Patents

Literature

59results about How to "Reduce the number of spawns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for reducing scales generated on surfaces of hot-rolled steel plates

InactiveCN101947557ALower the furnace temperatureReduce the number of spawnsTemperature control deviceWork treatment devicesChemical compositionSheet steel

The invention belongs to the technical field of hot-rolled strips and relates to a method for controlling the surface quality of hot-rolled steel plates, namely a preparation method for reducing scales generated on the surfaces of the hot-rolled steel plates. The chemical components of the steel in the method have wider application range and are especially suitable for the hot-rolled steel platescontaining such microalloying elements as Nb, V, Mn and Si. The hot-rolled steel plates have the following chemical components by weight: not less than 0.05% and not more than 0.20% of C, not more than 0.70% of Si, not less than 0.20% and not more than 2.00% of Mn, not less than 0.02% and not more than 0.10% of Nb, not less than 0.03% and not more than 0.15% of V, not more than 0.12% of Ti, not more than 0.040% of P, not more than 0.030% of S and the balance Fe and inevitable impurities. The control method dispenses with improvement of existing equipment, is simple and controllable in processconditions, realizes the aim of reducing the scales by controlling the slab tapping temperature, the finish rolling, initial rolling and final rolling temperature, the coiling temperature and the cooling method and has the advantages of low energy consumption, low cost and wide applicable scope.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Dry type working liner material for erosion resistance continuous casting tundish

InactiveCN1800105AImprove high temperature strength and slag erosion resistanceExtended service lifeTundishOxide

The invention relates to an amorphous refractory; especially to an erosion resistance concast intermedium finish-go-home work sark. It uses magnetite as main raw material and the light-burned magnesium oxide, boric acid, silicon powder and aluminum powder as accelerator and the resin, starch gum and so on as insurance contract. It adds one or some kinds of chrome green, compound chrome-magnesite brick, magnesite-chrome brick. The raw material is that (wt%): the magnesite 5-1mm is 10-35%, 1-0.2mm is 10-35%, <=0.074mm is 20-40%, <=0.088mm admixture is 5-20%, <=0.088mm accelerator is 1-5%, starch gum is 5-12%. Each raw material has a certain quality technology index.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hot rolled steel plate surface oxidation iron sheet control method for vanadium-containing automobile beam

InactiveCN101147920AImprove toughnessImprove stamping formabilityTemperature control deviceSurface oxidationImpurity

The present invention discloses a surface scale control method of hot-rolled steel plate for vanadium-bearing automobile frame. It is characterized by that the mass percentage of molten steel chemical components of raw material steel of said method is as follows: C is 0.06%-0.12%, Si is less than or equal to 0.30%, Mn is 1.05%-1.25%, V is 0.04%-0.10%, P is less than or equal to 0.025%, S is less than or equal to 0.015% and the rest is Fe and other impurity. Its slab drop-out temperature is controlled at 1200deg.C-1230deg.C, initial temperature of rough rolling is controlled at 940deg.C-1020deg.C and its final rolling temperature range, is 840deg.C-880deg.C.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

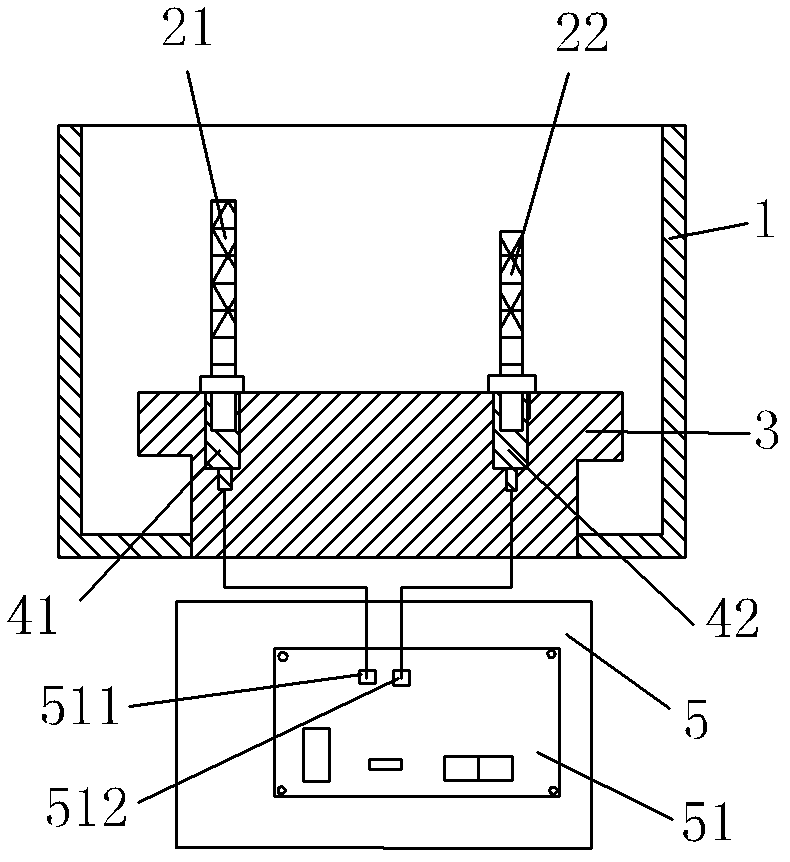

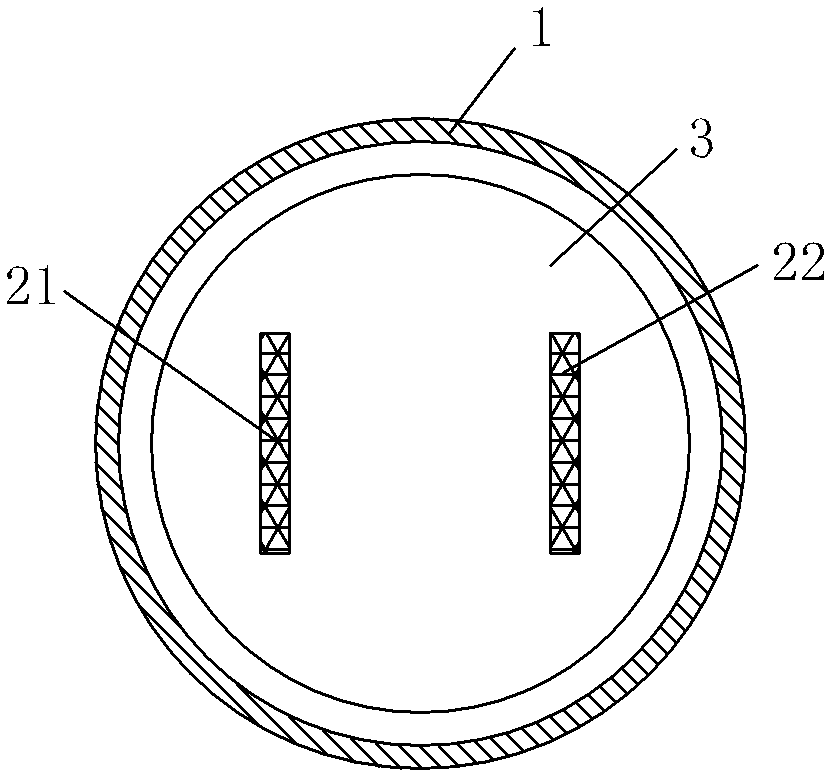

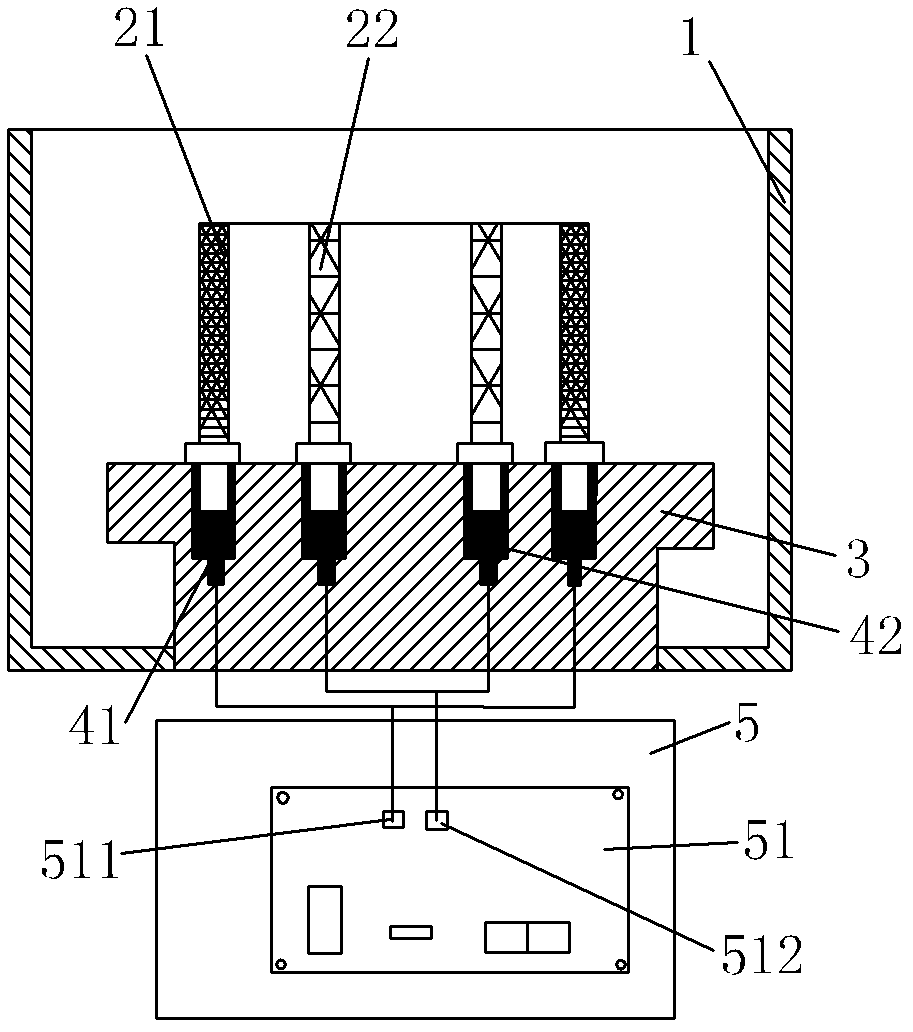

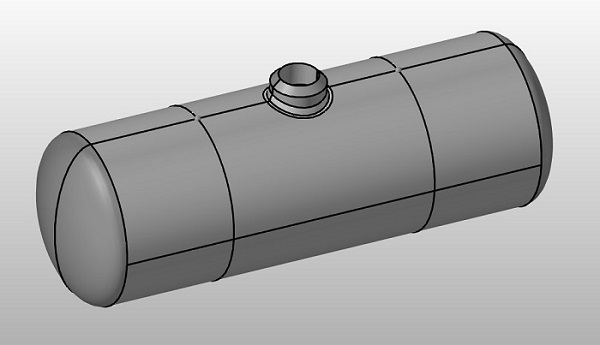

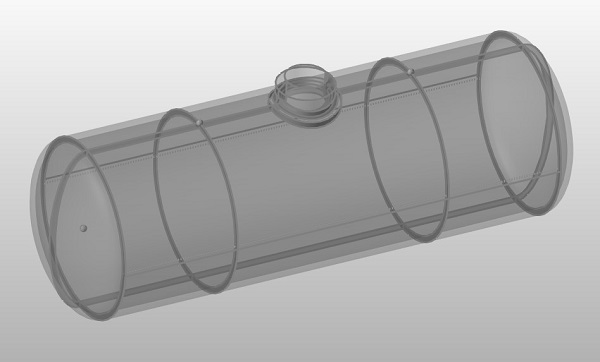

Device for manufacturing hydrogen water

The invention relates to a device for manufacturing hydrogen water, which comprises a container, at least one cathode electrode plate, at least one anode electrode plate and a host machine, wherein the container is made of electrical insulating material, the cathode electrode plate and the anode electrode plate are arranged at intervals in the container, the host machine comprises a circuit control panel, the cathode electrode plate is connected with an input end of the circuit control panel, the anode electrode plate is connected with an output end of the circuit control panel, and the electrolysis area of the cathode electrode plate is larger than the electrolysis area of the anode electrode plate. The device disclosed by the invention can be used for electrolyzing water and a solution containing water to form the hydrogen water of which the PH value is neutral.

