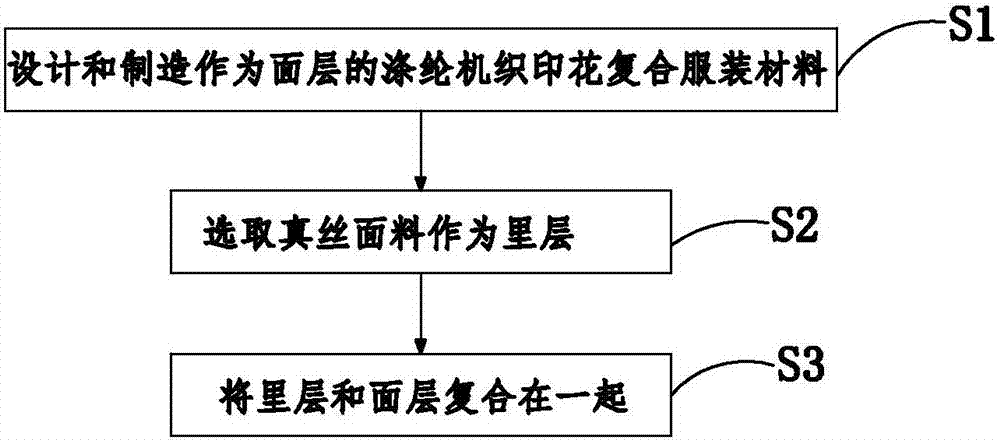

Dacron woven printing composite material and silk fabric composite product and production process thereof

A composite material and composite product technology, applied in the field of textiles, can solve the problems of hand-hardening of pure silk fabrics, high price of silk fabrics, and material-saving typesetting, etc., to improve the noble touch, facilitate the transportation of sweat and evaporation, and improve the feeling of comfort. The effect of strength properties and hard-to-wash care properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

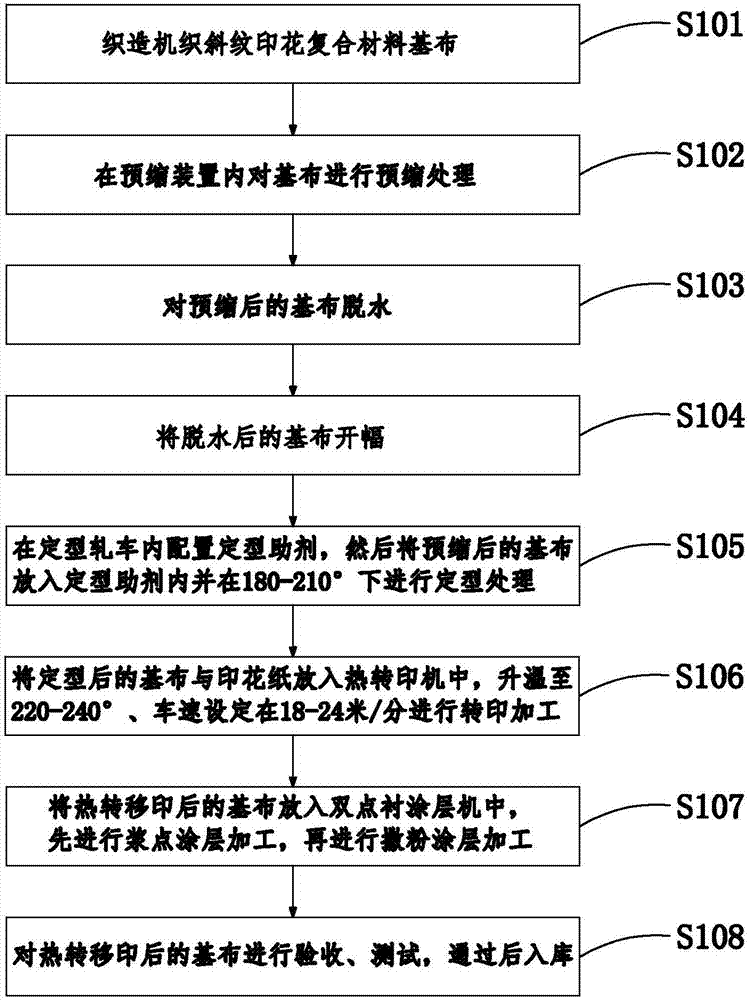

[0053] Embodiment 1: Woven twill printed composite material.

