Patents

Literature

145results about How to "Cool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of processing semi-worsted flax blended yarn

The present invention involves a processing method of semi-worsted flax blended yarn, and it belongs to flax blended yarn technical field. The counts of the semi-worsted flax blended yarn is 30-85 Nm / 2D, the raw materials consists of flax 10-60 and other fiber 40-90; degelatinizing, dyeing and preserving flax, pretreating other fiber, then putting together wool, blowing cotton, carding and drawing, then prespinning and shirting, last the products are prepared after cheese winding, twisting and double twisting processes. The invention combines the 'straight' of flax fiber and the 'softness' of other fibers effectively; the prepared semi-worsted flax blended yarn has many advantages of good textile strands and less granulite, it is suitable for the face fabric of thin summer inner wear and coat.

Owner:山东恒泰纺织有限公司

Health-caring botanical drink and preparation method thereof

The invention provides a health-caring botanical drink and a preparation method thereof. The invention selects oil orange, couchgrass root, fresh reed root, orange peel, kudzu-vine root, honeysuckle, fructus momordicae, liquorice, cane sugar and water as the raw material to produce the health-caring drink with scientific and reasonable formulations through use of advanced processing techniques. The invention can quench thirst, relieve summer-heat, cool body and remove pathogenic fire, and promote production of body fluid; the invention has sweet and sour taste with good color and lustre, and is purely botanical drink. The composition of the invention comes from the daily drink of the Dai Nationality, Wa Nationality, LaGu Nationality, BuLang Nationality, HaNi Nationality, Yi Nationality, JingPo Nationality and others and comes out by the modern technique finish machining. With a good social and economic benefit, the invention can carry forward our excellent cooking culture and benefit the whole society.

Owner:王晶

Anti-ultraviolet elastic fabric and production method thereof

InactiveCN101942736ASoft and plumpNon-irritatingFibre treatmentWoven fabricsExtensibilityUltraviolet

The invention discloses an anti-ultraviolet elastic fabric. Warp and weft yarns of the fabric at least comprise one full dull yarn, wherein the weft yarn at least comprises one elastic yarn; and the prepared finished product has weft extensibility of 5 to 30 percent and elastic recovery of over 80 percent, is comfortable to wear and has high size stability. The finished product has transmittance resistance of over 95 percent; the anti-ultraviolet UPF value is over 50; and the fabric has cool feel and a moisture absorption and fast drying function and is an ideal recreational material for autumn and summer.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

