Patents

Literature

104results about How to "Reasonable temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

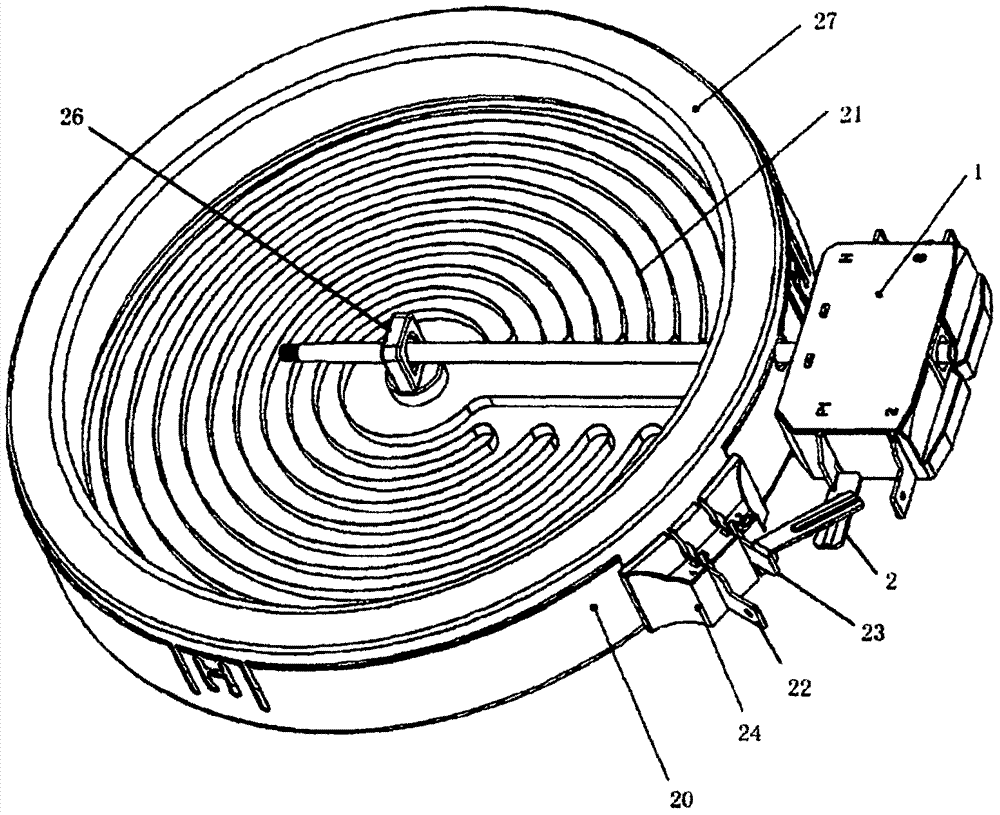

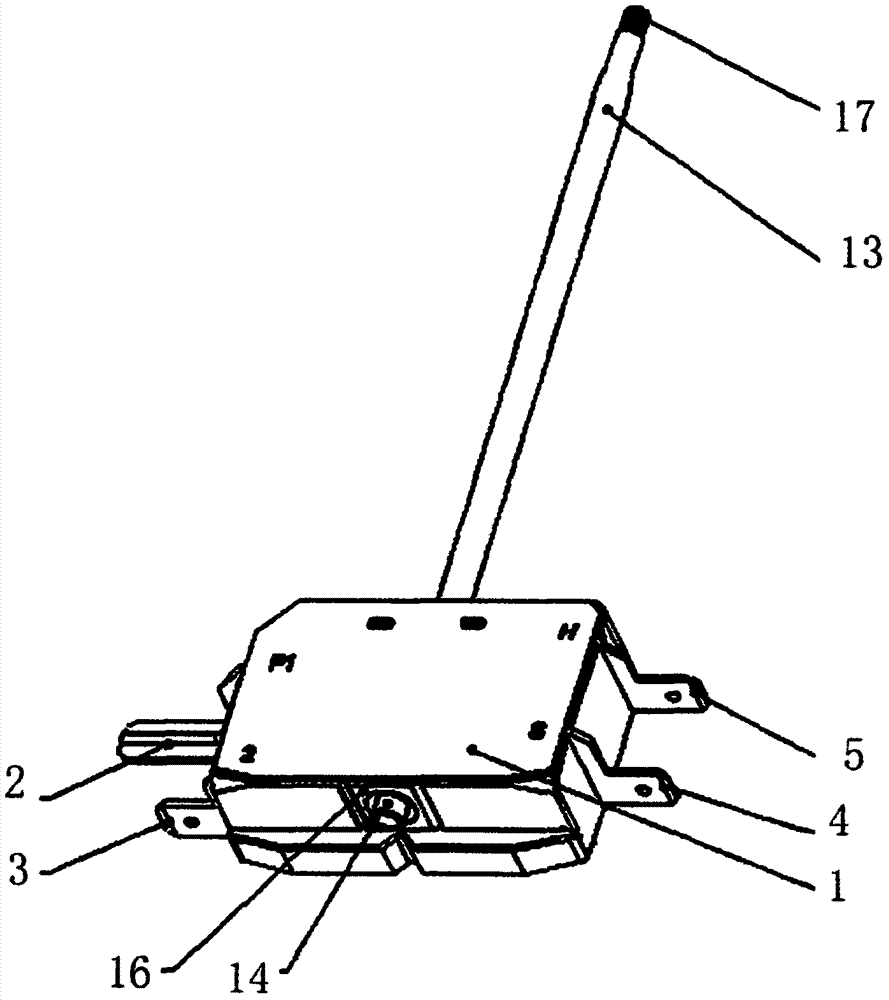

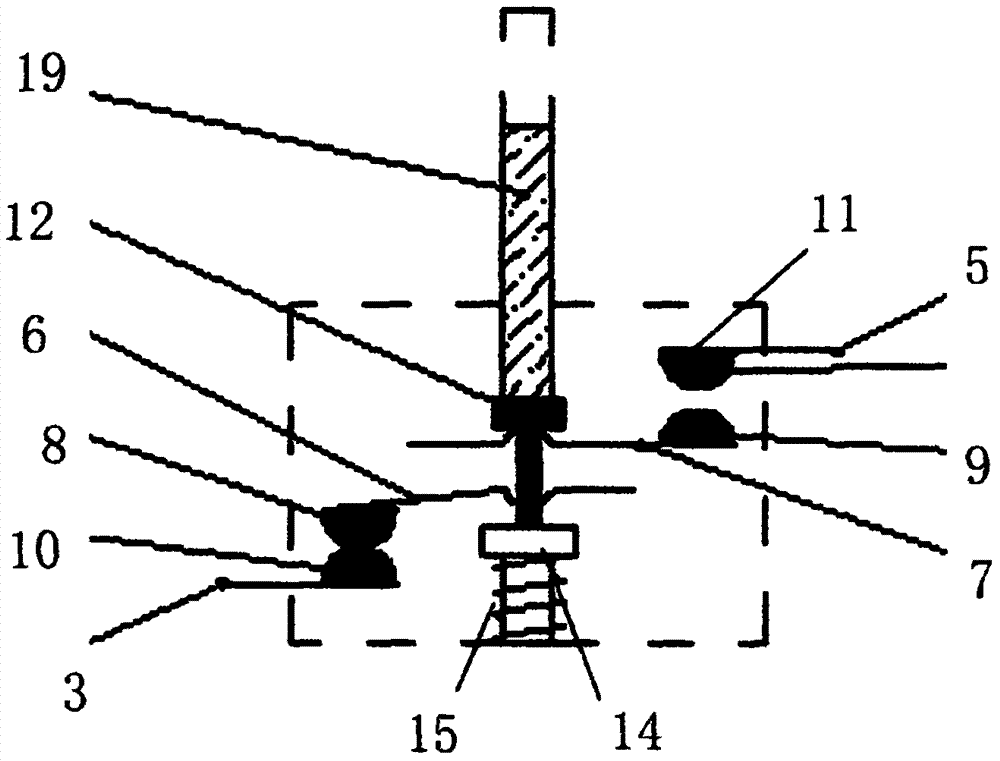

Novel temperature control heat insulation heating disc

InactiveCN107241818AReasonable structureEasy to installHeating element materialsTemperature controlThermostat

The invention discloses a novel temperature-controlled heat-insulating heating plate, which comprises a heating plate and a double-contact temperature controller. The invention has the beneficial effects of compact structure, convenient installation, rapid heating, safety and reliability, and long service life.

Owner:SHENZHEN FODA ELECTRIC

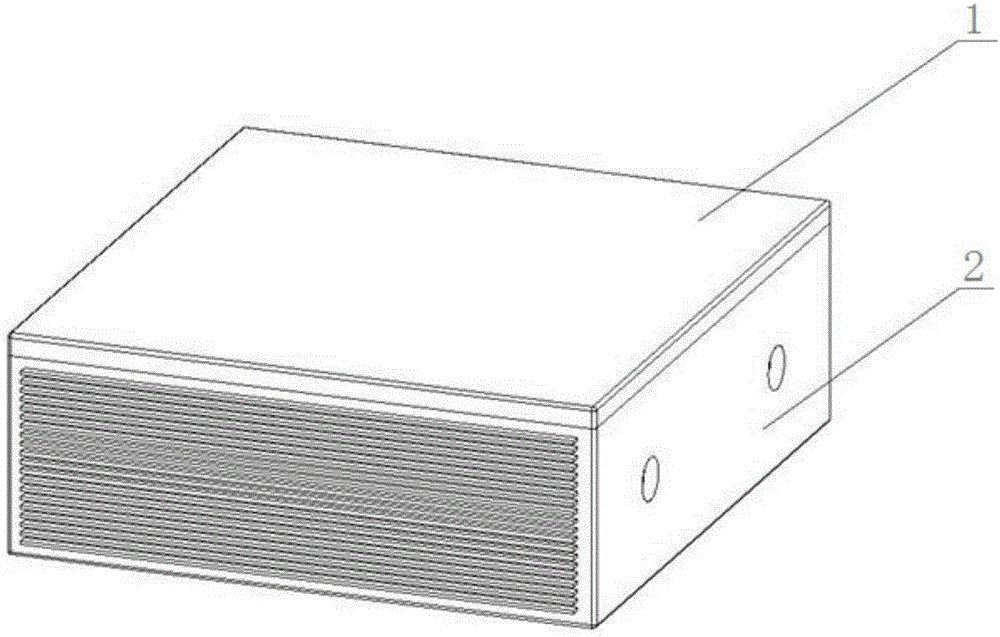

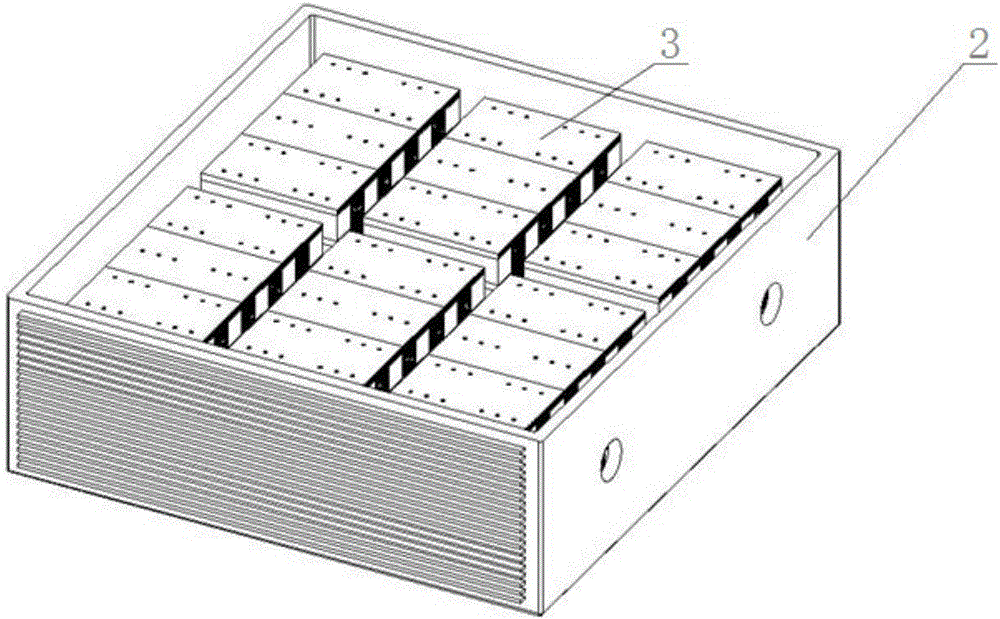

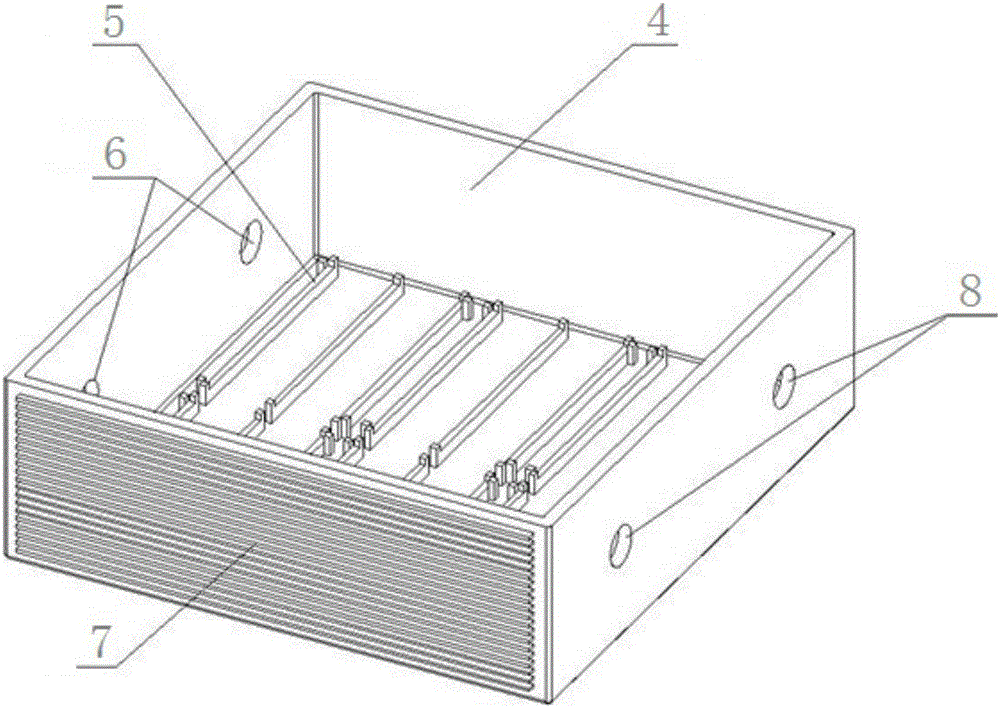

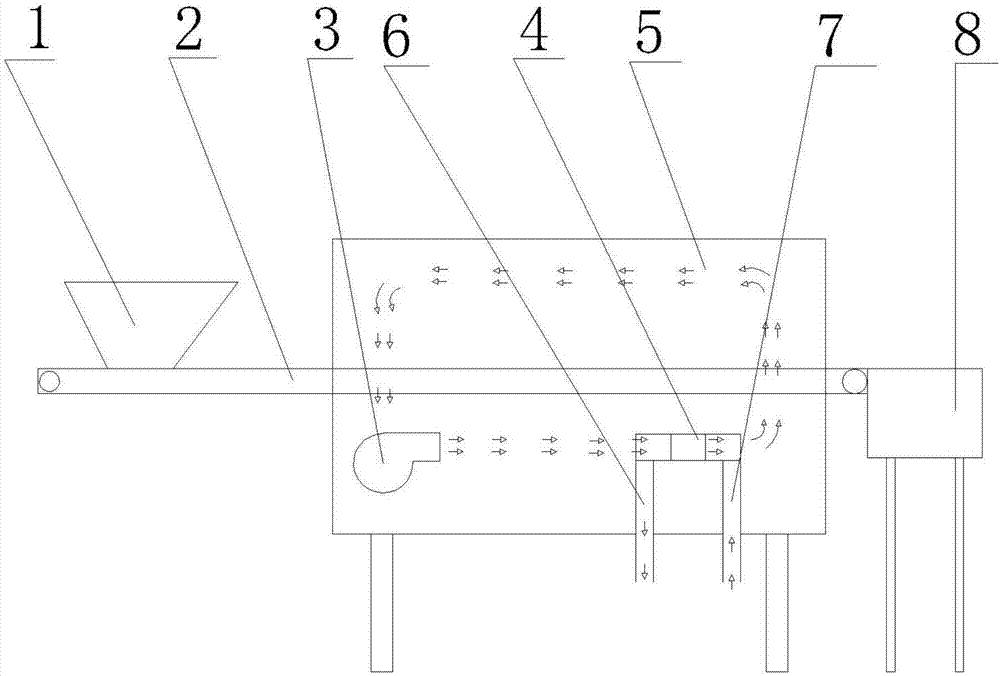

Air cooling device capable of adjusting temperature of electromobile power battery packs and application thereof

ActiveCN106848482AReasonable structural designEasy to useSecondary cellsCell component detailsTemperature controlPower battery

The invention relates to an air cooling device capable of adjusting temperature of electromobile power battery packs and application thereof. The air cooling device comprises a box body and a box cover, the power battery packs are arranged in the box body, each power battery pack comprises multiple layers of cooling plates arranged from top to bottom, a battery module and a cooling assembly are arranged between each two layers of the cooling plates at an interval, multiple temperature sensors are arranged on each cooling plate, and an air inlet and an air outlet are arranged on opposite side faces of the box body. Compared with conventional power battery cooling devices, the air cooling device is reasonable in structural design and convenient to mount and use. The air cooling device has better cooling effect, so that cooling efficiency of the power battery packs can be greatly improved; reasonable temperature control of the power battery packs can be realized, so that influence on service life and using effect of the power battery packs caused by the fact that the power battery packs are too high in temperature locally is avoided. In addition, the air cooling device can be matched with an air conditioning management system of an automobile for use, thereby having various using modes.

Owner:SHANDONG UNIV OF SCI & TECH

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

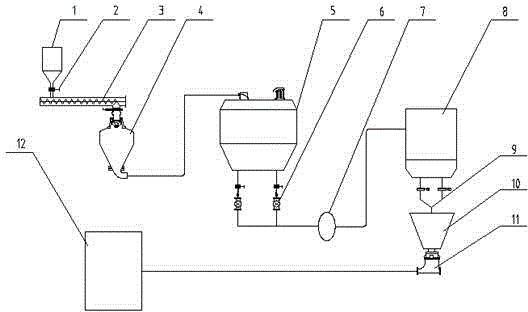

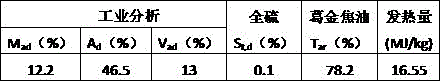

Method of comprehensively utilizing precipitator ash and slag of calcium carbide furnace

InactiveCN104086107AReasonable temperature controlRealize harmless treatmentCement productionCombustionSlag

The invention relates to a method of comprehensively utilizing precipitator ash and slag of a calcium carbide furnace. In the method, a calcium carbide furnace precipitator ash collecting system, a conveying system, an incineration system, an ash conveying system and a cement production system are mainly utilized; the calcium carbide furnace precipitator ash passes through a dust cabin, and is fed to an incineration device sequentially through a pressurizing device, a buffer device and an ejector of the conveying system; the calcium carbide furnace precipitator ash and coal ash accelerated by the ejector enter a combustion section of the incineration device, a cooling device is arranged at the outlet of the incineration device, and the cooled ash enters a cement raw material section through the ash conveying system by a conveying pump. The method provided by the invention mainly solves the problem of conveying and utilizing the calcium carbide furnace precipitator ash and slag. Meanwhile, two kinds of slag are comprehensively utilized by virtue of one process, so that the purposes of efficiency, energy conservation and environmental protection are realized.

