Patents

Literature

52results about How to "Improve flexural toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-ductility low-shrinkage anti-cracking concrete for bridge deck pavement and preparation method thereof

The invention belongs to the field of concrete structural materials, and discloses a preparation method for high-ductility low-shrinkage anti-cracking concrete for bridge deck pavement. The high-ductility low-shrinkage anti-cracking concrete for bridge deck pavement is characterized by comprising the following components in proportion: 135-155 kg / m<3> of water, a cementing material, 600-800 kg / m<3> of fine aggregate, 950-1150 kg / m<3> of coarse aggregate, 2.0-3.0 kg / m<3> of shrinkage-reducing ductility-increasing component,10-20 kg / m<3> of internal curing agent, 3.0-5.0 kg / m<3> of water reducing agent and hybrid fiber, wherein the cementing material comprises 320-380 kg / m<3> of cement and 20-40 kg / m<3> of coal ash in proportion; and the hybrid fiber comprises 0.8-1.0 kg / m<3> of organic polymer fiber and 40-50 kg / m<3> of steel fiber in proportion. According to the concrete and the preparation method for the concrete disclosed by the invention, reinforcement meshes on the bridge deck pavement layer can be cancelled.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Crack-resisting mortar for insulation of modified rubber powder and preparation method thereof

ActiveCN102225856AHigh compressive strengthImprove flexural strengthSolid waste managementCellulosePolymer science

The invention provides crack-resisting mortar for insulation of a modified rubber powder and a preparation method thereof. The crack-resisting mortar for insulation comprises the following raw materials in parts by weight: 5-60 parts of modified rubber powder, 50-110 parts of cement, 10-50 parts of sand, 0.5-2 parts of polypropylene fiber, 0.5-3 parts of dispersible latex powder, 2-3 parts of quick lime, 0.1-1 part of cellulose ether and 0.01-0.03 part of air entraining agent. The preparation method comprises the following steps: preparing a modifier; preparing the modified rubber powder; carrying out air-drying for later use; and carrying out mix preparation so as to obtain the crack-resisting mortar for the insulation of the modified rubber powder. Compared with the crack-resisting mortar for the insulation of the unmodified rubber powder, the compression strength, rupture strength and flexural toughness of the crack-resisting mortar in the invention are improved under the same flowability condition, wherein the rupture strength is larger than 450kpa, the compression strength is larger than 700KPa, the bonding strength is more than 180KPa, linear shrinkage is less than 1%, and the softening coefficient is more than 0.9. The crack-resisting mortar in the invention has a huge effect in the building field and a wide market prospect.

Owner:CHINA XINXING BAOXIN CONSTR CORP

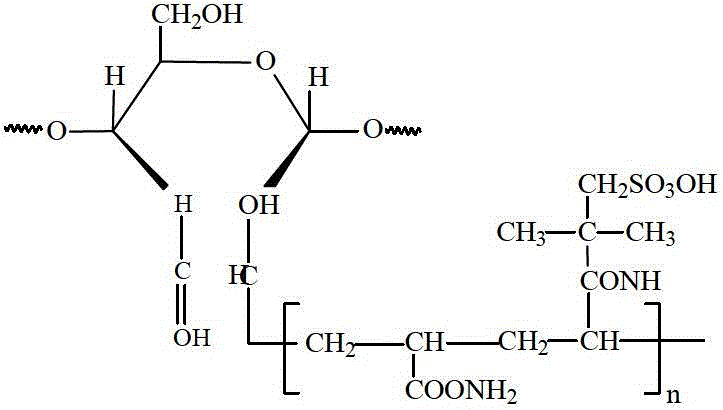

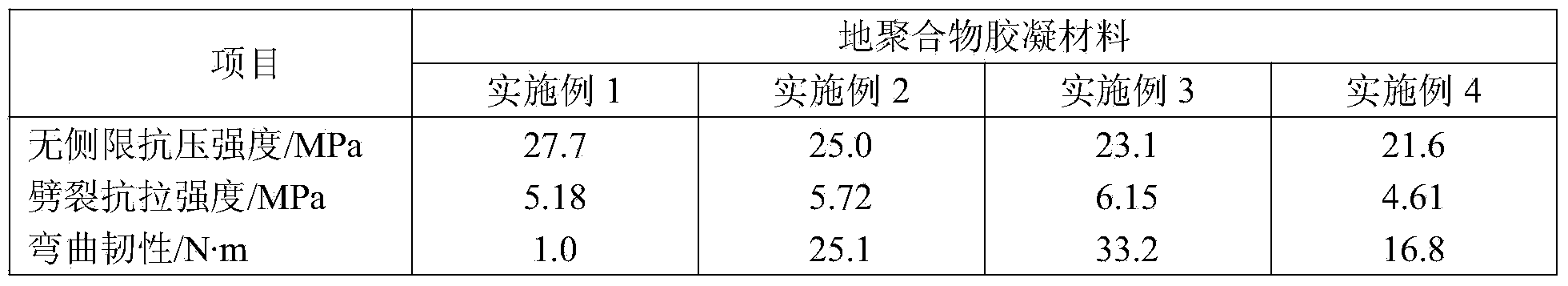

Corn straw fiber enhanced fly ash polymer gel material and preparation method thereof

The invention discloses a corn straw fiber enhanced fly ash polymer gel material and a preparation method thereof. In the preparation method, the corn straws are mixed into an alkali-excited fly ash polymer gel material, and then the mixture is subjected to certain maintenance conditions so as to enable the material system to have good properties. The corn straw, namely a waste which has not been effectively utilized, is used to enhance a poly gel material prepared from an industrial waste fly ash. A novel way is provided for waste utilization, the environment burden is relieved, the energy consumption is reduced, and the material performances are strengthened. The corn straw fiber enhanced fly ash polymer gel material is an unfired and clinker-free material, is a zero-carbon-emission environment-friendly engineering material, is according with the social development trend, and has a good social benefit and economic benefit.

Owner:SOUTHEAST UNIV

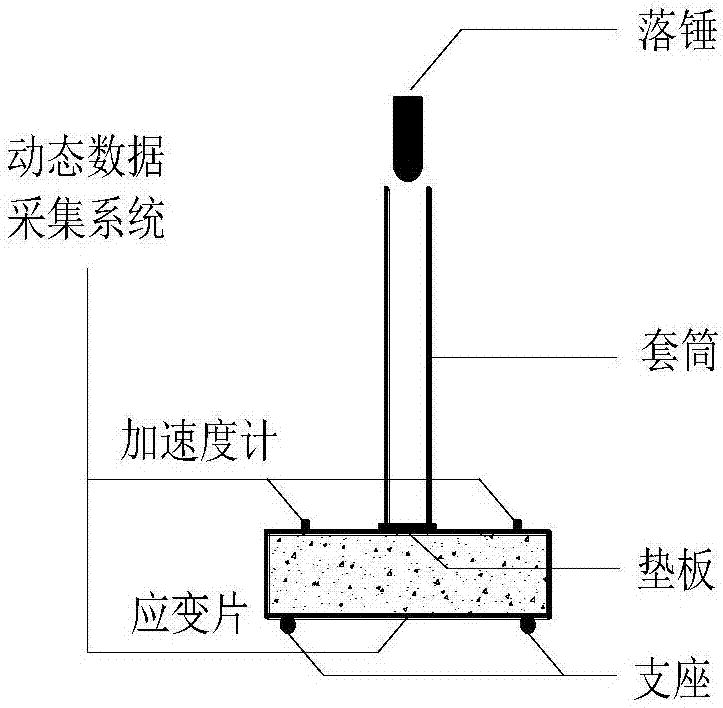

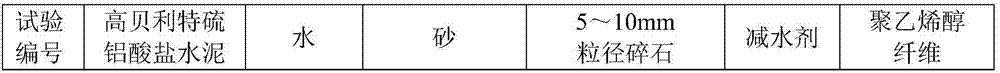

Fiber concrete for quick repair of airfield pavement, preparation and application

The invention relates to fiber concrete for quick repair of an airfield pavement, preparation and an application and belongs to the technical field of concrete. The weight of high-belite sulphate aluminum cement accounts for 16.0-20.0% of the total weight of a repair material; the weight of sand accounts for 21.5-34.1% of the total weight of the repair material; the weight of gravel accounts for 42.7-55.3% of the total weight of the repair material; a water-cement ratio is 0.31-0.42; a polyvinyl alcohol fiber is 12-15mm in length and 45 micrometers in diameter; the volume of the polyvinyl alcohol fiber accounts for 0.6-1.0% of the total volume of the repair material; and an effective solid mixing amount of a water reducer is 0.12-0.19% of the mass of the high-belite sulphate aluminum cement. A preparation method comprises the steps of pouring a cementing material and the sand in raw materials into a stirrer for uniform stirring, slowly pouring a mixed solution of the water reducer and the water into the stirrer, adding the polyvinyl alcohol fiber after a mixture is changed into colloid from a particle, and performing quick casting after uniform dispersion. The fiber concrete can be used for the quick repair of the broken airfield pavement.

Owner:BEIJING UNIV OF TECH

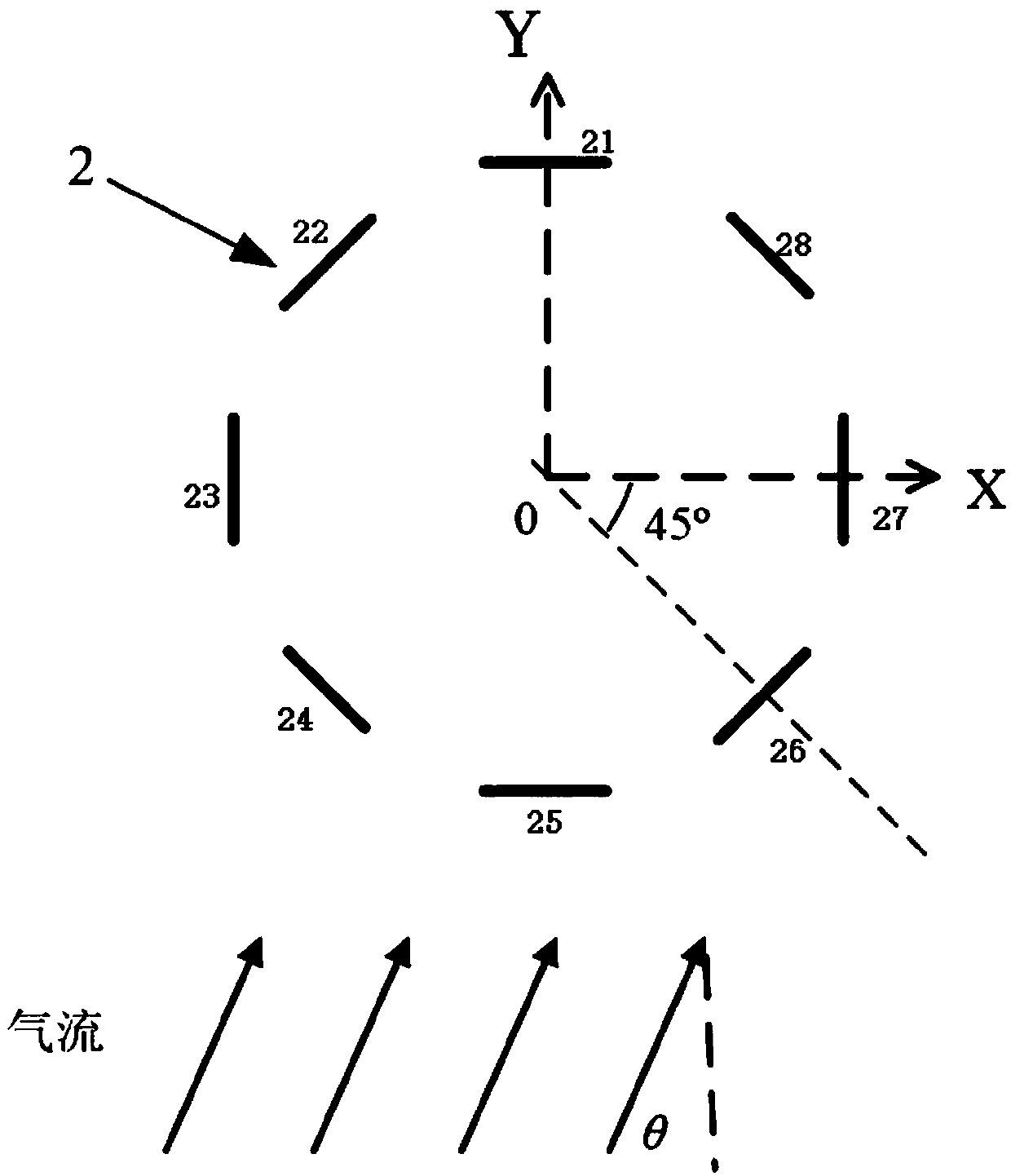

Piezoelectric fiber array sensor for sensing flow velocity change and measurement method thereof