Owner:山东真露生物科技有限公司

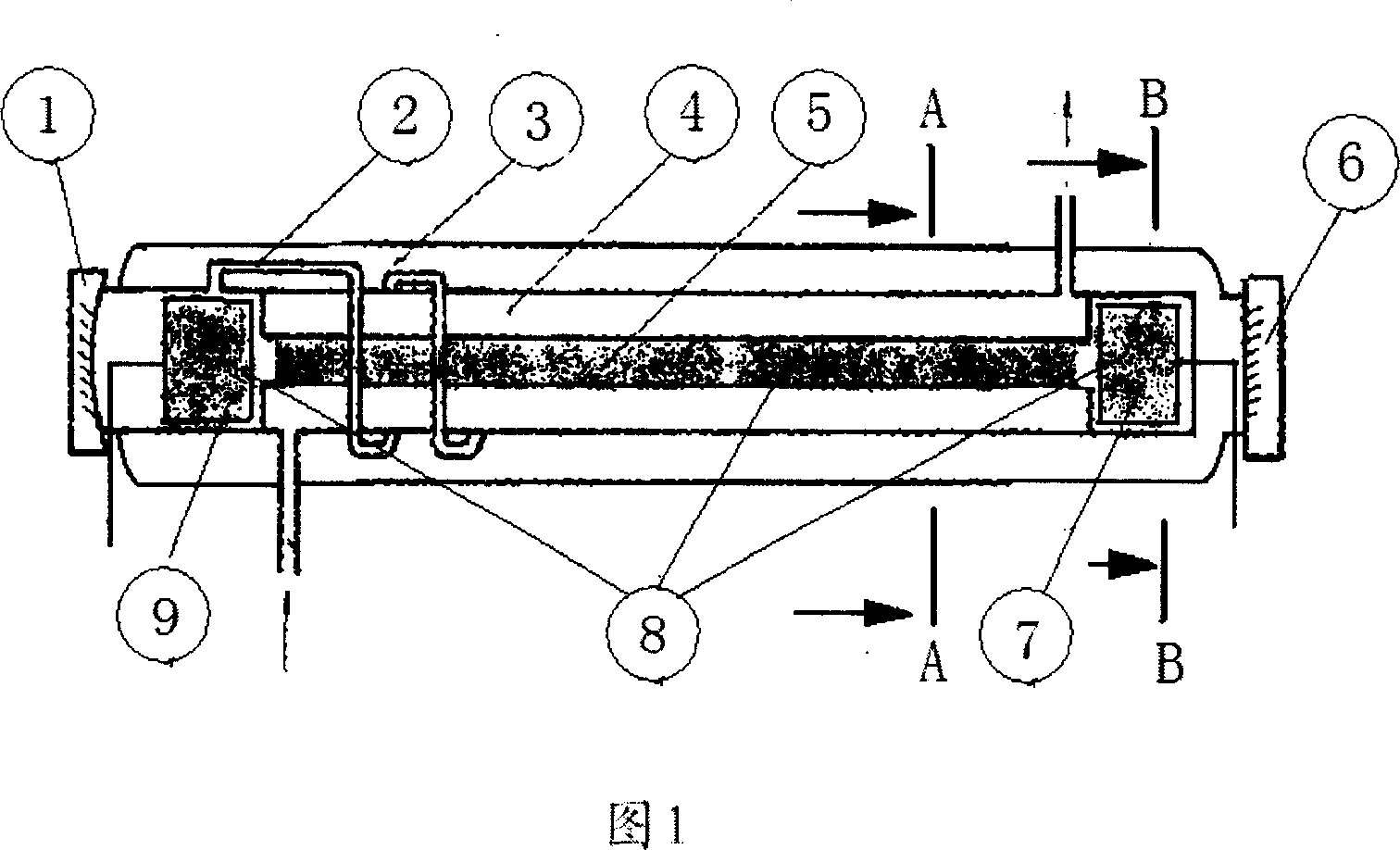

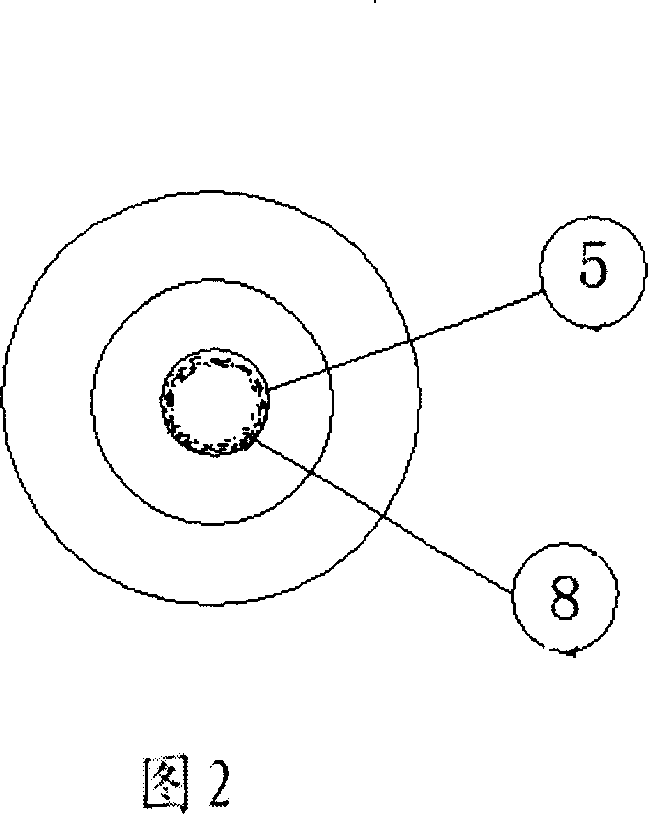

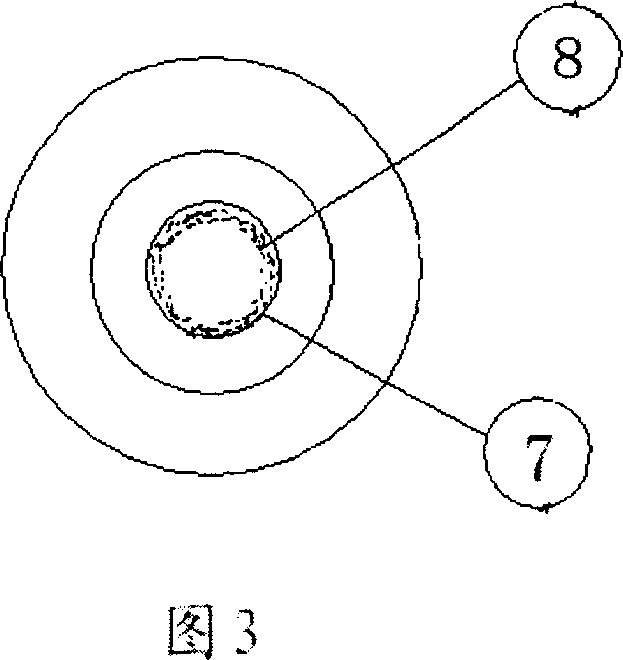

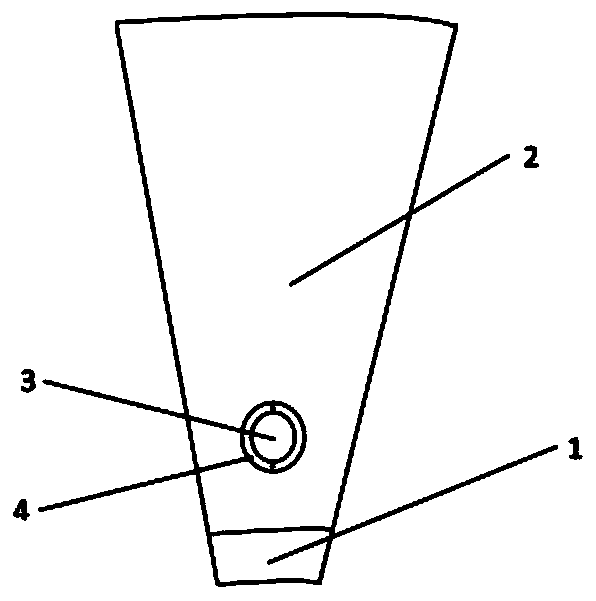

Photocatalytic sealed CO2 laser tube

InactiveCN101060226ARestore concentrationOvercoming activation energyGas laser constructional detailsEpoxyEngineering

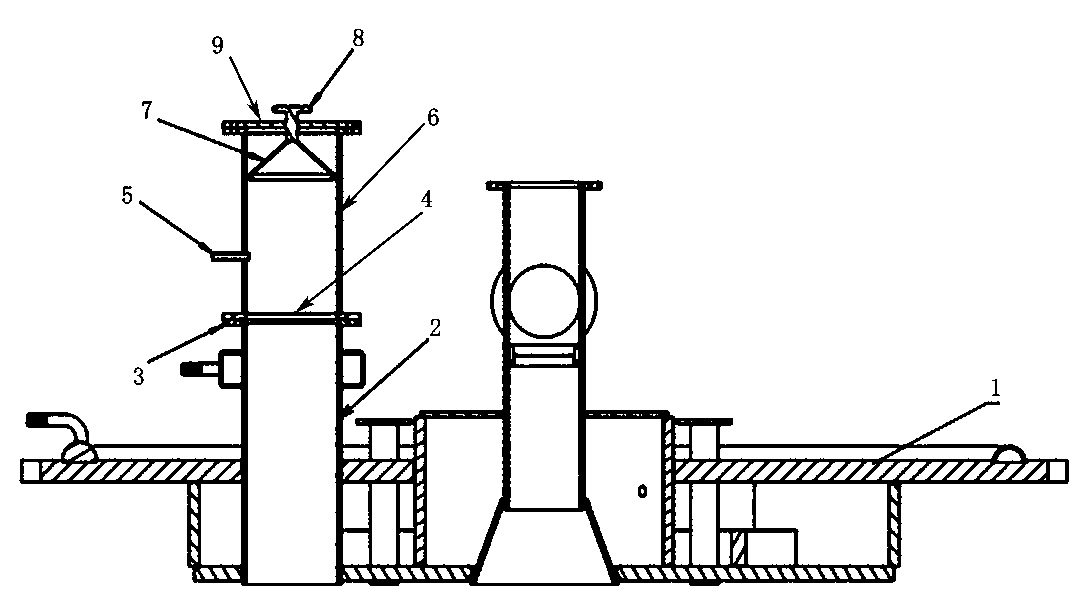

The related sealing-type CO2 laser tube comprises: a metal-plated full reflection mirror 1, a muffler 2 set in tube 4 to connect sheath 3 and tube 5, a gas storage sheath 3, a water cooling tube 4 set on top of a discharge tube 5 together in sheath 3, an output mirror 6 together with mirror 1 bonded on ends of laser tube ends by epoxy resin, the TiO2 photo catalyst 8 coated on inner wall of tube 5 and electrodes 7 / 9, and two electrodes 7 / 9 coaxial arranged on ends of tube 5. This invention is simple and convenient, prolongs product life time, reduces cost, and has well social and economic benefits.

Owner:王向阳

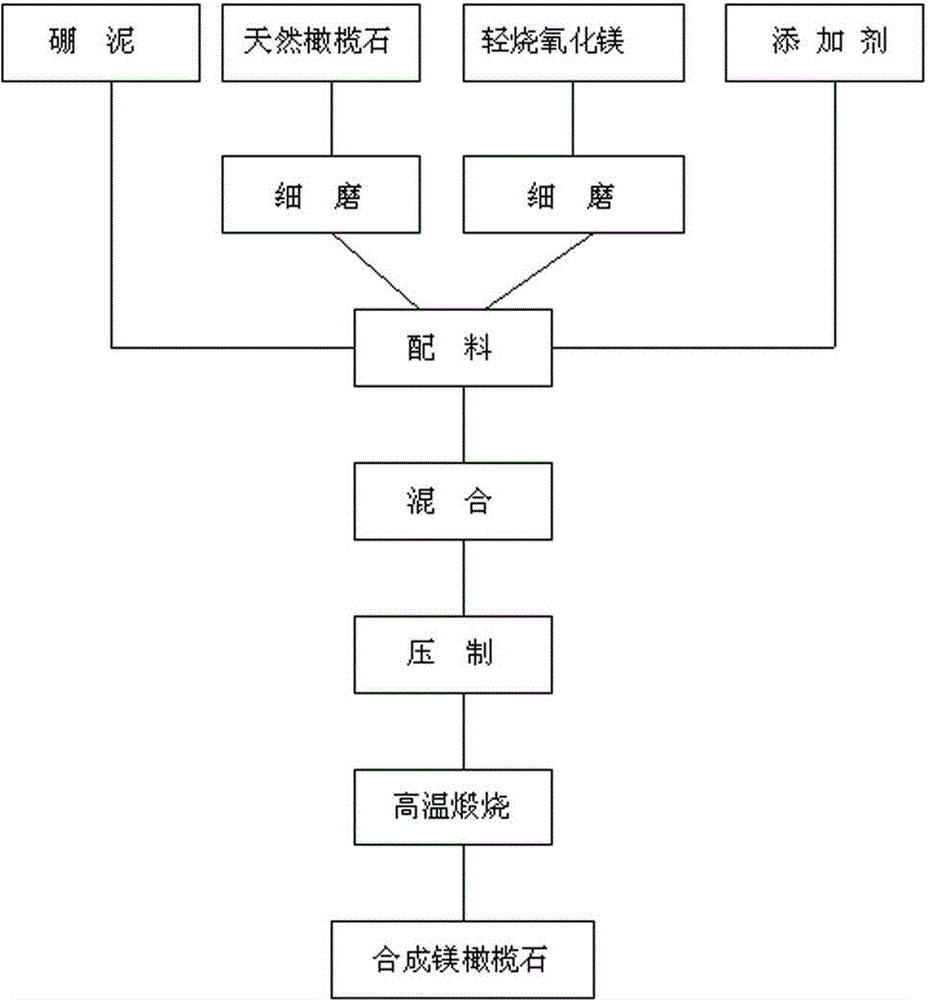

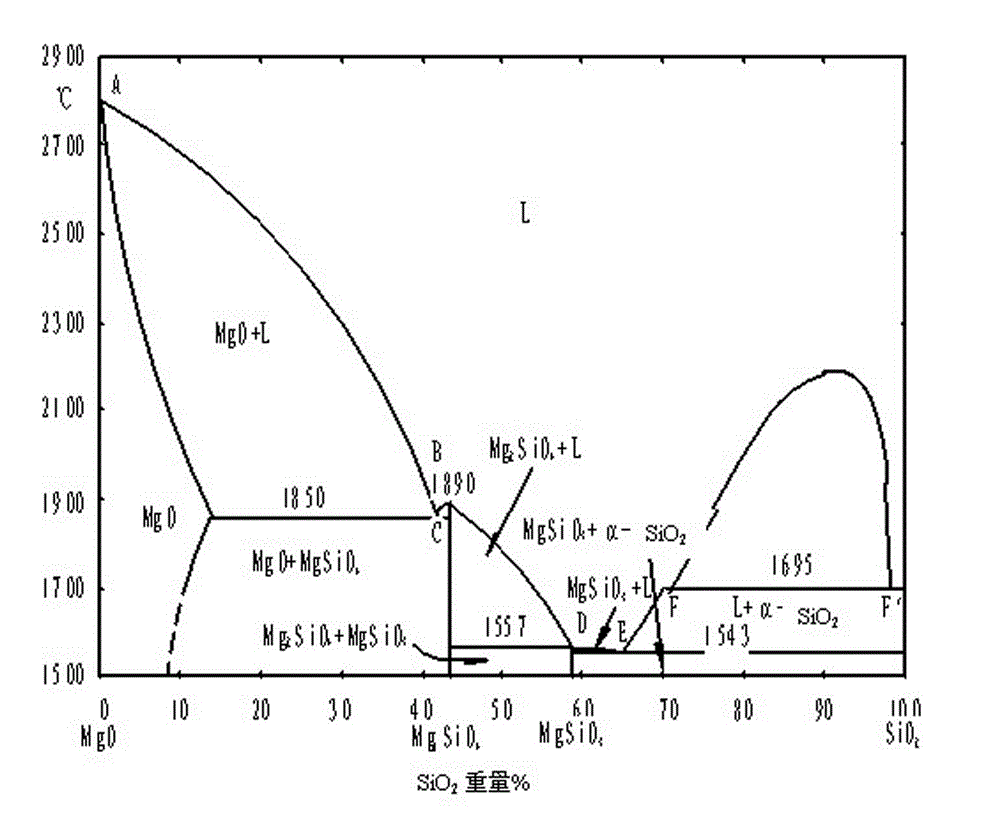

Method for preparing synthetic forsterite from boron slurry

InactiveCN102745701AAvoid pollutionReduce the number of spawnsAluminium silicatesEcological environmentMixed materials

The invention discloses a method for preparing synthetic forsterite from boron slurry. The method comprises the following steps of 1, adding lightly roasted magnesia powder and natural forsterite powder into boron slurry to obtain a mixed material, 2, adding a binder into the mixed material and mixing uniformly to obtain a bound material, 3, adding water into the bound material, mixing uniformly, pressing the mixture into globular materials by a ball press, and standing for maintenance, and 4, mixing the maintained globular materials and coal, putting the mixture into a high-temperature vertical kiln, heating to a temperature of 1550 to 1650 DEG C, and carrying out heat preservation for 3 to 4 hours to obtain the synthetic forsterite. The method has simple and reliable processes and solves the problem of the pollution produced by boron slurry on the ecological environment. The synthetic forsterite prepared by the method contains more than 60% of magnesium oxide.