Owner:XINJIANG TIANYE GRP +2

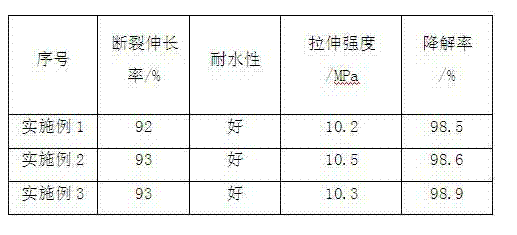

Production process of PVA (polyvinyl alcohol)-based composite packaging material

InactiveCN103540068ANo pollution in the processNo dopingFlexible coversWrappersPolyvinyl alcoholBiological materials

The invention discloses a production process of a PVA (polyvinyl alcohol)-based composite packaging material, relating to the field of film packaging materials. The production process comprises the following three technical processes: preparation of dialdehyde starch, preparation of jute fibers and preparation of a PVA-based composite film. According to the process method, in the preparation process of the dialdehyde starch, corn starch is used as a raw material, no pollution is caused, the cost is low, the raw material is sufficient, a far-infrared quick constant-temperature drying box is used as drying equipment, the dialdehyde starch is dried sufficiently, and no impurity is doped; in the preparation process of the jute fibers, the temperature control is reasonable, a right amount of reagent is added, the jute fibers are pulverized through a YSC-701 type ultrafine pulverizer, and the pulverized fibers are small in particle size and favorable in pulverization effect; and in the preparation process of the PVA-based composite film, parameters such as addition of each component, temperature, time and the like are strictly controlled, thereby ensuring that the prepared PVA-based composite film has favorable mechanical property and water resistance and can meet the requirements for practical production. By using the biological material as the raw material for production, the PVA-based composite film produced by the process is low in cost and degradable, thus greatly reducing environmental pollution.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

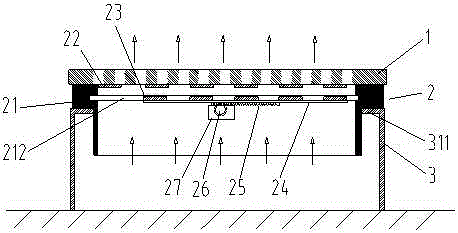

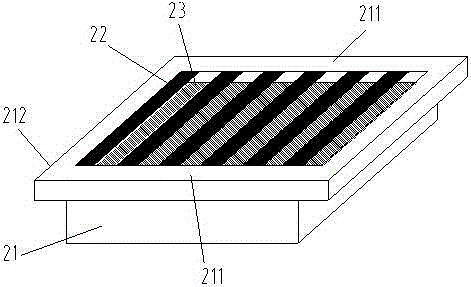

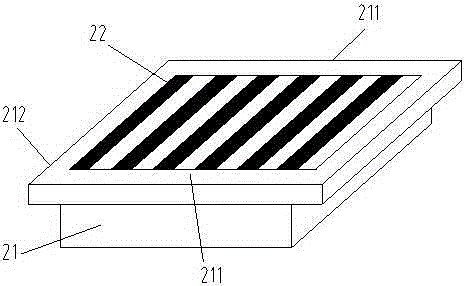

Adjustable ventilation device and control system therefor

ActiveCN105188312AAutomatic temperature adjustmentReasonable temperature controlCooling/ventilation/heating modificationsTemperature controlConventional ventilation

The invention discloses an adjustable ventilation device and a control system therefor. An air regulation apparatus is fixed on a floor support, and a ventilation floor is laid on a square frame. The square frame is provided with wind shield plates and movable wind shield plates, and ventilation gaps in a horizontal direction are respectively formed between the adjacent two wind shield plates. Inner sides, at which two ends of each wind shield plate are located, of two frames are respectively provided with a guide rail in a length direction. Two ends of each movable wind shield plate are respectively disposed on guide rails of the two frames in a sliding manner. The movable wind shield plates are respectively in fixed connection with the same connecting plate, and the width of each ventilation gap between two adjacent wind shield plates is less than or equal to the width of each movable wind shield plate. The lower side of a strip-shaped connecting plate is provided with racks in the length direction of the guide rail, and a gear is engaged with the racks. A torsional force steering engine drives the gear to rotate, so as to solve a problem that the effect of a convention air supply system is not ideal because a conventional ventilation floor structure is not reasonable and the ventilation cannot be changed easily. The invention belongs to the field of cabinet temperature control.

Owner:GUIZHOU POWER GRID INFORMATION & TELECOMM

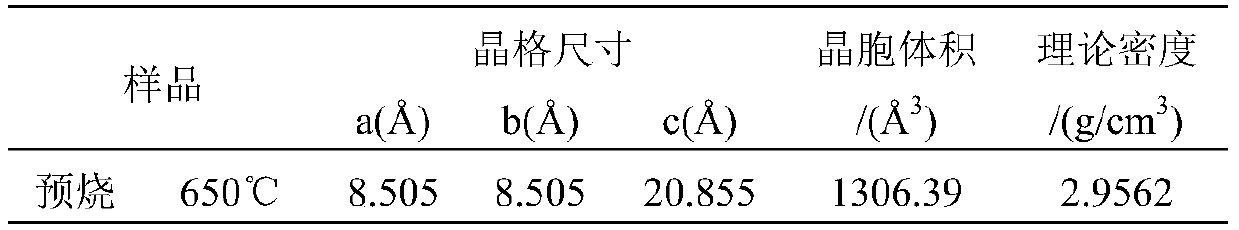

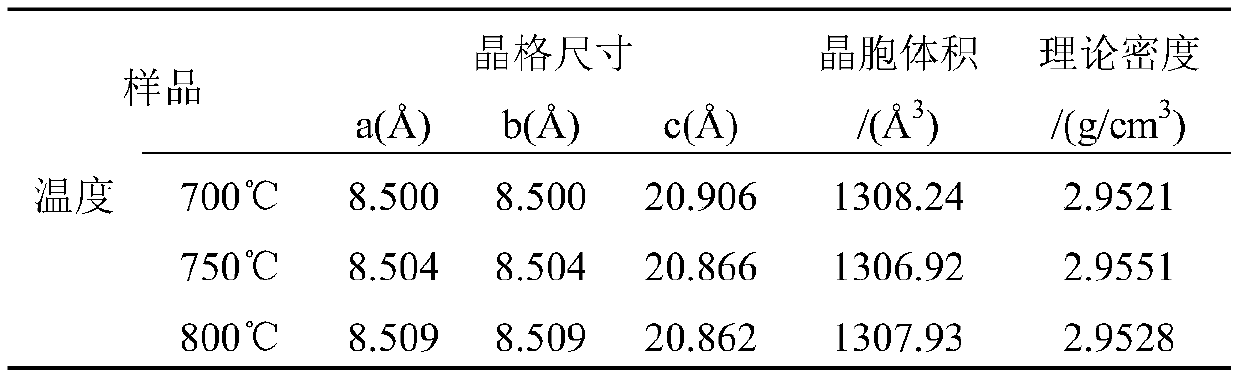

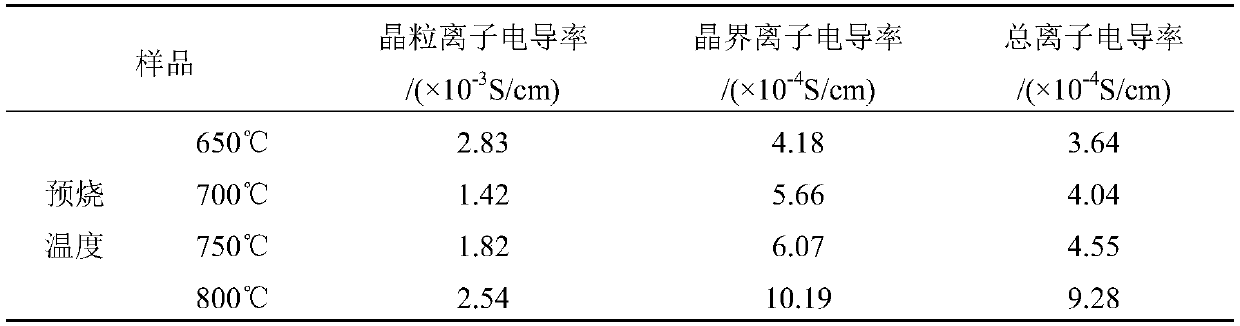

High-conductivity solid electrolyte prepared by sol-gel method

InactiveCN110885246ALower grain boundary resistanceImprove ionic conductivitySol-gelGlycol synthesis

The invention relates to the technical field of solid electrolyte, and in particular, relates to a high-conductivity solid electrolyte prepared by a sol-gel method. Any one or a composition of more oflithium nitrate, germanium oxide and tetraethoxysilane is used as a doping agent, lithium titanium aluminum phosphate is used as a main material, the doping agent is embedded into the lithium titanium aluminum phosphate framework by the sol-gel method, and an NASICON structure is formed; the solid electrolyte disclosed by the invention is small in grain boundary impedance, high in ionic conductivity, low in sensitivity to heat treatment temperature and suitable for industrial production, and integrates the characteristics of low synthesis temperature, low energy consumption, high product purity, small particle size and high density of traditional sol-gel; citric acid and ethylene glycol are adopted as auxiliary agents, environmental pollution is prevented, the temperature and the stirringrate are reasonably controlled, and the cost is reduced.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Tomato and kidney bean interplanting high-yield cultivation method

The invention relates to the technical field of vegetable planting cultivation, in particular to a tomato and kidney bean interplanting high-yield cultivation method. The method mainly includes the steps of tomato variety selection, seedbed soil arrangement, sowing, seedling management, site preparation and planting, seedling management, kidney bean variety selection, sowing and field management. Sowing time is scientifically set, temperature and illuminance of a greenhouse are reasonably controlled, fertilization and pest killing are reasonably carried out in different growth stages according to biological features of plants, and the plant spacing of the tomatoes and the kidney beans is scientifically and reasonably arranged, so that high yield of the tomatoes and the kidney beans can be achieved, residues of fertilizers used for the tomatoes can be used by the kidney beans, fertilization waste is reduced, production cost is reduced and economic benefits are increased.

Owner:陆佳乾

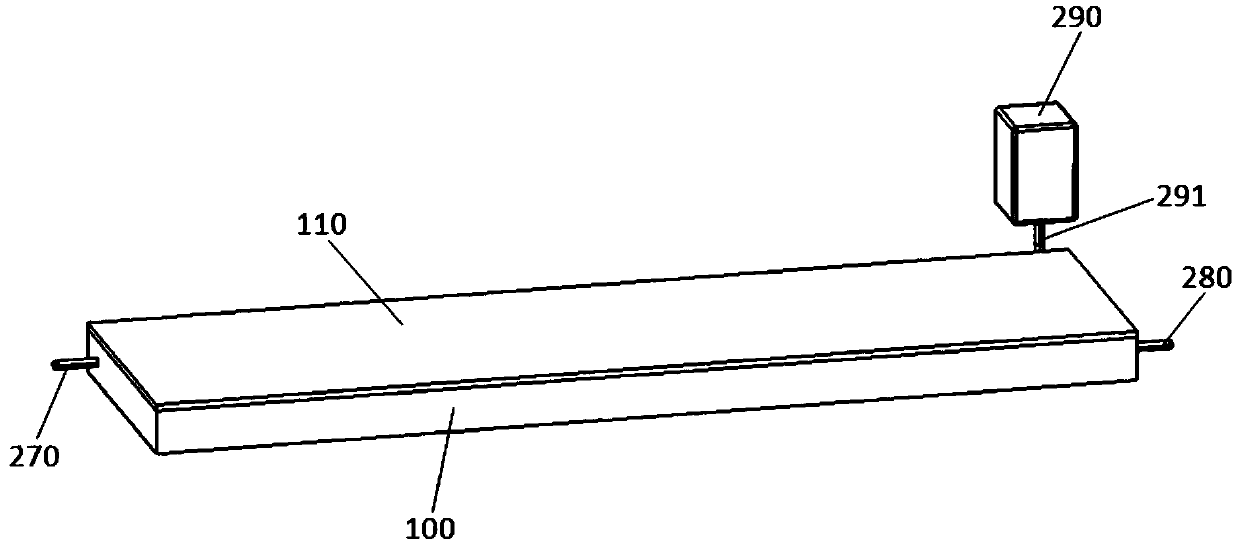

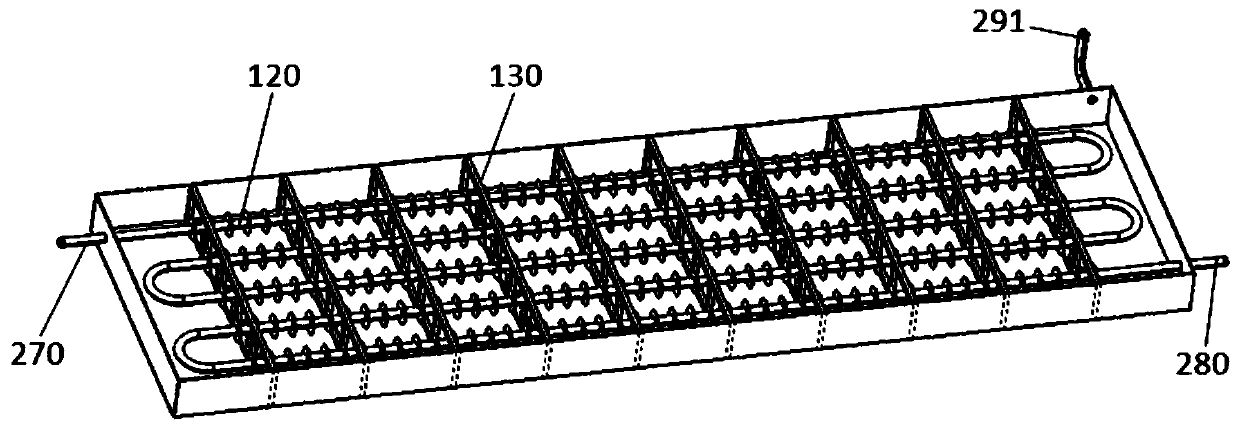

Commercial vehicle sleeping berth area conditioner and control method thereof

InactiveCN108248337ASmall temperature fluctuationsUniform temperatureAir-treating devicesVehicle heating/cooling devicesTemperature controlAutomatic control

The invention discloses a commercial vehicle sleeping berth area conditioner, comprising: a liquid heating berth structure, a radiator, an automatic temperature control system and a floor drain system; the liquid heating berth structure is arranged above a commercial vehicle toolbox and is basically the same as an original berth in position and size, so that modification is facilitated; the radiator is arranged in the liquid heating berth structure and is connected with an engine circulating cooling pipe; the radiator dissipates heat to the liquid heating berth structure so that uniform temperature is provided for the berth. The invention discloses a control method of the commercial vehicle sleeping berth area conditioner; sleeping berth area temperature is automatically controlled throughsignal feedback action among a temperature sensor, a flow sensor, a controller and an electric water valve; when a system leak occurs, an engine is protected, comfort is improved for passengers who rest in the sleeping berth area. The commercial vehicle sleeping berth area conditioner is safe and reliable to use.

