Anti-knocking steel box beam bridge deck paving structure and paving method

A bridge deck pavement and steel box girder technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of bridge structure damage, cracks, low stiffness, etc., so as to relieve the pressure of explosion shock waves and improve compressive strength , good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

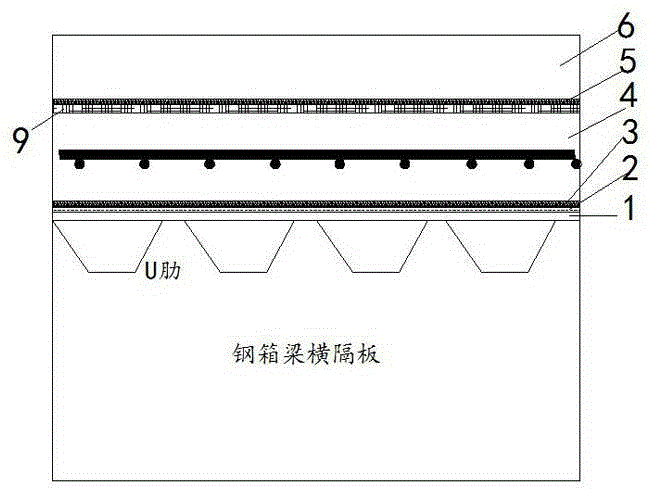

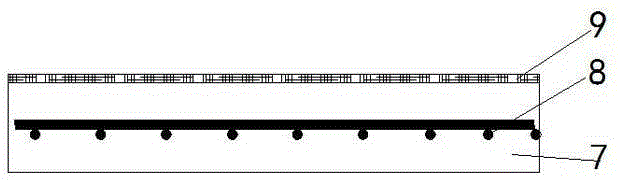

[0043] The pavement structure of the present invention is composed of a 40mm asphalt concrete wear layer on the upper layer and a 67mm thick GFRP-composite concrete anti-blast pavement layer on the lower layer. The GFRP-composite concrete anti-explosive pavement is the anti-explosive core layer, which is composed of a 65mm thick high-strength and high-toughness lightweight composite concrete with GFRP bars and a 2mm thick GFRP glass fiber reinforced sheet. As attached figure 1 As shown, the pavement structure from bottom to top is steel box girder deck 1, waterproof layer 2, lower bonding layer 3, GFRP-composite concrete anti-blast paving layer 4, upper bonding layer 5, and asphalt concrete abrasion layer 6. Among them, as attached figure 2 As shown, the GFRP-composite concrete anti-explosive paving layer is composed of a high-strength, hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com