Inclined fin type parallel flow heat exchanger and production process thereof

A parallel flow heat exchanger and manufacturing process technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the limitations of parallel flow heat exchanger quality, service life, process stability, and rationality Inadequate, affecting heat transfer efficiency and other issues, to achieve stable and reliable production process, not easy to gather and freeze, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

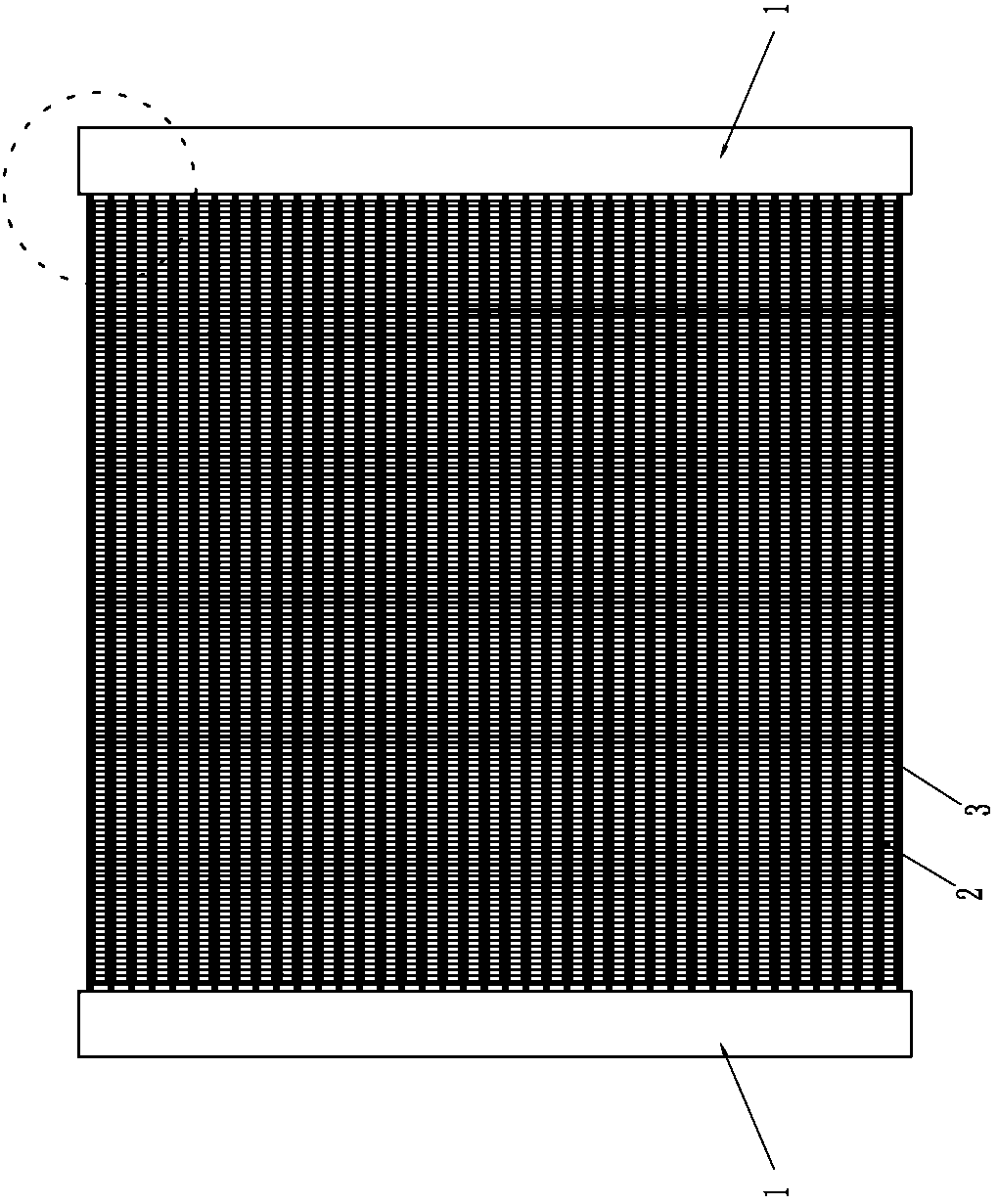

