Patents

Literature

168 results about "Jute fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jute is a natural fibre with golden and silky shine and hence called The Golden Fibre. Jute is the cheapest vegetable fibre procured from the bast or skin of the plant's stem. It is the second most important vegetable fibre after cotton, in terms of usage, global consumption, production, and availability.

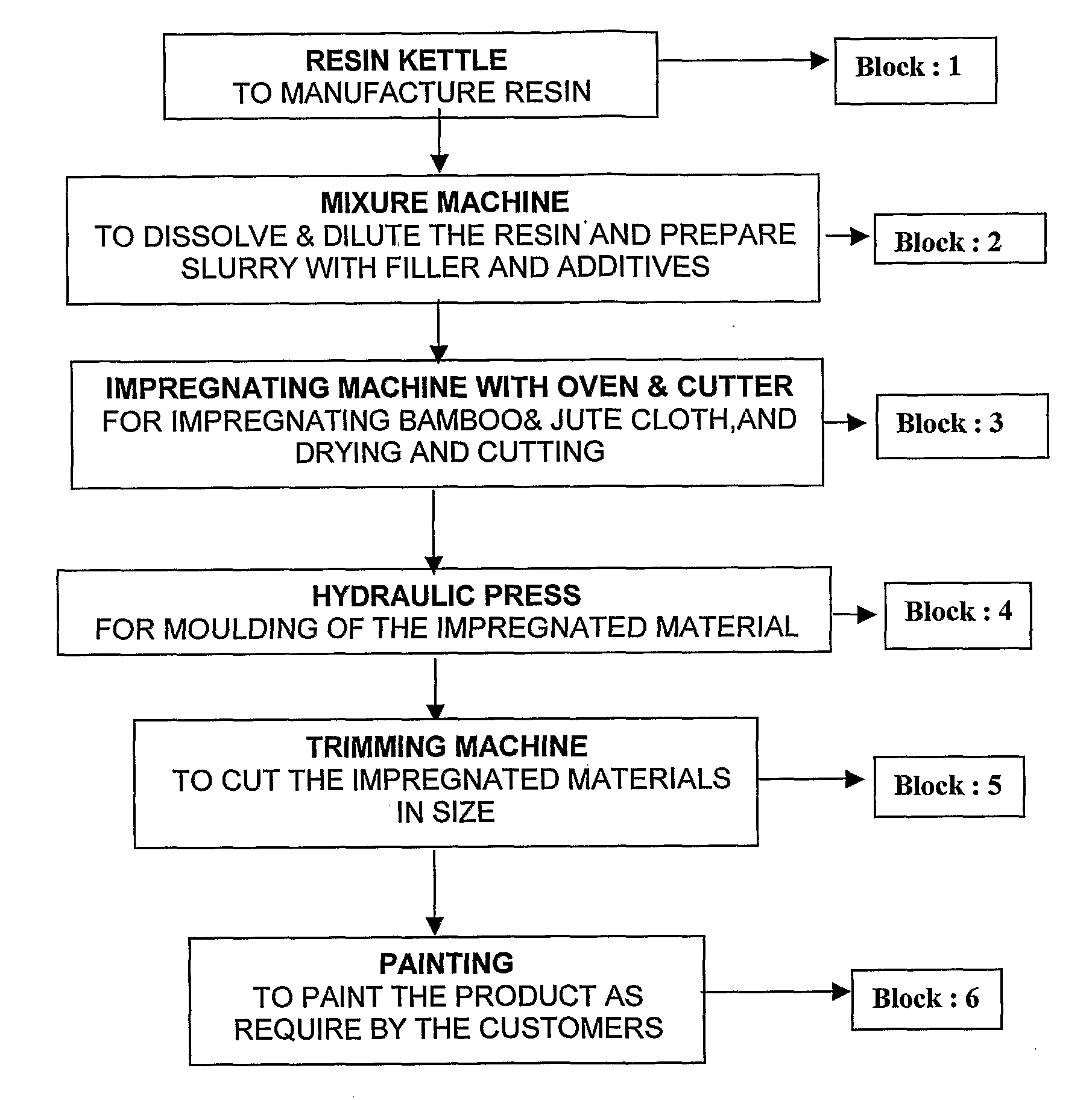

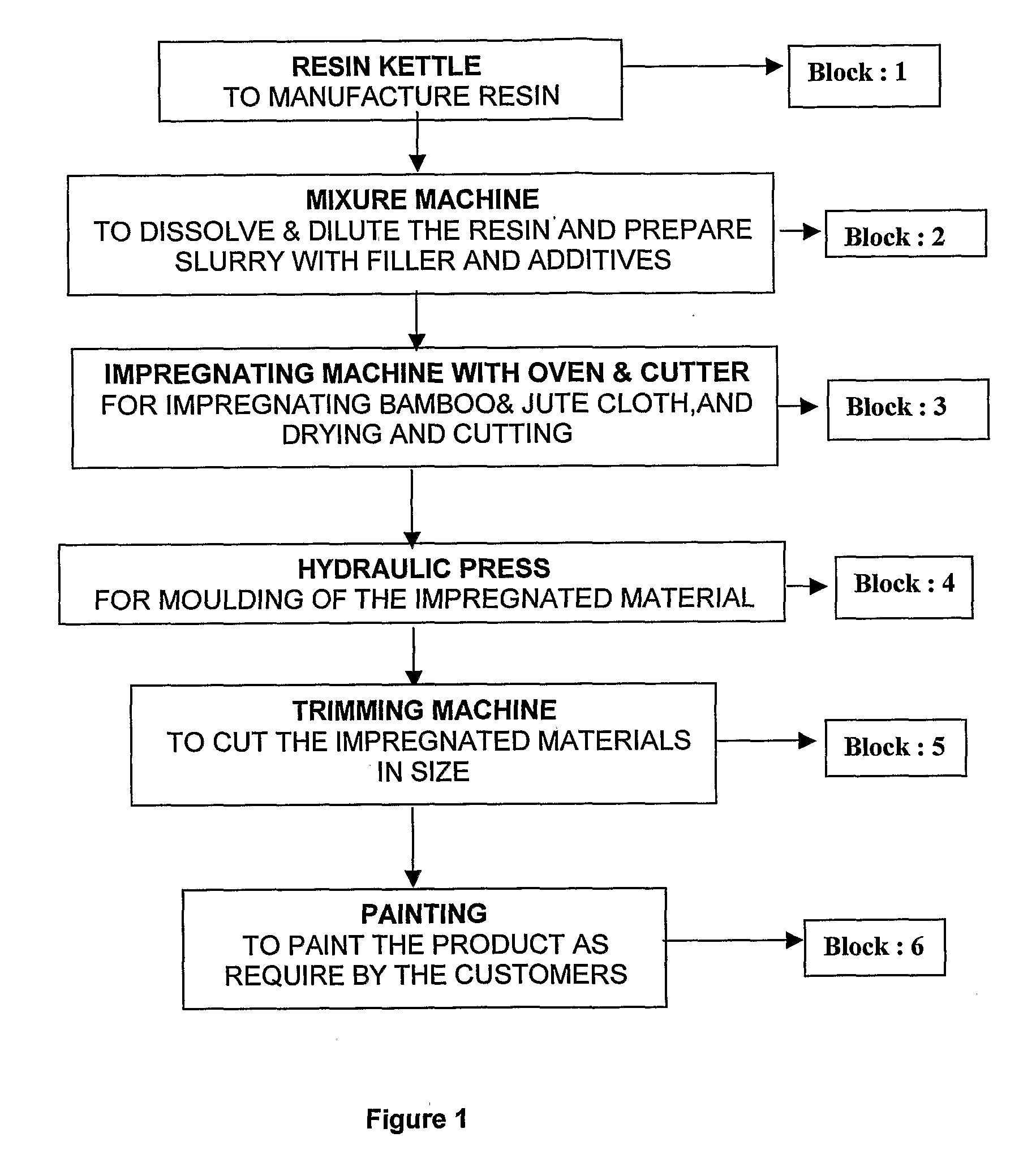

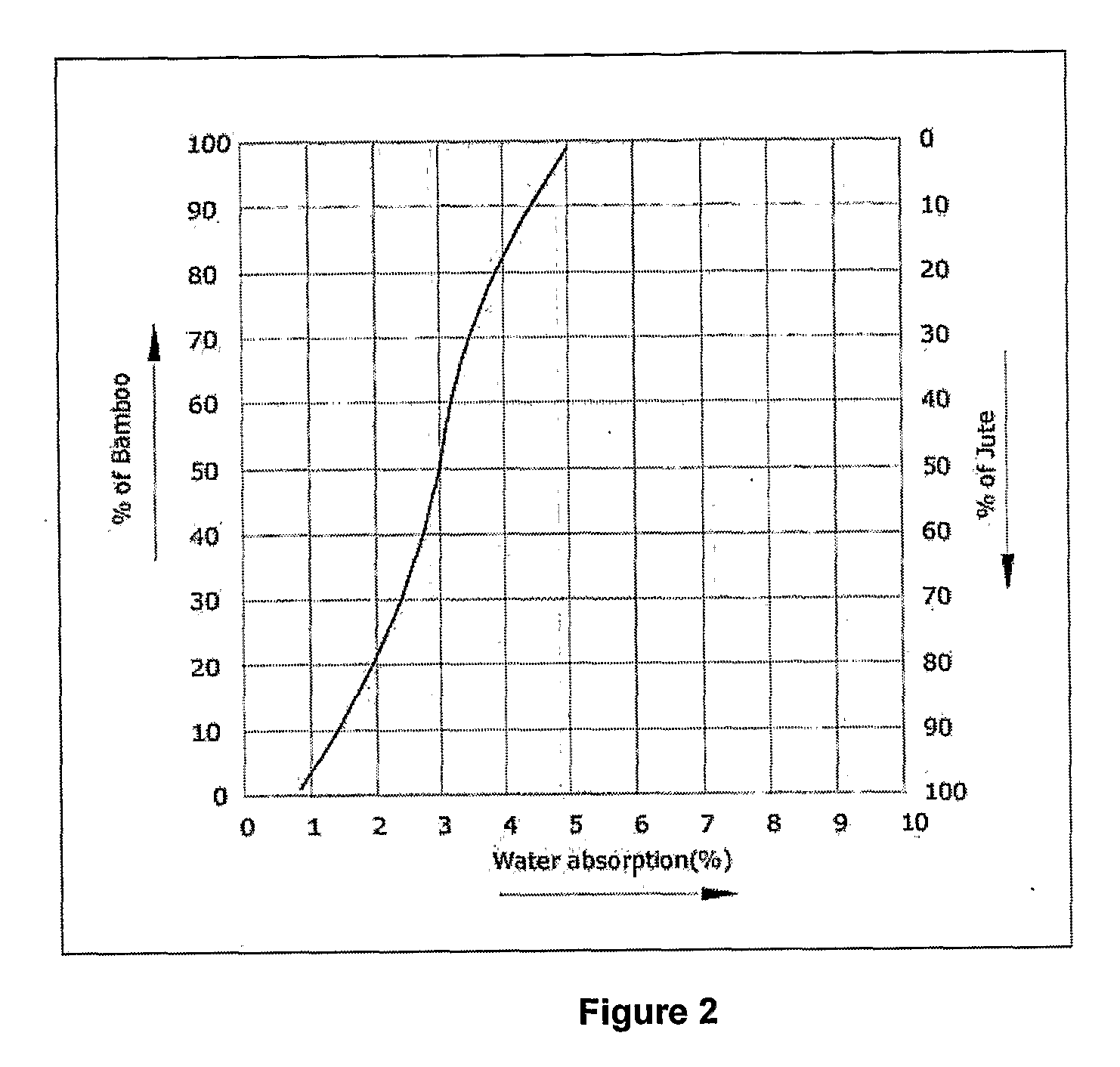

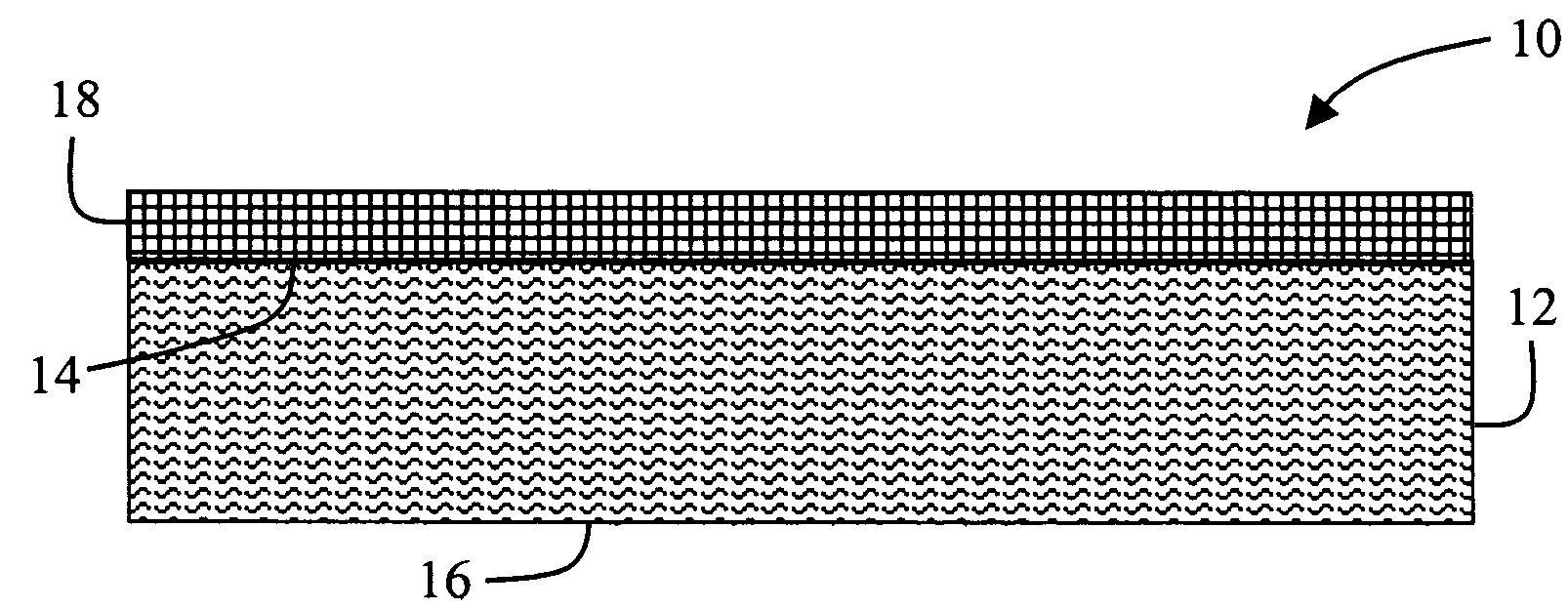

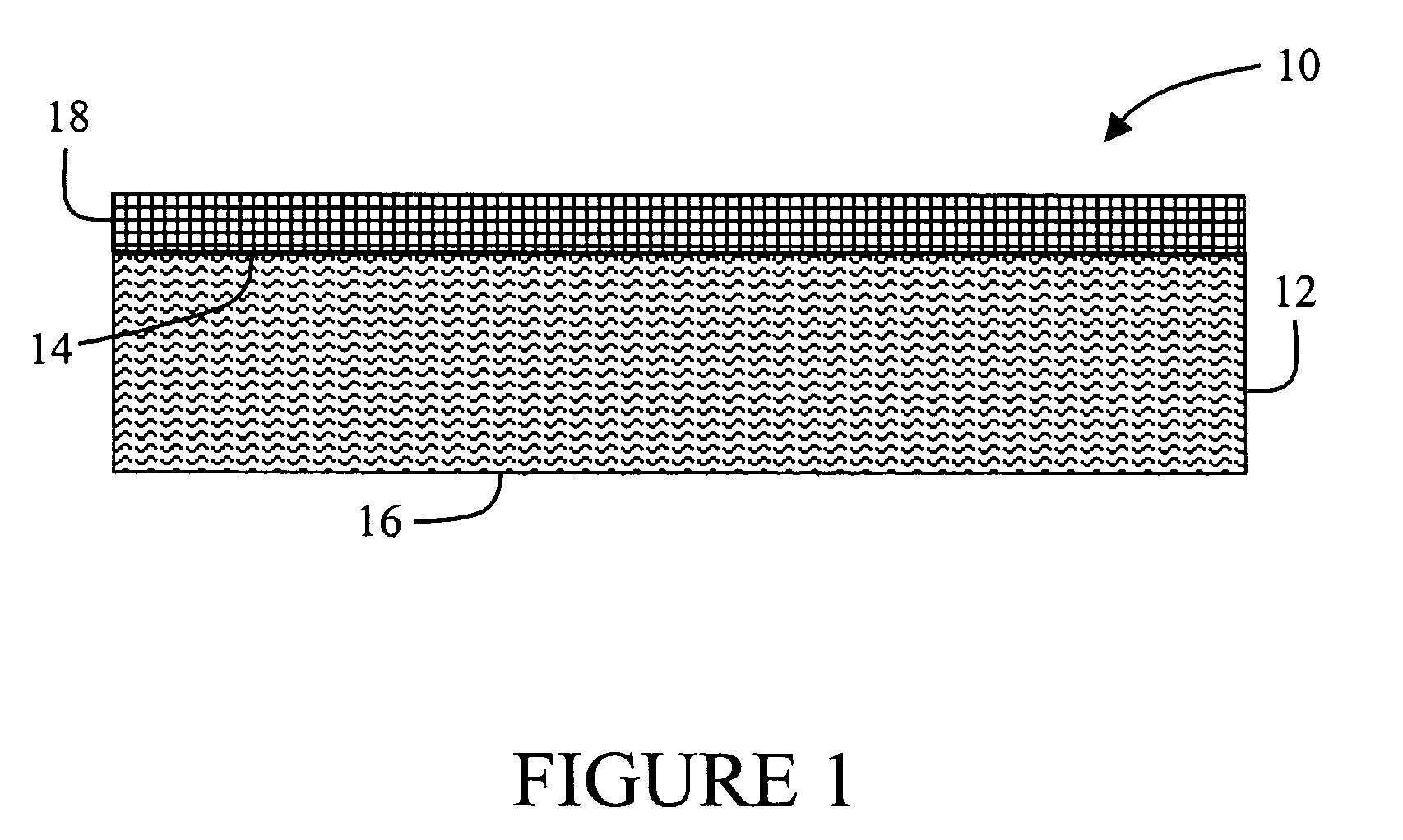

Natural Fibre Thermoset Composite Product and Method For Manufacturing the Same

InactiveUS20090130377A1High tensile strengthLow water absorptionLamination ancillary operationsLaminationDefinite periodSlurry

