Device for measuring high-temperature liquid level of sponge titanium in closed container

A closed container, sponge titanium technology, applied in the direction of the liquid level indicator for physical variable measurement, can solve the problems of easy air intake, large measurement error and high risk factor of the reactor, so as to reduce the fluctuation of the solution surface, reduce the number of generated, The effect of reasonable temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

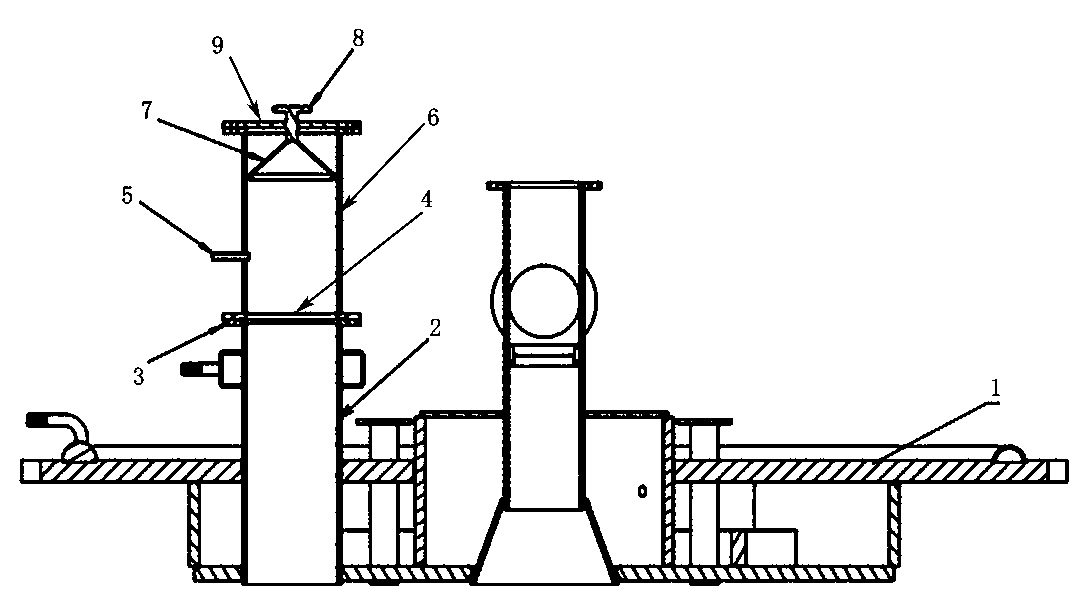

[0020] The technical solutions of the present invention will be further described below through specific implementation manners in conjunction with the accompanying drawings.

[0021] As shown in the figure, a device for measuring the high-temperature liquid level of sponge titanium in a closed container is installed on the large cover 1 on the top of the steaming furnace, including a connecting sleeve 2, a heat insulating sleeve 6, and a radar level gauge. With the heat insulating glass plate 4, the bottom of the connecting sleeve 2 is connected to the large cover 5, so that the interior of the return steamer communicates with the connecting sleeve 2, and the top of the connecting sleeve 2 passes through the flange 3 is connected to the bottom of the heat insulation sleeve 6, the radar level gauge is arranged on the top of the heat insulation sleeve 6, the height of the heat insulation sleeve 6 is 500mm, after the radar level gauge is installed, The antenna 7 of the radar lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com