Corn straw fiber enhanced fly ash polymer gel material and preparation method thereof

A technology of corn stalk fiber and cementitious material, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., and achieves the effects of low price, simple preparation process and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

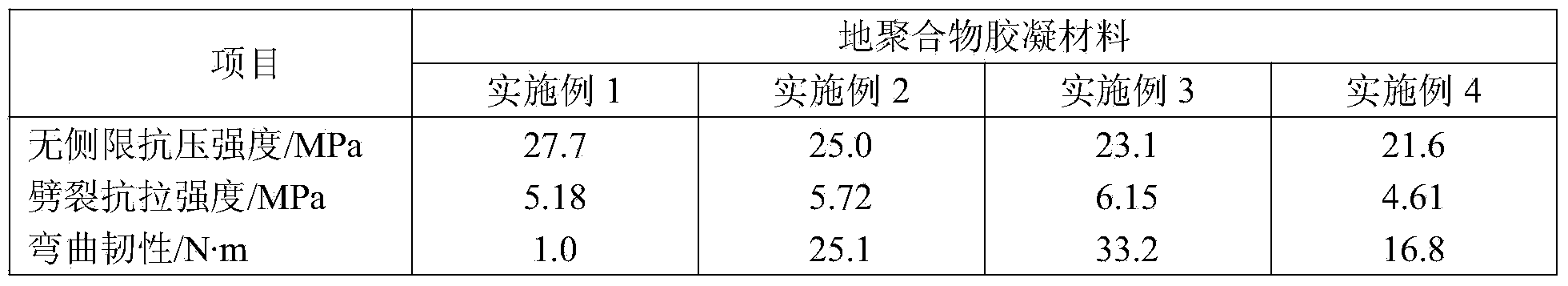

Examples

Embodiment 1

[0032] a. Mix sodium hydroxide and liquid sodium water glass to control its modulus M (SiO 2 ) / n(Na 2 O) is 1.5, made into an alkali activator, and aged for 24 hours for later use.

[0033] b. Incorporate the alkali activator into the fly ash, the Na introduced by the alkali activator 2 The mass percentage of O in fly ash is 10%, which is used to excite fly ash; the water-cement ratio of the control system is 0.4, and the sample is obtained.

[0034] c. Curing the sample at room temperature for 28 days to obtain the fly ash geopolymer cementitious material.

Embodiment 2

[0036]a. Dry the corn stalk fiber in an oven, dry it at room temperature, cut it into 2-4 cm long sections, and tap the fiber to remove the pectin on the surface of the fiber. Then use 1% NaOH lye to impregnate the fibers at a temperature of 60-80°C, then rinse with distilled water, and finally dry in an oven at a temperature of 80-90°C until the moisture content is about 5-10%, and store in a sealed bag spare.

[0037] b. Mix sodium hydroxide with liquid sodium water glass, control its modulus to 1.5, make alkali activator, and age for 24 hours before use.

[0038] c. Incorporate the alkali activator into the fly ash, the Na introduced by the alkali activator 2 O accounts for 10% of the mass percentage of fly ash and is used to stimulate fly ash; the water-cement ratio of the control system is 0.4; then the preserved corn stalk fiber is mixed into the previous mixture, and the fiber accounts for 1 mass percent of the mixture. %, the sample is obtained.

[0039] d. Curing t...

Embodiment 3

[0040] The rest of the conditions and steps of Example 3 are the same as in Example 2, except that the mass fraction of fiber in the mixture in step c is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com