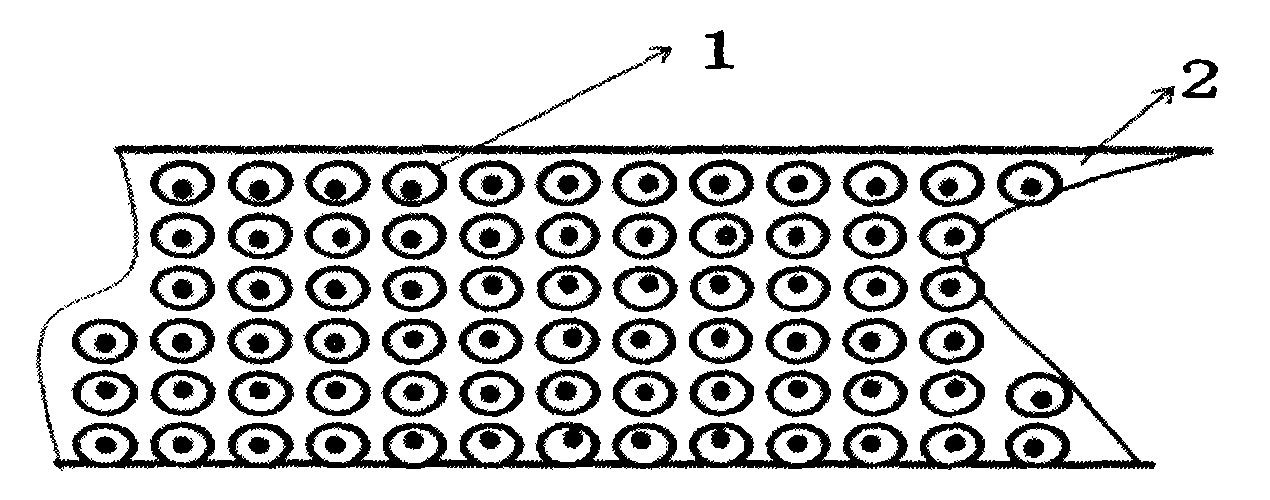

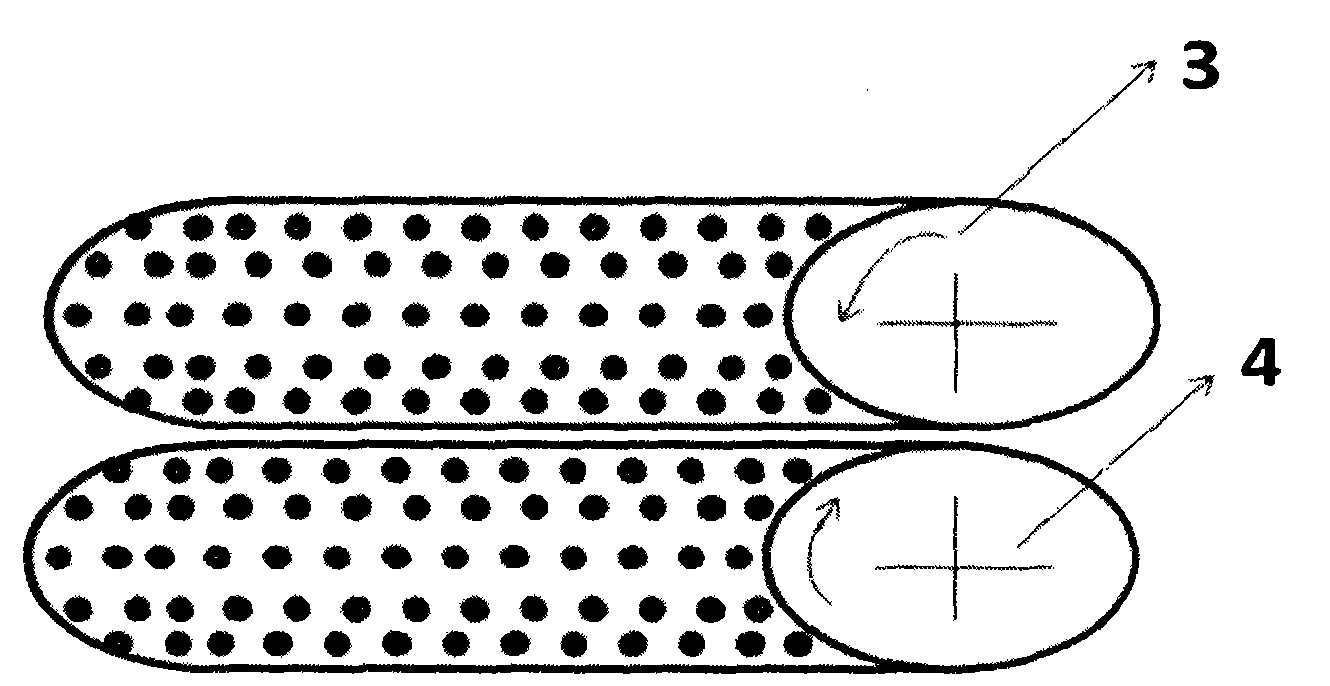

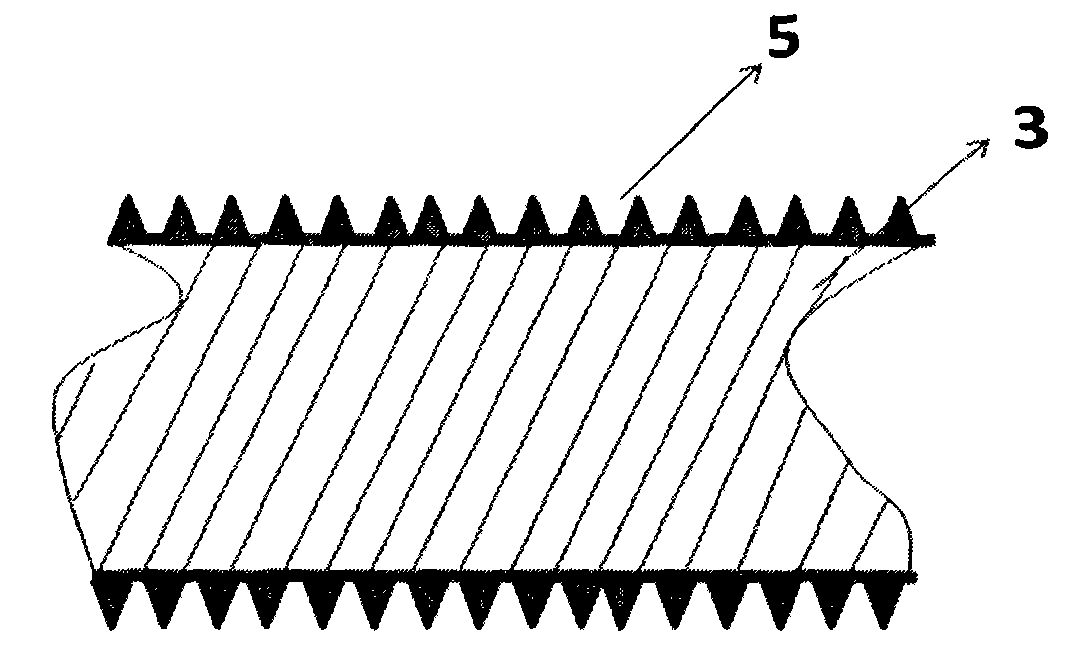

Bubble type flexible non-woven cloth and manufacturing method thereof

The invention discloses a piece of bubble type flexible non-woven cloth and a manufacturing method of the bubble type flexible non-woven cloth. Raw materials, namely, polylactic acid high polymers, are solidified into the cloth through melt spinning net laying and twice hot rolling. Annular nips are formed through the first time of hot rolling, point nips are formed through the second time of hot rolling, and finally the bubble type non-woven cloth is formed. Due to the fact that the nip area is small and the three-dimensional structure is obvious, the non-woven cloth is excellent in flexibility, small in contact area when making contact with the skin, fresh and cool, can not be attached to the human body, enables a user to feel nice and cool, and can be widely applied to disposal medical treatment and public health products such as sanitary towels, paper diapers, adult incontinence trousers, surgical gowns and operation cushions through combination with the advantages of polylactic acid fibers. Meanwhile, the polylactic acid raw materials have the advantages that the polylactic acid raw materials can be completely and naturally circulated and can be decomposed in a biological mode, energy consumption is lowered, and the environment protection role is played.

Owner:HAINING WEITAI BIOTECH CO LTD

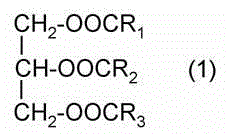

Oil composition, preparation method thereof and foodstuffs

ActiveCN105795000AFast crystallization rateShorten production timeDough treatmentCocoaOil and greaseChemical composition

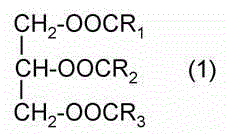

The invention relates to an oil composition, a preparation method thereof and foodstuffs. The oil composition is characterized in that the oil composition comprises triglyceride whose weight is not less than 30% of the total weight as shown in the following general formula (1); in the general formula (1), definitions of R1, R2, and R3 are shown in the specification. The composition does not contain trans-fatty acids, crystallization rate is higher, long time cooling and solidification for shaping at low temperature are not needed, production time is reduced, the composition has a cool mouthfeel without pasty mouthfeel, and the composition melts fast.

Owner:嘉里特种油脂(上海)有限公司

Oral liquid preparation for curing wind-heat type cold and preparation method thereof

InactiveCN102188533AGreat tasteRealize industrializationNervous disorderAntipyreticSolubilityCyclodextrin

The invention discloses an oral liquid preparation (a Chaiyin oral liquid) for curing a wind-heat cold and a preparation method thereof. To overcome the defects of traditional flavoring technologies of the Chaiyin oral liquid, a cyclodextrin complexation technique is employed, and other flavorings are used to carry out a combined taste modification. So the oral liquid preparation with a proper taste is developed, thereby industrialization of traditional Chinese medicine oral liquid preparation production with the applied cyclodextrin complexation technique is realized, the taste of the preparation is improved, the medication compliance of patients is increased, simultaneously water solubility of effective components with low polarity is improved through clathrate formation, and the quality and the stability of the preparation are improved.

Owner:LUNAN HOPE PHARM CO LTD

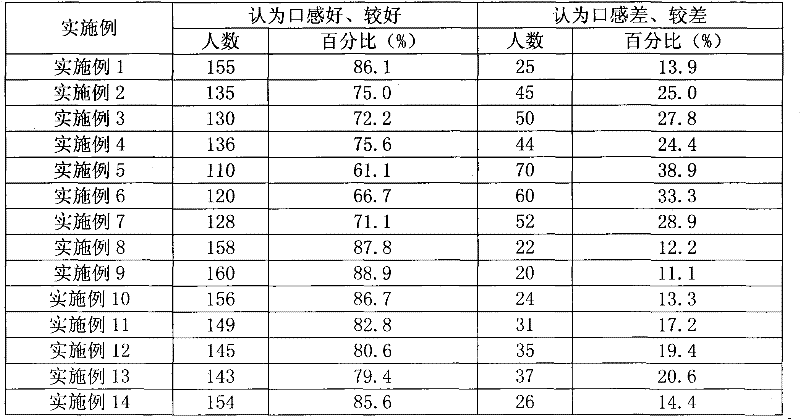

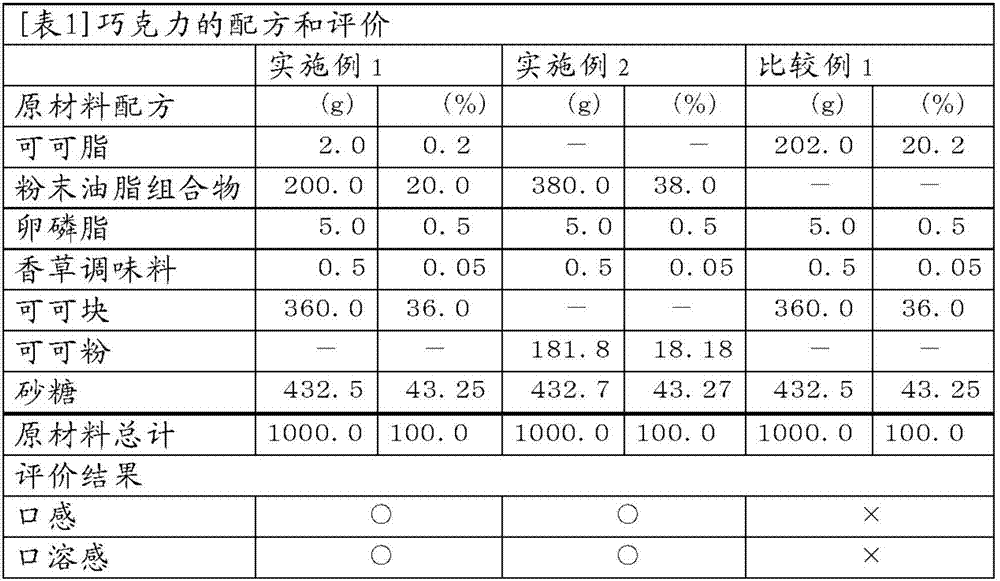

Powdered fat composition for chocolate

ActiveCN107404893AEasy to manufactureSoft tasteFatty acid esterificationFatty-oils/fats/waxes solidificationCarbon numberFatty acid