Owner:聂旺发

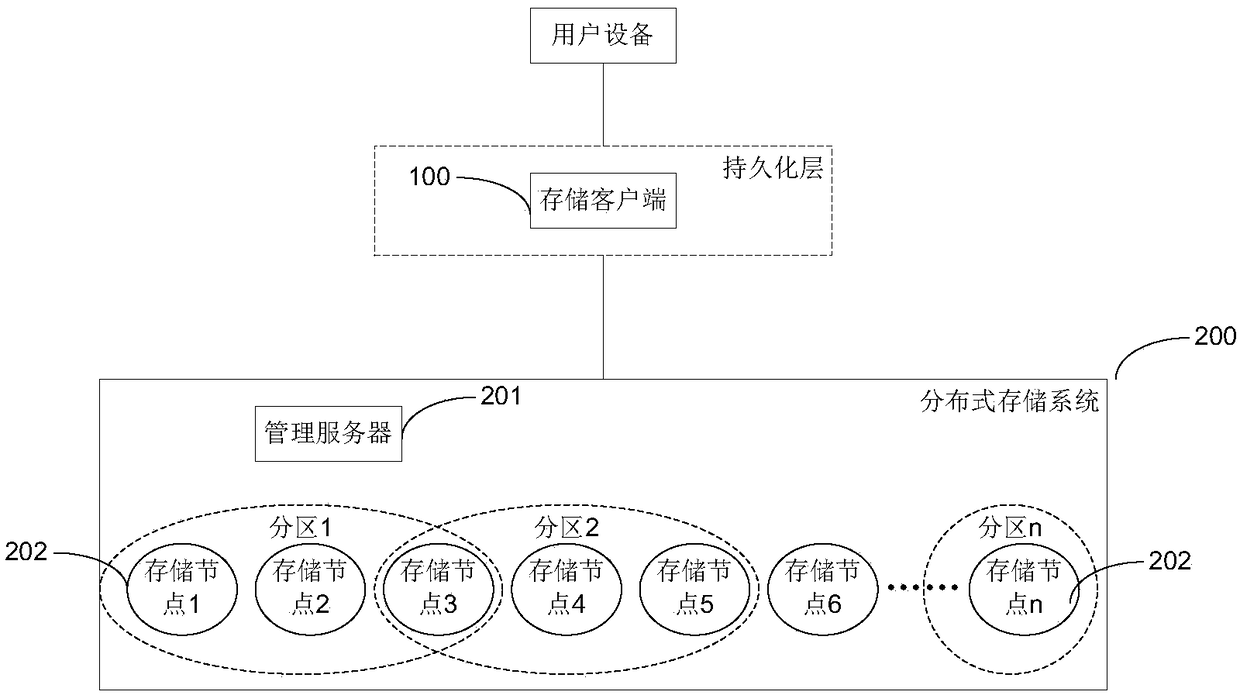

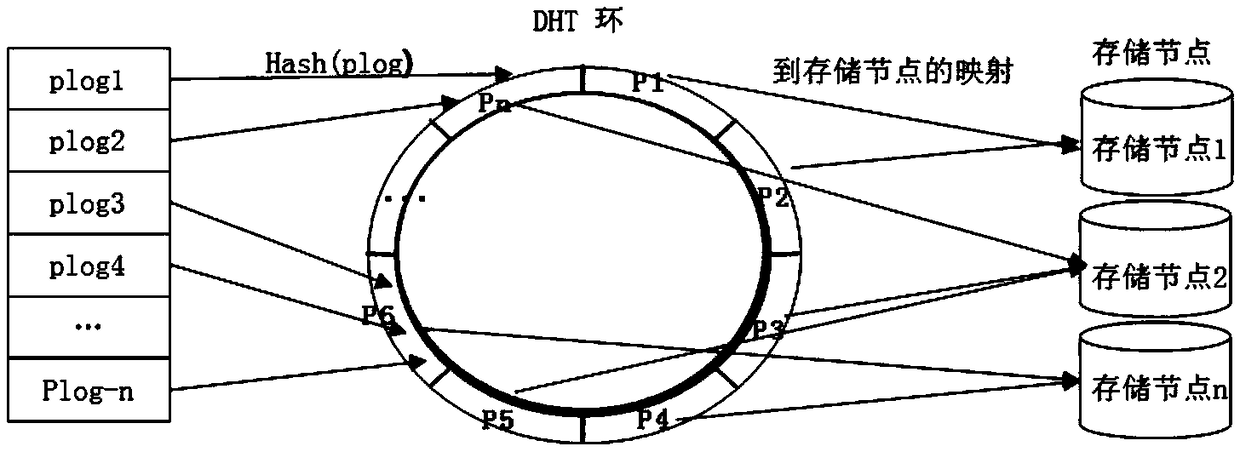

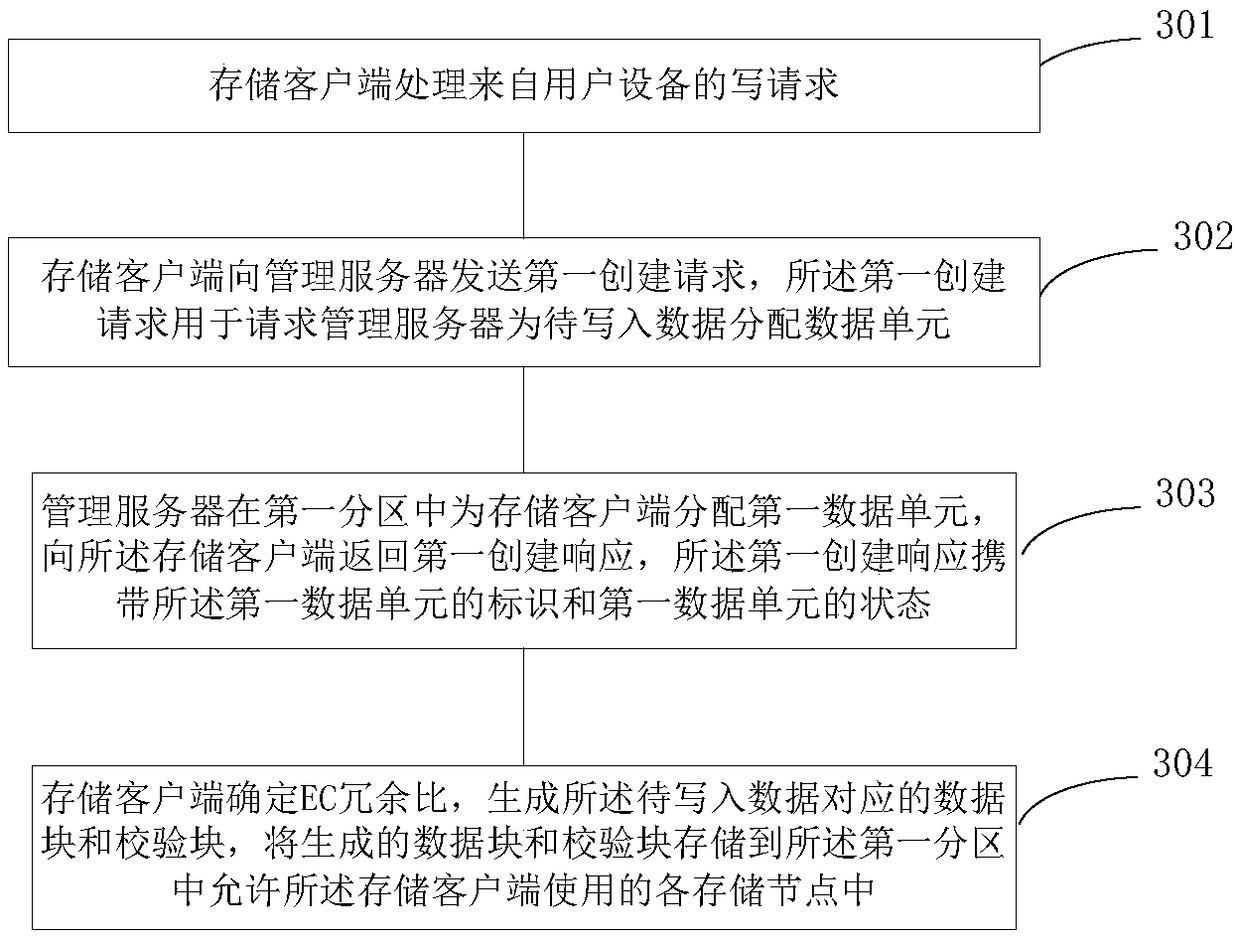

Data storage method, device and system

ActiveCN108780386ARealize dynamic adjustmentReduce the number of spawnsInput/output to record carriersProgram controlEngineeringDistributed memory systems

The invention provides a data storage method, device and system. A storage client needs to store data to be written into a distributed storage system. Storage nodes corresponding to a first data unitallocated by a management server for the data to be written are only a part of a storage node group. When the state of the first data unit returned by the management server is received by the storageclient, the numbers of data blocks and check blocks to be generated when EC encoding is performed on the data to be written can be determined, the storage client stores the generated data block and check block in the partial storage nodes designated by the management server in a partition in which the first data unit is located. Thus, dynamic adjustment of the EC redundancy ratio is realized, andthe management server can exclude nodes in the partition from the range of data storage to be written according to the needs, thereby reducing the IO amount of data storage.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

Rendering program online optimization method

ActiveCN105976421AReduce the number of spawnsReduce the number3D-image renderingComputational scienceErrors and residuals

The invention discloses a rendering program online optimization method comprising the following steps: building reduced programs of an original rendering program, selecting a plurality of reduced rendering programs as representative rendering programs according to the rendering cost and drawing error, and building a reduced dependency graph based on the dependence relationship; and in the rendering process, monitoring the parameters of a scene to be drawn, using a new round of online optimization when there is severe change, and completing one optimization through multiple cycles. The following operations are performed cyclically in each optimization: selecting K reduced programs from all the reduced programs as candidate reduced programs according to the reduced dependency graph, determining the current cycling result according to the drawing error and rendering cost, and deciding whether the current online optimization ends according to a plurality of cycling results. Optimal reduced rendering programs are selected dynamically, decoupling of rendering programs from a scene is realized, and the enumeration parameter space problem of off-line optimization is avoided. Moreover, rendering program error calculation and time measurement and scene drawing are carried out at the same time, operation is quick, and the real-time performance is strong.

Owner:ZHEJIANG UNIV

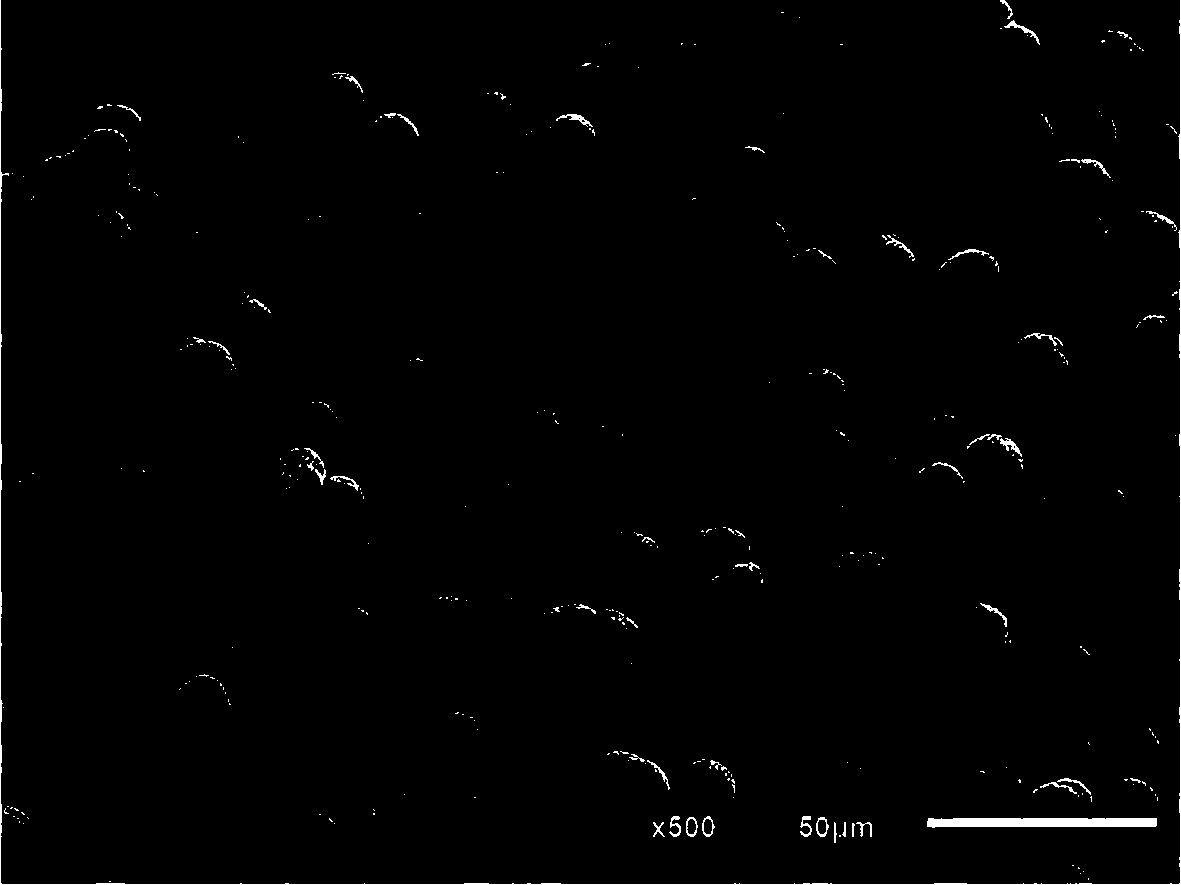

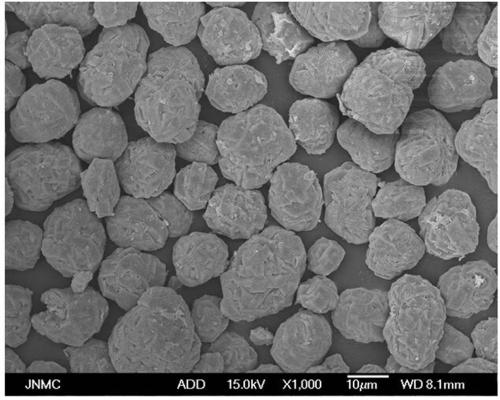

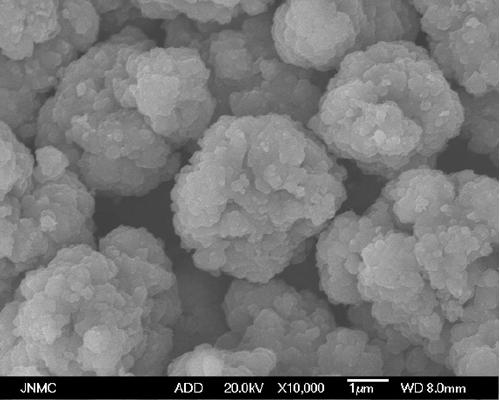

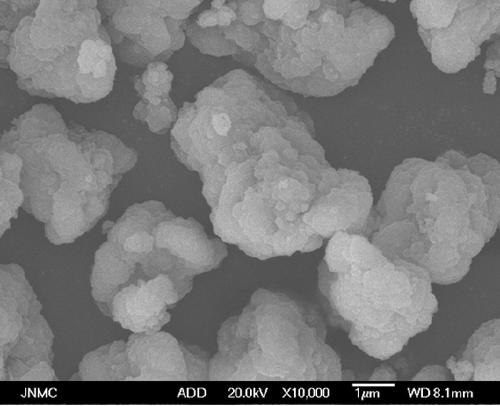

Preparation method of large-granularity cobaltosic oxide

InactiveCN108483512AAvoid excessive impuritiesCalcination equipment requirements are simpleCobalt oxides/hydroxidesCobalt oxideAmmonium hydroxide

The invention discloses a preparation method of large-granularity cobaltosic oxide. The preparation method is characterized by synthesizing cobalt carbonate of which the granularity is 20 to 30 mu m in a wet process in a shortest time through the ways of reducing nucleation number during a synthesis initial stage by taking a cobalt solution in certain concentration as a cobalt source, a sodium carbonate solution as a precipitator, an ammonia solution as a complexing agent and hydrazine hydrate as a reducing agent; oxidizing a synthetic product into hydroxyl cobalt oxide under a certain pH (Potential of Hydrogen) value condition after completing the synthesis by utilizing a hydrogen peroxide solution in certain concentration, then washing and drying a mixture, and calcining under a certaincondition, thus obtaining a large-granularity cobaltosic oxide product. By utilizing the technology, the spherical or spherical-like large-granularity cobaltosic oxide product of which the laser granularity is 15 to 25 mu m, the tap density is greater than 2.0 g / cm<3> and the specific surface area is 1.0 to 3.0 m<2> / g can be prepared within a short time.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

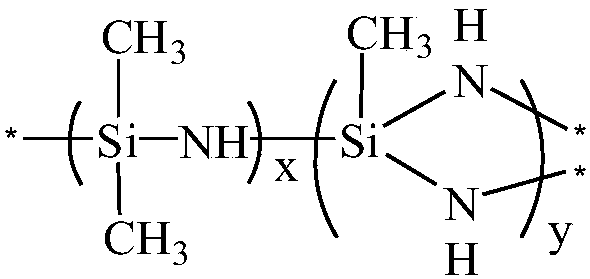

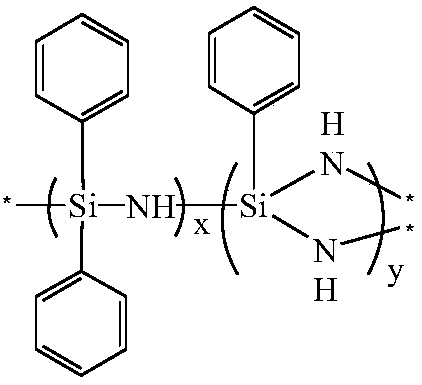

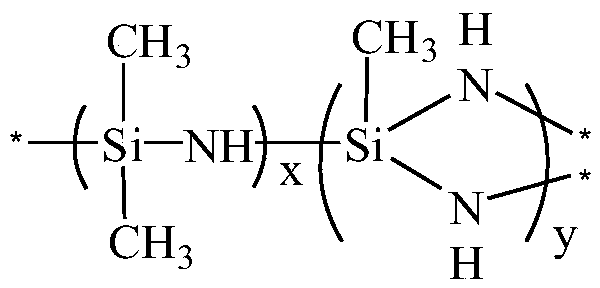

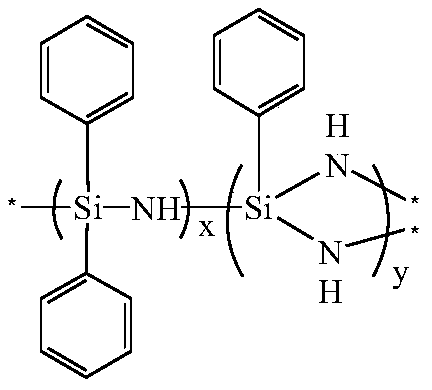

Room temperature curing agent for high-temperature-resistant organosilicon materials, preparation method and applications thereof

The invention provides a room temperature curing agent for high-temperature-resistant organosilicon materials, a preparation method and applications thereof. The room temperature curing agent comprises polysilazane and a catalyst, wherein the molecular structure of the polysilazane is optimized, and only contains difunctional Si-N chain segments and trifunctional Si-N chain segments, and the random branched structure is formed by a polymerization reaction; by adjusting the feeding ratio, pressurizing during the aminolysis and using ceramic ball-assisted mass transfer, the use amounts of the trifunctional silane and the ammonia gas for forming the trifunctional Si-N chain segment with the same content are substantially reduced, the molecular structure of the polysilazane is optimized, the generation of ammonium chloride is reduced, and the mass transfer and heat transfer control during the aminolysis is easily achieved; and the optimization does not affect the formation of the cross-linked network of the cured organosilicon material, and the structure optimizing meets the development trend of green chemistry.

Owner:INST OF CHEM CHINESE ACAD OF SCI

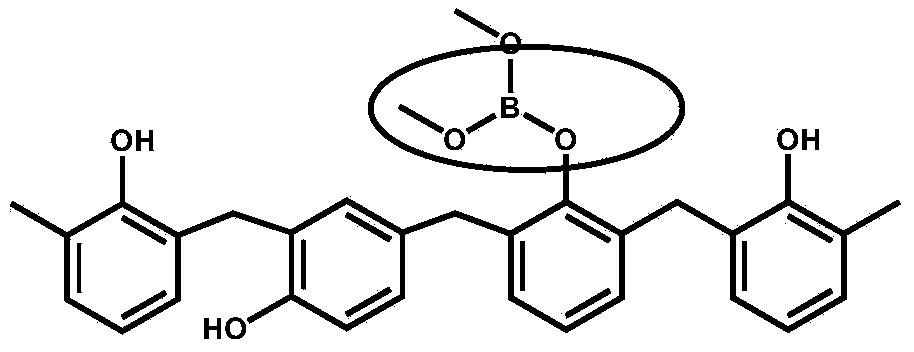

Technique for synthesizing boron-containing thermoplastic phenol formaldehyde resin by solvothermal process

The invention relates to a technique for synthesizing a boron-containing thermoplastic phenol formaldehyde resin by a solvothermal process, which comprises the following steps: adding a thermoplastic phenol formaldehyde resin, a boron-containing compound, oxalic acid and a solvent into a solvothermal reaction kettle, sealing, heating to 120-160 DEG C, keeping the temperature for 0.5-6 hours, cooling to room temperature, and removing the solvent contained in the product, thereby obtaining the boron-containing thermoplastic phenol formaldehyde resin, wherein the boron-containing compound uses an aromatic ring structure as the parent nucleus and hydroxymethyl and boron-containing structure as the substituent group of the aromatic ring structure, and the solvent is water or an alcohol solvent or a mixture of an alcohol solvent and water in a mass ratio of 1:(0.05-0.7). The method has the advantages of high raw material conversion rate and simple technical process; and the obtained product has the advantages of uniform molecular weight distribution and favorable heat resistance. Since the conversion rate of various raw materials is higher, the residual micromolecules do not need to be removed by water washing, thereby effectively reducing the sewage discharge.

Owner:XI AN JIAOTONG UNIV +1

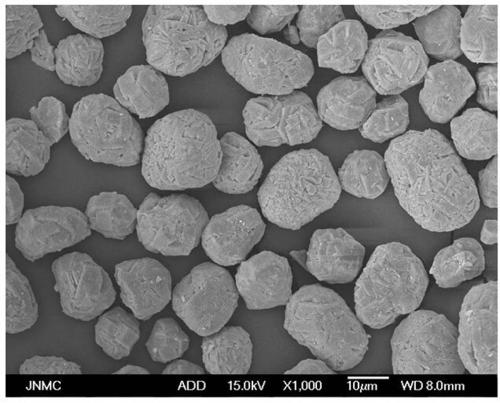

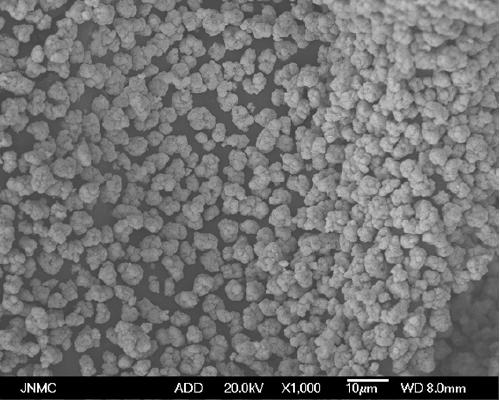

Preparation method of rare earth element-doped cobaltosic oxide

ActiveCN110002514ACrystal denseEvenly dispersedCobalt oxides/hydroxidesRare-earth elementLiquid ratio

The invention discloses a preparation method of rare earth element-doped cobaltosic oxide. The method comprises the following steps: rear earth element is added into a cobalt solution; with the extension of synthetic time, concentration gradient of the cobalt solution added to a reaction kettle increases or decreases; simultaneously, solid-to-liquid ratio of slurry in the reaction kettle is adjusted, and cobalt hydroxide with uniform doping is synthesized by a wet method; after the synthesis, the synthetic product is washed, dried and calcined to obtain a large granular or small granular rareearth element-doped cobaltosic oxide product.

