Toughening method for cement-based material

A cement-based material and toughening technology, which is applied in the field of cement-based material toughening, can solve the problems of high cost of reinforced mesh armor structure, endangering the safety of high-speed train operation, and long process time, so as to optimize the micro and mesostructure, Save resources and energy, suppress the effects of initiation and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

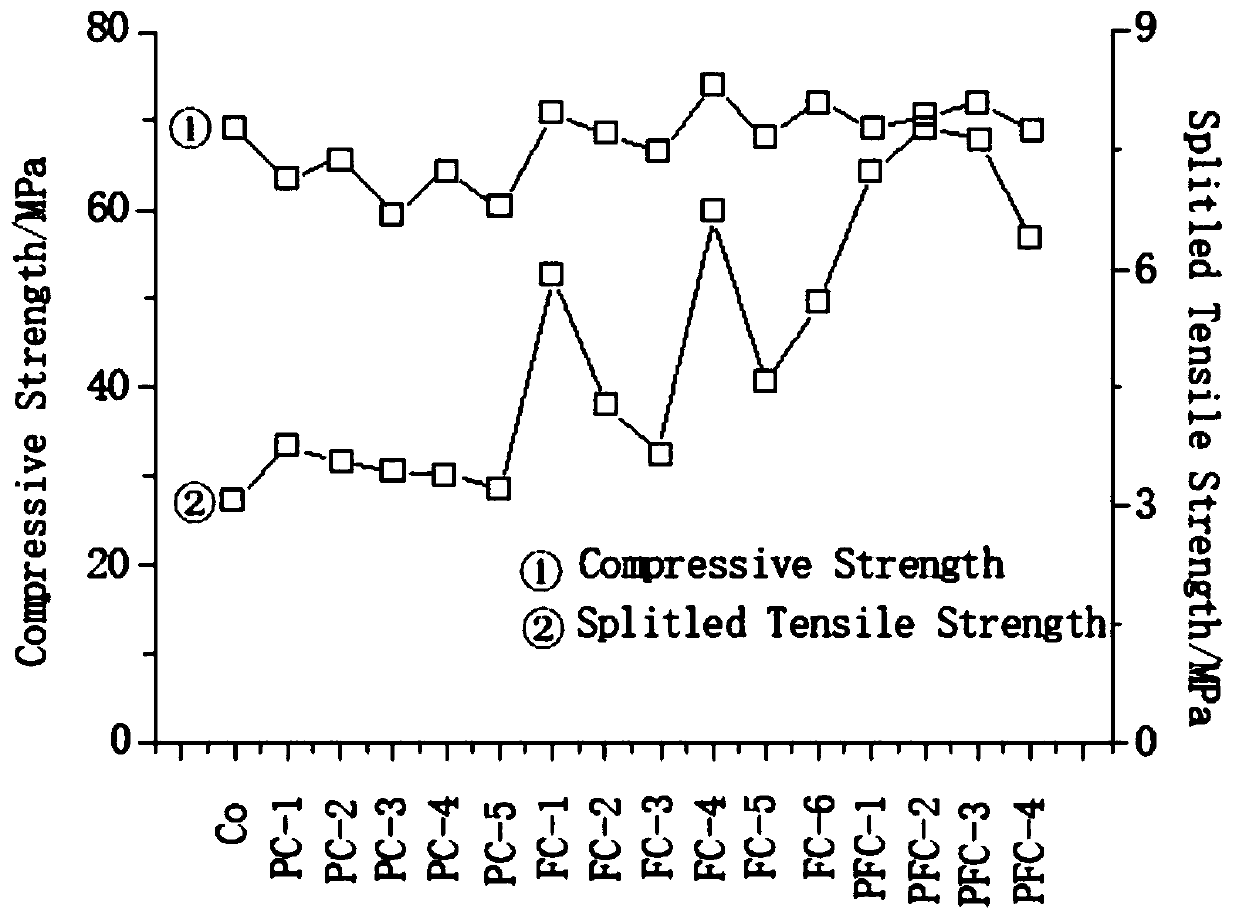

[0148] In addition to optimizing the material composition of the concrete preparation technology, in order to make the components evenly distributed in the system, the preparation method is an important aspect to ensure the flexural toughness of the concrete. Its key technology lies in the uniform mixing of fly ash, cement and polymer emulsion and the uniform distribution in the fiber cement matrix. There are two main methods for the uniform distribution of fibers in the cement matrix, one is the "dry first and then wet" mixing method, and the other is to sprinkle the fibers evenly while the cement matrix is wet mixing. Because the second method must have special equipment for uniform distribution of fibers, otherwise it is inefficient and unsafe to do it manually, so it is not suitable for use. For this reason, this embodiment adopts the mixing method of first drying and then wet: first mix the fibers, Coarse aggregate, fine aggregate, and cement are combined to make the fi...

specific Embodiment 1

[0193] Specific Example 1: Application of Fiber Reinforced Polymer Concrete in Tunnel Lining Engineering

[0194]According to the principle of the New Austrian Law, the tunnel project can be regarded as a two-stage construction. The first stage is the main support of the underground project, including anchor rods, steel mesh, steel arches and shotcrete, etc.; the second stage is constructed with cast-in-place concrete. Inner lining, including floor or invert.

[0195] (1) The lining is not an independent structure. The load it bears and its own performance are controlled by the characteristics of the surrounding strata. The construction of the lining in the underground structure is a problem of the interaction between the surrounding rock and the structure, and the focus is on the surrounding rock itself. stability conditions.

[0196] (2) The lining redistributes the load to the surrounding rock like a thin shell. Since the surrounding rock deforms together with the shotcre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

| Electric flux | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com