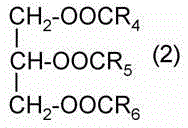

An objective of the present invention is to provide a powdered fat composition for chocolate that can impact a pleasant melt-in-the-mouth sensation and light mouthfeel similar to aerated chocolate without using a specialized device and merely by being cooled and set. The present invention is a powered fat composition for chocolate, the composition containing a powder-form fat composition that satisfies the following condition (a). (a) A fat composition that contains, with respect to 100 mass% of the total triglyceride content, 65 to 99 mass% of a XXX triglyceride having fatty acid residues X having a carbon number x at positions 1 to 3, and 35 to 1 mass% of at least one type of a X2Y triglyceride in which one fatty acid residue X of the XXX triglyceride has been replaced with a fatty acid residue Y having a carbon number y, the carbon number x being an integer selected from 8 to 20, and each carbon number y being independent, being an integer selected from x+2 to x+12, and satisfying y<=22.

Owner:THE NISSHIN OILLIO GRP LTD

Lotus leaf tea beverage and preparing method thereof

ActiveCN101228912AImprove extraction efficiencyImprove work efficiencyPre-extraction tea treatmentFood preparationVitamin CUltrasonic vibration

The invention relates to a lotus leaf tea beverage and a preparation method thereof, which comprises the following raw materials: lotus leaf, white sugar, Vitamin C, honey and water. The preparation method comprises the following steps: dipping fresh or dried lotus leaves in the water, grinding the lotus leaves into powder in a cooling mill after cleaning and water controlling, hot water extracting and filtrating the lotus leaf powder with ultrasonic vibration to acquire the supernatant of lotus leaf juice, adding white sugar, Vitamin C, honey and the rest water into the supernatant of lotus leaf juice and stir mixing, filtrating, sterilizing, heat exchanging, heat insulating and aseptic hot-filling to acquire finished products, the lotus leaf tea beverage. The product of the invention has the advantages of light yellow or brownish yellow color, elegant faint scent of lotus leaves, sweetish delicious flavor, cooling feeling and having refreshing and consciousness-restoring function to human body.

Owner:华敬士

Acer truncatum oil skincare cream and preparation method thereof

InactiveCN103083213AAnti-freckle and antisepticNourishingCosmetic preparationsToilet preparationsSide effectPeppermints

The invention relates to acer truncatum oil skincare cream and a preparation method thereof, which belong to the technical field of cosmetics. The acer truncatum oil skincare cream is prepared from the following raw materials in parts by weight: 450-650 parts of acer truncatum oil, 40-60 parts of astragalus mongholicus, 35-55 parts of kakorot, 10-30 parts of angelica root, 15-35 parts of peach blossom, 35-55 parts of peppermint leaves, 30-50 parts of albolene and 400-600 parts of distilled water. The acer truncatum oil skincare cream has the beneficial effects that a plurality of plants are subjected to scientific compatibility so as to achieve synergistic effects, has the functions of freckle removing, sterilization, nourishment, beautifying, skin care, moisture preservation and cooling, has remarkable effects, is safe and reliable, has no toxic and side effect and is applicable to long-term use.

Owner:昆明海之灵生物科技开发有限公司

Mask for repairing skin burnt by ultraviolet rays and preparation method thereof

InactiveCN104983648AQuick emergency responsePromote regenerationCosmetic preparationsToilet preparationsGlycerolUltraviolet

The invention discloses a mask for repairing the skin burnt by ultraviolet rays. The mask is prepared by steeping mask paper into liquid prepared by, by weight, the following raw materials of 0.1-3 parts of micromolecular hyaluronic acid, 0.1-2.5 parts of macromolecular hyaluronic acid, 0.7-30 parts of synthesized egg white powder, 1-7 parts of aloe extract, 0.7-9 parts of propylene glycol, 5-50 parts of 1,2-butanediol, 5-30 parts of glycerol, 20-80 parts of fructus kochiae extracting solutions, 20-80 parts of cortex mori radicis extracting solutions, 20-80 parts of witch hazel extracting solutions, 10-50 parts of water-soluble mint, 20-80 parts of honeysuckle extract, 0.5-5 parts of silk peptide, 0.5-5 parts of carnosine, 0.5-5 parts of collagen peptide, 20-70 parts of biological polysaccharide gum-1 and 1000 parts of water. The mask for repairing the skin burnt by the ultraviolet rays has the effects of calming, cooling and diminishing inflammation, moisture and nutrition are quickly supplemented, skin regeneration is promoted, skin whitening is enhanced, and the sequelae, such as inflammation generating, scar generating and skin darkening, of the skin being burnt by the ultraviolet rays can be prevented.

Owner:GUILIN HONGXU BIOTECH CO LTD

Mosquito repellent water containing green pepper extracts and preparation method of mosquito repellent water

InactiveCN105997675AAvoid bitesReconcile the smellAntibacterial agentsCosmetic preparationsGreen pepperConsciousness

The invention provides mosquito repellent water containing green pepper extracts and a preparation method of the mosquito repellent water. The mosquito repellent water is prepared from components in percentage by weight as follows: 1%-5% of plant extract, 40%-75% of ethanol and the balance of deionized water, wherein the plant extract is prepared from raw materials in parts by weight as follows: 25-40 parts of green pepper, 10-20 parts of lavender, 10-20 part of roses, 5-15 parts of wrinkled gianthyssop herbs and 5-15 parts of mint with a method shown as follows: the raw materials are mixed, cleaned, drained, dried and crushed, the crushed powder is added to the deionized water in a material-water ratio and extracted with a microwave-assisted extraction technology, an extracting solution is filtered, and filtrate is the plant extract. The mosquito repellent water has the mosquito repellent effect and further has the efficacy of refreshing, restoring consciousness, cooling, relieving itching, inhibiting and killing bacteria, protecting skin against bite by insects and the like; besides, raw materials of the product are from plants, and the mosquito repellent water is safe, non-toxic and applicable to various crowds and various skin.

Owner:NANJING INST FOR THE COMPREHENSIVE UTILIZATION OF WILD PLANTS CHINA COOP

Floral water for children

InactiveCN102988233ALow alcohol contentCoolCosmetic preparationsToilet preparationsAlcohol contentMedicine

The invention discloses floral water for children. The floral water comprises the following components in percentage by weight: 0.1-1 percent of methyl parahydroxybenzoats, 1.5-4 percent of dimethyl phthalate, 3-5 percent of mint oil, 10-20 percent of wormwood leaf extract, 1-5 percent of medical ethanol and the balance of water. The floral water for children is low in alcohol content, has the effects of cooling and refreshing, relieving itching and repelling mosquitoes, and is nonirritant to the skin of the children.