Owner:JINCHUAN GROUP LIMITED +1

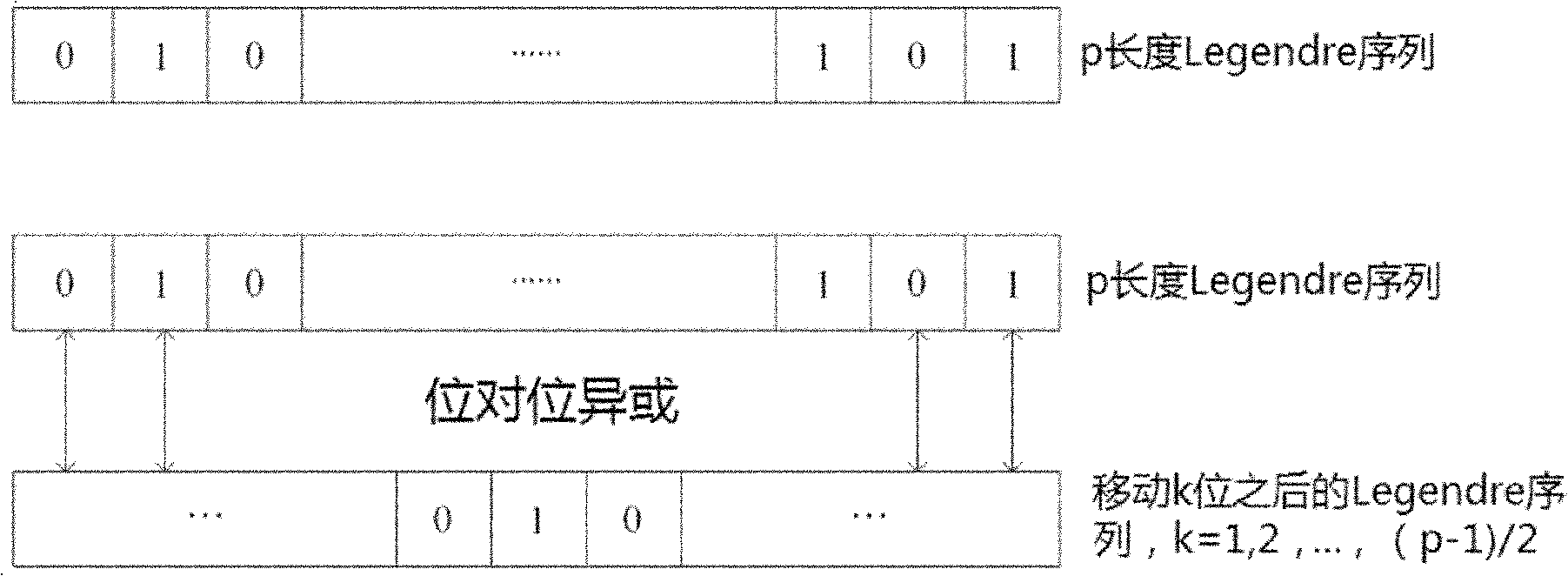

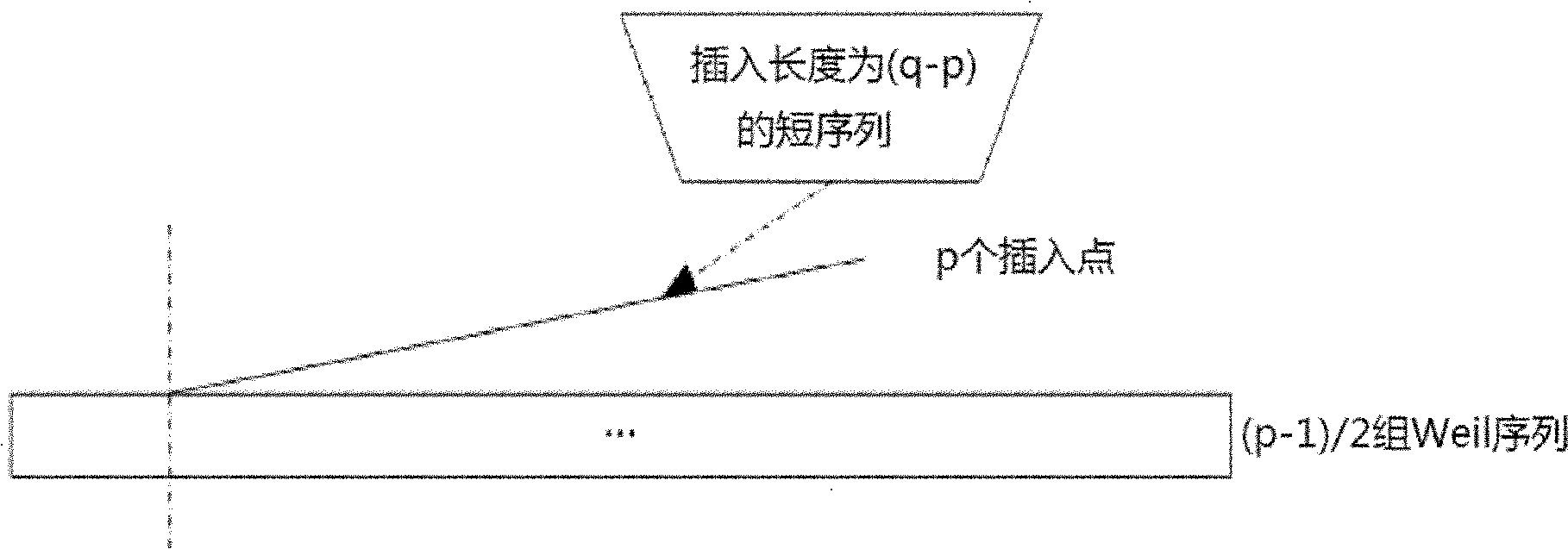

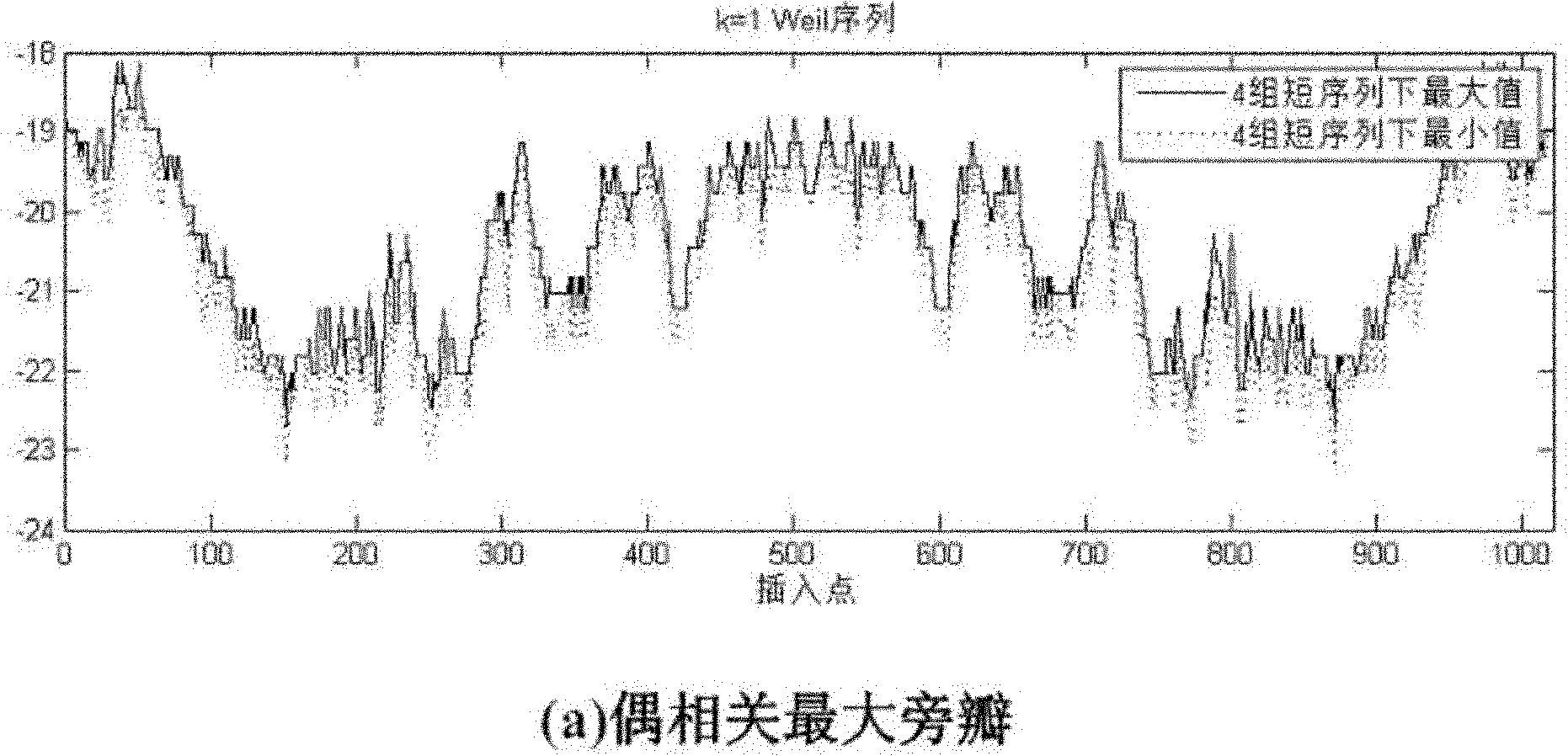

Method for generating spread spectrum code in satellite navigation system

InactiveCN101969353AQuick fixReduce the number of spawnsCode division multiplexSatellite radio beaconingInformation processingTelecommunications

The invention provides a method for generating a spread spectrum code in a satellite navigation system in the technical field of information processing. In the method, a spread spectrum code is subject to Legendre sequence generation processing and Weil sequence generation processing to acquire a spread spectrum code sequence, and the spread spectrum code sequence is subject to judgment of even cross-correlation and odd cross-correlation to acquire a required spread spectrum sequence. Based on the Weil sequence generation spread spectrum code, the method realizes the requirement of the satellite navigation system to the spread spectrum code, and has the advantages of great number of generation code sequences and good cross-correlation character of the sequence.

