Method for producing ferric oxide for permanent magnet presintered material

A production method and calcined material technology are applied in the field of production of iron oxide for permanent magnet calcined material, can solve the problems of high cost, poor product performance, complicated process and the like, and achieve low production cost, simple and reliable production process, No secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

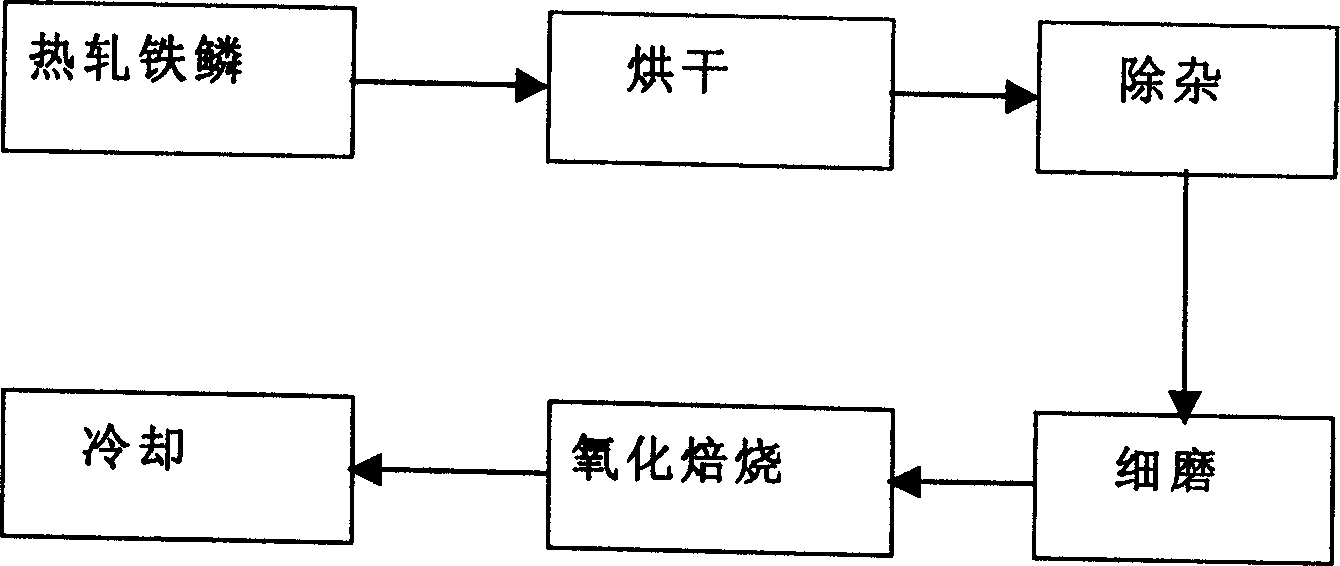

[0016] Referring to the accompanying drawings, a production method of iron oxide for permanent magnet calcined materials uses iron scale solid waste in the production process of hot rolling mills as raw material, and the raw material is first dried and dehydrated. No stickiness, no cake formation, improve grinding efficiency; Mechanical method is used to remove mechanical foreign matter in raw materials before fine grinding; The processed raw materials are finely ground, and the grinding method is dry continuous operation, which requires uniform fine grinding output The particle size is below 5um; the finely ground material is heated externally with gas, oxidized with air, the oxidation temperature is 720°C, and the oxidation time is 70 minutes; it can be sold as iron oxide for magnetic materials. Compared with the existing technology, the production process of the present invention is simple and reliable, with low material consumption and energy consumption, no secondary pollu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com