Wrapping type reinforcement solidification method for roadbed of high filled embankment

A solidification method and wrapping technology, applied in roads, excavations, roads, etc., can solve problems such as failure to achieve restraint, uncontrollable vertical displacement of soil, bulging reinforcement layer, etc., to solve the problem of poor activity and reduce The amount of sand and gravel, the effect of preventing shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

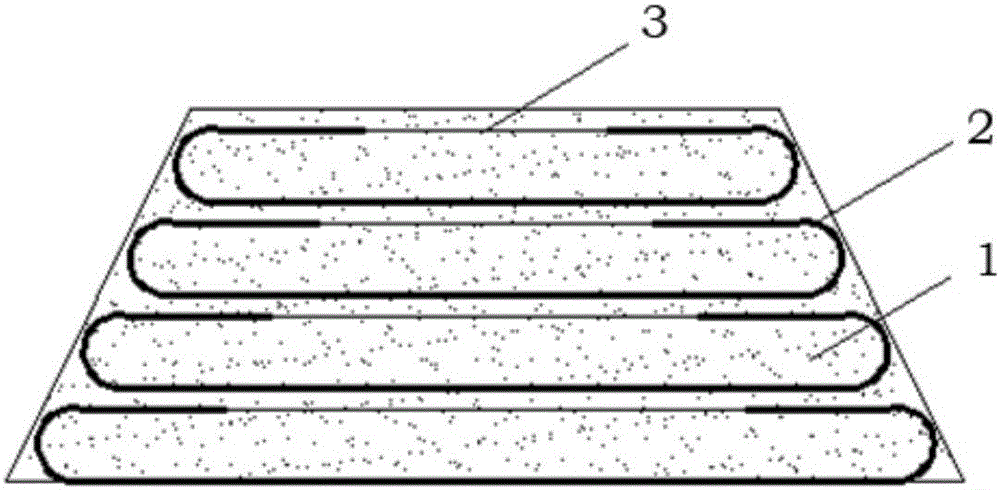

[0024] The present invention's wrap-type reinforced solidification construction steps are as follows:

[0025] Step 1, making the solidified soil material: the solidified soil material 1 is made by uniformly mixing the soil curing agent and the filler soil, the soil curing agent is 3-8% of the dry soil weight of the filler; the water content is 2-3% more than the optimal water content , an additional 2-3% is required for the chemical reaction between the soil curing agent and the roadbed filler; the raw materials of the soil curing agent are proportioned by weight: 8 parts of gypsum, 10 parts of quicklime, 20 parts of fly ash, 36 parts of blast furnace slag, silicic acid Dicalcium, magnesium silicate and aluminum silicate 3:2:3 mixture 30 parts, calcium chloride, sodium chloride and magnesium chloride 3:4:2 mixture 5 parts, aluminum sulfate, sodium sulfate and magnesium sulfate 2:4 : 9 parts of a mixture of 3.

[0026] Step 2, laying reinforcements: pave the reinforcements 2 ...

Embodiment 2

[0034] The steps of this embodiment are the same as in Example 1, except that the raw materials of the soil curing agent are proportioned by weight: 6 parts of gypsum, 12 parts of quicklime, 18 parts of fly ash, 42 parts of blast furnace slag, dicalcium silicate, silicon 28 parts of a mixture of magnesium sulfate and aluminum silicate 3:3:2, 7 parts of a mixture of calcium chloride, sodium chloride and magnesium chloride 4:3:2, a mixture of aluminum sulfate, sodium sulfate and magnesium sulfate 2:2:3 12 servings.

Embodiment 3

[0036] The steps of this embodiment are the same as in Example 1, except that the raw materials of the soil curing agent are proportioned by weight: 4 parts of gypsum, 14 parts of quicklime, 22 parts of fly ash, 45 parts of blast furnace slag, dicalcium silicate, silicon 16 parts of a mixture of magnesium sulfate and aluminum silicate 3:3:4, 4 parts of a mixture of calcium chloride, sodium chloride and magnesium chloride 3:3:2, a mixture of aluminum sulfate, sodium sulfate and magnesium sulfate 2:3:3 10 servings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com