Production method of polypropylene crude fiber and application method of combination polypropylene crude fiber and organic nano materials in sprayed concrete

A technology of organic nanomaterials and sprayed concrete, which is applied in the direction of single-component polypropylene artificial filament, melt spinning method, stretch spinning method, etc., can solve the problems of crack resistance, impermeability and fire resistance, which affect the safety and timely support It can reduce the waste of engineering materials, lighten the weight, and improve the bonding force and friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

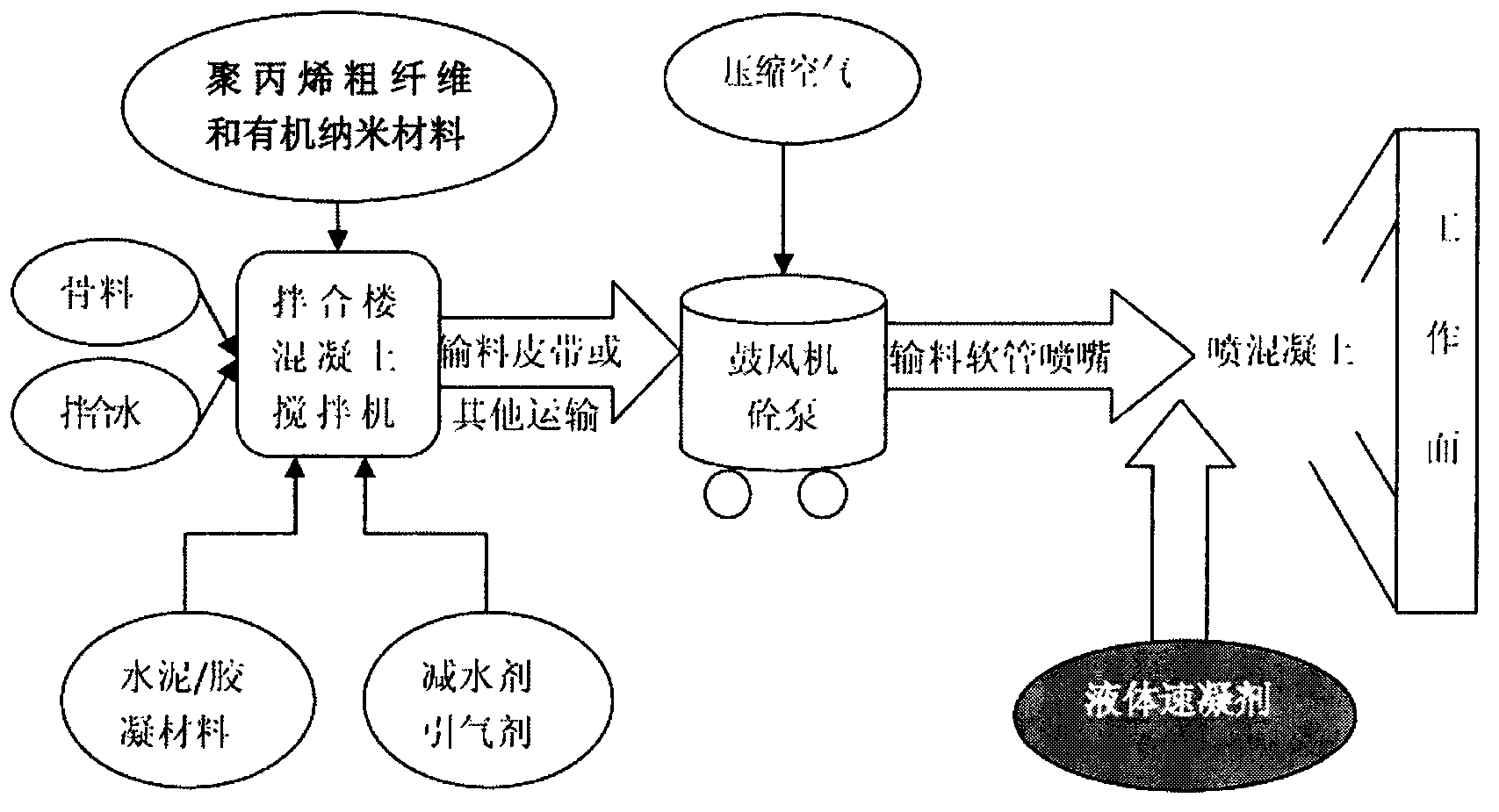

Method used

Image

Examples

Embodiment 1

[0053] Example 1: In this example, sprayed concrete with a strength grade of CF30 is prepared, and ordinary Portland cement with the label P.O42.5R is used. The water-cement ratio is 0.48, the sand rate is 60%, and the slump is 14-18cm, use 900 parts of sand, 680 parts of gravel, 3 parts of polypropylene crude fiber, 350 parts of cement, 8 parts of organic nanomaterials, and 208 parts of water. Put the materials into the forced mechanical stirring equipment in order until they are evenly stirred , adopt the shotcrete produced by the proportioning of this embodiment, the shot rebound rate is about 7%, the thickness of a spray layer can reach more than 500mm, and the dust concentration is reduced to 30%. When it adopts the cement of ordinary silicate 42.5#, 28 The daily strength can reach more than 45Mpa.

Embodiment 2

[0054] Embodiment 2: In this embodiment, the sprayed concrete whose strength grade is CF30 is prepared, and ordinary Portland cement whose label is P.O42.5R is used, the water-cement ratio is 0.48, the sand ratio is 60%, and the slump is 14-18cm, use 942 parts of sand, 691 parts of stone, 4 parts of polypropylene crude fiber, 221 parts of cement, 11 parts of organic nanomaterials, and 260 parts of water. Put the materials into the forced mechanical stirring equipment in order until they are evenly stirred , adopt the shotcrete produced by the proportioning of this embodiment, the shot rebound rate is about 7%, the thickness of a sprayed layer can reach more than 500mm, and the dust concentration is reduced to 35%. When it adopts the cement of ordinary silicate 42.5#, 28 The daily strength can reach more than 45Mpa.

Embodiment 3

[0055] Example 3: In this example, sprayed concrete with a strength grade of CF30 is prepared, and ordinary Portland cement with the label P.O42.5R is used. The water-cement ratio is 0.48, the sand rate is 60%, and the slump is 14-18cm, use 987 parts of sand, 701 parts of stone, 5 parts of polypropylene crude fiber, 388 parts of cement, 13 parts of organic nanomaterials, and 230 parts of water. Put the materials into the forced mechanical stirring equipment in order until they are evenly stirred , adopt the shotcrete produced by the proportioning of this embodiment, the shot rebound rate is about 8%, the thickness of a sprayed layer can reach more than 500mm, and the dust concentration is reduced to 35%. When it adopts the cement of ordinary silicate 42.5#, 28 The daily strength can reach more than 45Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com