Patents

Literature

83results about How to "The production process is simple and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beta-titanium alloy material in biology medical application

InactiveCN101081311AHigh strengthImprove wear resistanceSurgeryProsthesisBreaking strengthThick plate

The present invention discloses one kind of biomedicine beta-titanium alloy material comprising Ti-Nb 25-30 wt%, Zr 1-5 wt%, Fe 0.2-1 wt%, and Ta 10-15 wt%. The beta-titanium alloy material is produced through vacuum arc melting, casting, vacuum homogenizing under the protection of argon, cold rolling, forming solid solution, water quenching, artificial ageing, water cooling and other steps. It is produced into 2 mm thick plate, and has excellent comprehensive performances, including elastic modulus 40-60 GPa, breaking strength 600-910 MPa, yield strength 480-650 MPa, elongation 14-18 % and reduction of area 40-52 %. It has simple and reliable production process.

Owner:CENT SOUTH UNIV

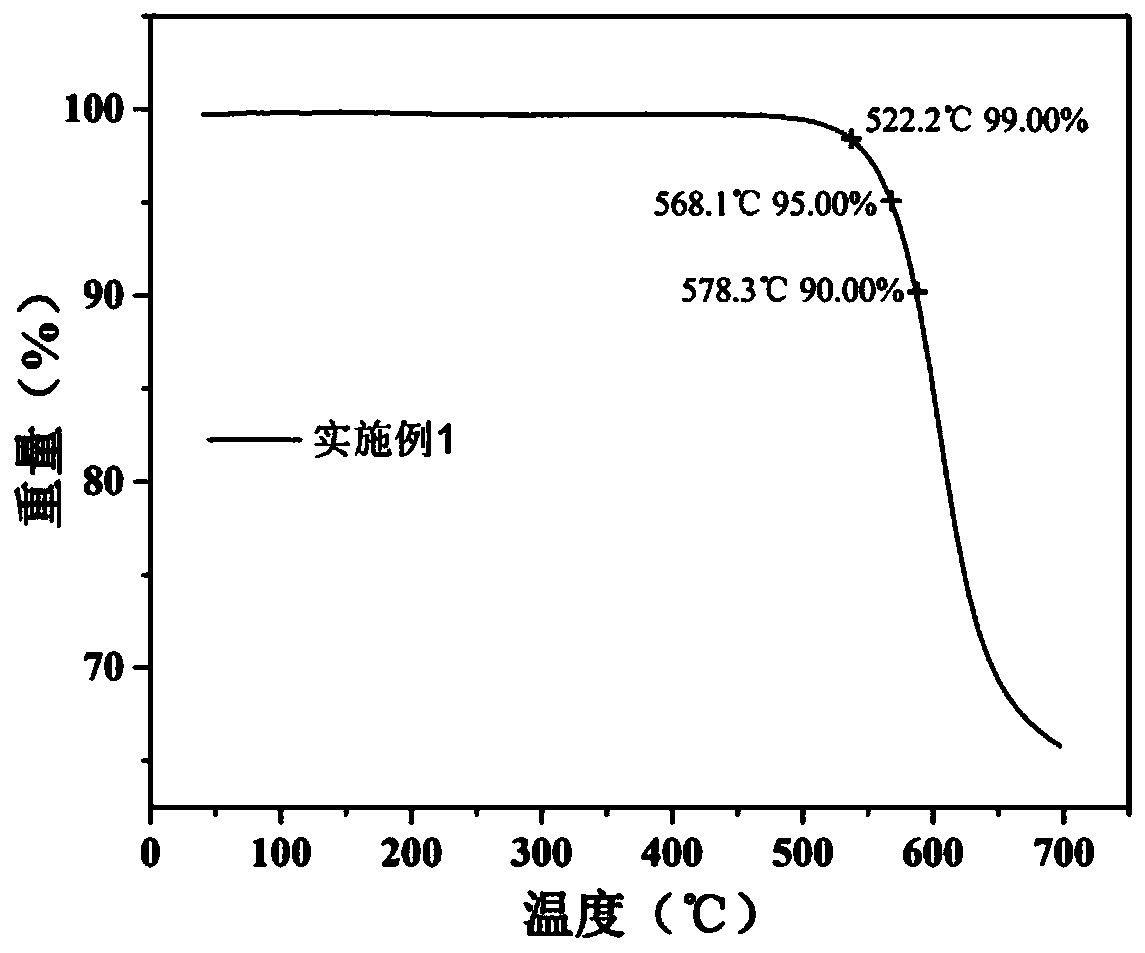

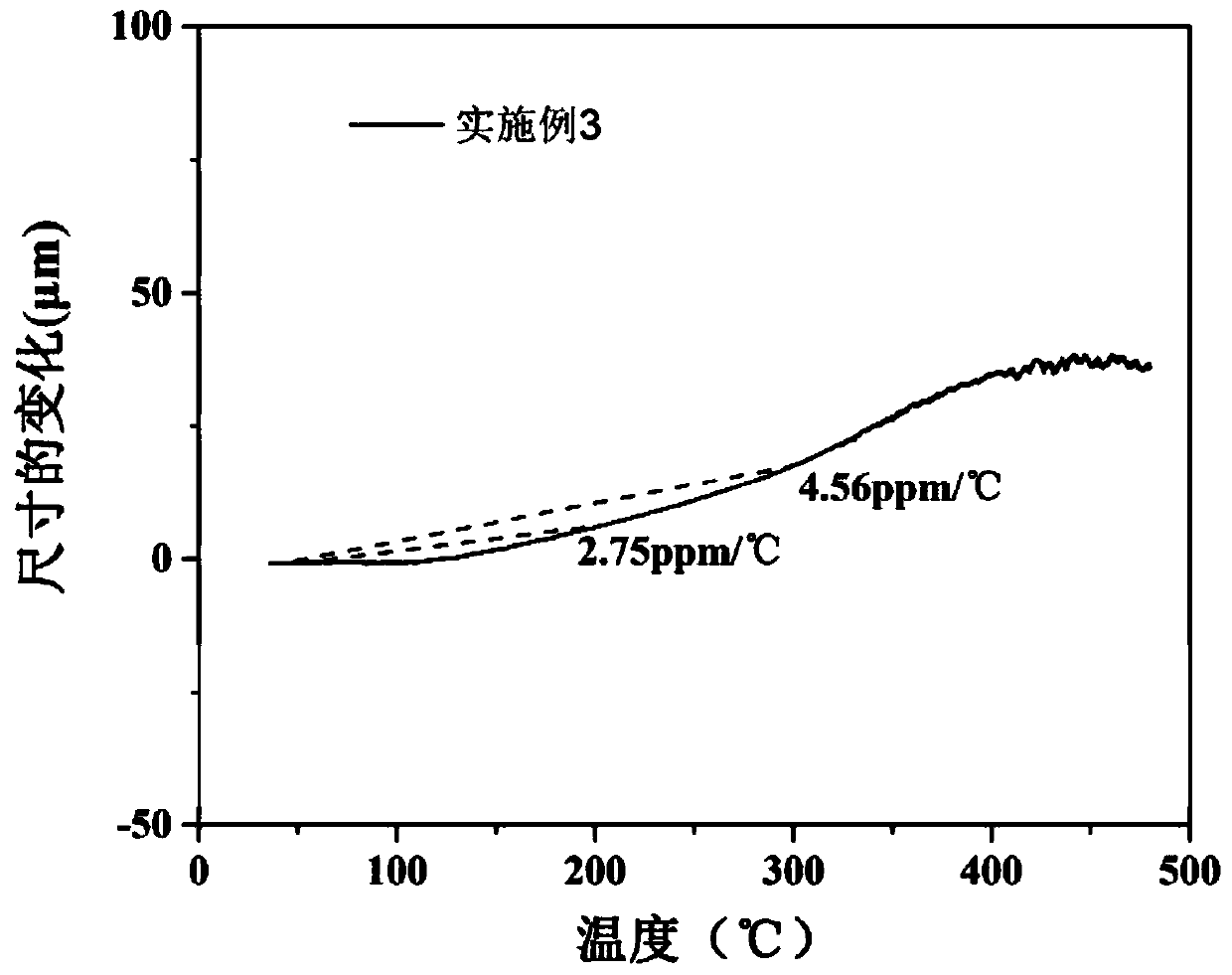

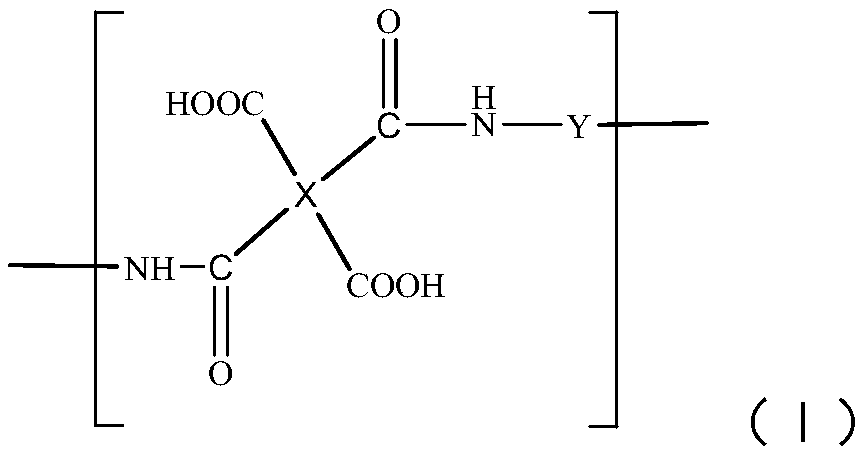

Polyamide acid and preparation method thereof, polyimide and preparation method of polyimide film

The invention discloses polyamide acid and a preparation method thereof, polyimide and a preparation method of polyimide film. The preparation method of the polyamide acid comprises: mixing polyphosphoric acid, 2,4-diaminophenol dihydrochloride, 4-(4-aminophenoxy)benzoic acid or 3-(4-aminophennoxy)benzoic acid, and tin powder, and dissolving by stirring to obtain a homogenous solution; adding phosphorus pentoxide, allowing to react to obtain a reaction product, precipitating the reaction product, filtering, and washing to an ether bond-modified diamine with benzoxazole structure; mixing an aromatic diamine and the ether bond-modified diamine with benzoxazole structure, adding the mixture to a polar organic solvent, and dissolving by stirring to obtain a diamine monomer mixed solution; adding an aromatic dianhydride, and allowing to react to obtain polyamide acid solution; coating the surface of a substrate with the polyamide acid solution, and drying and solidifying to obtain the polyimide film. The polyimide film herein has good solubility, good mechanical properties and high heat resistance.

Owner:武汉柔显科技股份有限公司 +1

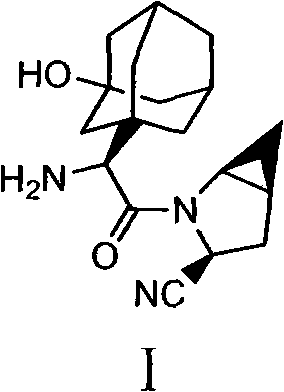

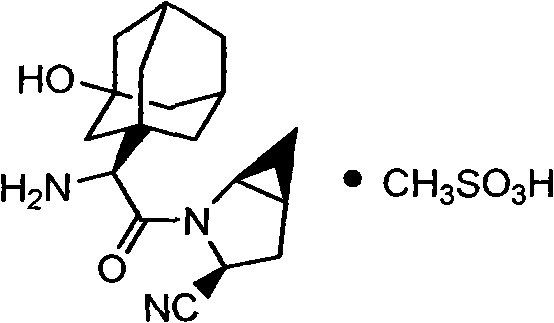

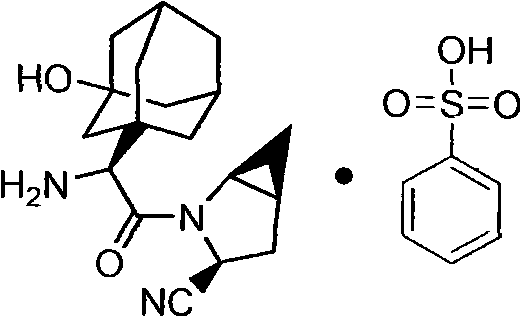

Medicinal salts of saxagliptin and preparation methods of medicinal salts

InactiveCN102086172AGood water solubilityImprove oral bioavailabilityOrganic active ingredientsOrganic chemistrySaxagliptinDiabetes mellitus

The invention provides medicinal salts of saxagliptin, and particularly relates to mesylate, meleate, malate, succinate and citrate as well as preparation methods of the medicinal salts. The medicinal salts have the advantage of good stability, and are not easy to degrade. Preparations with controllable quality and low cost, which are suitable for industrial production, are prepared from the medicinal salts and pharmaceutically acceptable carriers through a conventional preparation technology. The medicinal salts can be used for treating and / or preventing diabetes mellitus.

