Impeller manufacturing process and lateral blade cut punching-bending forming die

A manufacturing process and forming die technology, applied in the field of punching and bending forming die for side blade incision, can solve the problems of inability to ensure smooth operation of the fan, poor rigidity and strength, etc., and achieve reliable manufacturing process, good rigidity and strength, and simple die structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] The manufacturing process of the impeller of the present invention comprises the following steps:

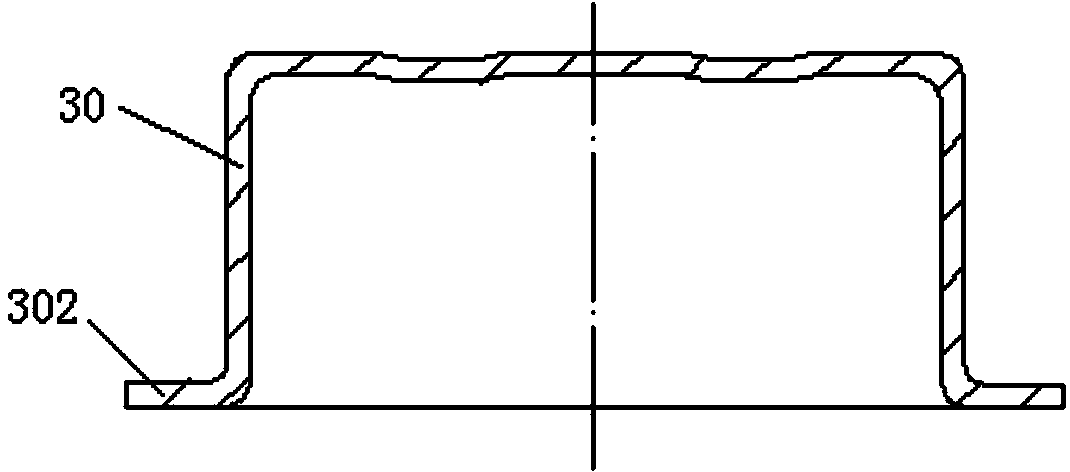

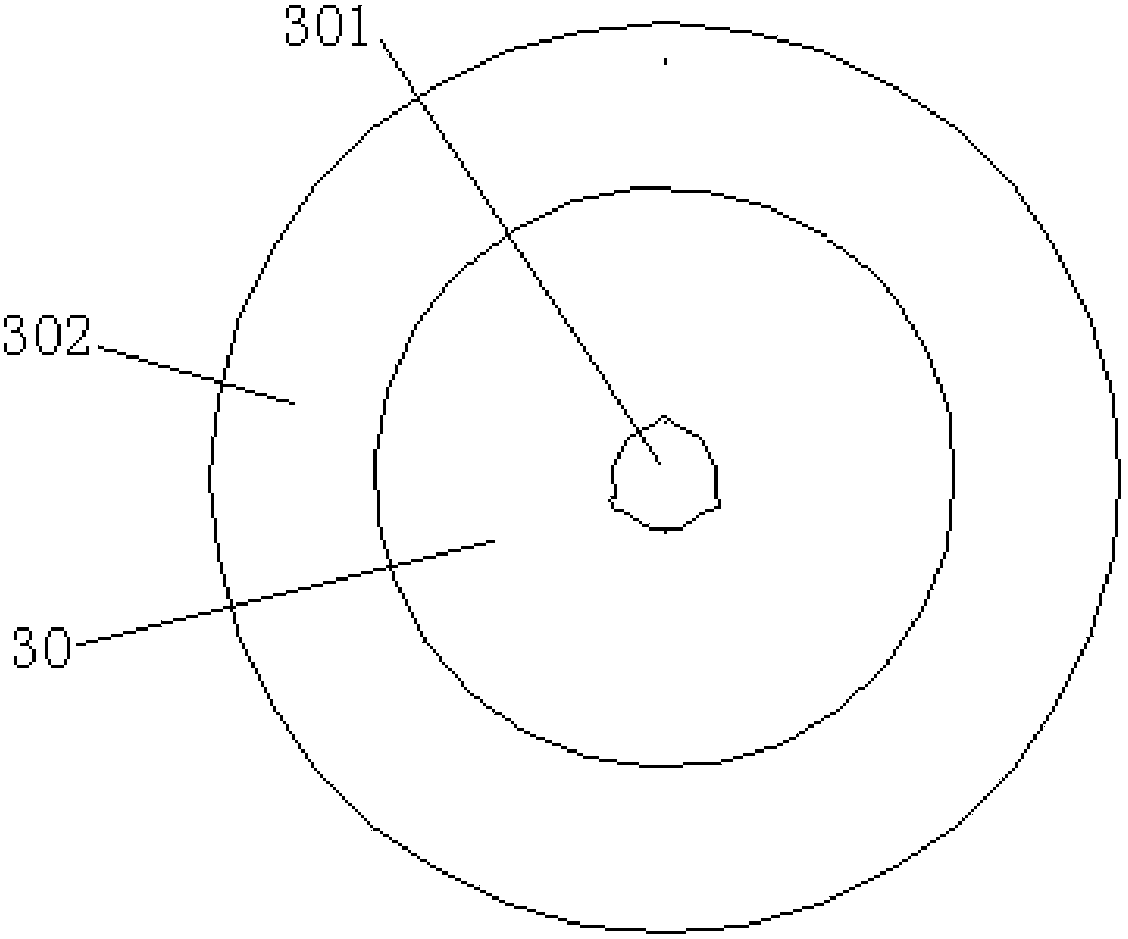

