Aramid fiber reinforced core having self repair function, and preparation method thereof

A self-repairing technology of aramid fiber, applied in the direction of fiber type, fiber treatment, fiber mechanical structure, etc., can solve the problems of macroscopic crack damage, shorten service life, and affect the normal use of optical cables, so as to speed up healing, improve bending toughness, The effect of optimizing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The overall pultrusion process is the same as the comparative example, except that the epoxy resin is modified with furan ring to improve the toughness, strength and interface compatibility of the optical cable core.

[0044] Furan ring-modified epoxy resin, its specific implementation steps are as follows:

[0045] (1) Under the cosolvent environment, add furfurylamine and epichlorohydrin dropwise at room temperature, and the ratio of furfurylamine, epichlorohydrin and solvent is divided into: 8~30 parts: 25~80 parts: 0~20 parts, The reaction generates chloroethanolamine.

[0046] (2) under the room temperature environment, 50~125 parts of 40~50% (weight percent) NaOH aqueous solutions are added to the above-mentioned chloroethanolamine, and the chloroethanolamine is dehydrated and cyclized,

[0047] (3) Use ether to extract the glycidylamine epoxy resin, collect the organic phase solution and distill under reduced pressure to remove the organic solvent (vacuum pressu...

Embodiment 2

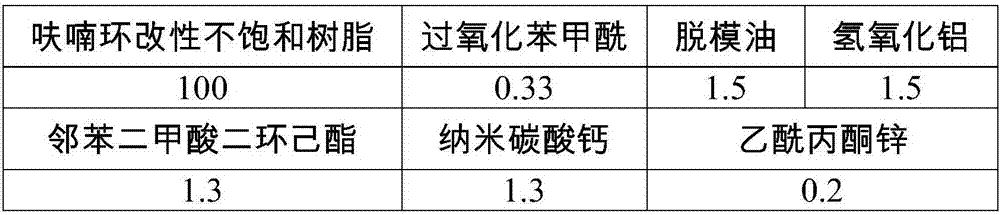

[0053] The overall pultrusion process is the same as in Example 1, except that a catalyst for promoting repair is added to promote the internal self-repairing performance of the material, and the formula (parts by weight) is as follows:

[0054]

[0055] After the pultrusion is completed, the above-obtained optical cable core is wound.

[0056] The optical cable core obtained in this example has a minimum bending radius of 0.5-1.5 cm, an elongation at break of 7%, and a repair rate of 50%.

Embodiment 3

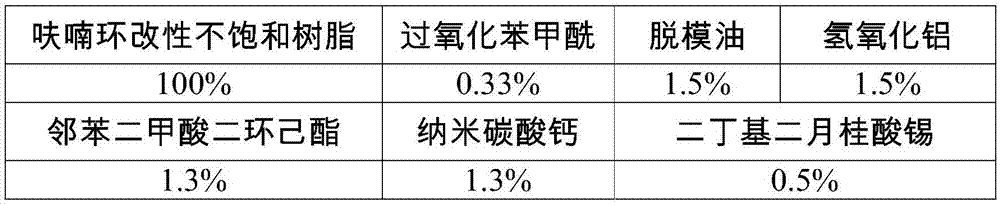

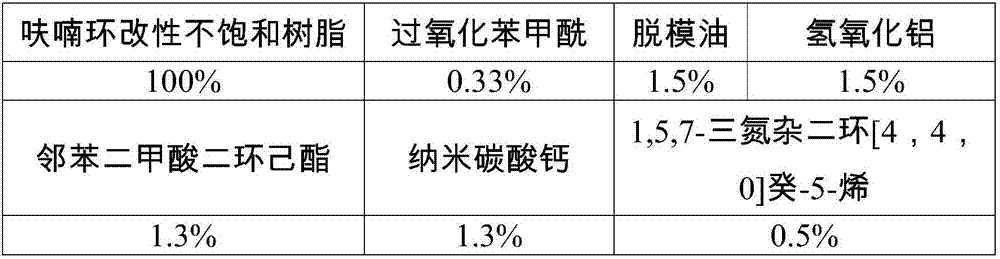

[0058] The overall pultrusion process is the same as in Example 1, except that a catalyst for promoting repair is added to promote the internal self-repairing performance of the material, and the formula (parts by weight) is as follows:

[0059]

[0060] After the pultrusion is completed, the above-obtained optical cable core is wound.

[0061] The optical cable core obtained in this example has a minimum bending radius of 0.5-1.5 cm, an elongation at break of 6%, and a repair rate of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com