Laser etching aluminum alloy surface texturing method

A technology of aluminum alloy surface and laser etching, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of long cycle time, expensive coating cost, environmental pollution, etc., and achieve increased adhesion and surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

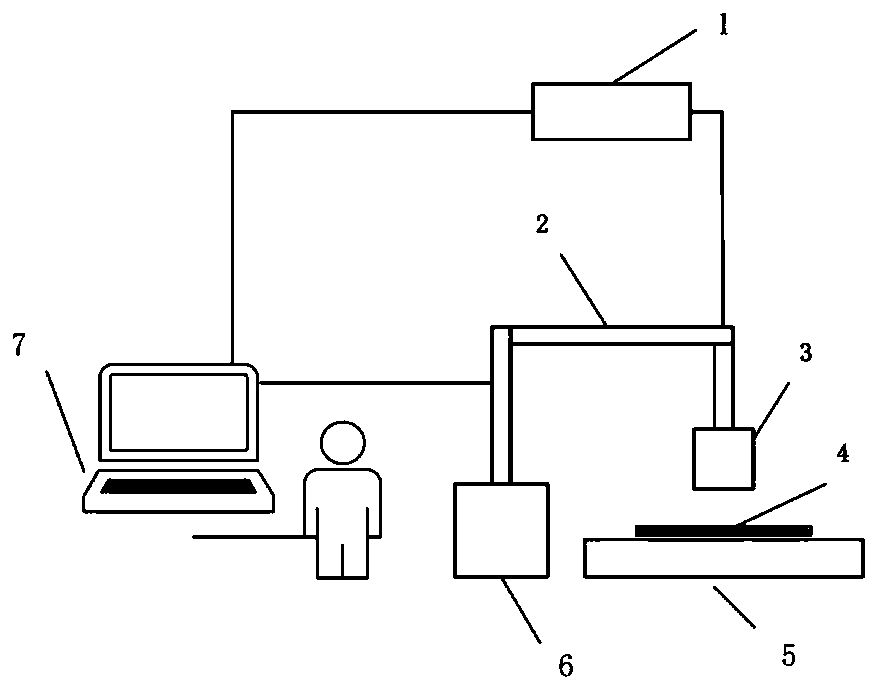

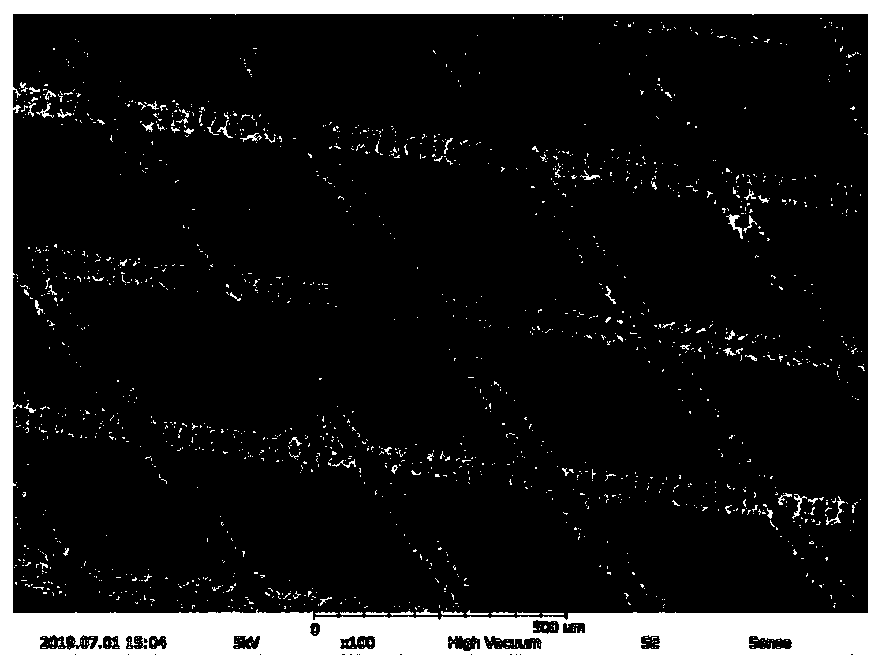

[0039] Such as figure 1 and figure 2 As shown, a method for laser etching the surface texture of aluminum alloy, the method includes using the vibrating mirror in the laser processing device to control the scanning path of the laser, etching different textured surfaces on the surface of the aircraft aluminum alloy skin, and scanning The speed is 2000mm / s, the frequency is 90kHz, the pulse width is 0.35μs, the number of scans is 1, the spacing is 0.3mm, the spot diameter is 50μm, and the power is 24W; the diameter of the pit produced by the laser on the surface of the aircraft aluminum alloy skin is 50μm, and the shape of the pit is similar It is circular, the pits are superimposed to form a scanning path, and the textured surface is diamond-shaped.

Embodiment 2

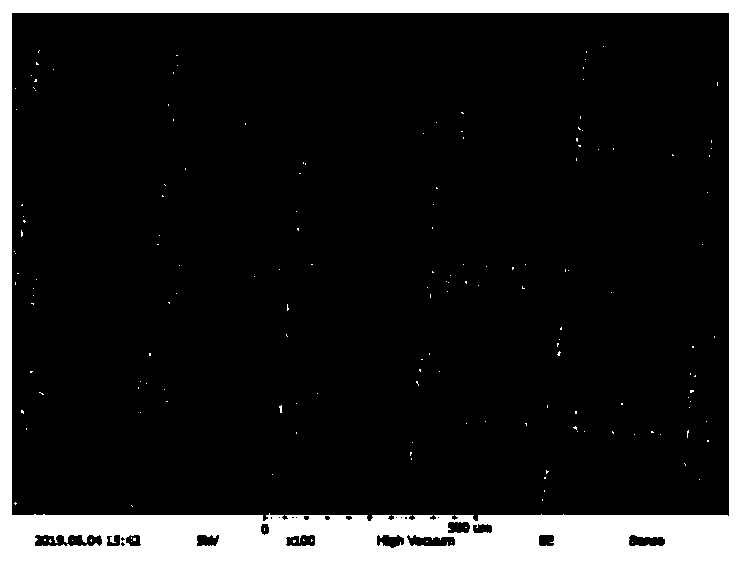

[0041] Such as figure 1 and image 3 As shown, the pit diameter is 45 μm, the texture surface is square, and the rest are the same as in Example 1.

Embodiment 3

[0043] Such as figure 1 and figure 2 As shown, the pit diameter is 50 μm, and the texture surface is diamond-shaped, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com