Owner:廖国超

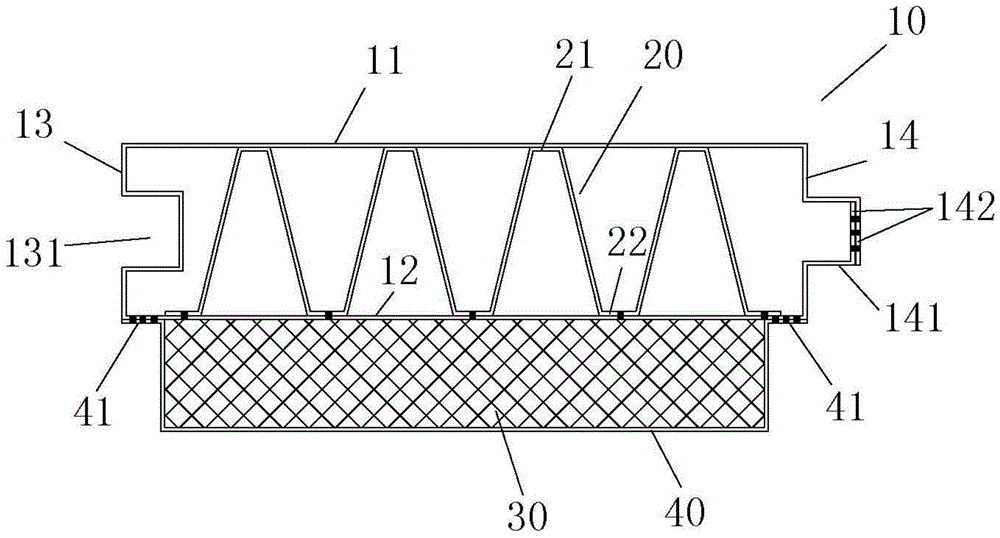

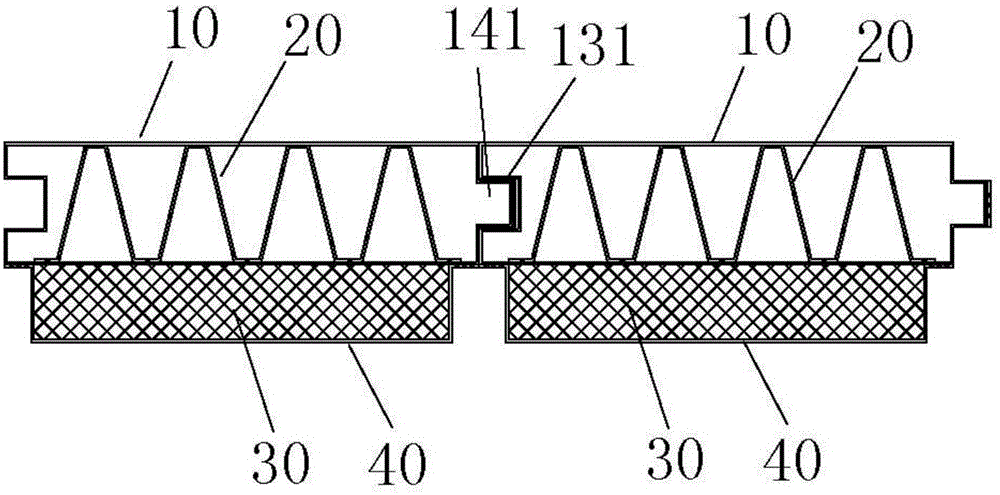

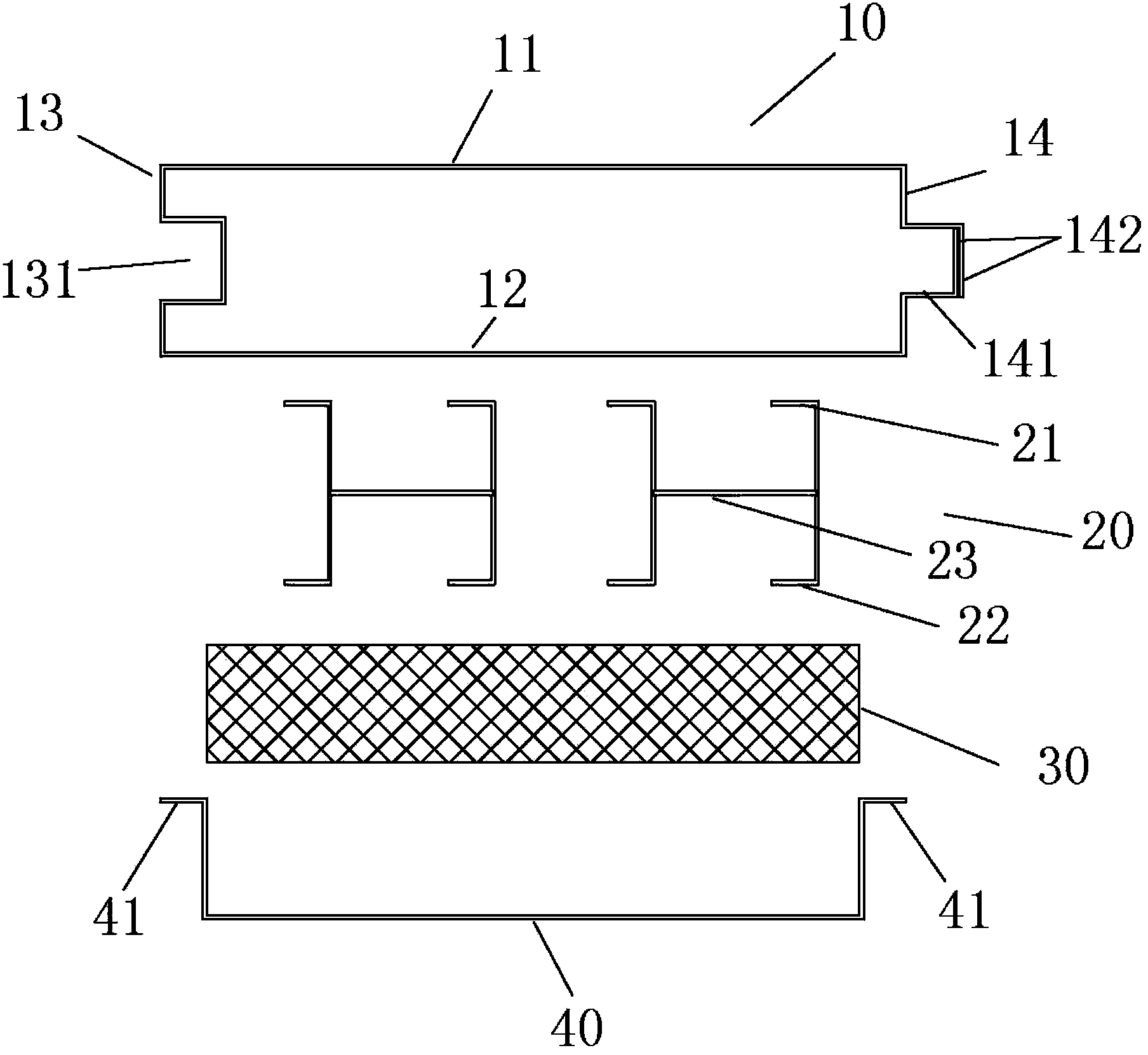

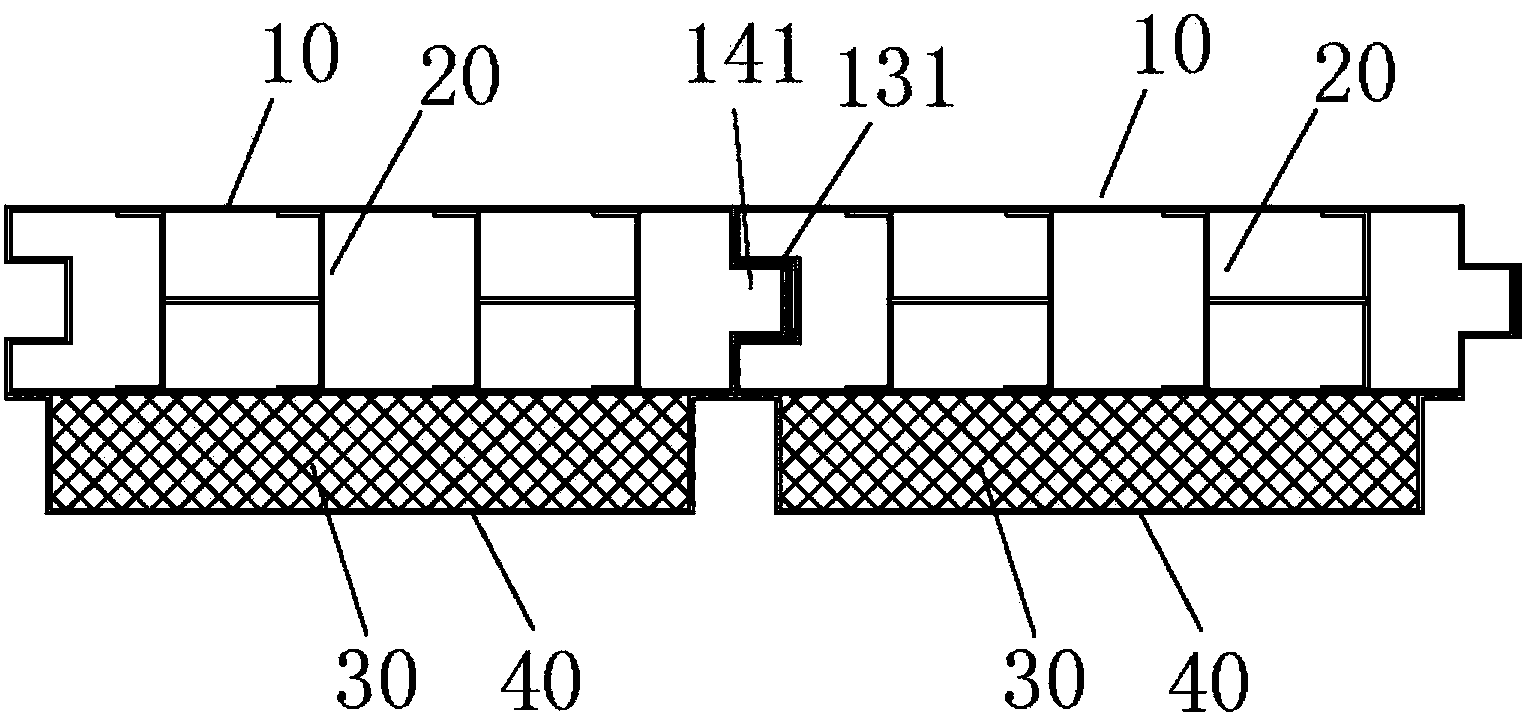

Assembling-typed thermal-insulating integrated wall board

InactiveCN104405076AHigh dimensional accuracyThe production process is simple and reliableBuilding componentsEngineeringLaser

The invention relates to an assembling-typed thermal-insulating integrated wall board comprising: a metal outer frame board, a metal corrugated board, a thermal-insulating cushion layer and a metal thermal-insulating sleeve board. When the wall board is assembled, the metal corrugated board is inserted in the metal outer frame board so that a wave trough plane of the metal corrugated board is attached to an inner wall surface of the metal outer frame board and a wave peak plane of the metal corrugated board is attached to an outer wall surface of the metal outer frame board. The wave trough plane of the metal corrugated board is fixed to the attaching point of the inner wall surface of the metal outer frame board in a laser penetrating welding manner. The thermal-insulating cushion layer is installed behind a concave part of the metal thermal-insulating sleeve board. Two end surfaces of the metal thermal-insulating sleeve board are attached to and are fixed to the inner wall surface of the metal outer frame board in a laser penetrating welding manner. A plurality of the wall boards can be combined. The assembling-typed thermal-insulating integrated wall board is ventilative, is thermal-insulating and is steady in structure.

Owner:钟伟杰

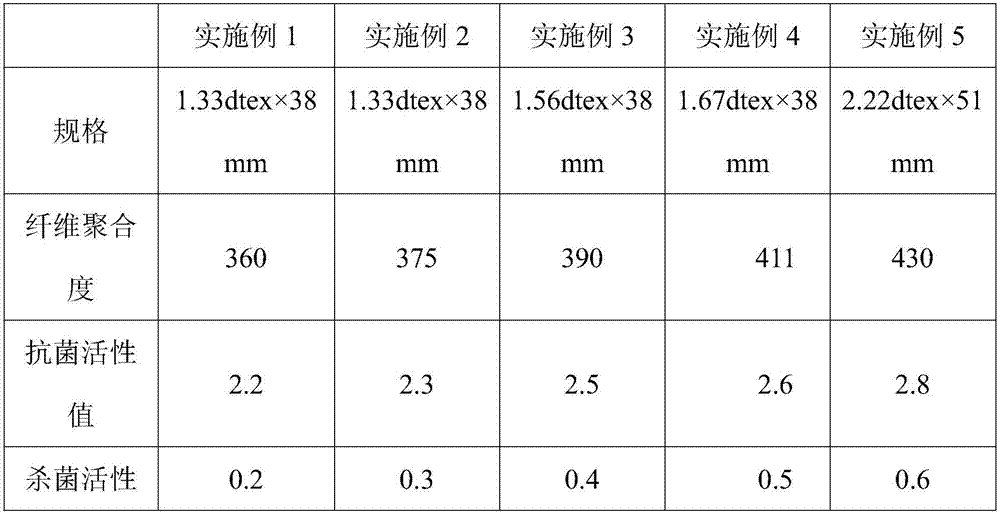

Multifunctional compound cellulose fiber and preparation method thereof

ActiveCN107502966AStable functionImprove solubilityArtificial filaments from cellulose derivativesArtifical filament manufacturePolymer scienceCellulose fiber

The invention discloses a multifunctional compound cellulose fiber and a preparation method thereof. By adoption of an advanced microcapsule preparation technique and modification of a cellulose fiber solution preparation process, a cellulose fiber is modified through polyvinyl alcohol, herba centellae, proteins and vitamins to obtain the multifunctional compound cellulose fiber by means of a cellulose fiber wet spinning process. The multifunctional compound cellulose fiber prepared according to the method is capable of meeting people's demands on moisture absorption, bacteria resistance, skin caring and the like of fibers, and a product is excellent in physical and mechanical performance and stable functionally and has a promising development prospect.

Owner:山东欣悦健康科技有限公司 +1

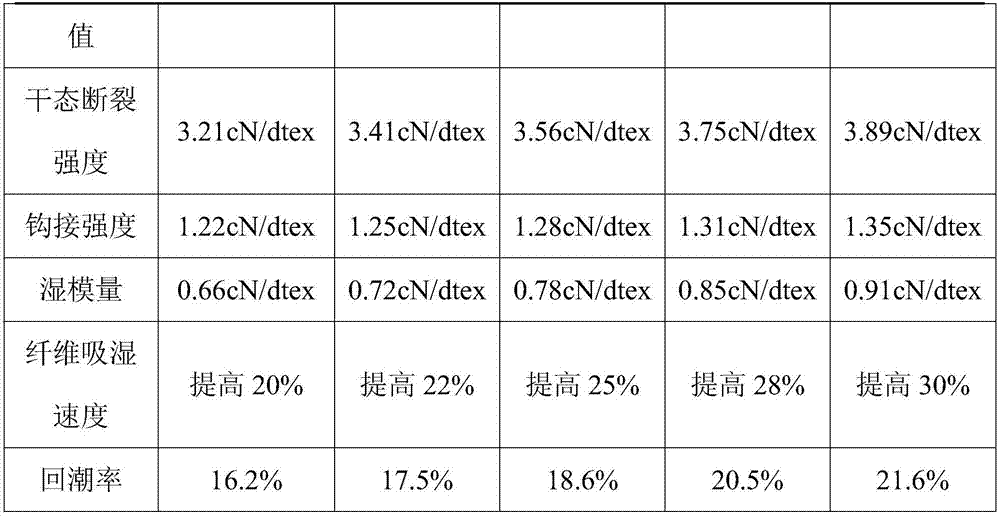

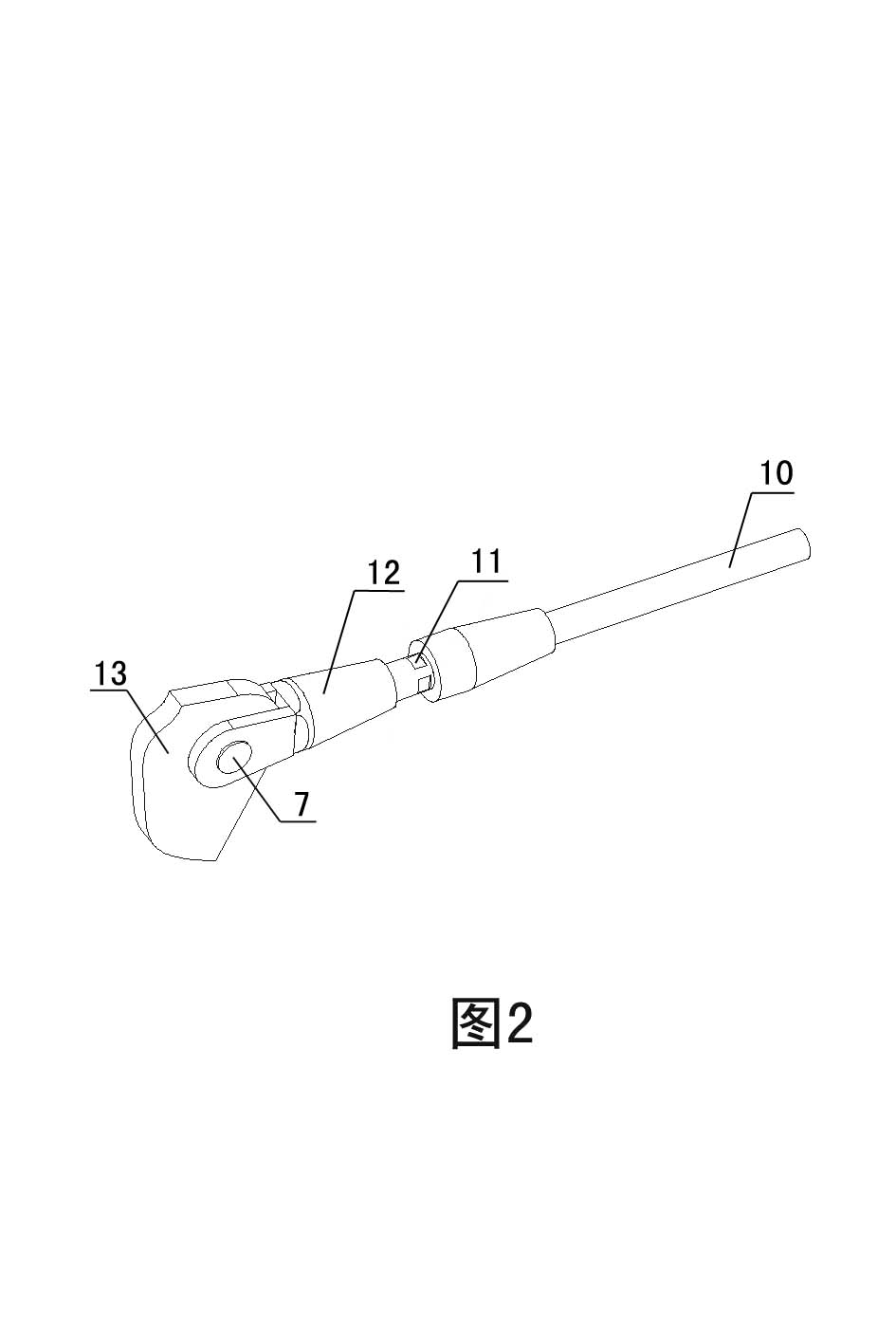

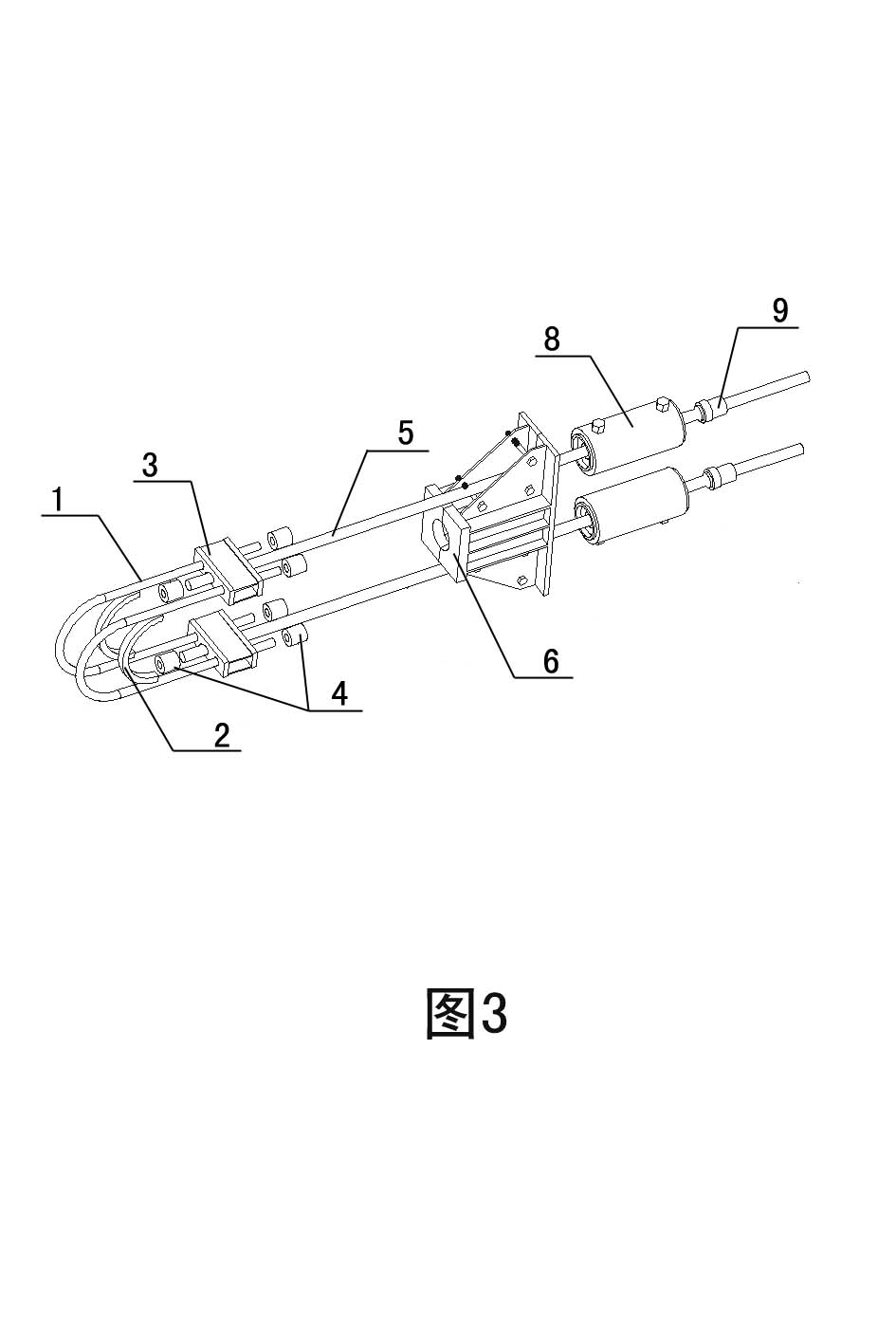

U-shaped tool device for prestressed steel structure tensioning construction and construction method

InactiveCN101845894ACompact designSimple and fast operationBuilding material handlingManufacturing technologyPre stress

The invention relates to a U-shaped tool device for prestressed steel structure tensioning construction and a construction method. The U-shaped tool device for prestressed steel structure tensioning construction is provided with a forked lug anchor head for bearing counterforce, and is provided with an inhaul cable cervical vertebra bearing base serving as a rear bearing point of a tensioning stress unit, and a tension rod conversion device. A U-shaped bearing pull ring is connected to the forked lug anchor head of a steel inhaul cable; and the section of the lug plate is not weakened, and the manufacturing technology can be simplified. A pressure sensor is arranged inside an oil pump, and the aim that the tension of two 2,500 kN lifting jacks and the oil pump system can reach 4,400 kN can be fulfilled. Meanwhile, the U-shaped tool device for the prestressed steel structure tensioning construction has the advantages of small volume, light total weight, simple manufacturing technology, simple and convenient implementing operation, high tension control precision, and the like, and is particularly applied to constructing super-tonnage tensioning members by adopting huge forked lug anchor head inhaul cable.