[0054] According to product use and performance positioning, this type of printing product should have good anti-pilling and abrasion resistance, silky soft, smooth and fluffy feel, sufficient four-sided elasticity, sufficient adhesion fastness, and excellent washability. The optimal weight per square meter of this type of product is 30-50 grams per square meter, and the yarn is selected from micro-net polyester low-elasticity yarn 15-75D. Considering the flatness requirements of the cloth surface required for printing, woven twill weave is generally used. Weaving on air-jet or clean water-jet looms.

[0055] Specifically, for the production method of the woven twill printed composite material in the present embodiment such as figure 1 shown, including the following steps:

[0056] S101: Weaving woven twill printed composite base fabric.

[0057] The weaving process of this kind of woven twill printing composite...

Embodiment 2

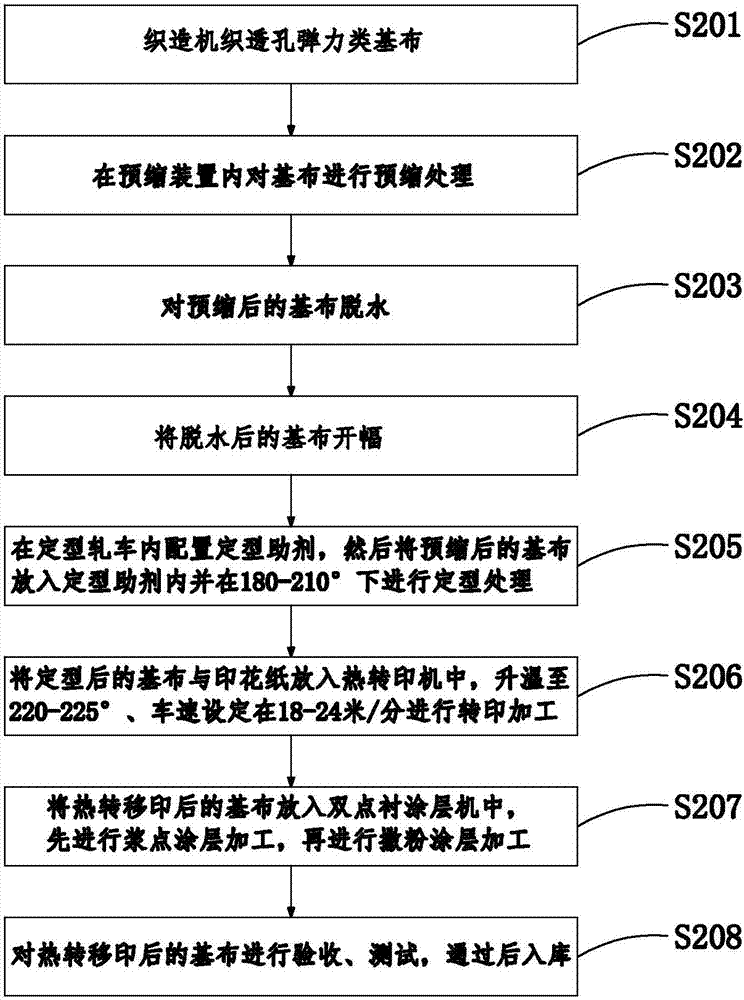

[0076] Embodiment 2: woven perforated tissue printing composite material.

[0077] Polyester filament woven through-hole weave products have very good anti-split performance, and thin fabrics in real silk are also cool through silk. It is a very cool fabric for clothing in summer, so it is also necessary to develop the printing of woven through-hole weave Composite materials are combined with this type of silk. The production method of this type of product is different from the above-mentioned woven twill product except that the specific weaving process is different, and the rest of the process and process formula are roughly the same.

[0078] Specifically, for the production method of the woven perforated tissue type printing composite material in this embodiment, such as figure 2 shown, including the following steps:

[0079] S201: Woven through-hole elastic base fabric.

[0080] The weaving process of this kind of woven through-hole elastic base fabric is as follows: s...

Embodiment 3

[0094] Embodiment three: woven plain weave elastic printing composite material.

[0095] According to product use and performance positioning, this type of printing product should have good anti-pilling and abrasion resistance, silky soft, smooth and fluffy feel, sufficient four-sided elasticity, sufficient adhesion fastness, and excellent washability. The optimal weight per square meter of this kind of product is 25-50 grams per square meter. The yarn is made of micro-net polyester low elastic yarn 20-75D, and the air-jet or clean water-jet loom is used to weave according to the plain weave.

[0096] Specifically, for the production method of the woven plain elastic type printing composite material in this embodiment such as image 3 shown, including the following steps:

[0097] S301: Weaving and woven plain elastic base fabric.

[0098] The weaving process of this kind of woven plain elastic base fabric is as follows: select the middle mesh and micro mesh polyester DTY20D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com