Owner:A B COMPOSITES PRIVATE

Preparation method for jute-based active carbon

InactiveCN102633259AIncrease profitIncrease added valueCarbon compoundsActivated carbonO-Phosphoric Acid

The invention discloses a preparation method for jute-based active carbon, and the method comprises the following steps of: weighing jute fibres or crushed jute stem materials, cleaning and drying, soaking in a beaker filled with a 3-5mol / L phosphoric acid solution, boiling for 3-10 hours in a water bath, adequately penetrating an activating agent into the fibres, then taking out and drying; placing in a vacuum tubular high-temperature sintering furnace, activating to 400-500 DEG C in a nitrogen atmosphere, insulating for 1-3 hours, or placing in a columnar quartz tube, placing in a microwave device, and performing a microwave irradiation reaction with a microwave irradiation power of 100-700 W and an irradiation time of 5-30 minutes in the presence of nitrogen used as protective gas; and cooling to a room temperature, then taking out, acid-washing and repeatedly water-washing until the pH is 6-7, and then drying to obtain the jute-based active carbon. The jute-based active carbon prepared by the method has the advantage of being high in methylene blue adsorption value and activation yield.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Composite thermoplastic sheets including natural fibers

ActiveUS7431980B2Non-fibrous pulp additionSynthetic resin layered productsSisal fiberCellulose fiber

A composite sheet material includes, in an exemplary embodiment a porous core that includes at least one thermoplastic material and from about 20 weight percent to about 80 weight percent of natural fibers based on a total weight of the porous core. The natural fibers include at least one of kenaf fibers, jute fibers, flax fibers, hemp fibers, cellulosic fibers, sisal fibers, and coir fibers.

Owner:HANWA AZDEL INC

Short-flow environmentally-friendly production method for jute fibers

ActiveCN102031568AShort production processEfficient removalYarnFibre treatment to obtain bast fibreChemical oxygen demandImpurity

The invention relates to a short-flow environmentally-friendly production method for jute fibers. The method is characterized in that: the principle of deep oxidation is adopted, and jute bast is subjected to identical bath degumming and bleaching. The method comprises the following steps of: 1) performing impurity removal and washing on the jute bast; 2) performing first identical bath degumming and bleaching by using 5 to 6 g / l of nano argil preparation, 6 to 7 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 10 g / l of hydrogen peroxide; 3) performing second identical bath degumming and bleaching by using 4 to 5 g / l of nano argil preparation, 4 to 6 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 12 g / l of hydrogen peroxide; 4) washing after degumming and bleaching; and 5) dehydrating, shaking, softening and drying the washed jute fibers. Compared with the prior art, the method has the advantages that: 1) the production process flow is shortened by adopting a deep oxidation method; 2) the produced jute fibers have good softness and high whiteness; and 3) the process wastewater is little and has low chromaticity, and the discharge of wastewater chemical oxygen demand (COD) is greatly reduced.

Owner:郑州银泰企业管理咨询有限公司

Method for preparing heavy metal complexing fiber by quickly modified jute through microwaves and application of fiber

InactiveCN104607157AComplete efficientlyShort manufacturing timeOther chemical processesWater contaminantsEpoxyMicrowave oven

The invention discloses a method for a preparing heavy metal complexing fiber by quickly modified jute through microwaves and the application of the fiber. The method comprises the following steps: (1) firstly, cooking jute fibers with boiling water, then soaking the cooked jute fibers with a sodium hydroxide solution, and baking the soaked jute fibers for preservation; (2) adding the preprocessed jute fiber and epoxy chloropropane into a solution, performing early stage etherification in a microwave oven, then adding activated monomers of complexing groups for ammoniation and heating in a water bath, taking out materials after reaction, cleaning the materials to obtain products, and placing the products in an oven, baking the products in the oven to constant weight so as to obtain a jute-based modified adsorbing material which can be used for processing unexpected heavy metal pollution and conventional heavy metal wastewater. In the preparation process, a microwave irradiation technology is used for quickly grafting and modifying basal bodies to prepare the fiber with a complexing function, the non-heat effect of the microwaves and the advantage of high grafting and penetrating power of the microwaves are fully utilized, a chemical grafting reaction can be quickly and efficiently completed, the preparation time is greatly shortened, and the method is simple to operate and is convenient and feasible.

Owner:HARBIN INST OF TECH

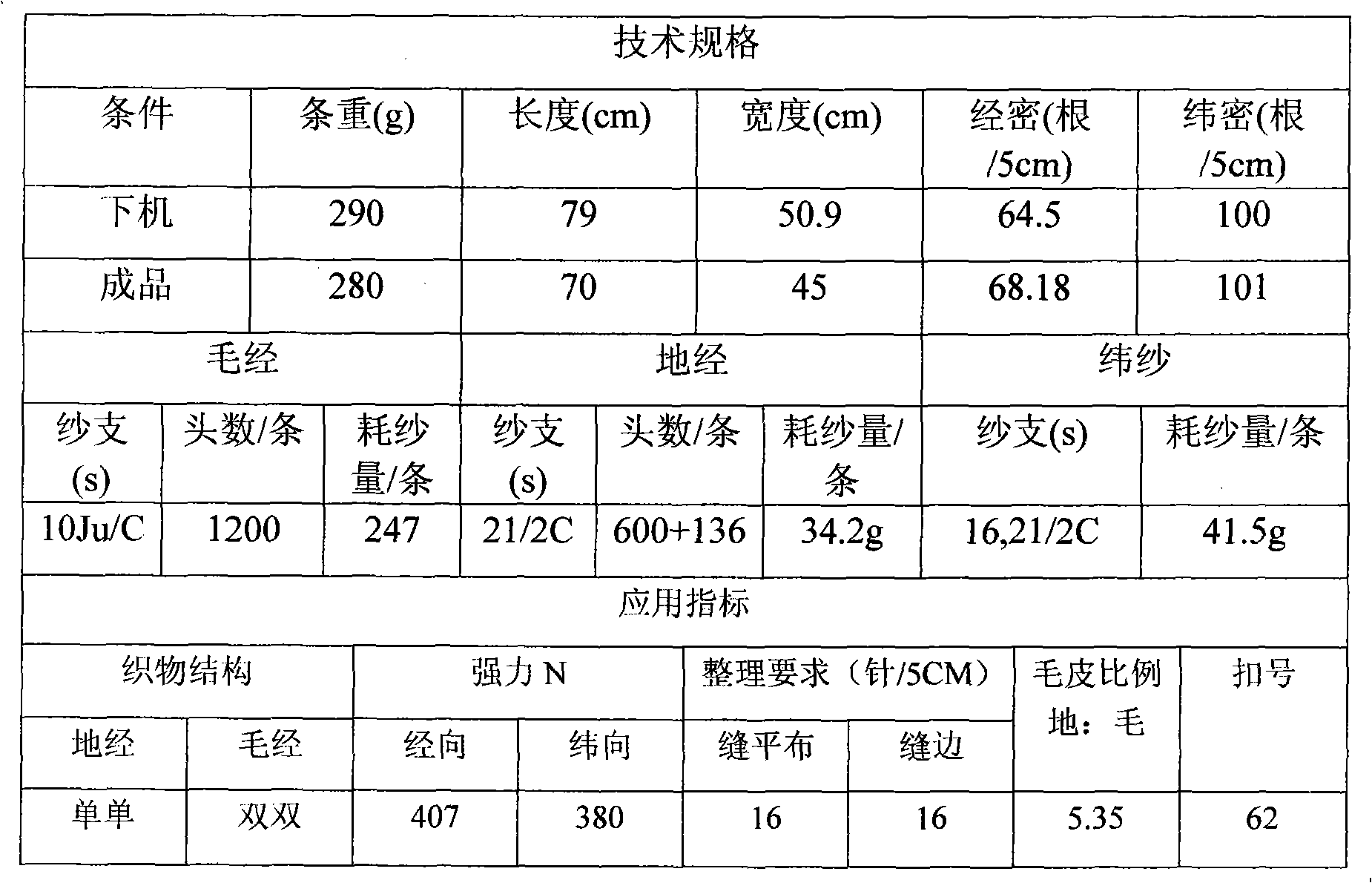

Method for producing jute natural antibiotic bath mat

InactiveCN101260588AGood antibacterialGood antibacterial effectBleaching apparatusDyeing processMoisture absorptionEngineering

The invention relates to a manufacturing method for a jute natural antibacterial floor towel, blending jute and cotton, adequately utilizing the characteristics of the jute such as excellent moisture absorption and moisture wicking, high strength and tensile stretch and good antibacterial and bacteriostatic capability. Jute fibre is humidified before spinning, and the humidified percentage reaches 12-15 percent; the mixture ratio of jute and cotton is 20-50 percent / 50-80 percent during spinning, the relative humidity of spinning environment reaches 83-86 percent, and the relative humidity of textile environment reaches above 85 percent; in order to make up strength and fix short fiber, the sizing ratio is adjusted below 1 percent, and softening treatment and flexible treatment are performed. The manufacturing method for the jute natural antibacterial floor towel changes the jute performance that jute can not be woven, and has the advantages of anti-bacteria, anti-corrosion, anti-wrinkle, moisture absorption, ventilation, flatness and flexibility, good slip resistant and so on.