Owner:BEIJING ACAD OF BUILDING ENG

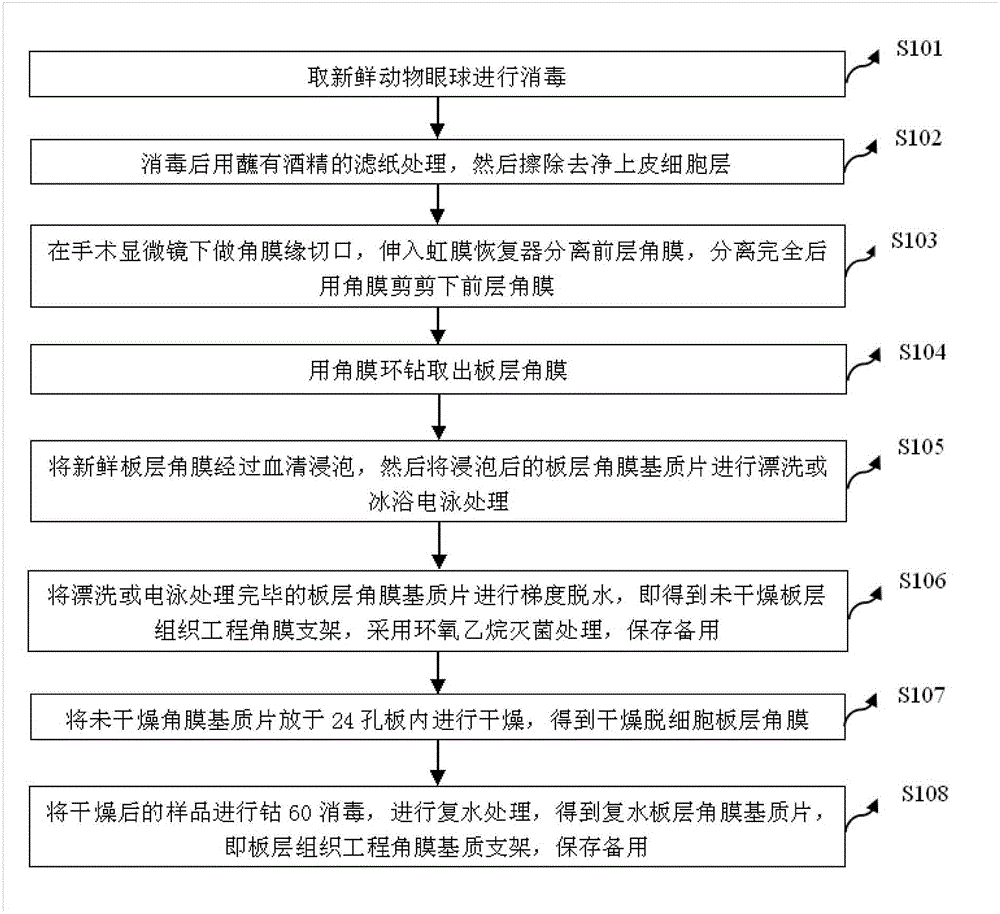

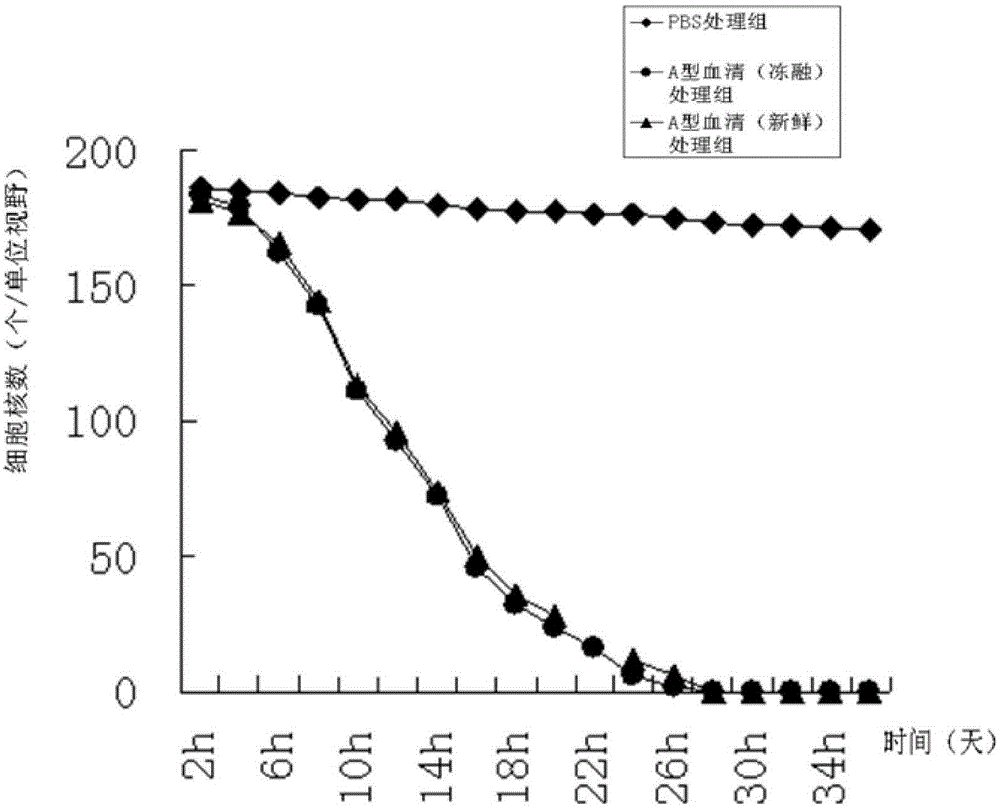

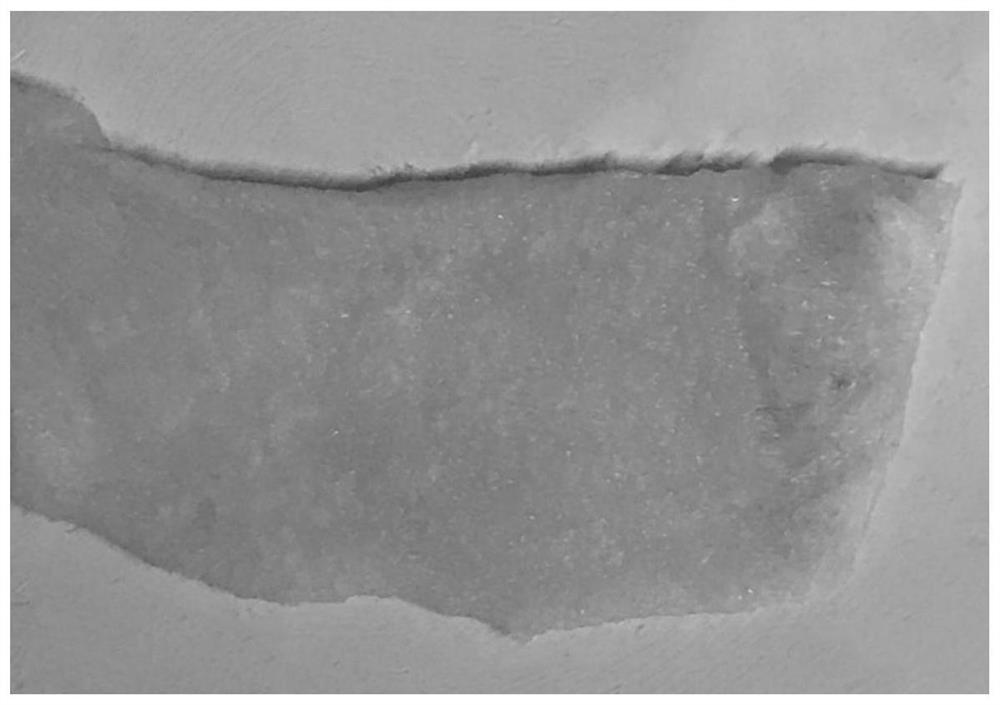

Method for preparing decellularized lamellar cornea matrix sheet

InactiveCN104645415AThe production process is simple and reliableShorten the timeProsthesisAnterior corneaEthylene Oxide Sterilization

The invention discloses a method for preparing a decellularized lamellar cornea matrix sheet. The method comprises the steps of disinfecting a fresh animal eyeball; treating with filter paper dipped with alcohol after disinfecting, and then erasing an epithelial cell layer; incising the corneal limbus under an operation microscope, stretching into an iris restorer to separate the anterior cornea, and then shearing the anterior cornea with corneal scissors; drilling the lamellar cornea with a corneal annulus; soaking the fresh lamellar cornea into serum, and then rinsing or performing ice-bath electrophoresis treatment; performing gradient dehydration after the treatment to obtain a non-dried lamellar tissue engineering corneal frame, sterilizing with ethylene oxide, and preserving for later use; drying the non-dried cornea matrix sheet in a 24-pore plate to obtain dried decellularized lamellar cornea; and sterilizing the dried sample with cobalt 60, and performing rehydration treatment to obtain a rehydrated lamellar cornea matrix sheet. The obtained cornea matrix sheet is high in transparency, low in structural destroy, good in biocompatibility, close to fresh cornea in performance and thorough in decellularization.

Owner:南昌大学第一附属医院 +1

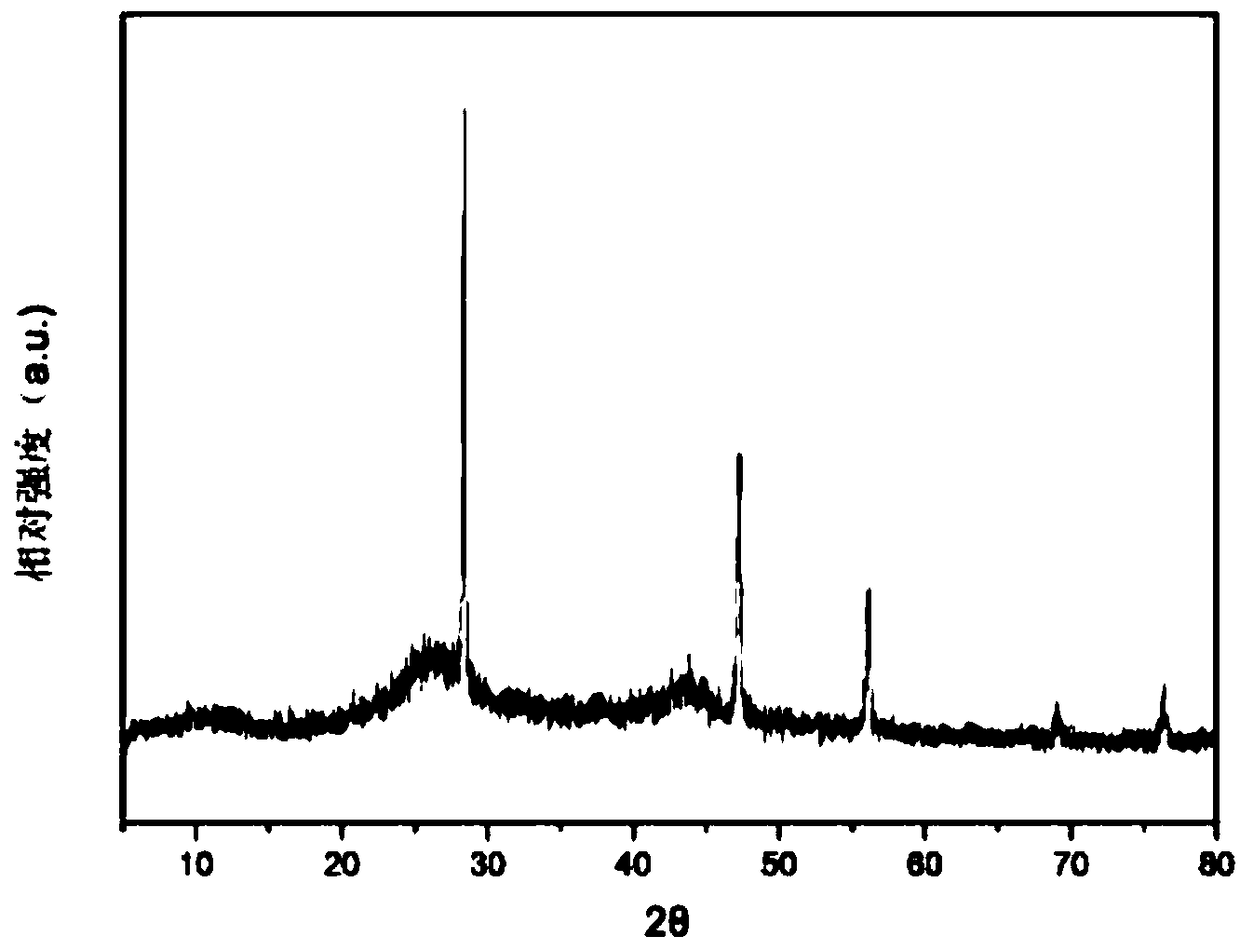

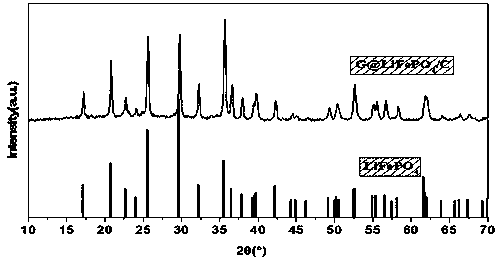

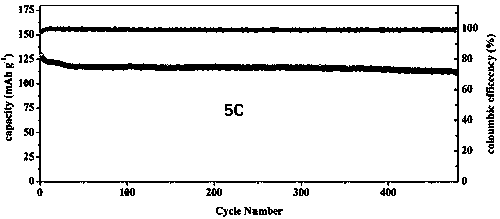

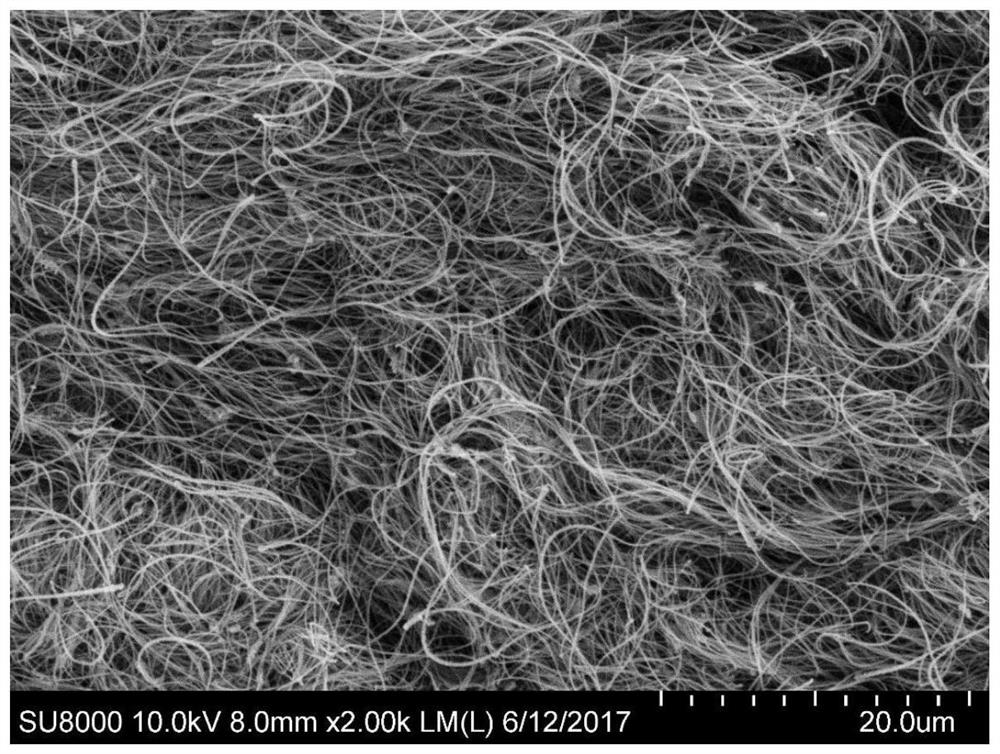

Preparation method and application of silicon/nitrogen-doped graphene composite material for lithium ion battery

InactiveCN108346791AImprove conductivityImprove cycle performanceCell electrodesSodium-ion batteryNitrogen doped graphene

Preparation method and application of a silicon / nitrogen-doped graphene composite material for a lithium ion battery belongs to preparation method and application of a silicon / nitrogen-doped graphenecomposite material. According to the preparation method of the silicon / nitrogen-doped graphene composite material, commercial silicon powder, a carbon source and a nitrogen source are mixed and subjected to wet ball-milling, a high-temperature solid-phase sintering synthesis technology is employed under an inert atmosphere after drying, a technical parameter during the reaction process is controlled, silicon content control of the silicon / nitrogen-doped graphene composite material is achieved, and the silicon / nitrogen-doped graphene composite material is obtained and is used for fabricating alithium ion battery negative electrode. The preparation method has the advantages that the material shows excellent cycle and rate performance when used as a lithium ion battery negative electrode, issimple and reliable in production process, available in raw material, low in equipment requirement, simple in synthesis circuit and high in operation step controllability and is convenient to control, large-scale quantitative preparation is easily achieved, and the integral electrochemical performance is greatly improved by the composite material.

