Polymer modification blast-furnace slag powder material

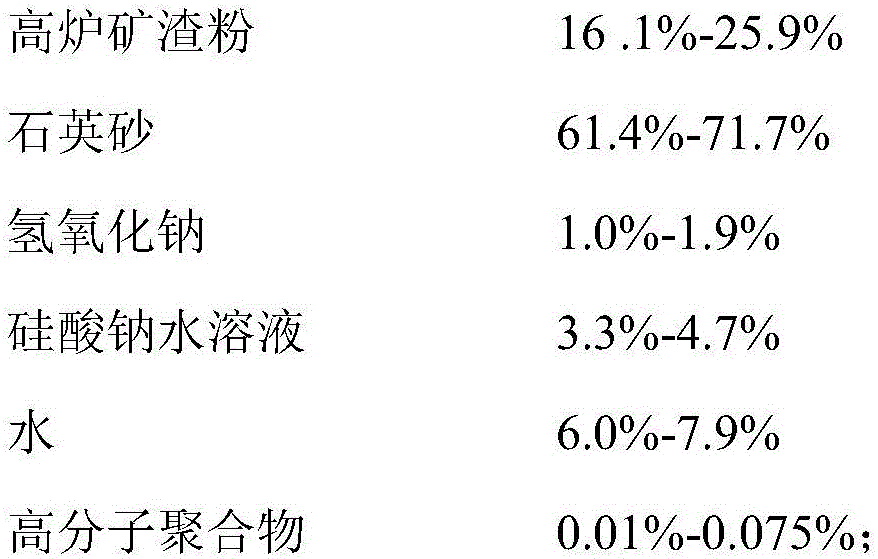

A technology of blast furnace slag powder and polymer, which is applied in cement production, etc., can solve the problems of high brittleness and low flexural strength, and achieve the effects of low elastic modulus, excellent impermeability, and high ultimate flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

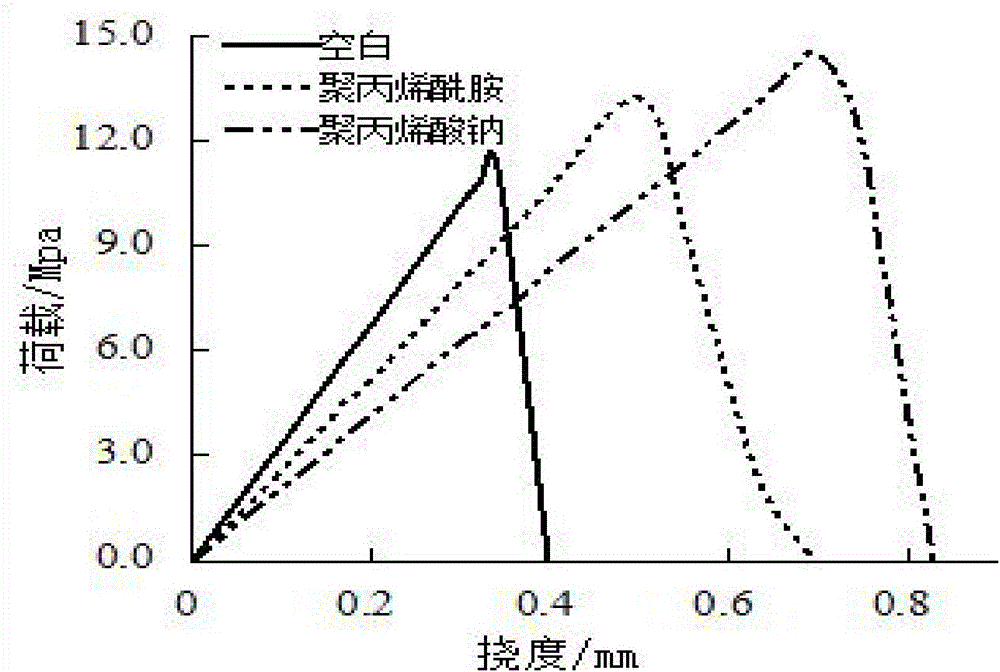

[0024] The ingredients are formulated according to the following mass percentages: 22.067% of blast furnace slag powder, 66.4% of quartz sand, 1.3% of sodium hydroxide, 4.0% of sodium silicate aqueous solution, 6.2% of water, and 0.033% of sodium polyacrylate. Polyacrylamide is used as a comparison, and the dosage is also 0.033%, while no high polymer is used as a blank sample group. According to the above ratio, combined with the preparation method of polymer-modified blast furnace slag powder material, curing to 28d.