Owner:石磊

Method for preparing heavy metal ion exchange fibers by virtue of roundpod jute capable of being modified by microwave and application

ActiveCN104562632AComplete efficientlyShort manufacturing timePhysical treatmentWater/sewage treatment by ion-exchangePolymer scienceMicrowave oven

The invention discloses a method for preparing heavy metal ion exchange fibers by virtue of roundpod jute capable of being modified by microwave and application. The method comprises the following steps: I. firstly boiling roundpod jute fibers by boiled water, then soaking the roundpod jute fibers by using a sodium hydroxide solution and drying and storing; and II. adding the roundpod jute fibers pretreated in the step I and a complexing group active monomer into the solution, carrying out reaction in a microwave oven, after reaction, taking out the material, and after cleaning, putting the product in the oven to be dried until constant weight is achieved to obtain a roundpod jute-base modified adsorption material which can be used for sudden heavy metal pollution and conventional heavy metal wastewater treatment, so that the hardness of water is effectively reduced. According to the invention, the matrix is rapidly grafted and modified by virtue of a microwave radiation technology in the preparation process to prepare fibers with complexing functions, so that the advantages of non-thermal effect of microwaves and strong grafting penetrating power are fully utilized, chemical grafting reaction can be quickly and efficiently accomplished, the preparation time is greatly shortened, and the method is simple to operate and convenient and feasible.

Owner:HARBIN INST OF TECH

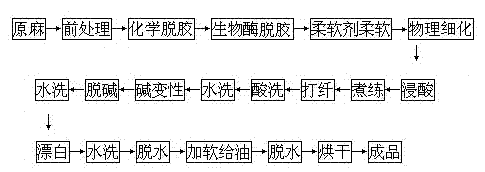

Processing method for refining jute fiber

InactiveCN102517650AAvoid damageImproved splittingBiochemical fibre treatmentVegetable materialPectinaseFiber strength

The invention discloses a processing method for refining a jute fiber, which comprises adopting sodium hydroxide solution to perform chemical degumming on raw jute after water bath or acid bath is carried out to the raw jute, adopting pectinase or laccase to perform biological enzyme degumming, and performing chemical degumming after physical refining is carried out to the jute fiber where a softening agent is sprayed. Damage to the fiber is reduced by adding the softening agent, the fineness is remarkably improved, the softening agent which is sprayed to the jute fiber prior to the physical refining of the jute fiber can reduce friction between the jute fibers, unnecessary fiber breakage is reduced when the physical refining is performed, the fact that the fiber is not damaged is guaranteed, the fiber strength is prevented from being lowered, part of colloid and impurity are exposed out of a surface layer of the fiber due to split separation of the jute fiber after physical refining, the colloid and impurity on the surface layer of the fiber can be removed through chemical degumming treatment after physical refining, the fiber can be further refined, the costs are reduced, and utilizing rate is improved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

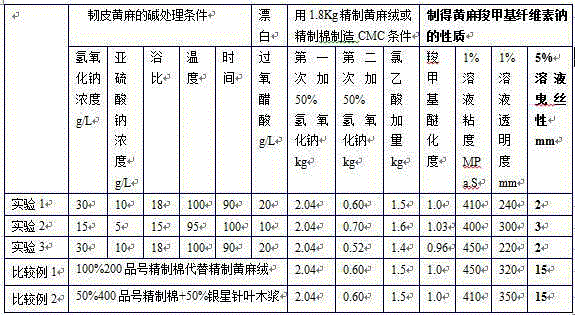

Method for preparing high-viscosity and high-etherification-degree sodium carboxymethyl cellulose from jute

The invention relates to a method for preparing high-viscosity and high-etherification-degree sodium carboxymethyl cellulose from jute. The special sodium carboxymethyl cellulose which is low in viscoelasticity and filament dragging ability is provided, and is suitable for being used as a printing-dyeing pasty material. The technological process of the method comprises the following steps: performing pretreatment on jute, performing composite alkaline treatment, bleaching, drying to obtain refined jute cellulose, performing alkalification under a low-temperature nitrogen charging oxygen insulation environment, using low-power ethanol as a medium, feeding segmentally, performing trapezoidal heating, etherifying alkali cellulose by using an etherifying agent as chloroacetic acid to obtain a product of which the ethyloic etherification degree is 1, the 1% aqueous solution viscosity is greater than 400 mPa. s, the 2.5% viscosity is greater than 10000 mPa. s, the PVT is greater than 0.50, and the filament dragging ability is smaller than 5 mm. The sodium carboxymethyl cellulose is very suitable for being used as the printing-dyeing pasty material. Through the adoption of the method, the production cost of sodium carboxymethyl cellulose is effectively reduced, the high-grade model sodium carboxymethyl cellulose is obtained, meanwhile, a high value-added way is found for resourceful jute, the product is stable, the process is reliable, the cost is lower, and an excellent market prospect is provided.

Owner:HANGZHOU HONGBO NEW MATERIALS +1

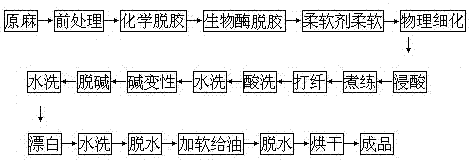

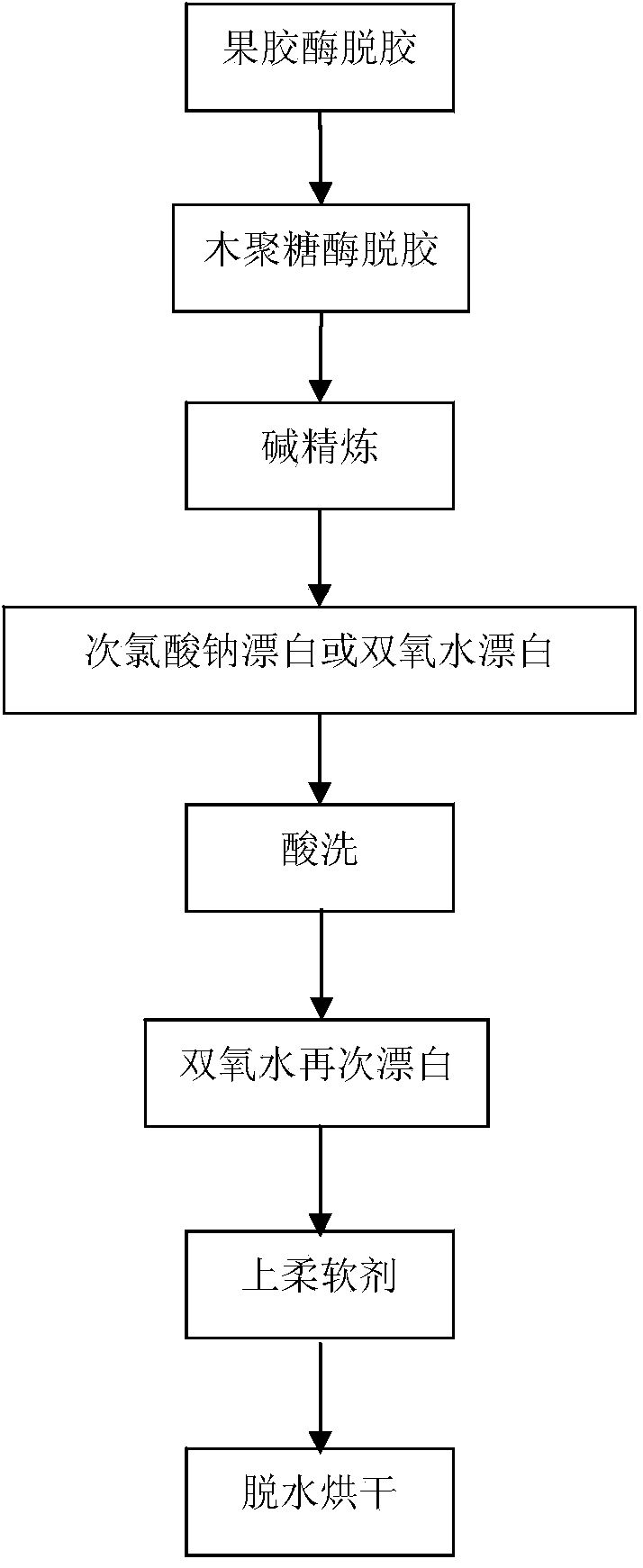

Jute fiber degumming method

The invention provides a jute fiber degumming method. The method comprises the following steps: (1) degumming by using pectinase, wherein the mass percentage of the pectinase relative to jute fibers is 0.5 to 2 percent; (2) degumming by using xylanase, wherein the mass percentage of the xylanase relative to the jute fibers is 0.5 to 2 ercent; (3) refining by utilizing caustic soda and sodium carbonate; (4) bleaching by using sodium hypochlorite or hydrogen peroxide; (5) performing acid pickling by using sulphuric acid; (6) bleaching again by using the hydrogen peroxide. According to the jute fiber degumming method, the jute fibers are degummed sufficiently by using the pectinase and the xylanase which have no damage to the jute fibers, have no pollution to environment, and have high specificity, so that the division number and the evenness of the jute fibers can be effectively improved; decomposed symbionts are sufficiently removed by refining and bleaching by using chemical methods, so that the jute fibers are refined and softened; the requirements on the yarns for textile and apparel are met; high-alkaline high-temperature chemical scouring treatment is avoided; the damage to fibers is reduced; pollution emissions are reduced.

