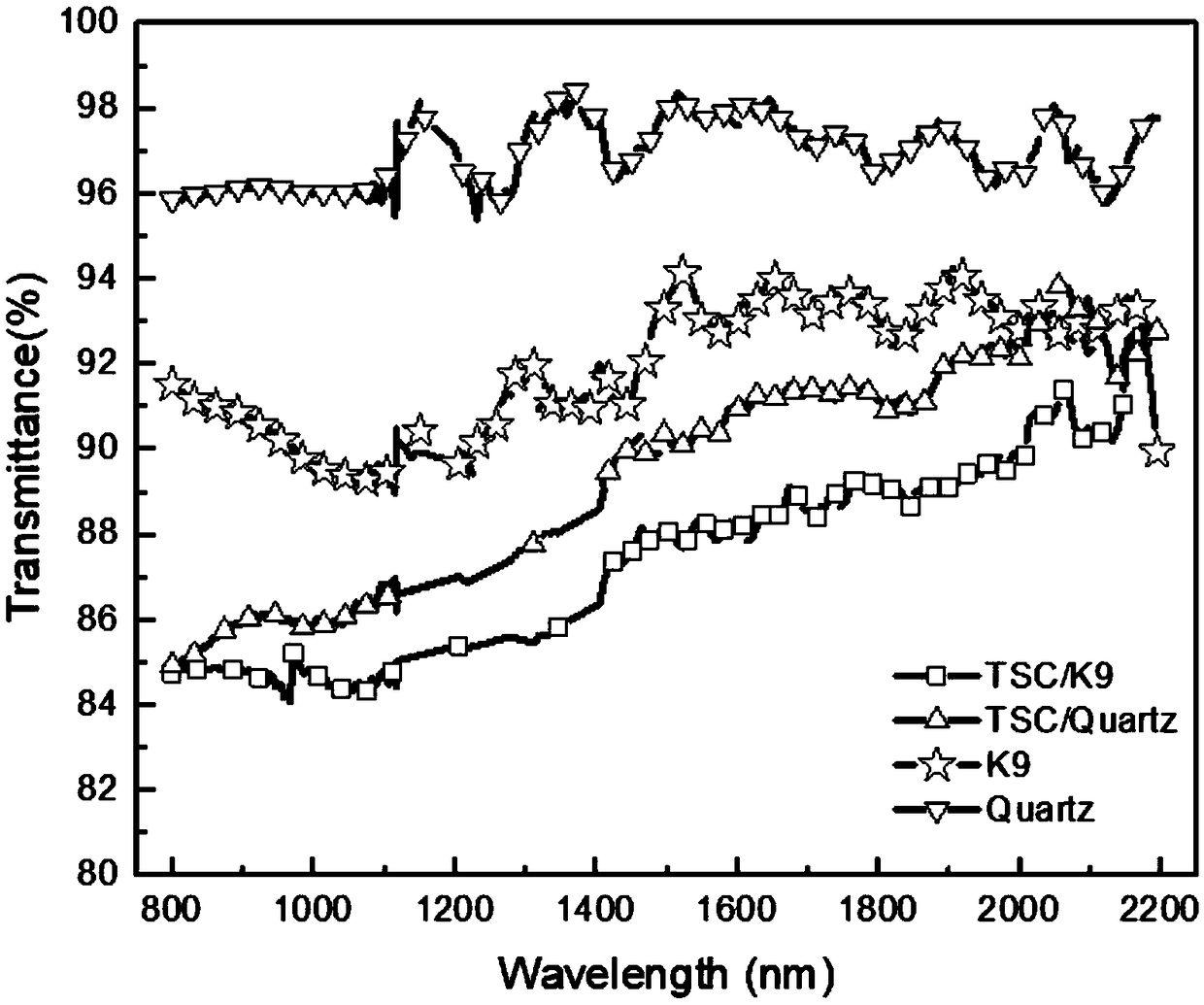

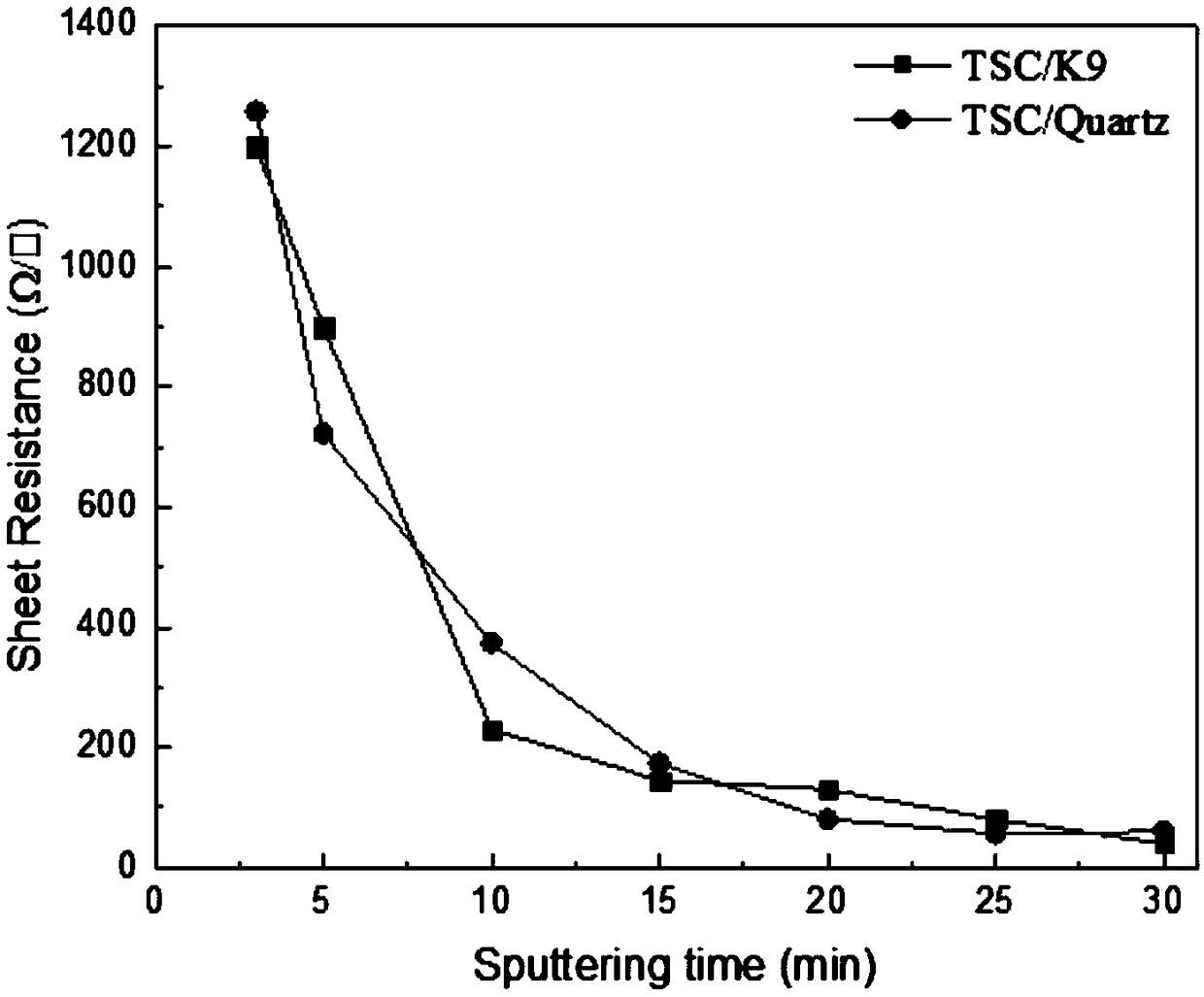

A ceramic thin film and film-forming technology, which is applied in ion implantation plating, metal material coating technology, coating, etc., can solve the problems of research in the field of optoelectronics, poor conductivity and transmittance, and infrared transmittance. Low-level problems, achieving good engineering application prospects, excellent near-infrared transmittance and conductivity, and reliable cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The present invention should adopt any suitable transparent substrate such as glass or quartz as the substrate, and the present embodiment adopts the K9 substrate and the quartz substrate as the substrate, adopts argon as the working gas, and conducts the process on it based on the DC sputtering method respectively. Thin film plating, prepare a kind of TSC ceramic film with high near-infrared light transmittance and conductivity, the specific operation is as follows:

[0024] Step 1: Target preparation:

[0025] Ti 3 SiC 2 Add the powder into deionized water and stir evenly to obtain Ti 3 SiC 2 dispersion, and then the Ti 3 SiC 2 Put the dispersion into an aluminum tray with a diameter of 90mm and a thickness of 3-4mm, and then put the aluminum tray in a vacuum oven at 120°C for 24 hours and take it out. Based on the above operations, a DC sputtering target is prepared. It should be vacuum-sealed and placed. For the target, please refer to the attached figure 1 ; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com