Method for preparing high-viscosity and high-etherification-degree sodium carboxymethyl cellulose from jute

A technology of sodium carboxymethyl cellulose and high etherification, applied in the chemical industry, can solve the problems of application fields and economic limitations, and achieve the effects of good fluidity, low viscoelasticity, and low dragging property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

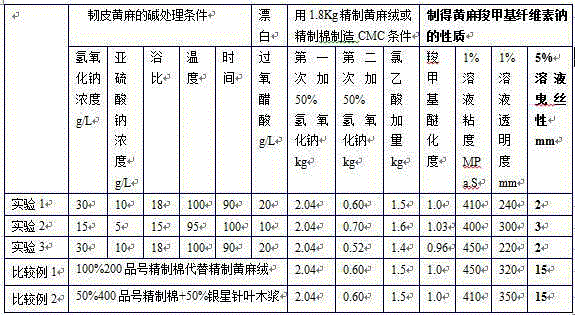

Embodiment 1

[0035] First, treat the juteine. The juteine treatment agent is: 30g / L sodium hydroxide, 10g / L sodium sulfite, 3g / L penetrant JFC, the weight-to-liquid ratio is 1:18, and the temperature is kept at 100°C for 90min. After bleaching, the bleaching agent is: 20g / L peracetic acid, 5g / LLEDTA sodium salt, 3g / L penetrant JFC, 5g / L soda ash, bath ratio 1:18, 70℃ for 60min. After washing with water, dehydration, and drying in the second stage (the first stage is 60°C and the second stage is 105°C), the refined jute fluff cellulose is obtained.

[0036] Take 1.8kg of refined hemp wool, add it to the kneader, add 3kg of 93% ethanol, 2.04kg of 50% concentration of liquid caustic soda, and alkalize at 15°C for 60min.

[0037] Add 0.5kg of a mixed solution of 1.50kg of chlorinated acid and 94% ethanol to the kneader, control the temperature below 20°C, and then add 0.60kg of 50% concentration of liquid caustic soda. The temperature was increased in stages, from 20°C to 75°C, about 40 mi...

Embodiment 2

[0044] Juterine treatment agent: 15g / L sodium hydroxide, 5g / L sodium sulfite, 1g / L osmotic agent JFC, liquor ratio 1:15, kept at 95°C for 100min. After bleaching, the bleaching agent is 5g / L peroxyl acid, 2g / LLEDTA sodium salt, 1g / L penetrant JFC, 6g / L soda ash, and the temperature is kept at 80°C for 60min. The following is the same as Example 1 except that the addition amount of chloroacetic acid is changed to 1.60㎏, and the secondary addition of 50% liquid caustic soda is changed to 0.70㎏.

[0045] The sodium carboxymethyl cellulose prepared from the obtained jute wool has a degree of carboxymethyl etherification of 1.03, a transparency of 1% aqueous solution of 30cm, a viscosity of 1% of 420mpa.s, a viscosity of 2.5% of 10500mpa.s, a PVI value of 0.50, and a wire drag Sex 3mm.

Embodiment 3

[0047] The preparation of refined jute cashmere is the same as in Example 1; then, except that the amount of chloroacetic acid added is 1.40 kg, and the secondary addition of 50% liquid caustic soda is 0.52 kg, other processes for preparing sodium carboxymethyl cellulose are the same as in Example 1. The obtained product has a degree of carboxymethyl etherification of 0.96, a 1% aqueous solution transparency of 22cm, a 1% viscosity of 500mpa.s, a 2.5% viscosity of 13500mpa.s, a PVI value of 0.52, and a 2mm wire drawability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com