Owner:SHANGHAI YIKE TEXTILE TECH

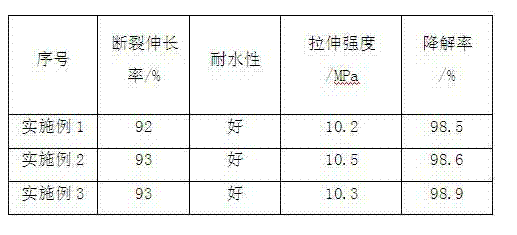

Production process of PVA (polyvinyl alcohol)-based composite packaging material

InactiveCN103540068ANo pollution in the processNo dopingFlexible coversWrappersPolyvinyl alcoholBiological materials

The invention discloses a production process of a PVA (polyvinyl alcohol)-based composite packaging material, relating to the field of film packaging materials. The production process comprises the following three technical processes: preparation of dialdehyde starch, preparation of jute fibers and preparation of a PVA-based composite film. According to the process method, in the preparation process of the dialdehyde starch, corn starch is used as a raw material, no pollution is caused, the cost is low, the raw material is sufficient, a far-infrared quick constant-temperature drying box is used as drying equipment, the dialdehyde starch is dried sufficiently, and no impurity is doped; in the preparation process of the jute fibers, the temperature control is reasonable, a right amount of reagent is added, the jute fibers are pulverized through a YSC-701 type ultrafine pulverizer, and the pulverized fibers are small in particle size and favorable in pulverization effect; and in the preparation process of the PVA-based composite film, parameters such as addition of each component, temperature, time and the like are strictly controlled, thereby ensuring that the prepared PVA-based composite film has favorable mechanical property and water resistance and can meet the requirements for practical production. By using the biological material as the raw material for production, the PVA-based composite film produced by the process is low in cost and degradable, thus greatly reducing environmental pollution.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

Jute/terylene/cotton blended yarn

A jute / polyester / cotton blended yarn comprises three types of fiber of jute, polyester and cotton and is characterized in that the weight of the polyester fiber accounts for 10-40 percent by weight of the total weight of the jute, the polyester and the cotton fiber. The fineness difference between the polyester fiber and the jute fiber and the fineness difference between the polyester fiber and the cotton fiber are both small. When being blended, the polyester fiber of the blended yarn can be cohered with the jute fiber and can also be cohered with the cotton fiber, thereby enhancing the cohesion among different types of fiber; and the spun blended yarn has better breaking strength. The invention discloses the content range of the added polyester fiber which can lead the breaking strength of the yarn to be more satisfactory during the blending of the jute fiber / cotton fiber with different weight percentages.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

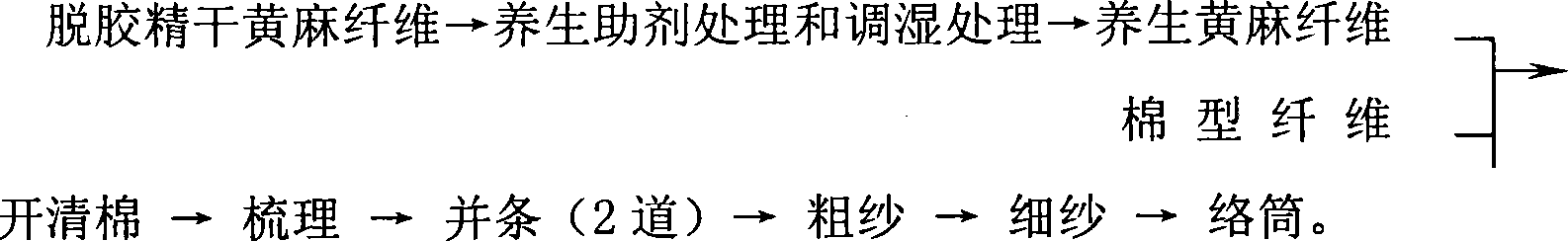

Health preserving jute blended yarn and preparation method thereof

InactiveCN101177810AReduce adverse effects of spinningRaise the ratioFibre treatmentLiquid/gas/vapor removal by centrifugal forceYarnEngineering

The invention pertains to the textile field and relates to a health jute blended yarns and a preparation method thereof, which is characterized in that the blending weight percentage of the health jute fiber and short-staple is 56 to 75: 44 to 25; through the treatment of health and conditioning of degumed and dried jute fibers and the improvement of spinning technique, the jute fibers generated stands a large proportion and the health jute blended yarns has smaller fineness, which can be used as clothes and home textile goods.