Owner:SHANGHAI JIAO TONG UNIV

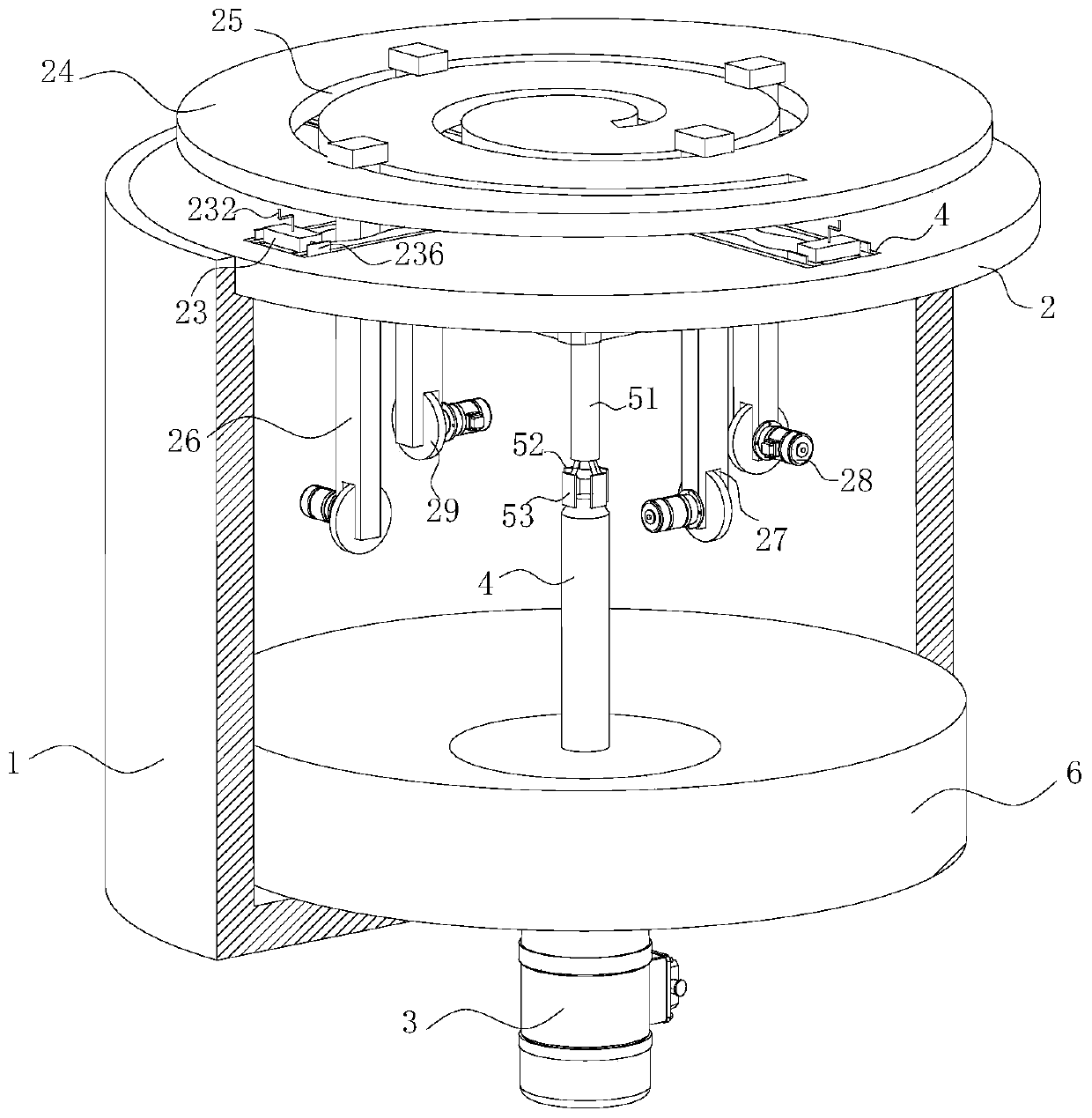

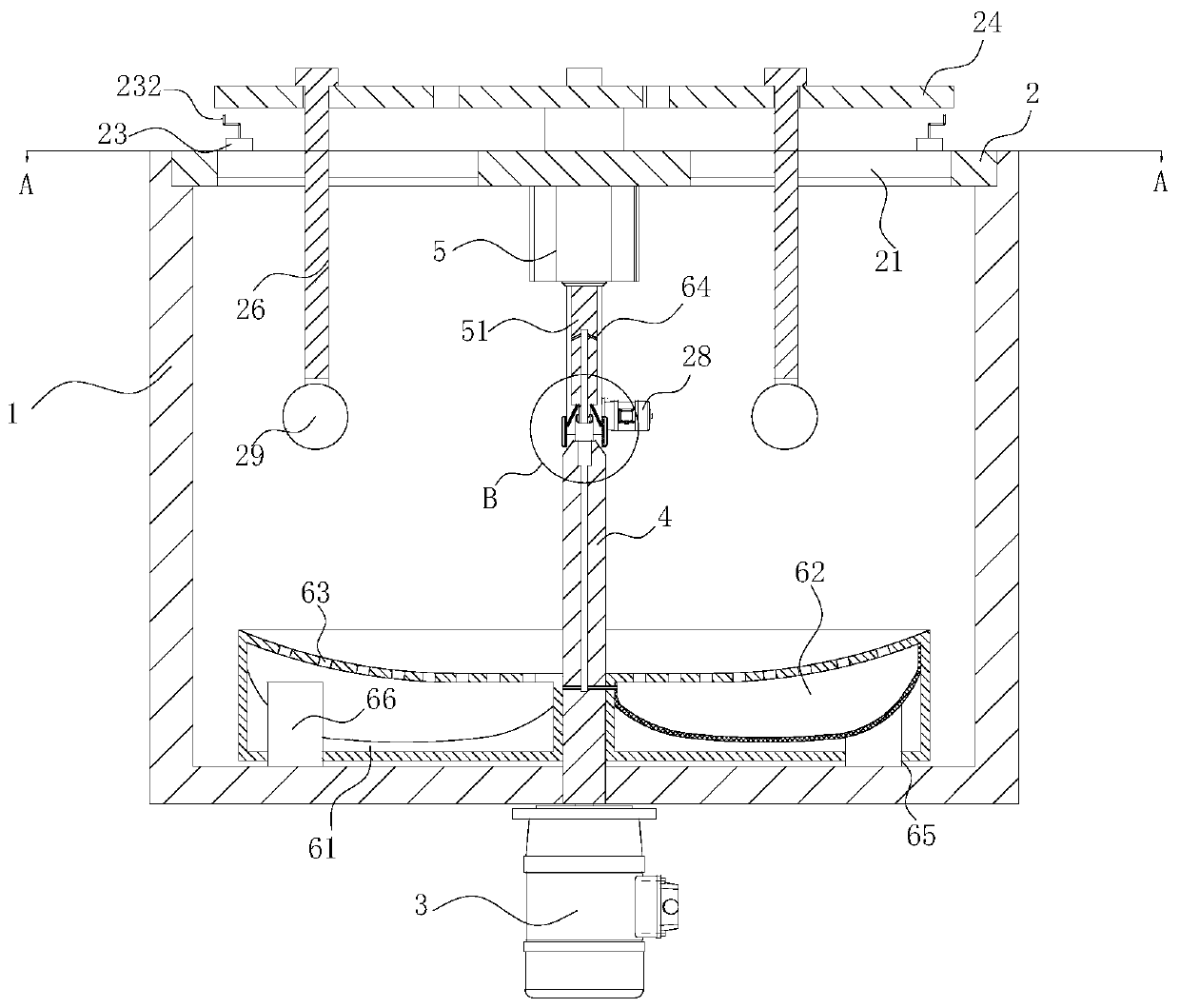

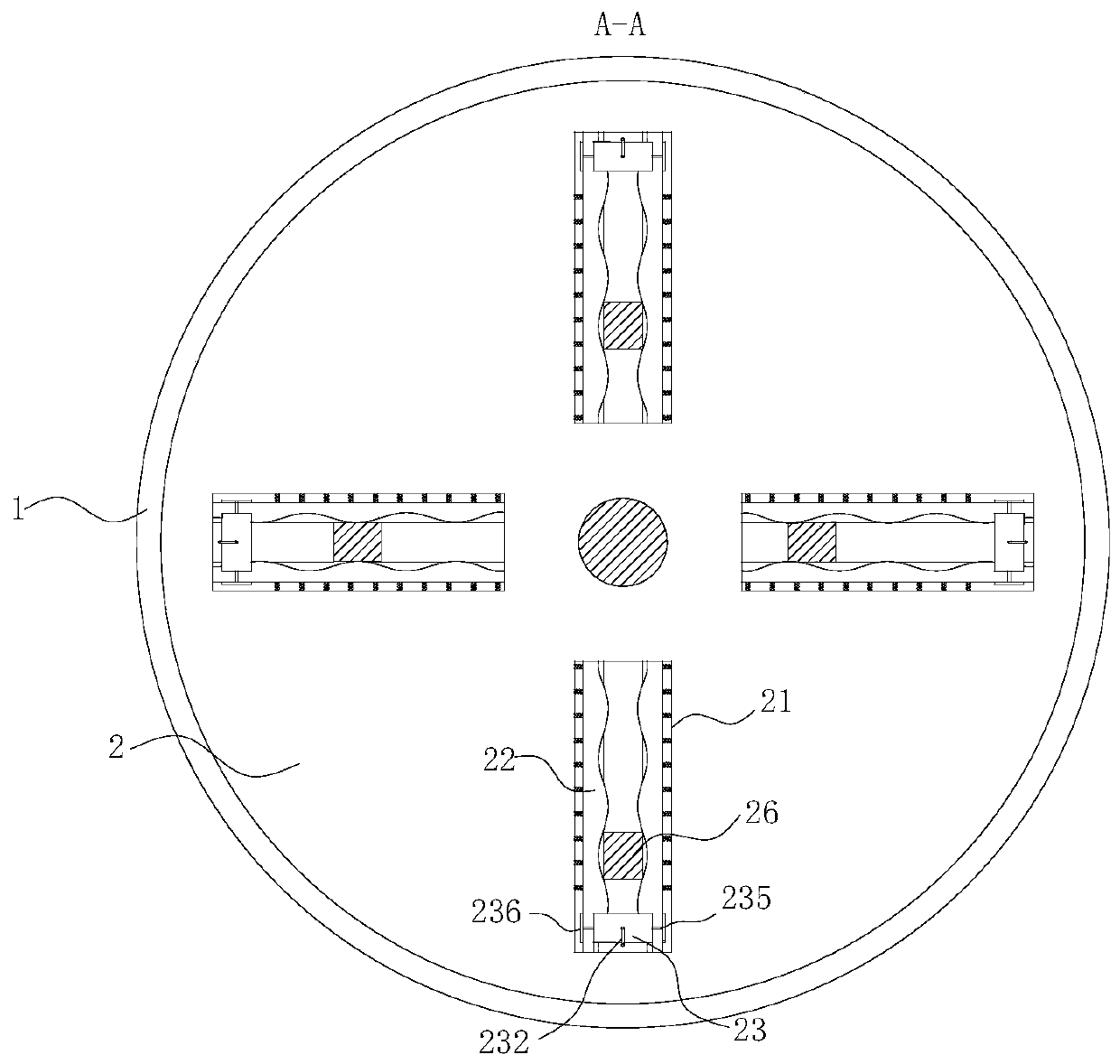

Multi-station numerical control lathe

ActiveCN110976919AReduce outputReduce instantaneous frictional heatAutomatic/semiautomatic turning machinesAuxillary equipmentNumerical controlRotational axis

The invention belongs to the technical field of numerical control lathes, and particularly relates to a multi-station numerical control lathe. The multi-station numerical control lathe comprises a shell, a fixed cover and a first motor. The first motor is mounted below the shell, and a first motor rotating shaft penetrates through the shell. The portion, in a shell inner cavity, of the first motorrotating shaft is fixedly connected with a support shaft. The maximum ends of first sliding grooves are elastically connected with wave plates through springs. Fixing blocks are mounted in the firstsliding grooves correspondingly. The portion, located in fixing block inner cavities, of the rotating shaft is fixedly connected with a rotating disc. Two hinge rods are hinged to the rotating disc. Asliding rod is hinged to the other end of each hinged rod, and the sliding rods penetrate through the fixing blocks in design. The ends, located at the outer sides of the fixing blocks, of the sliding rods are fixedly connected with fixing plates. According to the multi-station numerical control lathe, by arranging the fixing blocks, the wave plates and limiting grooves, moving rods can be defined from multiple aspects, so that processing wheels can accurately and rapidly cut the surface of a workpiece to be machined, and the arrangement of the four processing wheels greatly improves the working efficiency.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

Material for preventing diaper dermatitis and production method thereof

ActiveCN102512705BRelieve symptomsReduce the number of spawnsAbsorbent padsBandagesParticle compositionDiaper Dermatitis

The invention relates to a material for preventing diaper dermatitis and a production method thereof. The material for preventing diaper dermatitis is a composite rolled material with a sandwich structure; a granular composition for preventing and treating diaper dermatitis is clamped in a composite layer; and the composite rolled material is formed by performing hot-press composition by a hot roller and slitting. The invention has the characteristics that the material can prevent diaper dermatitis, and is not allergic, stable, continuous and effective and is convenient to use; and the material is applied to baby diapers.

Owner:中健生命科技(深圳)有限公司

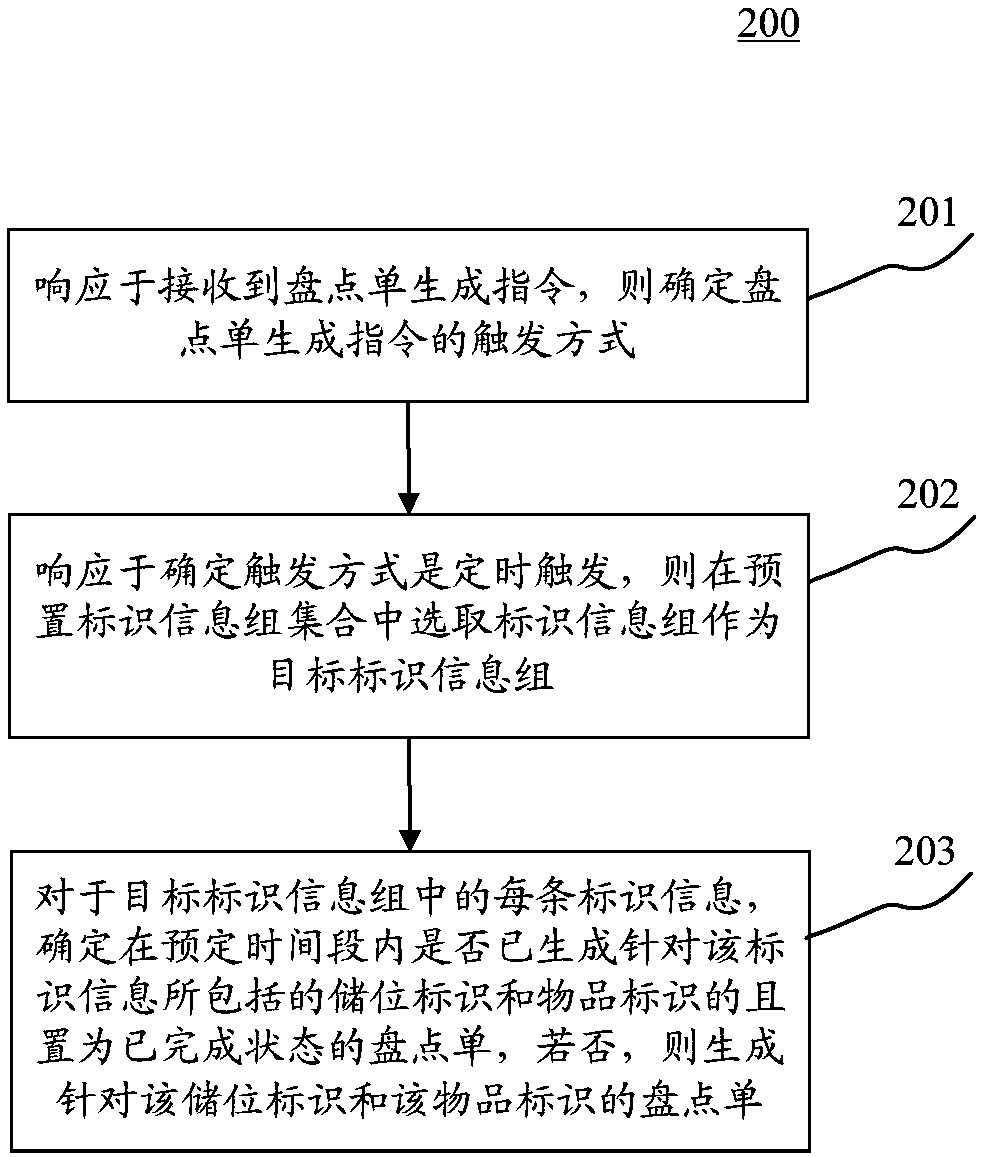

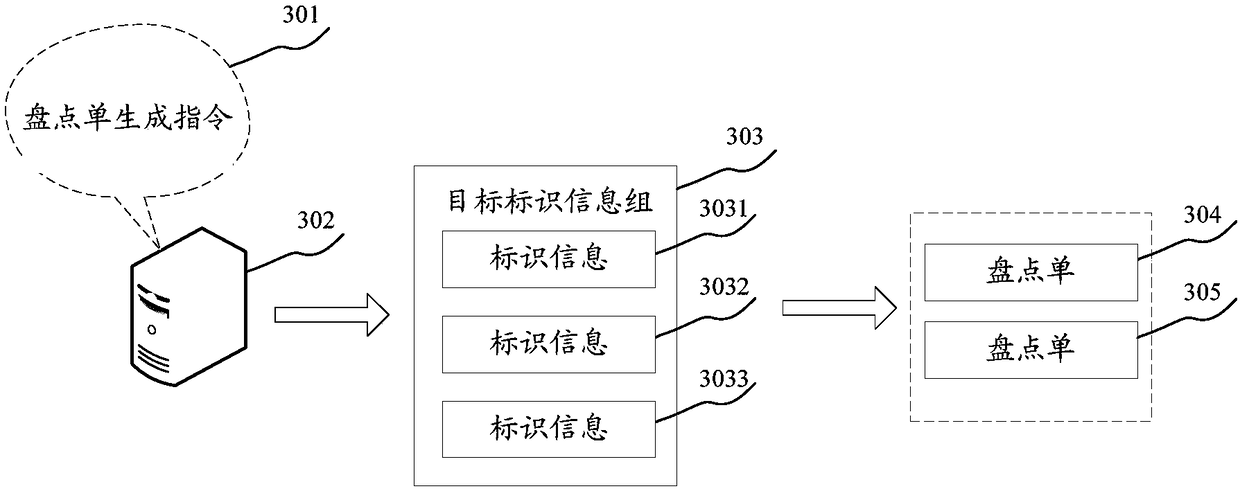

Inventory list generation method and device

ActiveCN108985673ARealize generationReduce the number of spawnsLogisticsCompletion StatusWorld Wide Web

The invention discloses an inventory list generation method and device. One embodiment of the invention comprises a step of determining a trigger mode of an inventory list generation instruction in response to the reception of the inventory list generation instruction, a step of selecting an identifier information group in a preset identifier information group set as a target identifier information group in response to a condition that the trigger mode is determined to be timing trigger, wherein each piece of identifier information in the identifier information group comprises a storage location identifier and an item identifier for each identifier information group in the preset identifier information group set, and a step of determining whether an inventory list which comprises the storage location identifier and the item identifier and is in a completion state is generated or not in a predetermined time period for each piece of identifier information in the target identifier information group, and generating an inventory list for the storage location identifier and the item identifier if not. According to the embodiment of the invention, the generation of a targeted inventory list is achieved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

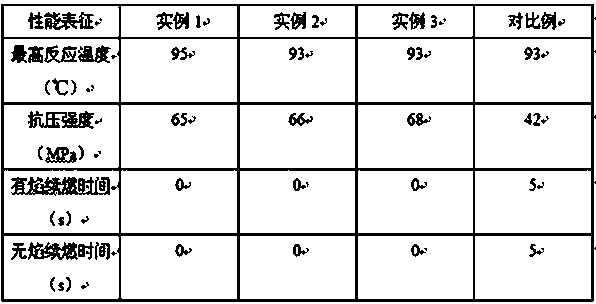

Preparation method of mining reinforcement material

InactiveCN109971159AExcellent flame retardantIncrease surface areaIn situ polymerizationLayered structure

The invention relates to a preparation method of a mining reinforcement material, and belongs to the technical field of mining materials. The preparation method of the mining reinforcement material ischaracterized in that based on the flame retardance characteristic of ammonium polyphosphate, with diatomite as a carrier, a double-component ammonium polyphosphate-diatomite inorganic composite flame-retardant filler is prepared by an in-situ polymerization method, and an ammonium polyphosphate-diatomite / synergist composite flame-retardant filler is designed on the basis of the double-componentcomposite flame-retardant filler with magnesium hydroxide the synergist; with good smoke absorbing effect of the diatomite with high specific surface area and based on the special layered structure and composition and also flame retarding, smoke suppressing and acid resisting functions of magnesium hydroxide, the prepared mining reinforcement material is allowed to have good flame retarding and smoke suppressing properties; cellular glass cloth is used as a reinforcing agent for the mining reinforcement material, so that the strength of the mining reinforcement material is effectively improved; and according to the invention, a synergistic effect between two flame-retardant elements silicon and phosphorus causes a decrease in the number of brittle amorphous carbon layers generated and an improvement in the flame retardance of the mining reinforcement material.

Owner:张文中

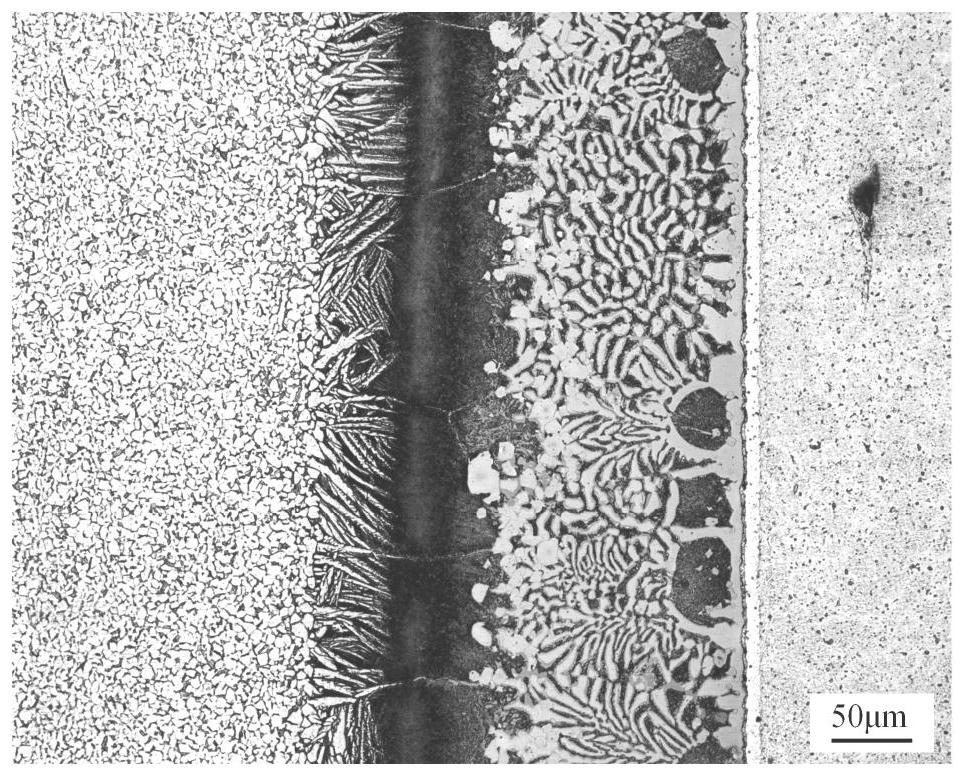

Mesh division method for multilayer multi-pass welding finite element model of header tube socket

PendingCN113158393AGuaranteed to generate successfullyReduce the number of spawnsGeometric CADDesign optimisation/simulationElement modelHeat-affected zone

The invention provides a mesh division method for a multilayer multi-pass welding finite element model of a header tube socket. The mesh division method comprises the following steps: establishing a finite element model of a saddle-shaped welding seam of the header tube socket; dividing the established finite element model of a saddle-shaped welding seam of the header tube socket into three parts, namely a welding seam area, a heat affected area and a base metal area; and carrying out mesh division on each segmented part. According to the method, the mesh region division sequence and the mesh generation minimum size are reasonably set, the mesh can be successfully generated, the generated mesh number is effectively reduced, the mesh generation time is shortened, and a foundation is laid for subsequent numerical calculation.