Owner:CHINA UNIV OF MINING & TECH

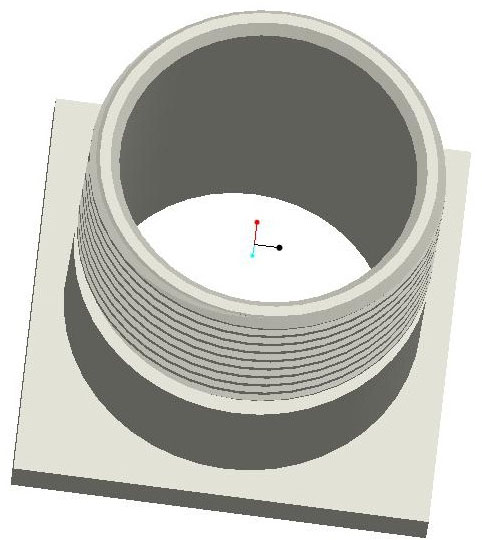

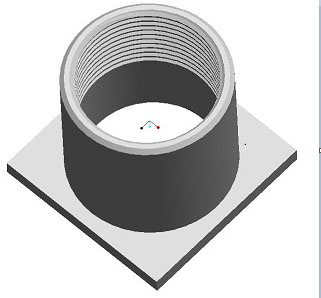

Centrifugal casting method for composite ring with Q345B steel inner layer and 40Cr steel outer layer

The invention provides a centrifugal casting method for a composite ring with a Q345B steel inner layer and a 40Cr steel outer layer, and belongs to the field of casting of ring-shaped parts. The centrifugal casting method is characterized by comprising the following process steps that (1) inner layer Q345B steel and outer layer 40Cr steel of the composite ring are smelted in different furnaces at the same time, the tapping temperature of the inner layer Q345B steel is 1650-1680 DEG C, and the tapping temperature of the outer layer 40Cr steel is 1600-1630 DEG C; (2) the preheating temperature of a casting mold ranges from 150 DEG C to 180 DEG C, and the preheating temperature of a casting ladle and the preheating temperature of a pouring gate range from 250 DEG C to 300 DEG C; (3) the outer layer is cast with the temperature ranging from 1520 DEG C to 1530 DEG C, and the casting speed is 24.5-25.5 kg / s; (4) the inner layer is cast with the temperature ranging from 1550 DEG C to 1570 DEG C, and the time interval between casting of the outer layer and casting of the inner layer is 27-29 s; and (5) mold stripping is carried out after cooling, then slow cooling is carried out, and the mold stripping temperature ranges from 1000 DEG C to 1050 DEG C. The centrifugal casting method has the advantages that the inner layer and the outer layer are completely melted and combined, and gaps in an interface are avoided; the combination strength is high, stress of the composite ring can be evenly distributed, and the wear resistance of the composite ring is improved; the production process is simple and reliable.

Owner:定州市金华蓝天汽车零部件有限公司 +1

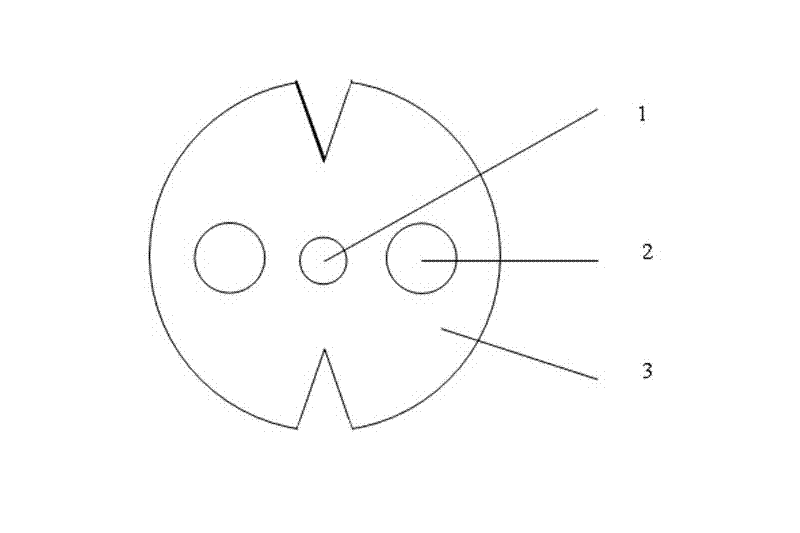

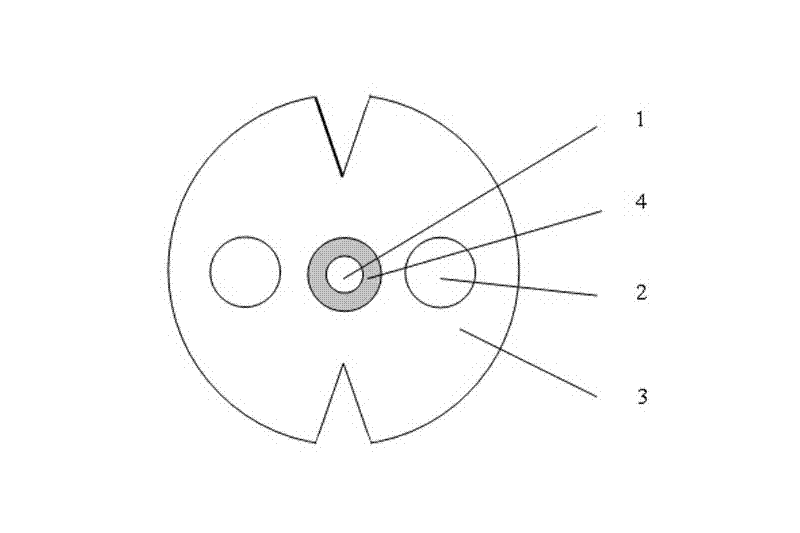

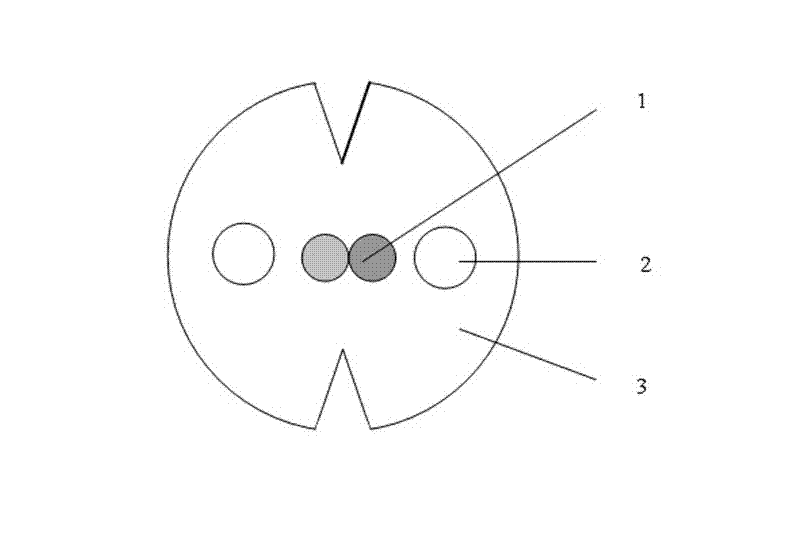

Circular rubber-covered-wire optical cable and manufacturing method thereof

ActiveCN102313945AReasonable designIndoor wiring is convenientFibre mechanical structuresFiberEngineering

A circular rubber-covered-wire optical cable and a manufacturing method thereof of the invention relate to a compact tensile antiflaming rubber-covered-wire optical cable used for indoor wiring and the manufacturing method thereof. In the cable, metal or non-metallic strengthening pieces are used to perform parallel reinforcement. Colored optical fibers and tightly packaged fibers, which have unequal quantities, are in the middle of the parallel strengthening pieces. Slotting circle sheaths cover the fibers and the strengthening pieces. Butterfly-type rubber-covered-wire optical cable is suitable for vertical, horizontal wiring or pipeline wiring in a FTTH building. Bending performance is excellent and tensile capacity is good. Construction operation is easy to be performed. A fiber unit,the strengthening pieces and the slotting sheath are comprised. The fiber unit is arranged in the middle part of the circular rubber-covered-wire optical cable. The strengthening pieces are parallelly arranged on two sides of the fiber unit. The slotting sheaths cover the fiber unit and the strengthening pieces.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

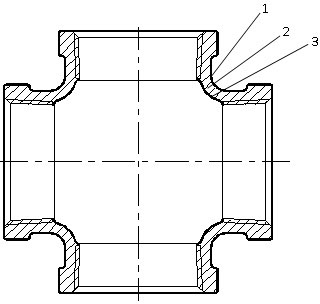

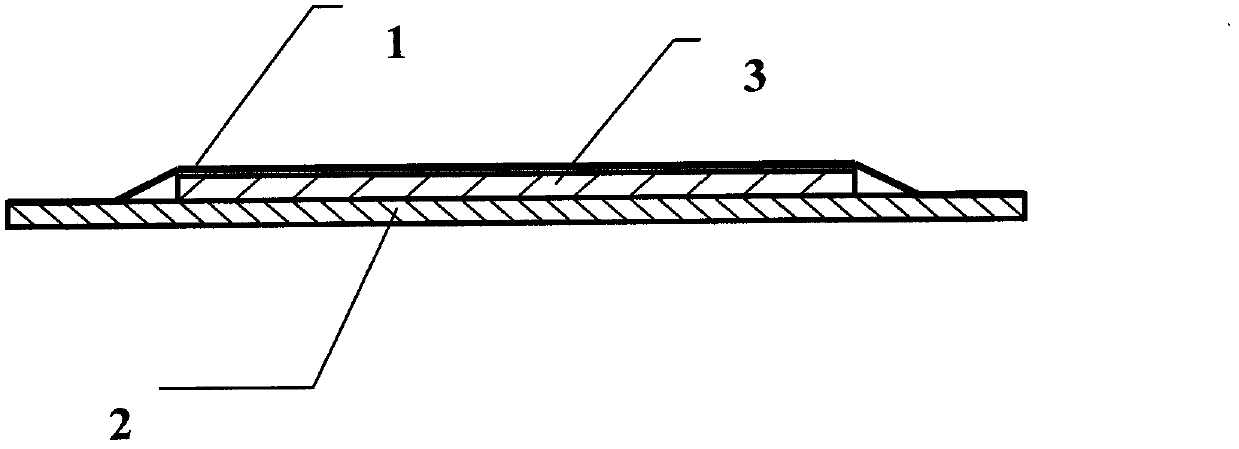

Pipe fitting with zinc plated at outer part and plastic coated at inner part as well as production process of same

The invention relates to a pipe fitting with zinc plated at the outer part and plastic coated at the inner part as well as a production process of the same. In order to overcome defects in the prior art, the invention provides the pipe fitting with the zinc plated at the outer part and the plastic coated at the inner part as well as the production process of the same. The technical scheme is that: the pipe fitting with the zinc plated at the outer part and the plastic coated at the inner part comprises a galvanized layer (1) and malleable steel piece base body (2), and also comprises a polyethylene or epoxy / polyester coating layer (3). The production process of the pipe fitting with the zinc plated at the outer part and the plastic coated at the inner part comprises the following steps of: blasting sand on an inner wall of a galvanized pipe fitting, deoiling the galvanized pipe fitting in a neutral environment, cleaning the galvanized pipe fitting by using hot water once, cleaning the galvanized pipe fitting by using hot water for the second time, preheating the galvanized pipe fitting, providing the galvanized pipe fitting with a facing, powdering the galvanized pipe fitting, removing the facing of the galvanized pipe fitting, curing, leveling and inspecting the galvanized pipe fitting, removing rust in screw threads of the galvanized pipe fitting, packaging the galvanized pipe fitting, and putting the galvanized pipe fitting in storage. The plastic coating process provided by the invention has the advantages of simplicity in operation, high production efficiency, high adhesion force, no easiness for the separation of layers and stability in product quality as the inner wall of the galvanized pipe is subjected to phosphating and sand blasting treatment.

Owner:ZHONGSHAN LESSO WALTON COATING STEEL PLASTIC PIPECO LTD

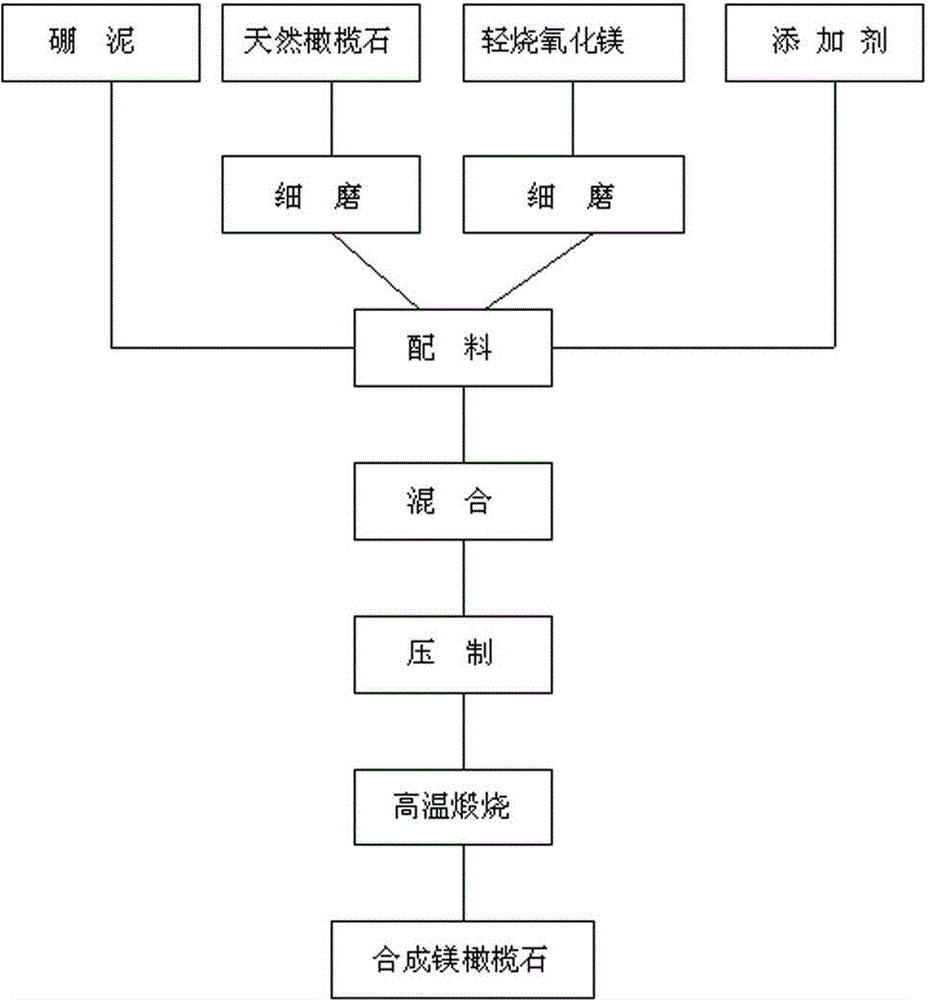

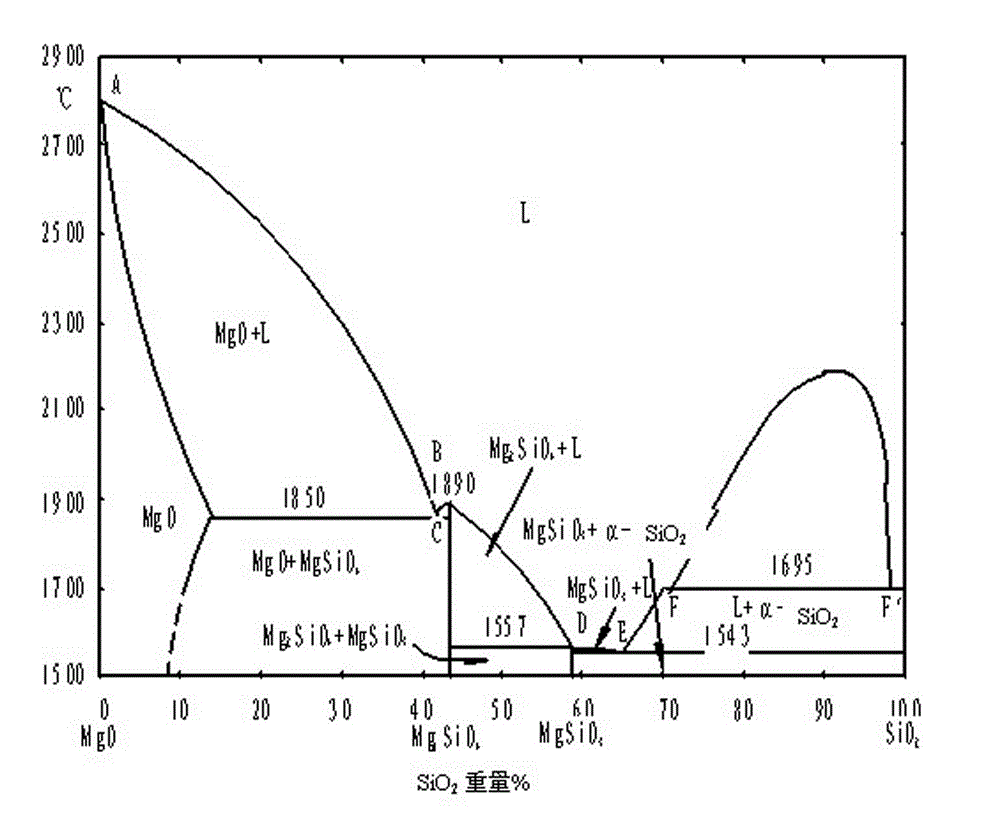

Method for preparing synthetic forsterite from boron slurry

InactiveCN102745701AAvoid pollutionReduce the number of spawnsAluminium silicatesEcological environmentMixed materials

The invention discloses a method for preparing synthetic forsterite from boron slurry. The method comprises the following steps of 1, adding lightly roasted magnesia powder and natural forsterite powder into boron slurry to obtain a mixed material, 2, adding a binder into the mixed material and mixing uniformly to obtain a bound material, 3, adding water into the bound material, mixing uniformly, pressing the mixture into globular materials by a ball press, and standing for maintenance, and 4, mixing the maintained globular materials and coal, putting the mixture into a high-temperature vertical kiln, heating to a temperature of 1550 to 1650 DEG C, and carrying out heat preservation for 3 to 4 hours to obtain the synthetic forsterite. The method has simple and reliable processes and solves the problem of the pollution produced by boron slurry on the ecological environment. The synthetic forsterite prepared by the method contains more than 60% of magnesium oxide.