ActiveCN107765030AHigh strengthImprove flexural toughnessIndication/recording movementFluid speed measurementFiberCantilevered beam

The invention relates to a piezoelectric fiber array sensor for sensing flow velocity change and a measurement method thereof. The sensor comprises a flexible base, micro array strip-shaped fiber sensing units, conductive thin film and electrode layers; the flexible base is in an axisymmetric shape and is provided with a plurality of side surfaces; the micro array strip-shaped fiber sensing unitsare fixed on the side surfaces through the ends of a suspension beam structure; output units which are composed of the conductive thin film and the electrode layers are arranged on the connection portions of the micro array strip-shaped fiber sensing units and the side surfaces. The measurement method comprises the steps that the piezoelectric fiber array sensor for sensing the flow velocity change is placed in a wind field, the micro array strip-shaped fiber sensing units of the sensor directly face the flow velocity direction, and output signals of the output units of the sensor are collected; then, through a linear fitting method, the mathematic relation of the flow velocity and the sensing electric signals is calibrated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

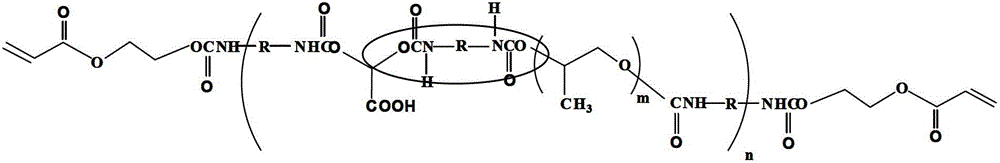

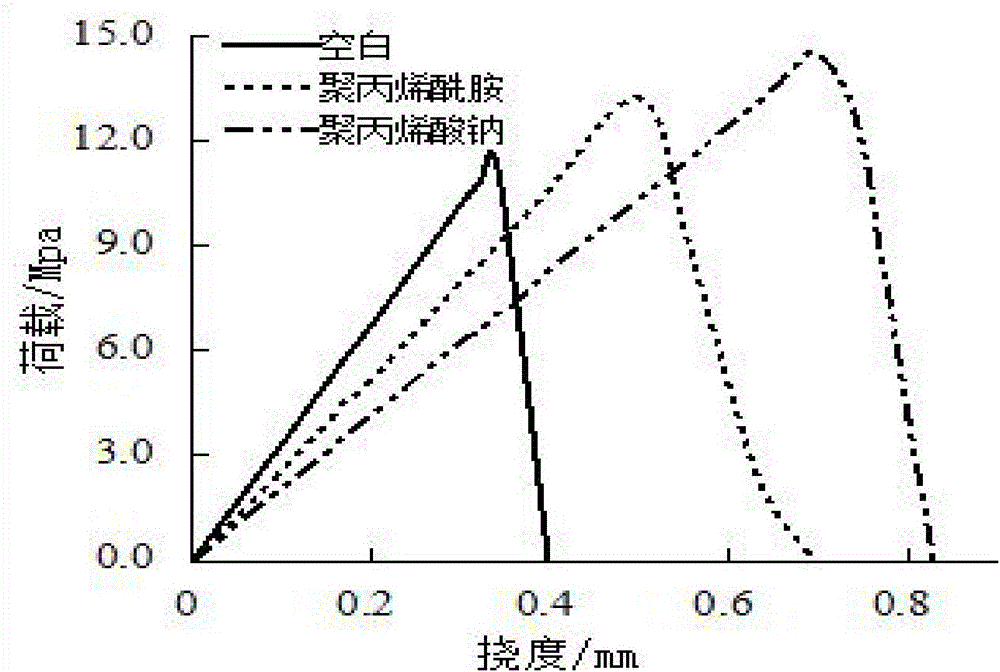

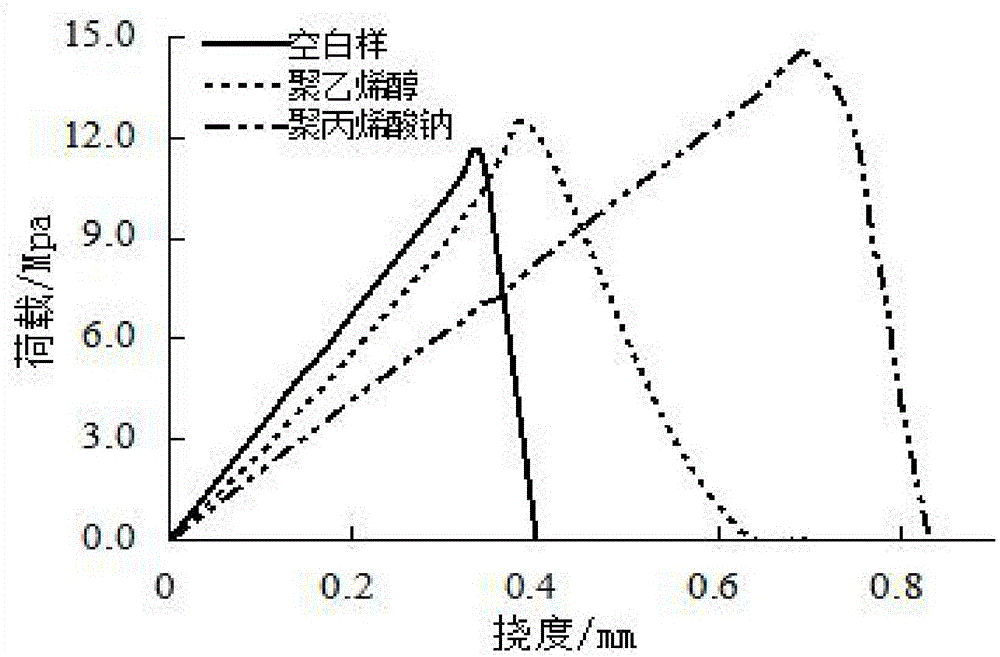

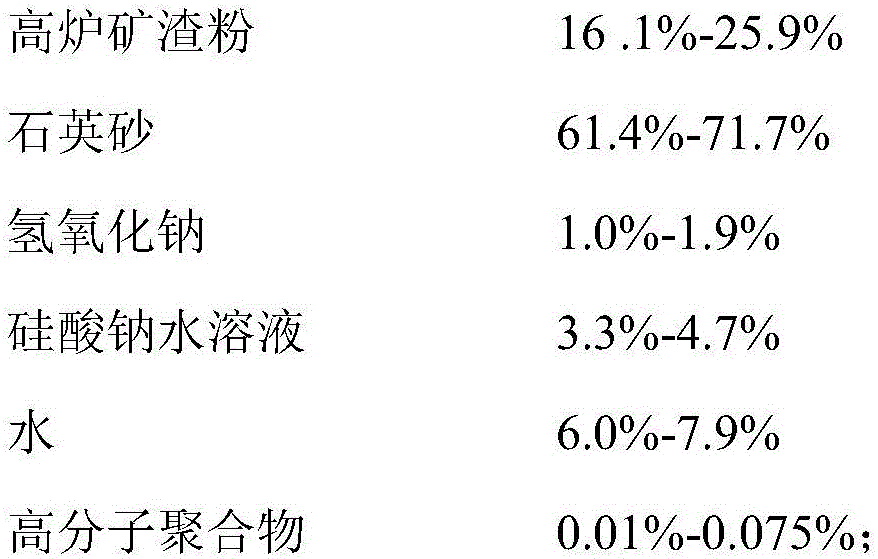

Polymer modification blast-furnace slag powder material

InactiveCN105800969AHigh ultimate flexural strengthImprove flexural toughnessCement productionSodium polyacrylateSodium silicate

The invention discloses a polymer modification blast-furnace slag powder material.The material is prepared from, by weight, 16.1-25.9% of blast furnace slag powder, 61.4-71.7% of silica sand, 1.0-1.9% of sodium hydroxide, 3.3-4.7% of a sodium silicate water solution, 6.0-7.9% of water and 0.01-0.75% of high-molecular polymer.The high-molecular polymer is sodium polyacrylate or polyacrylamide or polyvinyl alcohol.The polymer modification blast-furnace slag powder material has the high ultimate bending strength, high bending toughness and low elastic modulus, the deformation performance can be remarkably improved, the defects that the breaking strength is low and the brittleness is large are overcome, and meanwhile the polymer modification blast-furnace slag powder material has the advantages of resisting high temperature, resisting chemical corrosion, being good in anti-permeability, low in shrinkage rate and the like.

Owner:WUHAN UNIV OF TECH

Anti-knocking steel box beam bridge deck paving structure and paving method

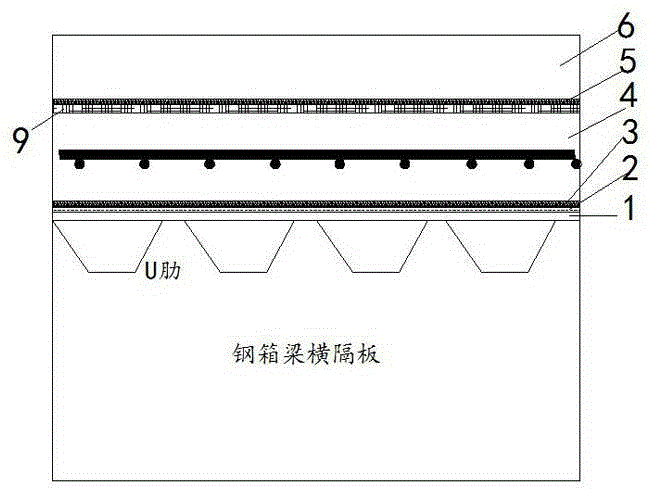

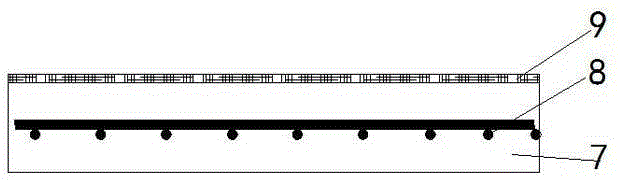

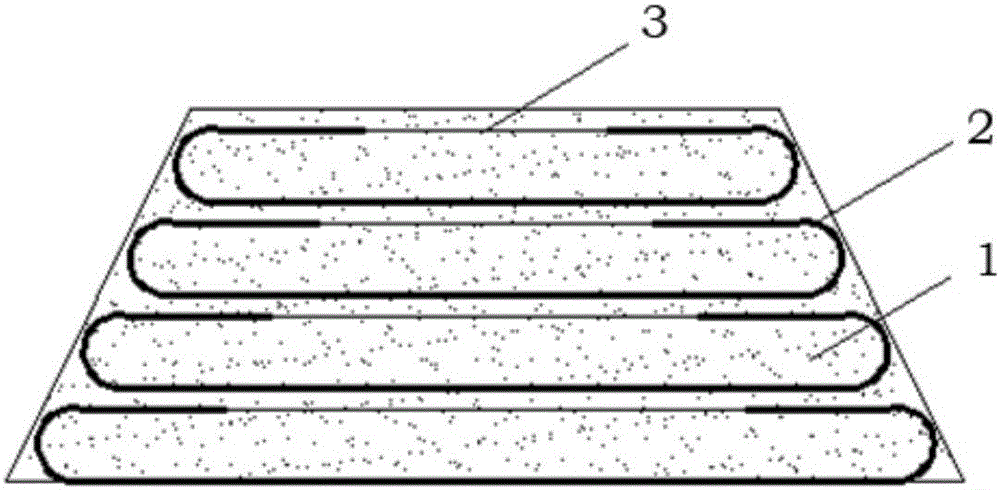

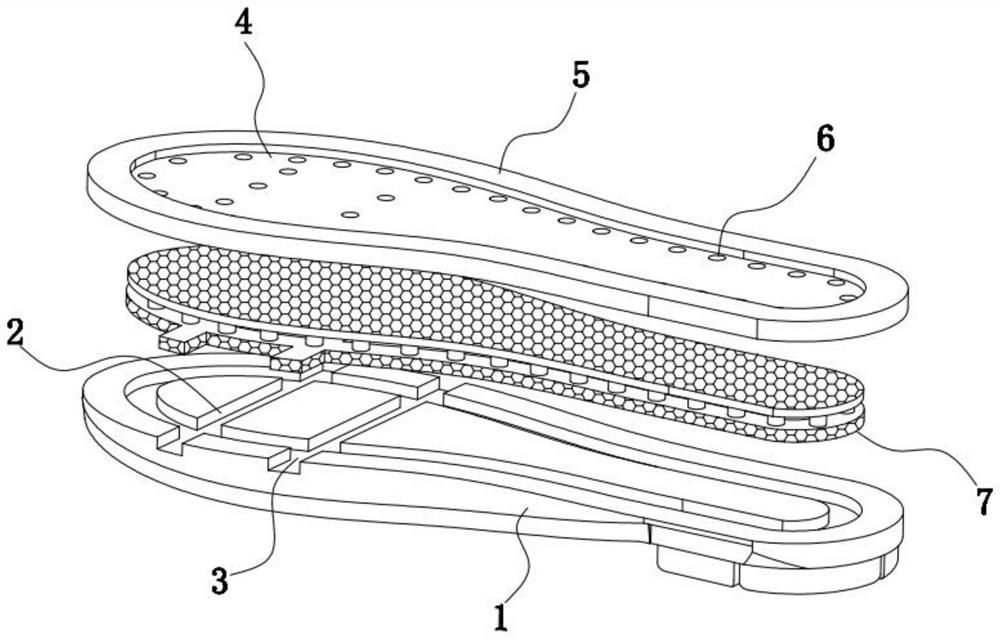

ActiveCN105401519AHigh strengthImprove toughnessBridge structural detailsBridge erection/assemblyGlass fiber reinforced polymerBridge engineering

