Patents

Literature

100results about How to "Brightly dyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of processing semi-worsted flax blended yarn

The present invention involves a processing method of semi-worsted flax blended yarn, and it belongs to flax blended yarn technical field. The counts of the semi-worsted flax blended yarn is 30-85 Nm / 2D, the raw materials consists of flax 10-60 and other fiber 40-90; degelatinizing, dyeing and preserving flax, pretreating other fiber, then putting together wool, blowing cotton, carding and drawing, then prespinning and shirting, last the products are prepared after cheese winding, twisting and double twisting processes. The invention combines the 'straight' of flax fiber and the 'softness' of other fibers effectively; the prepared semi-worsted flax blended yarn has many advantages of good textile strands and less granulite, it is suitable for the face fabric of thin summer inner wear and coat.

Owner:山东恒泰纺织有限公司

Method for manufacturing modal fiber

ActiveCN101545150AHigh strengthBrightly dyedArtificial filaments from viscoseInternational standardDissolution

The invention discloses a method for manufacturing modal fiber, which comprises basification reaction, ageing reaction, yellowing reaction, dissolution of viscose glue, filter of the viscose glue, defoaming of the viscose glue, ripening of the viscose glue, wet spinning, drawing and other related process steps. The method adopts cellulose pulp with alpha cellulose content of less than 95 percent as a raw material, uses common equipment for producing common viscose glue short fiber, and adopts the technology to control a simple and practical special process formulation and a spinning drawing mode to manufacture the modal fiber capable of reaching international standards. The method has the advantages of little investment, easily obtained and low-cost raw materials, high productivity and simple process operation; and the manufactured modal fiber has good quality and stable performance.

Owner:杭州奥通新材料智能科技有限公司

Bamboo fibre and ramie fibre mixed spinning fabric and method for production thereof

The invention discloses a blended face fabric and manufacturing method of bamboo fiber and ramie hemp, which is characterized by the following: adopting bamboo fiber and ramie hemp at 25-90:10-75 with 38-90 root per time for warp set, 34-80 root per time for weft density and 6s-32s count; slivering; spinning; warping, sizing; denting; weaving. The invention improves antibiotic, moisture-discharging property due to ramie, which is comfortable to wear.

Owner:湖南瑞亚高科集团有限公司

Liquid-based cell preservation solution

InactiveCN105409925ABrightly dyedLess inflammatory cellsDead animal preservationPotassiumCervical mucus

The present invention relates to pathological examination, especially to a liquid-based cell preservation solution used in pathologically examining cells such as human cervical mucus, sputum, urine, thoracic liquid, and tracheal mucus. The liquid-based cell preservation solution is characterized by being prepared from alcohols, a sodium phosphate buffer solution, disodium ethylenediamine tetraacetate, 0.08-0.12% sodium chloride, potassium chloride, formaldehyde, dithiothreitol, calcium acetate, magnesium acetate and the like. The cell preservation solution cannot only maintain the cell structure stability and reduce the agglomerated precipitation of the cell mucus and the cell breakage loss, but also enables the cells easily to be stained, improves the clarity of the cell sheets, and facilitates smooth performance of the examination work. Moreover, the cell preservation solution is low in cost and easy to promote and use.

Owner:孝感宏翔生物医械技术有限公司

Method for manufacturing high wet modulus fiber

InactiveCN101591814AHigh strengthBrightly dyedArtificial filament physical treatmentFilament manufactureInternational standardFiltration

The invention discloses a method for manufacturing high wet modulus fiber, which comprises the process steps of alkalization reaction, ageing reaction, etiolation reaction, viscose dissolution, viscose filtration, viscose defoaming, viscose maturation, spinning, drafting and post-treatment in turn, adopts cellulose pulp of which the alpha cellulose content is less than 95 percent as a raw material, uses a common device for producing ordinary viscose short fiber, and adopts a special process formulation and a spinning drafting mode with simple and practical process control to manufacture the high wet modulus fiber capable of meeting the international standard. The method has less investment, adopts easily obtained low-cost raw materials, and has high productivity and simple process operation, and the manufactured high wet modulus fiber has excellent quality and stable performance.

Owner:HANGZHOU AUTOON ENVIRONMENTAL TECH CORP

Method for staining medical tissue slice

The invention provides a medical tissue section staining method which comprises the following steps that: olefin is sliced into sheets, dewaxed and hydrated; sliced sheets are put into solution of picric acid, formaldehyde and glacial acetic acid after being heated, taken out and washed by running water; the sliced sheets are put into a 5 percent sodium thiosulfate solution to soak and washed by distilled water; the sliced sheets are put into an alcian blue solution to soak and washed by the running water; the sliced sheets are put into a preheated alkaline ethanol solution to soak and washed by the running water; under the lighttight condition, the sliced sheets are put into a haematoxylin working solution and washed by the running water and the distilled water; the sliced sheets are put into a saffron / acid fuchsine working solution and washed by the distilled water; the sliced sheets are put into a phosphotungstic acid solution to soaked, then transferred to the glacial acetic acid to soak and washed by the distilled water; the sliced sheets are dehydrated by ethanol; the sliced sheets are put into an ethanol saffron solution to soak, then dehydrated by the ethanol and sealed. The medical tissue section staining method has low cost and vivid staining, shortens the time for a staining flow and also increases the application range.

Owner:SHANDONG UNIV

Production method of high wet modulus synthetic fiber containing bamboo

InactiveCN101857983AHigh strengthBrightly dyedConjugated cellulose/protein artificial filamentsWet spinning methodsFiltrationRipening

The invention discloses a production method of a high wet modulus synthetic fiber containing bamboo, which comprises the following steps: taking cellulose bamboo pulp or the cellulose bamboo pulp mixed with one of cellulose wood pulp and cellulose cotton pulp as a mixed raw material, carrying out quaternization, maturing degradation, etiolation reaction, dissolving and grinding, viscose ripening, viscose filtration, defoaming, wet-method spinning forming, drafting and other relative process treatment steps and obtaining a functional fiber raw material by using common equipment for producing a common viscose short fiber, a special process formula and a spinning and drafting method. The invention solves a series of problems of difficult filtration, poor spinning and forming, instable quality of finished products, high consumption, low yield and the like existing in the production of single cellulose pulp, considers the characteristics of coolness, comfort, bacteriostasis, heath care and the like of natural bamboo fibers and also has the advantages of high wet modulus (Modal) fibers.

Owner:HANGZHOU AUTOON ENVIRONMENTAL TECH CORP

Blended yarn of acrylic fibers, linen fibers and milk protein fibers

The invention provides a blended yarn of acrylic fibers, linen fibers and milk protein fibers, which comprises the following components: 40-50 weight parts of acrylic fibers, 40-50 weight parts of linen fibers and 15-25 weight parts of milk protein fibers. The characteristics of the acrylic fibers, the linen fibers and the milk protein fibers are mutually complemented and the advantages of the three components are utilized by the blended yarn provided by the invention.

Owner:JIANGSU TONGHAI THREAD

Composite yarn and manufacturing method thereof

The invention discloses the new pattern composite yarn and making method, comprising the following steps: putting cellulose viscose and polyytrimethylene terephthalate fibre into twine machine or lapping yarn machine, carrying out twisting and ply doubling, making white yarn, then carrying out fore treatment, coloring, cleaning, soft finishing, and getting product. The cloth has good tension, rebound elasticity, crease-shedding effect, ventilating, absorbing sweat effect, and dyeing behaviour, resistance to ultraviolet radiation and static electricity effect. The method has the advantages of low cost.

Owner:YIBIN GRACE

Cation dacron bamboo fiber blended yarn

The invention provides a cation dacron bamboo fiber blended yarn which contains the flowing compositions by weight percent: 65-75% of 1.5D*38mm normal temperature and pressure dyed dacron fiber and 25-35% of 2D*51mm bamboo fiber. The cation dacron bamboo fiber blended yarn has the technical effects of good warm keeping performance, good air permeability, excellent pilling resistance and good sense of fur texture and is soft, bright in dyeing, mothproof and ultraviolet-proof.