Owner:聂旺发

Beta-titanium alloy material in biology medical application

InactiveCN101081312AImprove performanceMeet the requirements of biomedical useSurgeryProsthesisBreaking strengthUltimate tensile strength

The present invention discloses one kind of biomedicine beta-titanium alloy material comprising Ti-Nb 25-30 wt%, Zr 1-5 wt%, Fe 0.2-1 wt%, and Mo 10-15 wt%. The beta-titanium alloy material has non-toxic element and beta stabilizing element added into traditional biomedicine material, so that it has excellent comprehensive performances, including elastic modulus 45-66 GPa, breaking strength 650-960 MPa, yield strength 510-680 MPa, elongation 16-20 % and reduction of area 35-50 %. It has simple and reliable production process.

Owner:CENT SOUTH UNIV

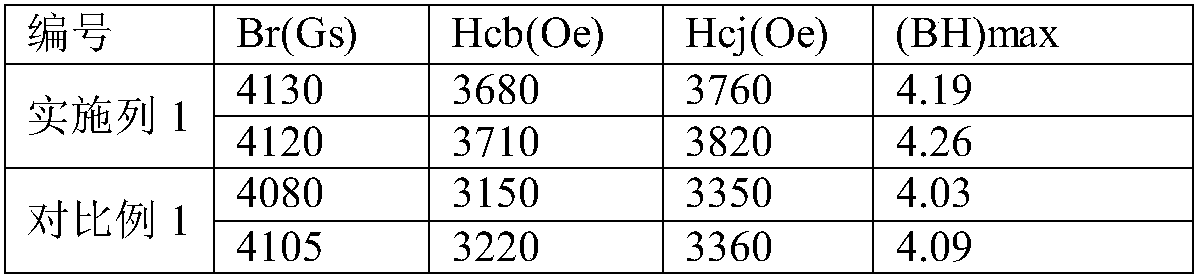

Preparation method of low-cost permanent magnetic ferrite material

ActiveCN109400139AThe production process is simple and reliableLow material consumptionInorganic material magnetismAdditive ingredientGranularity

The invention provides a method for manufacturing a high-performance permanent magnetic ferrite by using iron flakes, which are subjected to pretreatment to improve purity and activity thereof. The pretreatment includes: impurity removal, crushing, oxidization, fine milling and screening. The iron flakes, after the pretreatment, should satisfy the following items: total oxide purity is not less than 98.9%, average granularity is not more than 5 [mu]m and SiO2 content is not more than 0.1%. Through the special process, the high-performance permanent magnetic ferrite material can be produced. The method is simple and reliable, is low in consumption on raw materials and energy consumption, is low in production cost, and is free of secondary pollution. The product is free of any impurity phaseand is uniform in particle size. The formula of the product accords with the ingredient range of SrFe12O19 ferrite.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

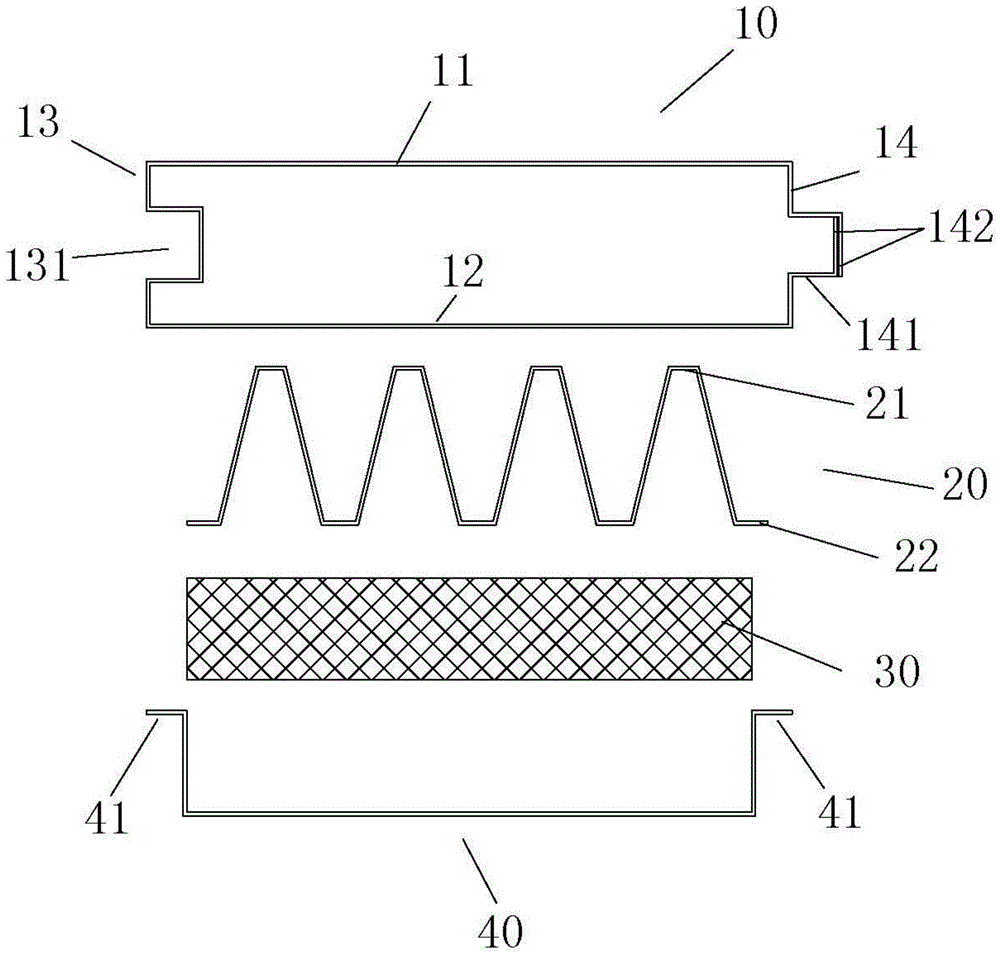

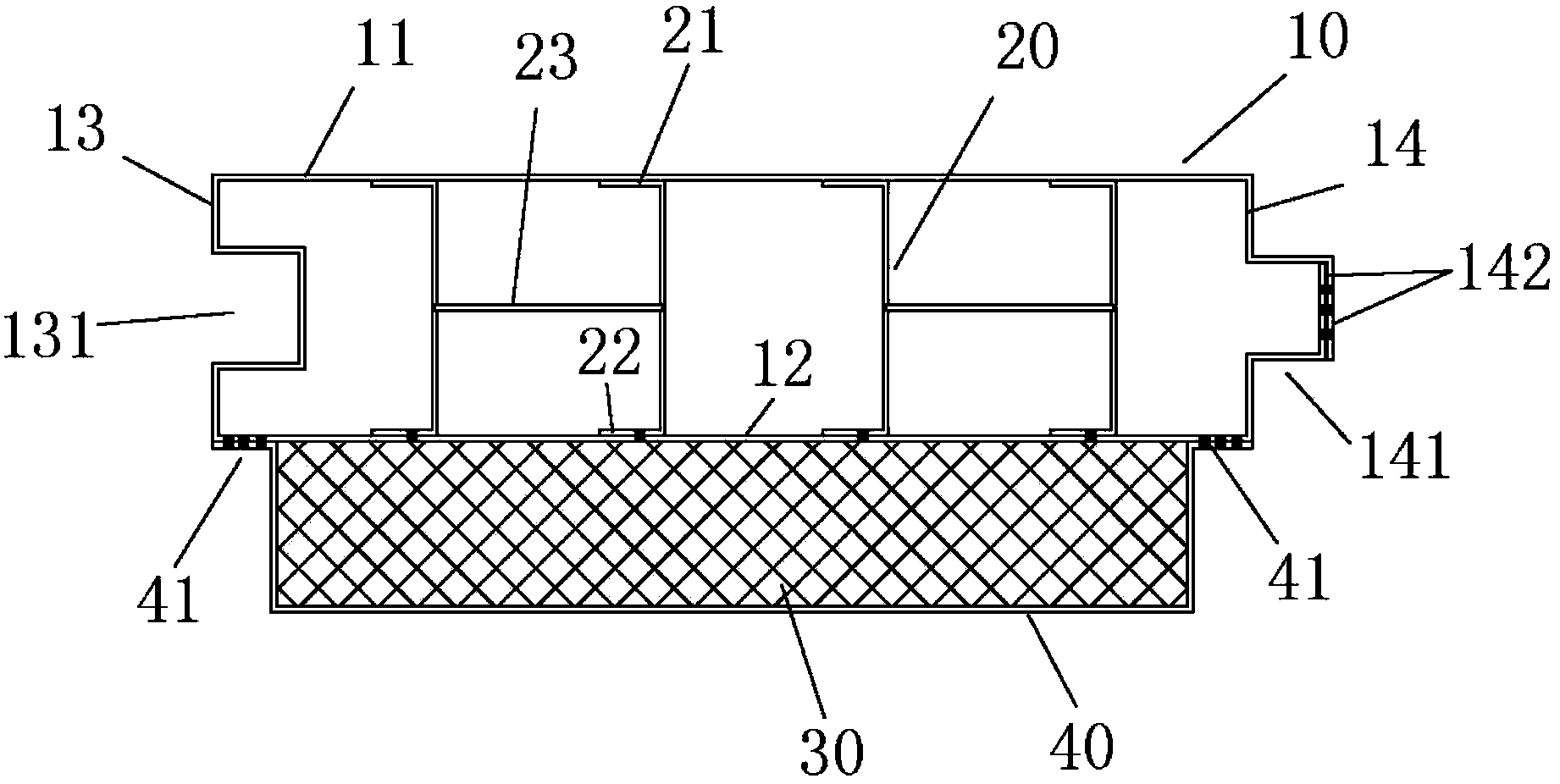

Assembly type integrated heat-insulting wall board

InactiveCN104264892AHigh dimensional accuracyThe production process is simple and reliableBuilding componentsEngineeringLaser

The invention relates to an assembly type integrated heat-insulting wall board which comprises a metal outer frame plate, a plurality of U-shaped metal plates, a heat-insulting cushion layer and a metal heat-insulting sleeve plate; during the assembly, the U-shaped metal plates are inserted in the metal outer frame plate at intervals, so that the bottom surfaces of the U-shaped metal plates and the inner wall surface of the metal outer frame plate are jointed with the top surfaces of the U-shaped metal plates and the outer wall surface of the metal outer frame plate respectively; at the joint of the bottom surfaces of the U-shaped metal plates and the inner wall surface of the metal outer frame plate, the fixed connection between the metal outer frame plate and the U-shaped metal plates is realized through laser penetration welding. After the adoption of the structure, the assembly type integrated heat-insulting wall board has the characteristics of multi-plate combination, ventilation, heat insulation and firm structure.

Owner:钟伟杰

Method for quickly preparing rapid-charging graphene-based positive electrode material

The invention discloses a method for quickly preparing a rapid-charging graphene-based positive electrode material. The method includes the steps of preparing a lithium iron phosphate precursor solution with specific concentration from iron nitrate nonahydrate as an iron source, lithium dihydrogen phosphate as a phosphorus source and a lithium source and citric acid monohydrate as a carbon source,adding a proper quantity of graphene oxide solution with ultrasonic operation and stirring sufficiently to ensure that graphene is dispersed in the solution evenly, adding the prepared solution intoa liquid storage tank, and subjecting the prepared solution to spray pyrolysis in the reduced atmosphere so as to obtain a black powder product. The method has the advantages that compared with traditional solid-phase mixing, the graphene is mixed with raw materials in the solution state, and even dispersion and coating of the graphene on an active material can be achieved to guarantee stability and uniformity of the black powder product; the black powder product is synthesized by one-step spray pyrolysis, and accordingly the method is simple and reliable in production technology, uniform in product stability, low in energy consumption, environment friendly and suitable for large-scale industrial production.