Owner:DONGHUA UNIV

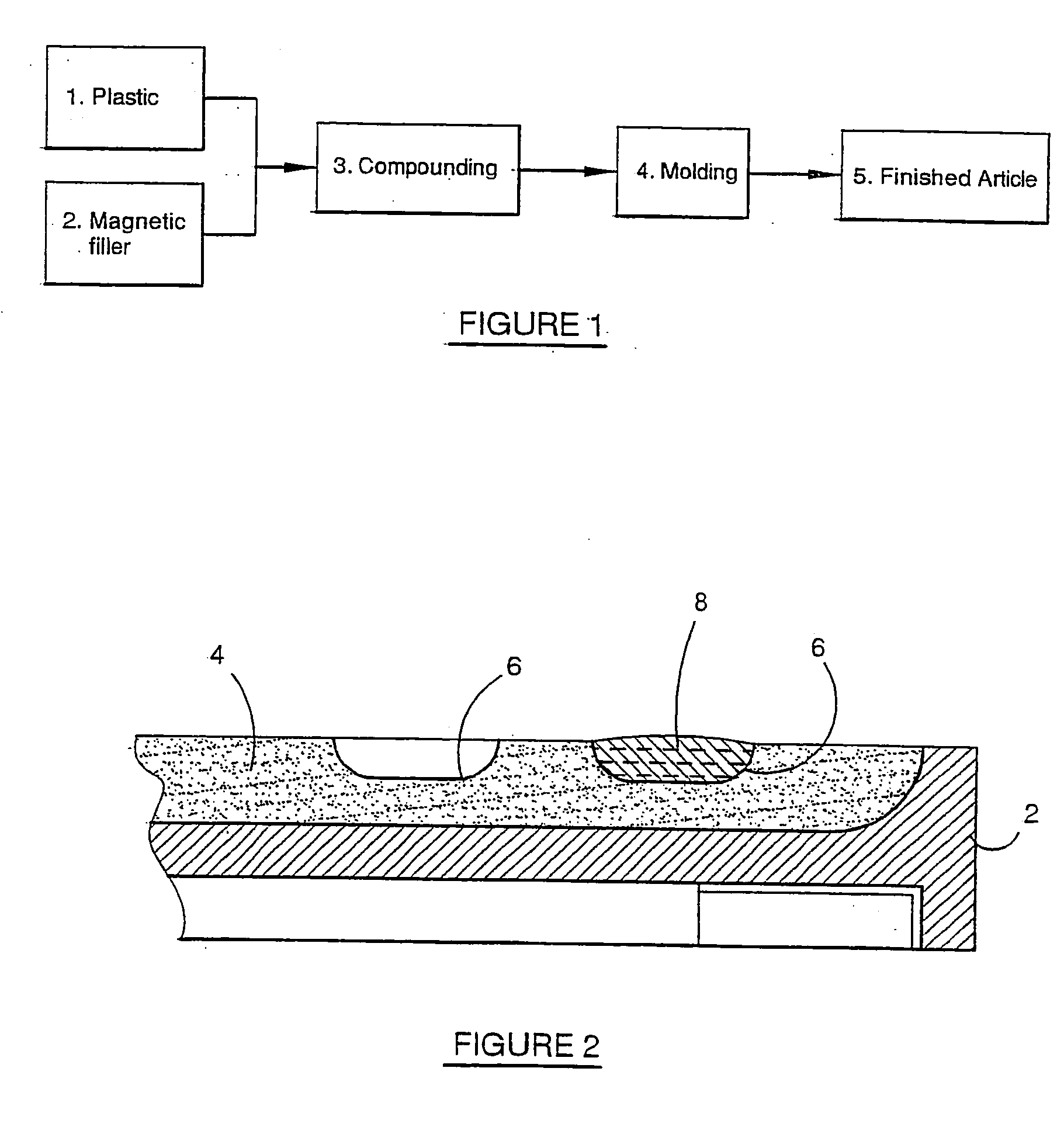

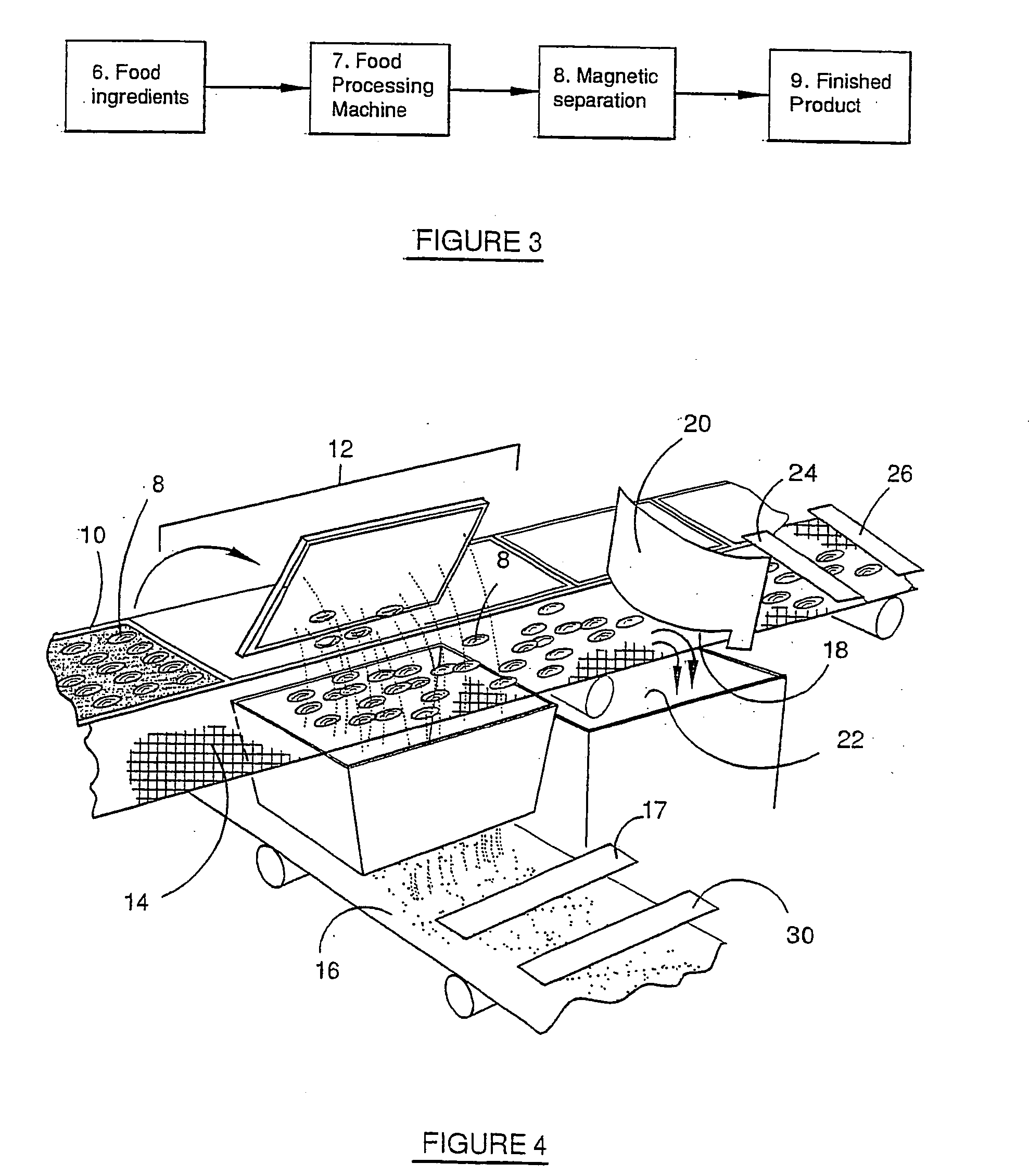

Moulding composition

In a food processing line, the equipment which is likely to fragment on breakage contains magnetically susceptible particles which are separated from the food by a magnetic separation stage. When the equipment is a starch carrying tray, the moulding mix contains 5-50% of magnetic filler, such as magnetite. Reinforcement with glass fibre and jute fibre modifies the compositions for moulding the trays. Moulding mixes based on polypropylene and thermosetting resins are described. A processing line using starch trays has a conveyor for food items and a conveyor for the starch in which the food items are moulded. Both have magnetic separators.

Owner:BELL GLENDA FAY

Jute/hemp/cotton blended yarn

A jute / hemp / cotton blended yarn comprises three types of fiber of jute, hemp and cotton and is characterized in that the weight of the hemp fiber accounts for 10-40 percent by weight of the total weight of the jute, the hemp and the cotton fiber. The fineness difference between the hemp fiber and the jute fiber and the fineness difference between the hemp fiber and the cotton fiber are both small. When being blended, the hemp fiber of the blended yarn can be cohered with the jute fiber and can also be cohered with the cotton fiber, thereby enhancing the cohesion among different types of fiber; and the spun blended yarn has better breaking strength. The invention discloses the content range of the added hemp fiber which can lead the breaking strength of the yarn to be more satisfactory during the blending of the jute fiber / cotton fiber with different weight percentages.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Decorative sheet

ActiveCN103193437ALightweight and high strengthWith fire insulationSolid waste managementSpecial ornamental structuresSludgeSoluble glass

The invention discloses a decorative sheet. The decorative sheet is characterized by comprising the following raw materials in parts by weight: 24-26 parts of zinc ore tailings, 12-14 parts of acetylene sludge, 10-12 parts of cement, 9-11 parts of mica flake, 1.5-2.5 parts of aedelforsite, 11-13 parts of jute fibre, 0.5-1 part of soluble glass and 25-27 parts of water. The decorative sheet is prepared through the following steps of: (1) mixing materials; (2) loosening the jute fibre; (3) making slurry; (4) blanking, wherein the pressurizing pressure is 4MPa; (5) pressing decorative patterns; (6) autoclaved curing; (7) trimming; and (8) drying. The decorative sheet has remarkable social benefit and economic benefit.

Owner:徐州宇之阳市场营销策划有限公司

Method of degumming jute fibres with complex enzyme (1)

InactiveUS20100240113A1Efficient removalHydrolasesMicrobiological testing/measurementPectinaseAqueous solution

A method of degumming jute fibres with complex enzyme, wherein said complex enzyme comprises pectinase and laccase, wherein comprising the steps of: a. soaking the jute fibres in the water solution of said complex enzyme made from pectinase and laccase, wherein the weight proportion of said complex enzyme water solution and jute fibres ranges from 12:1 to 40:1; b. adjusting the PH value of said complex enzyme water solution to more than 5.0, but no more than 6.5, and adjusting the temperature of said complex enzyme water solution to 35° C.-65° C., then keeping said complex enzyme water solution with such temperature value for 20-120 minutes; c. adjusting the PH value of said complex enzyme water solution to 7.5-9.5, and adjusting the temperature of said complex enzyme water solution to 40° C.-70° C.; then, keeping said complex enzyme water solution with such temperature value for 20-120 minutes; d. conducting enzyme deactivation of the jute fibres processed with said complex enzyme.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Environmentally-friendly fabric

The invention discloses an environmentally-friendly fabric formed by interleaving warps and wefts. The warps are organic cotton fibres or corn fibres, the wefts are luffa fibres, or lotus fibres, or jute fibres or interwoven fibres of several types of fibres, and decorative patterns or patterns are printed on the surface of the fabric by virtue of reactive dyeing. The environmentally-friendly fabric disclosed by the invention has the advantages that (1) no pollution can be produced to peripheral environment, the dustproof properties are good, and the clean class is high; (2) a weaving method is simple and feasible, the production efficiency is high, and the cost is low.

