Moisture-absorbing wear-resistant pilling-resistant flame-retardant fabric

A flame-retardant fabric and fabric technology, applied in the field of home textile fabrics, can solve the problems of poor wear resistance and moisture absorption, easy pilling, etc., and achieve good flame-retardant effect, thin cloth body, and good moisture absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

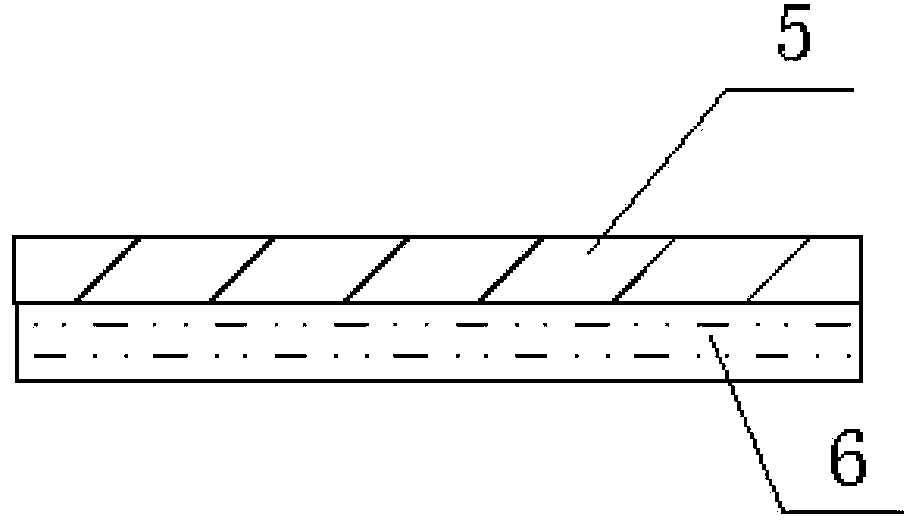

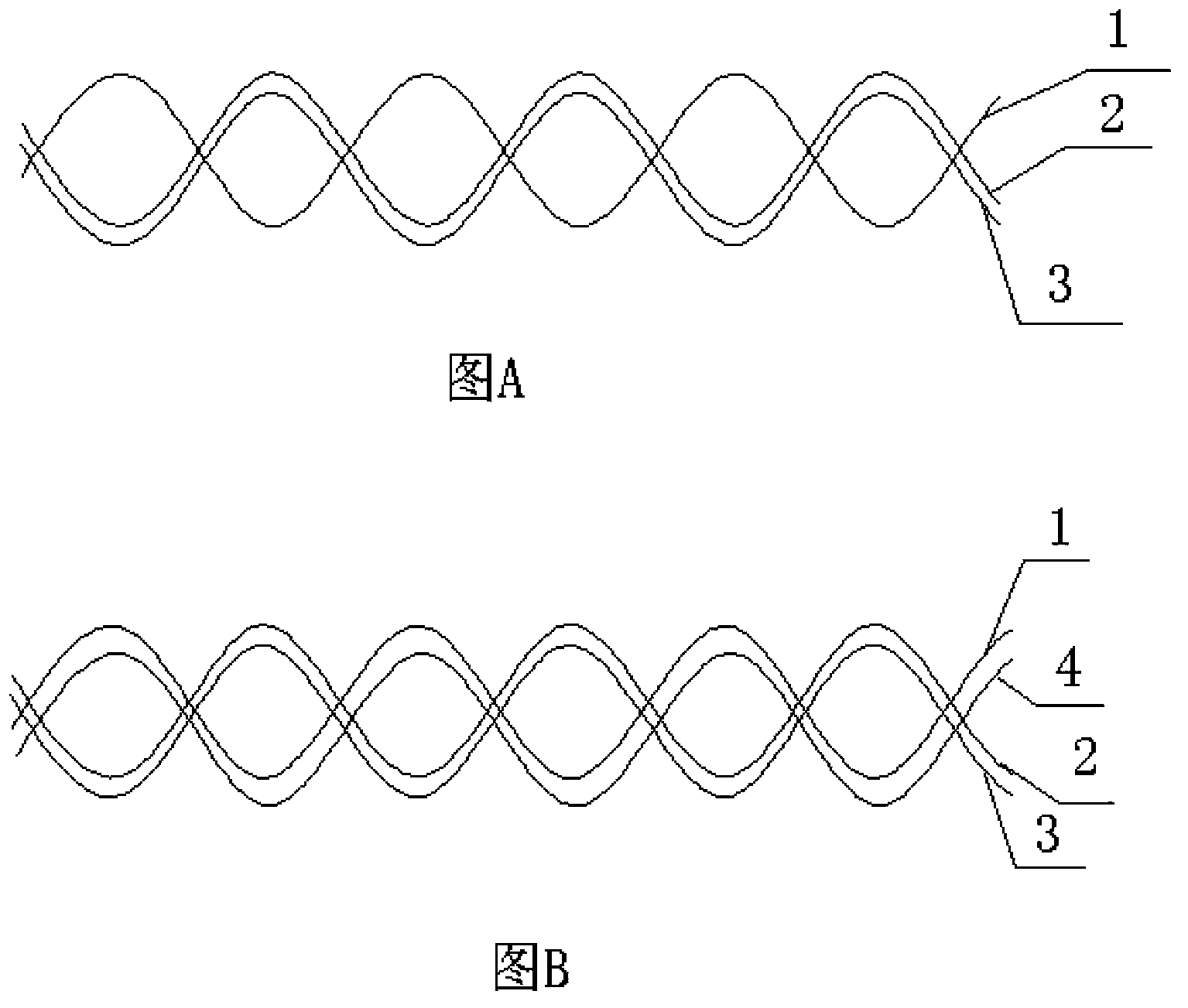

[0014] A kind of moisture-absorbing wear-resisting anti-pilling flame-retardant fabric of this embodiment, such as Figure 1-3 As shown, it includes a flame retardant layer and a fabric surface layer, and the fabric surface layer is pasted on the flame retardant layer; the flame retardant layer is woven from polychloride yarn impregnated with a flame retardant and treated with carbon dioxide laser radiation energy; the The surface layer of the fabric is made of warp yarns and weft yarns interwoven according to the organizational structure. The warp yarns are acrylic yarns, artificial fibers, and wool blended yarns. The winding direction of the man-made fiber is opposite to that of the acrylic fiber yarn and the wool in the warp; The winding direction of the thread and the wool is the same, while the winding direction of the artificial fiber and the regenerated cellulose fiber in the weft yarn is the same, and the winding direction of the artificial fiber and the regenerated ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com