Owner:JILIN UNIV

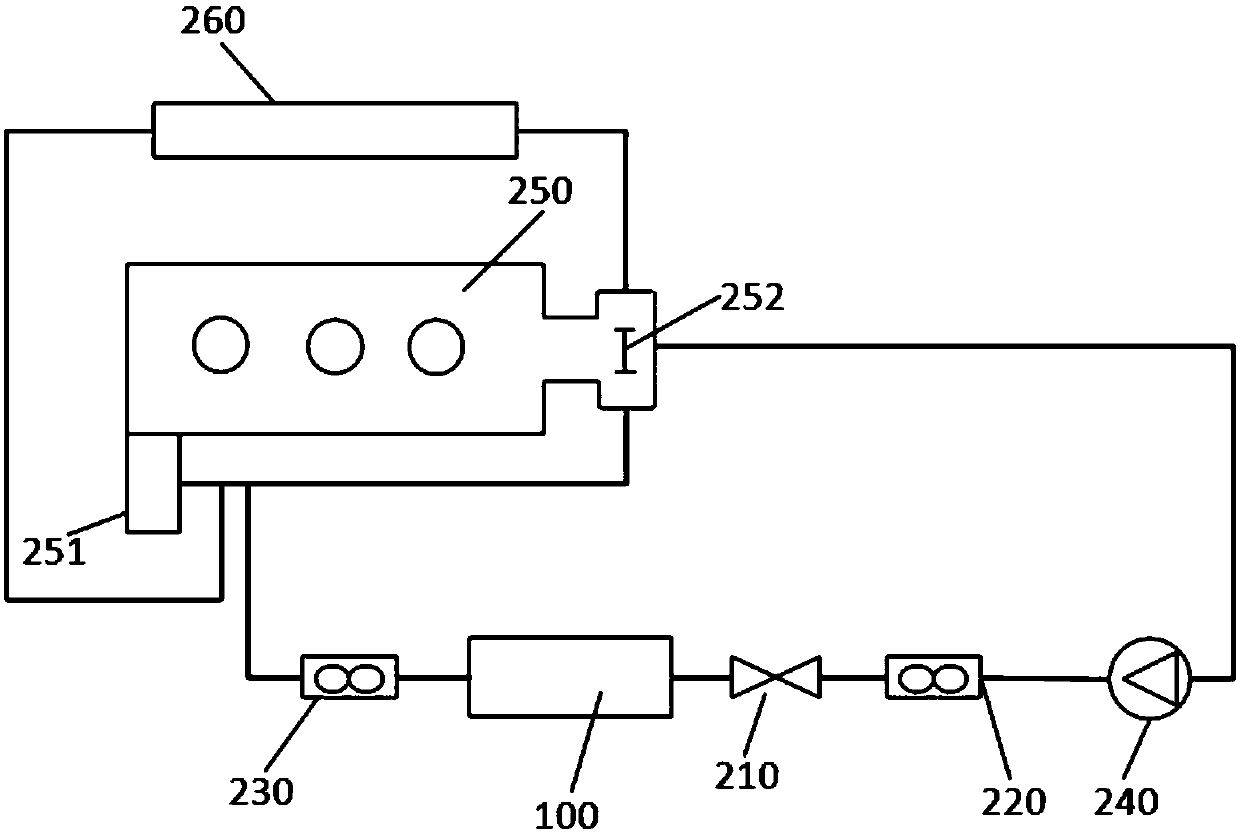

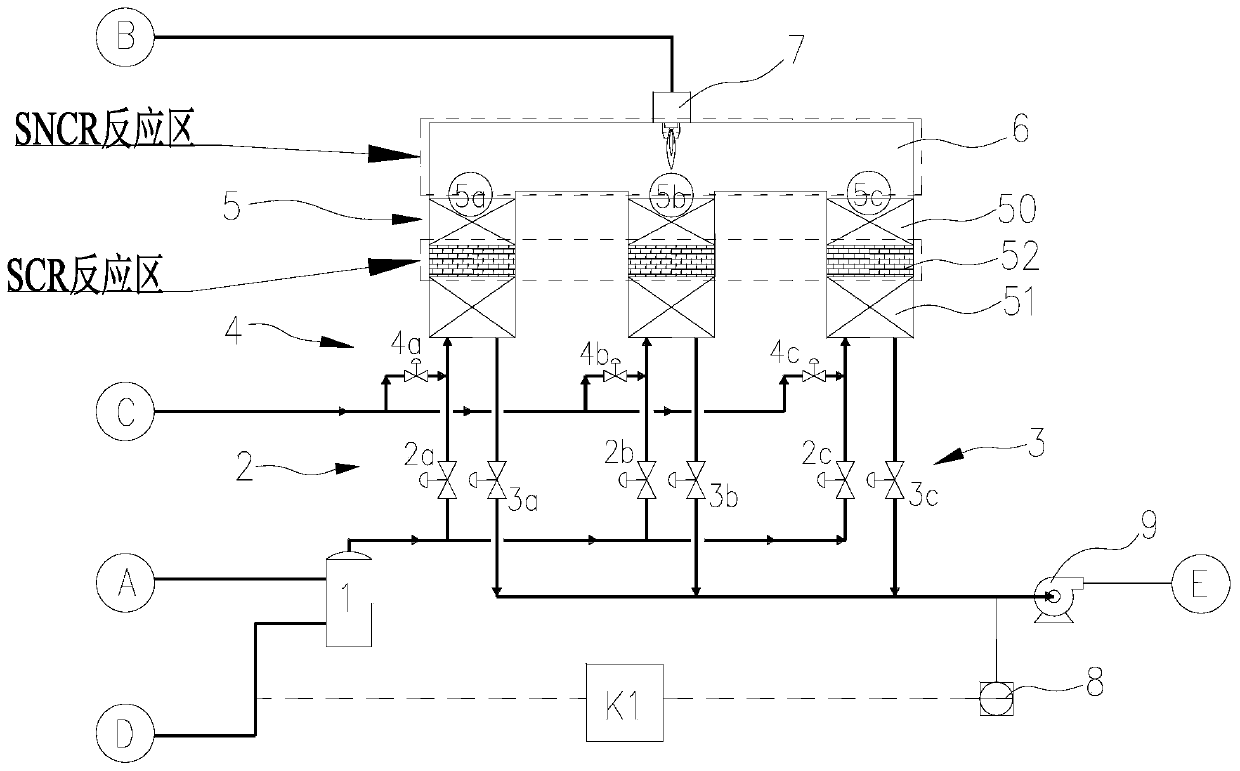

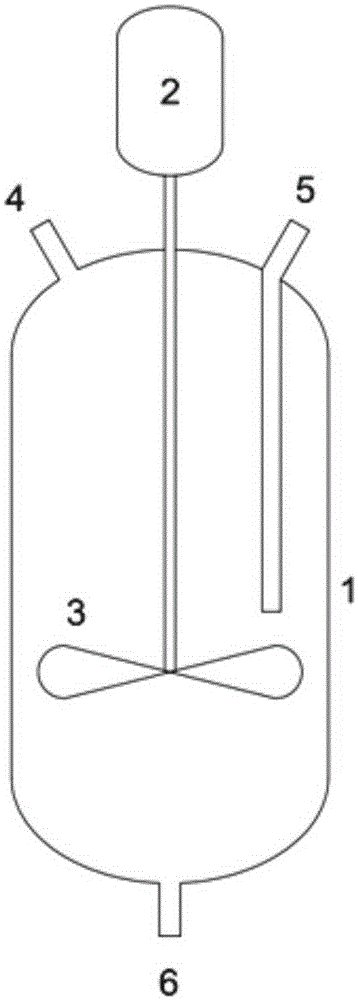

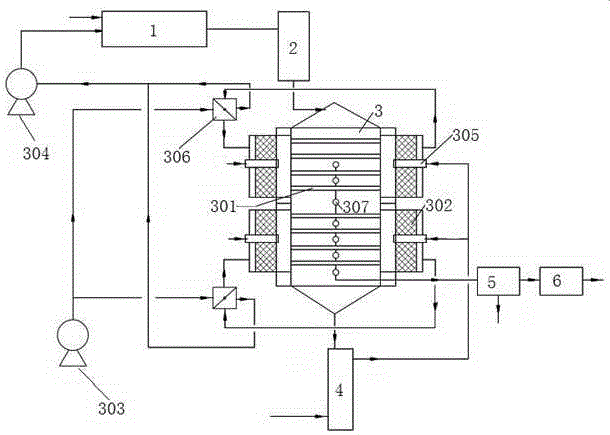

Treatment device and process integrating VOCs purification and denitration

PendingCN110605019AEfficient removalReduce energy consumptionDispersed particle separationIncinerator apparatusCombustorCombustion chamber

The invention discloses a treatment device and process integrating VOCs purification and denitration. The treatment device includes an RTO reactor; the RTO reactor comprises a combustion chamber and aplurality of regenerative chambers, the combustion chamber and the regenerative chambers are communicated, and the combustion chamber is located on the upper portions of the regenerative chambers; each regenerative chamber comprises an upper-section heat accumulator, a lower-section heat accumulator and a middle SCR catalyst bed layer; an air inlet valve, an air outlet valve and a purging valve are arranged at the bottom of any regenerative chamber; the input end of the gas inlet valve is connected with a buffer tank, and the buffer tank is connected with a VOCs waste gas pipeline and an ammonia gas pipeline; the input end of the purge valve is connected with a purge gas supply pipeline; a combustor is further arranged at the top of the combustion chamber, wherein the input end of the combustor is connected with a fuel gas pipeline. According to the device, the high-temperature environment in the RTO reactor is fully utilized in the SNCR-SCR reaction, ultra-clean emission of VOCs andNOx is achieved, and the purpose of reducing energy consumption is achieved. Meanwhile, a corresponding treatment process is provided, so that VOCs can be effectively purified and NOx can be effectively removed at the same time, and the operation is reliable.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