Owner:SHIHEZI UNIVERSITY

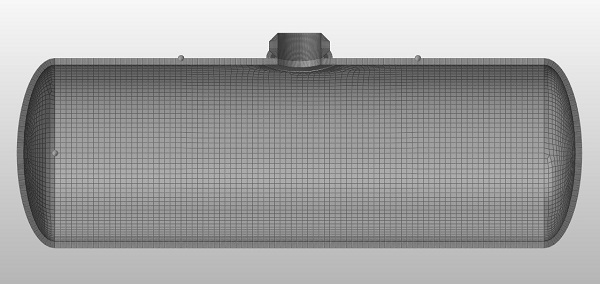

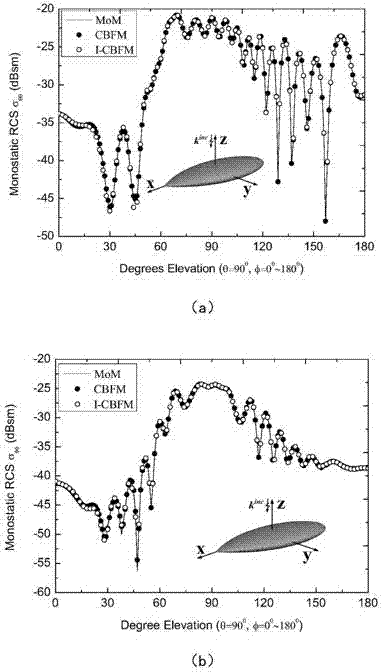

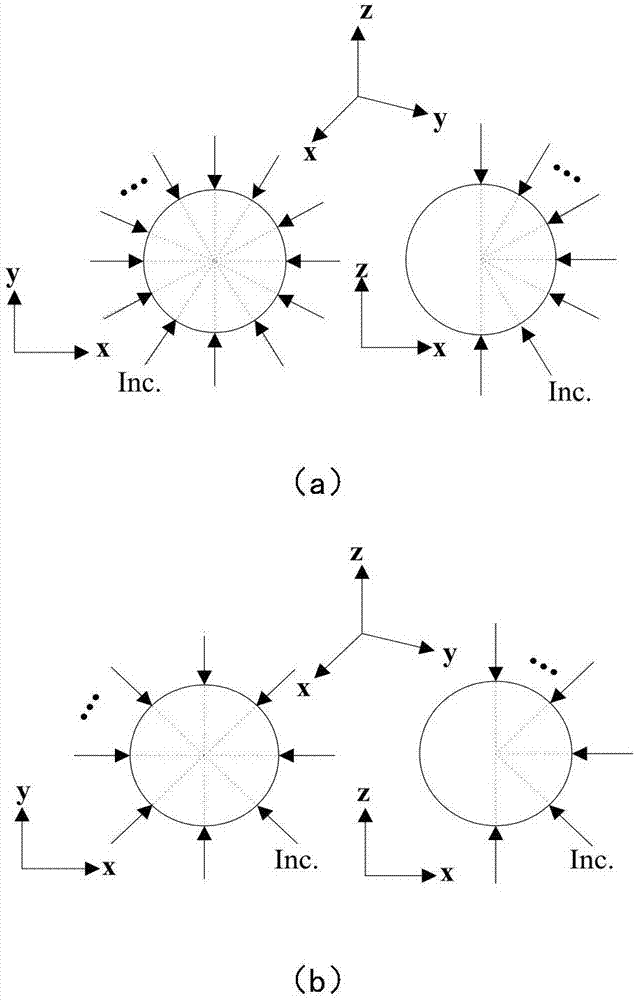

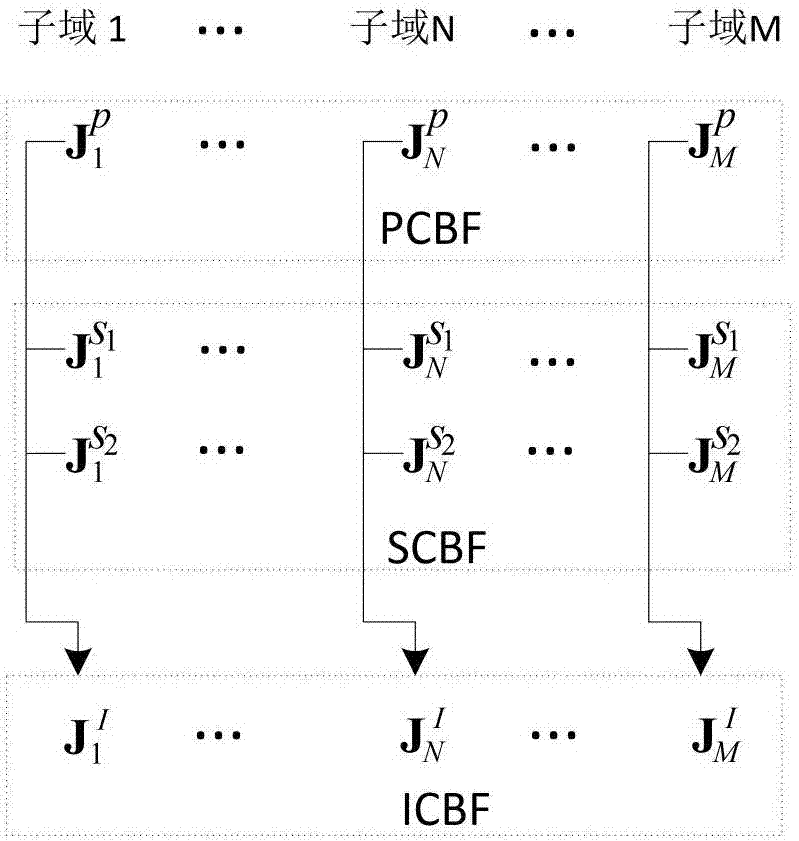

Improved CBFM (Characteristic Basis Function Method)-based method for fast solving target monostatic electromagnetic scattering characteristics

ActiveCN107145732AReduce the number of spawnsReduce the numberSpecial data processing applicationsInformaticsSingular value decompositionPower flow

The invention discloses an improved CBFM (Characteristic Basis Function Method)-based method for fast solving target monostatic electromagnetic scattering characteristics. According the method, firstly, redundant information existing in incident plane wave excitation is considered, and the redundant information content is removed by adopting an SVD (Singular Value Decomposition) algorithm; the coupling effect among sub-domains is fully considered, and a construction method of an ICBF (Improved Characteristic Basis Function) is provided; and the information of an original PCBF (Primary Characteristic Basis Function) and an SCBF (Secondary Characteristic Basis Function) is integrated in the ICBF, so that the current information on the surfaces of the sub-domains can be accurately represented. The method disclosed by the invention has the advantages that the number of incident plane waves is reduced by utilizing the SVD algorithm; the number of CBFs is further reduced through constructing the ICBF; a constructed reduced matrix is small in dimension and easy to store and solve; and therefore, the method is very suitable for analyzing the monostatic electromagnetic scattering characteristics of electrically large size targets.

Owner:ANHUI UNIV OF SCI & TECH

Forsterite synthesis method

A method for synthesizing forsterite is carried out according to the following steps: (1) lightly burned magnesia powder and natural forsterite powder with a particle size of 150-240 mesh are added to boron mud to make a mixed material; (2) Add magnesium chloride to the mixture and mix it evenly, add water and mix it evenly, press it into a spherical material, and let it stand for 10-20 hours for curing; (3) After mixing with coal, place it in a high-temperature shaft kiln for high-temperature calcination. The invention can not only treat the boron mud accumulated for many years, solve the environmental and ecological pollution of the boron mud that has been troubled for a long time, but also create a complete boron industrial chain, and find a new substitute that can meet the needs of today's increasingly scarce magnesium resources. Products, set a model for the local comprehensive and rational use of resources and the development of circular economy.

Owner:董少明

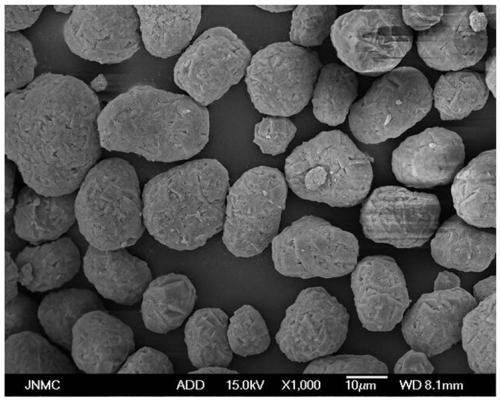

Preparation method of magnesium-doped cobaltosic oxide

ActiveCN110002512AGrowth inhibitionIncrease concentrationCobalt oxides/hydroxidesCobalt hydroxideMagnesium

The invention discloses a preparation method of magnesium-doped cobaltosic oxide. The method comprises the following steps: magnesium is added into a cobalt solution; with the extension of synthesis time, concentration gradient of the cobalt solution added to a reaction kettle increases; simultaneously, solid-to-liquid ratio of slurry in the reaction kettle is adjusted, and dense magnesium-doped cobalt hydroxide is synthesized by a wet method; after the synthesis, the synthetic product is washed, dried and calcined to obtain a magnesium-doped cobaltosic oxide product. The product obtained by the method has uniform doping distribution of magnesium, high tap density, large specific surface area and a spherical or spheroidal shape.

Owner:JINCHUAN GROUP LIMITED +1

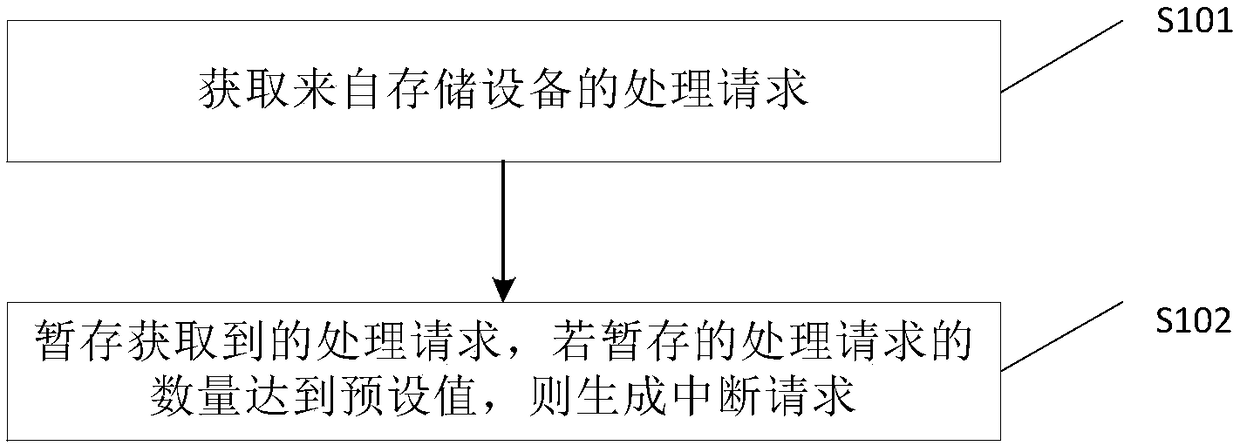

A method and apparatus for transaction processing

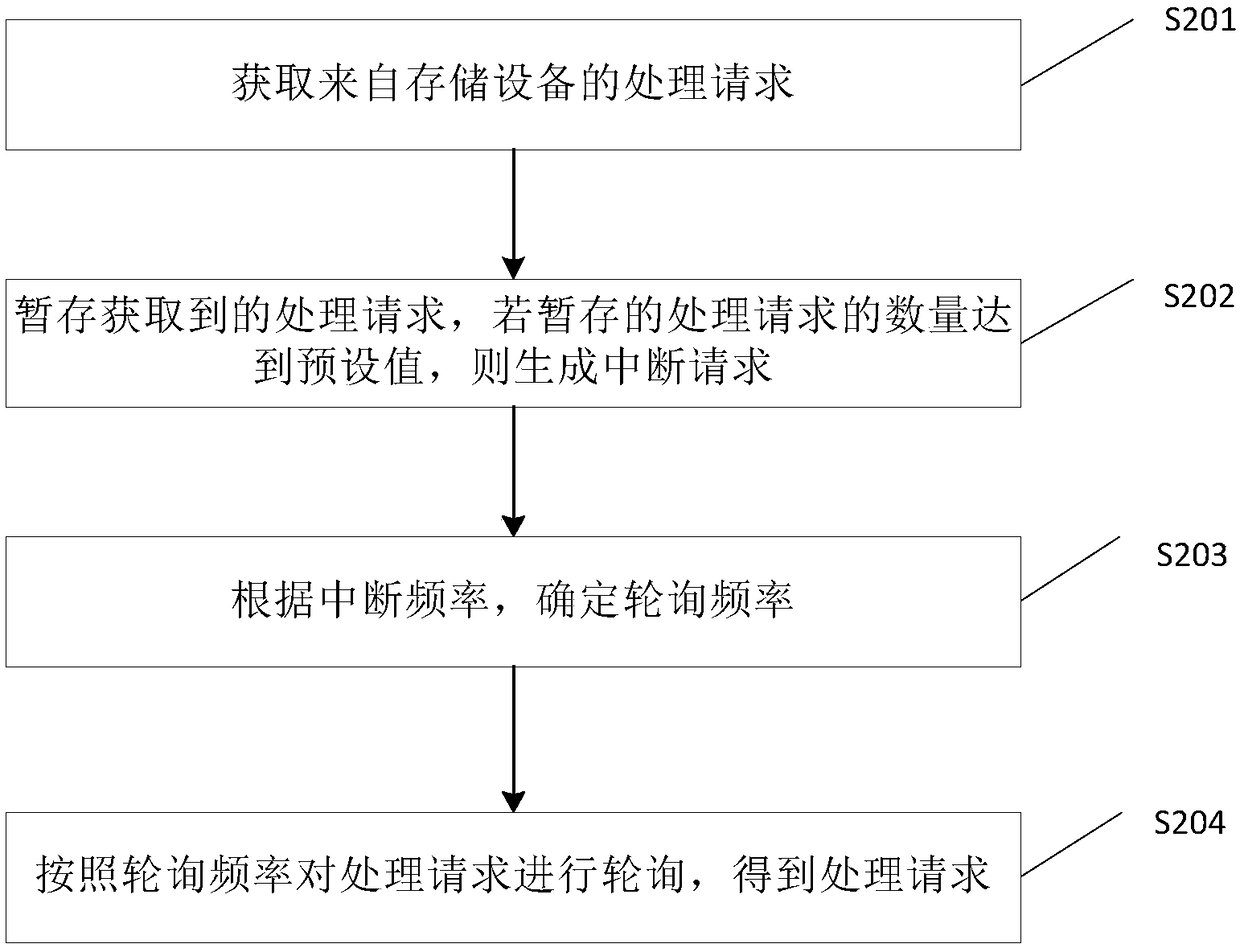

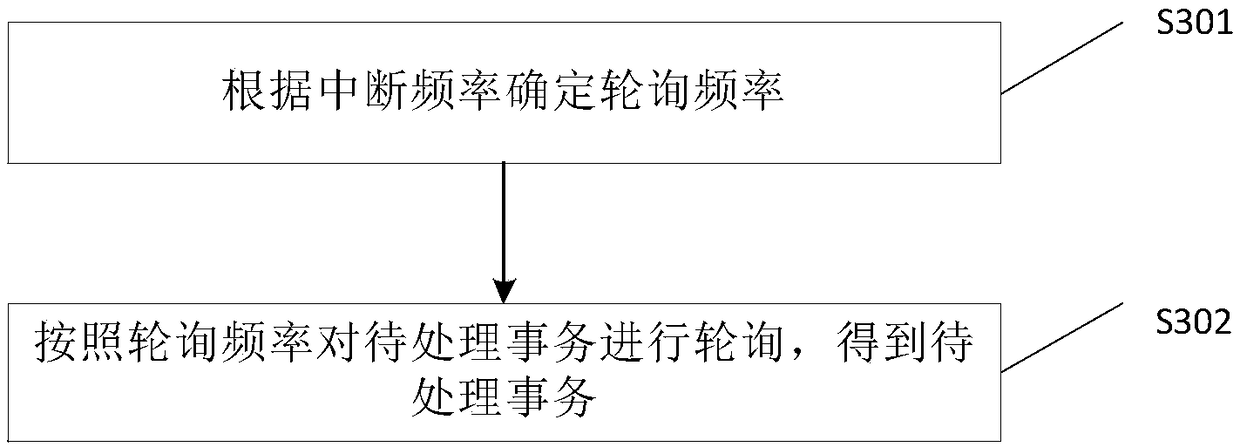

InactiveCN109086232AImprove work efficiencyImprove processing efficiencyTransaction processingInteraction timeTransaction processing system

A method and apparatus for transaction processing are disclosed in embodiment of that present application. By acquiring a processing request from a storage device, the processing request is used for requesting the transaction to be processed to temporarily store the acquired processing request, and if the number of processing requests reaches a preset value, an interrupt request is generated so that the server processes the transaction to be processed according to the interrupt request. By scratching the processing request, and when the number of requests processed reaches a preset value, an interrupt request is generated, which reduces the generation times of the interrupt request, thereby reducing the number of times the device acquires and processes the transaction to be processed according to the interrupt request, and reducing the interaction times between the processor and the storage device, thereby improving the working efficiency of the processor and the processing efficiencyof the transaction to be processed at the same time.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

