Grain storage bag and preparation method thereof

A grain bag, gingham technology, applied in chemical instruments and methods, bags, sacks, etc., can solve the problems of reducing the effect of grain preservation, affecting the strength of packaging bags, hidden dangers of safety, etc. The effect of improving the preservation quality and prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

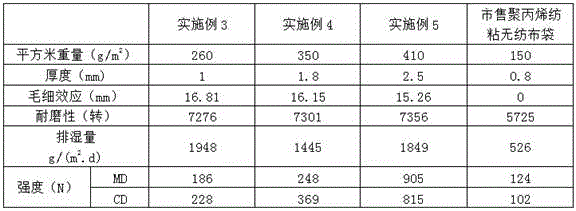

Examples

Embodiment 1

[0037] In step 101, polylactic acid slices are used to prepare the lower polylactic acid filament web.

[0038] Step 102, unwind the hemp fiber woven square cloth and lay it directly on the lower polylactic acid filament web, and the hemp fiber woven square cloth is prepared from jute fiber.

[0039] In step 103, polylactic acid slices are used to prepare the upper polylactic acid filament web.

[0040] Step 104, laying the upper layer polylactic acid filament web on the hemp fiber woven grid cloth, and placing the upper layer polylactic acid filament web, the hemp fiber woven grid cloth and the The three-layer fiber web composed of the lower polylactic acid filament web is sent as a whole to a three-roll mill for pre-reinforcement, wherein the roll surface temperature of the three-roll mill is 125-138°C, and the hot rolling and ironing time is 10-20s After exiting the three-roll rolling mill, the three-layer fiber web is wound to obtain a polylactic acid filament nonwoven fa...

Embodiment 2

[0045] Step 201, the melt index is 30-55g / 10min, the density is 1.24g / cm 3 , polylactic acid slices with a melting point of 165-170°C are first pre-crystallized at 30-40°C for 4-6h, then heated to 110°C at a rate of 10°C per hour, and then dried at 110°C for 6-8h , so that the water content of the polylactic acid slice reaches 0.035-0.045%.

[0046] In step 202, the polylactic acid slices that have been dried are fed, extruded by an extruder, and filtered, and then sent to a spinning box for spinning. The spinning temperature is controlled at 220-240° C., and the spinning speed is controlled as 4000-6000m / min, compressed air pressure is 0.3-0.5MPa, side blowing cooling temperature is 20-23°C, wind speed is 0.4-0.8m / s, and the working air volume for air stretching is 0.75-1m 3 / min, the spinning frequency of the spinning device is 500-700Hz. After the spinning, it is sucked by the airflow of the suction bellows under the netting curtain and falls on the netting curtain. The sp...

Embodiment 3

[0061] 1) Preparation of polylactic acid filament nonwoven fabric

[0062] (1) Preparation of lower polylactic acid filament web

[0063] a. Use a melt index of 30g / 10min and a density of 1.24g / cm 3 , polylactic acid chips with a melting point of 170°C;

[0064] b. Pre-crystallize the polylactic acid slices at 40°C for 4-6h, then raise the temperature to 110°C at 10°C per hour, and dry at 110°C for 6-8h, so that the water content of the polylactic acid slices reaches 0.035%;

[0065] c. Use a melt index of 55g / 10min and a density of 1.24g / cm 3 , polylactic acid slices with a melting point of 165°C, the polylactic acid slices are fed, extruded by an extruder and filtered, and then sent to the spinning box for spinning. The spinning temperature is controlled at 240°C, and the spinning speed is controlled at 6000m / min, the compressed air pressure is 0.5MPa, the side blowing cooling temperature is 23°C, the wind speed is 0.8m / s, and the working air volume of the airflow stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com