Owner:NANTONG SUZHONG TEXTILE

Dacron fine denier multi-hole flat fiber and method for producing same

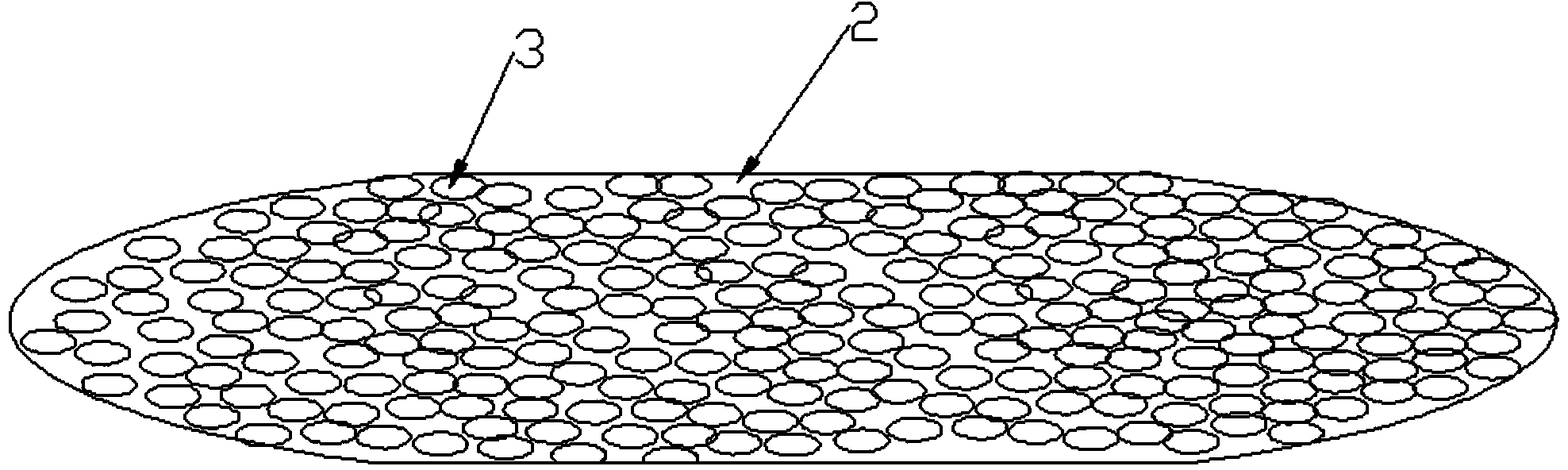

ActiveCN103510171ABeautiful appearanceImprove inner qualityNew-spun product collectionFilament/thread formingYarnFiber

The invention relates to the technical field of chemical fiber products, in particular to a dacron fine denier multi-hole flat fiber and a method for producing the dacron fine denier multi-hole flat fiber. The dacron fine denier multi-hole flat fiber comprises a fiber body. The fiber body is provided with 192 strips of monofilament, the cross section of each strip of monofilament is in the shape of a waist, the linear density of the fiber body is 207-253dtex, and the monofilament is evenly and irregularly distributed. The produced dacron fine denier multi-hole flat fiber is beautiful in appearance, good in inherent quality, small in inner-layer and outer-layer fluctuation, stable in tension, soft, long and straight in style, fine and smooth in hand feeling, even in dye absorption, bright-colored in dye, large in package density, high in capacity, consistent in whole package width, uniform in hardness, free of overlapped yarn and even in inner-layer and outer-layer quality, and is a high and new-tech product with high quality and high additional value.

Owner:ZHEJIANG HENGYOU CHEM FIBER CO LTD

Raw wool scouring agent

InactiveCN102041187AImprove cleaning rateLow residual fat rateOrganic detergent compounding agentsNon-ionic surface-active compoundsDiethylene glycolScouring agent

The invention relates to a raw wool scouring agent which is characterized by comprising the following components by weight percent: 40%-80% of iso-tridecanol polyoxyethylene ether, 2%-14% of alkyl aryl sodium sulfonate, 3%-8% of diethylene glycol, 2% of glycol and the balance of water. The invention further discloses a wool scouring agent with an antistatic function and a bactericidal function. The wool scouring agent has the advantages of high cleaning rate, low fan and oil content, excellent whiteness, good hand feeling and good biodegradability.

Owner:傅科杰

Method for preparing coarse denier and ultra-coarse denier viscose fiber and prepared fiber

InactiveCN101104956AEasy to useBroaden sources of raw materialsArtificial filaments from viscoseMelt spinning methodsCellulosePolymer science

The invention discloses a manufacturing method of coarse-denier and ultra-coarse denier viscose fibers and the fibers produced by the method. The method comprises using a cellulose xanthate polymer in viscous state, spraying from spinneret holes with high aperture into a coagulating bath solution composed of more than two components selected from sulfuric acid, zinc sulfate and sodium sulfate, allowing molding, subjecting the cellulose macromolecules in viscose elastic state to the combined tension of bath solution and air, and proportionally regulating the draft by different draft distributions to obtain coarse-denier or ultra-coarse denier viscose fiber. The method is simple and easy to operate. The produced coarse-denier and ultra-coarse denier viscose fibers have various specifications and excellent performance, and can meet the requirements of rich variety and specification of fibrous raw materials in textile industry. The invention enlarges the application range of viscose fibers.

Owner:CHTC HELON

Water-absorbing, wear-resistance, alkali-resistance, anti-pilling, and flame-retardant fabrics

ActiveCN103381689AIncrease elasticityStrong and goodPhysical treatmentSynthetic resin layered productsHome usePolyvinyl chloride

The invention relates to a water-absorbing, wear-resistance, alkali-resistance, anti-pilling, and flame-retardant fabrics, and belongs to the field of home-used textile fabrics. The fabrics comprise a flame-retardant layer and a fabric surface layer, and the fabric surface layer is attached to the flame-retardant layer. The flame-retardant layer is woven by polyvinyl chloride fiber yarns, which have been subjected to the processes of flame-retardant agent impregnation and carbon dioxide laser radiation energy treatment. The fabric surface layer is interwoven by the warp yarns and the weft yarns according to the fabric structure, the warp yarns are woven with acrylic fiber yarns, staple fibers, spandex, and wool blended yarns, and the weft yarns are woven with acrylic fiber yarns, staple fibers, spandex, wool blended yarns, and regenerated cellulose fiber blended yarns. The yarn counts of the warp yarns are in the range of 20S to 80S, and the yarn counts of the weft yarns are in the range of 20S to 80S. The fabric structure is in twill, satin or changed twill structures, and the fabrics have been subjected to a shrinkage treatment. The water-absorbing, wear-resistance, alkali-resistance, anti-pilling, and flame-retardant fabrics not only have the characteristic of soft fabrics, puffy hand-feeling, bright color and luster, and good heat insulation property like the acrylic fibers yarns, but also have the characteristic of anti-pilling ability, good water-absorbing ability, wear-resistance, alkali-resistance and fire-retardant ability.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