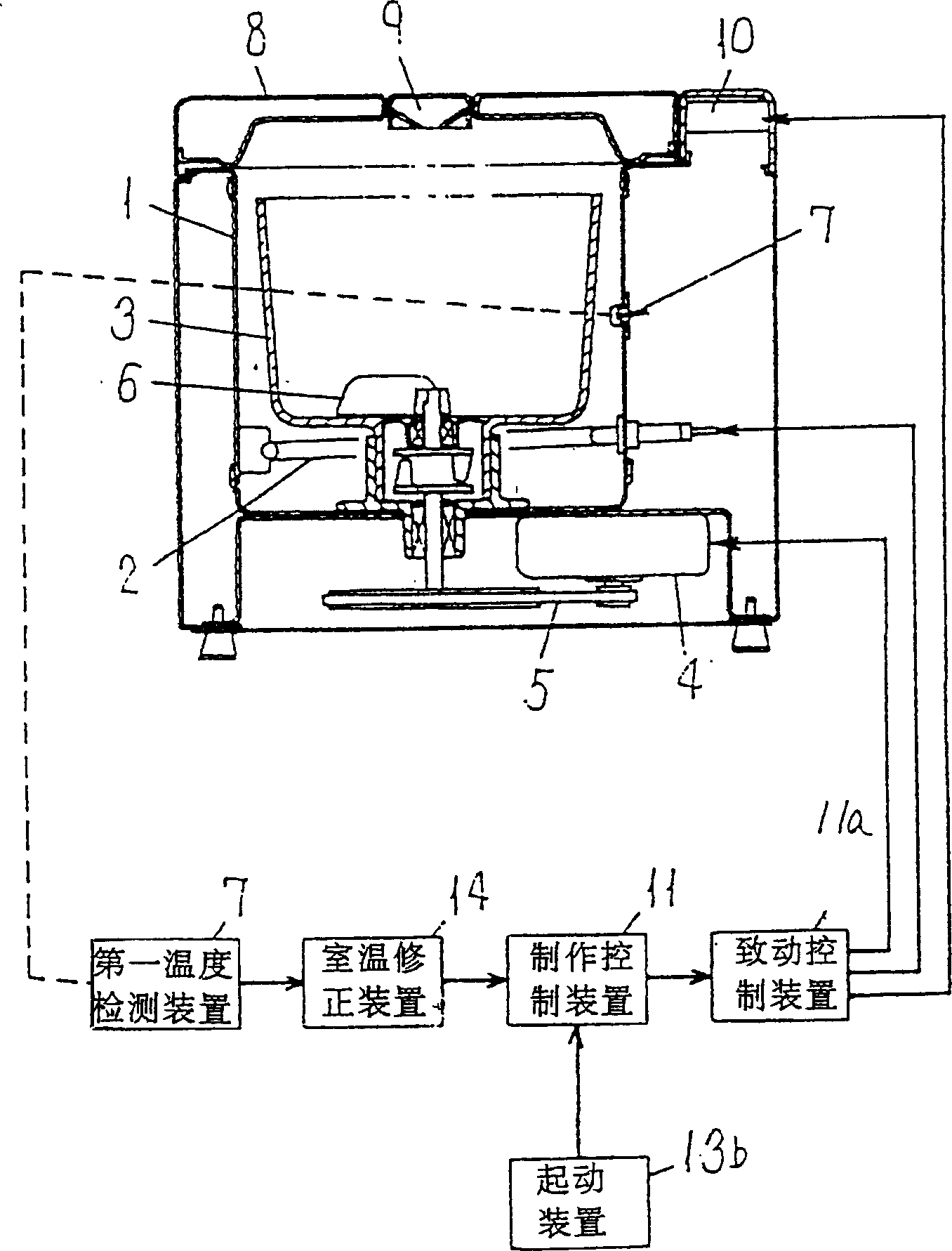

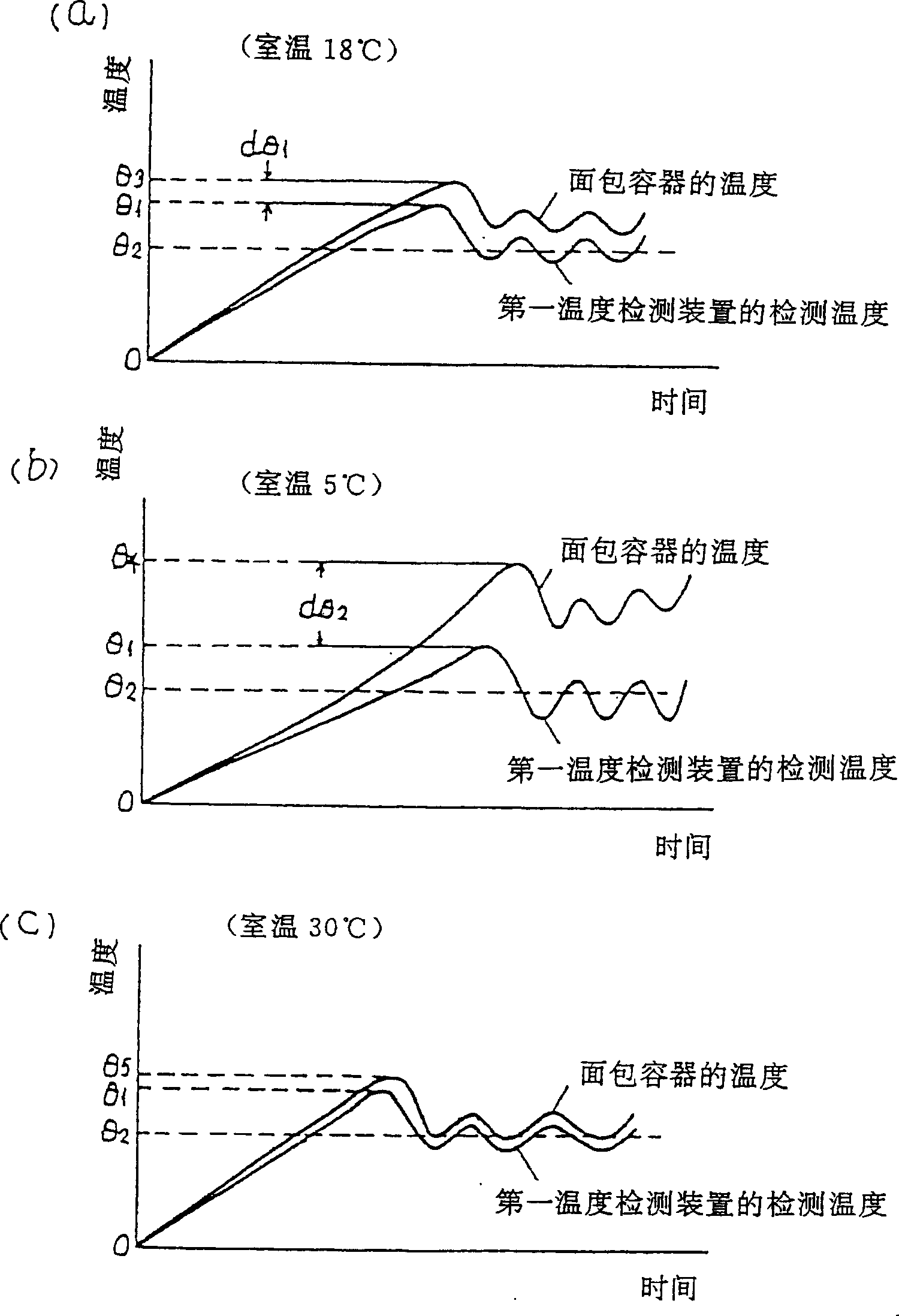

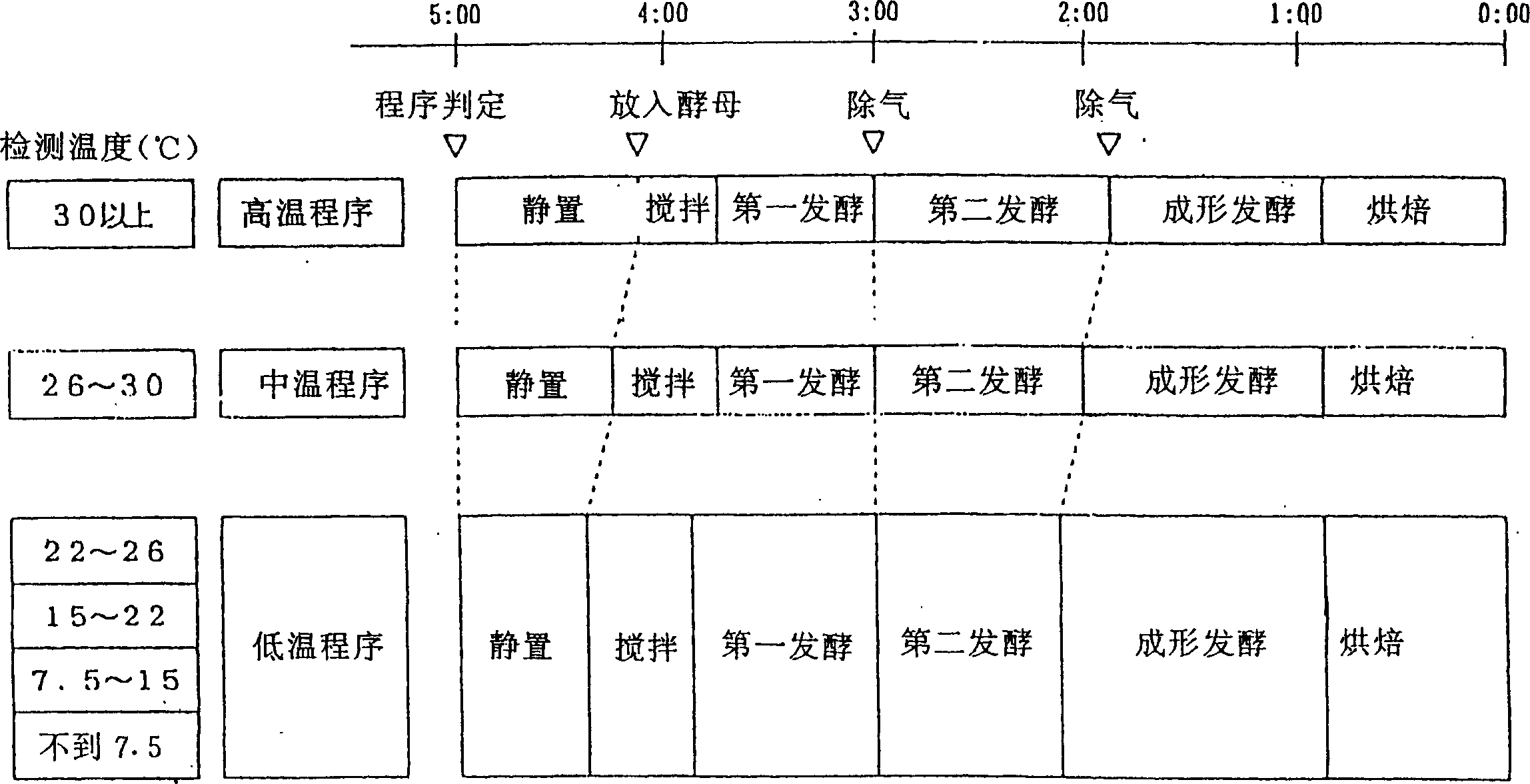

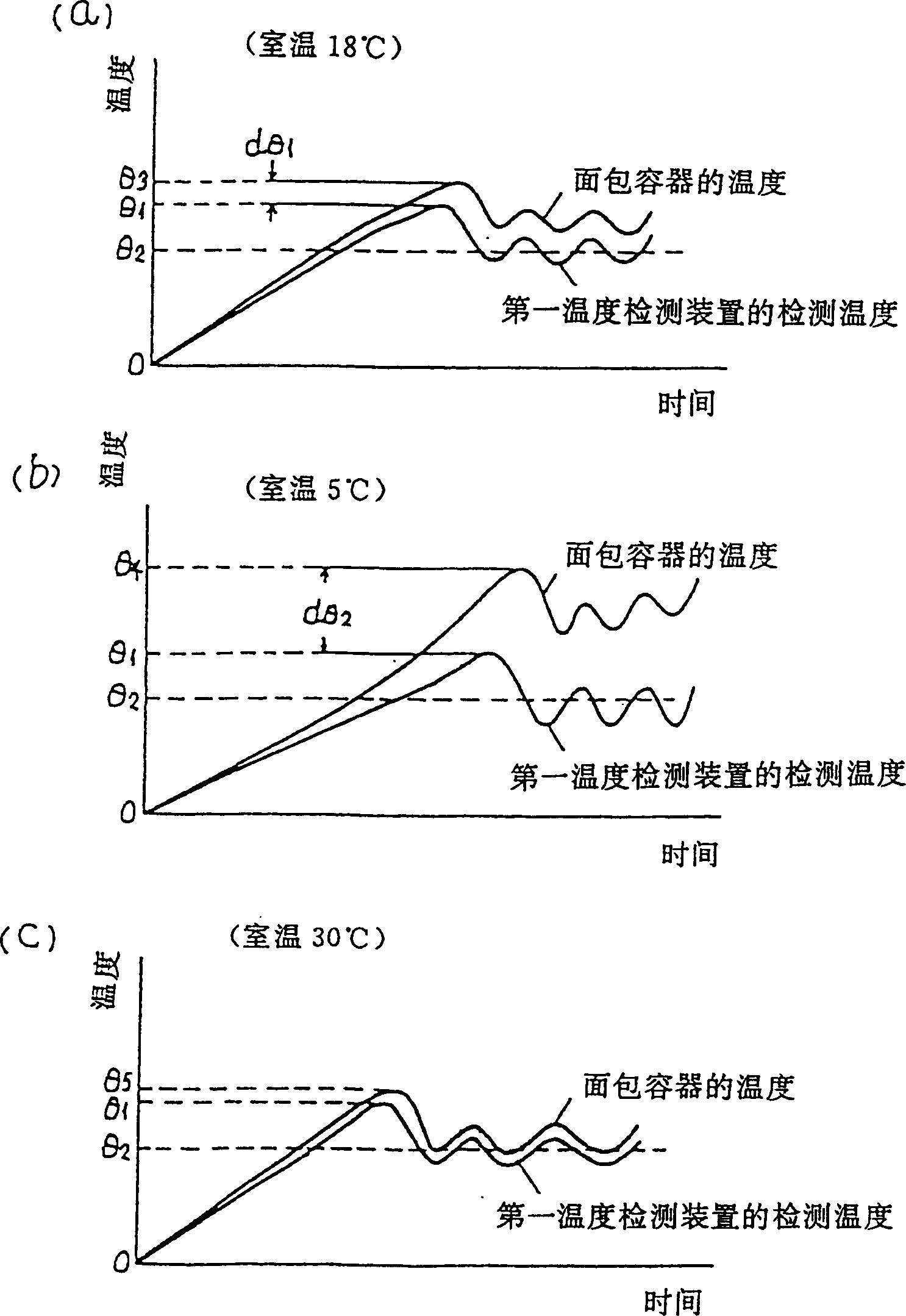

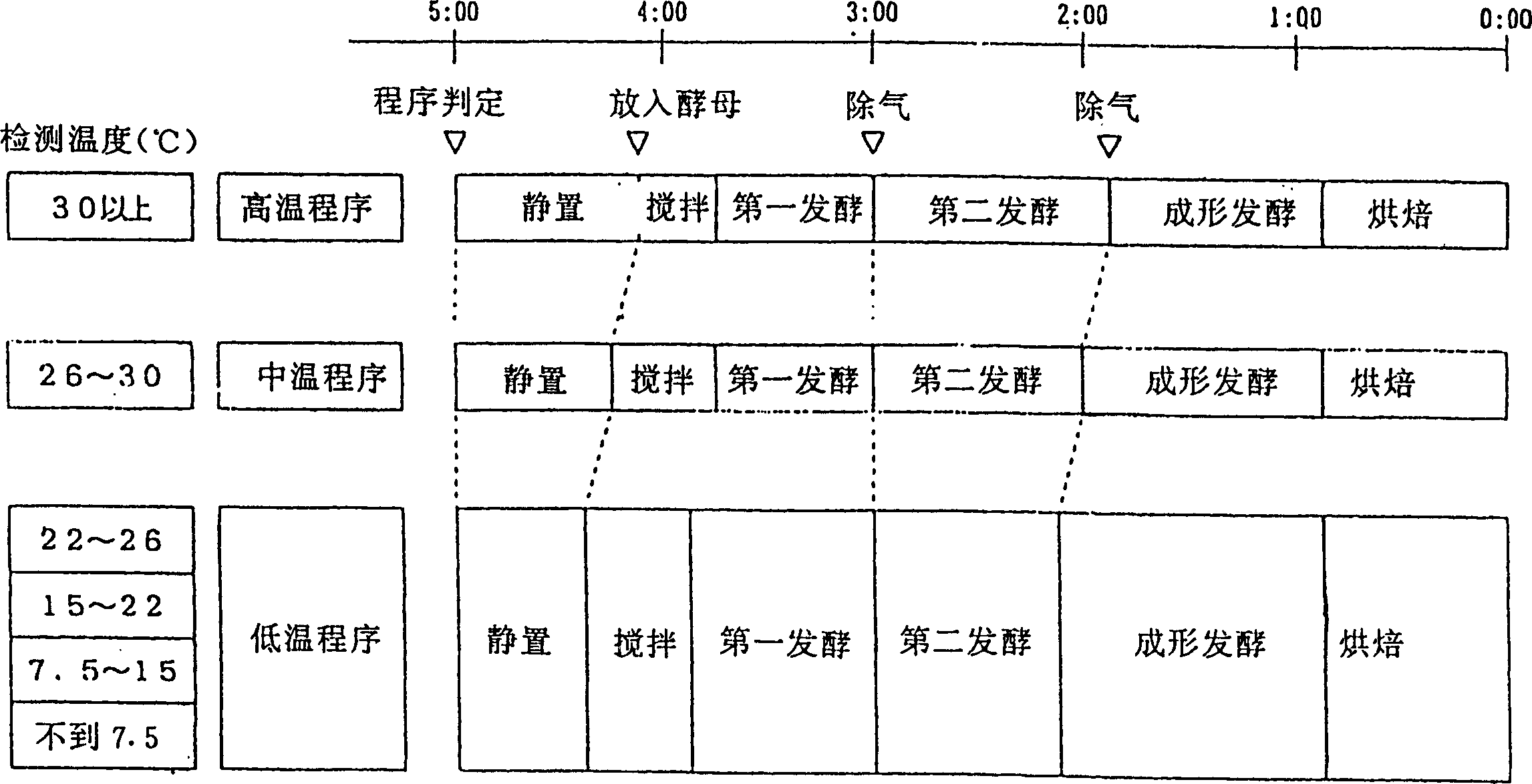

Automatic bread producing machine

InactiveCN1846583AGood correction valueReasonable temperature controlBread-toastersSpecial goods bakingTemperature controlRoom temperature

An automatic bread machine, which detects the temperature in the baking room to control the temperature of the bread container in the baking room, which can prevent the temperature of the bread container from being incorrectly detected due to the influence of the room temperature, and make the finished bread in good shape. It includes: a first temperature detection device (7) for detecting the temperature in the baking chamber (1); a room temperature correction device (14) for correcting the temperature measured by the detection device (7) according to the room temperature; The process control temperature is compared to control the production control device of the heating capacity of the heater (2) in each process.