Owner:顾月燕

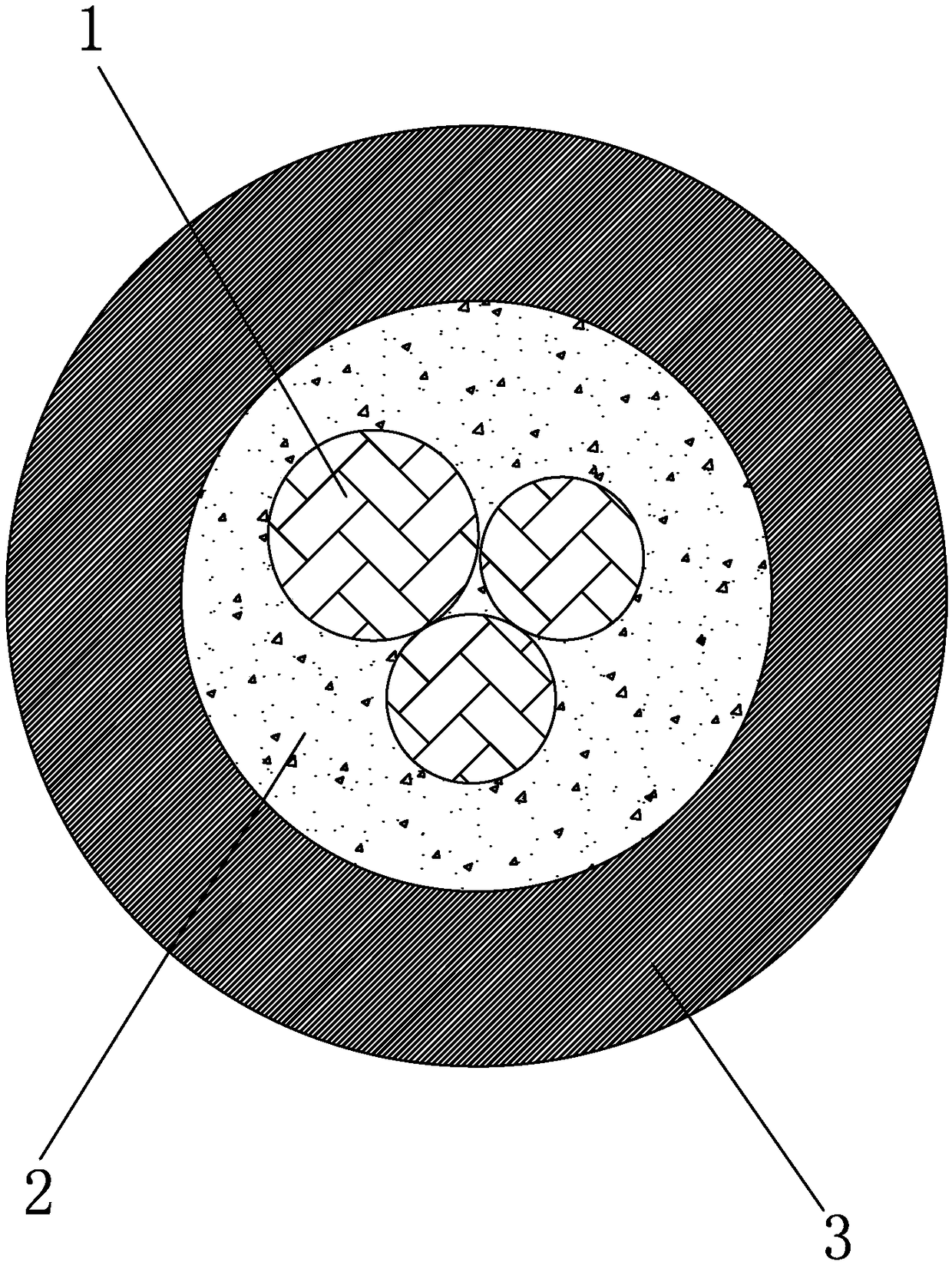

Nano antibacterial vortex spinning yarns and production technology thereof

InactiveCN108442005ASoft textureImprove comfortContinuous wound-up machinesOpen-end spinning machinesEngineeringAbnormal shaped

The invention discloses nano antibacterial vortex spinning yarns and a production technology thereof. Each nano antibacterial vortex spinning yarn comprises a yarn body, wherein the yarn body is of acore spun yarn structure and comprises core yarns and wrapping yarns; the wrapping yarns are wrapped outside the core yarns; the core yarns comprise irregular-cross-section polyester filaments, and tencil fibers and silver fibers which are located outside the irregular-cross-section polyester filaments; the surfaces of the irregular-cross-section polyester filaments are coated with a nano titaniumdioxide photocatalyst; the wrapping yarns are prepared from natural plant fibers formed by mixing soybean protein fibers and bamboo fibers. The nano antibacterial vortex spinning yarns disclosed by the invention have a soft texture, do not easily balling up and have good skin-friendly performance and air permeability; the irregular-cross-section polyester filaments are adopted and the wet permeability is good; the nano titanium dioxide photocatalyst and the silver fibers are matched so that the antibacterial performance is good; the soybean protein fibers and the bamboo fibers are provided with irregular grooves in the longitudinal direction and are matched with the irregular-cross-section polyester filaments to form a heat-dissipation and wet-conduction groove with a stereoscopic structure, so that bacterium breeding can be avoided.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

