Method for preparing synthetic forsterite from boron slurry

A technology for synthesizing forsterite and forsterite powder, which is applied in the direction of aluminum silicate and silicate, can solve the problems of unsatisfactory synthesis effect and high preparation cost, and achieve environmental and ecological pollution, less impurity content, and reduction of The effect of generating quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

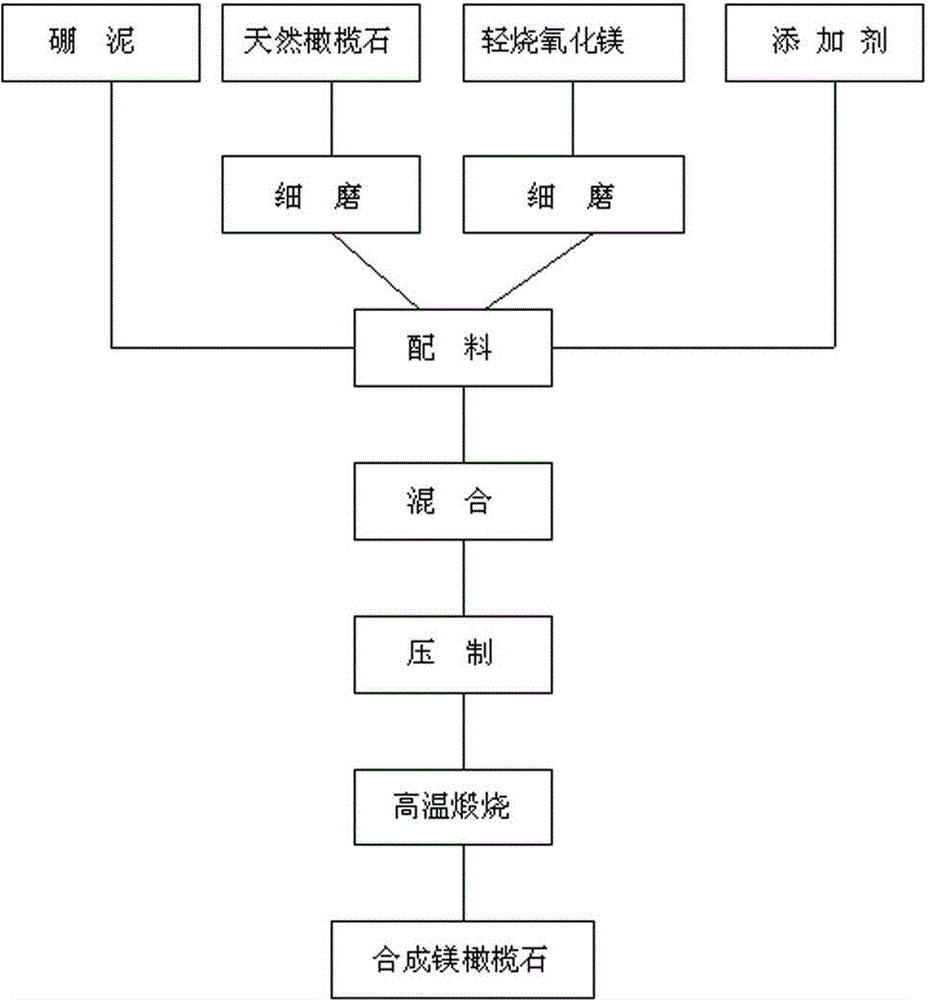

Method used

Image

Examples

Embodiment 1

[0028] The boron mud composition used contains SiO by weight percentage 2 28.79%, Fe 2 o 3 4.95%, Al 2 o 3 2.16%, CaO 2.09%, MgO 41.76%, B 2 o 3 1.22%, the balance is the loss on ignition and a small amount of impurities; the particle size is 100~200 mesh;

[0029] Grinding natural forsterite into fine powder of 150~240 mesh;

[0030] Grind the light-burned magnesia into a fine powder of 150-240 mesh;

[0031] Add the ground light-burned magnesia powder and natural forsterite powder into boron mud to make a mixed material, and the amount added is boron mud: natural forsterite powder: light-burned magnesia powder=1:0.2: 0.8;

[0032] Add binding agent magnesium chloride and mix uniformly in the mixed material, obtain combined material, the add-on of magnesium chloride is 2% of mixed material gross weight;

[0033] Add water to the combined material and mix evenly. The amount of water added is 15% of the total weight of the combined material, and then pressed into a ...

Embodiment 2

[0037] The composition of the boron mud used contains SiO by weight percentage 2 25.12%, Fe 2 o 3 5.78%, Al 2 o 3 3.97%, CaO 1.01%, MgO 44.65%, B 2 o 3 4.02%, the remainder is loss on ignition and a small amount of impurities; particle size is 100~200 mesh;

[0038] Grinding natural forsterite into fine powder of 150~240 mesh;

[0039] Grind the light-burned magnesia into a fine powder of 150-240 mesh;

[0040] The ground light-burned magnesia powder and natural forsterite powder are added to boron mud to make a mixed material, and the amount added is boron mud: natural forsterite powder: light-burned magnesia powder=1:0.16: 0.5;

[0041] Add binder magnesium chloride and mix uniformly in the mixed material, obtain combined material, the add-on of magnesium chloride is 1% of mixed material gross weight;

[0042] Add water to the combined material and mix evenly. The amount of water added is 14% of the total weight of the combined material, and then pressed into a sp...

Embodiment 3

[0046] The composition of the boron mud used contains SiO by weight percentage 2 29.45%, Fe 2 o 3 3.12%, Al 2 o 3 1.14%, CaO 2.84%, MgO 35.92%, B 2 o 3 4.61%, the balance is the loss of ignition components and a small amount of impurities; the particle size is 100~200 mesh;

[0047] Grinding natural forsterite into fine powder of 150~240 mesh;

[0048] Grind the light-burned magnesia into a fine powder of 150-240 mesh;

[0049] Add the finely ground light-burned magnesia powder and natural forsterite powder into boron mud to make a mixed material, and the amount added is boron mud: natural forsterite powder: light-burned magnesia powder=1:0.3: 0.7;

[0050] Add binding agent magnesium chloride and mix uniformly in the mixed material, obtain combined material, the add-on of magnesium chloride is 2% of mixed material gross weight;

[0051] Add water to the combined material and mix evenly. The amount of water added is 13% of the total weight of the combined material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com