The invention provides an anti-knocking steel box beam bridge deck paving structure and a paving method and belongs to the technical field of traffic transportation and the field of protection of bridge engineering. In the structure, the upper layer is an asphalt concrete wearing layer and the lower layer is a GFRP (Glass Fiber Reinforced Polymer)-composite concrete anti-knocking pavement layer, namely, a waterproof layer (2) is arranged on a steel box beam orthotropic bridge deck slab (1); a lower adhesive layer (3) is arranged on the waterproof layer (2); the GFRP-composite concrete anti-knocking pavement layer (4) is arranged on the lower adhesive layer (3); an upper adhesive layer (5) is arranged on the GFRP-composite concrete anti-knocking pavement layer (4); the asphalt concrete wearing layer (6) is arranged on the upper adhesive layer (5). The paving method comprises the following steps: (a) derusting a steel bridge deck by sandblasting; (b) performing anticorrosive coating on the steel bridge deck slab, and arranging the waterproof layer in a sprinkling way; (c) forming the lower adhesive layer on the waterproof layer in a coating mode; (d) strapping a GFRP glass fiber reinforced bar net, and then pouring high-strength high-toughness light composite concrete; (e) carrying out vibrating and maintaining, and afterwards adhering a GFRP glass fiber reinforced sheet on the upper surface of the concrete layer; (f) laying coarse sand on a contact surface between the GFRP sheet and the asphalt pavement layer, and arranging the upper adhesive layer in a sprinkling way; and (g) laying the asphalt concrete wearing layer.

Owner:ZHONGBEI UNIV

Wrapping type reinforcement solidification method for roadbed of high filled embankment

A wrapping type reinforcement solidification method for a roadbed of a high filled embankment is implemented as follows: solidified soil material making, concretely, the solidified soil material is made by uniformly stirring a soil curing agent and filler soil; reinforcement laying, concretely, reinforcements are horizontally crosswise arranged and completely paved on the surface of a lower bearing layer after being leveled in full width, a fixed geogrid is inspected and aligned while being pulled and paved forwards, and the reinforcements are flattened and straightened; solidified soil material paving, concretely, the solidified soil material is paved on the geogrid layer by layer, each layer is ground and formed after being paved uniformly, and grinding is conducted till the filling elevation of wrapping reinforcement solidified soil is reached; wrapping and reinforcement stretching, concretely, the reinforcements of the preserved reinforcement sections at the both sides are inflected upwards to wrap the outer side of the solidified soil material by certain length, and the inflected reinforcements at the both sides are connected by reinforcement stretching strips and paved longitudinally at an equal interval, to form a reinforced solidification wrapping body; and curing and molding, concretely, field soil covers or geomembrane caps the upper parts of the reinforced solidification wrapping bodies for 7-14 days for curing. According to the invention, the light reinforced structure with good deformation compatibility is provided, the dead-weight can be reduced, and thus the load borne by a foundation is effectively decreased.

Owner:四川天宜石油化工工程有限公司

Novel flexible composite shotcrete layer support material

The present invention relates to a novel flexible composite shotcrete layer support material which comprises the following components in parts by weight: 80-100 parts of cement, 80-120 parts of sands, 100-120 parts of stones, 60-100 parts of rubber particles, 40-60 parts of coal ash, 20-30 parts of hooked end steel fibers, 50-80 parts of water, 6-7 parts of a crosslinking agent, 5-8 parts of an additive, 2-10 parts of polyamic acid resin with a solid content of 10%-25% and 3-5 parts of a 1% silane coupler solution. The prepared shotcrete layer material is greatly improved in compression strength, rupture strength and flexural toughness. The novel flexible composite shotcrete layer support material can be applied to the field of support to surrounding rocks of complex rock layers with characteristics of high stress, soft rock, expansion, flowing deformation, fault structure fracture zones, mining influence and the like or other dynamic pressure tunnel as well as the field of underground engineering of tunnels, subways and the like.

Owner:SHANDONG UNIV

Aramid fiber reinforced core having self repair function, and preparation method thereof

InactiveCN107037550APromote healingImprove flexural toughnessFibre typesFibre mechanical structuresResin matrixAramid

The invention discloses an aramid fiber reinforced core having the self repair function, and a preparation method thereof. The reinforced core comprises aramid fiber and modified thermosetting resin matrix, wherein an active repair crosslinking group is introduced to the modified resin, under the action of catalyst, the reinforced core is made to have the self repair function. According to the method, characteristics of the self repair resin material and the aramid fiber are fully utilized, material fracture points can be discovered in advance, timely repair is carried out for the fracture points, and a repair rate reaches up to 80%. The method is advantaged in that not only can light weight and high strength be realized, permanent insulation property is realized, but also service life of optical cables can be prolonged through introducing the self repair group, and cost is saved.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV +1

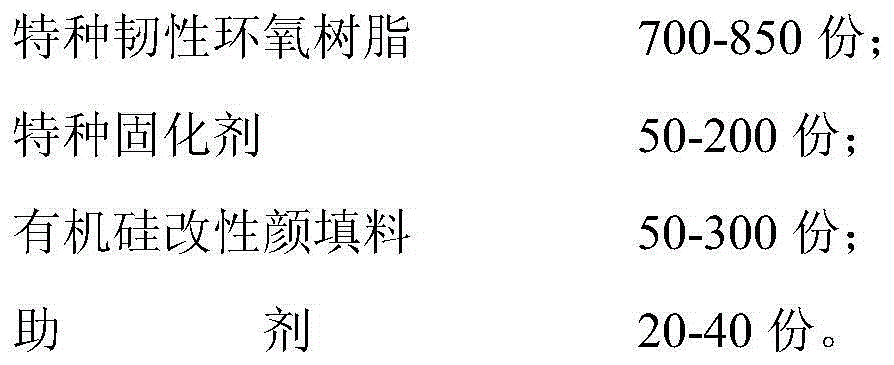

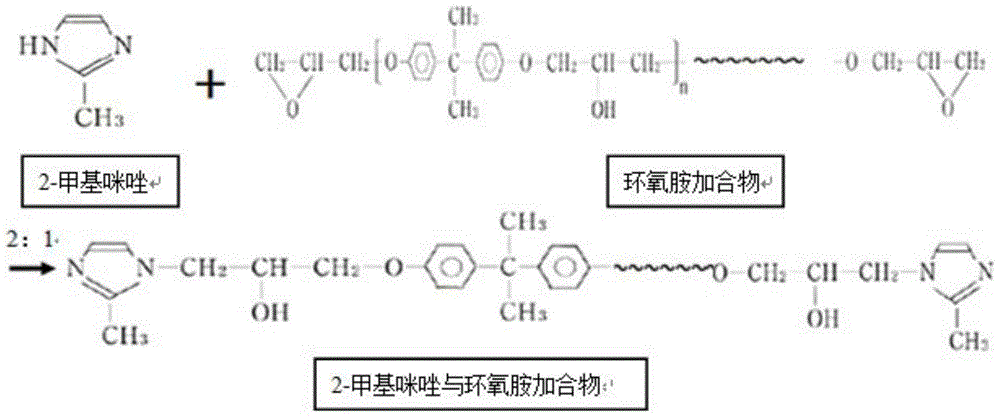

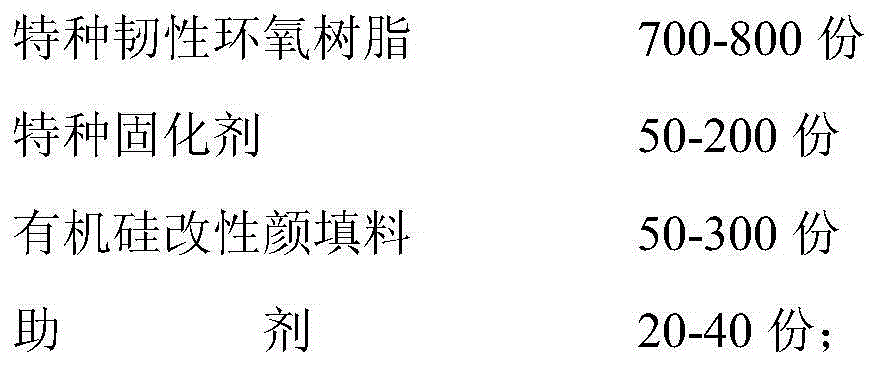

Anticorrosive powder coating composition for super-tough rapid-bending steel bar, preparation method and application thereof

InactiveCN103952057AImprove insulation performanceImprove permeabilityAnti-corrosive paintsEpoxy resin coatingsEpoxySpider web

The invention relates to an anticorrosive powder coating composition for super-tough rapid-bending steel bars, a preparation method and an application thereof; the composition comprises the following components by weight: 700-800 parts of special tough epoxy resin; 50-200 parts of special curing agents; 50-300 parts of organosilicon modified pigment filling materials; and 20-40 parts of auxiliary agents. The super-tough rapid-bending anticorrosive steel bars of the invention are mainly used for parts requiring heavy-duty anticorrosion in industries such as railway, roads, bridges, high-rise building basements, underground garages, harbours, wharves, dams and sewage treatment pools, chemical engineering, and the like, can increase the stability of steel bars, prolong the final service life of buildings, and have corrosion resistance nearly 800 times higher than naked steel bars. The powder coating composition of the invention also overcomes the generation of phenomena of powder wire drawing (like a spider web) during electrostatic spraying process, and cracking and stripping during rapid bending after film formation.