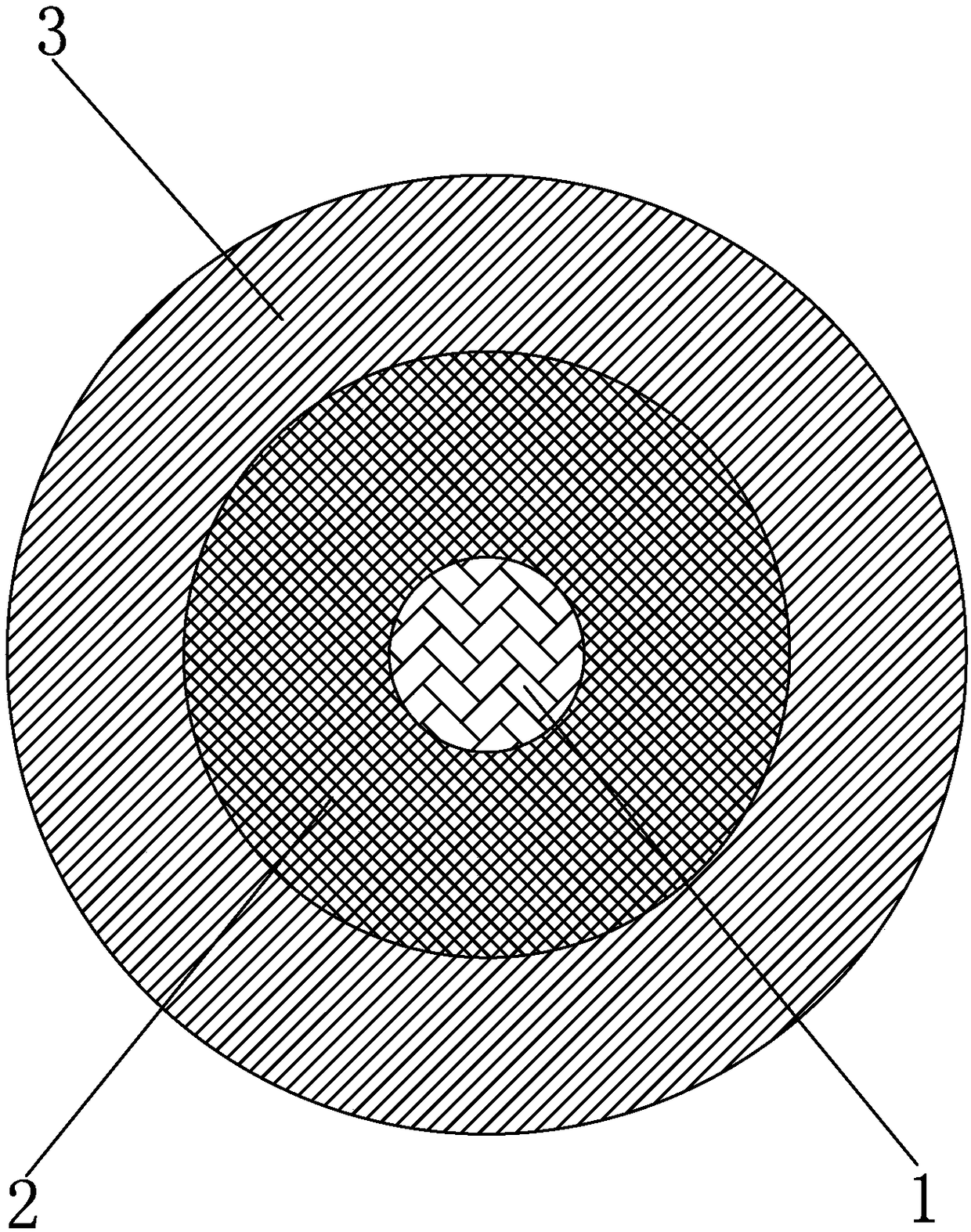

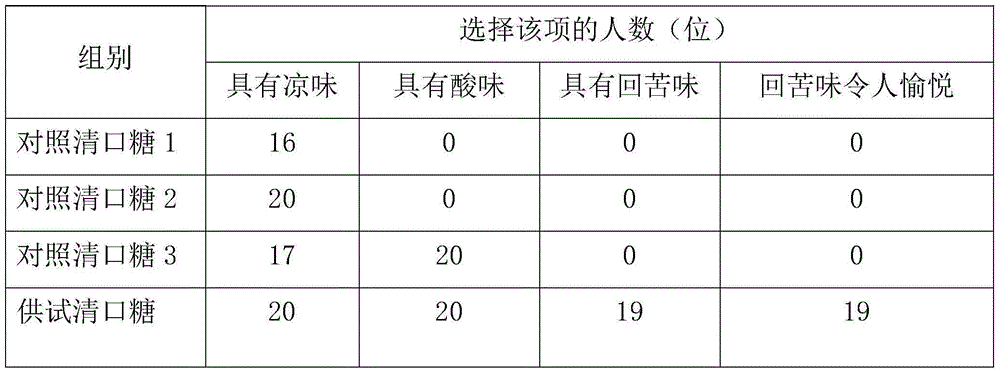

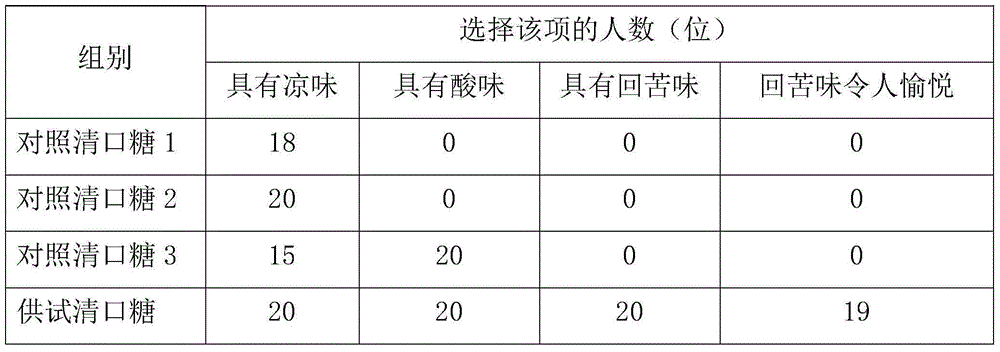

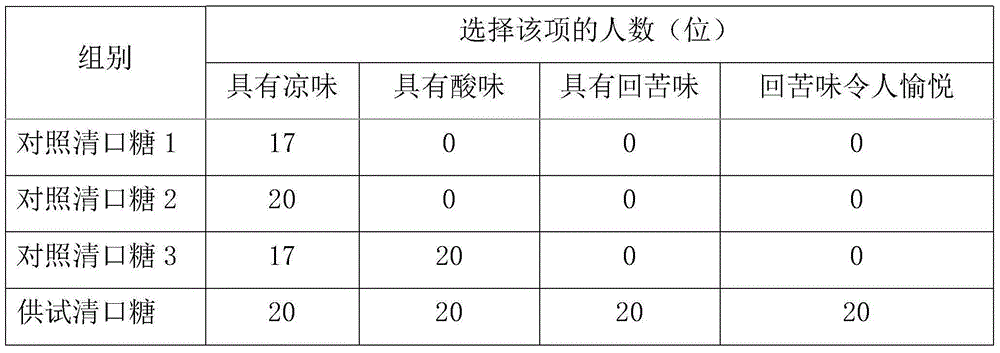

Sugar-free oral cleaning candy with rebitter taste and preparation method thereof

The invention relates to sugar-free oral cleaning candy with the rebitter taste. The oral cleaning candy is prepared from 70-80 parts of sorbitol, 10-20 parts of isomaltitol, 0.1-0.6 part of sucralose, 4 parts of citric acid, 0.1-2 parts of edible essence, 0.1 part of menthol and 0.5-1.0 part of magnesium stearat. The oral cleaning candy is cool and refreshing in mouthfeel and unique in flavor, and tooth decay, fat and hyperglycemia are not prone to being caused. The invention further relates to a preparation method of the sugar-free oral cleaning candy with the rebitter taste; the preparation method comprises the steps of hot melting, smashing, tabletting and the like. The method is simple and easy to operate, and the prepared product is stable in quality and easy to carry and eat.

Owner:苏州工业园区尚融科技有限公司

Recovery essential oil for sensitive skin and preparation method of same

ActiveCN107281040AGood chemical stabilityEasy to useCosmetic preparationsToilet preparationsHelichrysum italicum flowerRosmarinus

The invention discloses recovery essential oil for sensitive skin and a preparation method of same. The recovery essential oil is prepared from, by mass, 50-65% of macadimia nut oil, 15-20% of squalane, 2-5% of phytosterol, 2-6% of wheat germ oil, 5-10% of chamomile essential oil, 2-5% of helichrysum italicum essential oil, 1-2% of rosemary leaf oil, 0.2-0.5% of opopanax oil, 1-2% of vitamin E, and 0.2-0.5% of blue chamomile. All the essential oil components in the invention are pure plant-sourced products, so that the recovery essential oil is safe and green and has good permeability, can moisten skin, effectively alleviates various discomforts due to sensitive skin and reduces skin allergic symptoms, such as red rash on facial skin, itching, stabbing pain, dull skin and the like. The essential oil has the refreshing smell of blue chamomile and can heal skin from interior to exterior.

