Red mud geopolymer foam building block and preparation method thereof

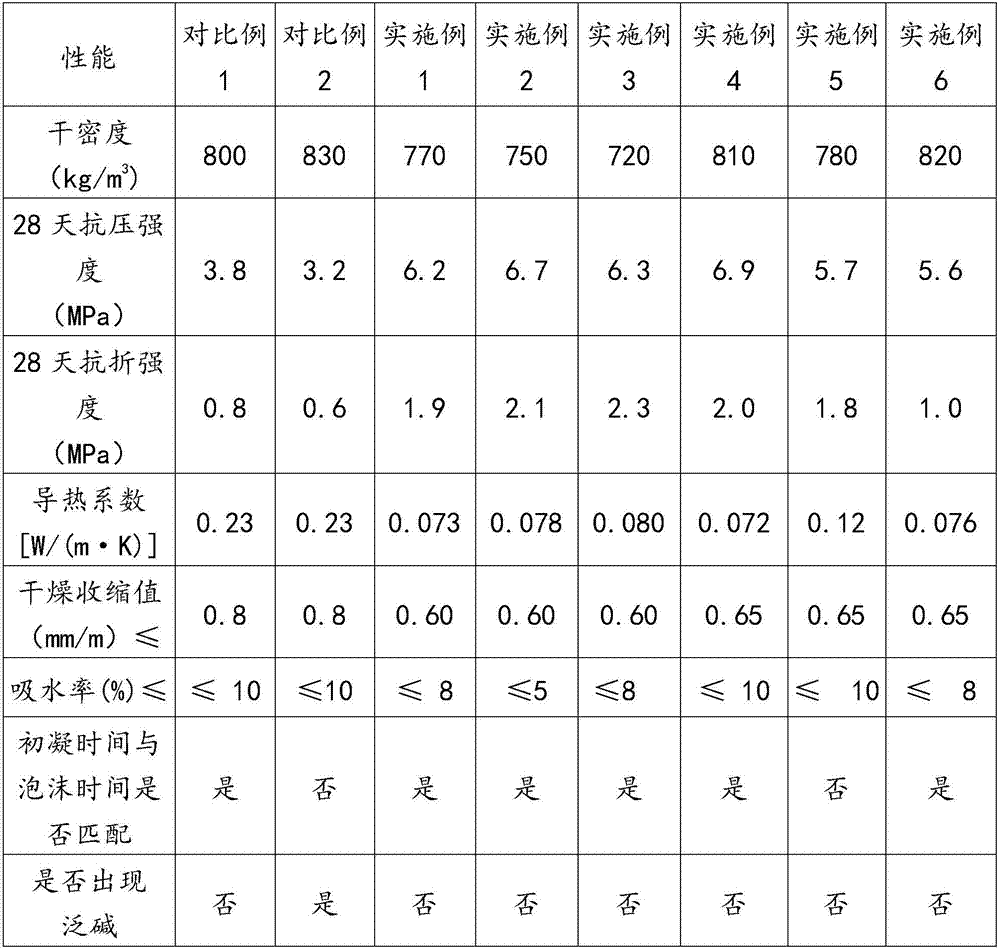

A technology of red mud geopolymer, which is applied in the field of red mud geopolymer foam block and its preparation, can solve the problems of low strength, efflorescence, high energy consumption, etc., and achieve improved thermal insulation performance and excellent thermal insulation performance , enhance the effect of flexural toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