Owner:NANCHANG HANGKONG UNIVERSITY

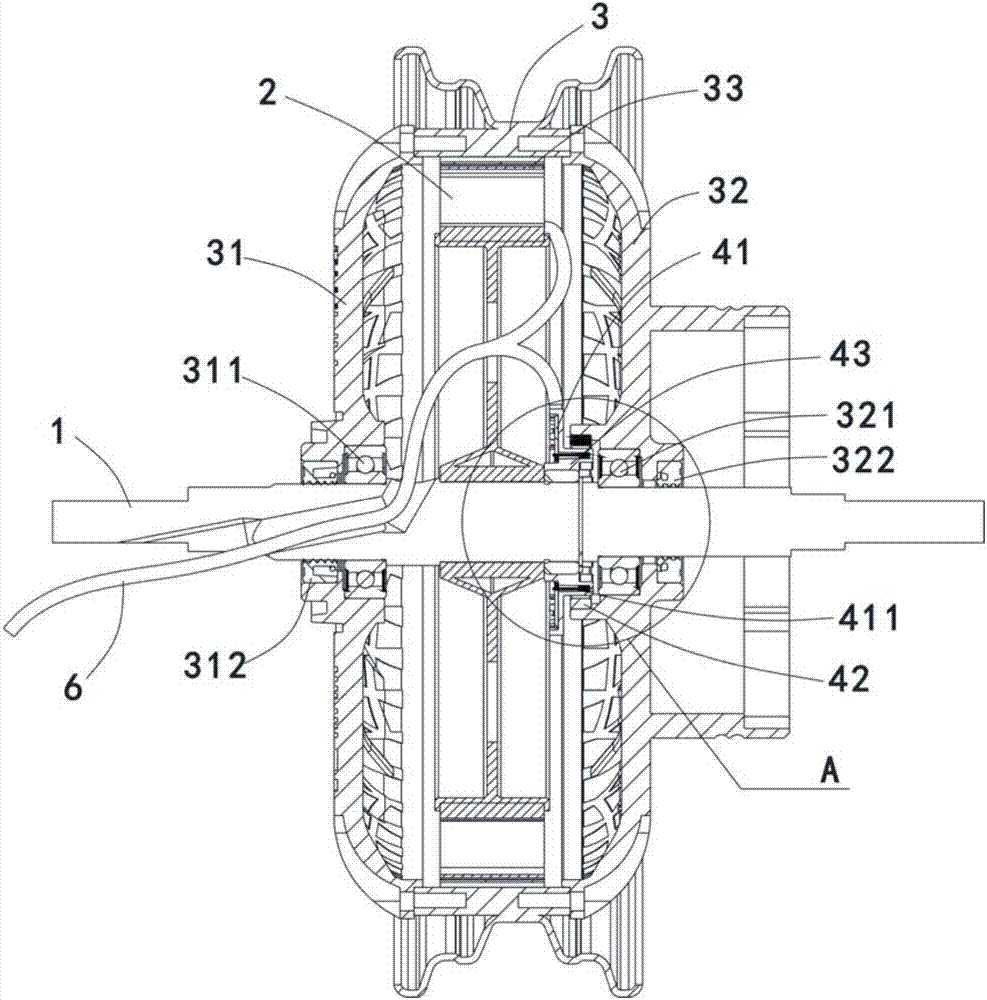

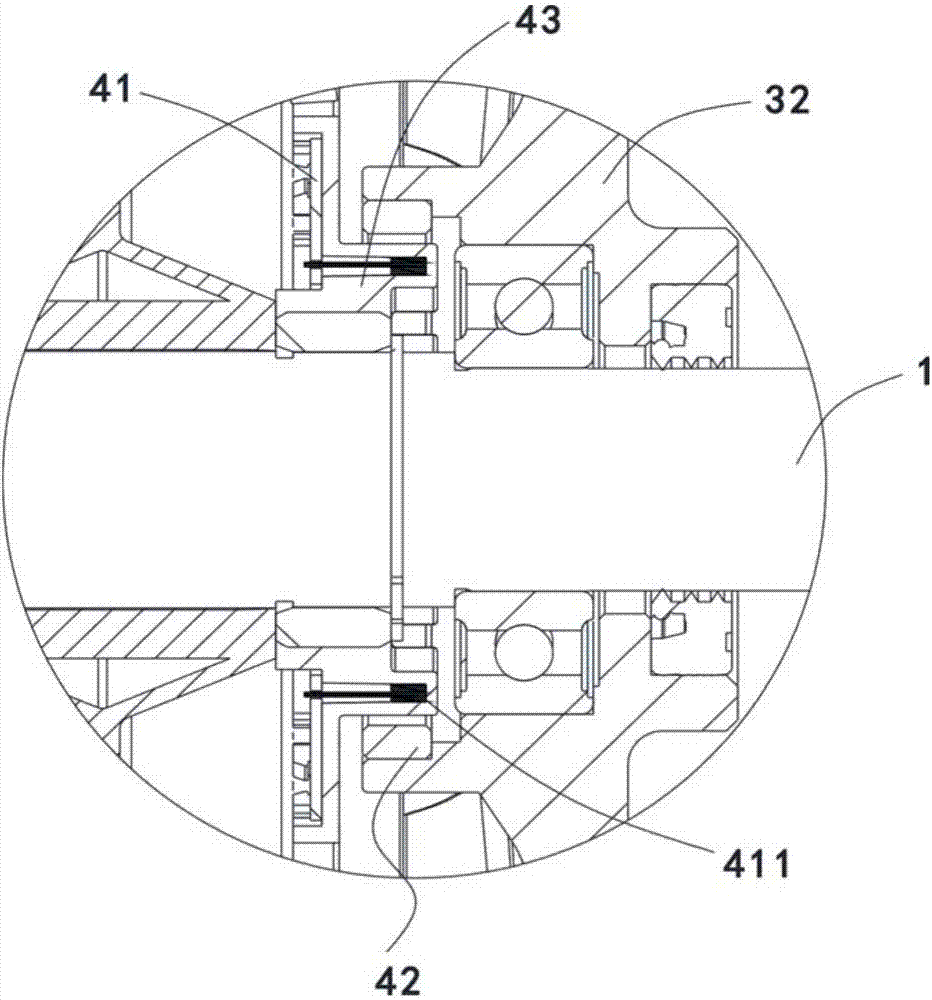

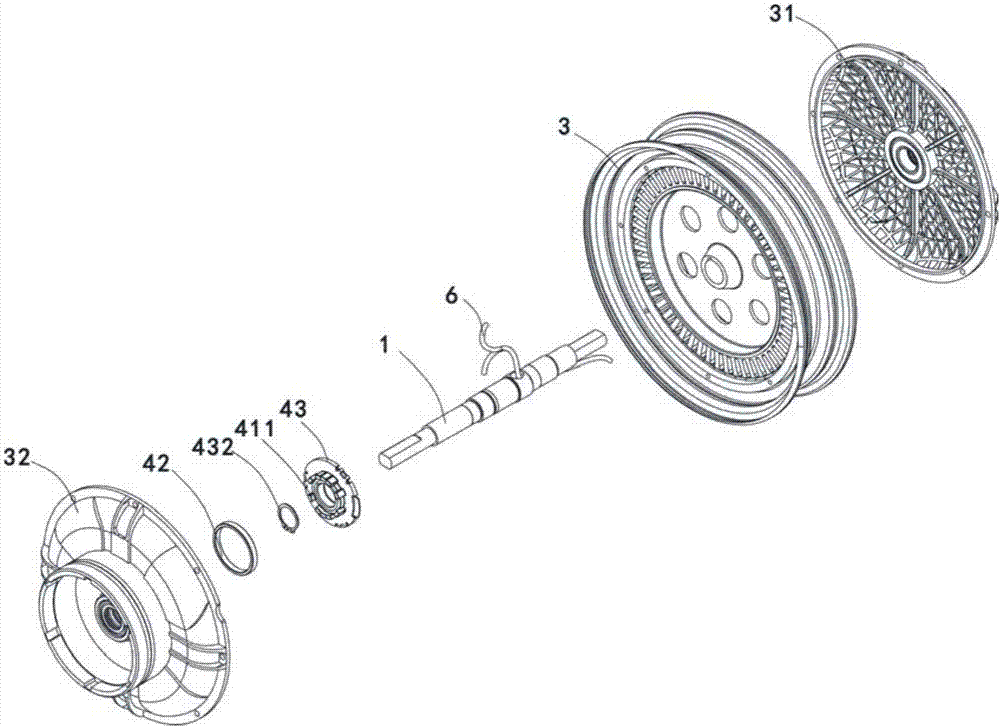

Wheel hub motor and position signal processing method thereof

ActiveCN107294337AImprove operational efficiencyLow costAssociation with control/drive circuitsElectronic commutatorsLocation detectionEngineering

The invention discloses a wheel hub motor. The wheel hub motor comprises a motor shaft, a stator, a rotor and a position detection device; the position detection device comprises a PCB (printed circuit board) and a magnetic ring; the PCB is provided with a plurality of magnetic induction components; when the magnetic ring is stationary or rotating, the magnetic induction components can sense the change of the magnetic flux of the magnetic ring; the rotor is provided with a left end cover and a right end cover which is used for installing a brake assembly; and the position detection device is arranged inside the right end cover. The invention also discloses an externally-arranged wheel hub motor; the rotor of the external wheel hub motor is provided with a left end cover and a right end cover which is used for installing a brake assembly; a motor shaft at the external side of the left end cover is provided with a housing; and a position detection device is arranged in the housing. The invention also discloses a position signal processing method of the wheel hub motor. The wheel hub motor of the invention has the advantages of simple structure, simple and reliable production process, reliable vibration resistance, low performance requirements for a controller and high accuracy. According to the wheel hub motor, position feedback avoids a heat source, mechanical angle and electrical angle output selections are provided, and the requirements of different control interfaces can be satisfied.

Owner:NINGBO BRANCH OF JIANGSU YADEA TECHNICAL DEV CO LTD +1

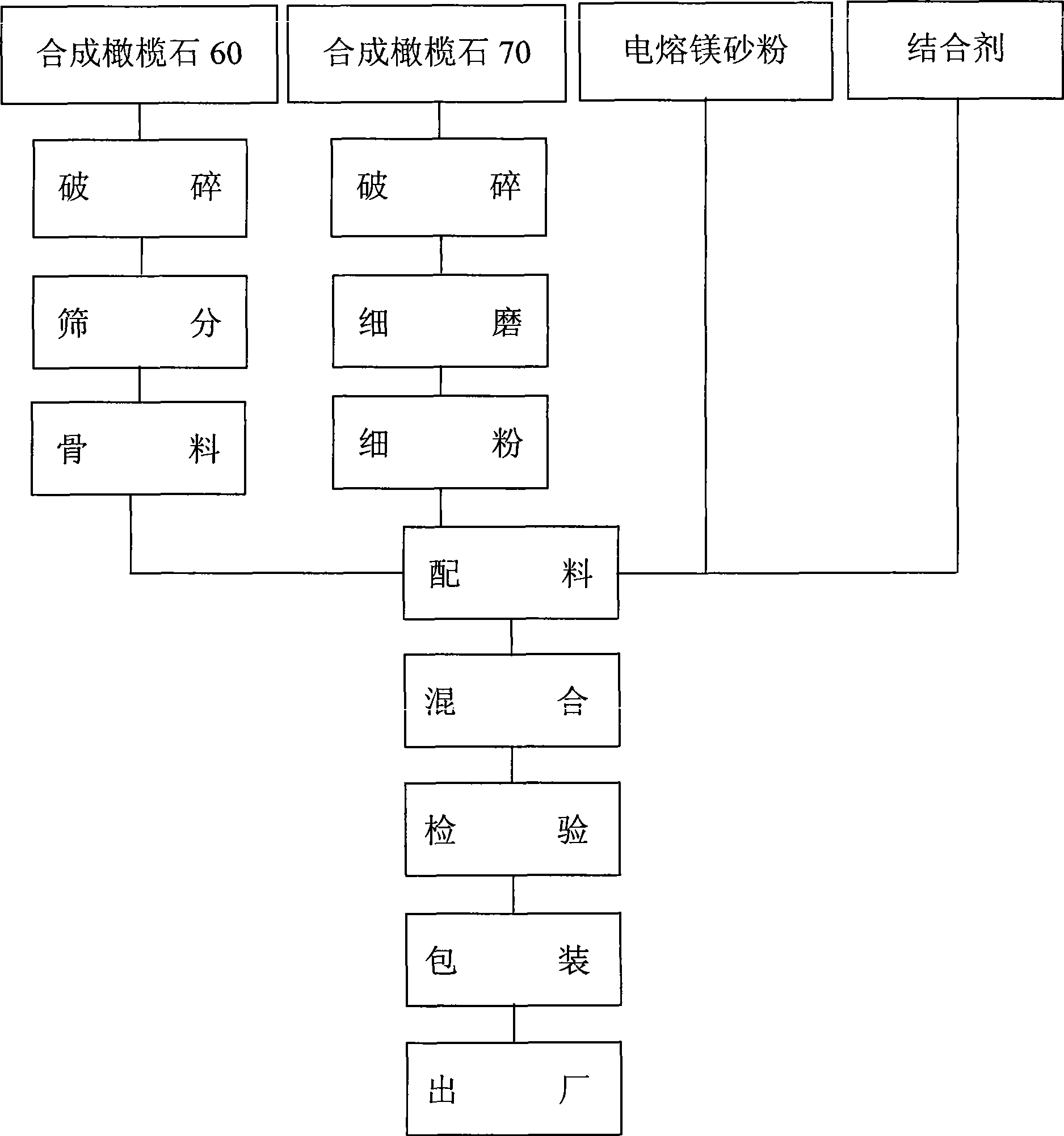

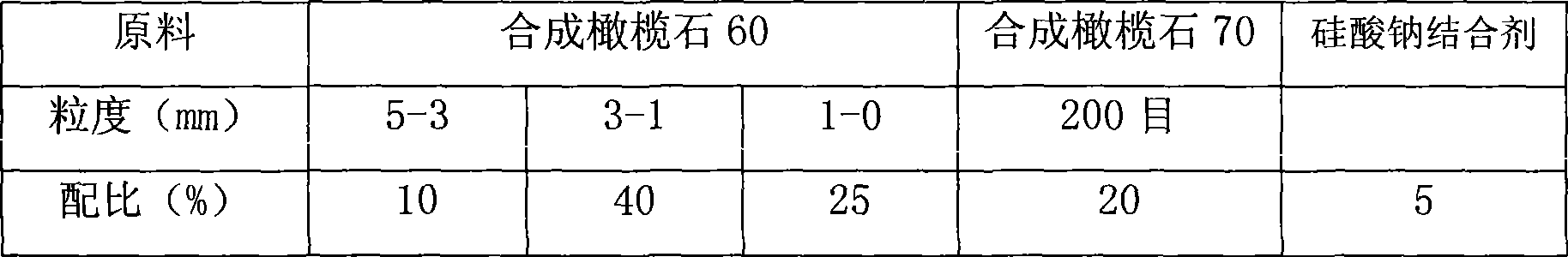

Synthesizing olivine gunning material and production method thereof

The invention relates to a synthesized olivine gunning mix and a producing method thereof. The synthesized olivine gunning mix is characterized in that the chemical compositions are: 60 to 70 percent of MgO, 25 to 30 percent of SiO2, 4 to 6 percent of Fe2O3, 0.001 to 2.5 percent of AI2O3, and 0.001 to 2.5 percent of CaO, and the ignition loss is 0.001 to 1.5 percent. The production technologies are material distribution, mixing, inspection and product packaging. The invention has the advantages that: a plurality of raw materials are adopted according to a certain proportion and treated with the procedures of material distribution, mixing, inspection, packaging and the like, thus causing the effective compositions of MgO, SiO2, Fe2O3 and the like to be uniform and have good dispersivity. The integration of common technical skills is adopted and the production technology is simple and convenient and reliable. Furthermore, nitrate, chloride and fluorite and the like which generate harmful gas to the environment and the equipment at high temperature do not exist in the raw materials, and the environment-protection and ecological benefits are good. In addition, the cost of the raw materials is low.

Owner:营口和平三华矿产有限公司

Preparation method of fluorescent colorful offset paper

InactiveCN102154922AFlexible operationThe production process is simple and reliableInorganic compound additionFluorescenceEngineering

The invention relates to a preparation method of fluorescent colorful offset paper, which comprises the steps of: completely changing the color of slurry into the required fluorescent yellow, fluorescent green, fluorescent red, fluorescent pink or fluorescent orange by utilizing several pigments, and then preparing the slurry into the fluorescent colorful offset paper according to the production procedures of finished papers of the conventional process. The preparation method of the fluorescent colorful offset paper is flexible, simple and convenient to operate and has a stable and reliable production process. The fluorescent colorful offset paper obtained through the preparation method disclosed by the invention has strong three-dimensional sense, a vivid color and an extremely good visual effect.

Owner:MCC MEILI CLOUD COMPUTING IND INVESTMENT CO LTD

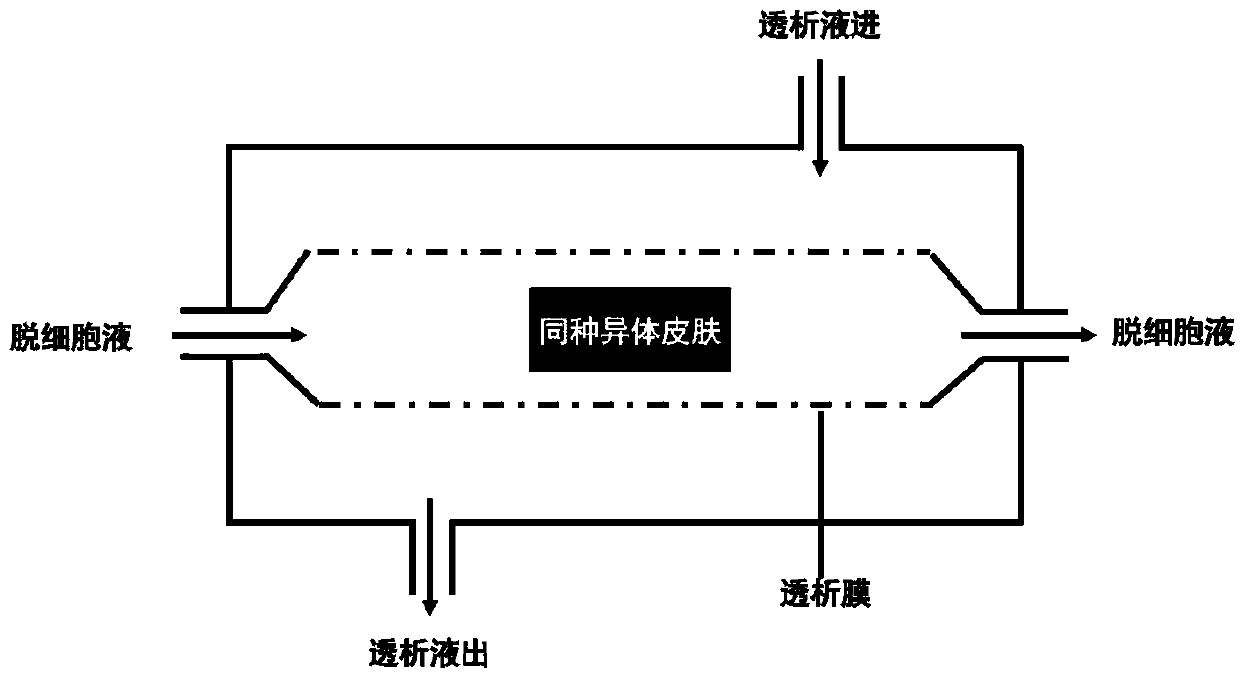

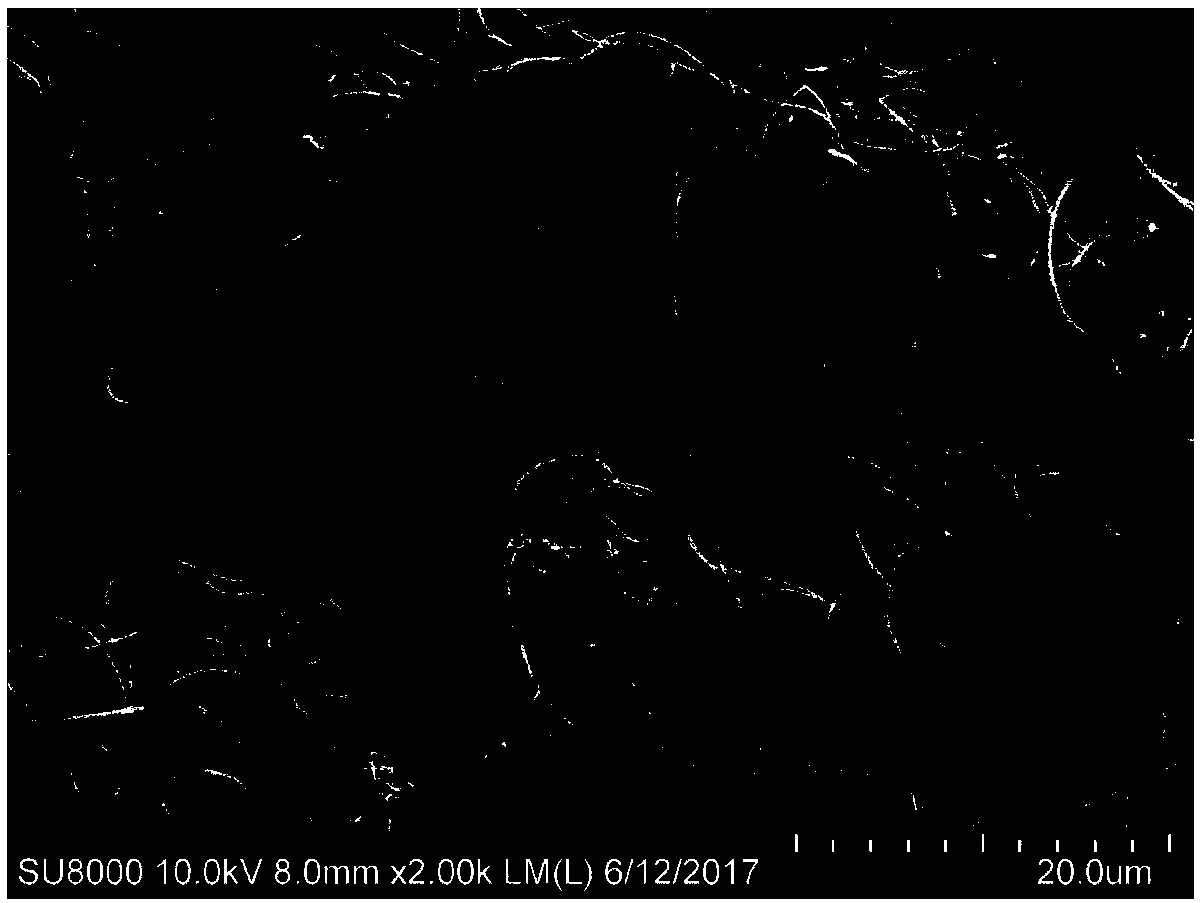

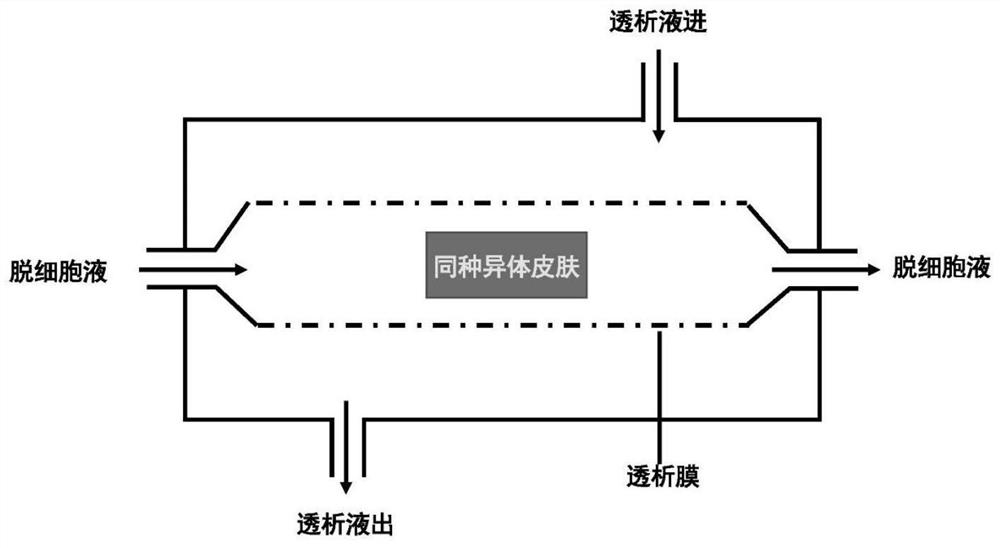

Preparation method of decellularized derma matrix of human source

ActiveCN109675112AReduce immune rejectionSatisfied with the repair effectProsthesisAdditive ingredientBiocompatibility Testing

The invention discloses a preparation method of a decellularized derma matrix of a human source. The preparation method specifically comprises the following steps: taking stored human source skin; eliminating subcutaneous attached fat ingredients; cleaning and disinfecting by using iodine and ethyl alcohol, after that, repeatedly soaking and washing the skin by using a hypotonic solution; treatingby using a Dispase II solution overnight; removing epidermis, and after that, washing by using normal saline, thus acquiring derma; treating by using a hypertonic saline solution; washing by using the normal saline; treating by using a decellularizion solution in a dialysis device, thus acquiring the decellularized derma matrix; washing by using the normal saline, to obtain the decellularized derma matrix of the human source. The preparation method is simple and convenient, adopts a simple and reliable production process, is capable of improving production efficiency, reducing production cost, and reducing environment pollution in the greatest degree; in addition, the obtained decellularized derma matrix reserves a skin basement membrane, and is beneficial to adhesion and multiplication of cells; at the same time, the decellularized derma contains abundant growth factors, so the decellularized derma matrix has good biocompatibility, and is more beneficial to supporting growth of the cells.