Owner:PANASONIC CORP

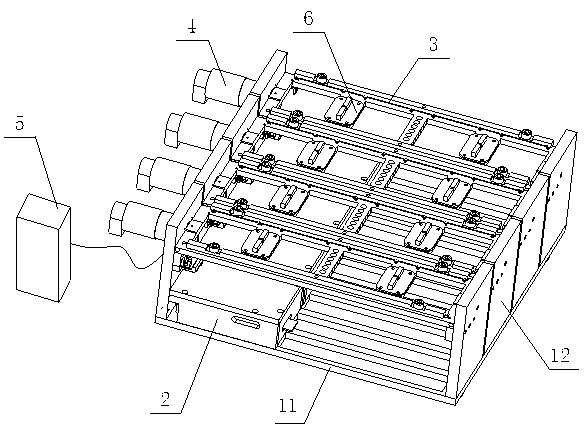

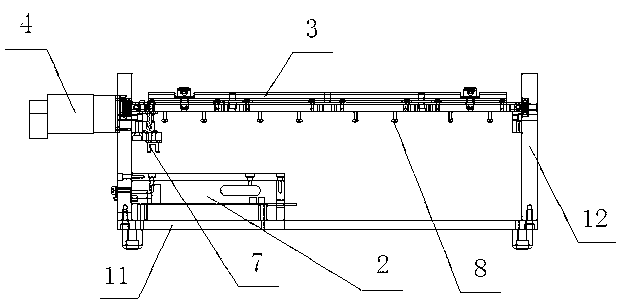

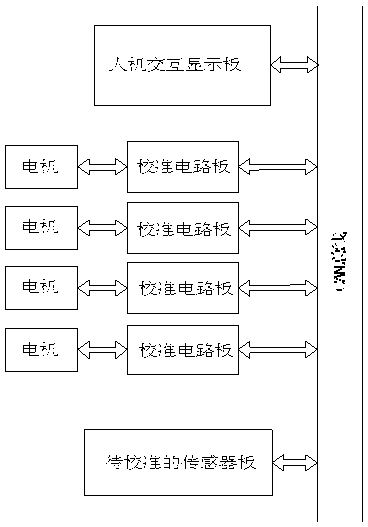

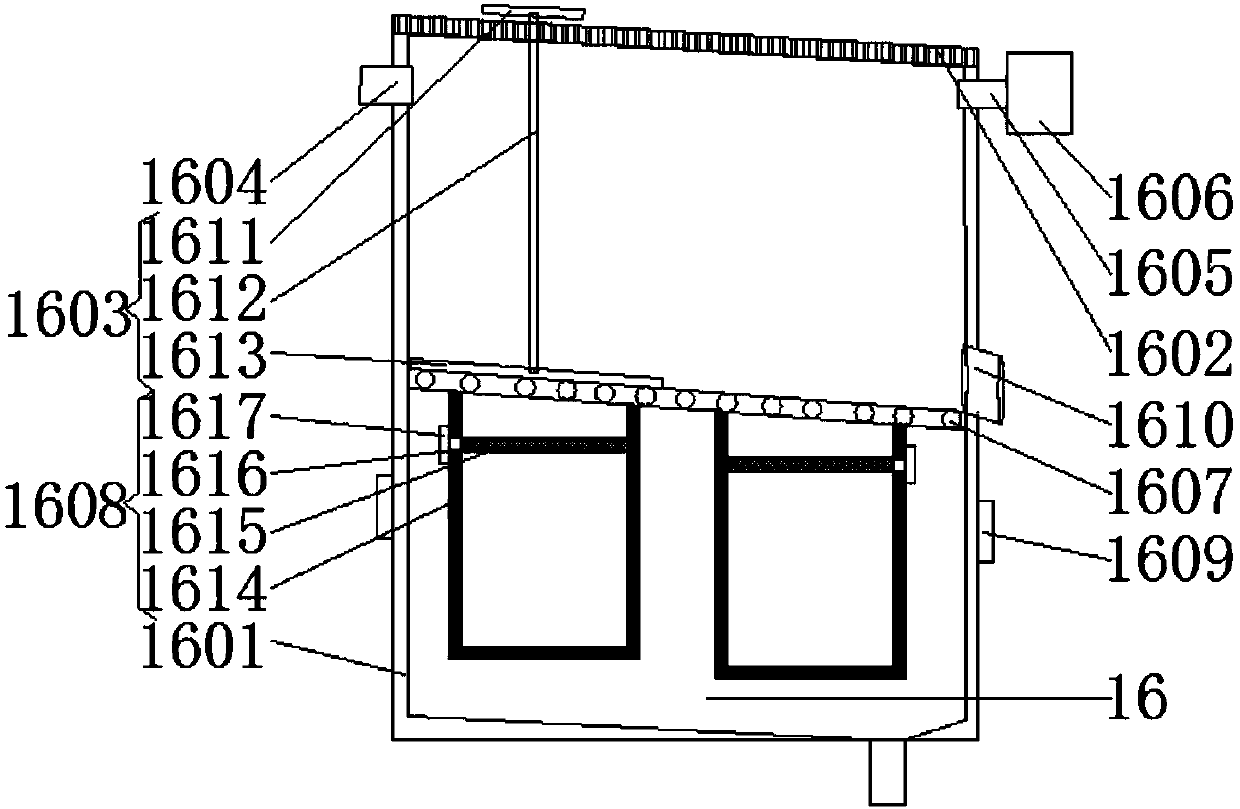

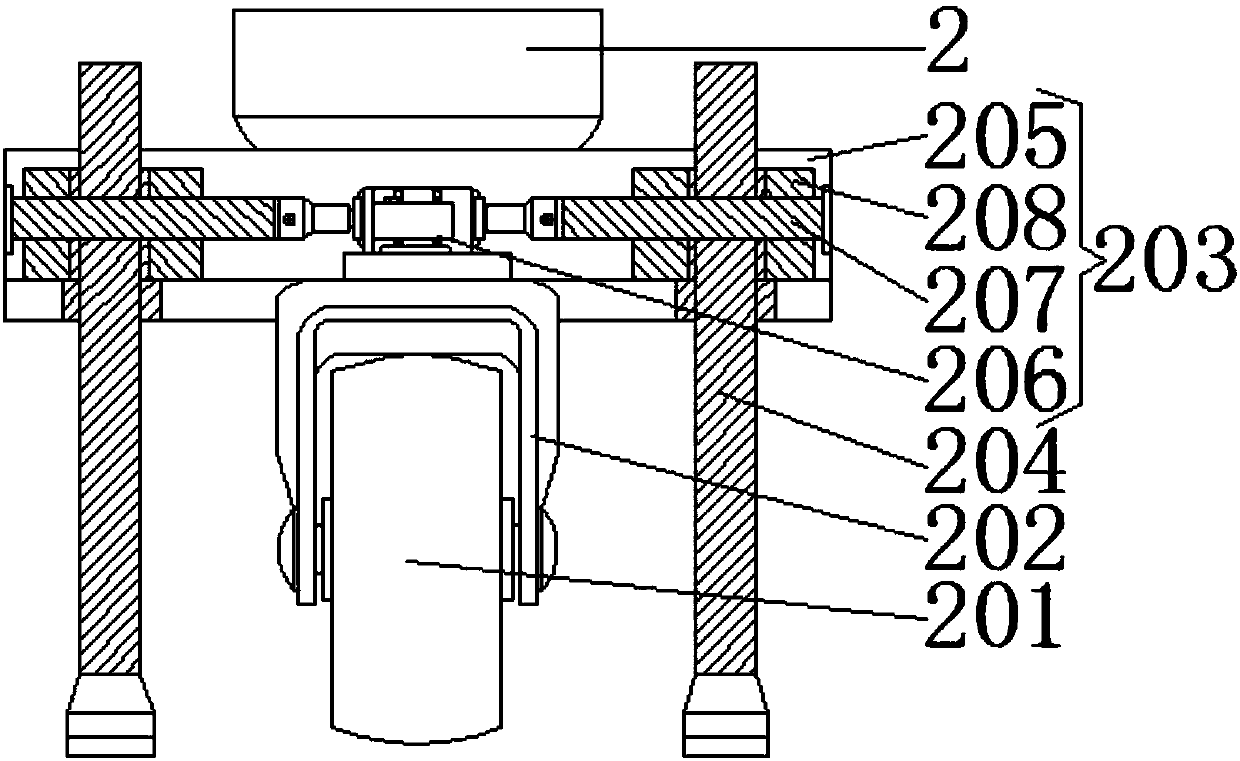

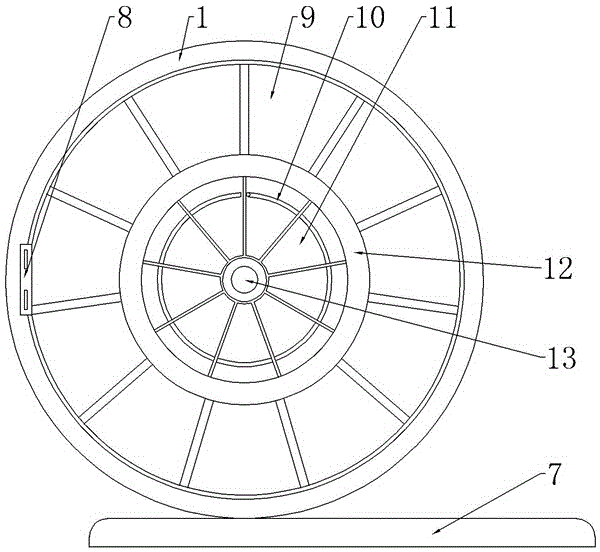

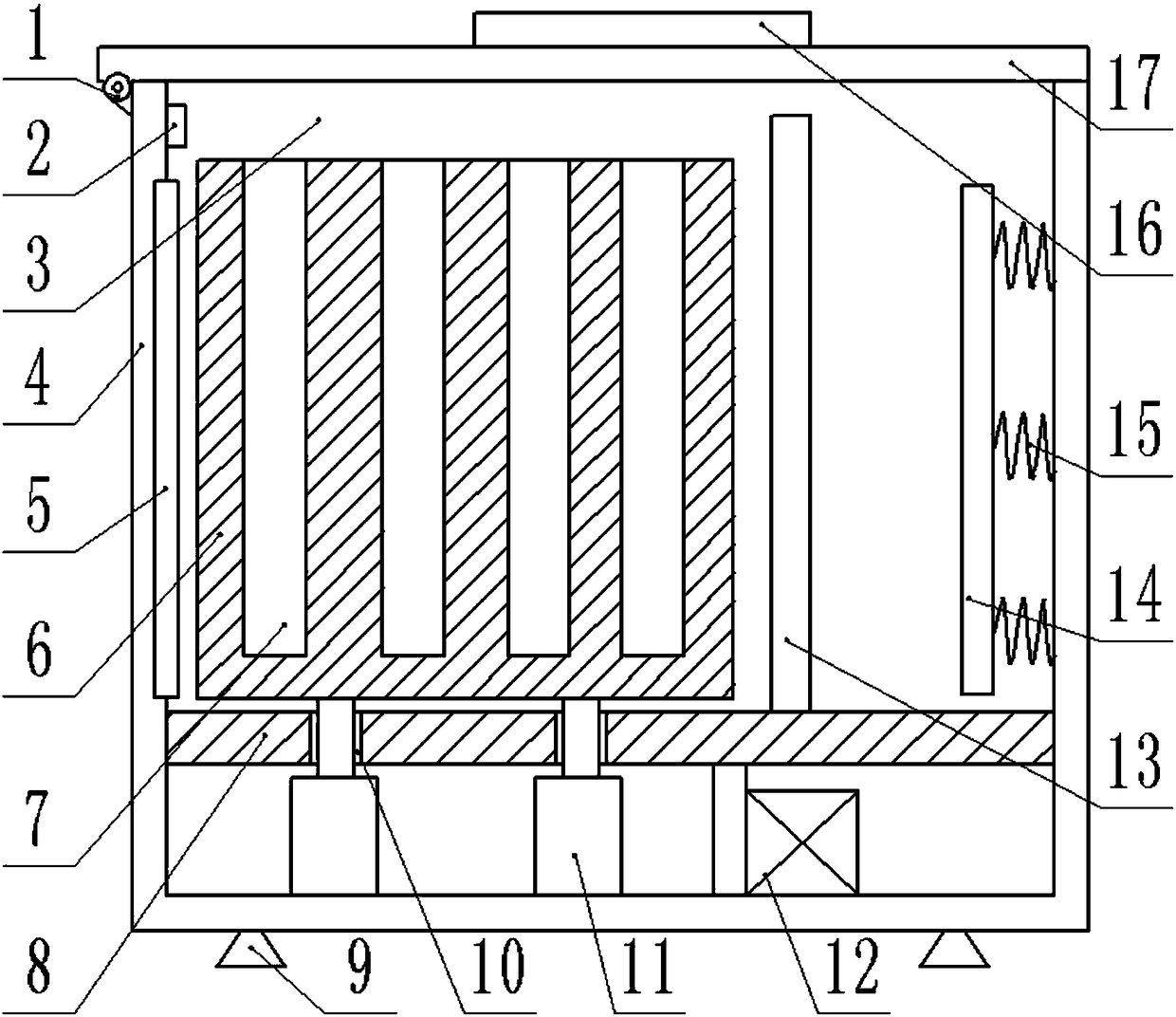

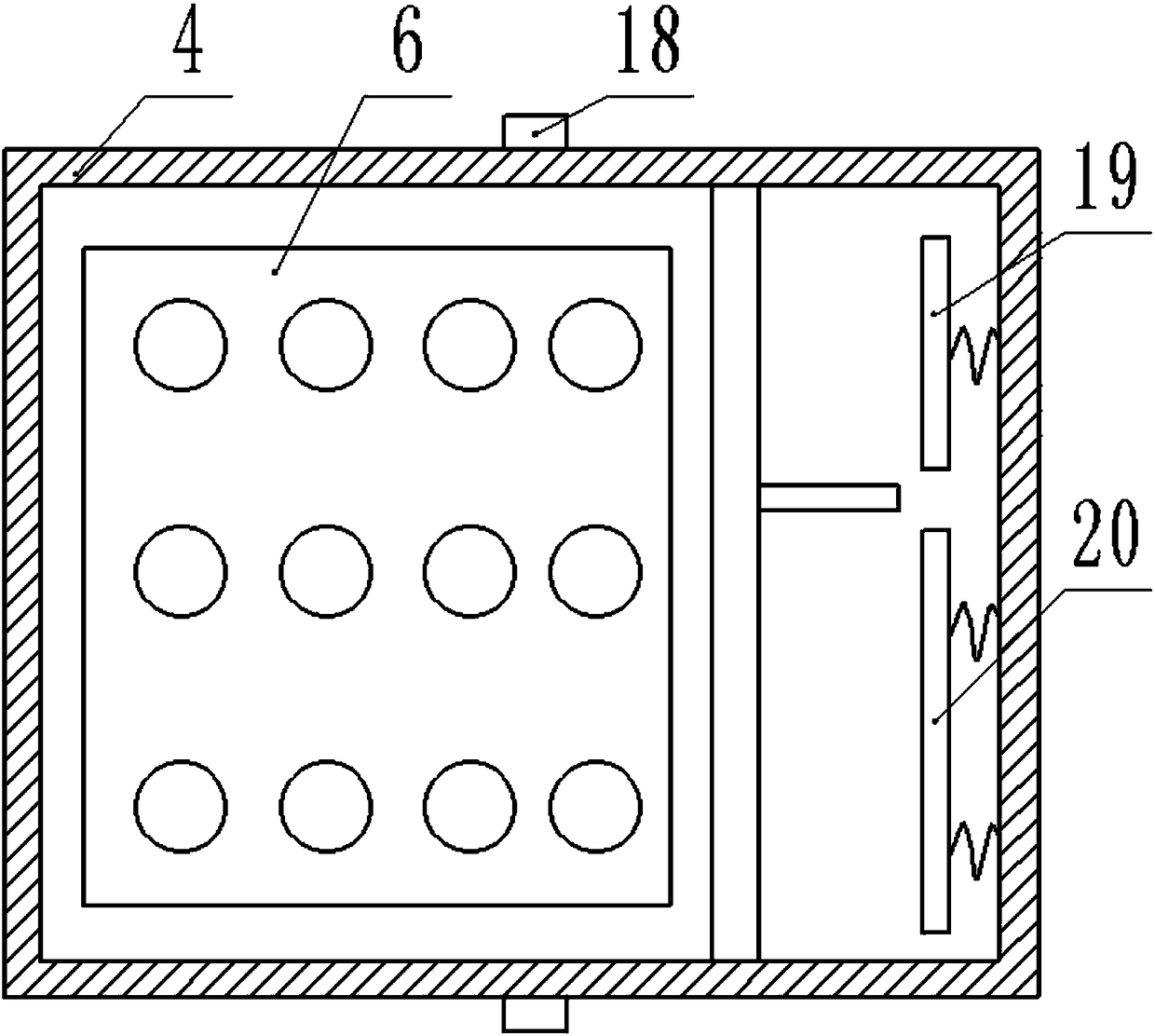

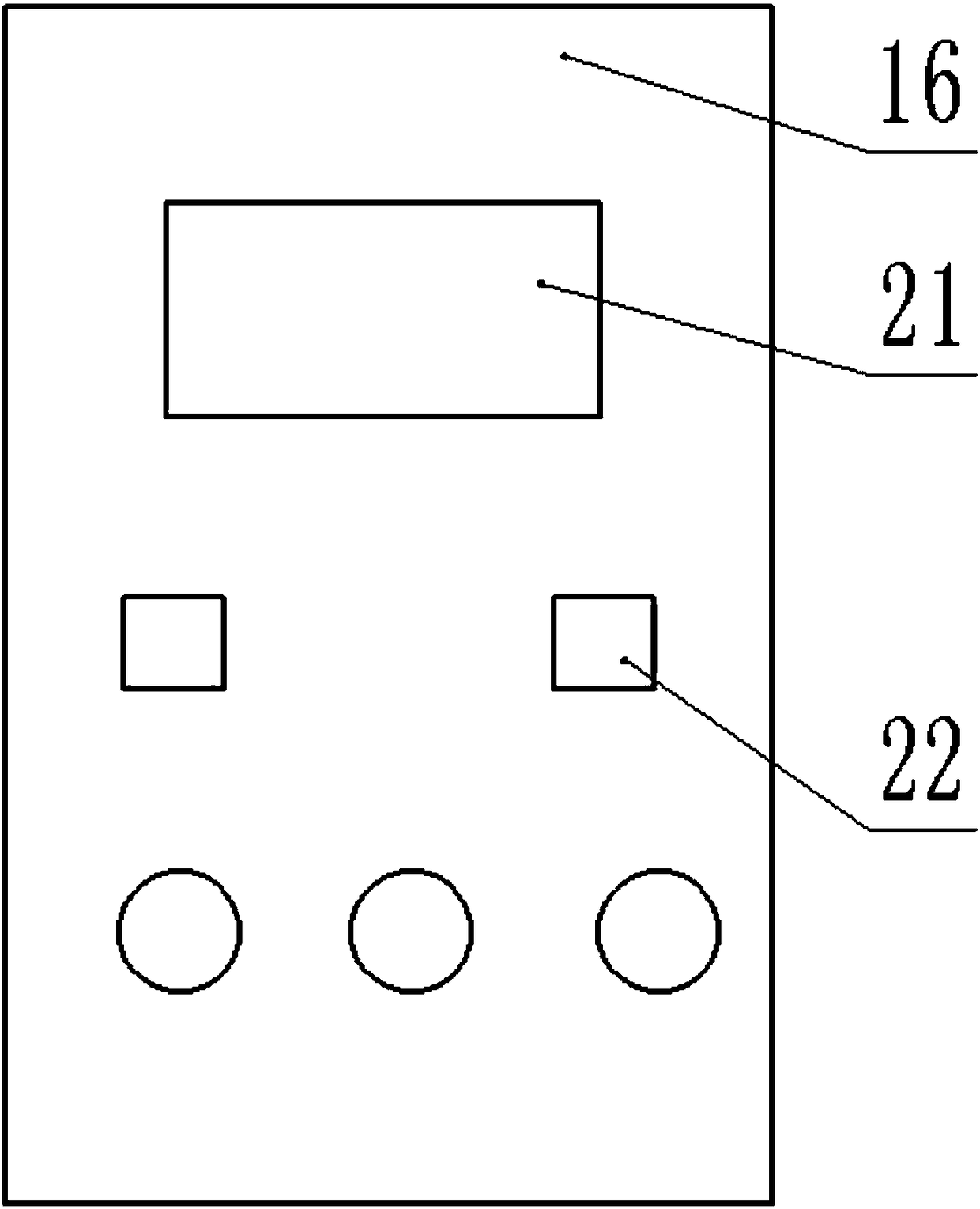

Gyroscope sensor calibrating device and calibrating method

ActiveCN103017785ARealize batch calibrationSolve the problem that the output data deviates from the zero pointMeasurement devicesLocation detectionDisplay board

The invention discloses a gyroscope sensor calibrating device which comprises a CAN (Controller Area Network) bus, a fixing table, a calibration circuit board, a rotating bracket capable of fixing a plurality of sensor plates, motors for driving the rotating bracket to rotate and a man-machine interaction display board, wherein the fixing table consists of a bottom plate and side plates which are symmetrically arranged on two sides of the bottom plate; the calibration circuit board is arranged on the bottom plate; two ends of a rotating shaft of the rotating bracket are respectively installed on the side plates on two sides of the bottom plate; sensor slot devices through which the sensor plates are supplied with power and communicate with other components are arranged on the rotating bracket; the sensor slot devices are connected with the CAN bus; the motors are installed on the side surfaces of the side plates and are connected with the rotating shaft of the rotating bracket; photoelectric limiting switches for controlling the motors to operate and detecting the position of the rotating bracket are further arranged on the side plates; and both the calibration circuit board and the man-machine interaction display plate are connected with the CAN bus. The invention also discloses a calibrating method of a gyroscope sensor.

Owner:张明铭

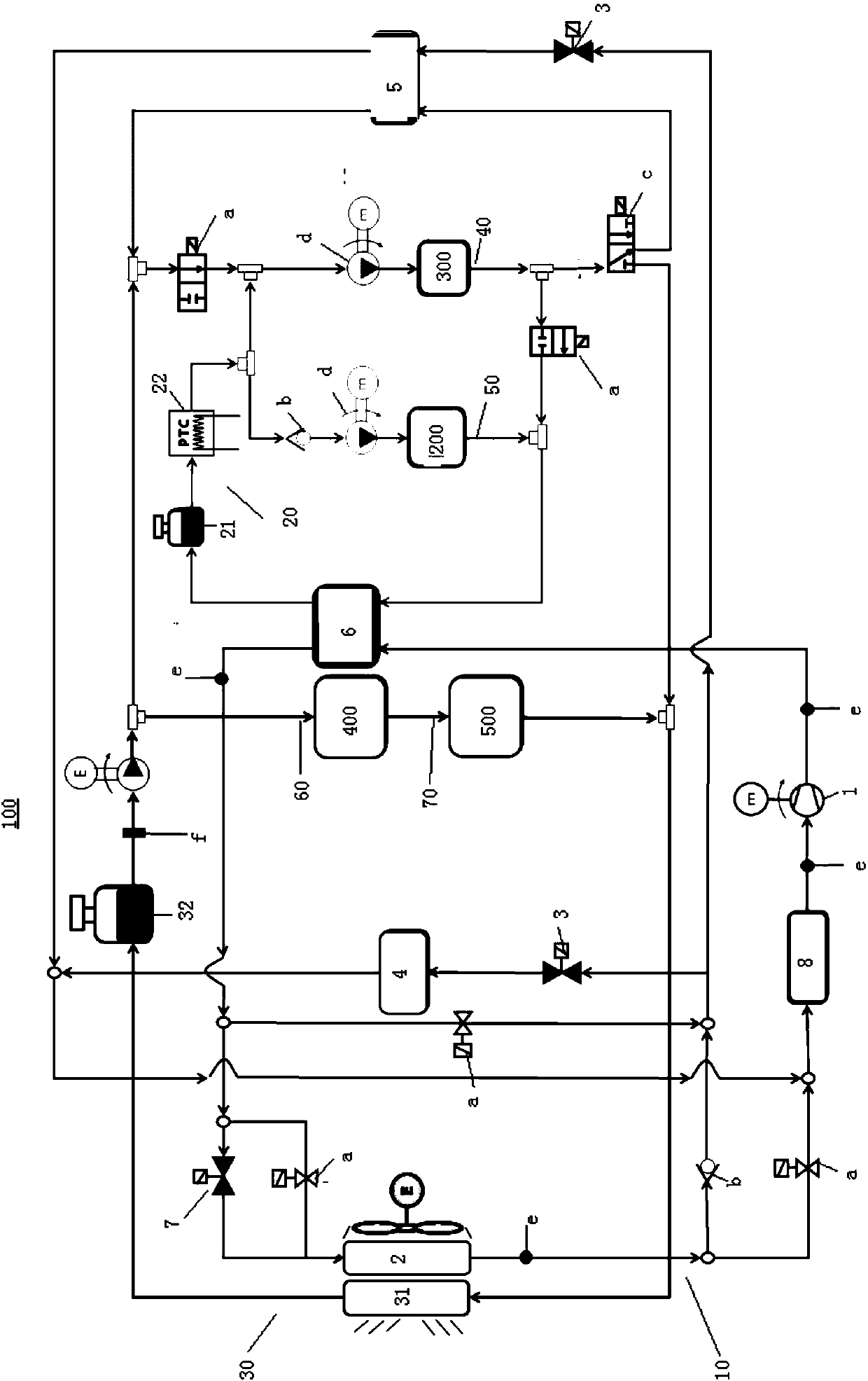

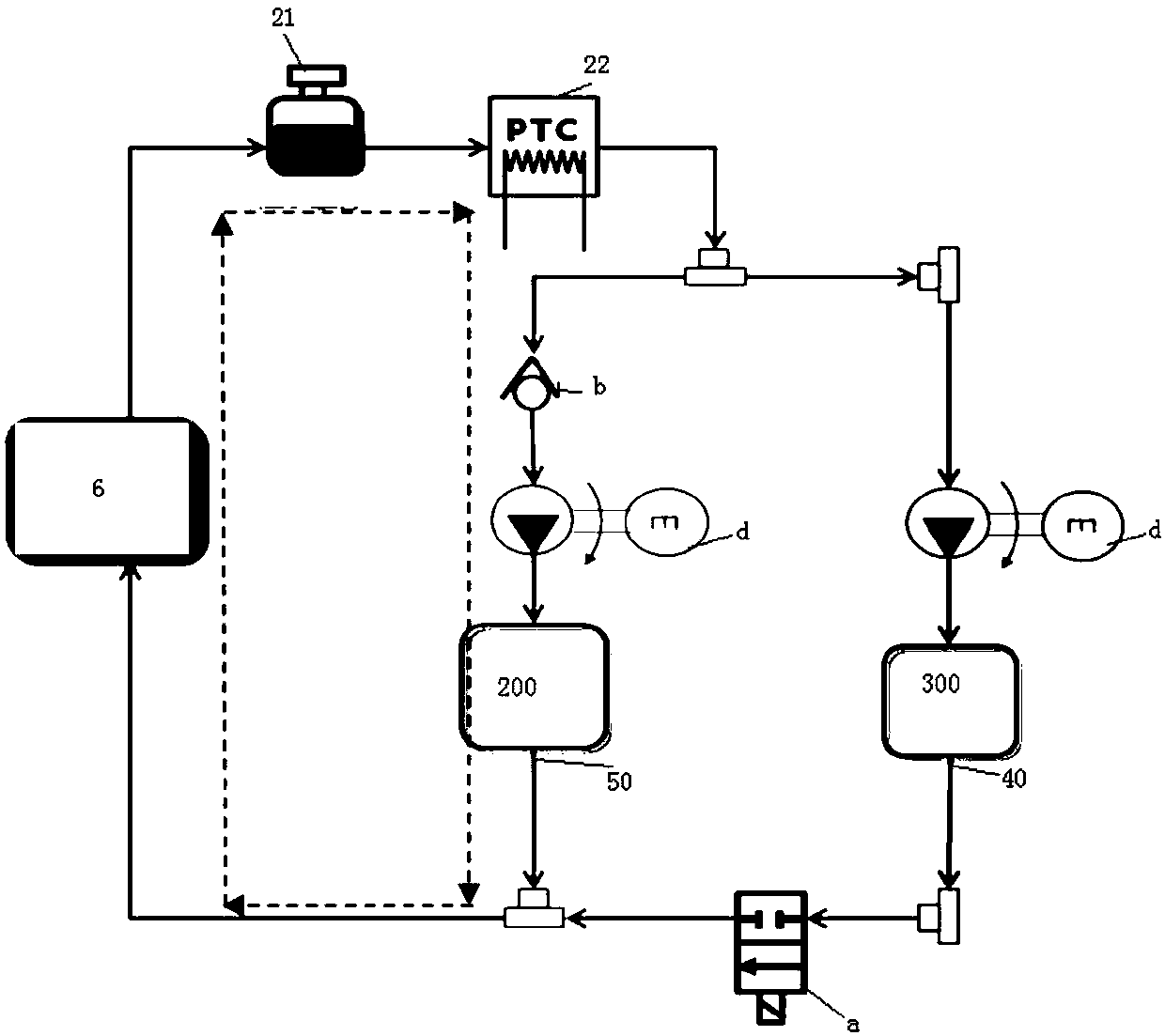

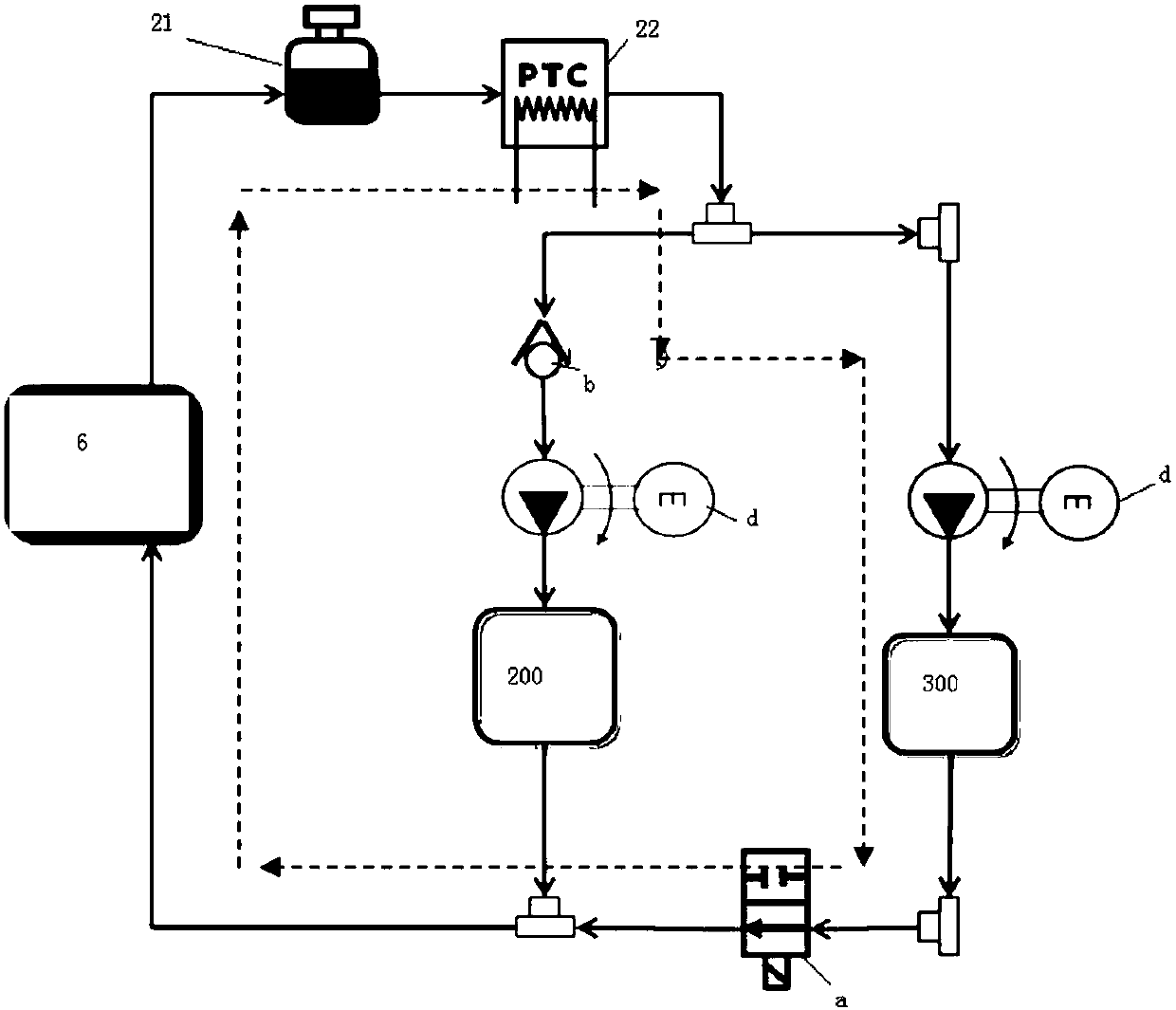

Heat management system of vehicle and vehicle

InactiveCN110116600AReasonable temperature controlControl temperature controlAir-treating devicesVehicle heating/cooling devicesSystems designDrive motor

The invention provides a heat management system of a vehicle and the vehicle. The heat management system comprises an air conditioning system, a PTC heating system and a heat dissipation system, wherein the air conditioning system comprises a compressor, an outdoor heat exchanger, a first throttling element, an evaporator and a water chilling unit; the compressor, the outdoor heat exchanger, the first throttling element and the evaporator are sequentially connected end to end; the evaporator is connected with the water chilling unit in parallel; and the water chilling unit further communicateswith a battery pack pipeline at a battery pack; the PTC heating system corresponds to a warm air core pipeline at a warm air core and the battery pack pipeline at the battery pack; and the heat dissipation system corresponds to a high-voltage system pipeline at a high-voltage system, a drive motor pipeline at a drive motor and the battery pack pipeline at the battery pack. The heat management system can reasonably control the temperatures of a cockpit, the battery pack, the high-voltage system and the drive motor, so that the temperature control of the whole vehicle is reasonable, integratedcontrol is achieved, and the purpose of accurate and intelligent cooling system design can be achieved.