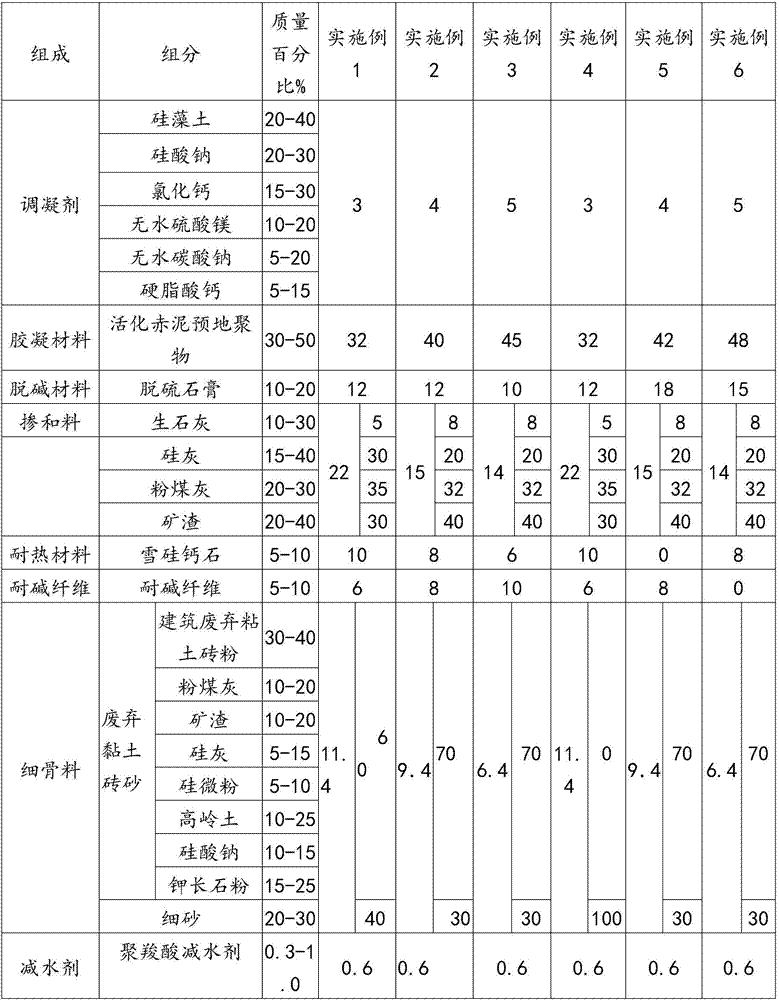

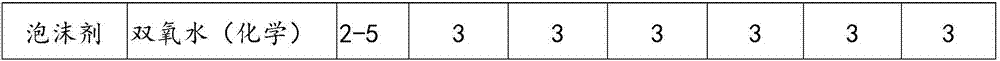

[0037] Red mud geopolymer foam blocks, by mass percentage, include: activated red mud pre-geopolymer 32%, fine aggregate 11.4%, desulfurized gypsum 12%, polycarboxylate superplasticizer 0.6%, admixture 22% %, coagulant 3%, tobermorite 10%, alkali-resistant fiber 6%, hydrogen peroxide 3%. The mass concentration of the hydrogen peroxide is 30%.

[0038] The components and mass fractions of the coagulation regulator are: diatomite 25%, sodium silicate powder 25%, calcium chloride 18%, anhydrous sodium carbonate 12%, anhydrous magnesium sulfate 12%, calcium stearate 8% %.

[0039] Prepared by the following steps:

[0040] Step A1: drying the red mud, crushing it and sieving it to obtain red mud powder;

[0041] Step A2: add anhydrous sodium carbonate, anhydrous magnesium carbonate, calcium stearate, sodium silicate, calcium chloride and mix to obtain a coagulation regulator;

[0042] Step A3: Add desulfurized gypsum to the activated red mud pre-geopolymer, then add water and m...

Embodiment 2

[0056] Red mud geopolymer foam blocks, by mass percentage, include: activated red mud pre-geopolymer 40%, fine aggregate 9.4%, desulfurized gypsum 12%, admixture 15%, coagulant 4%, polycarboxylate Acid-based superplasticizer 0.6%, tobermorite 8%, alkali-resistant fiber 8%, hydrogen peroxide 3%. The mass concentration of the hydrogen peroxide is 30%.

[0057] The components and mass fractions of the coagulation regulator are: diatomite 40%, sodium silicate powder 20%, calcium chloride 15%, anhydrous sodium carbonate 5%, anhydrous magnesium sulfate 10%, calcium stearate 10% %.

[0058] Prepared by the following steps:

[0059] Step A1: drying the red mud, crushing it and sieving it to obtain red mud powder;

[0060] Step A2: add anhydrous sodium carbonate, anhydrous magnesium carbonate, calcium stearate, sodium silicate, calcium chloride and mix to obtain a coagulation regulator;

[0061] Step A3: Add desulfurized gypsum to the activated red mud pre-geopolymer, then add wate...

Embodiment 3

[0075] Red mud geopolymer foam blocks, by mass percentage, include: activated red mud pre-geopolymer 45%, fine aggregate 6.4% (among them, waste brick clay sand 70%, fine stone sand 30%), desulfurized gypsum 10% %, admixture 14% (including quicklime 8%, silica fume 20%, fly ash 32%, slag 40%), coagulation regulator 5%, polycarboxylate superplasticizer 0.6%, snow silica calcium Stone 6%, alkali-resistant fiber 10%, hydrogen peroxide 3%. The mass concentration of the hydrogen peroxide is 30%.

[0076] The components and mass fractions of the coagulation regulator are: 20% diatomite, 30% sodium silicate powder, 30% calcium chloride, 5% anhydrous sodium carbonate, 10% anhydrous magnesium sulfate, 5% calcium stearate %.

[0077] Prepared by the following steps:

[0078] Step A1: drying the red mud, crushing it and sieving it to obtain red mud powder;

[0079] Step A2: add anhydrous sodium carbonate, anhydrous magnesium carbonate, calcium stearate, sodium silicate, calcium chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com