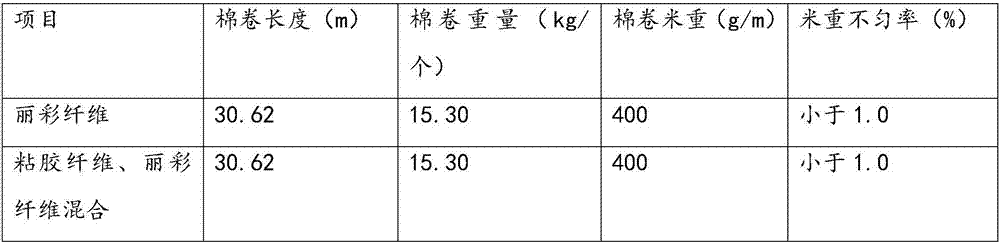

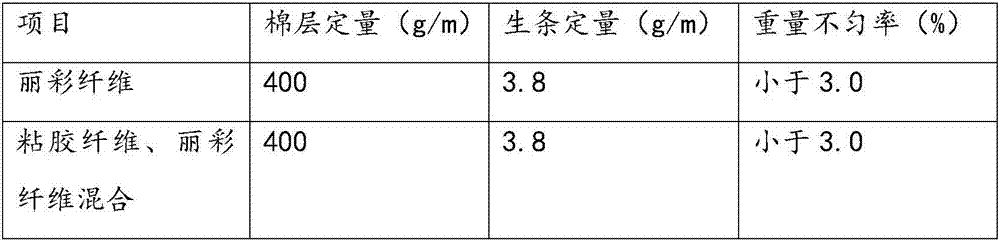

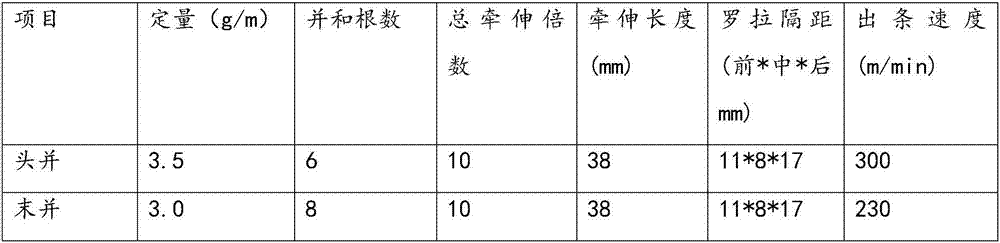

Viscose fiber and leecy fiber blended yarn and spinning technology thereof

The invention discloses a viscose fiber and leecy fiber blended yarn and a spinning technology thereof. The blended yarn comprises viscose fibers with the fiber content blending ratio of 60-70%, and leecy fibers with the fiber content blending ratio of 30-40%. The fibers are woven into the yarn through the spinning technology. Firstly, after the leecy fibers are subjected to opening and picking and cotton carding, the leecy fibers and the viscose fibers are mixed, then opening and picking and cotton carding are carried out, and the leecy fibers and the viscose fibers can be mixed to be uniform; due to the fact that the leecy fibers with the durable physical bacteriostasis function are added, the viscose fiber finished products can be prepared into the yarn with the antibacterial function directly through the following spinning technology, it is not needed to independently carry out antibacterial treatment on the viscose fiber finished products, the technology is simplified while the antibacterial effect is guaranteed, the production cost is reduced, fabric woven from the viscose fiber and leecy fiber blended yarn can be rapidly dyed, the colors are gorgeous, gradually varied and rich in layering sense after the fabric is colored, and multiple colors can be obtained through one time of dyeing.

Owner:宜宾恒丰丽雅纺织科技有限公司

Blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber

The invention provides a blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber. The blended yarn is characterized by comprising the following components: 60-70 weight parts of acrylic fiber, 15-25 weight parts of jute fiber and 15-25 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of acrylic fiber, jute fiber and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:JIANGSU TONGHAI THREAD

Nylon-acrylon-pupa azelon blended yarn

The invention provides a nylon-acrylon-pupa azelon blended yarn which comprises the following components in parts by weight: 40-50 parts of nylon, 40-50 parts of acrylon and 15-25 parts of pupa azelon. The invention complements the mutual characteristics of the nylon, acrylon and pupa azelon, and displays the advantages of the nylon, acrylon and pupa azelon.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

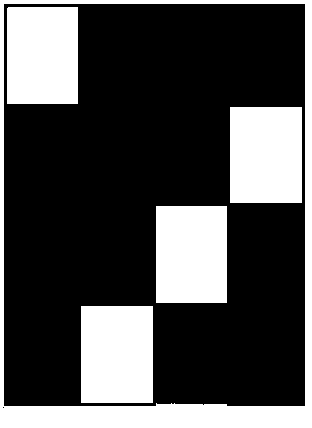

Semi-worsted double-core color-spun wrapped yarn and production method thereof

The invention relates to semi-worsted double-core color-spun wrapped yarn and a production method and application thereof. The semi-worsted double-core color-spun wrapped yarn comprises PTT shape memory filaments, polyester filaments, semi-worsted colored Jutecell fibers, colored antibacterial acrylic fibers, polyamide fibers and wool fibers. The semi-worsted double-core color-spun wrapped yarn has the advantages that the wrapped yarn is diversified in pattern, high in three-dimensional performance, rich in layering change, rich in color, good in moisture absorption performance, good in dyeing performance, bright in color, good in elasticity, small in shrinkage rate, good in fullness, soft in touch, noble and elegant, unique in style, glossy and suitable for being used to produce high-end fabric, decoration cloth, beddings and the like, untoward effects generated when the yarn contacts with a human body can be avoided, and fabric produced by the yarn is free of constraint and pressure during wearing and is good in wear resistance.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Oxidation method for high-hardness high-gloss aluminum and aluminum alloy ceramic texture

The invention provides an oxidation method for high-hardness high-gloss aluminum and aluminum alloy ceramic texture. The method comprises the following steps: oxidizing: putting an aluminum product tobe processed in an anodic oxidation solution; applying an oxidation voltage to form an oxide film layer on the surface of the aluminum product; keeping the anodic oxidation solution at a balanced temperature of 10 DEG C below zero to 10 DEG C; sealing and steaming: putting the aluminum product with the oxide film layer in a steam-closing device; and processing the aluminum product with steam. Compared with the prior art, the invention has the advantages that the hardness and the surface gloss of the oxide film layer of the aluminum or aluminum alloy product is further improved, and a crinklephenomenon is overcome so that the produced aluminum product has higher wearing resistance, corrosion resistance and decoration.

Owner:深圳市宝安区福永祥兴五金制品厂

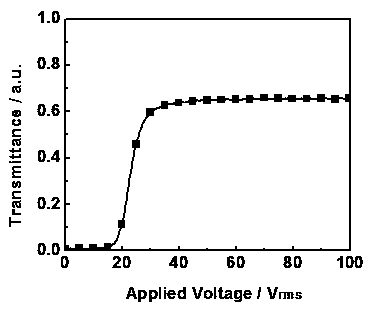

Color polymer dispersed liquid crystal thin film and preparation method thereof

PendingCN107703667ABrightly dyedIncrease contrastLiquid crystal compositionsNon-linear opticsMicrometerPolymer chemistry

A color polymer dispersed liquid crystal thin film material comprises, by mass, 100 parts of mixture, 1-10 parts of curing agent, 0.1-2 parts of spacers and 0.5-3 parts of dyes. The mixture comprises,by mass, 40-70% of thermal polymerization monomers and 30-60% of liquid crystals. The invention further discloses a preparation method of the material. The method includes the steps that the thermalpolymerization monomers, the nematic liquid crystals, the curing agent, the dyes and spacers are mixed in a certain ratio and uniformly stirred, and the mixture is sandwiched between two conductive thin films plated with indium tin oxide; after being extruded by a roller shaft, the mixture is put into a heat curing machine for curing to obtain the polymer dispersed liquid crystal thin film with the thickness of 10-30 micrometers. The polymer dispersed liquid crystal thin film material has the advantage that thin films prepared through the method are good in thermal stability and high in bonding force, the thin films in different colors can be prepared by means of different dyes, and the thin films are rich in color, good in visual effect and wide in application field.

