Production method of jhouta and dacron blended yarn

A production method and technology of blended yarn, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of high clean production level of cooked hemp degummed emulsified liquid mineral oil, backward jute processing technology, water environment pollution, etc., to improve spinnability The effect of improving the toughness and softness, changing roughness and weakness, and producing less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The jute is firstly pretreated. During the pretreatment, the jute is pretreated with 10% water and 5% softener for 24 hours.

[0007]

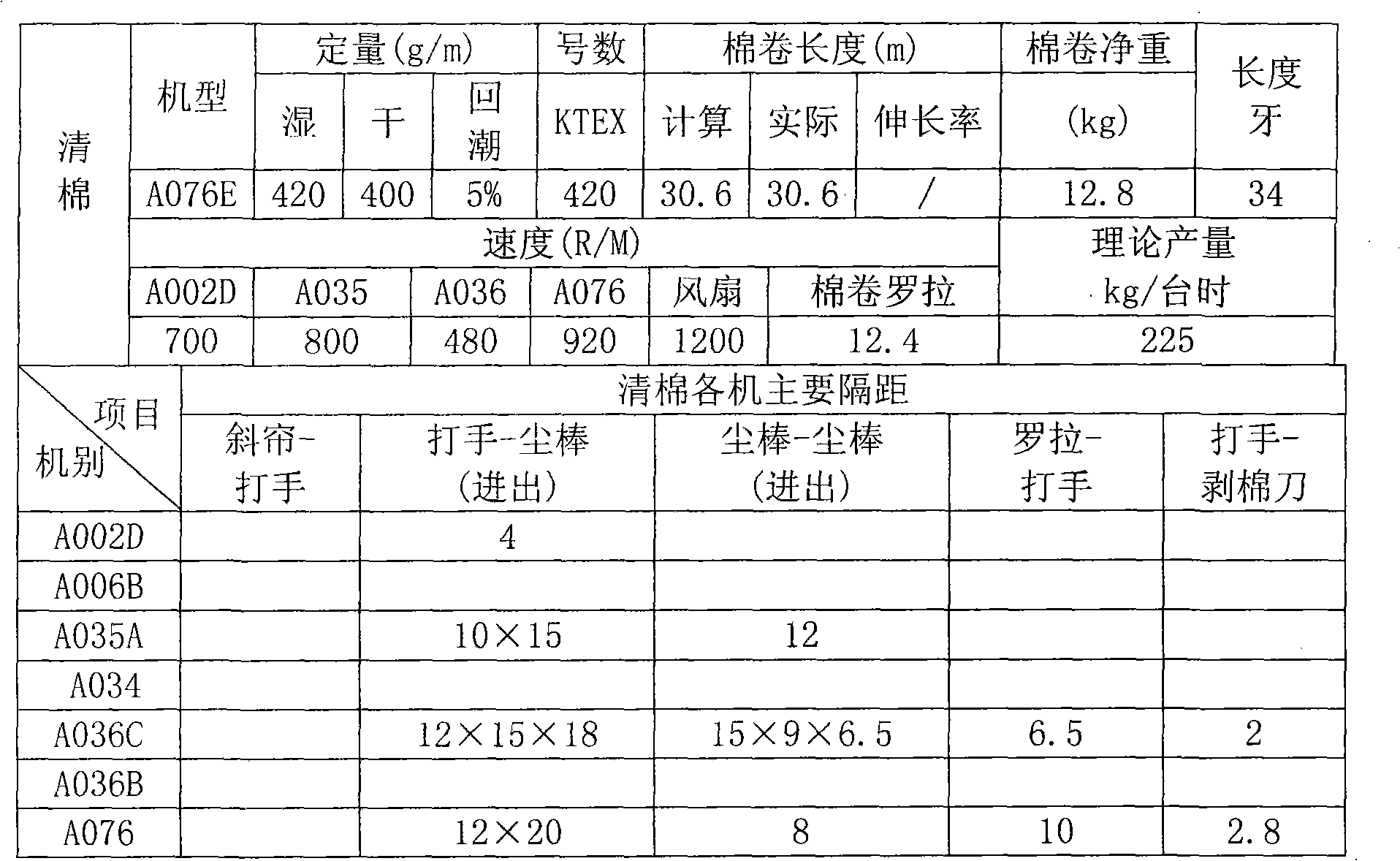

[0008] Take 45% jute and 55% polyester, put it on the cleaning machine for the following treatment:

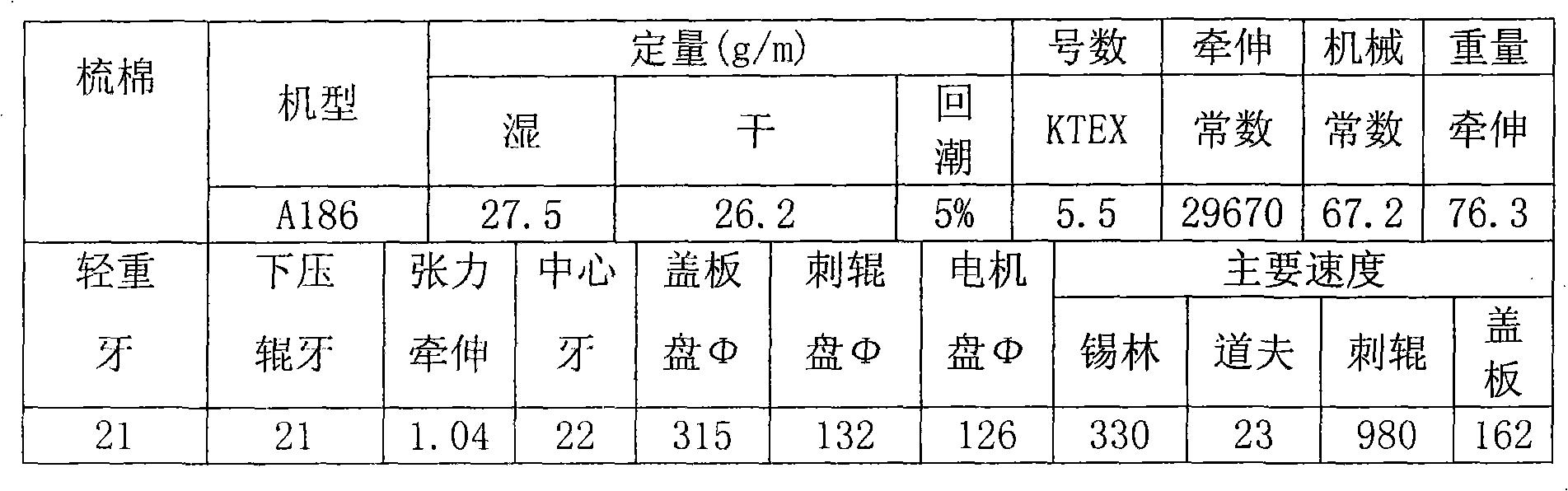

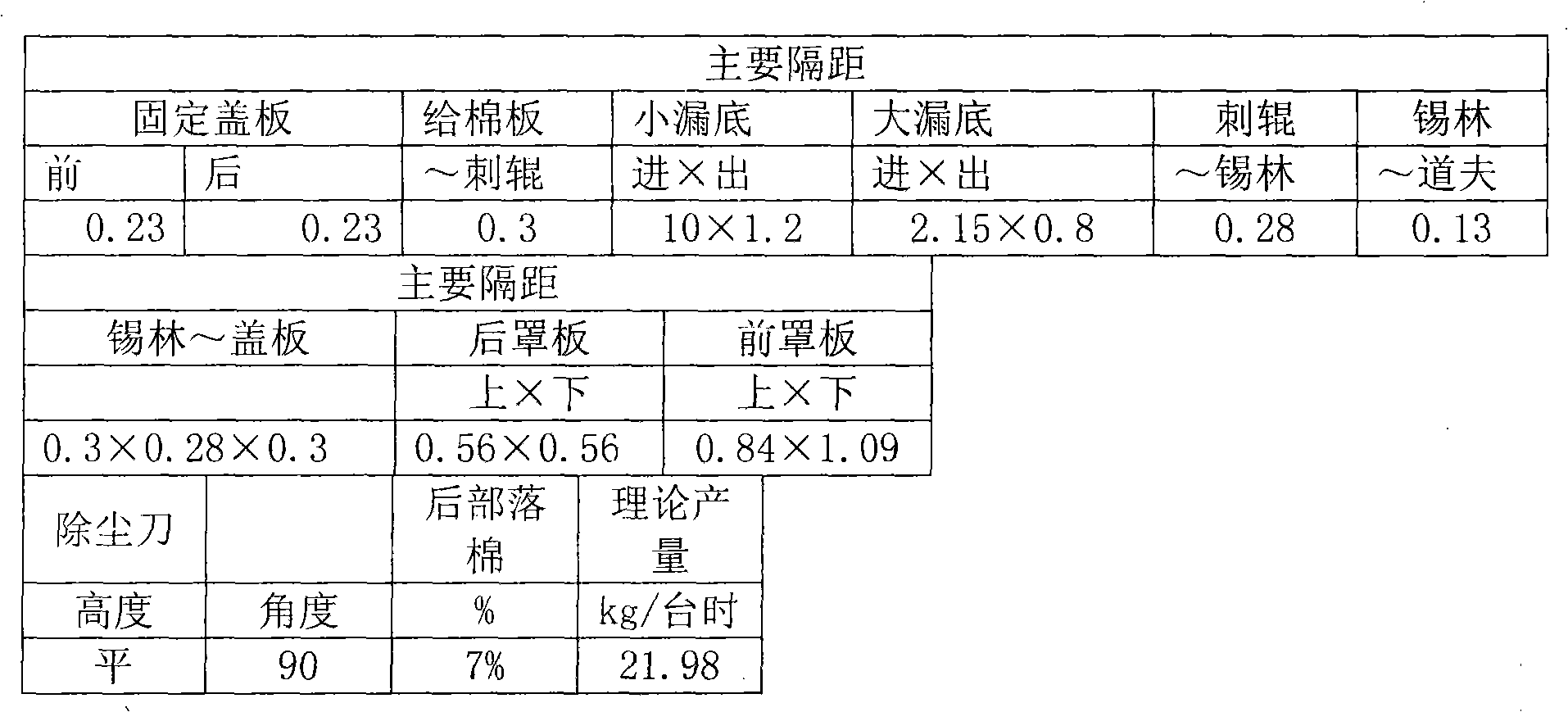

[0009] After the cleaning is completed, enter the carding program. In this program, the mixture of jute and polyester that has been cleaned is carded. In order to make the impurities in the jute and chemical fibers less residual, the carding cotton type drain is A86C. In this process, the degree of separation of the fibers is 1.2tex-0.7tex. The specific operations are shown in the table below:

[0010]

[0011]

[0012] The carded fiber enters the drawing frame program, and the drawing frame adopts three drawing frames, adopts A272F drawing frame, and completes the drawing frame work through the following operations that require mechanical precision:

[0013]

[0014] Carry out roving after the drawing frame is completed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com