Production process of PVA (polyvinyl alcohol)-based composite packaging material

A composite packaging material and production process technology, which is applied in the field of packaging materials, can solve the problems of poor mechanical properties and water resistance of products, lower water permeability of polyvinyl alcohol base, environmental pollution, etc., achieve good crushing effect, low cost, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Preparation of dialdehyde starch: weigh 25g Dissolve completely in 980ml of distilled water at 21°C, then add 98g of cornstarch, stir mechanically at 36°C for 3.9 h, after the reaction is over, filter the mixture, and wash the filter cake with water repeatedly until no ions, and then washed with acetone, using a far-infrared rapid constant temperature drying oven to gradually increase the temperature and dry to obtain white dialdehyde starch;

[0017] (2) Preparation of jute fiber: put the jute fiber into YSC-701 ultrafine pulverizer, wash it 4 times with distilled water at 51°C, then stir it with 1mol / L NaOH solution at room temperature for 24 hours, and it becomes neutral after washing with distilled water. After that, wash with ethanol four times, centrifuge, and dry at 105°C for 23 h;

[0018] (3) Preparation of PVA-based composite film: uniformly disperse the dialdehyde starch prepared in step (1) in distilled water, gelatinize at 85°C for 21min, add 6g of P...

Embodiment 2

[0019] Example 2: The rest are the same as in Example 1, except that in the step (2), the distilled water is washed 5 times, and the ethanol is washed 5 times; Glycerin, the cooling time is 1h.

Embodiment 3

[0020] Example 3: The rest are the same as in Example 1, except that in the step (1), the distilled water is washed 5 times, and the ethanol is washed 5 times; in the step (3), the gelatinization temperature is controlled to be 90° C. 38g glycerin, cooling time is 1h.

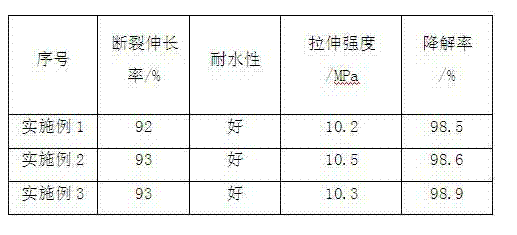

[0021] After the above process steps, the PVA-based composite film sample is taken out to be tested:

[0022]

[0023] It can be seen from the above data that the elongation at break and tensile strength produced are relatively high, the elongation at break is above 90%, and the tensile strength is above 10MPa, so the mechanical properties are good. After testing, its water resistance It is also very good, with a degradation rate of over 98%, basically completely degradable, and less environmental pollution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com