[0040] a. Blanking and deep drawing: a metal sheet is drawn and blanked to form a drawn part with a flange, such as figure 1 As shown, wherein, the drawing part 30 includes a cup-shaped body, and the bottom of the cup-shaped body has a flange 302 . This step can be completed by the blanking and deep drawing die in the prior art, and the metal sheet can be aluminum sheet L1060.

[0041] b. top surface punching: a shaft hole 301 is punched out in the center of the top surface of the drawn part 30, such as figure 2 Shown; This step can be finished by punching die in the prior art.

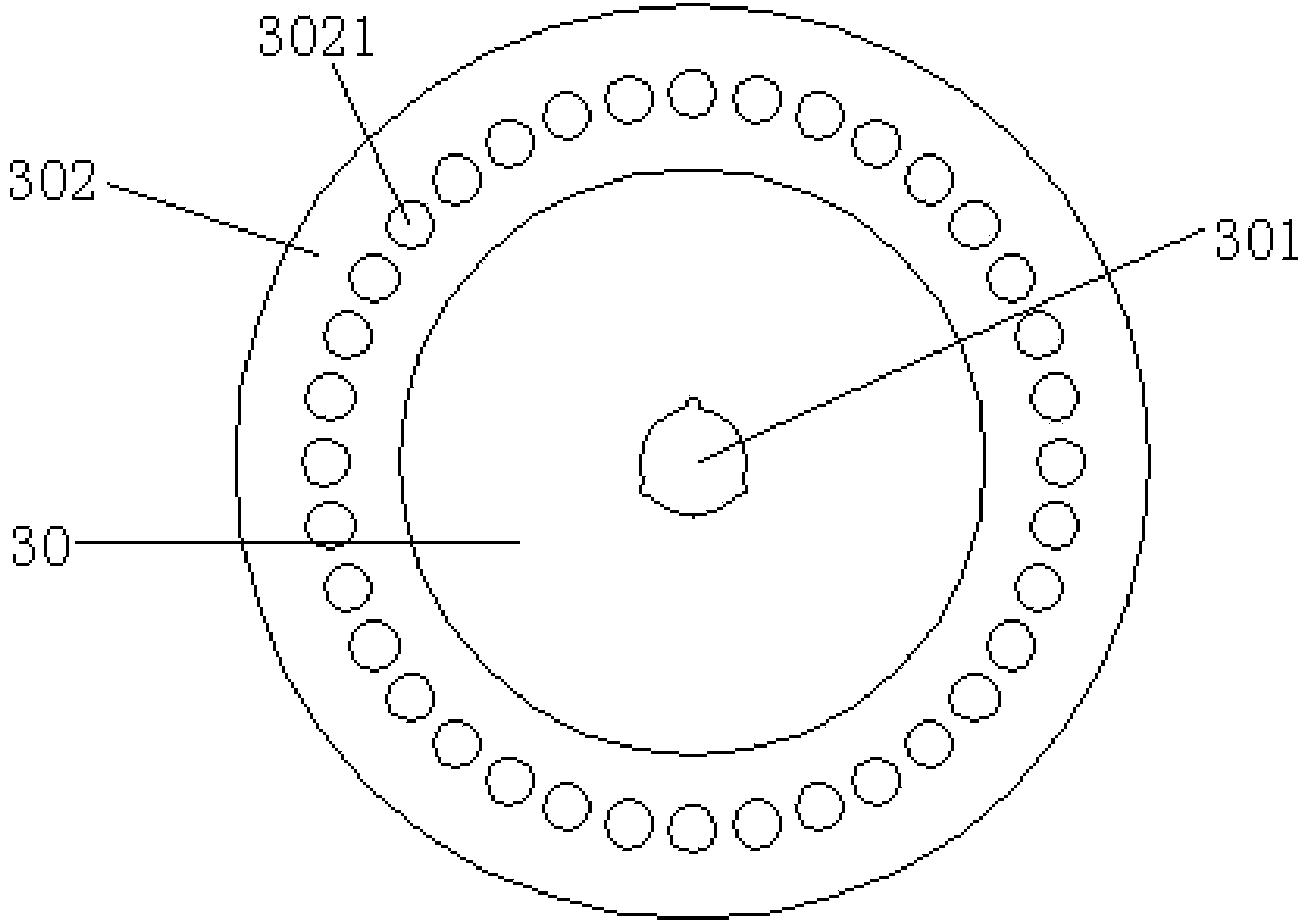

[0042] c. Flange punching: 36 positioning process holes 3021 are uniformly punched out along the circumferential direction of the flange 302 of the drawing part 30, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com