Owner:国润恒科(天津)防腐工程技术有限公司

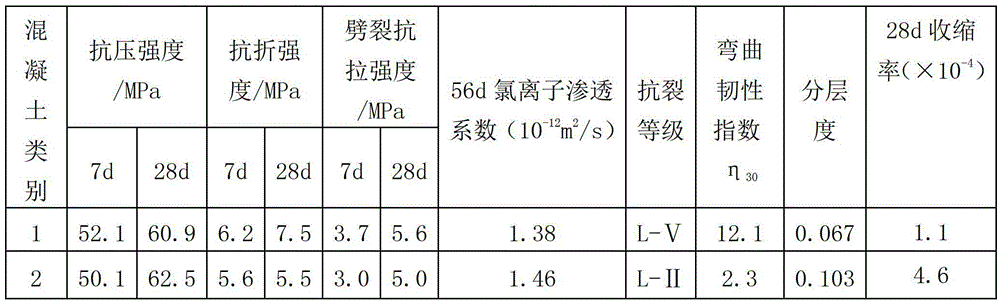

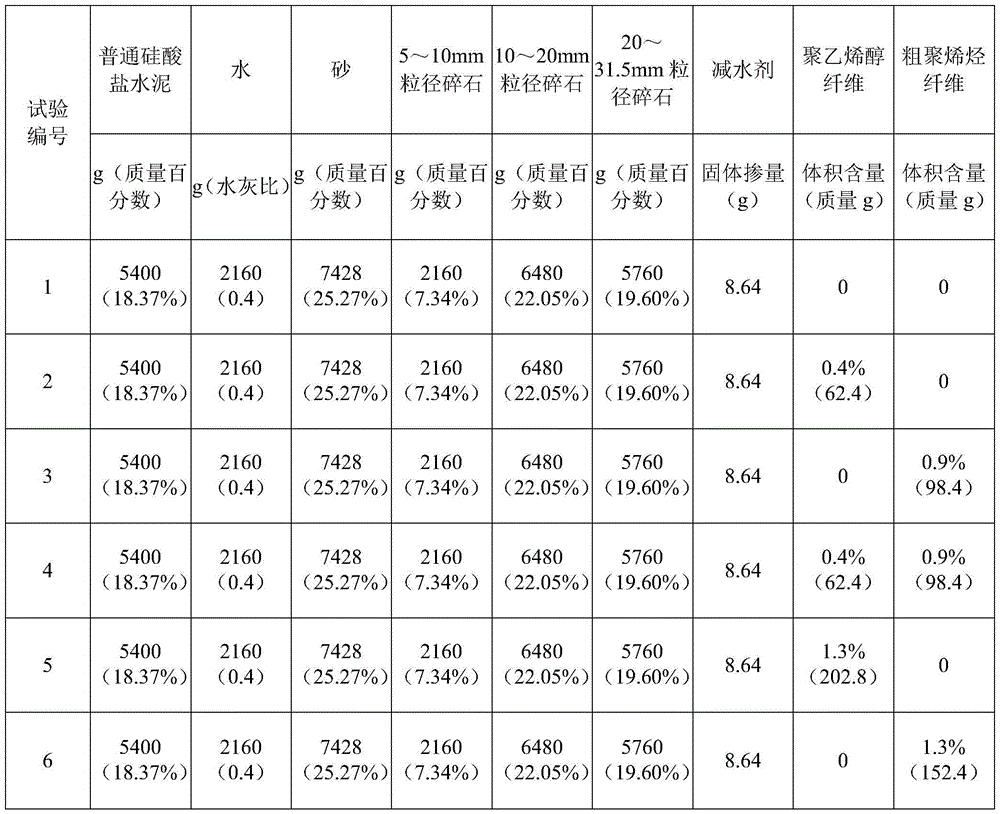

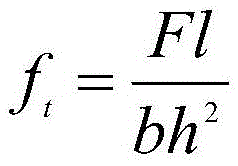

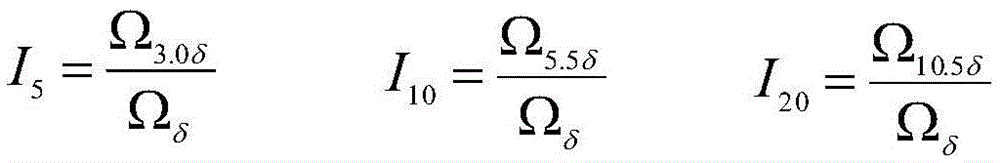

Hybrid fiber high-crack-resisting and high-tenacity airfield pavement concrete and preparation method thereof

The invention discloses hybrid fiber high-crack-resisting and high-tenacity airfield pavement concrete and a preparation method thereof, and belongs to the technical field of concrete. The concrete is prepared from ordinary Portland cement, water, sand, gravel, polyvinyl alcohol fibers, crude polyolefin fibers and a water reducing agent. In the preparation process, the gravel, the sand, the cement and the crude polyolefin fibers are firstly poured into a blender and evenly stirred, then a mixed solution of the water reducing agent and the water is poured into the blender, and when the mixture is converted into a colloidal state from a particle state, the polyvinyl alcohol fibers are mixed for stirring; after the fibers are evenly dispersed, briquette pouring and maintenance are carried out. According to the hybrid fiber high-crack-resisting and high-tenacity airfield pavement concrete and the preparation method thereof, the crack resistance and tenacity of cement concrete can be remarkably improved, the durability of a civil aircraft airfield pavement in China can be improved, the structural quality of the airfield pavement can be comprehensively improved, the service life can be prolonged, and a large amount of maintenance and rebuilding cost is saved for the country.

Owner:北京中企卓创科技发展有限公司 +1

EVA shoe sole and preparation process thereof

PendingCN111154173AImprove flexural toughnessImprove crack resistanceLow-density polyethylenePolymer science

The invention relates to an EVA shoe sole and a preparation process thereof. The EVA shoe sole comprises the following components in parts by weight: 50-70 parts of EVA, 20-30 parts of modified low-density polyethylene, 10-20 parts of a filler, 10-15 parts of a flame retardant, 5-8 parts of color master batch, 2-4 parts of a foaming agent, 0.4-0.8 part of a bridging agent, 0.2-0.4 part of an accelerant, 0.5-0.6 part of stearic acid, 0.3 to 0.5 part of N,N'-ethylene bisstearamide, and 0.1 to 0.2 part of triallyl isocyanurate, wherein the modified low-density polyethylene is a jute fiber / nitrilerubber / low-density polyethylene compound. The preparation process comprises the steps: S1, banburying; S2, open milling; S3, cooling; S4, slitting; S5, mold pressing; and S6, edge trimming. The produced shoe sole has good anti-cracking performance.

Owner:FUJIAN JOYYOU SPORTS GOODS

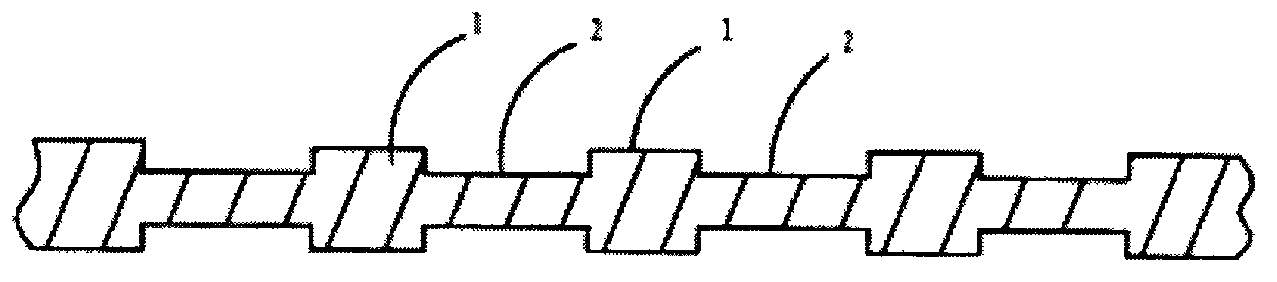

Structure enhanced synthetic fiber for concrete and preparation thereof

InactiveCN101348342AHigh compressive strengthHigh tensile strengthMelt spinning methodsSevering fibresRough surfacePolyamide

The invention relates to a structurally reinforced synthetic fiber for concrete. The synthetic fiber is prepared by processes of fusion, spinning, dispersion and fixing, and the synthetic fiber comprises the following components: 20 to 70 percent of polypropylene, 25 to 75 percent of polyethylene, 0 to 25 percent of polyamide, 0.05 to 0.5 percent of nucleating agent and 0.1 to 0.5 percent of antioxidant. The synthetic fiber of the invention has rough surface and clear contour, and has good dispersibility and cement basal body with excellent cementing property; the product has not only the functions of steel fibers, but also advantages of synthetic fibers, so that the synthetic fibers of the invention is mainly used to replace weld metal screens and steel fibers in the concrete panel structure for improving the bending resistant, shock resistant and fatigue resistant performance of concrete.

Owner:南京派尼尔科技实业有限公司

High-abrasion-resistance composite alloy ring piece and preparing technology thereof

InactiveCN107354383AImprove bindingHigh densityVacuum evaporation coatingSputtering coatingSurface layerGlow plasma

The invention proposes a high-wear-resistant composite alloy ring and its preparation process, which includes an annular alloy steel base material, a transitional infiltrated layer, and a hard alloy cladding layer. The transitional infiltrated layer has a thickness of 0.2-0.7mm and is hard The thickness of the alloy cladding layer is 1-3mm. Through reasonable raw material ratio and coating selection, arc-added glow ion plating technology and synchronous laser cladding technology are used to treat the base material respectively, and a composite alloy with three-layer structure is obtained. The ring, base material, permeable layer and cladding layer are well combined, have excellent wear resistance, corrosion resistance, toughness and stability, high surface density, significantly improved mechanical properties, and effectively prolong the service life of the product.