Owner:GREAT WALL MOTOR CO LTD

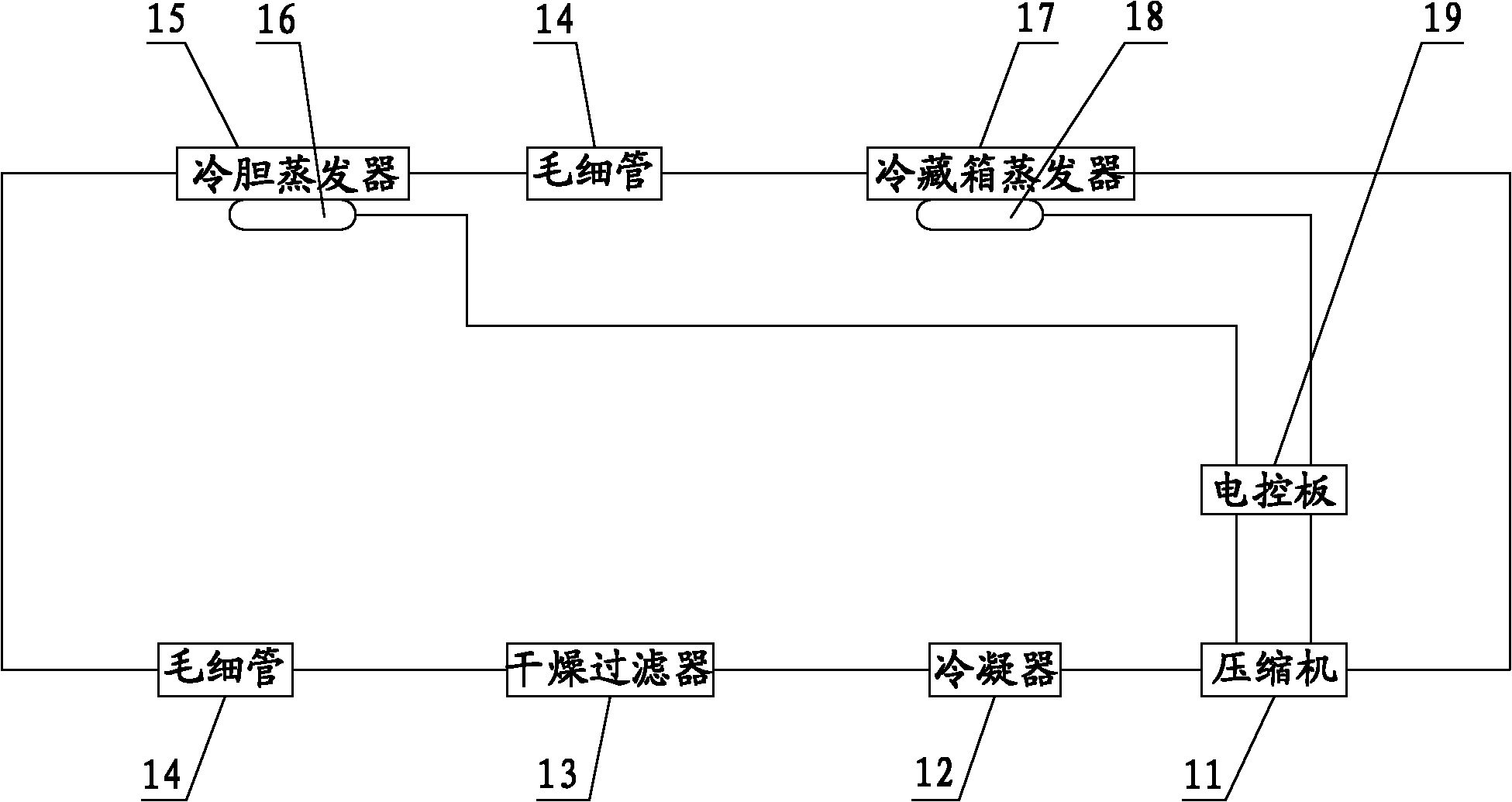

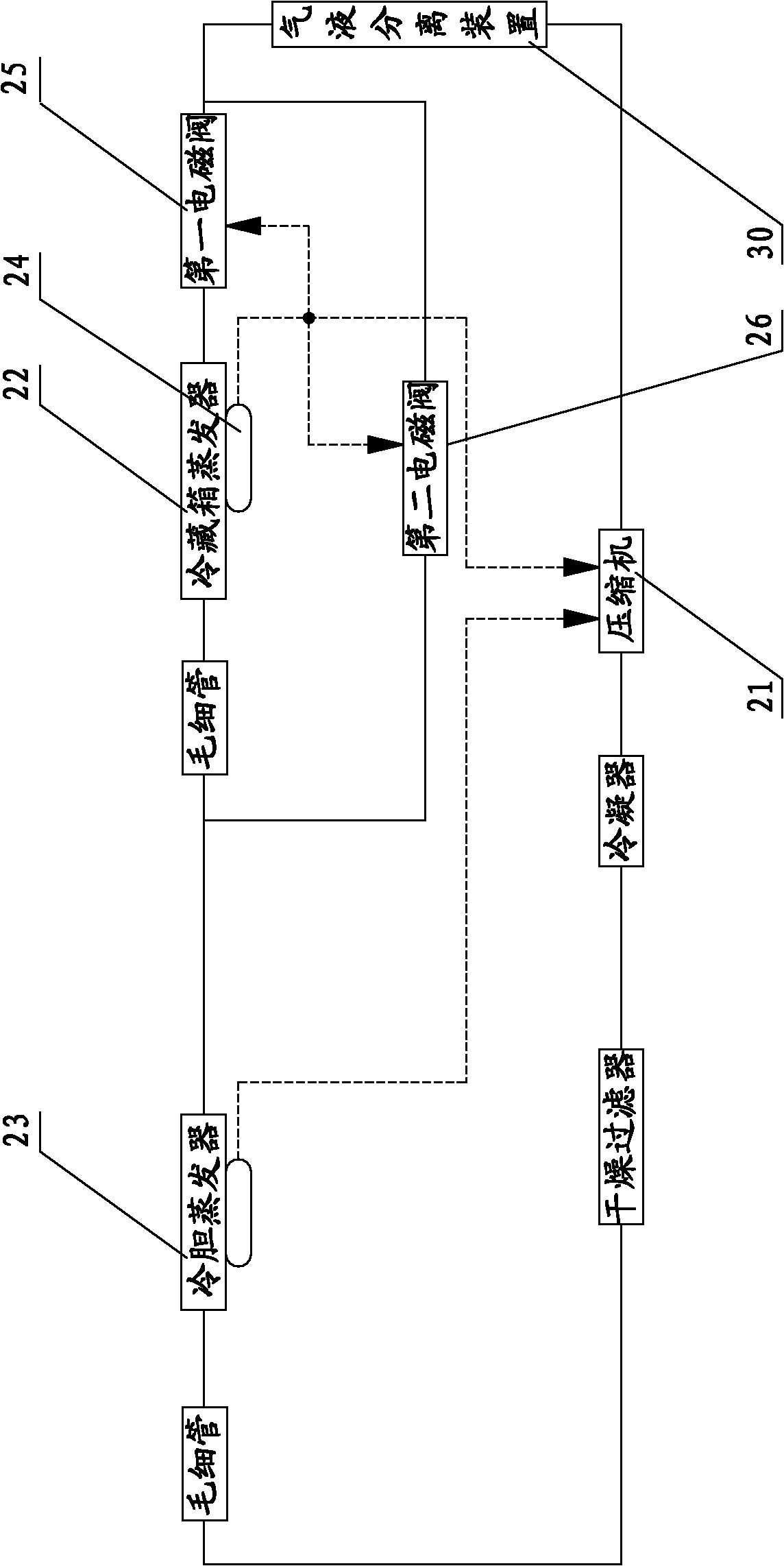

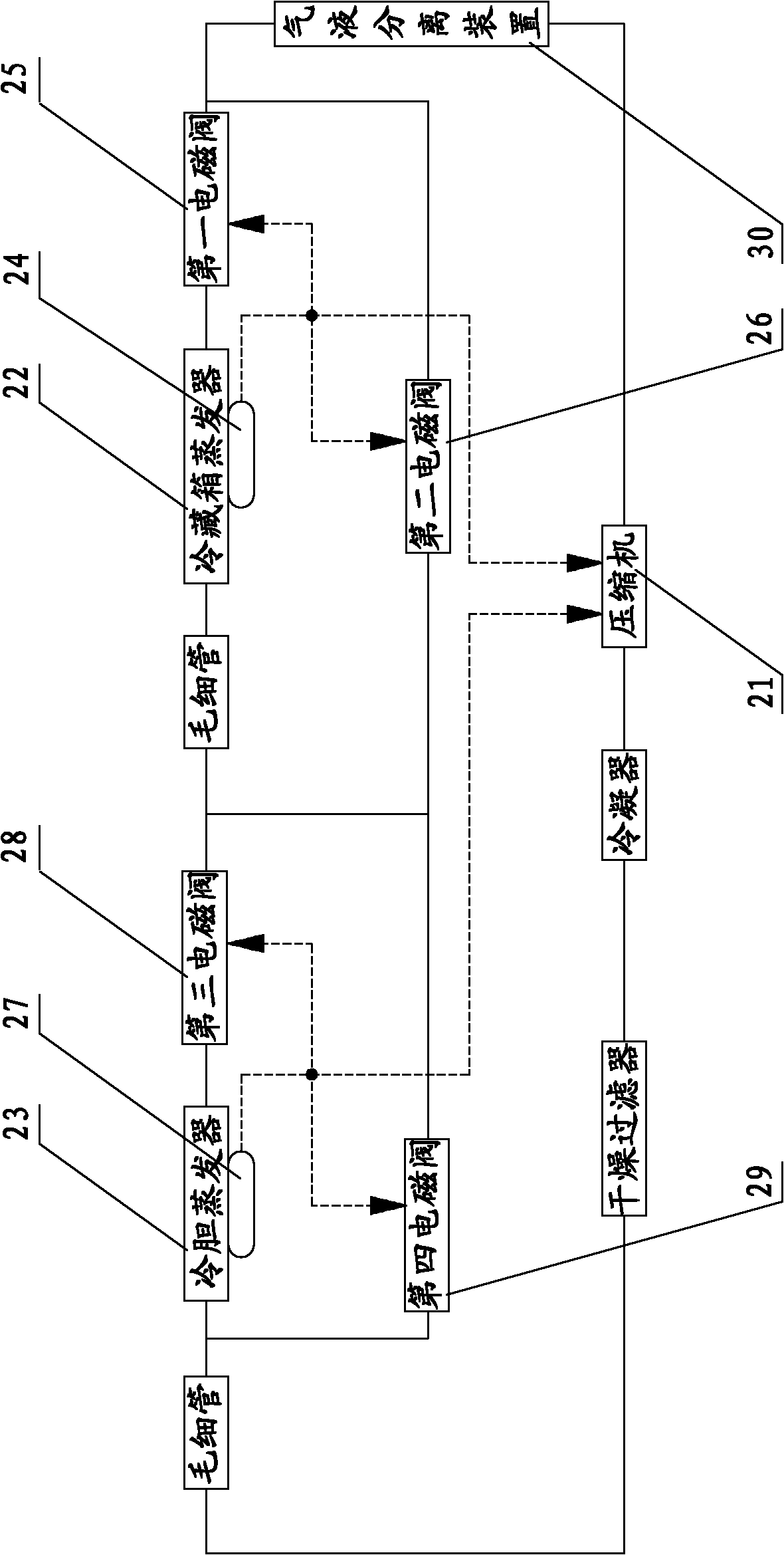

Water dispenser and compressor refrigerating system thereof

InactiveCN101982714AImprove reliabilityTemperature controlCompression machines with several evaporatorsFluid circulation arrangementTemperature controlEngineering

The invention discloses a compressor refrigerating system for a water dispenser, which comprises a compressor, a freezer evaporator, a cold liner evaporator, a first temperature sensor for detecting the temperature of the freezer evaporator, and a first branch loop connected with a first major loop of the freezer evaporator in parallel, wherein, the first temperature sensor controls one of the first major loop and the first branch loop to be connected and the other one to be disconnected when the compressor works. The compressor refrigerating system has the advantages that the temperature of a freezer can be effectively and reasonably controlled and is not affected by temperature control of a cold liner by means of coordination of the first major loop and the first branch loop, thus the controllability and the reliability of the water dispenser can be enhanced. The invention also provides the water dispenser comprising the compressor refrigerating system.

Owner:QIDI ELECTRIC GROUP

Rain-preventing pollution-free cultivation technique for summer black grapes

InactiveCN105432417AHigh in nutrientsGood yieldClimate change adaptationAnimal repellantsAdditive ingredientGreenhouse

The invention relates to the technical filed of grape planting, in particular to a rain-preventing pollution-free cultivation technique for summer black grapes. The rain-preventing pollution-free cultivation technique comprises the following steps that a greenhouse is constructed; deep pit fertilization is carried out; seedling transplanting and planting are carried out; germination accelerating is carried out in spring; fertilization management is carried out; pruning is carried out; temperature and humidity are controlled; picking is carried out. According to the rain-preventing pollution-free cultivation technique, the content of various nutrition ingredients of the summer black grapes is high, the yield and quality are good, pulp is fine, and the earnings of farmer households can be increased.

Owner:全椒县管坝民族玉龙生态农业发展有限公司

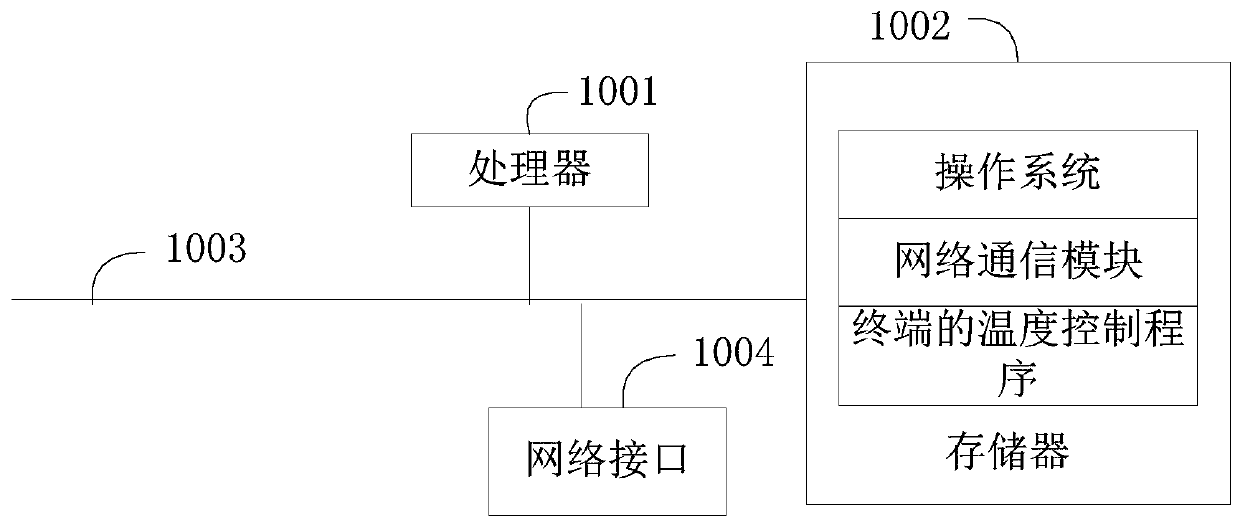

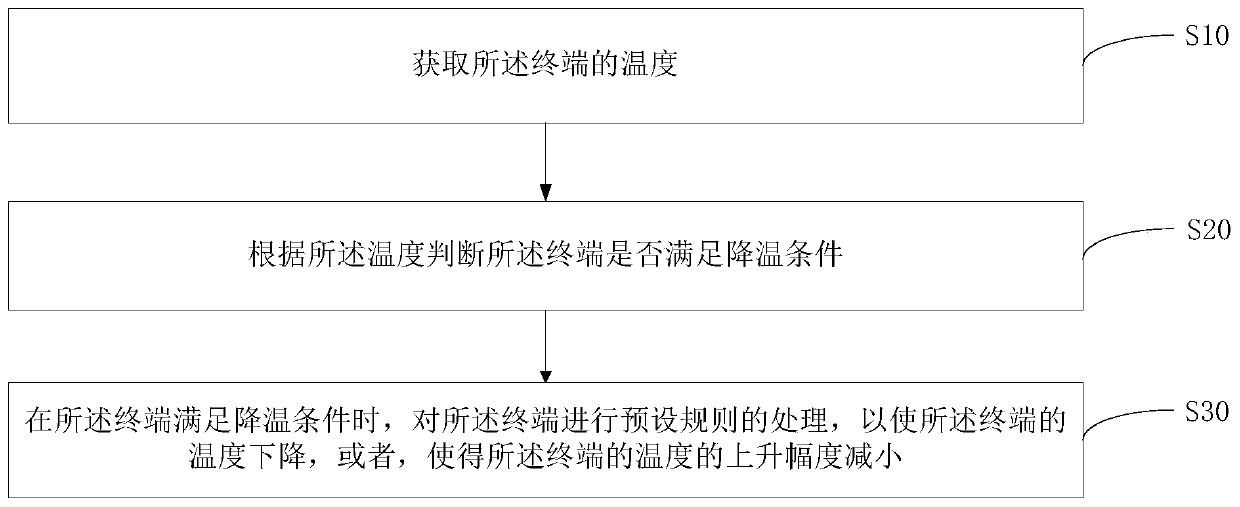

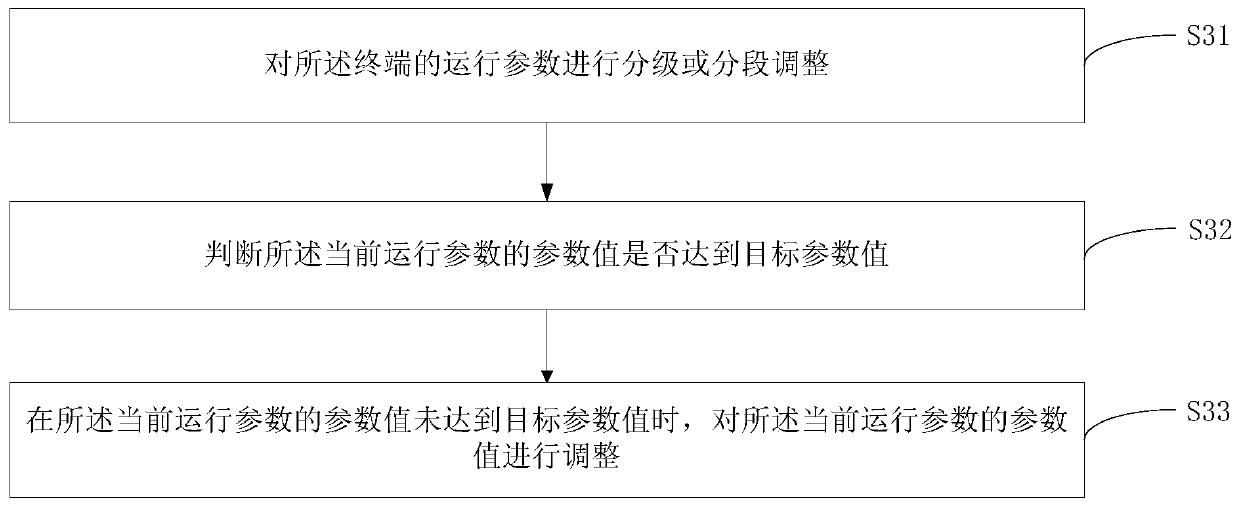

Terminal, temperature control method thereof and computer readable storage medium

PendingCN110750148AReasonable temperature controlReduce the temperatureDigital data processing detailsTemperature controlProcess engineering

The invention discloses a temperature control method of a terminal, the terminal is provided with a temperature sensor, the temperature sensor is used for detecting the temperature of the terminal, and the temperature control method of the terminal comprises the following steps: acquiring the temperature of the terminal; and when the terminal meets the cooling condition, carrying out preset rule processing on the terminal so as to reduce the temperature of the machine body or reduce the rising amplitude of the temperature of the machine body. The invention further provides a terminal and a computer readable storage medium. The temperature control of the terminal is reasonable.