Owner:江苏红运果服饰有限公司

Blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber

The invention provides a blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber. The blended yarn is characterized by comprising the following components: 60-70 weight parts of acrylic fiber, 15-25 weight parts of jute fiber and 15-25 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of acrylic fiber, jute fiber and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:JIANGSU TONGHAI THREAD

Natural fibrilia decorative board

InactiveCN101463580ASimple processing technologyReduce weightFibreboardLayered productsPolymer scienceAdditive ingredient

The invention relates to a composite basic material decoration board, in particular to an environment-friendly thermoplastic natural wool and flax fiber decoration board; in terms of weight percentage, the board comprises the ingredients as follows: 30%-50% of wool, 30%-50% of flax, and 20% of polypropylene fiber; the wool, the flax and the polypropylene fiber undergo mixing and mould pressing to make the decoration board. The flax is a fibrilia comprising flax fibers, or jute fibers, or ambary fibers, or mixed fibrilia. The decoration board of the invention is an energy-saving and environment-friendly natural wool and flax fiber composite basic material decoration board which is easy to process, low in cost, toxic-free, reproducible, degradable, light in weight, has good hygroscopic property, and can absorb noise.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

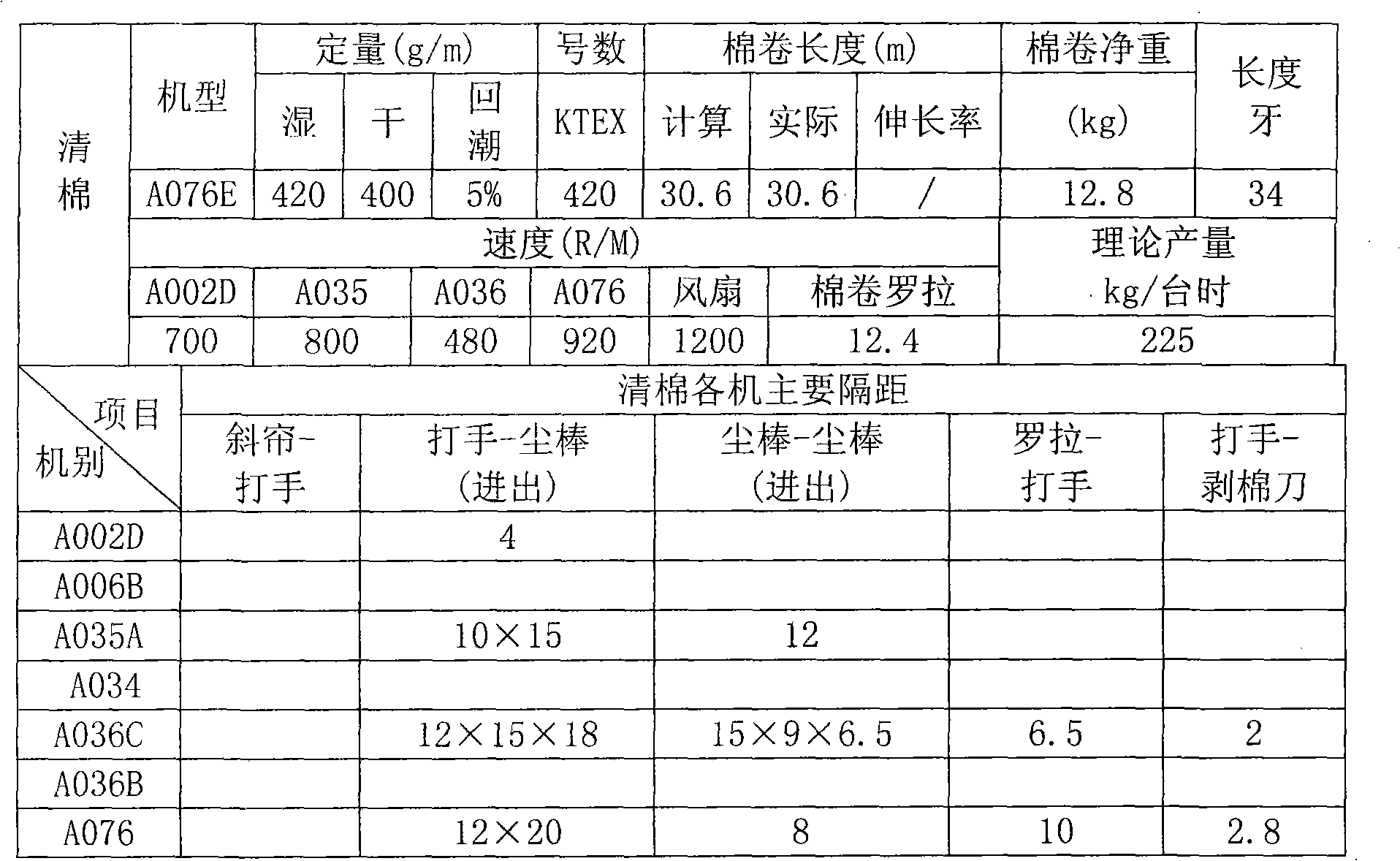

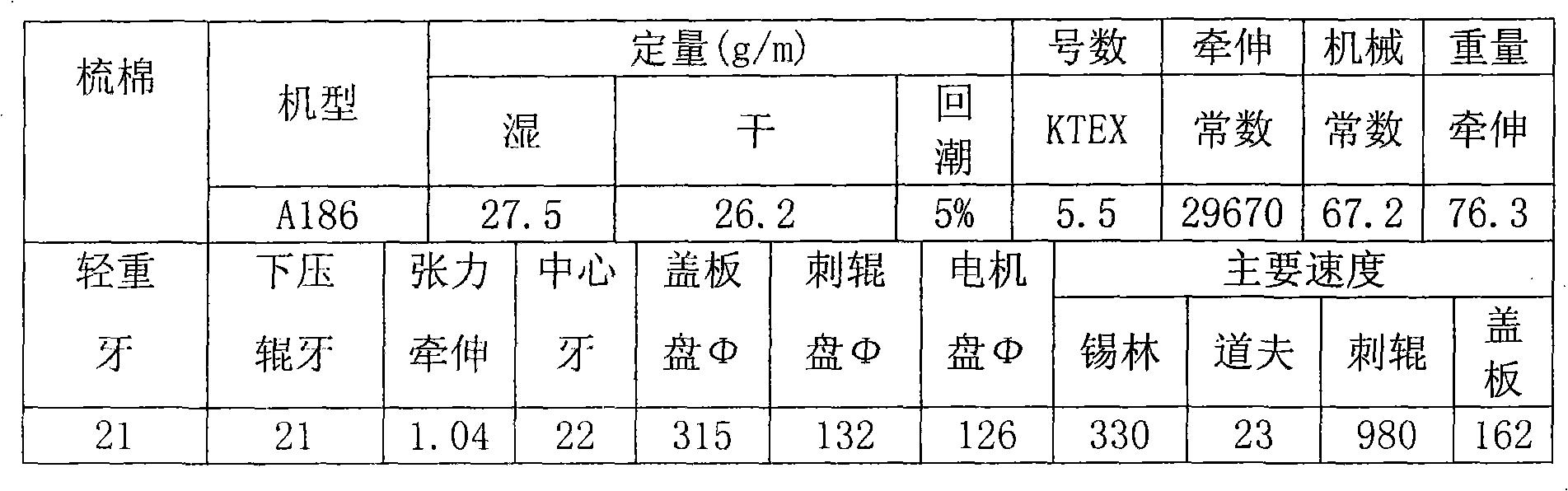

Production method of jhouta and dacron blended yarn

The invention discloses a method for producing the blended spinning of jute and terylene. The method comprises the following steps that: firstly, the jute is added with 10 percent of water and 5 percent of softener and preheated for 24 hours; the jute and the terylene are picked up according to a proportion and subjected to the working procedures of scutching, cotton carding, drawing, coarse spinning, fine spinning, and cheese winding; in the step of cotton carding, the striking times is 480 rmp and the carding time is twice; when impurities in the jute and chemical fibre are treated, a cotton-type sieve for cotton carding is A86C; a separation degree of the fibre is between 1.2 and 0.7 tex; in the step of coarse spinning, the twisting number of coarse yarn is between 80 and 85; and in the step of fine spinning, a relative humidity of fine yarn is between 65 and 70 percent. A jute product produced by adopting the technology changes the weakness of coarseness and hardness of jute fibre, improves the spinnability and softness of the fibre and has small production pollution.

Owner:RUGAO RUXING TEXTILE

Method for manufacturing seat cushion with jute fibre

ActiveCN101172571AGood puffing effectImprove acupuncture effectUpholstery fillingFibre treatment to obtain bast fibrePectinaseAntibiosis

The invention relates to a manufacturing method of a seat cushion made of jute fiber. The method comprises the following steps: firstly, the soaking is performed to jute in compound enzyme water solution prepared by pectase and laccase, and the weight ratio of the compound enzyme water solution and the jute is 12 : 1 to 40 : 1; the pH value of the compound enzyme water solution is firstly adjusted into 4.0 to 6.5, and the compound enzyme water solution is warmed up to 35 to 65 DEG C, and the temperature is kept for 20 to 120 minutes; and then pH value of the compound enzyme water solution is adjusted to more than 8.0 and less than and equal to 9.5, and the compound enzyme water solution is kept for 20 to 120 minutes at 14 to 70 DEG C; then the enzyme inactivation process is performed to the jute processed through the compound enzyme; secondly, jute fiber after being degumed is mixed with chemical fiber, and carding, mesh placement and needling are performed to the chemical fiber; thirdly, the mixed fiber after being needled is thermally pressed and molded; fourthly, a sleeve body is coated. The seat cushion manufacuted by the invention is soft and comfortable, has no urtication feeling when being used by people, and has good antibiosis and anti-acarine performance.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Jute Degumming Process

InactiveUS20070192964A1Full effectEasy to processDry-cleaning apparatus for textilesBleaching apparatusLacquerBleach

