A kind of hand-sewing method of front chest lining for high-grade suits or coats

A chest lining and manual technology, applied in the direction of sewing tools and other directions, can solve the problems of front hanging or back space, etc., and achieve the effect of simple production process and good fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

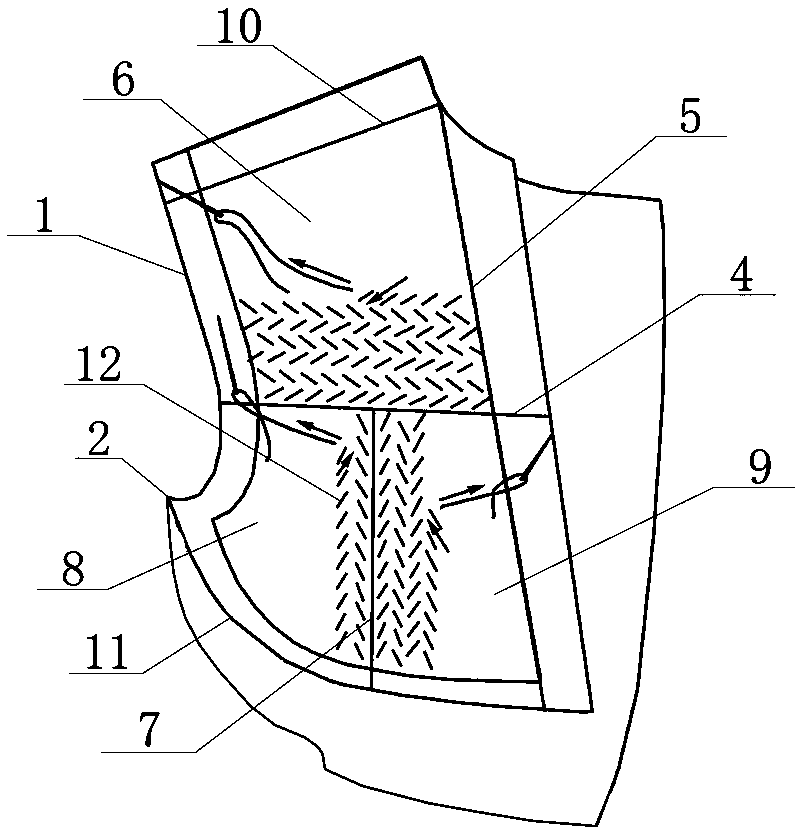

[0019] The present invention will be described in detail below in conjunction with accompanying drawing: A kind of front chest liner hand sewing method that is used for high-grade suit or overcoat making according to the present invention, this front chest liner comprises respectively by chest liner, ponytail liner and The front left chest lining and the front right chest lining which are sewn together by the chest cotton lining. The manual sewing method of the front chest lining includes the sewing of the front left chest lining and the sewing of the front right chest lining, wherein the front left chest lining The sewing method comprises the steps of combining figure 1 Shown:

[0020] 1a) Draw three hand-stitched areas on the front left chest lining after the upper and lower linings have been laminated. Starting from the armpit point 2 of the armhole line 1, draw a line 2-3cm upward along the armhole line 1. Horizontally draw a midline 4 perpendicular to the dart line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com