Owner:广州科缇生物科技有限公司

Multifunctional air vortex spinning yarn

The invention discloses a multifunctional air vortex spinning yarn which comprises a core yarn, a middle yarn and a covering yarn, wherein the core yarn is formed by twisting and combination of firstyarn bundles, second yarn bundles and third yarn bundles; the first yarn bundles are carbon fiber filaments; the second yarn bundles are nylon fiber filaments; the third yarn bundles are polyester fiber filaments; the middle yarn is aramid fiber short fiber; the core yarn is located in the middle yarn; the covering yarn is a fire retardant fiber layer; and the covering yarn is spirally wound and wrapped outside the middle yarn. The multifunctional air vortex spinning yarn is reasonable in structure, the core yarn and the middle yarn enter from a vortex spinning core tube, the covering yarn enters from a vortex spinning outer tube, and the produced multifunctional air vortex spinning yarn is less in hairs and does not pill; because the middle yarn in aramid fiber short fiber, the core yarnis uniform in stress, good in structure strength, and uneasy to fracture, and can be used as high-strength yarn; the covering yarn adopts combination of flame-retardant acrylic fiber and tencel fiber,has good flame retardant performance, and is smooth in surface, comfortable in wearing good in wear resistant property, and easy to wash, can dry fast, and has a cold feeling.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

Preparation method of floral water for children

InactiveCN103830131ALow alcohol contentWith mosquito repellentCosmetic preparationsToilet preparationsAlcoholSterile water

The invention discloses a preparation method of floral water for children, which comprises the following steps: (1) adding 0.1-1% of methyl parahydroxybenzoats and 10-20% of folium artemisiae argyi extract into appropriate sterile water, and stirring until a clear solution is obtained; (2) adding 1.5-4% of dimethyl phthalate and 3-5% of mint oil into 1-5% of medical ethanol, and mixing uniformly; (3) mixing the mixtures of the steps (1) and (2), adding water to 100%, and stirring uniformly to obtain a finished product. By adopting the method disclosed by the invention, the prepared floral water for children contains a small amount of alcohol, has the functions of cooling, itching reliving and mosquito repellence, and is non-irritant to the skin of children.

Owner:顾月燕

Pear syrup brown sugar candy and production method thereof

The invention discloses a production method of pear syrup brown sugar candy, comprising the following steps: 1) mixing brown sugar, Isomaltulose alcohol with water and then heating and stirring, or mixing brown sugar, white sugar, Isomaltulose alcohol with water and then heating and stirring to gain syrup; 2) adding concentrated pear juice into the syrup and then heating and stirring to gain pear juice syrup; 3) drying treatment of the pear juice syrup in vacuum to gain dewatering syrup; 4) evenly adding into the dewatering syrup into mixture consisting of atomized menthol and eucalyptus oil to gain mixed syrup; 5) pouring the mixed syrup into a mould for shaping. The invention also simultaneously discloses a pear syrup brown sugar candy gained according to the method. The pear syrup brown sugar candy of the invention has the efficacy of moistening the lung and throat and relieving cough, etc.

Owner:ZHEJIANG UNIV

Preparation method of coated fruit juice jelly

The invention discloses a preparation method of a coated fruit juice jelly. A crispy sugar coating with a certain thickness is added on the outer surface of a fruit juice jelly in the manner of polishing, therefore people feel cool and refreshed after eating the fruit juice jelly; and a mouth feel of crisp outside and soft inside provides people with a special characteristic of chewing, thereby enriching the eating interest of fondants. Meanwhile, the hardness and the toughness of the fruit juice jelly are improved with the method, thereby offering users a brand new experience of eating the fondants and making the product applicable to more children.

Owner:江门澳崎高质食品有限公司

Preparation method for mint tea

The invention discloses a preparation method for mint tea. The mint tea employs mint leaf as a raw material, and is prepared by performing fresh leaf picking, withering, cell disruption, fermentation, baking frying, shaping, drying and the like. The mint tea does not contain caffeine, and brewed tea is fragrant and mellow in mouthfeel and rich and bright in soup color, the tea contains a large amount of flavonoids. The mint tea has the health-care efficacy of inhibiting platelet aggregation, preventing thrombus, preventing atherosclerotic, directly inhibiting generation of free radical, preventing ageing, resisting cancers, preventing radiation, resisting allergy and the like.

Owner:丁春英

Pharmaceutical composition for treating dermatitis and eczema and preparation method thereof

InactiveCN102379878AAntibacterial and analgesicCoolHydroxy compound active ingredientsAerosol deliveryEmulsionCurative effect

The invention discloses a pharmaceutical composition for treating dermatitis and eczema, which comprises fluocinolone acetonide, borneol, and a emulsion base. The advantage of the invention is that borneol is used in the medicament, which has antibiotic and pain-relieving effect, and has cool and refreshing feeling that makes patient feel comfortable. The pharmaceutical composition of the invention has a simple process, is convenient for preparation and application, has significant curative effect, is not easy to cause recurrence, can moisten skin, and is applicable to dermatitis, eczema, psoriasis, non-specific pruritus ani and reproductive organ pruritus.

Owner:JILIN AODONG GROUP DALIAN PHARMACEUTICAL CO LTD

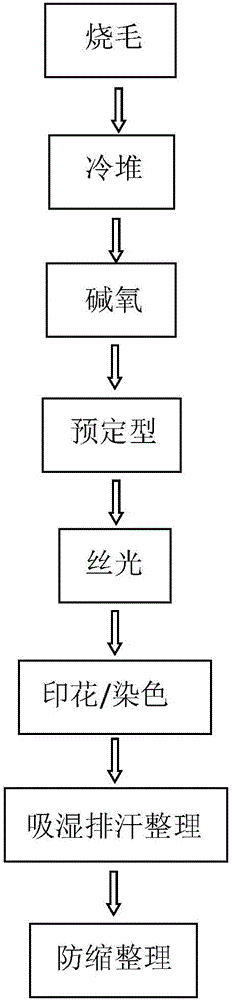

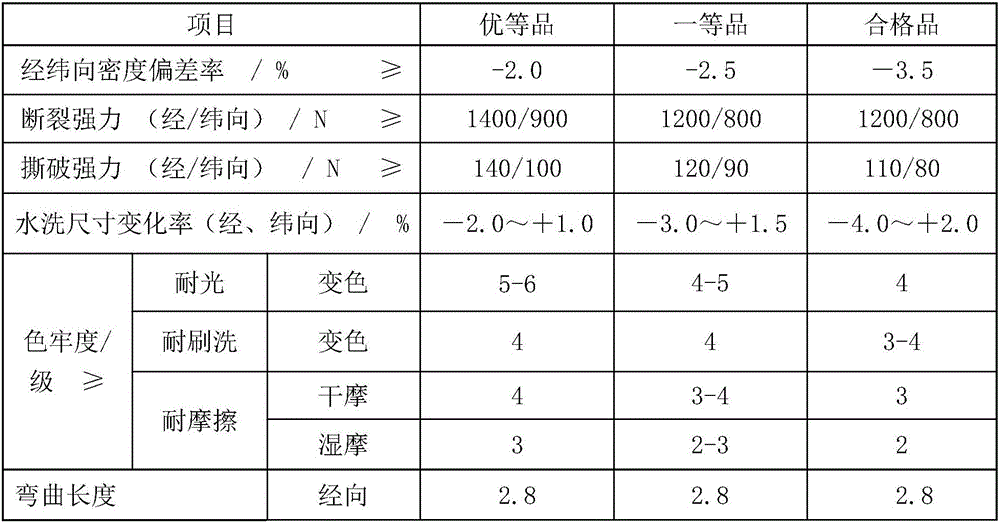

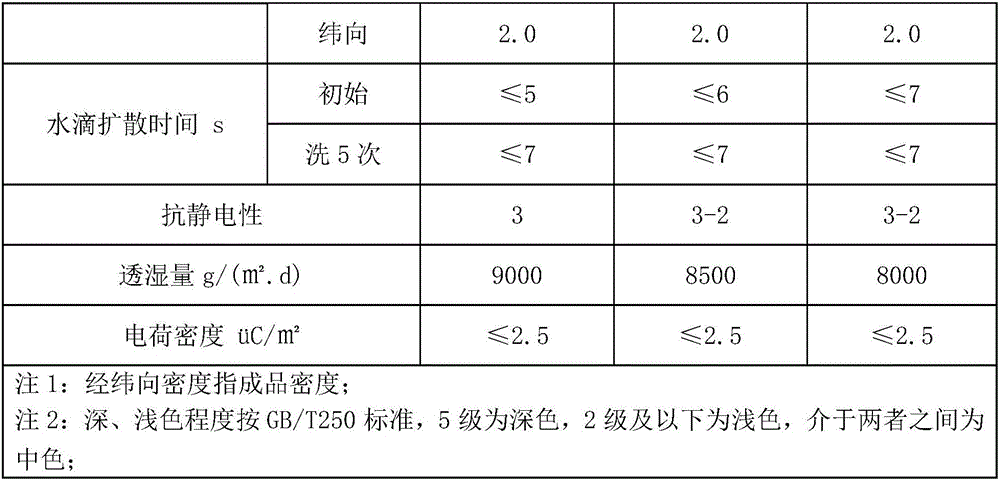

Production method for high-strength anti-static nylon dyeing cloth with moisture absorbing and sweat releasing functions