A jute degumming process that features effective removal of impurities like pigment and xylogen in jute fiber with an easy process and low cost. The jute degumming process is attained by unpacking and bunching raw jute. Treating the raw jute with an aqueous solution of compound enzyme made from pectase and laccase. The jute is then patched up for a predetermined duration wherein it is rinsed with hot water. An aqueous solution of reductive bleaching agent is then added to bleach the jute followed by adding a decolourizer thereto. The resulting jute is stamped, rinsed, oiled, dehydrated, dried whereby the jute fiber is decolorized and an impurity free jute fiber is obtained.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

EVA shoe sole and preparation process thereof

PendingCN111154173AImprove flexural toughnessImprove crack resistanceLow-density polyethylenePolymer science

The invention relates to an EVA shoe sole and a preparation process thereof. The EVA shoe sole comprises the following components in parts by weight: 50-70 parts of EVA, 20-30 parts of modified low-density polyethylene, 10-20 parts of a filler, 10-15 parts of a flame retardant, 5-8 parts of color master batch, 2-4 parts of a foaming agent, 0.4-0.8 part of a bridging agent, 0.2-0.4 part of an accelerant, 0.5-0.6 part of stearic acid, 0.3 to 0.5 part of N,N'-ethylene bisstearamide, and 0.1 to 0.2 part of triallyl isocyanurate, wherein the modified low-density polyethylene is a jute fiber / nitrilerubber / low-density polyethylene compound. The preparation process comprises the steps: S1, banburying; S2, open milling; S3, cooling; S4, slitting; S5, mold pressing; and S6, edge trimming. The produced shoe sole has good anti-cracking performance.

Owner:FUJIAN JOYYOU SPORTS GOODS

Preparation method of high-interfacial-bond-strength jute-polylactic acid composite material

InactiveCN107129669ASimple processProcess parameters are easy to controlVegetal fibresMaterials preparationInterfacial bond

The invention discloses a preparation method of a high-interfacial-bond-strength jute-polylactic acid composite material. The method is characterized by comprising the steps of pretreatment, silicon dioxide sol treatment, hydrolytic treatment, and preparation of the modified jute fiber-polylactic acid composite material. The fiber pretreatment can remove the non-cellulosic substances, so that grooves are generated on the fiber surface, thereby being beneficial to generating mechanical anchoring actions in the reinforced composite material preparation process; and the pretreatment can endow the fibers with uniform color. By performing the silicon dioxide sol treatment and hydrolytic treatment, a coarse structure can be formed on the fiber surface, thereby further enhancing the mechanical anchoring actions of polylactic acid on the fiber surface. The method has the advantages of simple technique and controllable conditions; and the prepared composite material has the advantages of favorable compatibility between jute fibers and polylactic acid, high interfacial bond strength, obvious reinforcement effects and lower cost.

Owner:SHAOXING UNIVERSITY

Grain storage bag and preparation method thereof

ActiveCN105755674AImprove preservation qualityNatural bacteriostasisBio-packagingDomestic containersGrain storageNonwoven fabric

The invention discloses a grain storage bag and a preparation method thereof and relates to the field of packaging. The grain storage bag is prepared from polylactic acid fibers and jute fibers. The preparation method of the grain storage bag comprises the following steps: preparing a lower layer polylactic acid filament fiber web by adopting a polylactic acid chip; unwinding jute fiber woven roving cloth and directly laying on the lower layer polylactic acid filament fiber web; preparing an upper layer polylactic acid filament fiber web by adopting the polylactic acid chip, and laying on the jute fiber woven roving cloth to form three layers of fiber webs; pre-reinforcing the three layers of fiber webs to obtain polylactic acid filament non-woven fabric; compounding the polylactic acid filament non-woven fabric through an ultrasonic method, cutting according to a certain specification and then sewing and thermally-sealing to obtain the grain storage bag. According to the grain storage bag disclosed by the invention, point-like compounding is performed by using the degradable polylactic acid fibers, the jute fibers with unique fiber cavity structures and the ultrasonic method, so that the grain storage bag has the advantages that the grain quality deterioration is delayed, the grain storage period is prolonged, and the damage due to collision in the grain transporting process is buffered.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

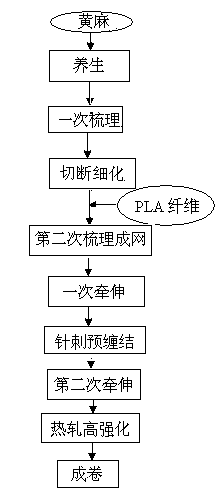

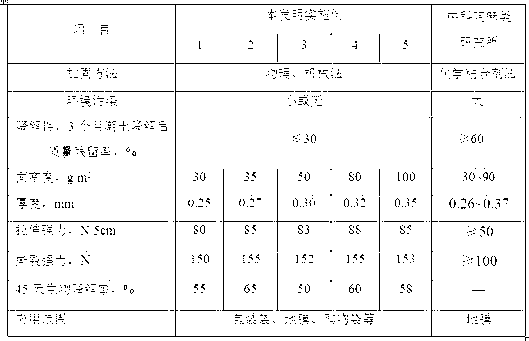

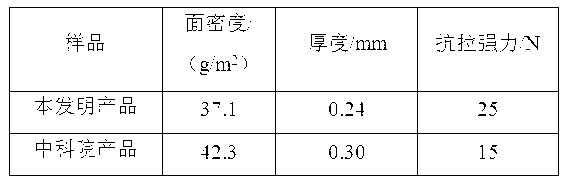

Thin jute fiber non-woven fabric for packaging and production method for thin jute fiber non-woven fabric

The invention discloses a thin strong-strength environment-friendly jute fiber non-woven fabric for packaging and a production method for the thin jute fiber non-woven fabric, and belongs to a non-woven material and a processing method for the same. The thin jute fiber non-woven fabric for packaging comprises the following components in percentage by weight: 65 to 75 percent of jute fiber and 25 to 35 percent of poly lactic acid (PLA) fiber. The thin jute fiber non-woven fabric for packaging is produced by the following steps of performing enzymatic treatment and primary combing on jute serving as a raw material, cutting and thinning the jute fibers, mixing the jute fibers with the PLA fibers, performing secondary combing and primary drafting crossing to form a mesh, performing secondary drafting after needling pre-entanglement, and performing a hot rolling procedure to melt, solidify and shape the PLA fibers. The thin jute fiber non-woven fabric is strong in strength and short in process flow and degradable, can be widely used for upscale shopping bags, mulching films and other packaging materials, and has broad market prospect, and the jute fibers are required to be degummed.

Owner:安吉振兴布业有限公司

Jute fiber degumming process

InactiveCN104419987AReduce decomposition rateGood removal effectFibre treatment to obtain bast fibreDecompositionPhysical chemistry

The invention discloses a jute fiber degumming process. The jute fiber degumming process mainly comprises the following steps of raw jute cleaning, raw jute pickling, rinsing, primary alkali-hydrogen peroxide bathing, raw jute beating, rinsing, acid pickling, washing and airing. Jutes are degummed and bleached by using the primary alkali-hydrogen peroxide bathing method, the alkali and hydrogen peroxide are mutually acted, the alkali removes gum, hemicelluloses, xylogen and other impurities in jute fibers and also provides an alkali environment for the decomposition of hydrogen peroxide; hydrogen peroxide is very stable in an acid medium, and the decomposition velocity is very low; however, hydrogen peroxide can be activated in an alkali medium, and hydrogen peroxide molecules are decomposed to bleach the jute fibers. Simultaneously, and particularly importantly, the xylogen can be oxidized, and the oxidized xylogen can be dissolved in high-temperature strong aqueous alkali under experiment conditions, so that the removal of the xylogen is facilitated.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Method for producing anti-wrinkle and non-ironing clothing fabrics

InactiveCN108118428AImprove wrinkle resistanceImprove wear resistanceWeft knittingWarp knittingWrinkle skinCotton fibre

The invention relates to a method for producing anti-wrinkle and non-ironing clothing fabrics. The fabrics are characterized in that the fabrics comprise the following blended fiber raw materials, byweight, 40-70 parts of protein fiber, 20-40 parts of jute fiber and 10-20 parts of cotton fiber, wherein flushing treatment, bleaching treatment, surface softening treatment, dehydrating and drying treatment and vaporizing treatment are sequentially conducted on the jute fiber before the jute fiber is blended with the protein fiber and the cotton fiber, and a non-formaldehyde anti-wrinkle finishing agent is added to the production process of a blended textile for non-ironing finishing. The fabrics have the advantages of being good in wrinkle and wearing resistance, and ironing is not needed after washing.

Owner:桐庐恒昌服饰有限公司

Special health preserving adjuvant for jute fiber

The invention discloses a special auxiliary agent used for curing jute fibre, comprising 0.5 to 3 proportions of emulsifier, 5 to 7 proportions of amino silicone oil with an amino value ranging from 0.3 to 0.4 and molecule ranging from 300 to 30000, and 0.5 to 3 proportions non-ionic penetrant. Quaternary ammonium salt softener can also be added into the auxiliary agent so as to further enhance the softness of the curing auxiliary agent. The special auxiliary agent for the curing of jute fibre can fully enter into an internal core of the jute fibre by the function of the penetrant, thus improving the softness of the jute fibre and intensifying the cohesion force among the fibre.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com