Owner:ANHUI TONGSHENG RING

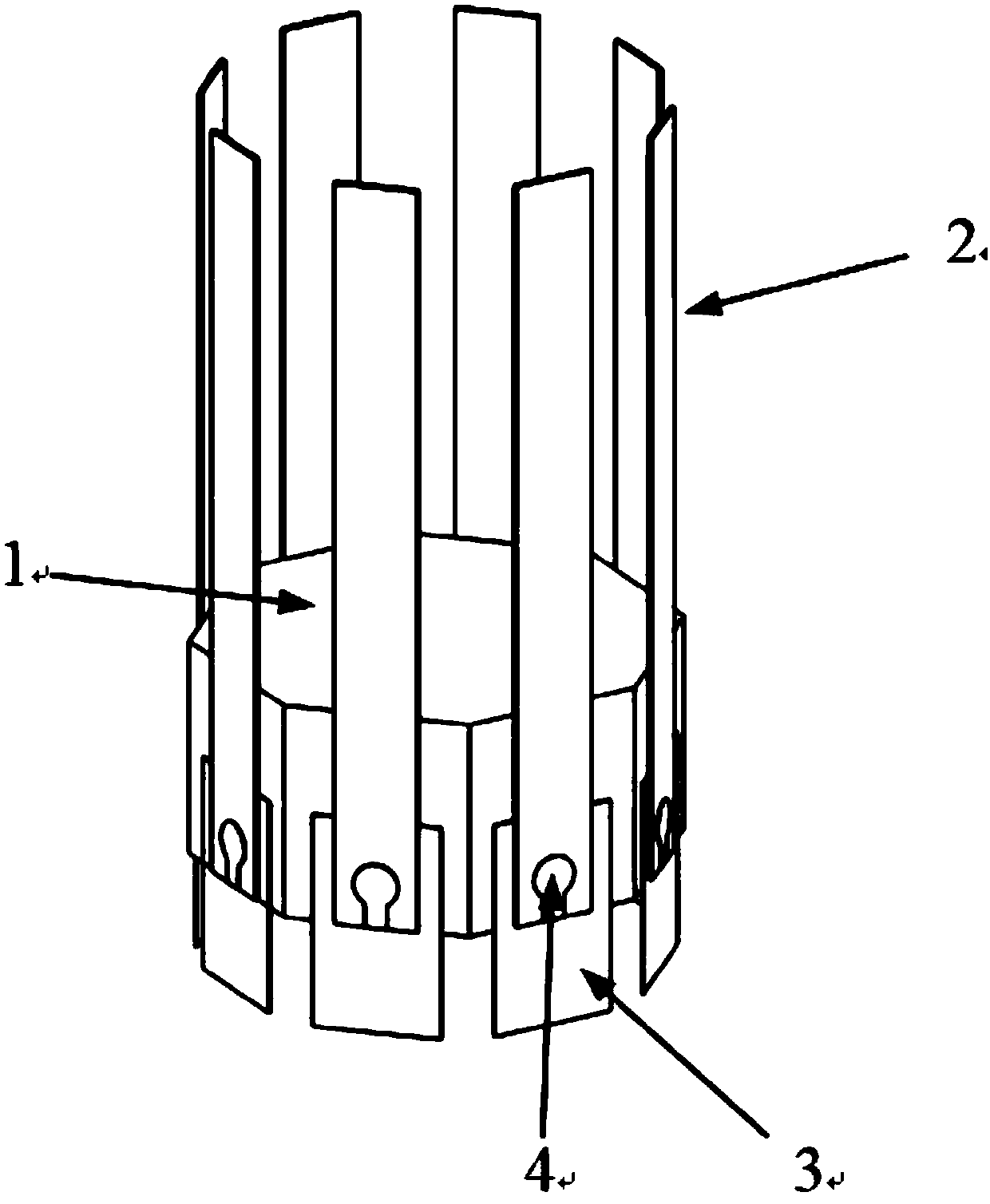

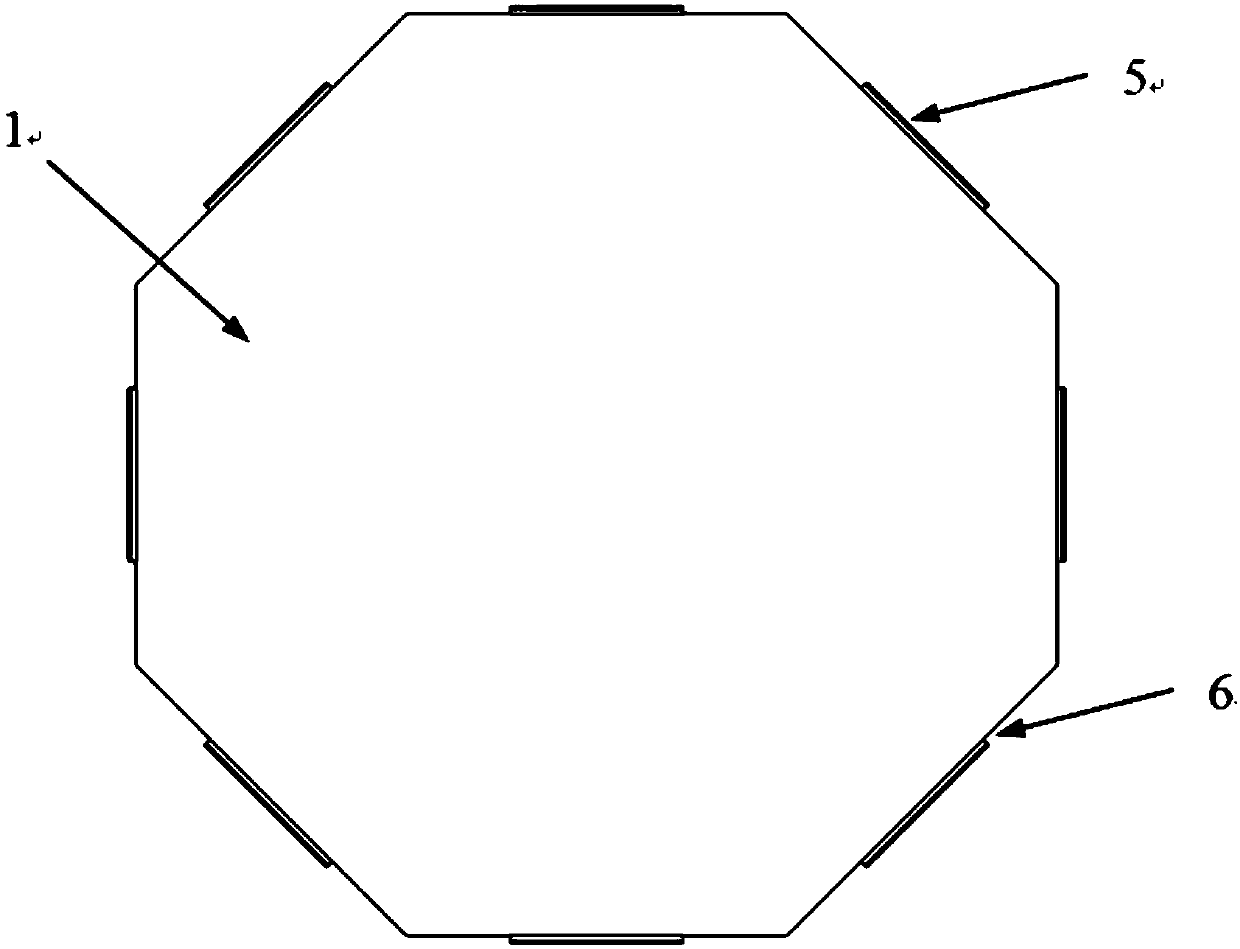

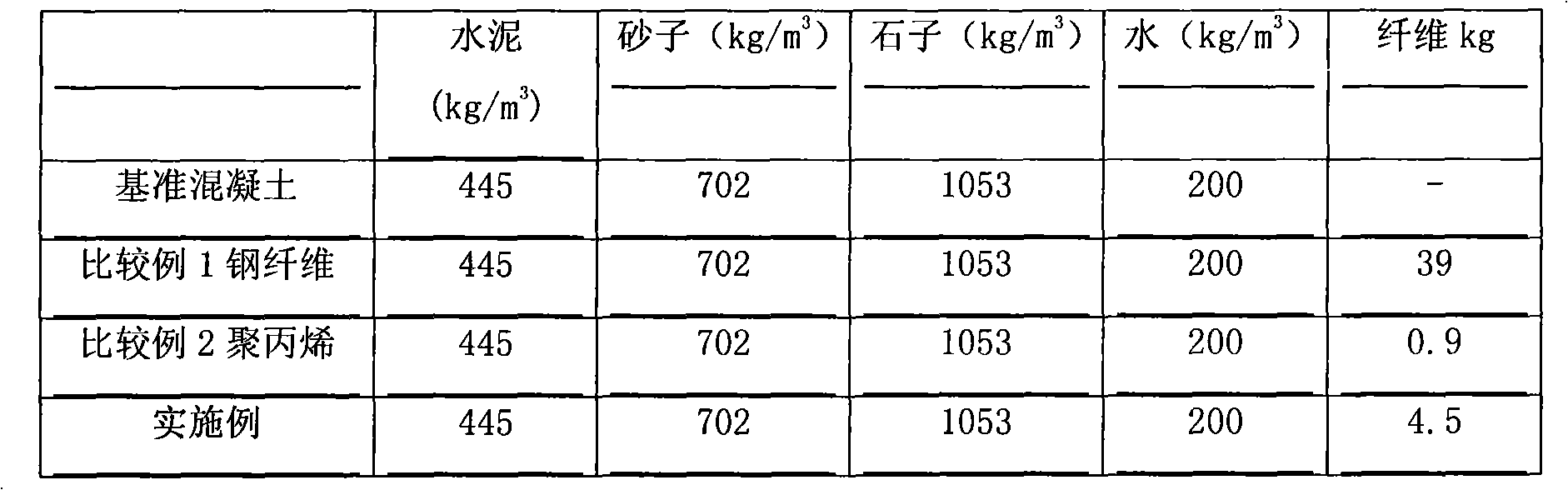

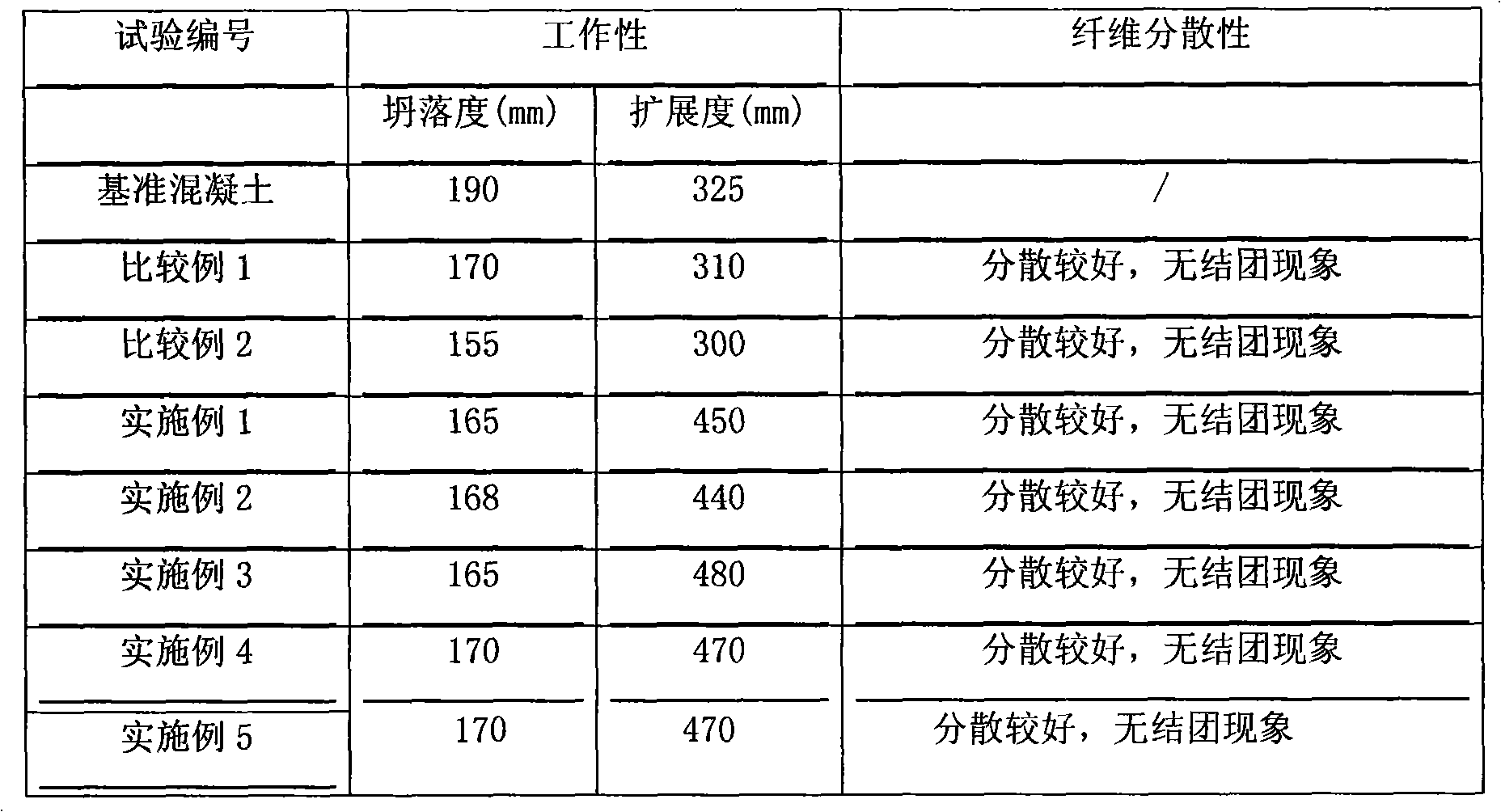

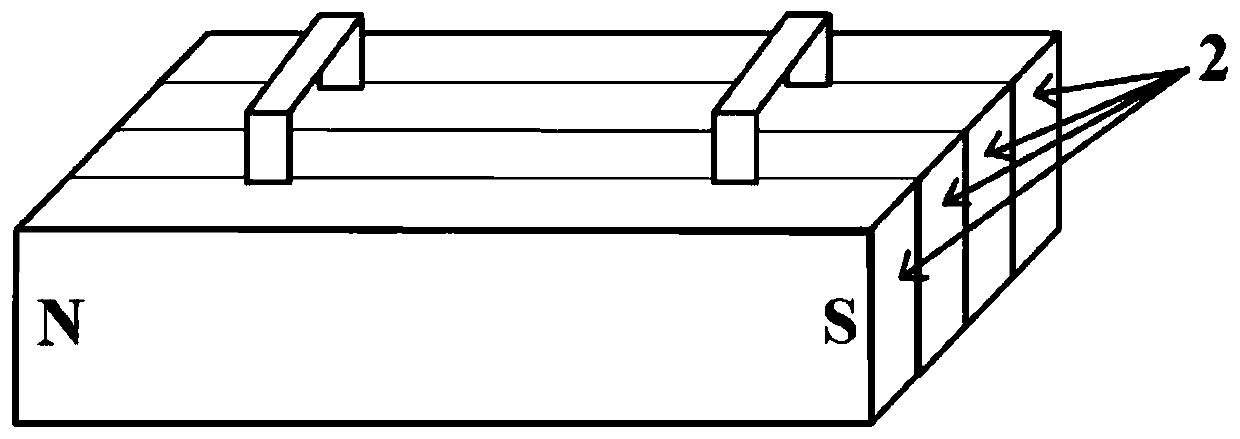

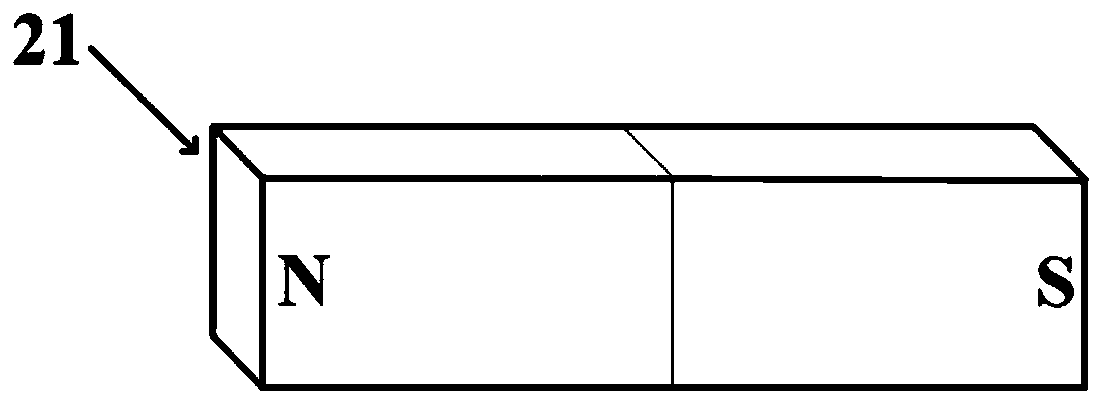

Flat plate magnetic field orienting device and method for preparing unidirectionally oriented steel fiber reinforced concrete

PendingCN111216242AAchieve orientationOrientation is accurateCement mixing apparatusEngineeringFiber-reinforced concrete

The invention provides a flat plate magnetic field orienting device and method for preparing unidirectionally oriented steel fiber reinforced concrete. The device comprises a flat plate which is formed by multiple bar magnets through homopolar alignment and parallel fixed combination. According to the method for preparing unidirectionally oriented steel fiber reinforced concrete by the flat platemagnetic field orienting device, when the steel fiber reinforced concrete is prepared and poured into a designated area with a known method in the field and subjected to vibration, the flat plate magnetic field orienting device is placed in any surface of a steel fiber reinforced concrete mixture which is liquefied under vibration, the magnetic field produced by the device can magnetize steel fibers which are randomly disoriented in the concrete mixture and drive the steel fibers to rotate to the same direction, and after the steel fiber reinforced concrete is hardened, the unidirectionally oriented steel fiber reinforced concrete is prepared. The method has the advantage that the method can be applied to direction control of the steel fibers in structural concrete such as floors, pavements and slabs in practical engineering sites.