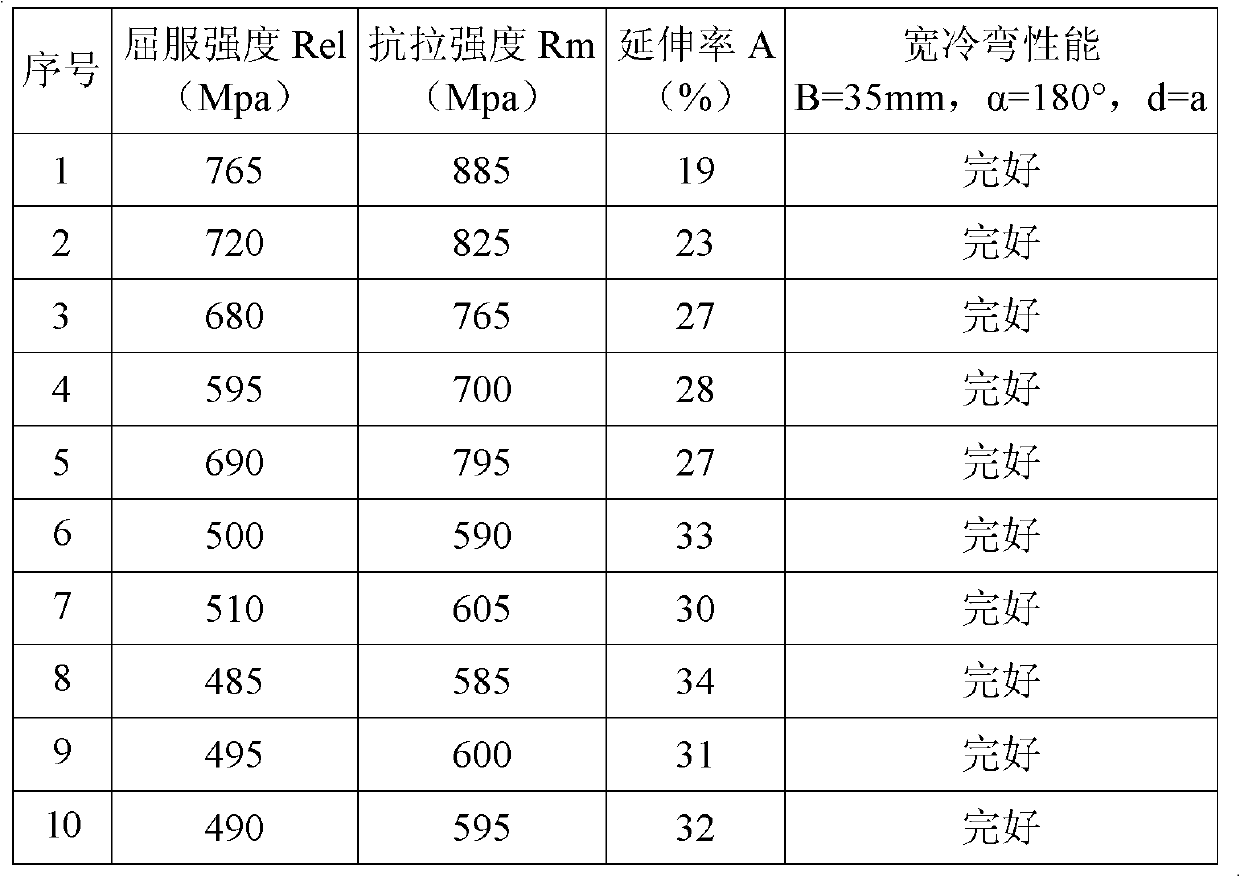

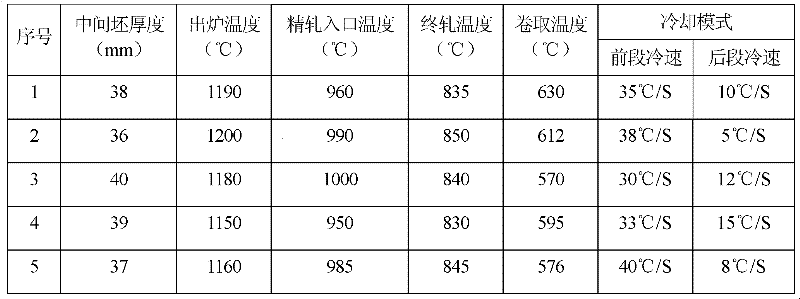

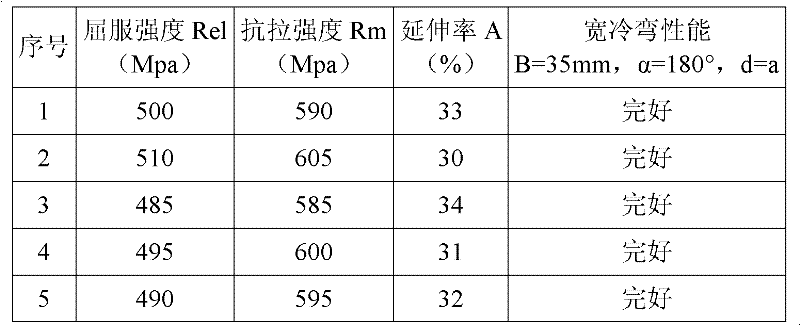

Composite micro-alloying hot rolled steel plate containing V and Nb and preparation method thereof

InactiveCN101899614BLower the furnace temperatureReduce the number of spawnsChemical compositionMetallurgy

The invention belongs to the technical field of hot continuous rolled plate strips, in particular relates to a composite micro-alloying hot rolled steel plate containing V and Nb and a preparation method thereof, which can achieve the purpose of controlling the surface quality thereof. The composite micro-alloying hot rolled steel plate containing V and Nb, which is provided by the invention, notonly can reduce the generation of red scales but also can not increase the production cost. The composite micro-alloying hot rolled steel plate comprises the following chemical components in percentage by weight: C which is greater than or equal to 0.06% and is less than or equal to 0.08%, Si which is greater than 0.20% and is less than or equal to 0.30%, Mn which is greater than or equal to 0.70% and is less than or equal to 0.90%, V which is greater than 0.04% and is less than or equal to 0.05%, Nb which is greater than or equal to 0.02% and is less than or equal to 0.03%, P which is less than or equal to 0.025%, S which is less than or equal to 0.015%, and the balance iron and inevitable impurities. The preparation method provided by the invention has no need of reconstructing the existing equipment, has simple and controllable technological conditions, realizes the purpose of reducing the generation of scales by controlling the tapping temperature, the precision rolling temperature, the finishing temperature, the coiling temperature and the cooling mode of a plate blank, and has the advantages of low energy consumption and low cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Device for measuring high-temperature liquid level of sponge titanium in closed container

PendingCN109238402AReduce distractionsReal-time measurementLevel indicators by physical variable measurementProcess efficiency improvementRadarThermal insulation

The invention discloses a device for measuring the high-temperature liquid level of sponge titanium in closed container. The device comprises a connecting sleeve, a thermal insulation sleeve, a radarliquidometer and a thermal insulation glass plate, wherein the bottom of the connecting sleeve is connected with the top big cover of a sealed reactor used for sponge titanium production to enable theinner part of the sealed reactor to be communicated with the connecting sleeve; the top of the connecting sleeve is connected with the bottom of the thermal insulation sleeve through a flange; the radar liquidometer is arranged on the top of the thermal insulation sleeve; a radar liquidometer antenna downwards extends into the thermal insulation sleeve, and the instrument display unit of the radar liquidometer is upwards exposed out of the thermal insulation sleeve; in addition, through a fixed sealing structure, the fixing of the radar liquidometer on the thermal insulation sleeve and the sealing of the top of the thermal insulation sleeve are realized; the bottom of the thermal insulation sleeve is also provided with the thermal insulation glass plate which can be penetrated by radar wave; and an argon blowing pipe which is provided with an opening on the thermal insulation sleeve is arranged between the thermal insulation glass plate and the radar liquidometer. By use of the device, the non-contact measurement of the radar liquidometer for the high-temperature liquid level can be realized, and in addition, the device can be safely used in sealed high-temperature environment.

Owner:洛阳双瑞万基钛业有限公司

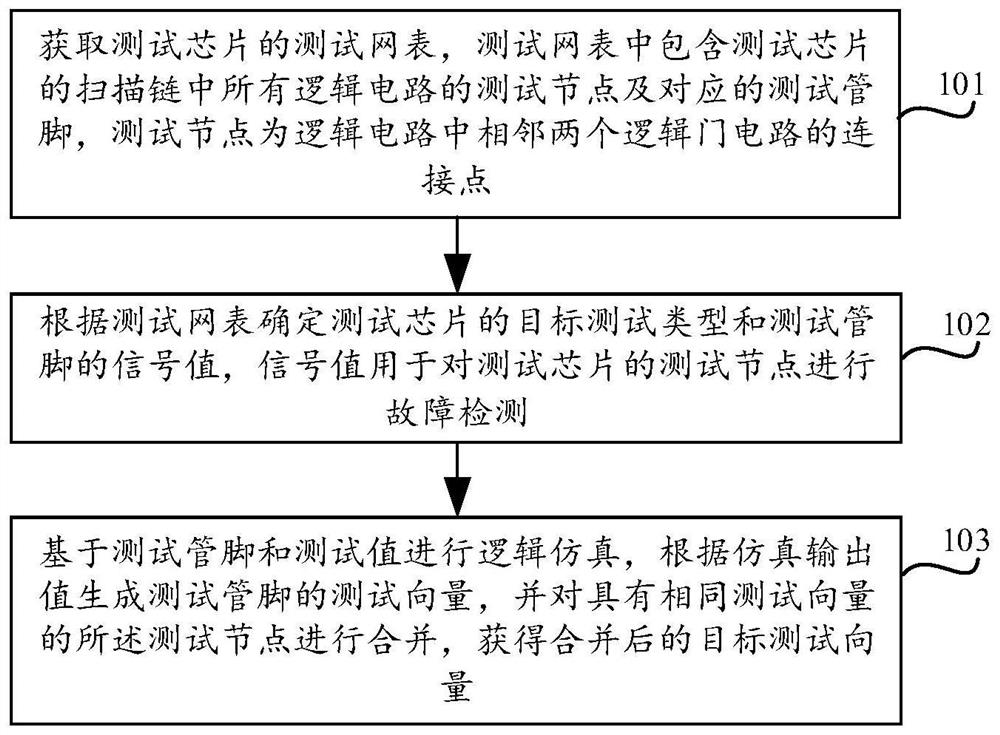

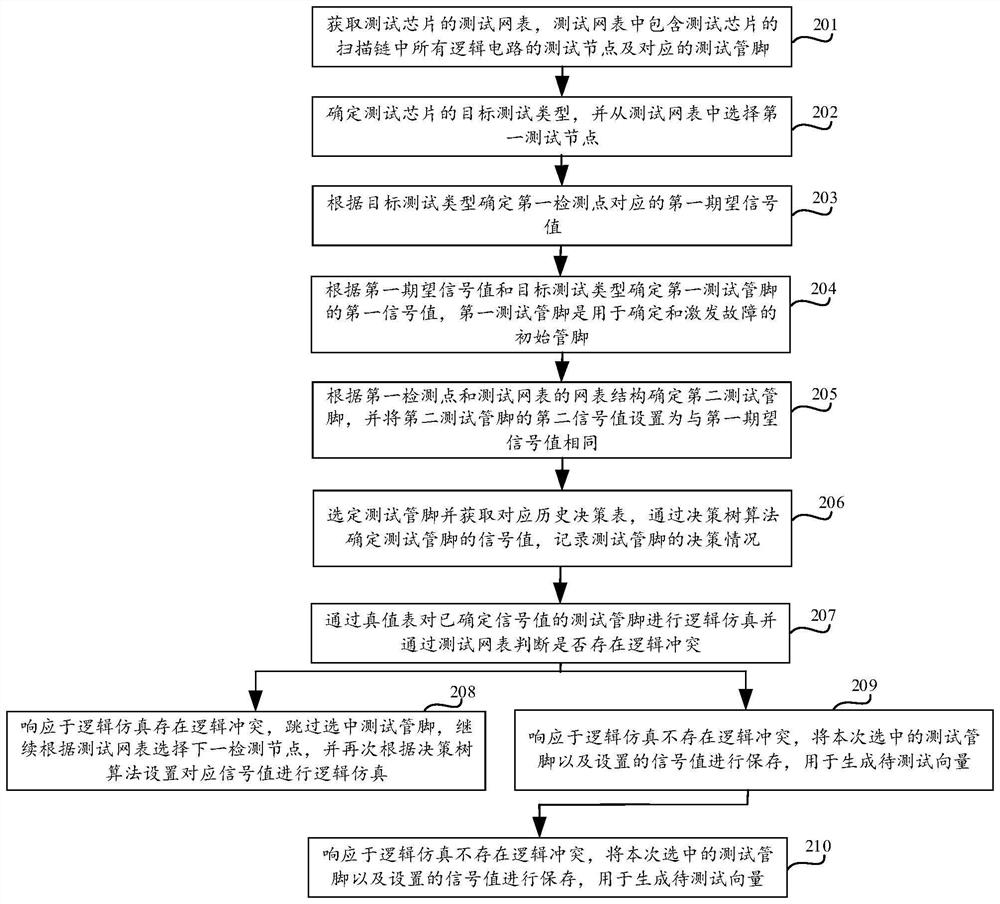

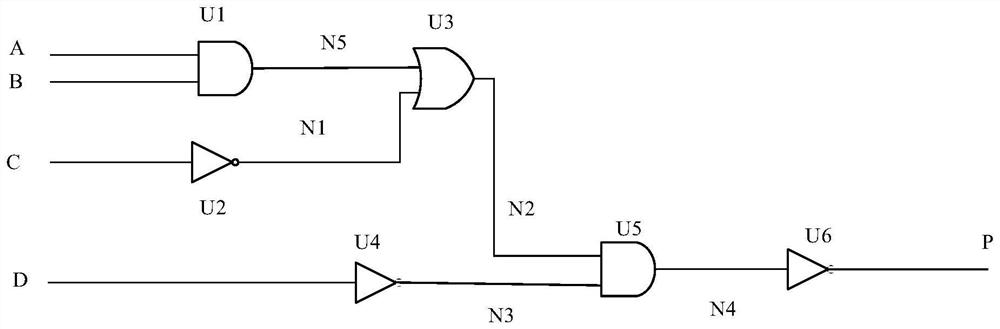

Test vector generation method and device and storage medium

PendingCN114398848AReduce the number of spawnsEliminate data redundancyComputer aided designSpecial data processing applicationsLogisimTest vector

The invention discloses a test vector generation method and device and a storage medium, and relates to the field of chips.The method comprises the steps that a test netlist of a test chip is obtained, and the test netlist comprises test nodes and corresponding test pins of all logic circuits in a scan chain of the test chip; determining a target test type of the test chip and a signal value of a test pin according to the test netlist, wherein the signal value is used for performing fault detection on a test node of the test chip; and performing logic simulation based on the test pins and the test values, generating test vectors of the test pins according to simulation output values, and merging the test nodes with the same test vectors to obtain a merged target test vector. The test vectors of the test nodes are generated in a mode of calibrating the test nodes in the test netlist, compared with a mode of detecting the test chip according to the number of test pins, redundancy elimination of the test vectors can be achieved, the number of times of detection can be reduced, and the test efficiency of chip detection can be improved.

Owner:无锡玖熠半导体科技有限公司

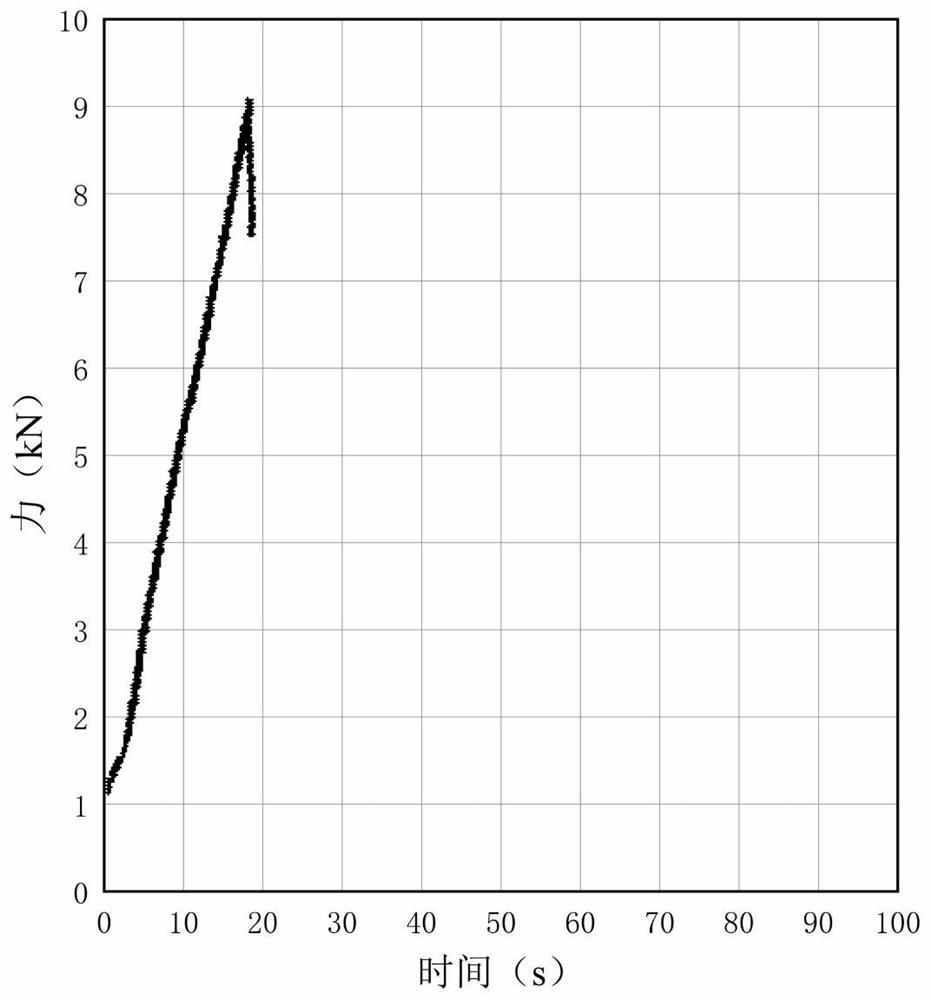

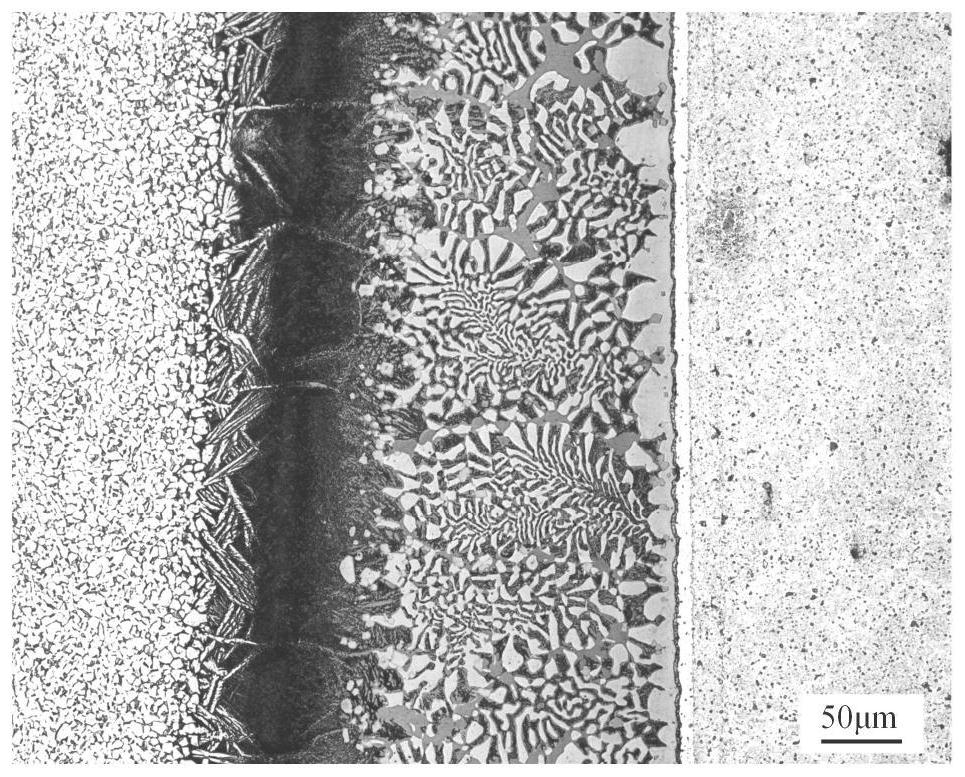

Transition liquid phase diffusion bonding method for additive manufacturing stainless steel and zirconium alloy

