Polyamide acid and preparation method thereof, polyimide and preparation method of polyimide film

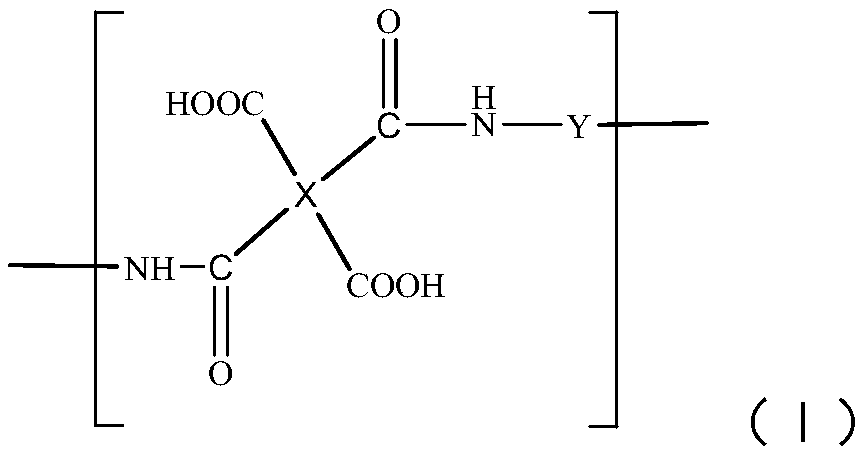

A polyimide film and polyimide technology are applied in the field of intermediate polyamic acid and preparation, polyimide and polyimide film preparation, and can solve the problem of poor solubility, poor solubility and difficult processing. Polyimide materials and other problems, to achieve the effect of improving solubility, good processability, simple and reliable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