Owner:HEBEI UNIV OF TECH

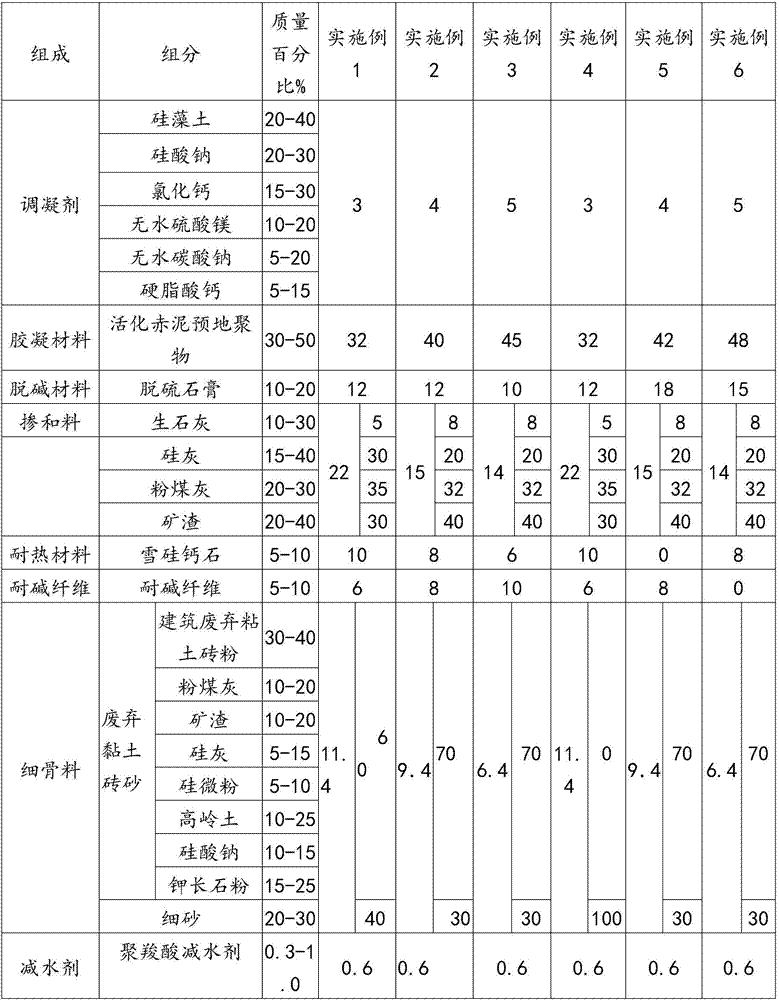

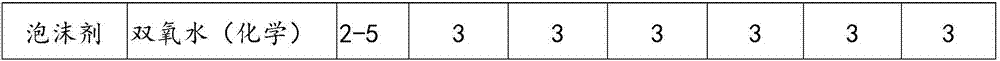

Red mud geopolymer foam building block and preparation method thereof

InactiveCN107572920ASolve the ubiquitous problemImprove thermal insulation performanceCement productionCeramicwareFiberThermal insulation

The invention provides a red mud geopolymer foam building block and a preparation method thereof. The red mud geopolymer foam building block is prepared from the following components in percentage bymass: 30-50% of activated red mud pre-geopolymer, 6-15% of fine aggregate, 10-20% of desulfurized gypsum, 10-25% of admixture, 2-8% of thickening time control agent, 5-10% of tobermorite, 5-8% of alkali-proof fiber and 3-5% of hydrogen peroxide. By adopting the technical scheme of the invention, the problem of efflorescence of a red mud lightweight wall building block is solved; meanwhile, by adding the tobermorite with excellent thermal insulation property, the thermal insulation property of the red mud and foam building blocks is remarkably enhanced.

Owner:南宁恒慕科技有限责任公司 +1

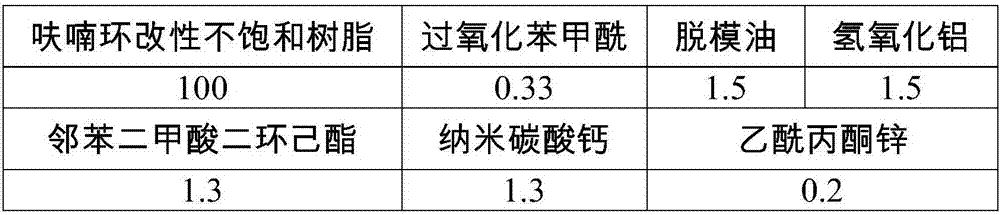

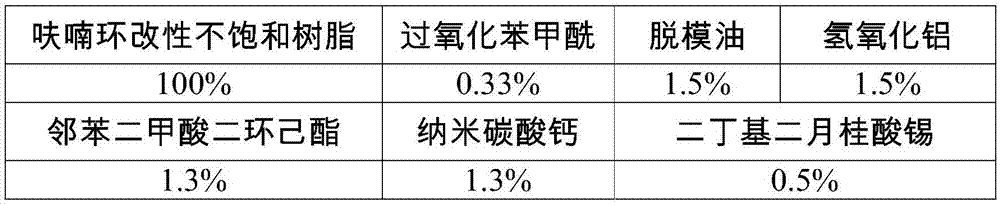

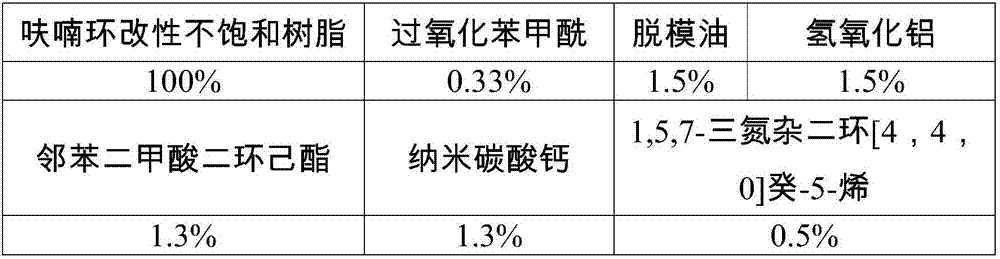

Road cement concrete rubber particle surface modifier

The invention discloses a rubber particle surface modifier for road cement concrete, which relates to a wasted rubber particle surface modifier used in road-use cement concrete. The mixture ratio of the modifier is as above: the modifier has wild material source, low price and convenient manufacture, which can carry out the modification treatment to the rubber particles in a wasted rubber particle processing plant or a concrete mixing location, the modified rubber particles can be directly packaged in a damp state or be properly dried and packaged to leave the factory. Compared with the unmodified rubber particle one, the cement concrete prepared by modified wasted rubber particles can increase the compressive strength by 20%, the breaking strength by 10%-30% and the flexural toughness by 30%-50% under the condition of the same fluidness, thereby having valuable economic and social benefit.

Owner:TONGJI UNIV

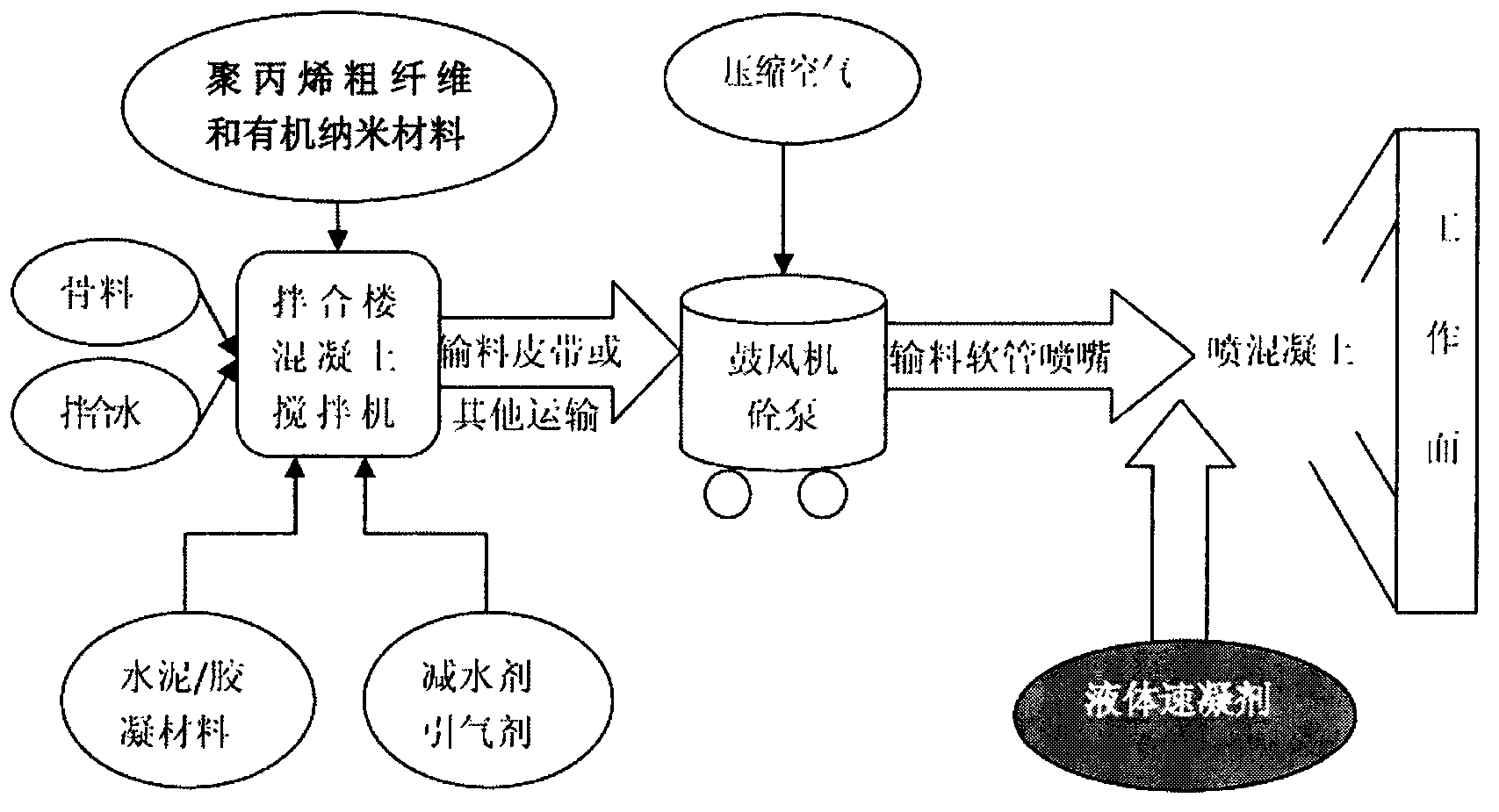

Production method of polypropylene crude fiber and application method of combination polypropylene crude fiber and organic nano materials in sprayed concrete

InactiveCN102797051AReduce rebound rateLow costArtificial filament heat treatmentMonocomponent polypropylene artificial filamentShotcreteFrost

The invention discloses a production method of polypropylene crude fiber and an application method of the combination of the polypropylene crude fiber and organic nano material combined in sprayed concrete. The application method is characterized by comprising the following components in parts by weight according to the feeding sequence: 900 parts-1226 parts of sands, 680 parts-820 parts of stones, 3-14 parts of polypropylene crude fiber, 350 parts-516 parts of cement, 8 parts-60 parts of organic nano materials, 208 parts-312 parts of water and an additive, and stirring uniformly to form the sprayed concrete. In short, due to the adoption of the polypropylene crude synthetic fiber and the organic nano composite materials, the performances of crack control, permeability prevention, bending resistance, toughness, fatigue resistance, impact resistance, frost resistance and fire resistance and explosion resistance of the crude fiber sprayed concrete can be improved obviously.