Owner:XIJING UNIV

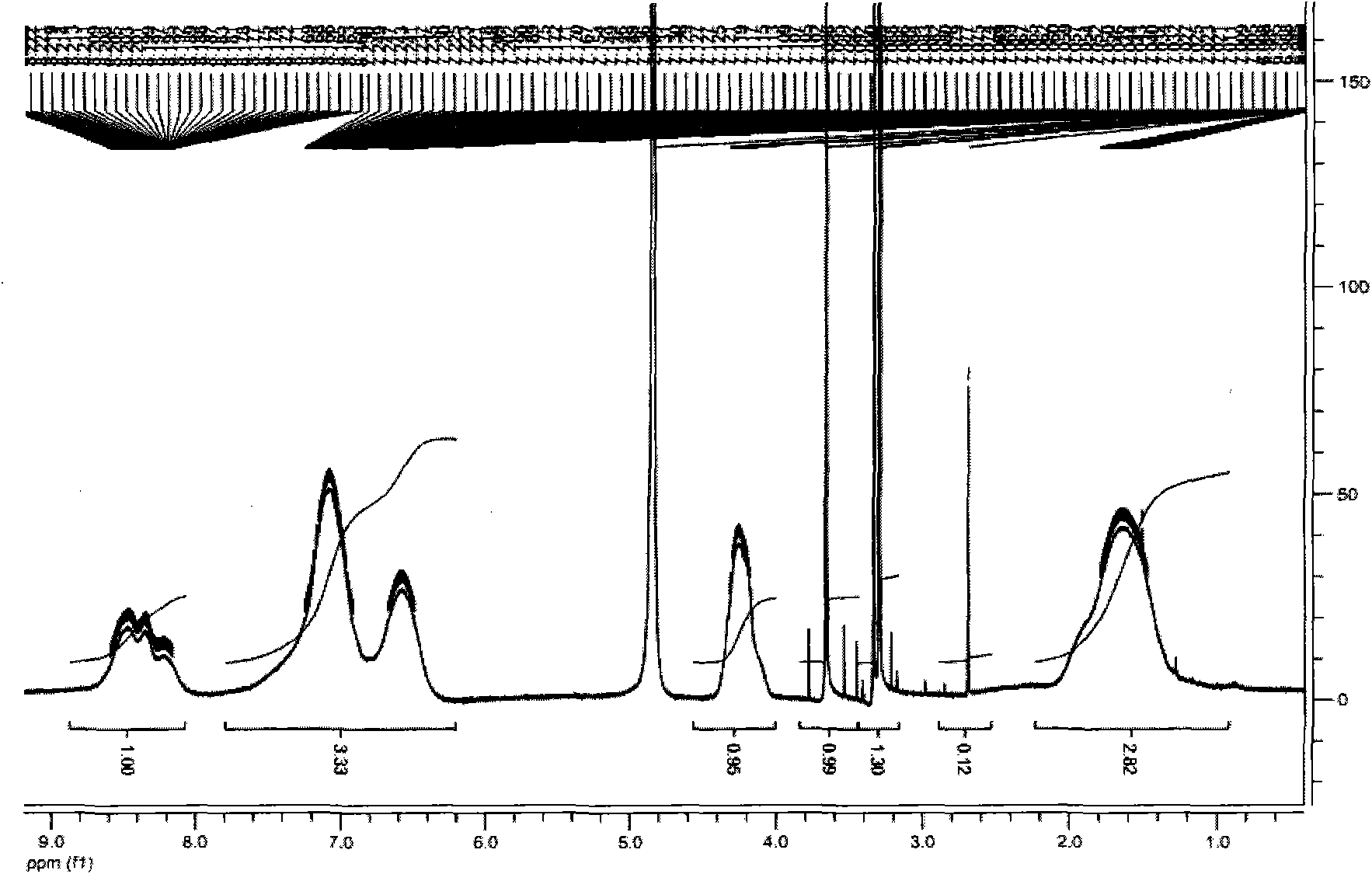

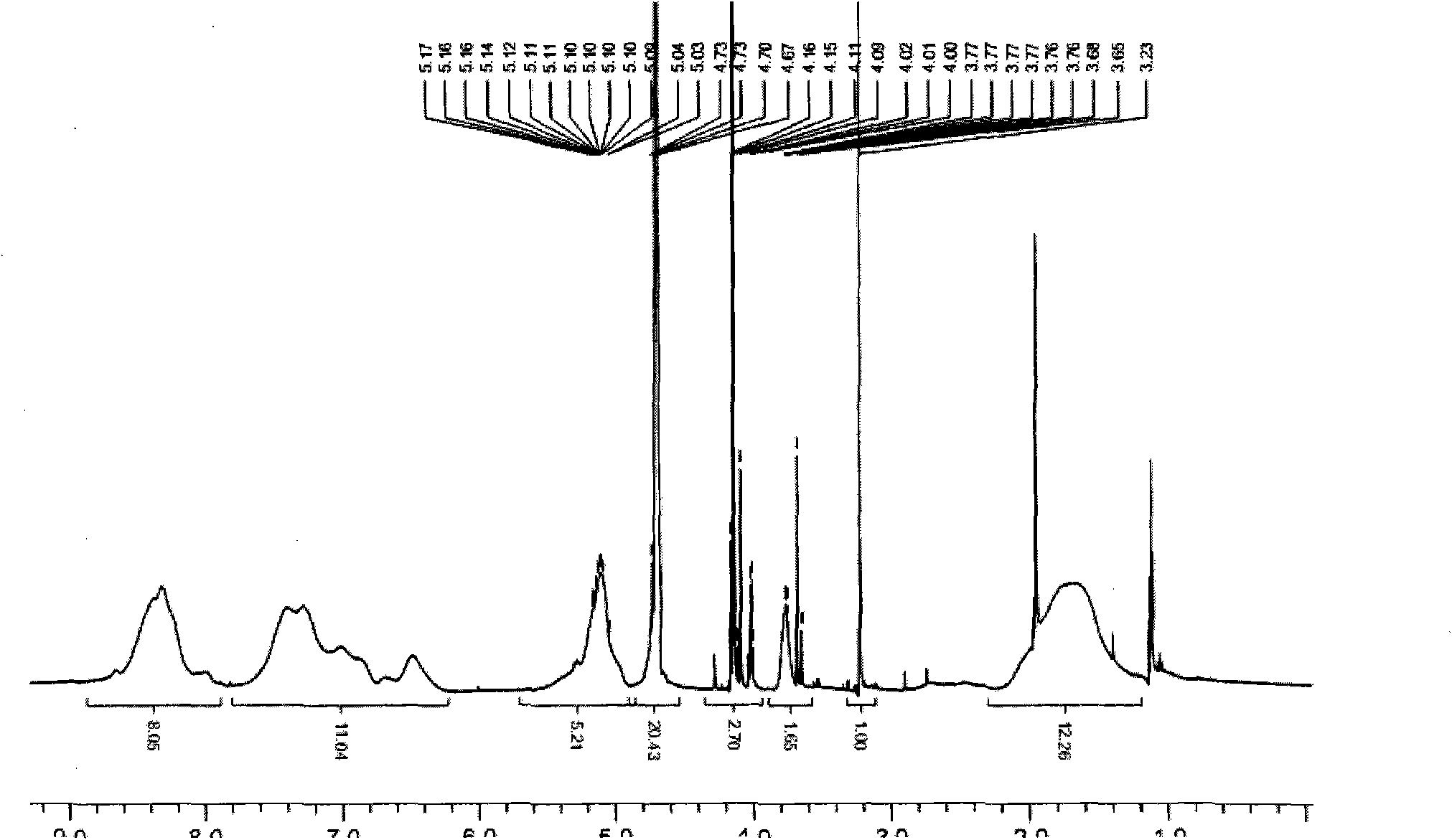

Naphthaquinone-type brown reactive disperse dye and preparation method thereof

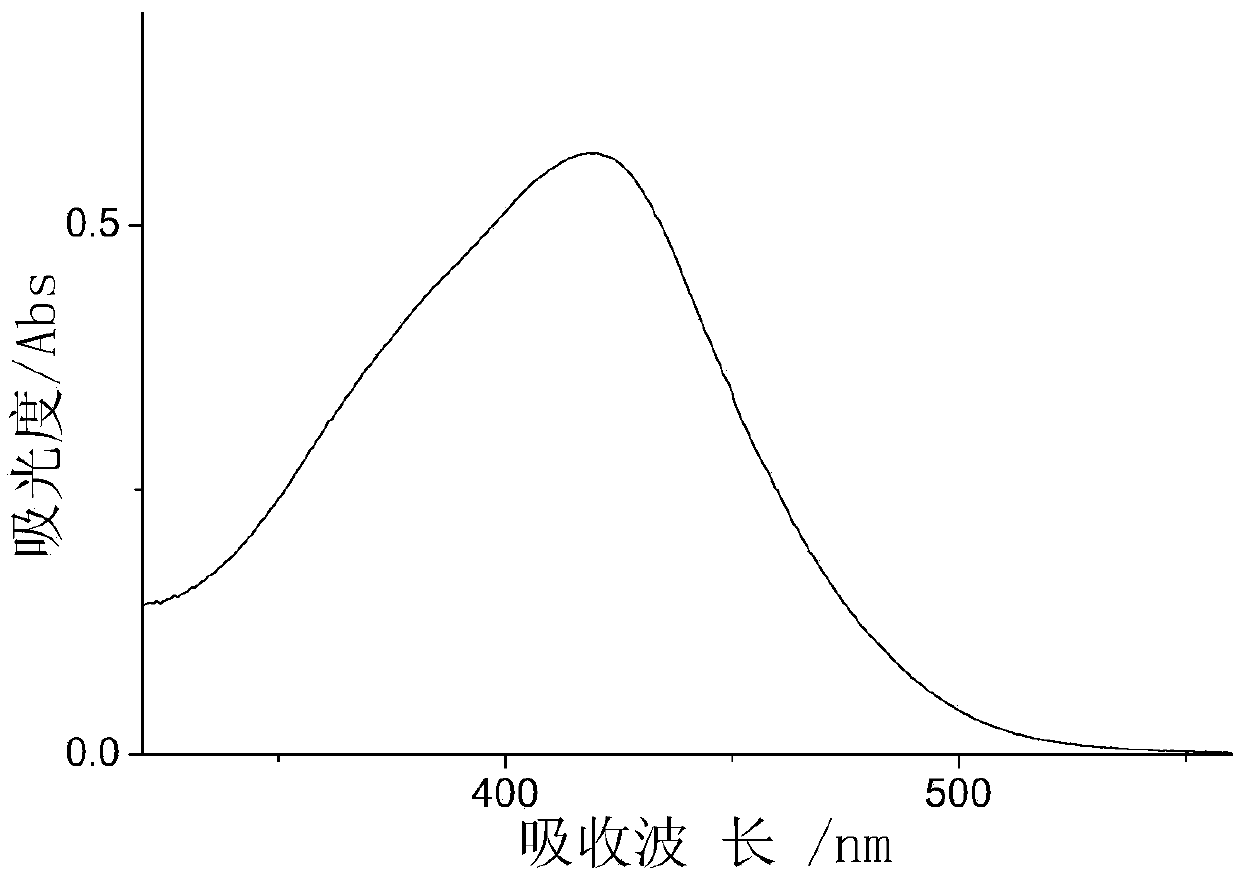