Owner:上海仁康科技有限公司

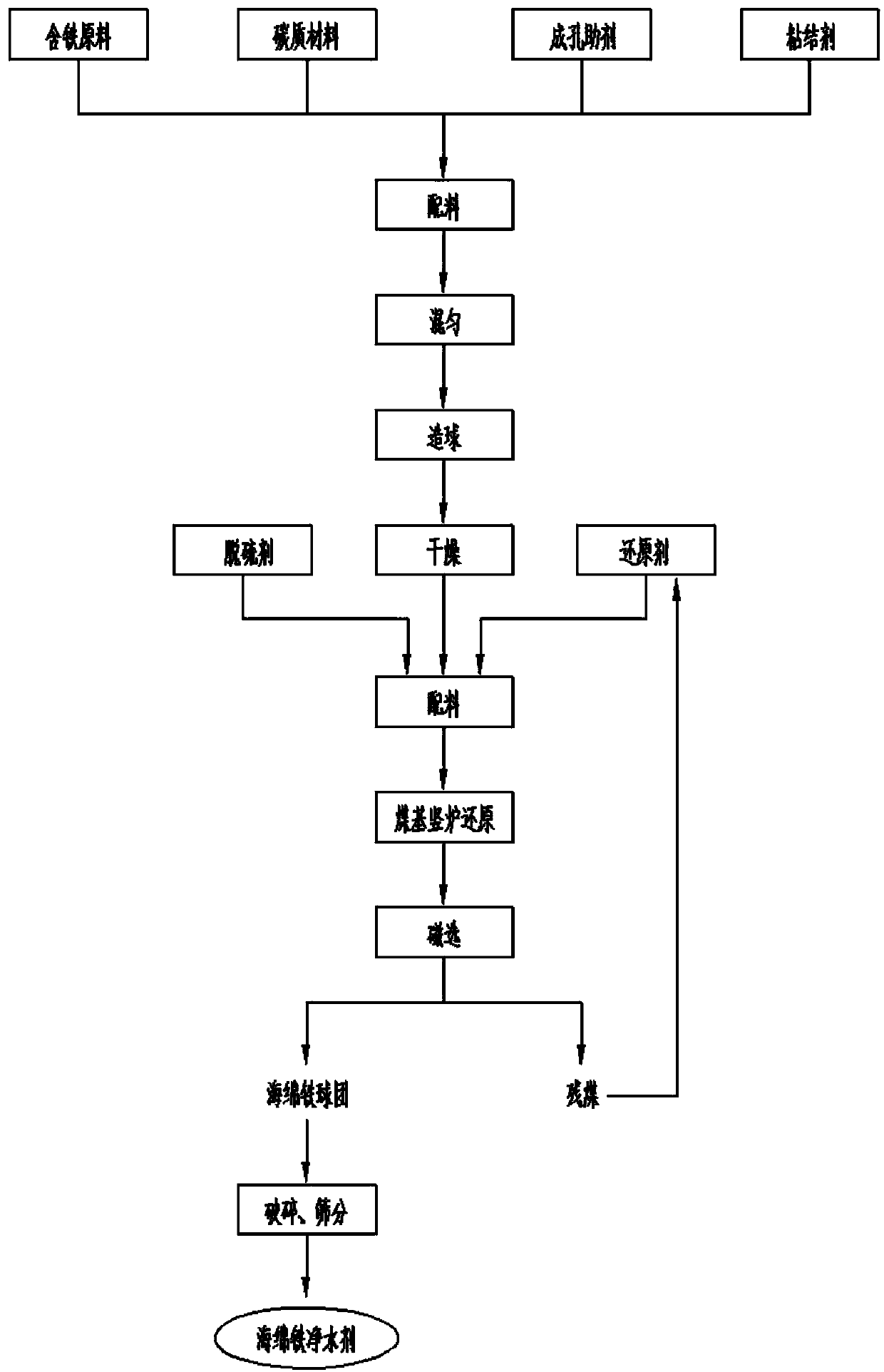

Production technology of sponge iron for water purifying agent

ActiveCN107827197AThe production process is simple and reliableRealize large-scale productionWater contaminantsWater/sewage treatment by flocculation/precipitationFlocculationWastewater

The invention relates to a production technology of sponge iron for a water purifying agent. The production technology comprises steps as follows: (1), a dried and finely ground iron-containing raw material is mixed uniformly with a carbonaceous material, a pore-forming auxiliary and binder components, and a mixture is pressed into balls; (2), green balls are dried and mixed uniformly with a reducing agent and a desulfurizing agent, preheating, reducing and cooling are performed in a coal shaft furnace, and a sponge iron mixture is obtained; (3), after the sponge iron mixture is subjected to magnetic separating, sponge iron metallized pellets and residual coal are obtained; sponge iron particles obtained after crushing and screening of the sponge iron metallized pellets are used as the water purifying agent. The production technology has the remarkable advantages of being advanced, reliable, stable in product quality, low in production cost, high in production efficiency and environmentally friendly, and large-scale production can be realized; the produced sponge iron water purifying agent has the advantages of large specific surface area, high specific surface energy, higher electrochemical enrichment, physical absorption and flocculation precipitation and the like, and can be widely used for treating various kinds of wastewater with difficulty in biochemical degradation.

Owner:WUHAN COSRED SCI & TECH LTD

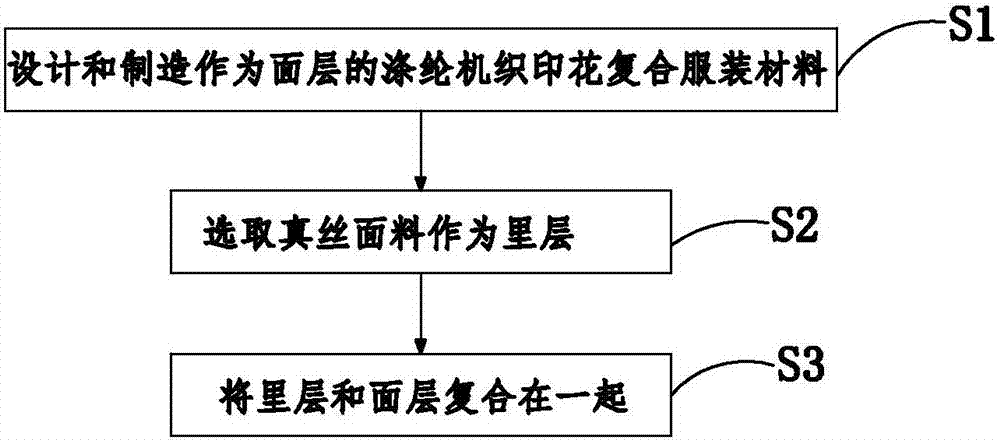

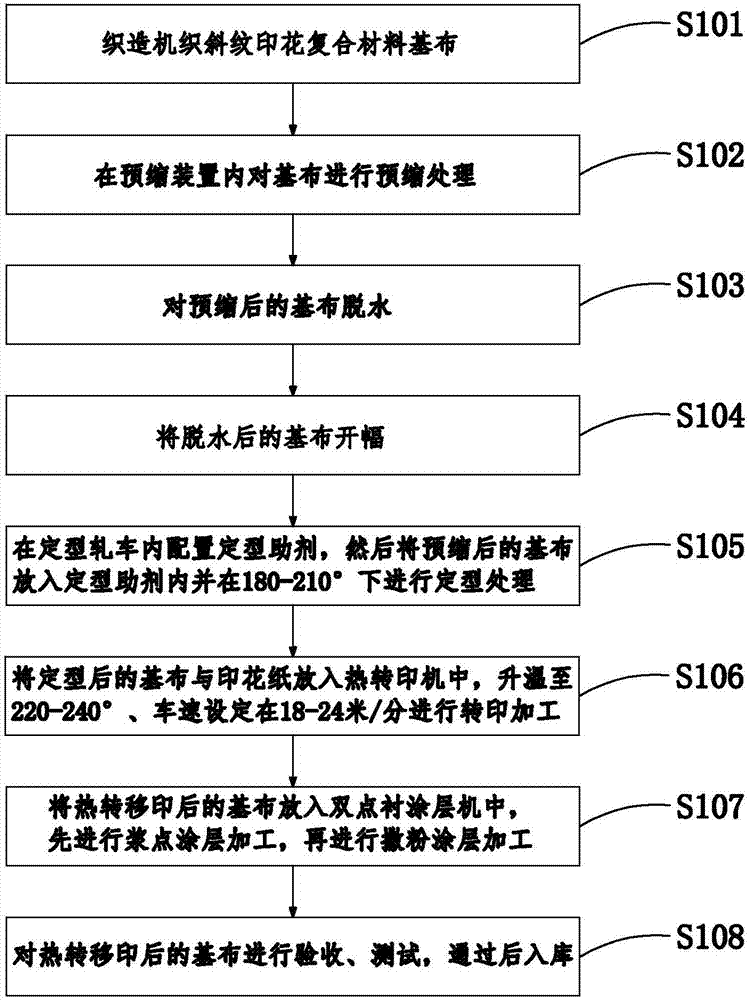

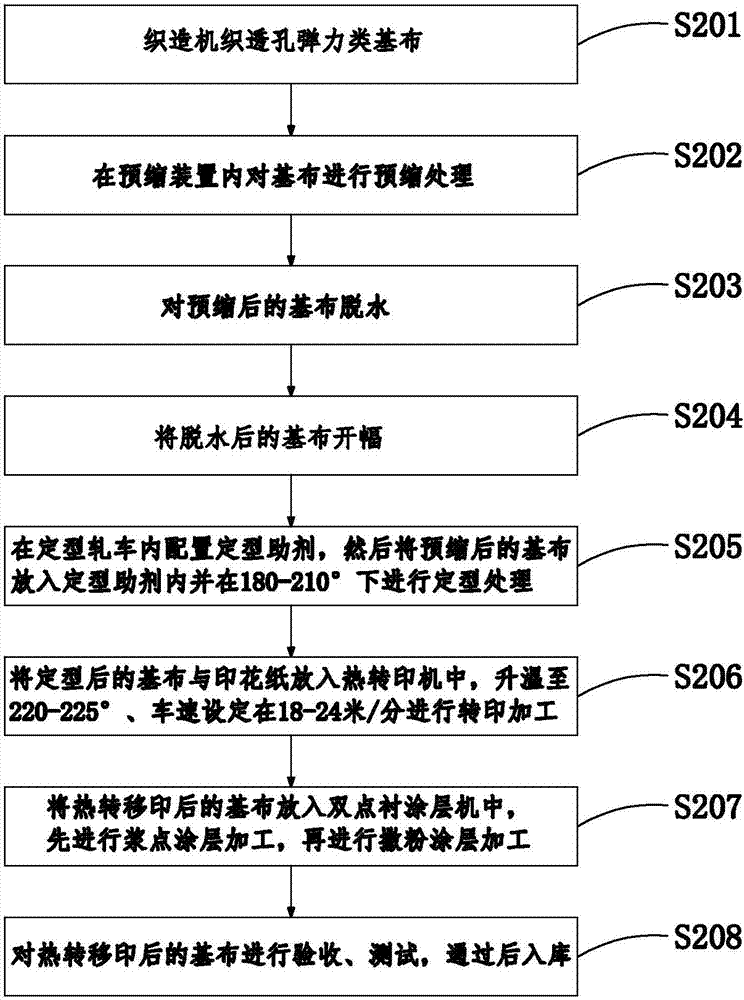

Dacron woven printing composite material and silk fabric composite product and production process thereof

InactiveCN107160760AImprove noble touchImprove mechanical performanceLamination ancillary operationsSynthetic resin layered productsSurface layerSilk fabric

The invention relates to a Dacron woven printing composite material and silk fabric composite product and a production process thereof. The production process includes the steps: designing and manufacturing Dacron woven printing composite materials serving as surface layers; selecting silk fabrics to serve as inner layers; recombining the inner layers and the surface layers together. According to the production process of the Dacron woven printing composite material and silk fabric composite product, suitable, light, thin, soft and smooth market silk fabrics and improved printing composite materials are combined into needed printing composite Dacron silk fabrics through a specific combined process, a three-step method production process is simpler and more reliable, the inner layers and the outer layers are single-component cloth materials, dyeing and finishing are more convenient, indexes such as color fastness of the fabrics are effectively controlled, the production cost of the printing Dacron materials of the outer layers is lower than that of real silks, and the price of the printing Dacron materials is much lower than that of the pure real silks with the same weight.

Owner:CPL NEW MATERIAL TECH CO LTD

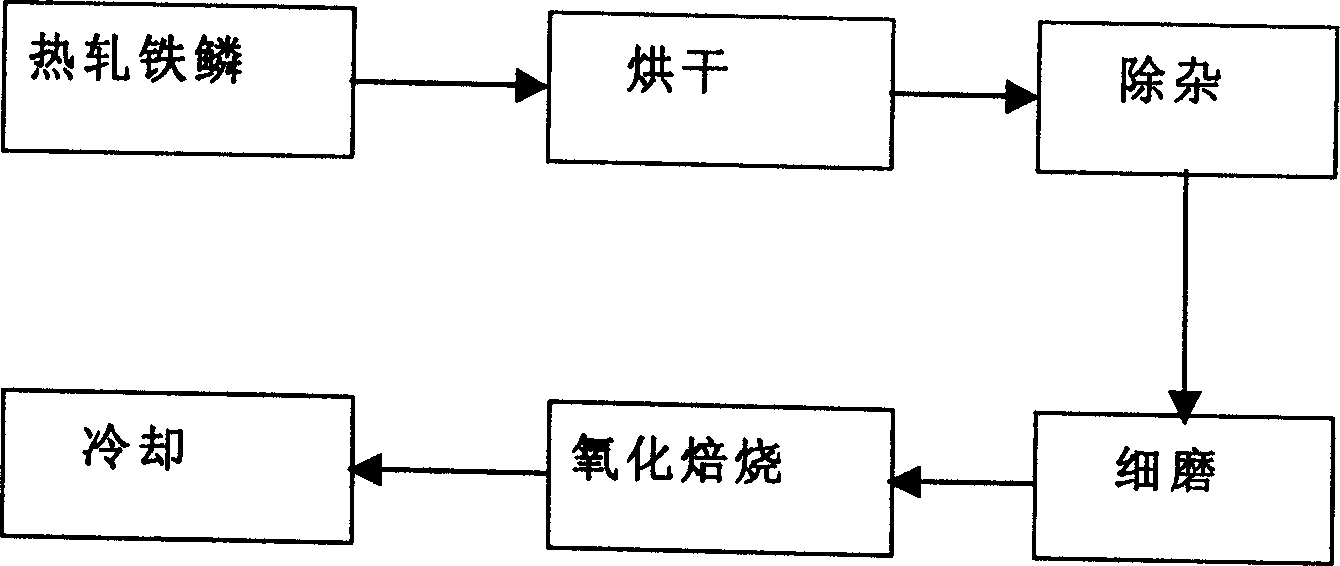

Method for producing ferric oxide for permanent magnet presintered material

ActiveCN1640850AThe production process is simple and reliableReduce manufacturing costInorganic material magnetismDiiron TrioxidePollution

The present invention relates to the production process of ferric oxide for presintered permanent magnetic material. Waste iron scale from hot rolling mill as material is processed through the steps of stoving, eliminating impurity, grinding, cooling, etc. to produce the red brown ferric oxide material of average particle size 5 micron, Fe2O3 content 99.0 %, and ferrous oxide content less than 0.20 %. Compared with available technology, the present invention has the advantages of simple and reliable production process, low material and power consumption, no secondary pollution, low product cost and high product quality.