Owner:林 英男

Toughening method for cement-based material

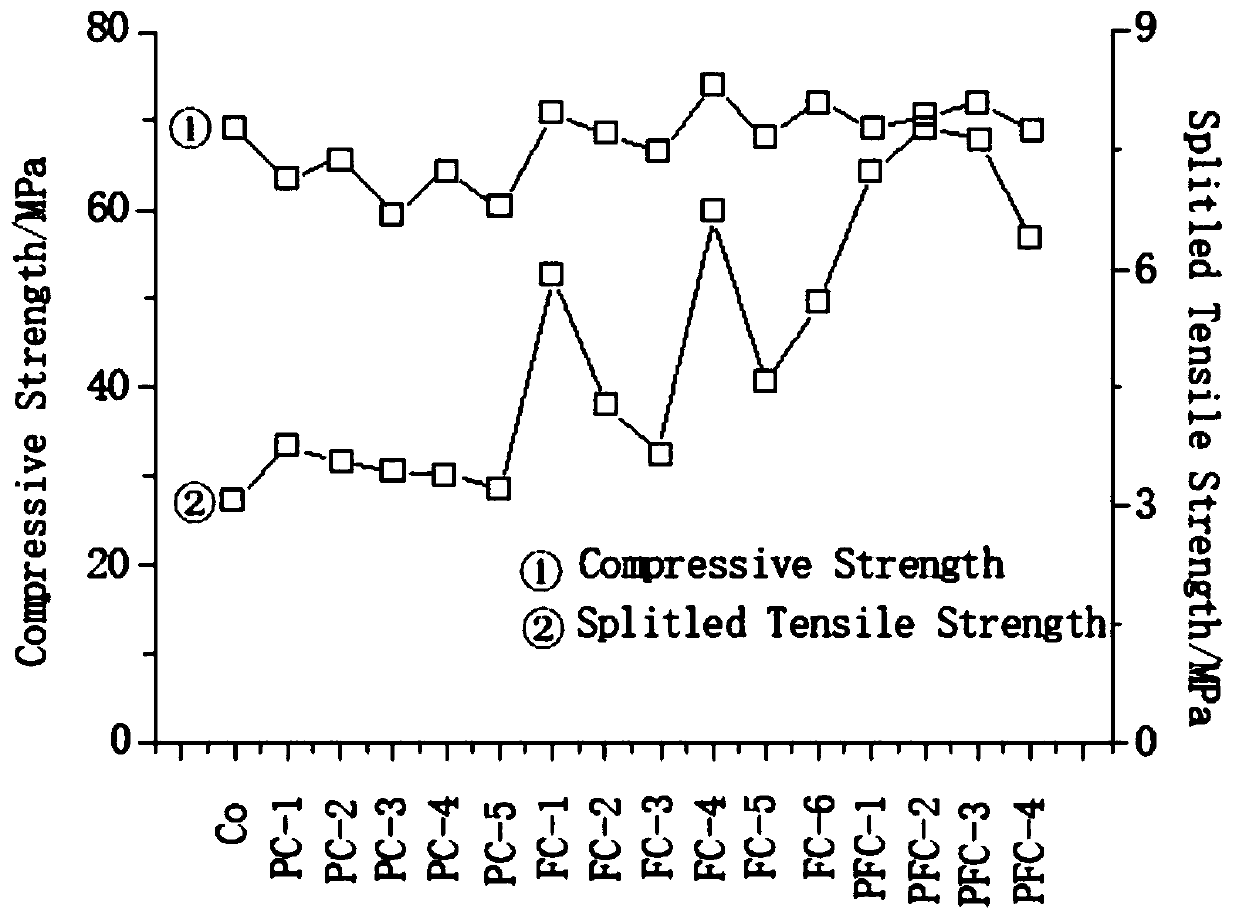

The invention discloses a toughening method for a cement-based material. The method comprises the following steps of selection of raw materials, design of a mixing ratio and mixing of the raw materials. The selection of the raw materials further comprises the following steps of gel material selection, fine aggregate selection, coarse aggregate selection, polymer selection, fiber selection and water reducing agent selection. According to the method, a composite technology for industrial waste residues, fibers, polymers and cement clinker is adopted, the performance of each composition with different chemical components is superposed in a structure forming process, the compositions gradually play a role step by step at the corresponding performance level, and the effect of complementing advantages is achieved; the capacity of reinforcing and toughening a cement matrix is greatly improved .The high-performance cement-based composite material with the strength grade of 60 MPa is prepared,and the bending toughness and fracture performance of the material are improved.

Owner:SHENZHEN YJY BUILDING TECH +1

Sprayed concrete for roadway

The invention provides sprayed concrete for a roadway. The sprayed concrete is prepared from the following raw materials in parts by weight: 80-120 parts of cement, 40-60 parts of superfine aggregate, 80-100 parts of fine sand, 10-20 parts of fibers, 6-12 parts of rubber powder, 7-10 parts of nano aluminum oxide, 3-8 parts of polyacrylamide, 8-14 parts of an MK-1 reinforcing agent, 1.5-5 parts of a water reducing agent, 6-10 parts of a flame retardant and 10-18 parts of an accelerator. According to the invention, an inorganic-organic co-hybrid polymer dispersion group system is formed on the basis of the principle of an inorganic-organic ultrafine powder assembly, coating and dispersion system, so that moderate toughness and rigidity can be achieved, excellent guniting material indexes such as high adhesion, cracking resistance, impermeability, reinforcement and support and the like are achieved, and the concrete also has relatively strong toughness, ductility, heat insulation and shock absorption performance.

Owner:河南省宜居建材科技有限公司

Crack-resisting mortar for insulation of modified rubber powder and preparation method thereof

ActiveCN102225856BHigh compressive strengthImprove flexural strengthSolid waste managementCelluloseLatex rubber

The invention provides crack-resisting mortar for insulation of a modified rubber powder and a preparation method thereof. The crack-resisting mortar for insulation comprises the following raw materials in parts by weight: 5-60 parts of modified rubber powder, 50-110 parts of cement, 10-50 parts of sand, 0.5-2 parts of polypropylene fiber, 0.5-3 parts of dispersible latex powder, 2-3 parts of quick lime, 0.1-1 part of cellulose ether and 0.01-0.03 part of air entraining agent. The preparation method comprises the following steps: preparing a modifier; preparing the modified rubber powder; carrying out air-drying for later use; and carrying out mix preparation so as to obtain the crack-resisting mortar for the insulation of the modified rubber powder. Compared with the crack-resisting mortar for the insulation of the unmodified rubber powder, the compression strength, rupture strength and flexural toughness of the crack-resisting mortar in the invention are improved under the same flowability condition, wherein the rupture strength is larger than 450kpa, the compression strength is larger than 700KPa, the bonding strength is more than 180KPa, linear shrinkage is less than 1%, and the softening coefficient is more than 0.9. The crack-resisting mortar in the invention has a huge effect in the building field and a wide market prospect.

Owner:CHINA XINXING BAOXIN CONSTR CORP

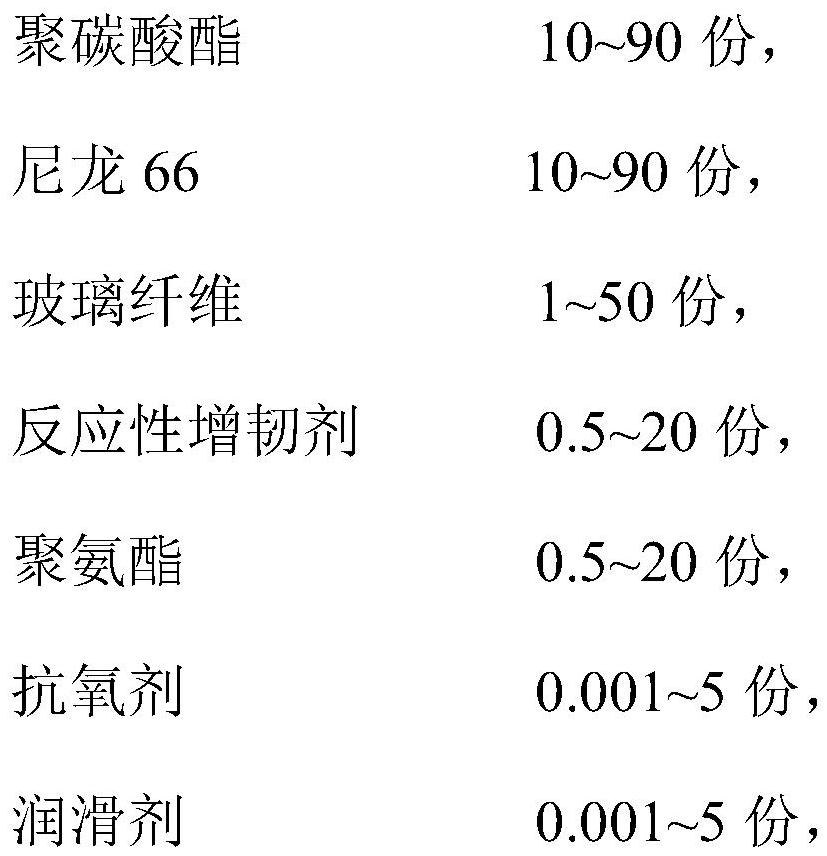

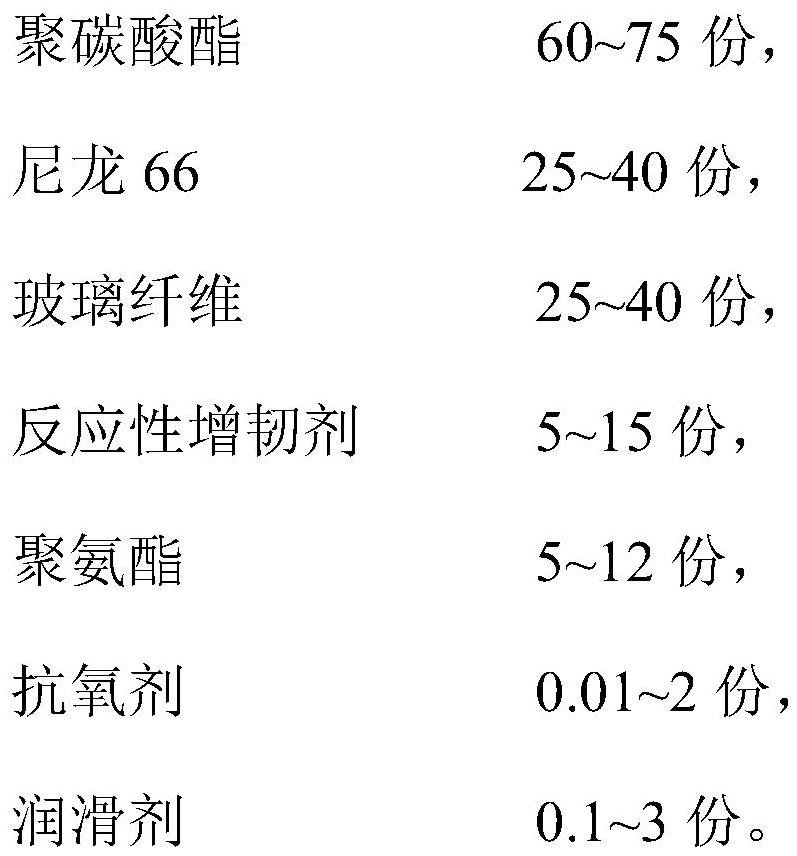

Glass fiber reinforced polycarbonate composition as well as preparation method and application thereof

The invention provides a glass fiber reinforced polycarbonate composition as well as a preparation method and application thereof. The composition is prepared from the following raw materials in partsby weight: 10-90 parts of polycarbonate, 10-90 parts of nylon 66, 1-50 parts of glass fibers, 0.5-20 parts of a reactive toughening agent, 0.5-20 parts of polyurethane, 0.001-5 parts of an antioxidant and 0.001-5 parts of a lubricant, wherein the diameter of the glass fiber is 8-15 microns; and the reactive toughening agent has a reactive group capable of reacting with both nylon 66 and polycarbonate, and D50 is greater than 100 nm. According to the glass fiber reinforced polycarbonate composition, through the synergistic effect of the reactive toughening agent and the polyurethane, the glassfiber reinforced polycarbonate alloy composition is endowed with a good matte effect, and the requirements of various processes for glossiness can be met; and meanwhile, relatively high processability and enough toughness are kept.

Owner:TIANJIN KINGFA NEW MATERIAL

Preparation method of anti-puncture breathable sole and safety shoe with sole

InactiveCN112568551APlay the role of secondary protectionStrong puncture resistanceSolesDomestic footwearFiberAcrylic resin

The invention discloses a preparation method of an anti-puncture breathable sole, and belongs to the technical field of labor protection articles. The preparation method is characterized in that: composite fibers are firstly formed, carbon nanotubes are contained in the composite fibers, the carbon nanotubes are evenly distributed in a net-shaped structure formed by acrylic resin under the actionof ultrasonic dispersion, and therefore the prepared composite fibers are high in tensile strength and good in bending toughness; and after molding, the sole has an extremely strong anti-puncture effect, a honeycomb foaming body integrally molded by foaming is arranged between the outsole and the midsole, and the honeycomb foaming body is exposed on the surface of the midsole and the side surfaceof the outsole, so that after the safety shoe is manufactured, air in the shoe can be ventilated and dissipated through the honeycomb foaming body, and when the midsole is subjected to the action force of stepping, the honeycomb foaming body can improve the wearing flexibility of the sole, and meanwhile, the puncture resistance is not influenced.