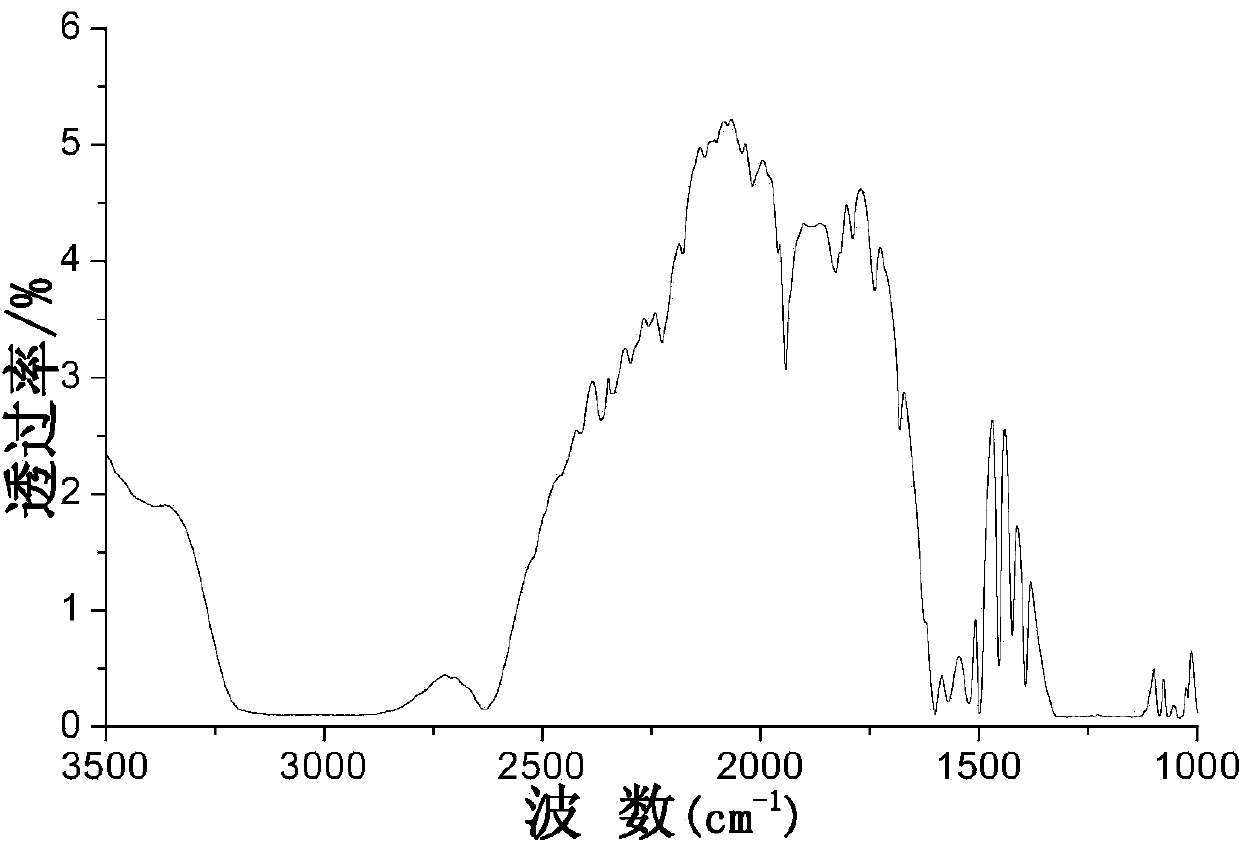

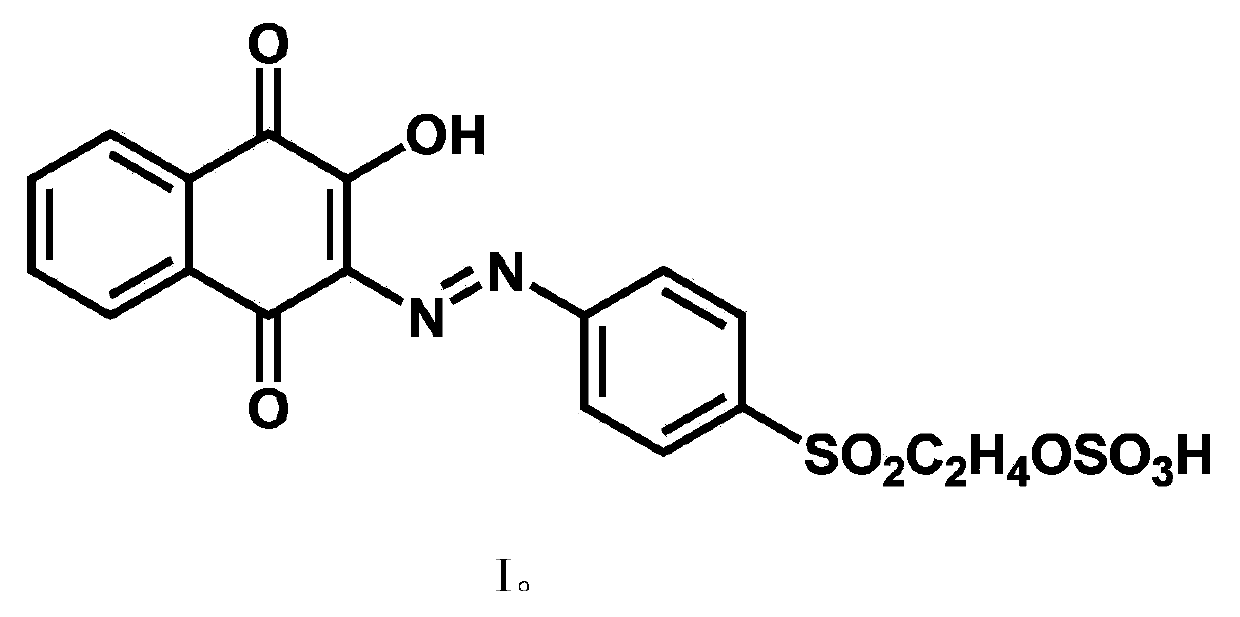

ActiveCN104031408AImprove performanceHigh color fixing rateReactive dyesDyeing processDisperse dyeFine chemical