Owner:SHANGHAI TRANSSION CO LTD

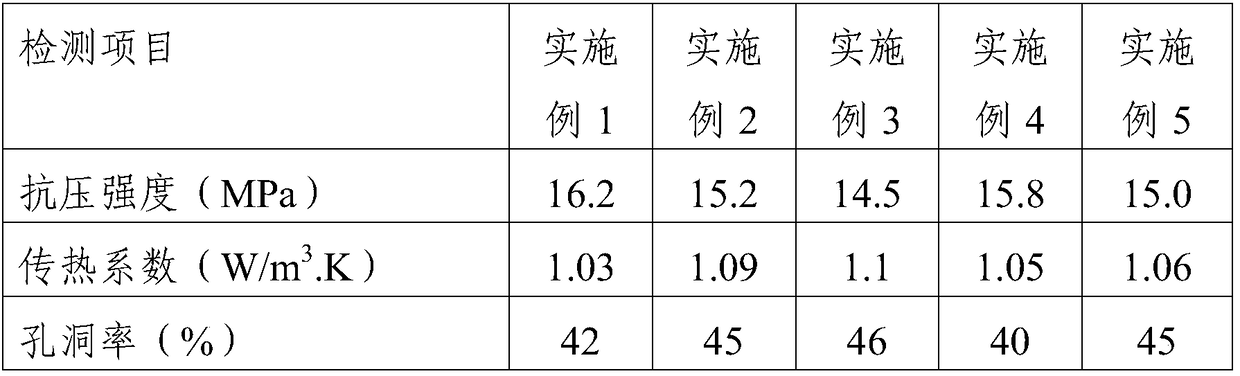

Manufacturing technique of high-adding-quantity fly ash sintered hollow brick

InactiveCN108285325AHigh plasticity indexHigh strengthCeramic materials productionCeramicwareBrickFree cooling

The invention provides a manufacturing technique of a high-adding-quantity fly ash sintered hollow brick. The manufacturing technique comprises the steps of 1, using a 150-180 mesh sieve to conduct sieving; 2, weighing 52-57 parts of fly ash, 12-20 parts of kaolin powder, 13-16 parts of high-viscosity attapulgite clay powder, 5-9 parts of nepheline syenite powder and 2-5 parts of mica powder whichare obtained through sieving, adding weighed substances into a stirrer, adding 8-13 parts of canal mud and 14-18 parts of water after stirring, continuing to conduct mixing to obtain a mixture, and conducting aging; 3, conveying the aged mixture into a double-shaft stirrer to be stirred and kneaded, and conveying the mixture to a twin-stage vacuum brick extruder to be shaped; 4, conducting drying; 5, firing hollow dry brick bodies in a furnace; 6, conducting natural cooling.

Owner:HEXIAN MINGSHENG ENVIRONMENTAL PROTECTION MATERIAL

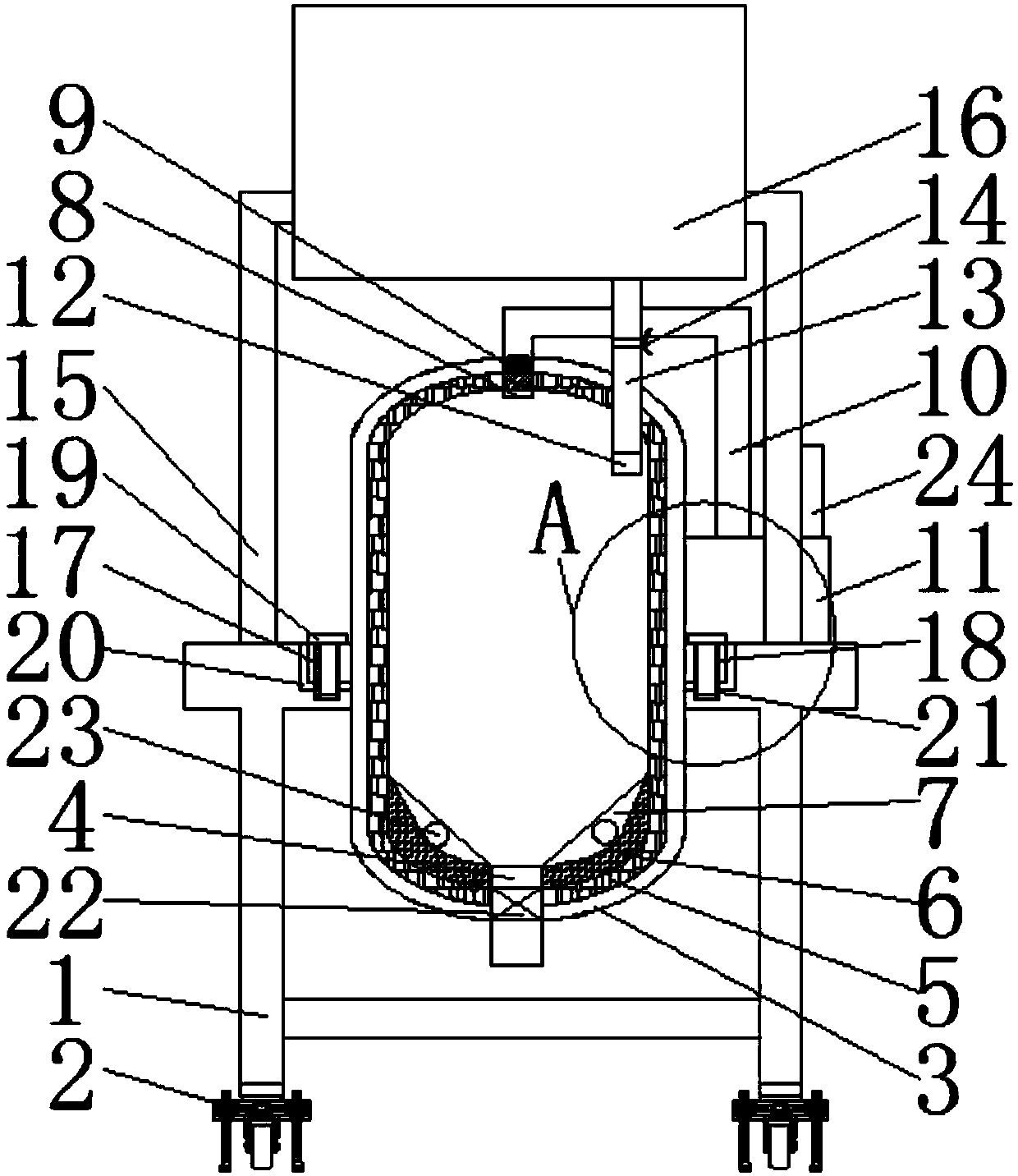

Filtering and crystallizing device for chemical product processing

ActiveCN107670322AWater evaporates quicklyRapid crystallization dryingSolution crystallizationFiltration circuitsFiltrationHeat conducting

A filtering and crystallizing device for chemical product processing comprises an underframe, wherein universal wheels are fixedly connected to symmetrical positions of the bottom of the underframe; acrystallizing barrel is fixedly connected to one side, away from the universal wheels, of the underframe; a thermal insulation layer is arranged on the inner cavity of the crystallizing barrel; heaters are fixedly connected to the bottom of the inner surface of the thermal insulation layer and are positioned on the two sides of a crystal leaking port; heat-conducting sealing layers are fixedly connected to one sides, away from the thermal insulation layer, of the heaters; a filtering device is fixedly connected to one side, away from the underframe, of a supporting frame; one side, near the crystallizing barrel, of the filtering device is communicated with a feed pipe. The invention relates to the technical field of chemical product processing. The filtering and crystallizing device for chemical product processing can quickly evaporate moisture of a chemical product to quickly crystallize and dry the chemical product and can reasonably control the temperature to prevent crystallization evaporation, so that the processing efficiency is improved; multiple filtration is performed on the chemical product, so that a filtrate is pure and the quality of a processed product is guaranteed;through integrated arrangement, the product loss is reduced.

Owner:安徽海蓝生物科技有限公司

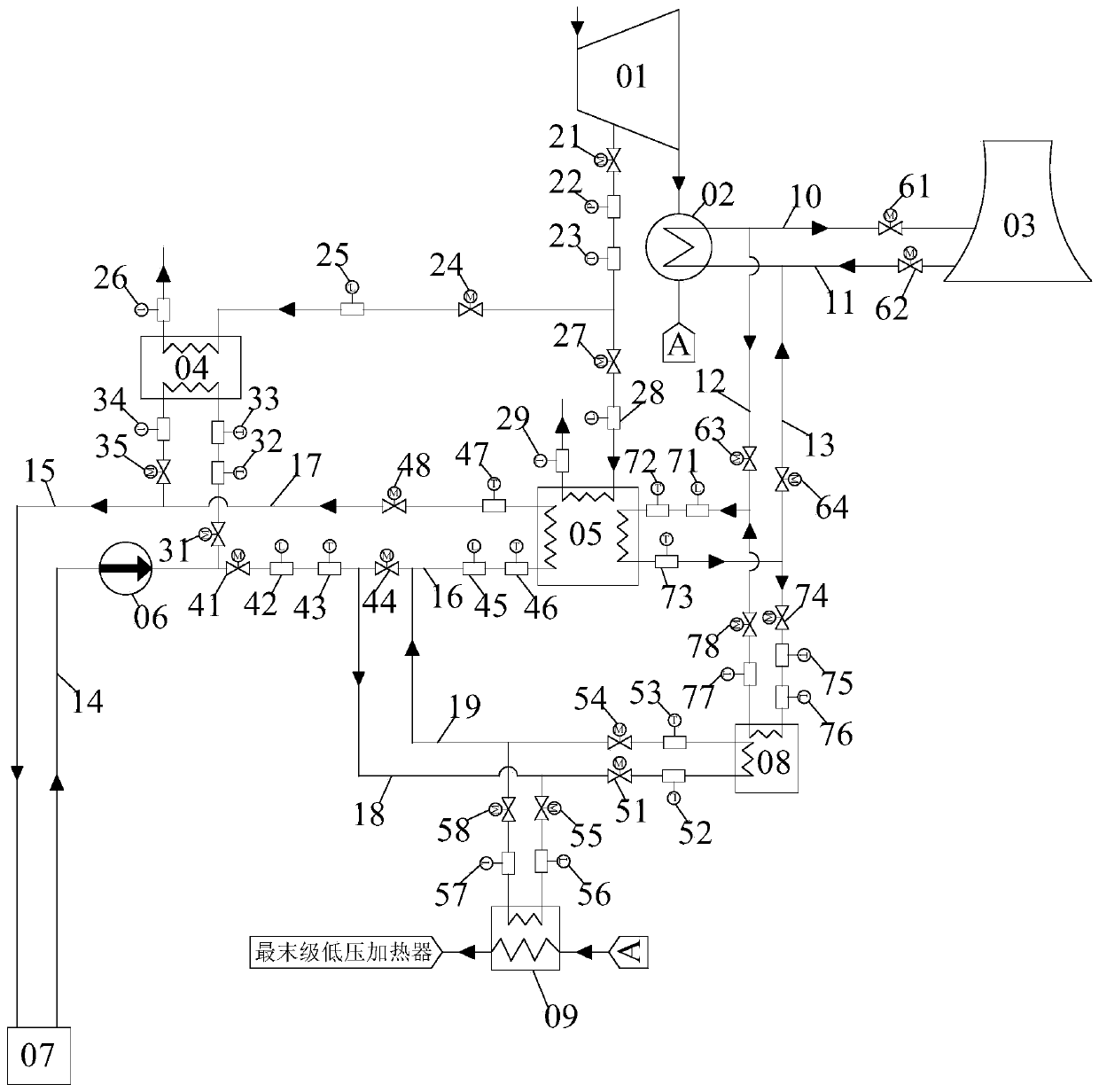

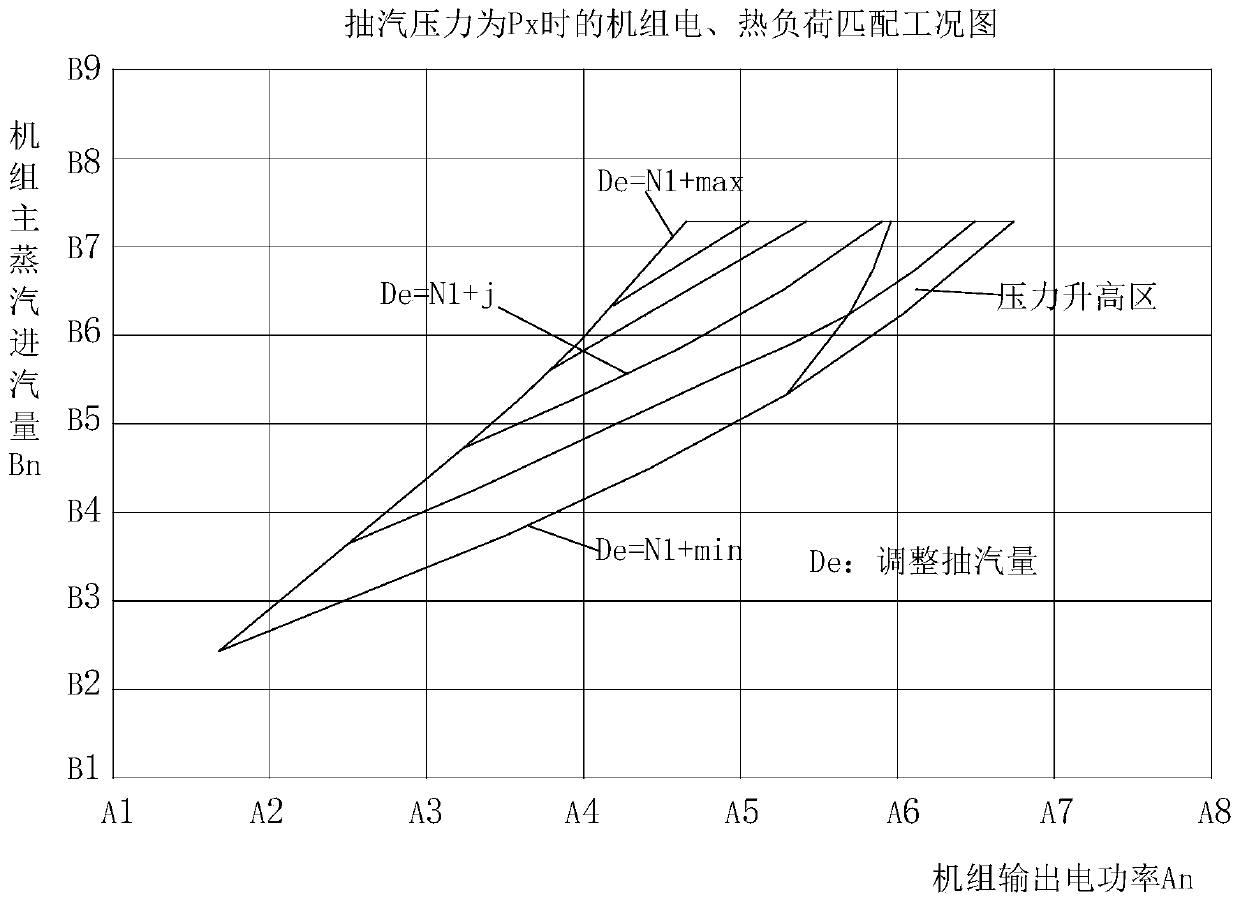

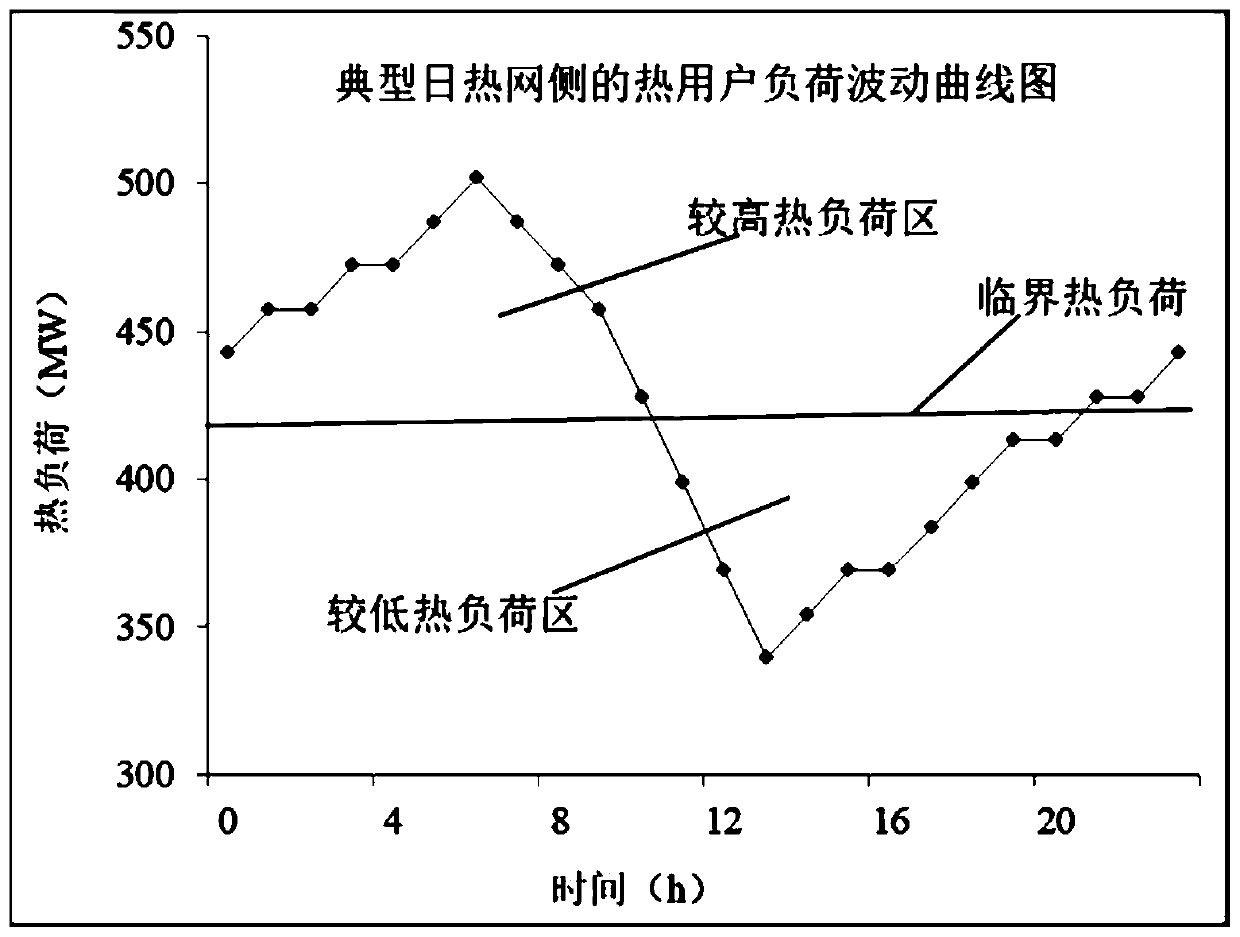

Complex combined heat and power generation heat supply system based on low-temperature waste heat recovery and electric heating load adjusting method

ActiveCN111520808AGuaranteed uptimeAchieving real-time heat load demandLighting and heating apparatusSpace heating and ventilation detailsCooling towerCogeneration

The invention discloses a complex combined heat and power generation heat supply system based on low-temperature waste heat recovery and an electric heating load adjusting method, and belongs to the technical field of central heating. The complex combined heat and power generation heat supply system comprises a thermoelectric unit, a condenser, a cooling tower, a heat supply network initial station, an absorption heat pump and a heat exchange station. According to the complex combined heat and power generation heat supply system based on the low-temperature waste heat recovery and the electricheating load adjusting method, an absorption heat pump performance coefficient prediction model is established based on parameter changes of factors such as steam, heat supply network water and circulating water entering the absorption heat pump and exiting from the absorption heat pump, accurate prediction of an absorption heat pump performance coefficient is achieved, and the operation condition of a combined heat and power generation unit is reasonably arranged through heat load prediction of the heat supply system; meanwhile, electric load and thermal load meeting requirements are output,and efficient and stable operation of the combined heat and power generation unit is achieved; and when the real-time heat load requirement is met, the difference between the absorption heat pump andthe supplied heat load is balanced through the absorption heat pump, and a first water-water heat exchanger and a second water-water heat exchanger are reasonably designed. Efficient operation of theabsorption heat pump is achieved while it is guaranteed that the whole system saves energy and is efficient.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Extraction method of bone oil by using benzene

InactiveCN104893822ASimple processReasonable temperature controlFatty-oils/fats productionChemistryBenzene

An extraction method of aggregate oil by using benzene relates to the technical field of bone glue production. Through cooperation of pressure tank with a circulation pattern of liquid state into gaseous state and then into liquid of benzene, grease within the bone block is extracted and then packaged. The invention has the beneficial effects that the method is simple in process and reasonable in temperature; the circulation pattern of liquid state into gaseous state and then into liquid of benzene achieves low-cost oil extraction and thorough oil extraction, so as to provide good raw material for the bone glue preparation; and the method uses simple steps to reach obvious effect and is easy for popularization and usage.

