Anticorrosive powder coating composition for super-tough rapid-bending steel bar, preparation method and application thereof

A technology of powder coatings and compositions, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as patent publications that have not yet been found, and achieve excellent resistance to chloride penetration, improve corrosion resistance, and adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

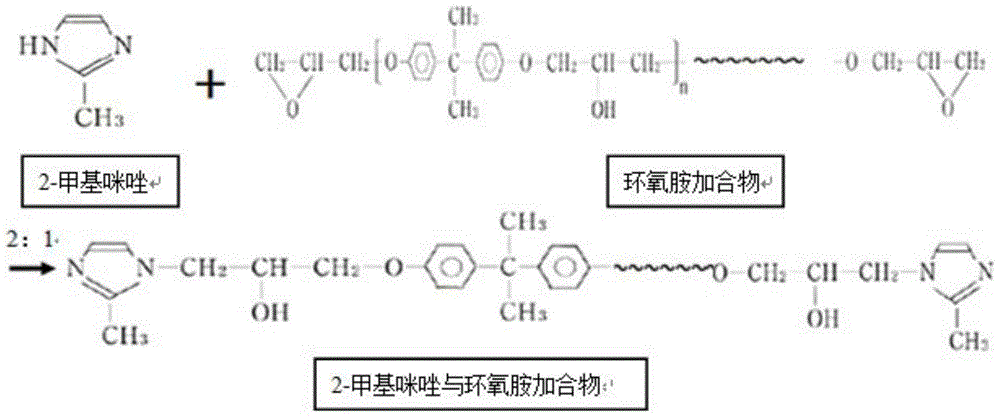

Method used

Image

Examples

Embodiment 1

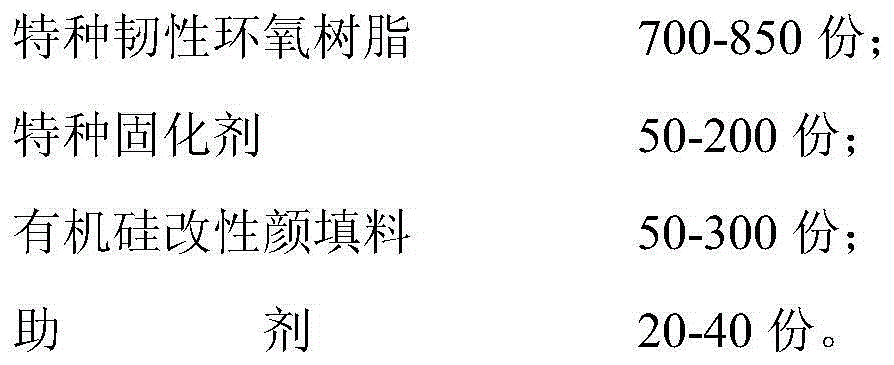

[0047] A super-tough and extremely fast-bending steel bar anti-corrosion powder coating composition and a preparation method thereof, the raw material components and parts by weight are respectively:

[0048]

[0049] Add the above-mentioned materials to a high-speed mixer, dry-mix them, and then add them to an extruder, melt, knead, cool, and tablet at an extrusion temperature of 80-120°C, and then pulverize, classify, sieve, Packaged to become a powder coating finished product.

[0050] Moreover, the special super-tough epoxy resin is self-made.

[0051] The self-made special epoxy resin is synthesized from three materials, the names are: NPES-907, YDCN-500-80P, OPL-350, the first two are purchased from Taiwan Formosa Plastics Group South Asia Epoxy Resin Kunshan Company, Composition of YDCN-500-80P o-cresol novolac epoxy resin (purchased from Korea Kukdo Chemical). The matching ratio of the three is: 300-500:30-50:200-300

[0052] Among them, OPL-350 is a self-made ni...

Embodiment 2

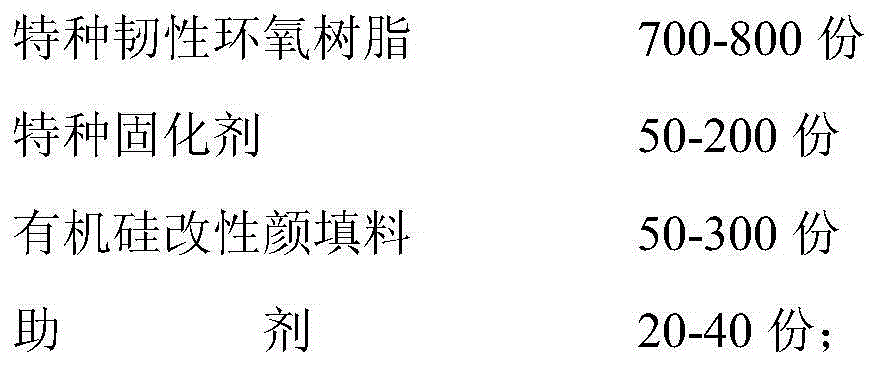

[0070] A super-tough and rapidly bendable anti-corrosion powder coating composition for steel bars, its raw material components and parts by weight are as follows: the preparation method of its self-made raw materials is the same as in Example 1.

[0071]

[0072] Wherein the preparation method of self-made special epoxy and curing agent is shown in embodiment 1, and the organic silane treatment process of pigments and fillers is also the same as embodiment 1.

[0073] The preparation method of the above-mentioned super-tough and rapidly bendable steel bar anti-corrosion powder coating composition, the steps are as follows:

[0074] Add the above-mentioned materials to a high-speed mixer, dry-mix them, and then add them to an extruder, melt, knead, cool, and tablet at an extrusion temperature of 80-120°C, and then pulverize, classify, sieve, Packaged to become a powder coating finished product.

Embodiment 3

[0076] A super-tough and rapidly bendable anti-corrosion powder coating composition for steel bars, its raw material composition and parts by weight are shown in Table 1, wherein the preparation method of self-made special epoxy and curing agent is shown in Example 1, and the organosilane treatment process of pigments and fillers is also the same Example 1, but the ratio of materials is changed, see Table 1. The preparation method of the super-tough and rapidly bendable steel bar anticorrosion powder coating composition is the same as that in Example 2.

[0077] The usage method of super-tough and rapidly bendable steel bar anticorrosion powder coating composition of the present invention can be as follows:

[0078] The production of the coated steel bar of the present invention is carried out in a professional production factory in the form of a production line, and its main process flow: steel bar surface treatment (shot blasting and derusting) → steel bar heating (intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com