The invention relates to a naphthaquinone-type brown reactive disperse dye and a preparation method thereof, belonging to the field of dye chemistry in fine chemical engineering. The structure of the dye is disclosed as Formula I. The dye has the advantages of excellent color fastness and excellent light fastness, and can be used for dyeing terylene-cotton blended fabrics.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

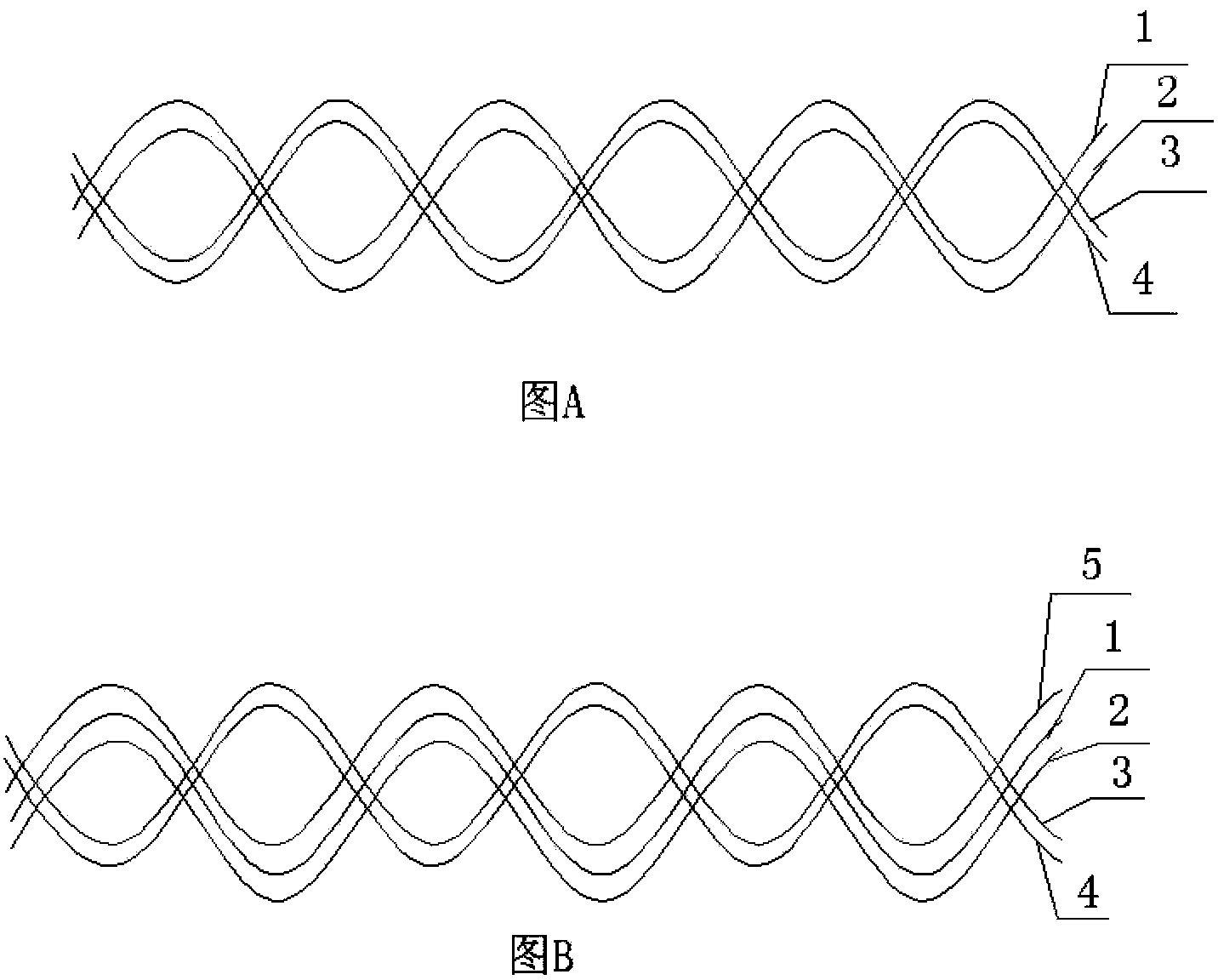

Healthful environmentally friendly negative oxygen ion flame-retardant complex-function jacquard curtain fabric

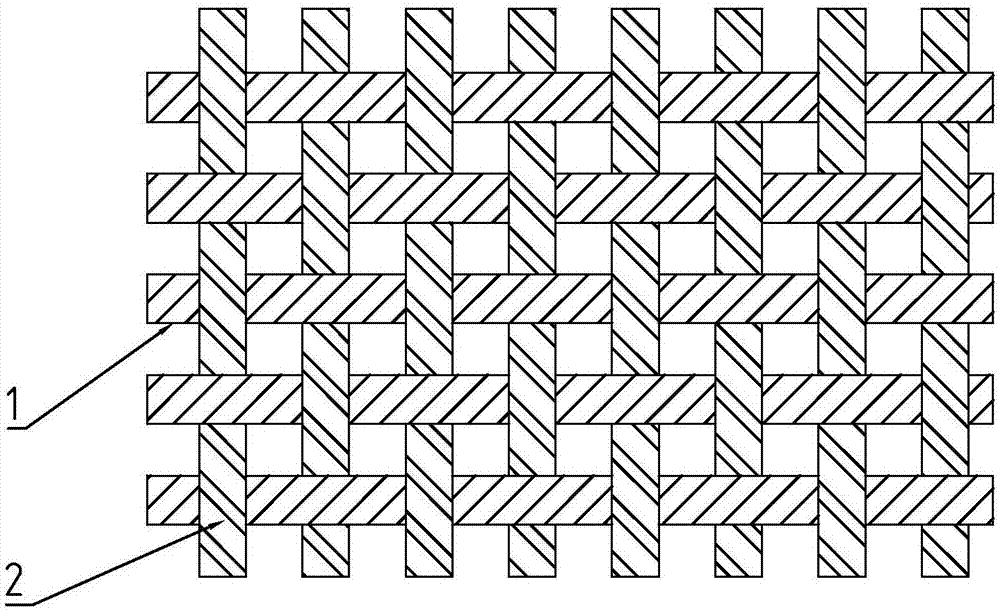

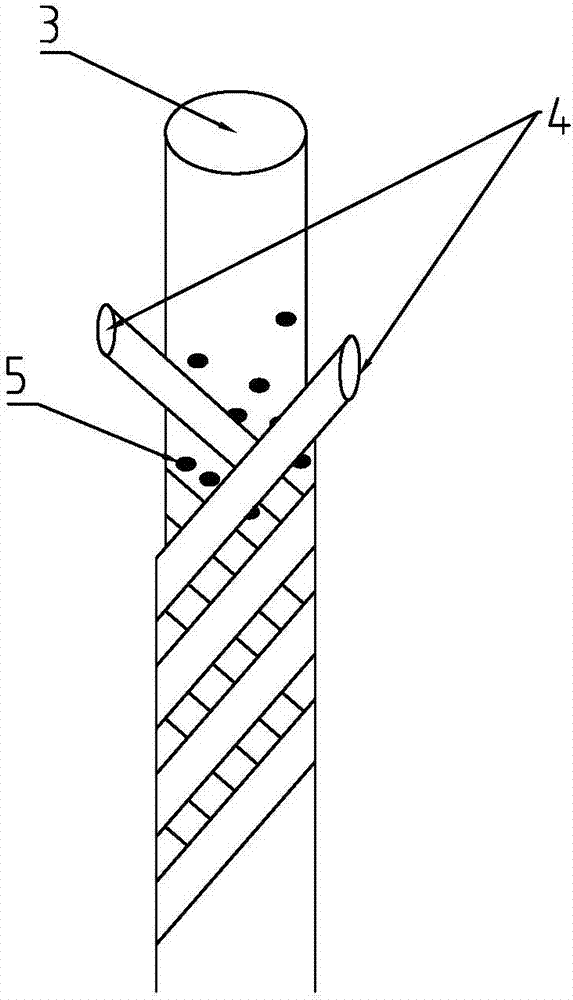

ActiveCN107142596AImprove flame retardant performanceClear textureCurtain accessoriesFlame-proof filament manufactureYarnFiber