Owner:安徽省淮河制胶有限公司

Method for synthesizing calcium polycarbophil

The invention relates to a method for preparing drugs, in particular to a method for synthesizing calcium polycarbophil. The method for synthesizing calcium polycarbophil comprises the following steps of: 1) fully dissolving magnesium sulfate and divinyl glycol in water, increasing the temperature to 76 DEG C; 2) dropwise adding mixed liquor of crylic acid and azodiisobutyronitrile, and reacting for 3 hours under a temperature-keeping condition; 3) washing with clean water at 76 DEG C, thereby obtaining magnesium polycarbophil; 4) fully stirring the magnesium polycarbophil and the aqueous solution of calcium carbonate, increasing the temperature to 100 DEG C, and reacting for 6.5 hours; and 5) putting down, centrifuging, drying and crushing, thereby obtaining the end product. The reaction time and the temperature control are reasonable, so that the yield of the end product of the calcium polycarbophil is close to 100%, the content of calcium in mass item reaches 22%, and the method is obviously progressed, compared with the conventional synthesizing method.

Owner:ZHEJIANG TOP MEDICINE

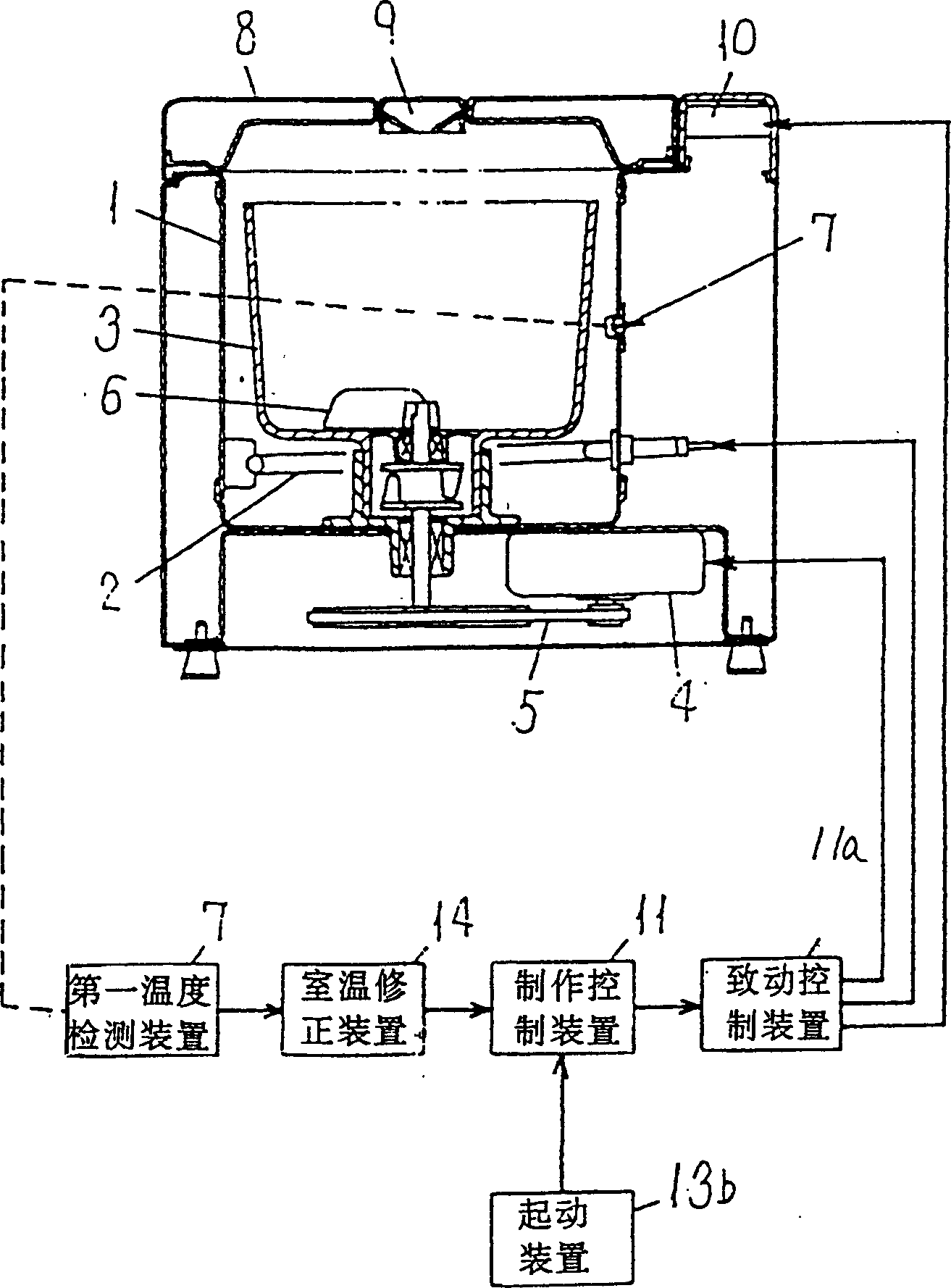

Automatic bread machine

InactiveCN1618385AReasonable temperature controlGood correction valueBread-toastersBaking plantsTemperature controlRoom temperature

An automatic bread machine, which detects the temperature in the baking room to control the temperature of the bread container in the baking room, which can prevent the temperature of the bread container from being incorrectly detected due to the influence of the room temperature, and make the finished bread in good shape. It includes: a first temperature detection device (7) for detecting the temperature in the baking chamber (1); a room temperature correction device (14) for correcting the temperature measured by the detection device (7) according to the room temperature; The process control temperature is compared to control the production control device of the heating capacity of the heater (2) in each process.

Owner:PANASONIC CORP

Method for casting axle box cover

InactiveCN103060661AImprove performanceImprove pass rateFoundry mouldsFoundry coresChemical compositionIntermediate frequency

The invention discloses a method for casting an axle box cover. The axle box cover comprises the following raw materials by weight: 30 to 35 percent of new iron, 30 to 35 percent of waste steel and 30 to 35 percent of old iron, wherein the weight percentage of the three raw materials is 100 percent; and the axle box cover comprises the following chemical components: 3.6 to 3.8 percent of C, 1.8 to 2.4 percent of Si, less than 0.25 percent of Mn, less than 0.8 percent of P and less than 0.02 percent of S; and after being balled by adopting a 7-8REMG balling agent, the content of Mg is 0.045 to 0.3 percent, and the content of rare earth (RE) is 0.02 to 0.04 percent. The raw materials are smelted in an intermediate frequency furnace, the smelting temperature is 1,500 to 1,570 DEG C, and the casting liquid obtained by smelting is cast into the axle box cover at the temperature of between 1,390 and 1,410 DEG C. According to the casting method, the chemical components are reasonable, so that the performance of the casting is effectively improved; and the casting temperature and the casting time are reasonably controlled, the tissue grains are fine and uniform, the casting defects are reduced, the yield of casting blanks is improved, the investment can be reduced, and the cost is reduced.

Owner:QINGDAO SANHESHAN CASTING GROUP

Preparation method of EVA elastomer

The invention discloses a preparation method of an EVA elastomer. In a single polymerization kettle, ethylene and vinyl acetate carry out free radical copolymerization in a solvent in the presence of an initiator; the free radical copolymerization comprises a pre-polymerization phase, a chain propagation phase, and a chain termination phase; and the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures to prepare the EVA elastomer. According to the method, the controlled pre-polymerization phase, the chain propagation phase, and the chain termination phase are performed at different temperatures, thus the chance of implosion is largely reduced; the temperature runaway of polymerization and initiator loss caused by once heating are relieved, the reactions of polymerization monomers carry out completely, higher monomer conversion rate and copolymerization yield can be obtained; the copolymerization speed is guaranteed, at the same time, the solid content of products is increased, and the VAc content of polymerization products is adjusted to produce EVA elastomer products for satisfying different needs.

Owner:CHINA PETROLEUM & CHEM CORP +1

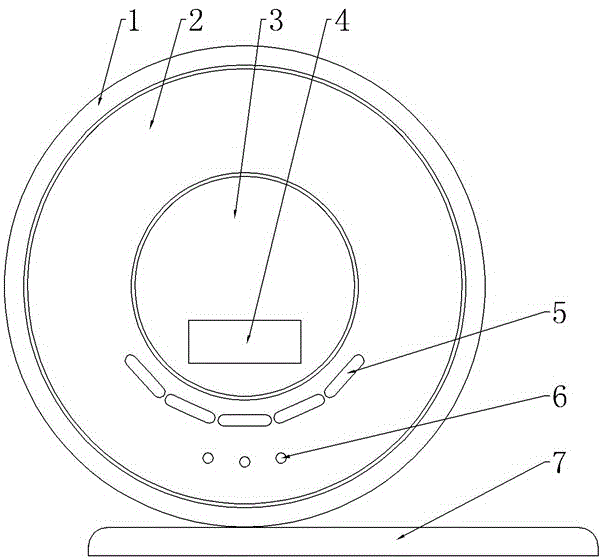

Small-sized cosmetic refrigerator

InactiveCN104534768AImprove textureReduce heat exchange timeLighting and heating apparatusDomestic refrigeratorsEngineeringRound face

A small-sized cosmetic refrigerator comprises a base and a refrigerator body fixedly connected to the base, wherein the refrigerator body is of a laterally-arranged cylinder structure, an opening is formed in one side round face of the refrigerator body, and a combined refrigerator door structure is arranged on the side round face. A two-layer storage check structure is arranged in the refrigerator body in the cylindrical face direction, two layers of storage checks are concentrically and annularly arranged on a tangent plane circle of the refrigerator body, and a stretching shaft is arranged at the center. The combined refrigerator door structure is a round refrigerator door fit with the refrigerator body and comprises an outer side annular refrigerator door and a round refrigerator door body, wherein a stretching piston is arranged at the position of the circle center of the round refrigerator door, and the stretching shaft is sleeved with the stretching piston. The small-sized cosmetic refrigerator is small in size, can be conveniently arranged on a dressing table and other places, reasonably controls temperature moderation and humidity, enables the service life of cosmetics to be prolonged and enables the using effect to be better.

Owner:CENT SOUTH UNIV

Fruit slowly freezing process and slowly freezing apparatus

ActiveCN107535919ASimple processReasonable temperature controlFruits/vegetable preservation by freezing/coolingL&D processProcess engineering

The invention discloses a fruit ice-slowing process and an ice-slowing device, which mainly include the following steps: preheating, starting the fan, and feeding steam into the heat exchanger; cutting, importing the selected fruit into the hopper; transporting and heating, starting Conveyor chain, the fruits are arranged in the conveyor chain and pass through the box at a constant speed to slow down the ice; remove the residue. The beneficial effects of the invention are that the process is green and natural, the process is simple, the temperature control is reasonable, and the time control is precise, which can effectively solve the problem of long ice-slowing time; at the same time, the quality of the product is guaranteed, and the sintering waste gas is used for secondary utilization, reducing energy consumption , scientific and reasonable.

Owner:临沂大林食品股份有限公司

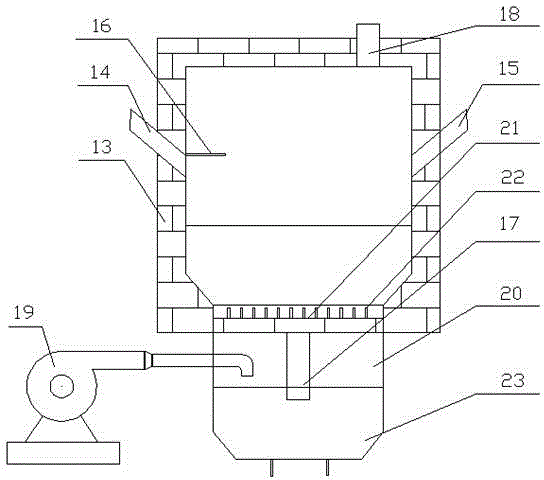

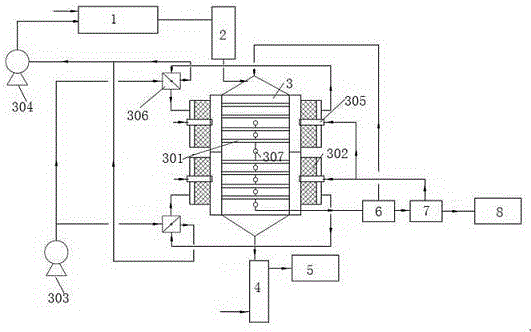

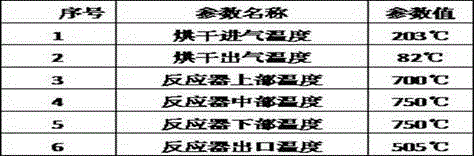

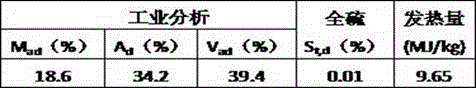

Heat accumulation type block-shaped oil shale pyrolysis treatment system and method

PendingCN106433723APyrolytic treatment achievedSimple designDirect heating destructive distillationSpecial form destructive distillationTreatment systemOil shale

The invention belongs to an oil shale pyrolysis treatment process and in particular relates to a heat accumulation type block-shaped oil shale pyrolysis treatment system and method. Aiming at the problems in the prior art, the invention provides the heat accumulation type block-shaped oil shale pyrolysis treatment system and method; the oil shale pyrolysis treatment system comprises a chain plate type drying machine, a hopper and a heat accumulation type pyrolysis reactor, wherein the hopper is connected with the chain plate type drying machine. According to the heat accumulation type block-shaped oil shale pyrolysis treatment system and method, a built-in heat accumulation type radiation tube is used as a heating source; the heat accumulation type radiation tube is reasonably arranged so that reasonable control of temperature of a reactor is realized; the design of the radiation tube can be simplified so that the investment cost is reduced. Meanwhile, the system realizes pyrolysis treatment on oil shale with a wide grain diameter range, and large-scale production can be realized.

Owner:SHENWU TECH GRP CO LTD

Test tube box for biotechnological cells

InactiveCN108554478AReasonable temperature controlEasy to placeHeating or cooling apparatusTest tube stands/holdersHydraulic cylinderTemperature control

The invention provides a test tube box for biotechnological cells, and belongs to the technical field of kits. The test tube box comprises a box body and a moving plate, wherein the box body is a cuboid and is in horizonal placement; an outer layer is made of an aluminum alloy material; an inner cavity is formed inside the box body; a rotating shaft is fixedly connected with the outer surface of the box body; the upper surface of an upper end cover is provided with a control device; the control device is in linear connection with each electric appliance; a transverse rod is arranged at the middle part of the inner cavity; the transverse rod is fixedly connected with the inner surface of the box body; test tube grooves are formed inside a fixing disc, and are in matrix arrangement; the lower end of the fixing disc is connected with an ascending and descending hydraulic cylinder; the middle part of the ascending and descending hydraulic cylinder also passes through the transverse rod; arubber block is arranged between the ascending and descending hydraulic cylinder and the transverse rod; a condensing tube is arranged at the left part of the fixing disc; the condensing tube is fixedon the inner surface of the box body. The test tube box has the advantages that the structure design is simple; the use is convenient; the carrying is convenient; the temperature control on a test tube is reasonable; the popularization and the use are convenient.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Regenerative garbage pyrolysis power generation system and method thereof

PendingCN106497586AEasy to cleanSimple designSpecial form destructive distillationIncinerator apparatusCarbonizationProcess engineering

The invention belongs to a clean garbage disposal technology, and particularly relates to a regenerative garbage pyrolysis power generation system and a method thereof. In allusion to the problems in the prior art, the invention provides the regenerative garbage pyrolysis power generation system and the method thereof. The regenerative garbage pyrolysis power generation system comprises a chain plate-type dryer, a hopper and a regenerative pyrolysis reactor, wherein the hopper is connected with the chain plate-type dryer. The regenerative garbage pyrolysis power generation system and the method thereof are different from other garbage disposal technologies with too high cost or a complicated process; a built-in regenerative radiant tube is used as a heating source, and through reasonable arrangement of the regenerative radiant tube, reasonable control over the temperature of the reactor is achieved; the design of the radiant tube can be simplified, so that the investment cost is reduced; dioxin is not produced, so that the regenerative garbage pyrolysis power generation system is environment-friendly, and combined with the comprehensive utilization of garbage byproducts, clean and effective garbage recycling disposal is achieved. Meanwhile, a continuous carbonization process is achieved, the process is simple, the production efficiency is higher and the production cost is reduced.

Owner:SHENWU TECH GRP CO LTD

Preparation method of hyacinth bletilla flower tea

InactiveCN108552384ASweet aftertasteSimple preparation processTea substituesTemperature controlAgroforestry

The invention relates to the technical field of flower tea preparation and especially relates to a preparation method of hyacinth bletilla flower tea. The treatment occasion of hyacinth bletilla flowers is controlled, temperature control is reasonable, so after the prepared hyacinth bletilla flower tea is soaked, the hyacinth bletilla flowers keep an original state in tea liquor and undamaged; andthe tea liquor of the hyacinth bletilla flower tea is purple and attractive in color, subtly fragrant and pleasant in smell and fresh and sweet in aftertaste.

Owner:遵义湄潭天禾生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com