Flat plate magnetic field orienting device and method for preparing unidirectionally oriented steel fiber reinforced concrete

A technology of steel fiber reinforced concrete and magnetic field orientation, which is applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc. There is no problem of lifting, etc., to achieve the effect of improved bending toughness, improved flexural strength, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

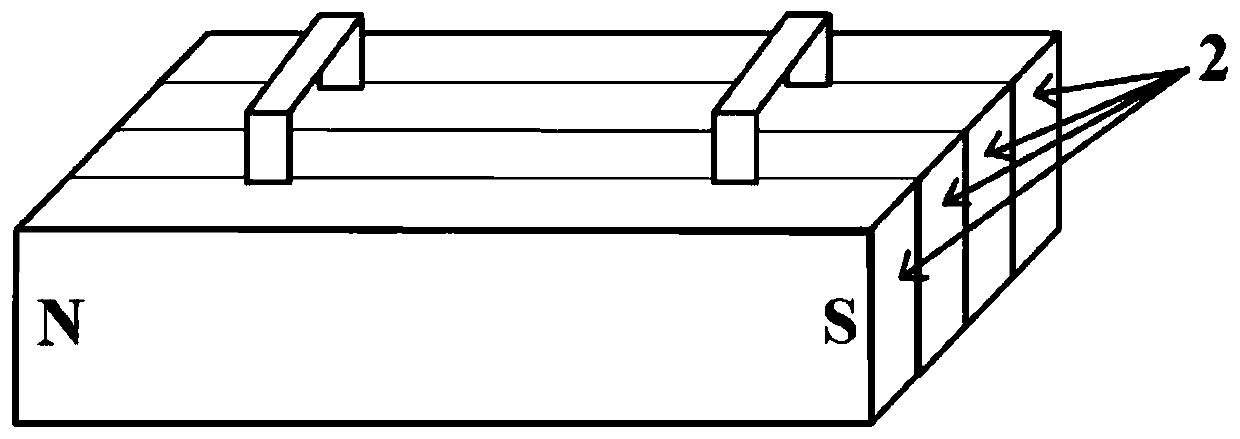

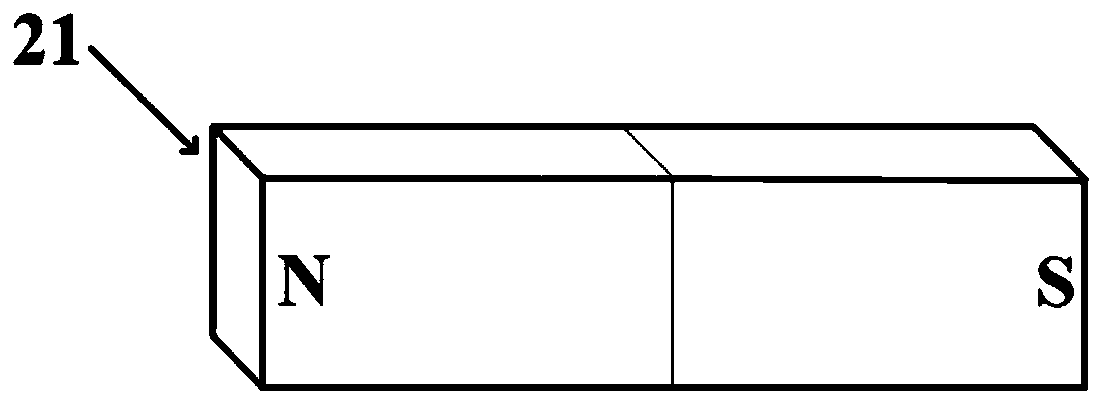

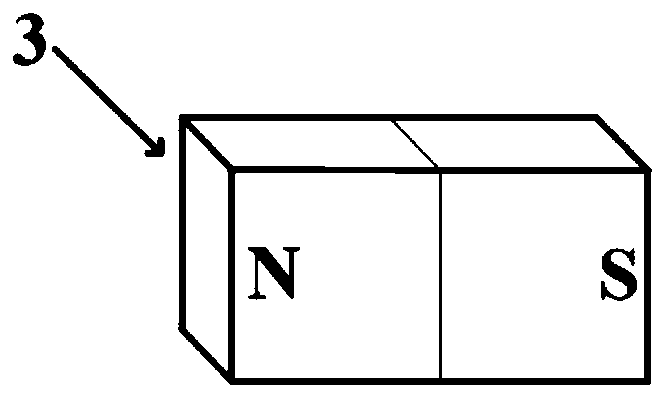

[0041] The flat magnetic field orientation device 1 has a size of 300mm×100mm×25mm, and is composed of four larger bar magnets 21 aligned with the same poles and arranged side by side. The bar magnet is a commercially available alnico bar magnet with a length of 300 mm, a section width of 25 mm, and a height of 25 mm, and the surface magnetic induction is 0.1T.

[0042] S1, the strength grade determined according to the known design method is C30. The mass mix ratio of the components is water: cement: sand: stone: water reducer: steel fiber = 180: 380: 835: 975: 3.6: 47, which is called Take the required amount of water, cement, sand, stone, high-efficiency water reducer, and steel fiber. The steel fiber used is low-carbon steel material, steel wire cut-off hook type, with a diameter of 0.5mm and a length of 30mm. Put the weighed water, cement, sand and stone into the mixer and mix thoroughly for 120s, sprinkle steel fibers evenly and add the weighed mixing water and high-effi...

specific Embodiment 2

[0048] The flat magnetic field orientation device 1 has a size of 300mm×100mm×25mm, and is composed of four larger bar magnets 21 aligned with the same poles and arranged side by side. The bar magnet is a commercially available alnico bar magnet with a length of 300 mm, a section width of 25 mm, and a height of 25 mm, and the surface magnetic induction is 0.1T.

[0049] S1, the strength grade determined according to the known design method is C35. The mass mix ratio of the components is water: cement: sand: stone: water reducer: steel fiber = 180: 400: 860: 930: 4: 62, which is called Take the required amount of water, cement, sand, stone, high-efficiency water reducer, and steel fiber. The steel fiber used is a low-carbon steel wire with a cut end hook type, a diameter of 0.5mm, and a length of 30mm. Put the weighed water, cement, sand and stone into the mixer and mix thoroughly for 120s, sprinkle steel fibers evenly and add the weighed mixing water and high-efficiency water ...

specific Embodiment 3

[0055] The flat magnetic field orientation device 1 has a size of 300mm×100mm×25mm, and is composed of four larger bar magnets 21 aligned with the same poles and arranged side by side. The bar magnet is a commercially available alnico bar magnet with a length of 300 mm, a section width of 25 mm, and a height of 25 mm, and the surface magnetic induction is 0.1T.

[0056] S1, the strength grade determined according to the known design method is C35. The mass mix ratio of the components is water: cement: sand: stone: water reducing agent: steel fiber = 180: 400: 900: 900: 4.2: 78, which is called Take the required amount of water, cement, sand, stone, high-efficiency water reducer, and steel fiber. The steel fiber used is low-carbon steel material, steel wire cut-off hook type, with a diameter of 0.5mm and a length of 30mm. Put the weighed water, cement, sand and stone into the mixer and mix thoroughly for 120s, sprinkle steel fibers evenly and add the weighed mixing water and hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com