The invention provides a wear-resistant and flame-retardant healthful environmentally friendly negative oxygen ion complex-function jacquard curtain fabric with good attractiveness. The flame-retardant healthful environmentally friendly negative oxygen ion complex-function jacquard curtain fabric comprises a base cloth layer, wherein the base cloth layer is formed by flame-retardant polyester fibers used as weft yarns and negative oxygen ion fibers used as warp yarns by jacquard weaving; the flame-retardant polyester fibers comprise polyester fibers and flame-retardant fibers which are spirally wound on the polyester fibers in an intersected manner; and dispersed flame-retardant particles are arranged between the flame-retardant fibers and the polyester fibers. By the flame-retardant healthful environmentally friendly negative oxygen ion complex-function jacquard curtain fabric, the negative ion generating effect is obvious, characteristics of light fastness and wear resistance of the polyester fibers are kept, and meanwhile, the flame retardancy is good. The fabric is clear and elegant in texture, is attractive and elegant, and is dyed colorfully, and the decoration and the functionality are integrated.

Owner:浙江西大门新材料股份有限公司

Blended yarn of acrylic fiber, kapok fiber and cuprammonuium

InactiveCN102851815AIn line with the trend of environmentally friendly clothingBrightly dyedYarnCuprammonium rayonYarn

The invention provides a blended yarn of acrylic fiber, kapok fiber and cuprammonuium, which comprises the components in parts by weight: 45-55 parts of acrylic fiber, 25-35 parts of kapok fiber and 15-25 parts of cuprammonuium. The blended yarn of the acrylic fiber, the kapok fiber and the cuprammonuium is complementary in characteristics and exerts the advantages of the acrylic fiber, the kapok fiber and the cuprammonuium.

Owner:JIANGSU TONGHAI THREAD

Acrylic fiber, ramie fiber and soybean protein fiber blended yarn

The invention provides an acrylic fiber, ramie fiber and soybean protein fiber blended yarn which comprises the following components by weight parts: 55-65 parts of acrylic fibers, 20-30 parts of ramie fibers and 10-20 parts of soybean protein fibers. The blended yarn disclosed by the invention can be sued for complementing the features of the acrylic fibers, the ramie fibers and the soybean protein fibers, and has the advantages of the acrylic fibers, the ramie fibers and the soybean protein fibers.

Owner:JIANGSU TONGHAI THREAD

Moisture-absorbing wear-resistant pilling-resistant flame-retardant fabric

InactiveCN103350546AGood hygroscopicityThin and softPhysical treatmentSynthetic resin layered productsWear resistantMoisture absorption

The invention relates to a moisture-absorbing wear-resistant pilling-resistant flame-retardant fabric and belongs to the field of household textile fabrics. The moisture-absorbing wear-resistant pilling-resistant flame-retardant fabric is a fabric formed by interweaving warp yarns and weft yarns according to the texture, wherein the warp yarns are acrylic yarns, artificial fibers and wool blended yarns; the weft yarns are acrylic yarns, artificial fibers, wool blended yarns and regenerated cellulose fiber blended yarns; the yarn count of the warp yarns is 20-80; the yarn count of the weft yarns is 20-80; the texture is twill, satin weave or rearranged twill texture; and the fabric is a fabric subjected to shrinkage treatment. The fabric has the characteristics of softness of acrylic yarn fabric, fluffy handfeel, bright color and high heat retention property, and also has the characteristics of high pilling resistance and high moisture absorption property.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

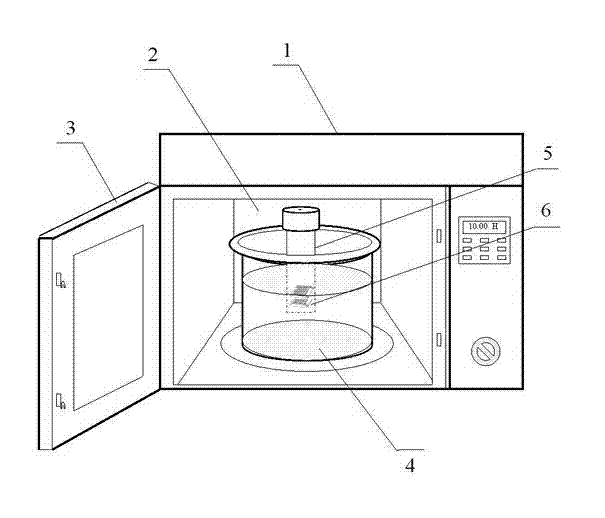

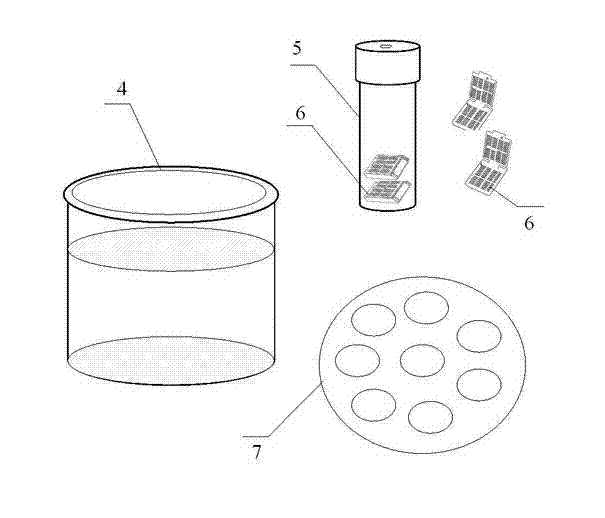

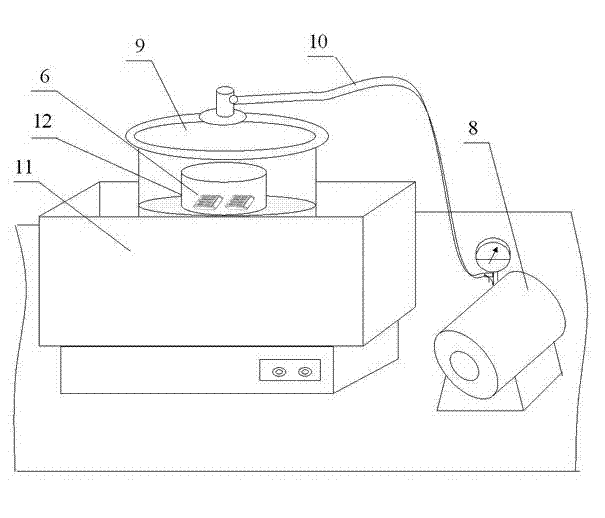

Method for fast flaking paraffin by microwave radiation water bath diathermy and device

InactiveCN102768145AAvoid spillingPrevent evaporationPreparing sample for investigationParaffin waxMedicine

The invention provides a method for fast flaking paraffin for a biological tissue sample and a device. A microwave radiation water bath diathermy is applied to help reagents which are weak in absorbing energy and paraffin be fast heated. The device for fast flaking paraffin is characterized by comprising a microwave radiation water bath diathermy part having the function of fast processing a tissue sample, and a vacuum negative pressure waxing part having the function of fast waxing the tissue sample. The procedure of flaking paraffin comprises the steps of fast tissue fixing, fast tissue dehydration and transparent handling once or twice and fast waxing. The reagents special for flaking paraffin comprises a fast fixing solution, a fast dehydration transparent reagent and a fast decalcification solution. The method and the device have the flexibility of processing tissue samples individually or in batch and the capability of processing different tissue samples simultaneously, and are stable and reliable in the flaking quality, and applied to the fast paraffin flaking and pathologic diagnosis for biological tissue samples for the pathology and inspection in the hospital, scientific research institutes and other organizations.