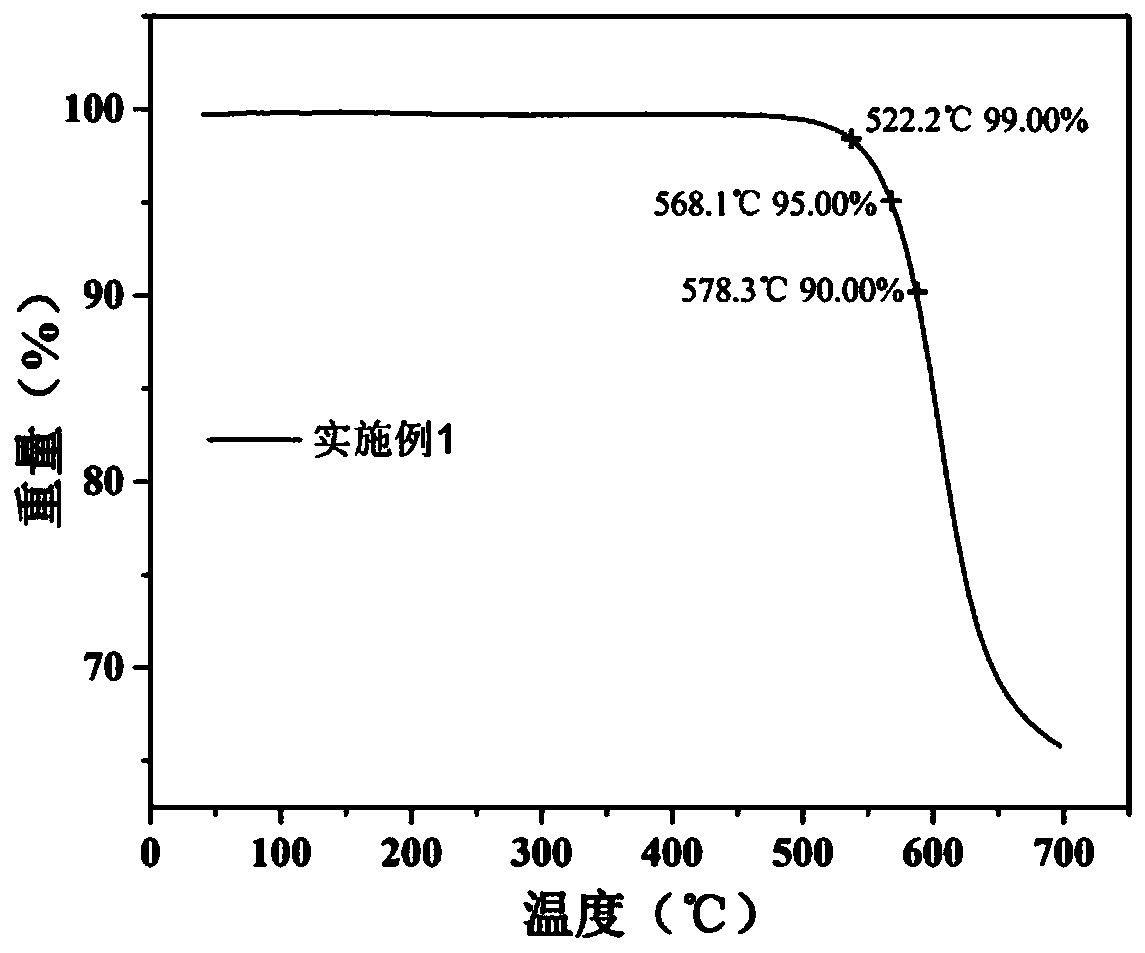

[0056] Polyimide film embodiment 1 (PMDA / p-ABO / ODA)

[0057] In a three-neck flask (100ml) equipped with a stirring rod and a nitrogen inlet, add 4,4-diaminodiphenyl ether (ODA) (1.001g, 0.005mol), Y1-NH 2 6-amino-2-(4-(4-aminophenyl) phenyl)-benzoxazole (p-ABO) (1.587g, 0.005mol) and N-methylpyrrolidone (30ml ), wherein the sum of the molar weights of ODA and AAB is 0.01mol. Under the protection of nitrogen, after mechanical stirring at 0~50° C. to be completely dissolved, add pyromellitic anhydride (PMDA) (2.181 g, 0.01 mol) to the solution, keep the temperature of the reaction system constant, react 1 to 24 hours to obtain a polyamic acid solution with a viscosity of 10.7Pa·s; after the above polyamic acid solution is decompressed to eliminate air bubbles, it is coated on a clean glass plate with a wet film thickness of 1 to 300μm, and then heated at 80°C After drying in a vacuum oven for 5 hours, it was cured in a nitrogen oven at 150° C. for 1 hour, 350° C. for 1 hour, ...

Embodiment 2

[0058] Polyimide film embodiment 2 (PMDA / m-ABO / ODA)

[0059] Except for Y2-NH 2 6-amino-2-(3-(4-aminophenyl)phenyl)-benzoxazole (m-ABO) (1.587g, 0.005mol) of Experimental Example 1 replaced 6-amino-2-(4- Except for (4-aminophenyl)phenyl)-benzoxazole (p-ABO), the others were the same as in Example 1 to obtain a polyimide film 2. However, the obtained polyamic acid solution had a viscosity of 5.42 Pa·s.