Owner:宝武环科南京资源利用有限公司

Medical high-polymer non-woven fabric splint

InactiveCN102885668AThe production process is simple and reliableImprove consistencyFractureControl qualityNonwoven fabric

The invention discloses a medical high-polymer non-woven fabric splint, and aims to provide a medical high-polymer non-woven fabric splint, which has the advantages of high production efficiency, easiness in controlling quality and reduction in the product cost. The medical high-polymer non-woven fabric splint comprises a waterproof layer, a buffer layer and a framework layer, wherein the framework layer is formed between the waterproof layer and the buffer layer; and the waterproof layer is compounded with the buffer layer by sewing. The medical high-polymer non-woven fabric splint is suitable for producing and manufacturing medical splints.

Owner:WEIHAI ZHONGHE REHABILITATION MATERIAL

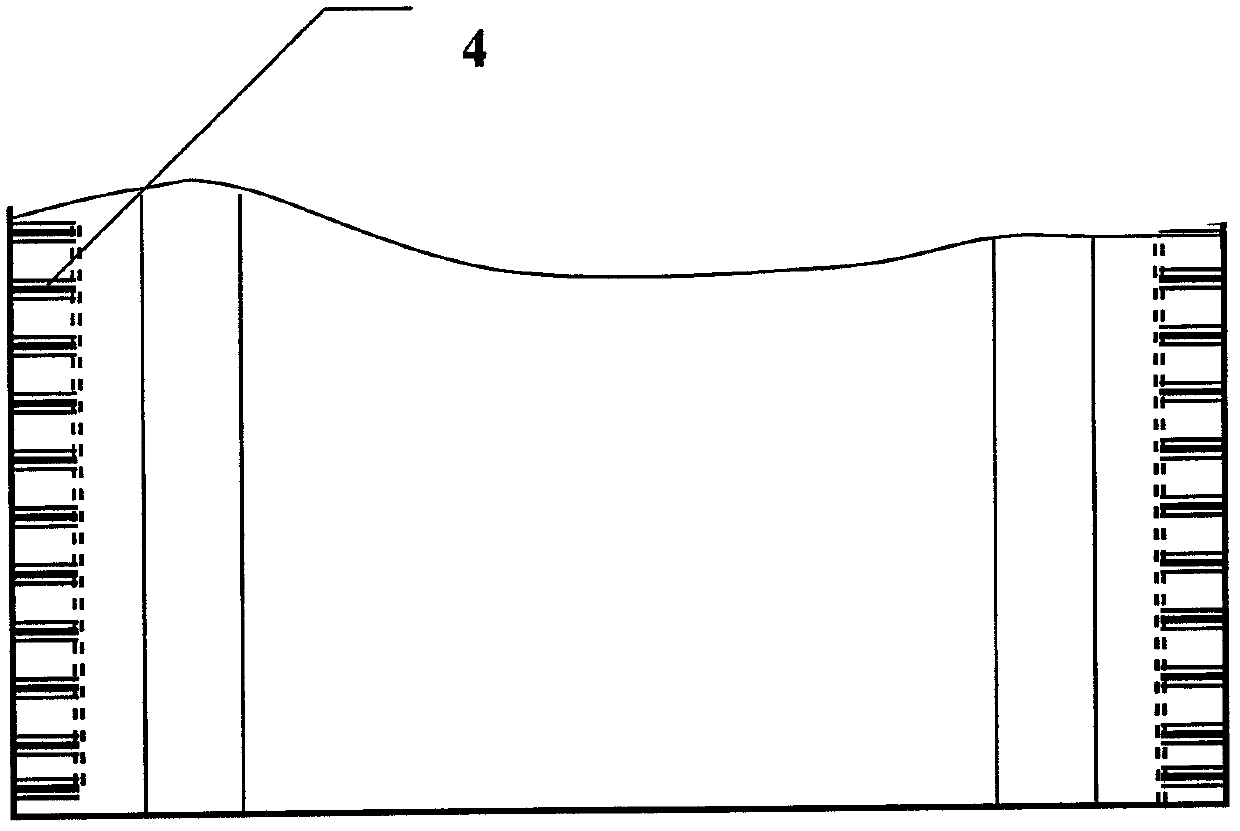

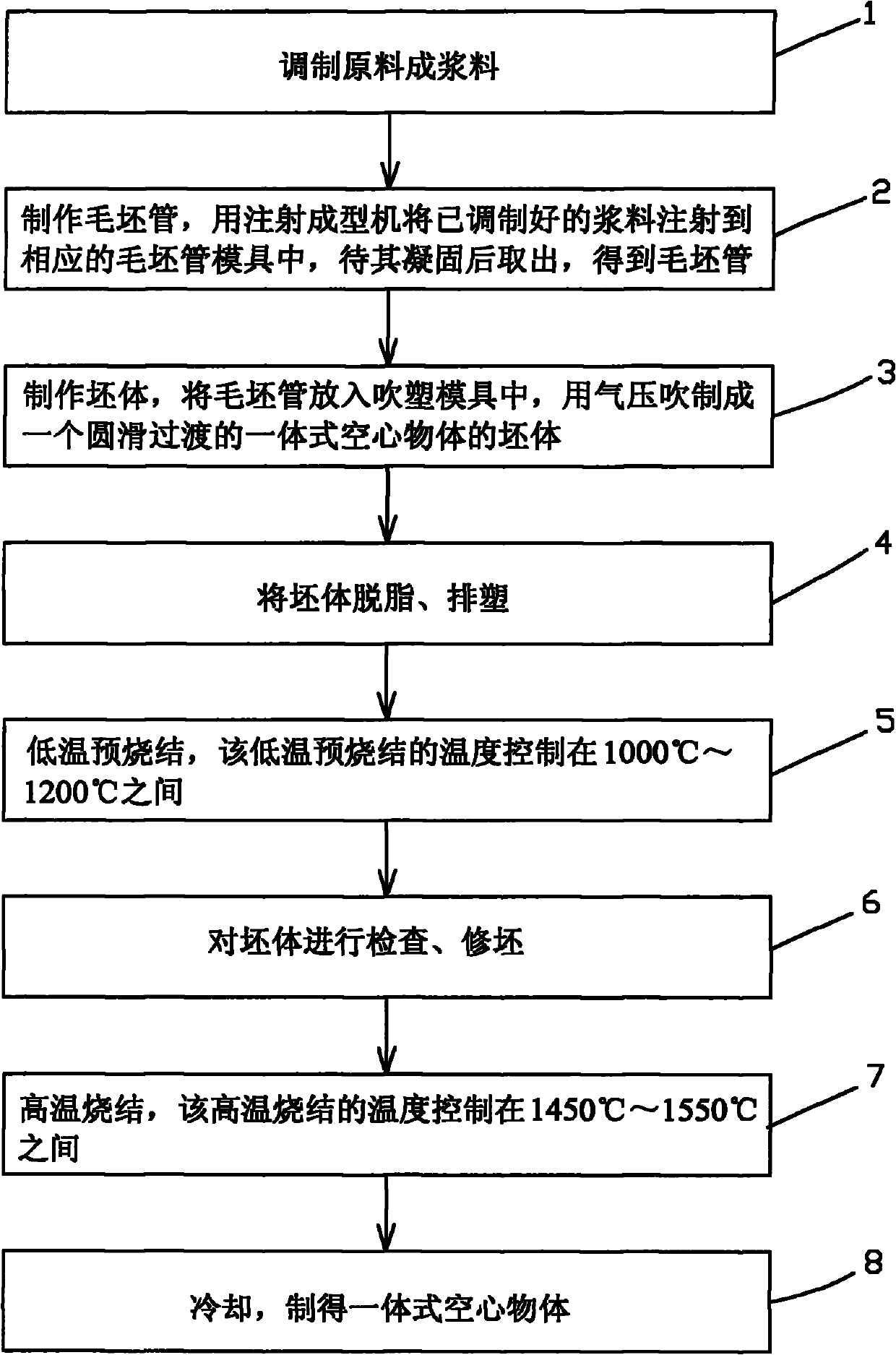

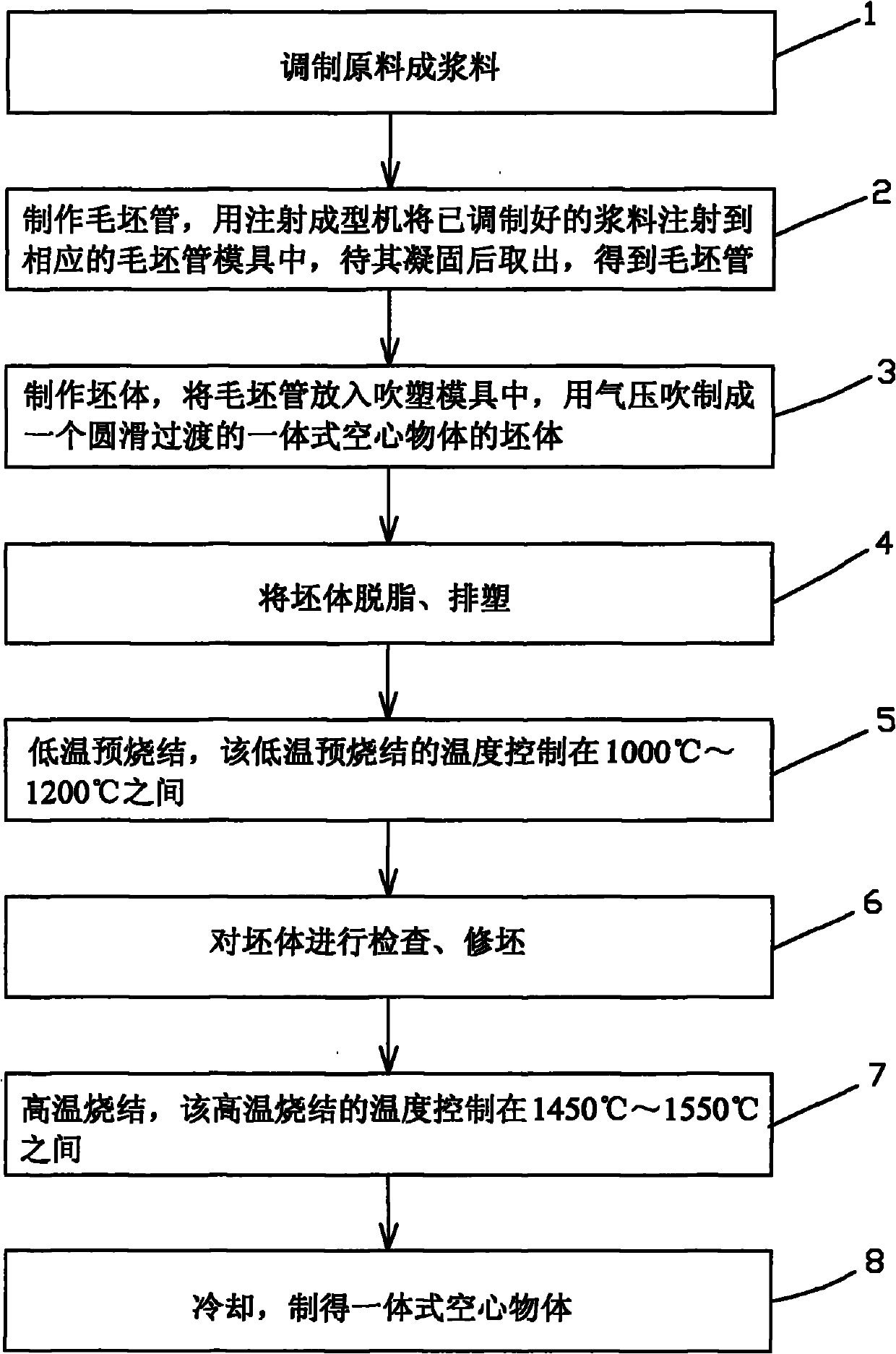

Method for preparing hollow object by blow molding of zirconia ceramic

ActiveCN102020469AThe production process is simple and reliableImprove yieldInjection molding machineTemperature control

The invention provides a method for preparing a hollow object by blow molding of zirconia ceramic. The method comprises: a step 1 of mixing raw materials to prepare slurry; a step 2 of preparing a blank tube, which is to inject the prepared slurry into a corresponding blank tube mold with an injection molding machine, take the blank tube out after the blank tube is solidified and obtain the blank tube; a step 3 of preparing a blank, which is to place the blank tube into a blow molding mold, and form the blank of a circular transition integrated hollow object by blowing under air pressure; a step 4 of degreasing the blank and removing plastic; a step 5 of pre-sintering at a low temperature kept between 1,000 and 1,200 DEG C; a step 6 of detecting and trimming the blank; a step 7 of sintering at a high temperature kept between1,450 and 1,550 DEG C; and a step 8 of cooling to obtain the integrated hollow object. The method has a simple and reliable preparation process, reduces production cost, has high yield and is favorable for industrial mass production, and the prepared hollow object has high size precision and a long service life.

Owner:深圳市宏通新材料有限公司

Zinc-selenium tea drink and processing technology thereof

InactiveCN105494730AThe production process is simple and reliableGreat tastePre-extraction tea treatmentTea extractionSucroseEpigallo-catechin gallate

The invention relates to a zinc-selenium tea drink and a production technology thereof. The zinc-selenium tea drink is prepared from components as follows: 30 g of zinc-selenium tea juice, 0.2 g of honey and 0.1 g of vitamin C. The zinc-selenium tea drink has a simple formula, is free of pigments, preservatives and cane sugar, is green and natural, tastes good and can reserve the aroma of green tea. With the adoption of the technology, under the condition that no pigments, preservatives and cane sugar are added, production of the zinc-selenium tea drink is realized, the taste of the drink is guaranteed, and the aroma of green tea is reserved.

Owner:GUIZHOU XIANZONGCAO AGRI DEV CO LTD

Radiation protection gypsum lath and preparation thereof

The invention discloses a radiation protection paper surface plasterboard and a method for manufacturing the same. The formula of the radiation protection paper surface plasterboard is as follows: radiation protection materials including 5 to 40 percent of barium sulphate, 10 to 20 percent of calcium carbonate, 5 to 10 percent of quartz powder and other additives are added in the formula of the plasterboard; the plasterboard is mainly applied to the non bearing wall system and the man-carrying or non man-carrying suspended ceiling system and can effectively avoid radiations such as X rays and Gmman rays etc., and has the advantages of non-toxicity, odorlessness, low price, convenient construction and good protective property; so that the plasterboard can be widely applied to the architectural decoration.

Owner:孙小力

Method for preparing hot casting mold

InactiveCN104671736AThe production process is simple and reliableImprove performanceRare earthRoom temperature

The invention discloses a method for preparing a hot casting mold. Cork powder, rare earth, ceramic aggregate, gypsum powder and silica gel are taken as raw materials. The method comprises the following process steps: (a), adding the cork powder, ceramic aggregate and gypsum powder into a stirrer for mixing, thereby forming a mixture; (b), heating the mixture formed in the step (a), controlling the temperature to be 70-80 DEG C, slowly adding silica gel in the heating process, uniformly stirring, finally adding the rare earth after the silica gel addition is finished, heating at a speed of 5-8 DEG C per hour, stopping heating when the temperature rises to 120-150 DEG C, and preserving the temperature for 3-5 hours; and (c) performing injection molding on the mixture subjected to complete heat preservation in the step (b), cooling to room temperature, thereby obtaining the finished product. The method disclosed by the invention has the beneficial effects that the production process is simple and reliable, the manufactured mold is stable in performance, the toughness and hardness are enhanced by virtue of the added silica gel and ceramic aggregate, the service life can be greatly prolonged, the production cost is reduced, and the economical benefits are improved.

Owner:昆山迪赛斯恩模具设计有限公司

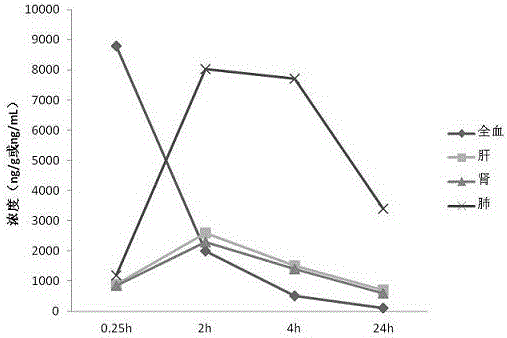

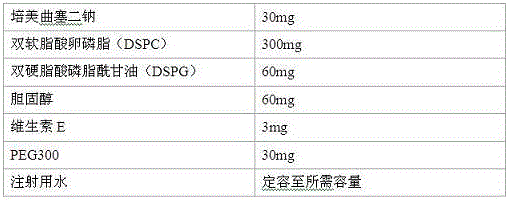

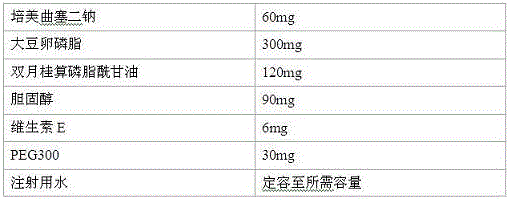

Pemetrexed disodium injection solution and preparation method thereof

InactiveCN106176608AGood curative effectSmall toxicityOrganic active ingredientsPharmaceutical non-active ingredientsSide effectCholesterol

The invention relates to a pemetrexed disodium injection solution and a preparation method thereof. The injection solution contains pemetrexed disodium, neutral phospholipid, charged phospholipid, cholesterol, an antioxidant and a suspending agent. The injection solution provided by the invention has appropriate particle size distribution, is high in encapsulation efficiency and good in stability, and can be distributed in cancerization organs in a targeting manner, the curative effect of the pemetrexed disodium is improved, and the toxic and side effects are reduced.

Owner:JIANGSU HANSOH PHARMA CO LTD

A kind of preparation method of human-derived acellular dermal matrix

ActiveCN109675112BReduce immune rejectionSatisfied with the repair effectProsthesisCell adhesionIodophor

Owner:上海仁康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com