InactiveCN106283308AEasy to takeWith durable antistaticMercerising of indefinite length fabricsSingeingHeat resistanceMoisture absorption

The invention discloses a production method for high-strength anti-static nylon dyeing cloth with moisture absorbing and sweat releasing functions, and belongs to the technical field of dyeing. The production process includes singeing, cold batching, alkali-oxygen bathing, pre-shaping, mercerizing, printing / dyeing, moisture absorption and sweat release finishing, anti-shrinking finishing and finished product forming. The production method has the advantages that basic fabric is obtained through special processing of nylon and long-stapled cotton, and through functional dyeing and finishing, the nylon dyeing cloth has the characteristics of the nylon, such as high strength, high wear resistance, high heat resistance and high corrosion resistance, and also has thin cotton and long length as the long-stapled cotton as well as multiple functions such as moisture absorption, air permeation, comforting and heat dissipation.

Owner:SUNTEX

Cosmetic composition with cool and refreshing use feeling, and preparation method thereof

InactiveCN107753314AMild and non-irritating to the eyesCoolCosmetic preparationsToilet preparationsChemistrySkin temperature

The invention discloses a cosmetic composition with cool and refreshing use feeling. The cosmetic composition is characterized by comprising the following components in parts by weight: 5 to 25 partsof volatile oil, 0.1 to 1.5 parts of acrylic acid (ester) copolymer sodium and 0.1 to 0.5 part of lecithin. The cosmetic composition, which is prepared by adding the volatile oil with specific contentand specific variety into the formula of the cosmetic composition, has high demulsification speed during coating on the basis of guaranteeing the emulsification stability of the product, takes away part of skin temperature through volatilization of the water and the volatile oil, enables the skin to have certain cool feeling, does not influence the odor of the product and is mild and non-irritantto skin, particularly eyes, during use.

Owner:HUAANTANG BIOTECH GRP CO LTD

Preparation process of agaricus bisporus functional beverage

InactiveCN104824769AThe preparation method is scientific and reasonableShort processFood preparationBiotechnologyEngineering

The present invention discloses a preparation process of an agaricus bisporus functional beverage. The preparation process specifically comprises the following steps: agaricus bisporus cleaning; color protecting; pre-cooking; cutting and pulping; primarily sterilizing; cooling; inoculating and fermenting; mixing; homogenizing; secondarily sterilizing; and canning. The preparation process disclosed by the present invention is scientific and reasonable, and is short in flow and easy for quality control, and the produced agaricus bisporus functional beverage is good in quality.

Owner:吴中区胥口精益生物医药研究所

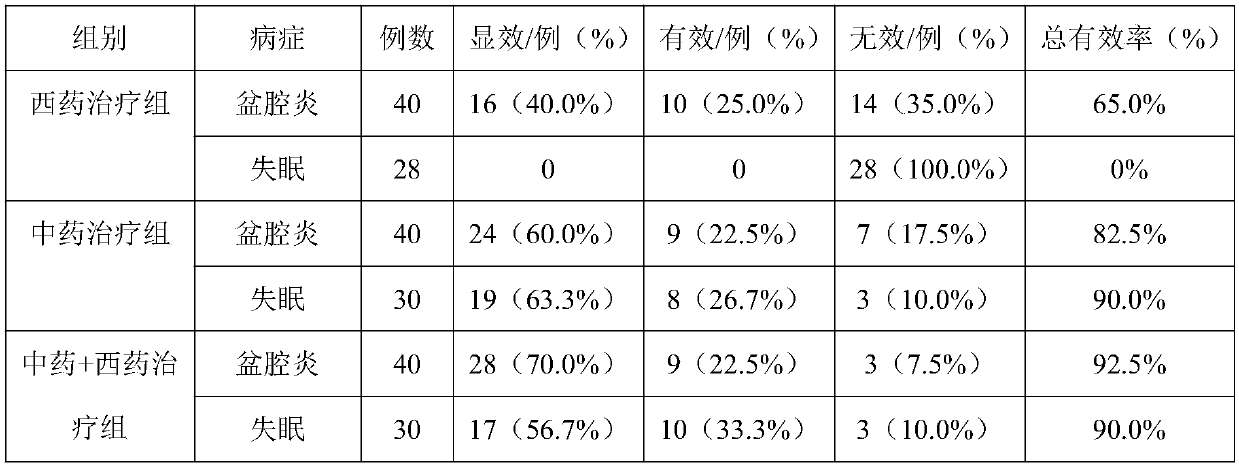

Traditional Chinese medicine composition for treating chronic pelvic inflammation, and preparation method thereof

ActiveCN107753800AImprove fatigueImprove restlessnessSexual disorderPlant ingredientsWestern medicineSide effect

The invention discloses a traditional Chinese medicine composition for treating chronic pelvic inflammation, and a preparation method thereof. The traditional Chinese medicine composition comprises the following raw materials in parts by weight: 6-9 parts of herba taraxaci, 5-7 parts of fructus gardeniae, 4-6 parts of flos lonicerae, 3-5 parts of mesona chinensis benth., 3-5 parts of semen coicis,and 1-3 parts of radix glycyrrhizae. The traditional Chinese medicine composition has the efficacies of clearing away heat and detoxifying, removing blood stasis and eliminating stagnation, not onlycan be used for treating chronic pelvic inflammation, but also can be combined with western medicines for use, the efficacies are enhanced, the toxic and side effects of the western medicines can be reduced, and the syndromes of susceptible fatigue, insomnia, vexation, impatience and the like can be improved.