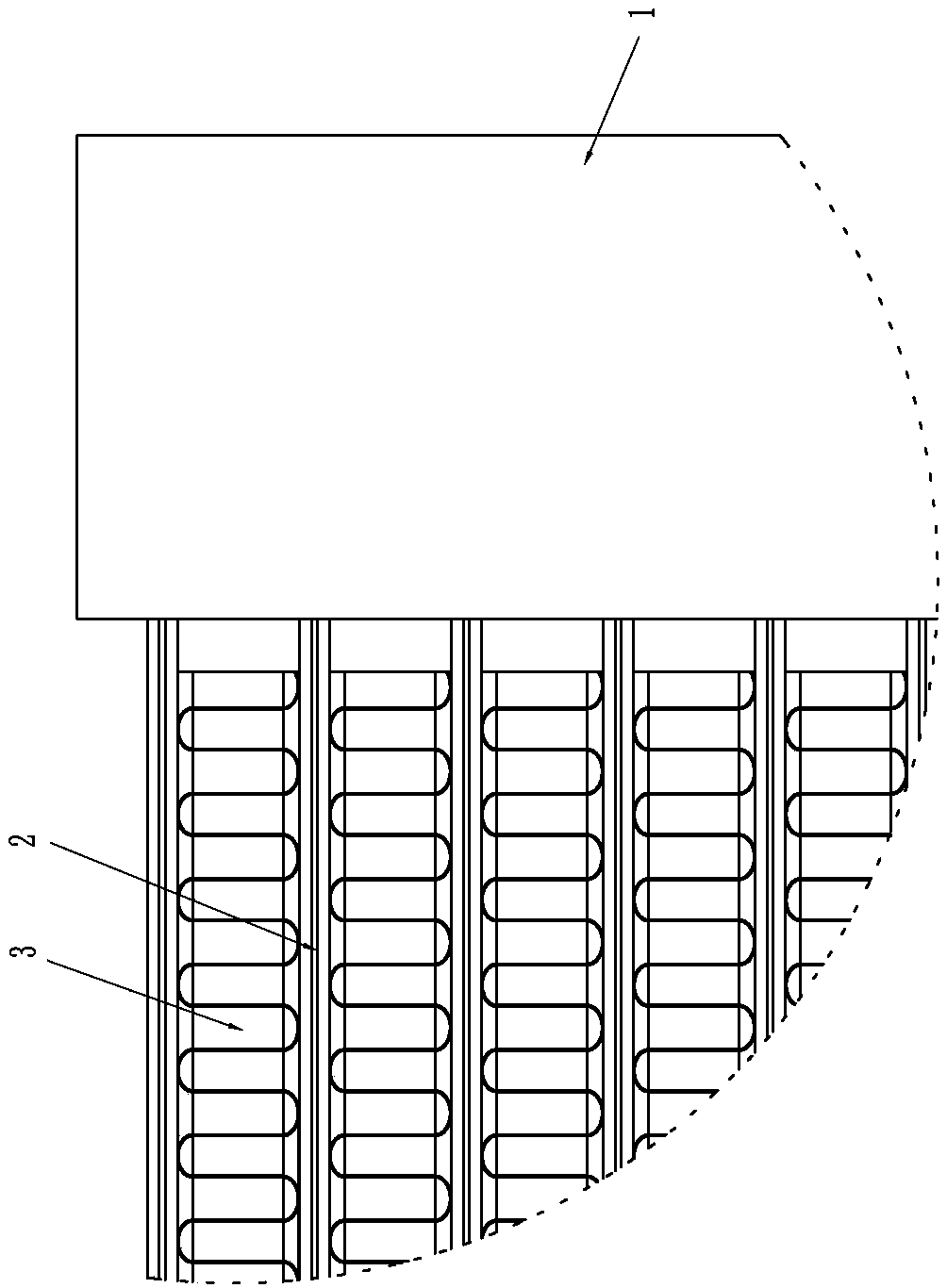

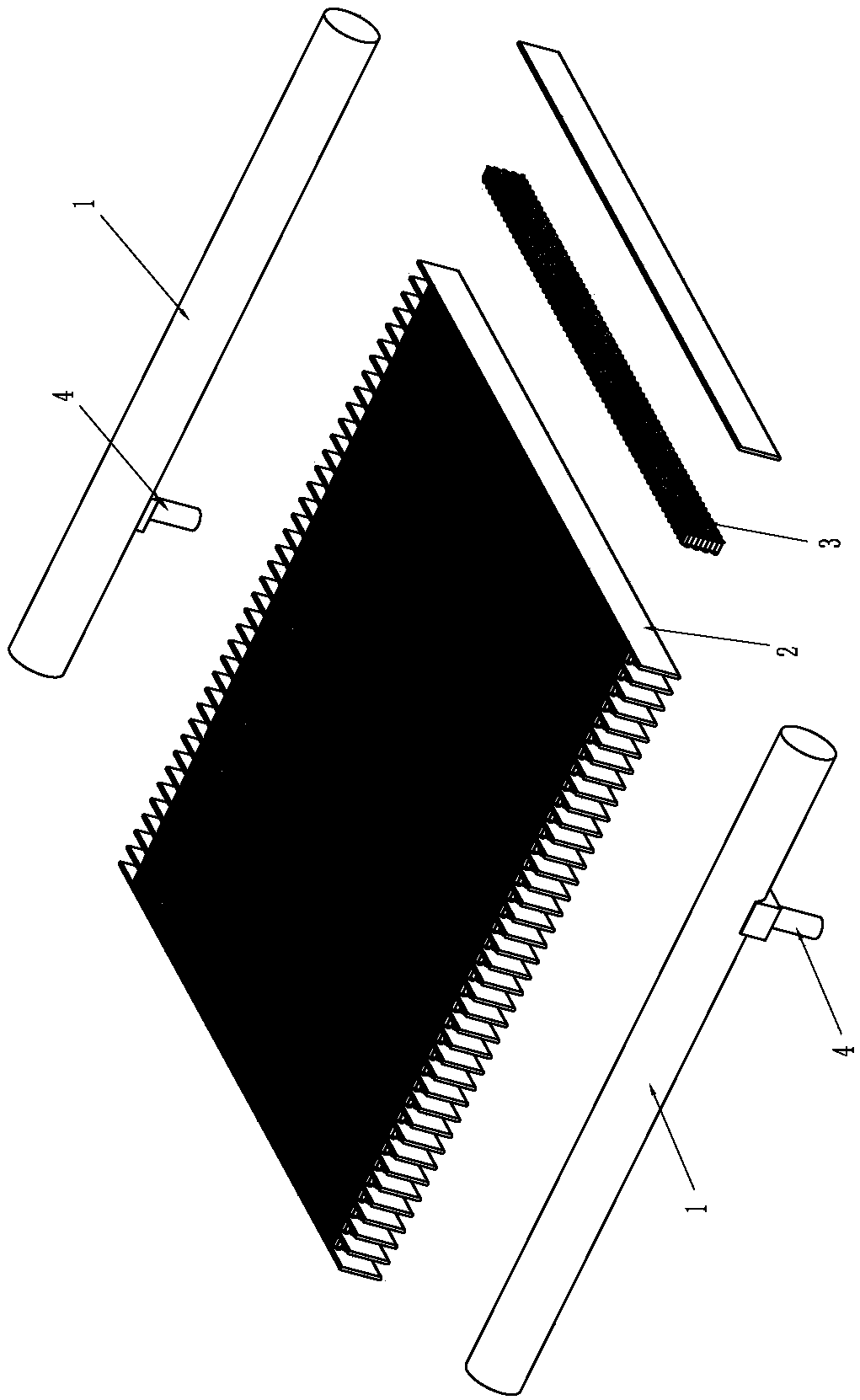

[0046] Please refer to Figure 1 to Figure 10 As shown, it shows the specific structure of the embodiment of the present invention; the inclined-fin parallel flow heat exchanger can be widely used in the fields of air conditioners, refrigerators, etc., and its structural design is simple, ingenious and reasonable, which greatly improves the heat transfer Performance, has great promotion and application value. The descriptions of directions such as "up, down, left, right, front, and back" in this article are described by taking the illustrations in the drawings as examples, and are not limited to the directions.

[0047] The inclined-fin 3-type parallel flow heat exchanger includes a pair of headers 1 that are parallel to each other and separated from each other, and several flat tubes that are connected to the inner chambers of the two headers 1 at both ends and arranged in parallel with left and right intervals. Tubes 2 , partitions arranged in the header 1 , and inclined fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com