Embodiment 3

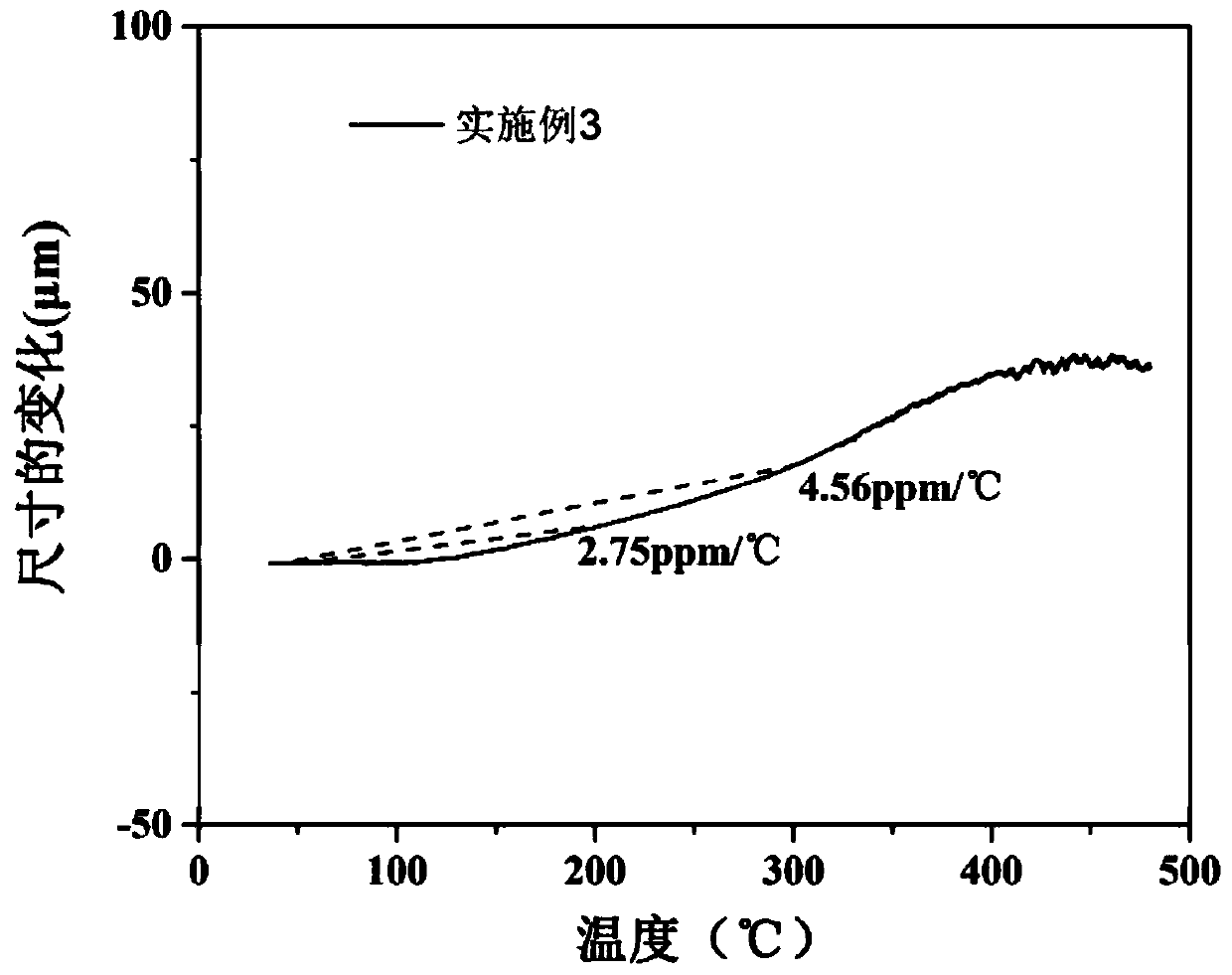

[0060] Polyimide film embodiment 3 (s-BPDA / p-ABO / PPD)

[0061] In a three-neck flask (100ml) equipped with a stirring rod and a nitrogen inlet, add p-phenylenediamine (PPD) (0.541g, 0.005mol), Y1-NH 2 6-amino-2-(4-(4-aminophenyl) phenyl)-benzoxazole (p-ABO) (1.587g, 0.005mol) and N-methylpyrrolidone (30ml ), wherein the sum of the molar weights of PPD and AAB is 0.01mol. Under the protection of nitrogen, stir mechanically at 0~50°C and after the solution is completely dissolved, add 3,3′,4,4′-biphenyltetracarboxylic dianhydride (s-BPDA) (2.942g , 0.01mol), keep the temperature of the reaction system constant, and react for 1-24 hours to obtain a polyamic acid solution with a viscosity of 5.67Pa·s; decompress the above polyamic acid solution to eliminate air bubbles, and then coat it on a clean glass plate , with a wet film thickness of 1-300 μm, followed by drying in a vacuum oven at 80°C for 5 hours, followed by curing in a nitrogen oven at 150°C for 1 hour, 350°C for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com