Processing method for refining jute fiber

A technology for refining jute and a processing method, which is applied in the directions of biochemical fiber treatment, chemical post-treatment of fibers, fiber treatment, etc. The effect of splitting separation, improving the thinning rate, and preventing the decrease of fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

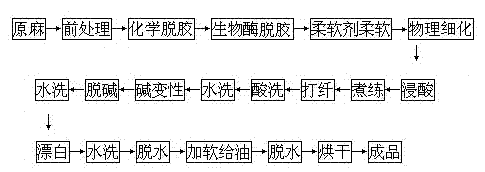

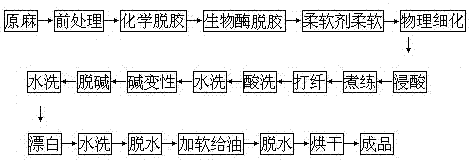

Image

Examples

Embodiment 1

[0018] Finally, bleaching, washing, dehydration, softening and oiling, dehydration, and drying are carried out to obtain refined jute fibers.

[0019] Example 2

Embodiment 2

[0021] Finally, bleaching, washing, dehydration, softening and oiling, dehydration, and drying are carried out to obtain refined jute fibers.

[0022] Example 3

Embodiment 3

[0024] Finally, bleaching, washing, dehydration, softening and oiling, dehydration, and drying are carried out to obtain refined jute fibers.

[0025] The fineness of the physically thinned fiber is 10.8% higher than that of the fiber without physical thinning, and the fiber fineness can reach 617 public branches, and the fineness has been significantly improved. The softener can reduce the friction between jute fiber and fiber, reduce unnecessary fiber breakage during physical thinning, ensure that the fiber is not damaged, prevent the decline in fiber strength, and the jute fiber after physical thinning is Splitting and separation occurs, so that part of the colloid and impurities are exposed on the surface of the fiber. After physical thinning, chemical degumming can remove the colloid and impurities on the surface of the fiber, which can further refine the fiber, reduce the cost, and improve the utilization rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com