PendingCN114871559APromote formationReduce residual stressNuclear energy generationWelding/soldering/cutting articlesSS - Stainless steelCopper foil

The invention discloses a transition liquid phase diffusion bonding method for additive manufacturing stainless steel and zirconium alloy, which comprises the following steps of: (1) sequentially stacking a high-temperature-resistant spacer, zirconium alloy, copper foil, nickel foil, additive manufacturing stainless steel and a high-temperature-resistant spacer in sequence to form a whole to be welded; (2) the whole to be welded is placed in a vacuum diffusion furnace cavity, vacuumizing is conducted, the diffusion welding temperature ranges from 880 DEG C to 980 DEG C, the diffusion welding pressure ranges from 0.5 MPa to 3 MPa, and the heat preservation time ranges from 60 min to 90 min; the thicknesses of the copper foil and the nickel foil are 30 microns to 50 microns; according to the method, the copper foil and the nickel foil are introduced between the zirconium alloy and the additive manufacturing stainless steel, so that the generation number of brittle phases in a diffusion welding joint is reduced to a certain extent, the residual stress of a connecting interface of the additive manufacturing stainless steel and the zirconium alloy can be effectively reduced, the generation of cracks is inhibited, and the comprehensive mechanical property of the welding joint is improved; and the shear strength result of the joint shows that the shear strength is greater than 90 MPa.

Owner:JIANGSU UNIV OF SCI & TECH

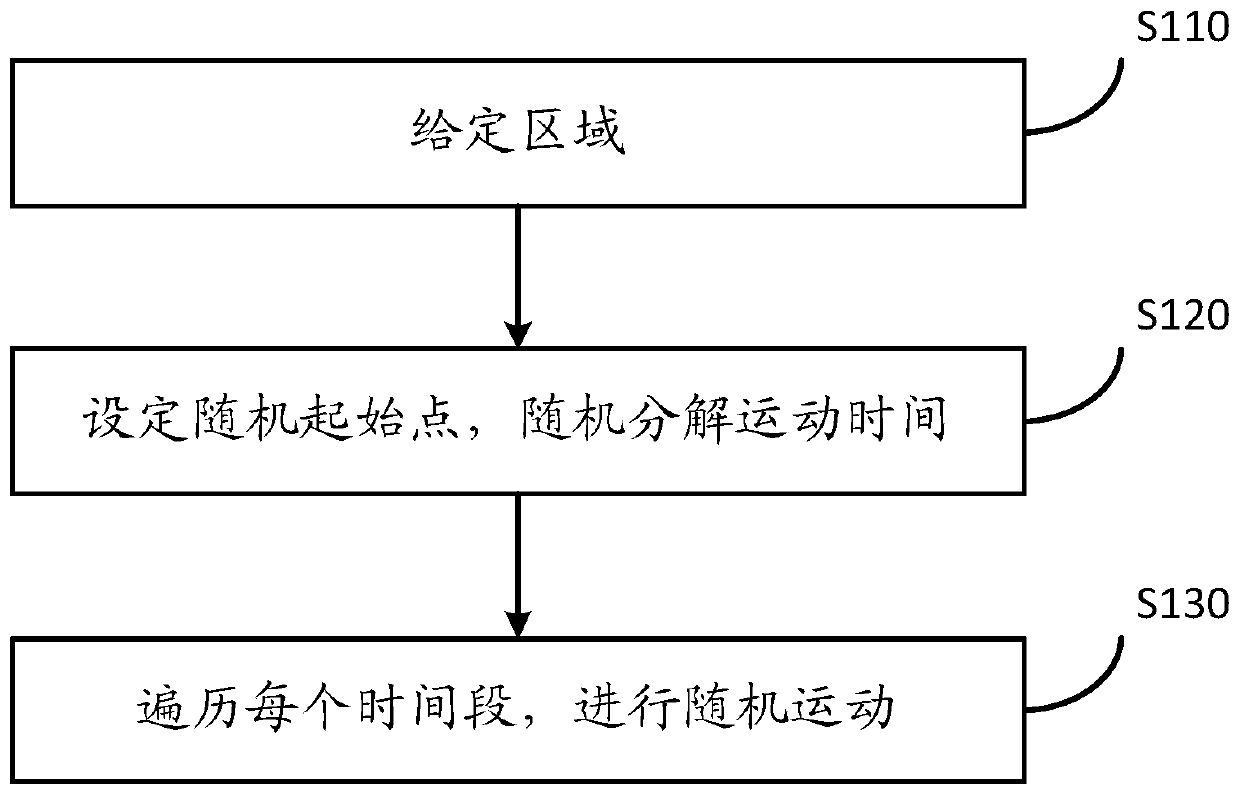

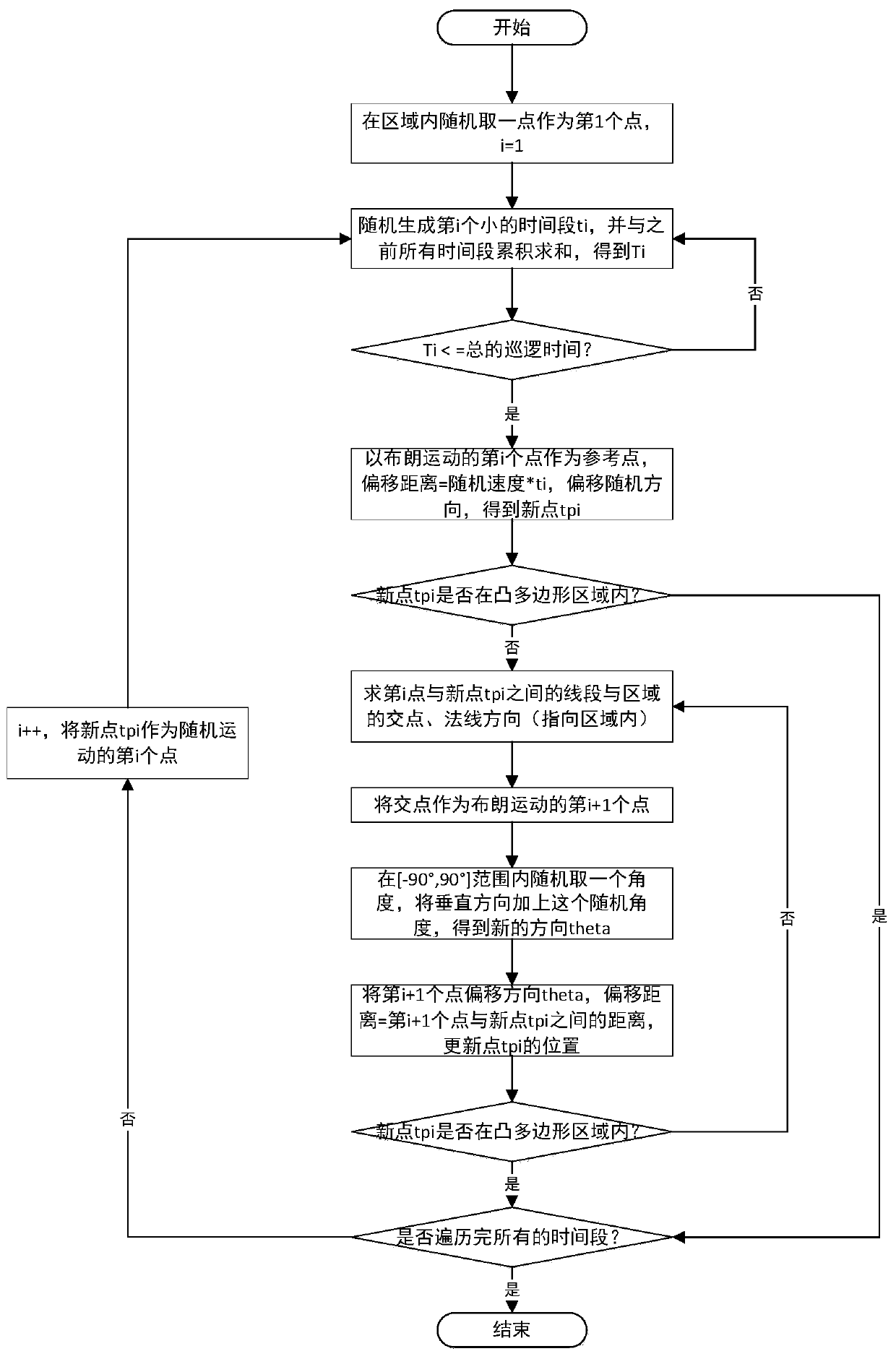

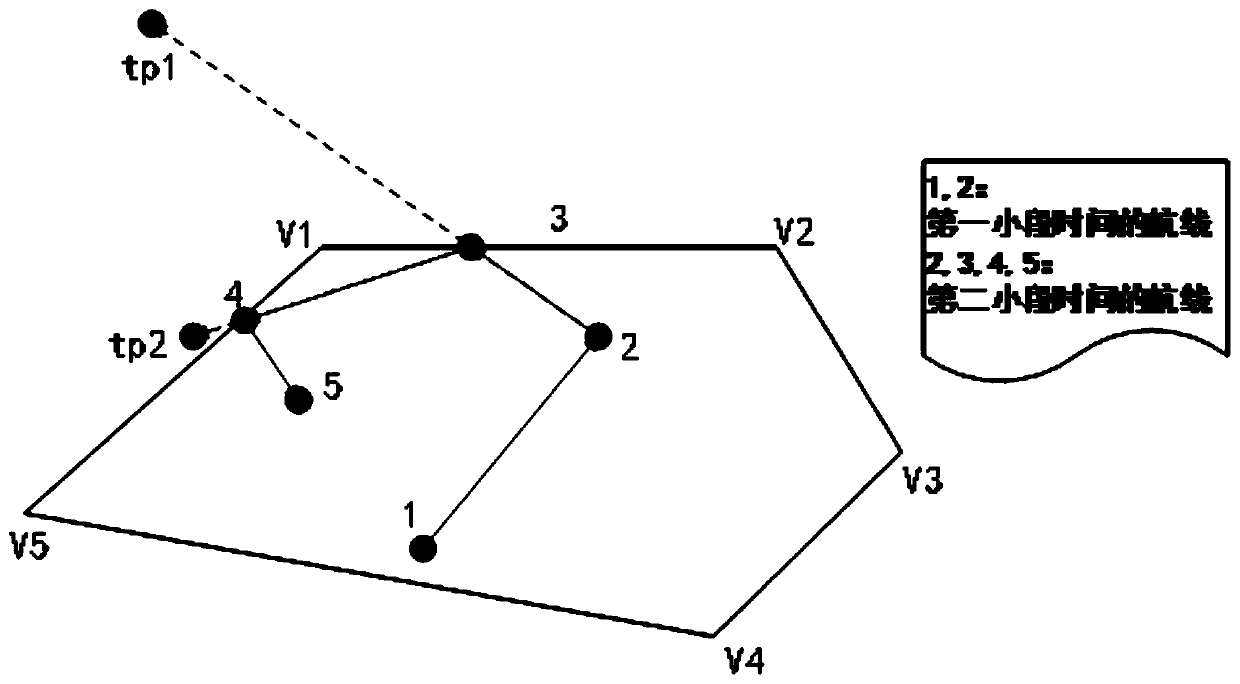

Method for realizing random motion of entity in fixed area and storage medium

ActiveCN110263475AReduce the number of spawnsReduce the number of judgmentsDesign optimisation/simulationSpecial data processing applicationsTime segmentAlgorithm

The invention discloses a method for realizing random motion of an entity in a fixed area and a storage medium. The method comprises the following steps: randomly selecting a path starting point in a limited area; sequentially and randomly generating a time period ti of each stage, accumulating the sum of the current random time periods until the total patrol time is reached, starting from a first time period, randomly moving at a constant speed, wherein the speed is random, calculating whether an end point of the current time period is in an area in advance, if the end point of the current time period exceeds the area, taking an intersection point as a transfer point in the time period, and starting from the intersection point to continue new random movement until the time period runs out; circularly executing the above steps in sequence until all random time periods are completely maneuverable. Therefore, in a given area, random motion of the combat entity in the area can be achieved according to the method, compared with a conventional random path generation algorithm, the number of times of generation of the random points and the number of times of judgment of whether the random points are located in the area are reduced, and the execution efficiency is improved.

Owner:BEIJING HUARU TECH

Compound amino acid health product and preparation method thereof

The invention relates to a compound amino acid health product, and belongs to the field of health-care food. The compound amino acid health product is prepared from the following raw materials in parts by weight: 2.5-3 parts of L-alanine, 4.5-5 parts of L-glutamic acid, 10 parts of fructose, 15-20 parts of oligoisomaltose, 0.002-0.003 part of vitamin C, 0.0006-0.0008 part of vitamin B1, 0.0002-0.0004 part of vitamin B2, 0.0003-0.0004 part of vitamin B6, 0.0001 part of vitamin B12 and 8-10 parts of alpha-linolenic acid. The invention also provides a preparation method of the compound amino acidhealth product. The compound amino acid health product has a scientific formula and obvious mutual synergistic effects among the components, and has the effects of improving the immunity of human bodies, reducing blood fat, preventing cardiovascular and cerebrovascular diseases, relieving fatigue, enhancing physical strength, protecting eyesight, benefiting intelligence, delaying senescence, dispelling the effects of alcohol and protecting liver, and the like.

Owner:丁杰

Meshing method for finite element model of pile foundation spiral buried pipe heat exchanger

PendingCN111125943AGuaranteed to generate successfullyReduce the number of spawnsGeometric CADDesign optimisation/simulationMesh gridStructural engineering

The invention provides a meshing method for a finite element model of a pile foundation spiral buried pipe heat exchanger in a fan-shaped soil area. The meshing method comprises the steps that the finite element model of the pile foundation spiral buried pipe heat exchanger in the fan-shaped soil area is established; the built finite element model of the pile foundation spiral buried pipe heat exchanger in the fan-shaped soil area is segmented into four parts including lining concrete, soil, a pile foundation inner cylinder and a pile foundation outer circular ring column; and mesh generationis carried out on each segmented part. According to the method, the sequence of grid region division and the minimum size of grid generation are reasonably set, successful grid generation can be guaranteed, the number of generated grids is effectively reduced, the grid generation time is prolonged, and a foundation is laid for subsequent numerical calculation.

Owner:中国人民解放军63926部队

Room-temperature curing agent, preparation method and application of a high-temperature-resistant organic silicon material

The invention provides a room temperature curing agent for high-temperature-resistant organosilicon materials, a preparation method and applications thereof. The room temperature curing agent comprises polysilazane and a catalyst, wherein the molecular structure of the polysilazane is optimized, and only contains difunctional Si-N chain segments and trifunctional Si-N chain segments, and the random branched structure is formed by a polymerization reaction; by adjusting the feeding ratio, pressurizing during the aminolysis and using ceramic ball-assisted mass transfer, the use amounts of the trifunctional silane and the ammonia gas for forming the trifunctional Si-N chain segment with the same content are substantially reduced, the molecular structure of the polysilazane is optimized, the generation of ammonium chloride is reduced, and the mass transfer and heat transfer control during the aminolysis is easily achieved; and the optimization does not affect the formation of the cross-linked network of the cured organosilicon material, and the structure optimizing meets the development trend of green chemistry.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com