Steel fiber cement-based composite material based on nanoscale reinforcement and preparation method thereof

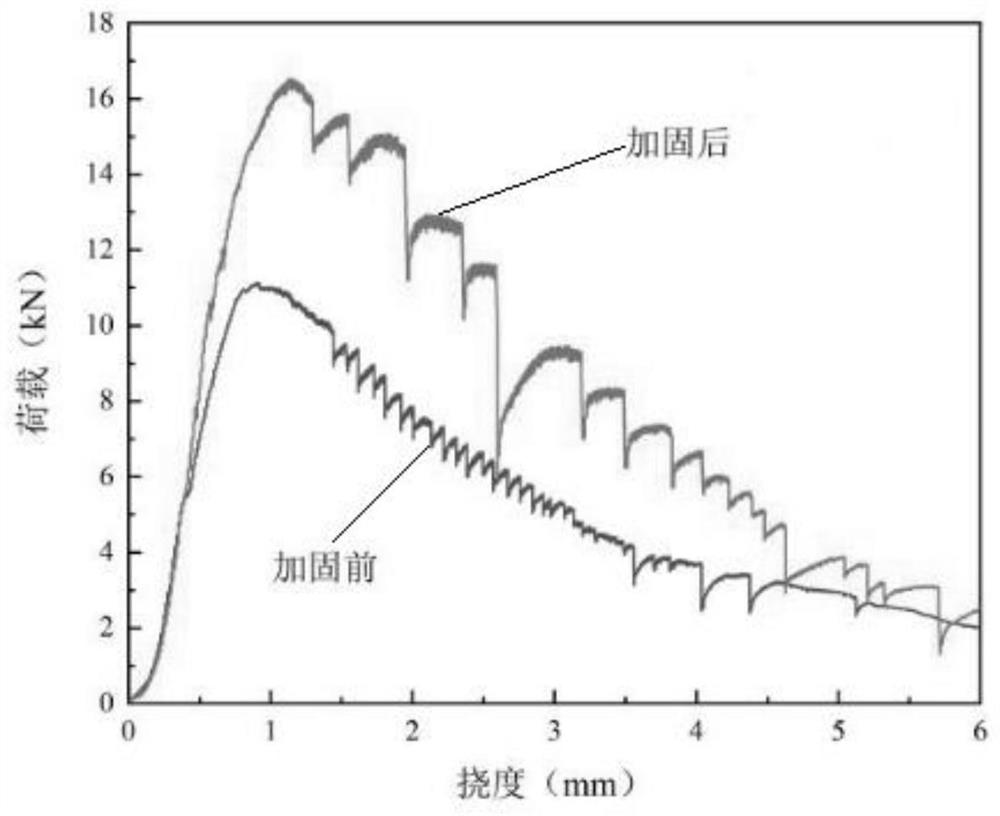

A nano-scale, composite material technology, applied in clay preparation devices, mixing operation control, cement mixing devices, etc., can solve the problem of reduced fluidity of steel fiber cement-based composite materials, increased electrochemical corrosion, and increased production costs. and other problems, to achieve the effect of using green materials, improving mechanical properties, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the steel fiber cement-based composite material based on nanoscale reinforcement provided by the present invention comprises the following steps:

[0040] Mixing the nanocellulose fibers with part of the water, performing stirring pre-dispersion and ultrasonic dispersion in sequence to obtain a nanomaterial suspension; the part of the water accounts for 15-20% of the total water mass;

[0041] Mix cement, silica fume, river sand, water reducer, steel fiber, nanomaterial suspension and remaining water to obtain cement-based composite slurry;

[0042] The cement-based composite slurry is sequentially molded, formed, demolded and maintained to obtain the steel fiber cement-based composite material based on nanoscale reinforcement.

[0043] The invention mixes nano cellulose fibers with part of water, and performs stirring pre-dispersion and ultrasonic dispersion in sequence to obtain nano material suspension. In the present invention, it is prefe...

Embodiment 1

[0059] A steel fiber cement-based composite material based on nanoscale reinforcement. The ratio of its raw materials is shown in Table 1. The cement is P O 42.5R ordinary Portland cement, the average particle size of silica fume is 0.24 μm, and the average particle size of river sand is Particle size ≤ 1.18mm, the water reducer is polycarboxylate water reducer, the diameter of the steel fiber is 0.2mm, the length is 13mm, the length of the nanocellulose fiber is 300-400nm, the diameter is 20-50nm, the preparation method is as follows :

[0060] (1) weighing: take raw material by the proportioning in table 1;

[0061] (2) Preparation of nanomaterial suspension: measure a little water in the container, the quality of the water taken accounts for 20% of the total water quality, and add the magnetic rotor and the nanocellulose fiber of getting a good sample respectively in the container with water, Stir for 5min under the condition that the rotating speed is 1000rpm (stirring te...

Embodiment 2

[0080] A steel fiber cement-based composite material based on nanoscale reinforcement, the ratio of its raw materials is shown in Table 3, and the rest are the same as in Example 1.

[0081] The ratio of raw materials of table 3 embodiment 2 steel fiber cement-based composite material

[0082] Cement / g Silica fume / g River sand / g water / g Superplasticizer / g Steel fiber / g Nanocellulose fiber / g Example 2 863 215.7 1078.5 169.5 32.4 156 0.579

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com