Owner:泉州朗盟鞋业有限公司

Waterproof concrete, concrete member and preparation method of concrete member

InactiveCN106747075AReduce connectivityHigh sphericityDischarging arrangementShrinkage crackingBreaking strength

The invention discloses waterproof concrete. The waterproof concrete comprises components as follows: 42.5R ordinary Portland cement, a foaming agent, a coagulation accelerator, a water reducing agent, a foam stabilizer, a waterproof agent and nano-SiO2. The invention further discloses a concrete member and a preparation method thereof. Pores in the waterproof concrete become smaller and more uniform, degree of sphericity is increased, and communication ratio of the pores is reduced; plastic shrinkage cracking value is reduced by 82.1%, cracks of level 2 or higher of plastic shrinkage cracks disappear, and proportion of cracks of level 1 is as high as 70.1%; 3d breaking strength and compressive strength are increased by 41.7% and 16.0% respectively, and 28d breaking strength and compressive strength are increased by 25.0% and 10.0% respectively; certain bearing capacity and better pseudo-ductility can be kept in a period of time after initial cracking of a sample, and bend ductility is remarkably improved.

Owner:上海君道住宅工业有限公司

Steel fiber cement-based composite material based on nanoscale reinforcement and preparation method thereof

PendingCN113072343AImprove mechanical propertiesWide range of materialsSolid waste managementMixing operation control apparatusCellulose fiberWater reducer

The invention provides a steel fiber cement-based composite material based on nanoscale reinforcement and a preparation method thereof, and relates to the technical field of cement-based composite materials. The composite material provided by the invention is prepared from the following components in percentage by mass: 25 to 40 percent of cement, 7.5 to 10.5 percent of silica fume, 35 to 50 percent of river sand, 5 to 7.5 percent of water, 1 to 1.5 percent of water reducing agent, 5 to 9 percent of steel fiber and 0.01 to 0.15 percent of nano cellulose fiber. A small amount of nano cellulose fibers are added into the steel fiber cement-based composite material, a steel fiber-cement matrix interface transition area is subjected to nano-scale improvement in a mode of reinforcing a matrix through the nano-crystalline cellulose fibers, and the mechanical property can be remarkably improved under the condition of low steel fiber mixing amount; the nano-crystalline cellulose fiber has hydrophilicity and can be tightly combined with the cement matrix, so that the mechanical property of the composite material can be improved; and the nano cellulose fiber also has the characteristics of wide material sources and environmental protection.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Expansive concrete for construction of ultra-long concrete structure

The invention discloses expansive concrete for construction of an ultra-long concrete structure. The expansive concrete comprises the following raw materials in parts by weight: 180 parts of water, 300 parts of cement, 550 parts of sand, 860 parts of cobblestone, 105 parts of coal ash, 35 parts of an expanding agent, and 55 parts of steel fiber. By adding an aluminite powder expanding agent, the concrete is enabled to subjected to certain volume expansion in a hydration process, and generate cement with proper self-stress under constraint conditions, thereby enhancing the structure of ultra-long concrete.

Owner:四川国泰高新管廊产业投资有限公司

Crack, oil and high temperature resistant polymer modified exterior wall material and production technology thereof

The invention relates to a building wall material, and concretely relates to a crack, oil and high temperature resistant polymer modified exterior wall material and a production technology thereof. The technology comprises the following steps: mixing modified rubber powder, polyurethane elastomer, a tetrafluoroethene-hexafluoropropene copolymer, isoprene rubber, re-dispersible latex powder, quicklime, cellulose ether and an air entraining agent through a mixer, kneading through a kneader, placing the obtained mixture in a die, and compacting through a flat vulcanizer to obtain an exterior wall panel. The above exterior wall material product made in the invention reduces the use amount of wood fibers, the production cost and the sheet unit weight, and has improved compressive strength, flexural strength, bending toughness, oil resistance and high temperature resistance. The polyurethane elastomer added in the invention effectively improves the mechanical properties of a polypropylene cable material; fluorubber added in the invention has high temperature and oil resistance; and other fillers added in the invention can enhance other physical properties and the processability of the cable.

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

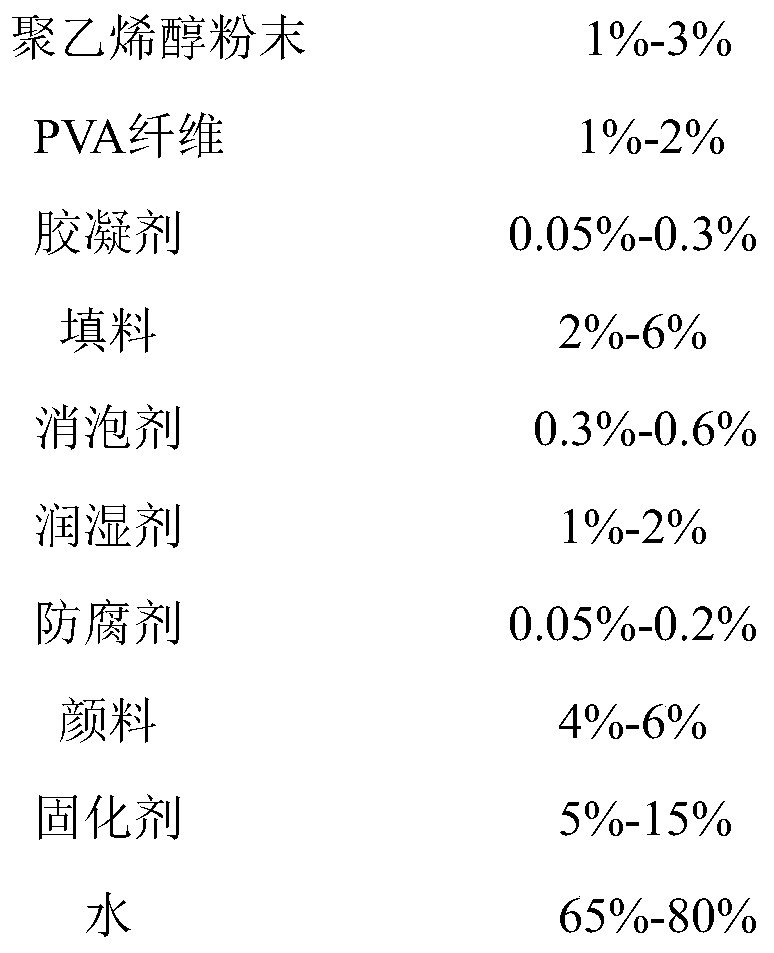

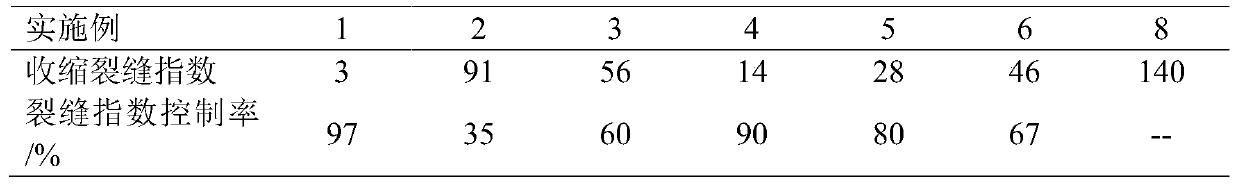

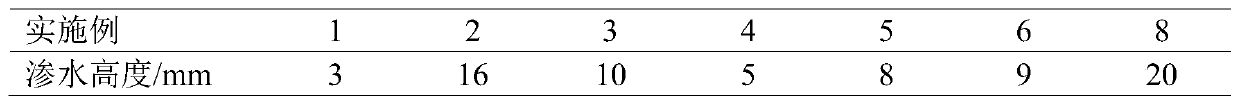

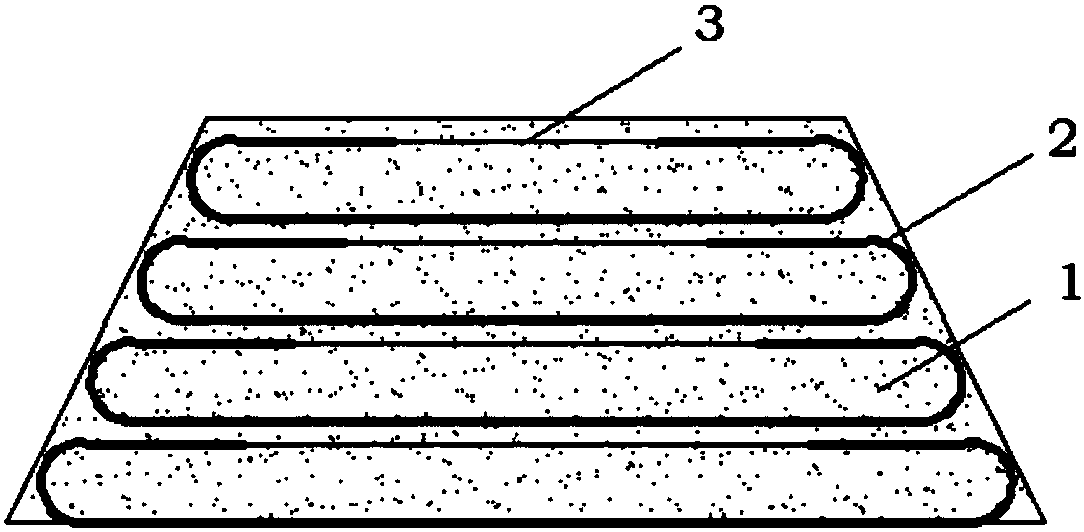

Green ultralight crack-resistant polyvinyl alcohol substrate and preparation method thereof

The invention relates to the technical field of ecological slope protection substrates, and specifically discloses a green ultralight crack-resistant polyvinyl alcohol substrate and a preparation method thereof. The preparation method comprises the following steps: (1) weighing raw material soil, and carrying out drying and sieving for subsequent usage; (2) adding a curing agent into sieved raw material soil, and carrying out uniform mixing; (3) adding water into a mixture obtained in the step (2), and carrying out uniform mixing under stirring; and (4) adding polyvinyl alcohol powder, polyvinyl alcohol fiber, a gelling agent, a filling material, an anti-foaming agent, a wetting agent, a preservative and a pigment into a mixture obtained in the step (3) according to certain addition amounts, and carrying out uniform mixing under stirring. The lightweight material provided by the invention guarantees the strength of a composite soil body to meet the ecological protection requirements of a slope, has the advantages of cracking resistance, impermeability, erosion resistance, ultralight weight, beautiful appearance and the like at the same time, reduces the load of a slope surface, can prevent slope protection plants from dying due to soil loss, provides a green element to the slope surface before vegetation germination, avoids visual fatigue caused by a dark substrate, and enables the slope surface to achieve a landscape effect.

Owner:HUBEI UNIV OF TECH

Wrapped Reinforcement Method for High Embankment Subgrade

A wrapping type reinforcement solidification method for a roadbed of a high filled embankment is implemented as follows: solidified soil material making, concretely, the solidified soil material is made by uniformly stirring a soil curing agent and filler soil; reinforcement laying, concretely, reinforcements are horizontally crosswise arranged and completely paved on the surface of a lower bearing layer after being leveled in full width, a fixed geogrid is inspected and aligned while being pulled and paved forwards, and the reinforcements are flattened and straightened; solidified soil material paving, concretely, the solidified soil material is paved on the geogrid layer by layer, each layer is ground and formed after being paved uniformly, and grinding is conducted till the filling elevation of wrapping reinforcement solidified soil is reached; wrapping and reinforcement stretching, concretely, the reinforcements of the preserved reinforcement sections at the both sides are inflected upwards to wrap the outer side of the solidified soil material by certain length, and the inflected reinforcements at the both sides are connected by reinforcement stretching strips and paved longitudinally at an equal interval, to form a reinforced solidification wrapping body; and curing and molding, concretely, field soil covers or geomembrane caps the upper parts of the reinforced solidification wrapping bodies for 7-14 days for curing. According to the invention, the light reinforced structure with good deformation compatibility is provided, the dead-weight can be reduced, and thus the load borne by a foundation is effectively decreased.

Owner:四川天宜石油化工工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com