Owner:CHANGSHA COMBINE MEDICAL TECH

Two-sided bi-color blended yarn weaved fabric

ActiveCN104452040AGood hygroscopicityImprove breathabilityDyeing processWoven fabricsDisperse dyeYarn

The invention discloses two-sided bi-color blended yarn weaved fabric. The fabric is formed by weaving surface filaments and bottom filaments. The surface filaments are 50D / 36F cationic dyed polyester filaments, and the bottom filaments comprise 50D / 36F polyester filaments and polyurethane filaments. The finishing technique of the fabric comprises slitting, shearing, gray cloth pre-sizing, dyeing, lustring, washing, dehydrating and sizing. Two kinds of dye, namely the disperse dye and the activated dye are adopted for dyeing in the dyeing process. The disperse dye is used for dyeing the bottom filaments, and the active dye is used for dyeing the surface filaments. In this way, two colors can be dyed on one piece of cloth, dyed colors are more distinctive, the cloth has hygroscopicity and is static resistant, the comfortable degree of the fabric is improved, and therefore the usage rate and the popularizing rate are increased.

Owner:CHANGSHU OXIYI TEXTILE CO LTD

Canapina-fiber regenerated fiber and ramie-fiber union shell fabric and producing method

The invention discloses a clothing mixed-spinning from flax renewable fiber and ramie fiber and its production method. Its characteristic is adopting the two things as raw materials to spin. The proportion of said flax renewable fiber and ramie fiber is 40 to 90:10 to 60, warp density is 38 to 90item per hour, weft density is 34 to 80 item per hour, and count is 6 second to 32 second, some steps are included as following: making items, spinning silk, warping, starching silk, slashing and textile weaving. The clothing blends advantages of the two. Use the anti-bacterial and hygroscopic of flax fiber to eliminate ramie fiber's flaws of prickle. This method improves the feel and appearance of flax products, overcome all-jute products' rough, hard and easily wrinkling.

Owner:湖南布伊尔竹麻科技有限公司

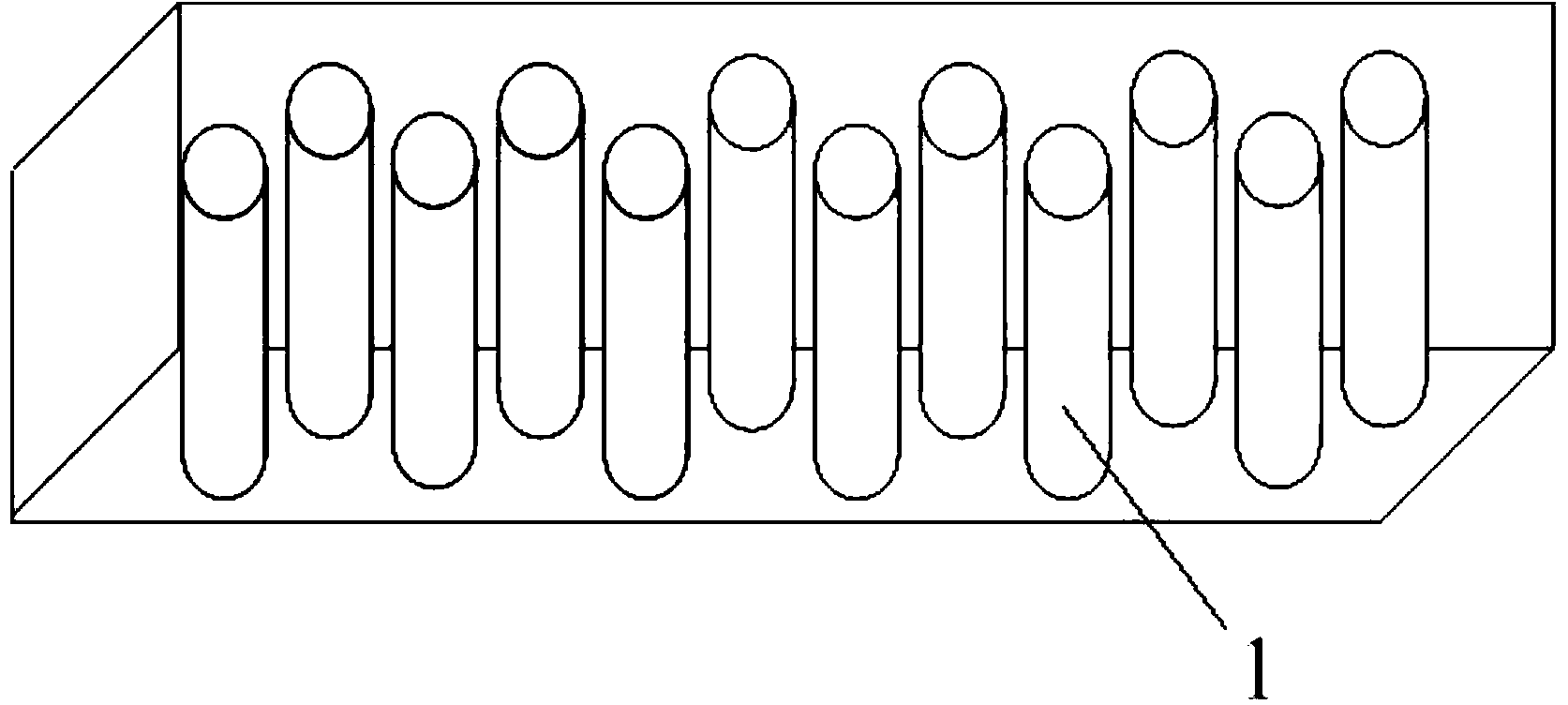

Method for producing bamboo fibre summer sleeping mat

InactiveCN101372112AImprove antibacterial propertiesGood hygroscopicityReed/straw treatmentPulping with inorganic basesFiberRaw material

The invention relates to a preparation method used for a bamboo fiber mat, comprising the procedures as follows: pulp dipping, squeezing, crushing, aging, yellowing, dissolving, filtrating, maturing, deaeration, spinning, solidifying, cutting, post-processing and knitting; compared with the prior art, the method has reasonable process, natural and easily gained raw material; the bamboo fiber mat gained by the method has excellent natural antibacterial performance and wet-absorbing / desorbing performance, is beneficial to protecting the environment, and has the advantages of soft hand-feeling, good suspension performance and bright coloration, and the like at the same time.

Owner:SHANGHAI JIAAN BEDDING

Dyeing and finishing method of fiber fabric containing PLA and PHBV

ActiveCN104499306AUniform dyeingGood shaping effectSucessive textile treatmentsBiochemical fibre treatmentChemistryEnzyme

The invention discloses a dyeing and finishing method of a fiber fabric containing PLA and PHBV. The dyeing and finishing method comprises the following steps: sewing blank cloth; desizing; tentering; drying; shaping; dyeing; and carrying out post-treatment; particularly, desizing, namely putting the blank cloth into a penetrating agent solution with the concentration being 3.5g / L-4.5g / L; padding in an enzyme solution with the enzyme concentration being 0.6g / L-1.2g / L; dyeing, namely by utilizing disperse dyes, controlling the temperature by phases; in the first phase, continually raising the temperature at 35-55 DEG C at the speed of 2-2.5 DEG C / min; in the second phase, continually raising the temperature at 55-85 DEG C at the speed of 1-1.5 DEG C / min, and keeping the temperature for 8-15 minutes after the temperature is raised to 85 DEG C; in the third phase, continually raising the temperature at 85-100 DEG C at the speed of 0.5-1 DEG C / min, and keeping the temperature for 8-15 minutes after the temperature is raised to 100 DEG C; and in the fourth phase, cooling the temperature to 50 DEG C from 100 DEG C at the speed of 1-2 DEG C / min so as to finish the whole dyeing process. The dyeing and finishing method has the advantages of rapidness in coloring, uniform dyeing and uneasiness of de-coloring.

Owner:NINGBO XINDACHANG WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com