[0025] The WAY-300 automatic flexural and compressive testing machine was used to measure the compressive and flexural strength, and the Instron1394 universal servo instrument was used to measure the flexural toughness. The results are shown in Table 1 and Table 2. The indentation ratio indicates the index of mortar flexibility and toughness. The lower the indentation ratio, that is, relatively speaking, the higher the flexural strength, which also reflects th...

Embodiment 2

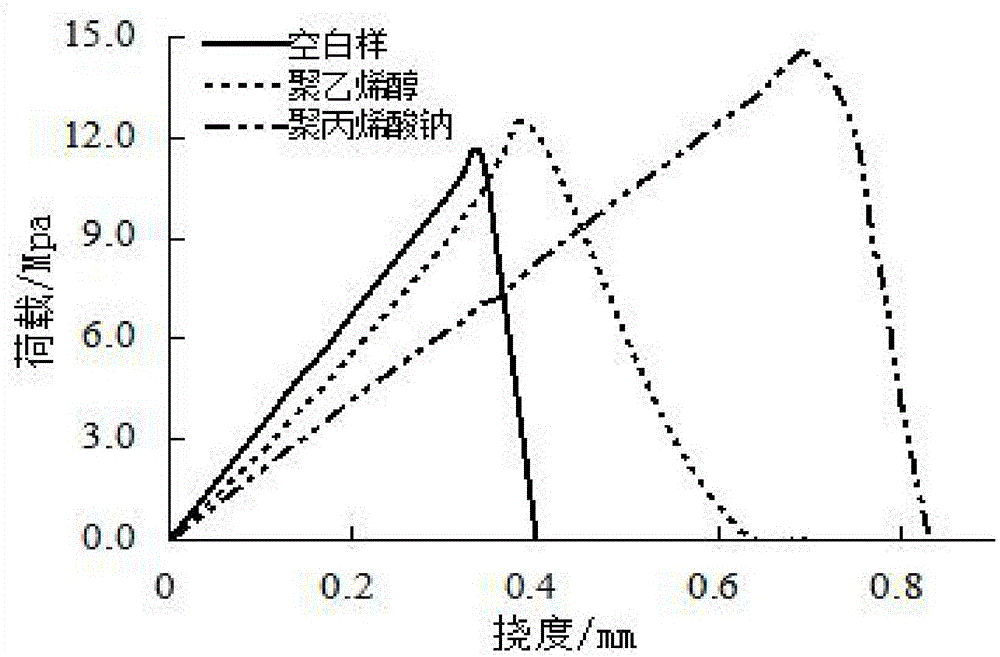

[0033] The ingredients are formulated according to the following mass percentages: 22.067% of blast furnace slag powder, 66.4% of quartz sand, 1.3% of sodium hydroxide, 4.0% of sodium silicate aqueous solution, 6.2% of water, and 0.033% of sodium polyacrylate. Polyacrylamide is used as a comparison, and the dosage is also 0.033%, while no high polymer is used as a blank sample group.

[0034] According to the above ratio, combined with the preparation method of polymer modified blast furnace slag powder material, curing for 28 days, using the WAY-300 automatic flexural and compressive testing machine to measure the compressive and flexural strength, and the Instron1394 universal servo instrument to measure the flexural toughness , the results are shown in Table 3 and Table 4.

[0035] Table 3 Mechanical properties of different polymer modified slag powder

[0036]

[0037] According to Table 3, sodium polyacrylate and polyvinyl alcohol can be obtained to modify blast furna...

Embodiment 3

[0042] The ingredients are formulated according to the following mass percentages: 25.925% of blast furnace slag powder, 61.4% of quartz sand, 1.9% of sodium hydroxide, 4.7% of sodium silicate aqueous solution, 6.0% of water, and 0.075% of sodium polyacrylate. At the same time, no high polymer is added as a blank sample group. Combined with the preparation method of polymer modified blast furnace slag powder material, curing until 28d, using WAY-300 automatic flexural and compressive testing machine to measure the compressive and flexural strength of 3d, 7d, 28d, and explore its performance under this ratio Toughening effect, the results are shown in Table 5.

[0043] table 5

[0044]

[0045]According to Table 5, it can be obtained that sodium polyacrylate has a modification effect on blast furnace slag powder. Compared with the blank sample, the flexural strength of 3d, 7d, and 28d increased by 42.05%, 45.76%, and 33.86%, respectively. It can be seen that polyacrylic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com