Owner:湖南知达医药科技有限公司

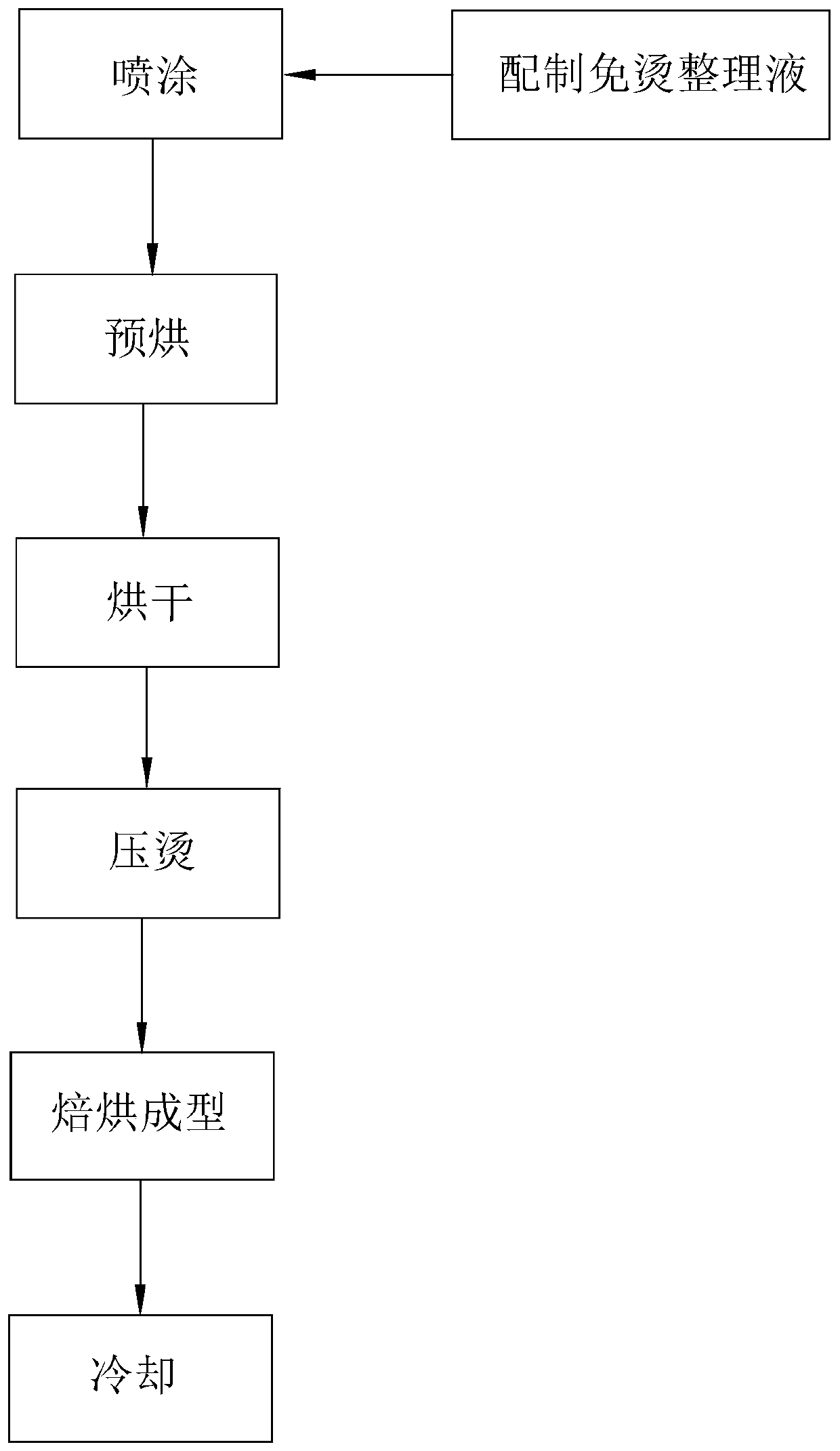

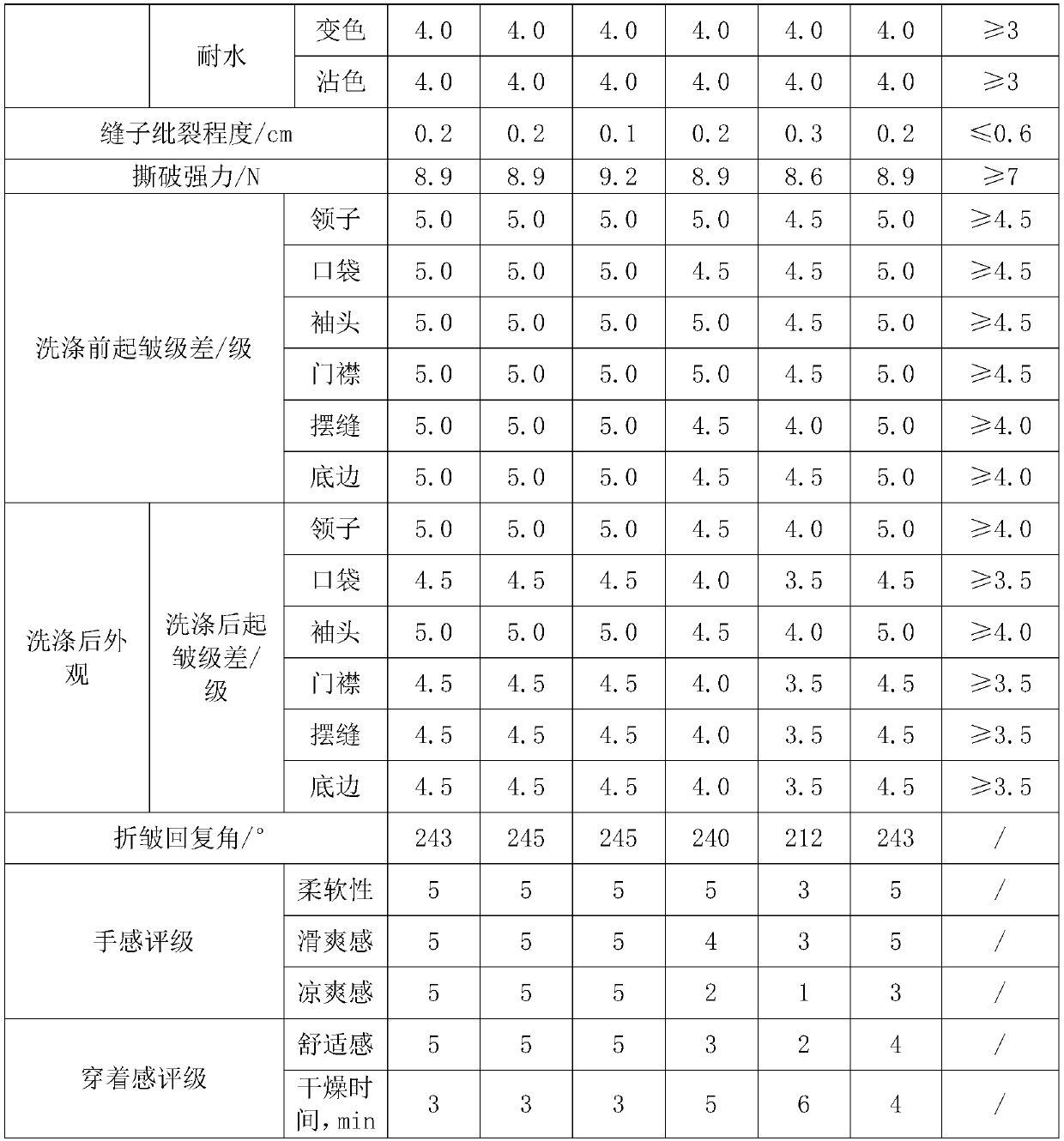

Garment ironing-free cool feeling finishing process

InactiveCN110468585AIncrease suppleness and smoothnessSolve wrinkle-prone defectsWrinkle resistant fibresGrip property fibresEngineeringSolvent

The invention discloses a garment ironing-free cool feeling finishing process, and relates to the technical field of textile after-finishing.According to key points of the technical scheme, the garment ironing-free cool feeling after-finishing process comprises the following steps: spraying, pre-baking, drying, pressing, baking for setting, and cooling; ironing-free finishing liquid is prepared with water as a solvent, and contains the following components: a modified dihydroxy divinyl urea cross-linking agent, a catalyst, an anti-wear finishing agent, a three-proof finishing agent, a siliconsoftener and a clothing cooler.The addition of the silicone softener can increase the softness and smoothness of a garment, and the temperature of the garment can be reduced by the combination of thesoftener and the clothing cooler, thereby reducing the sweltering feeling and increasing the comfort of wearing the garment.

Owner:北京金添仕制衣有限公司 +1

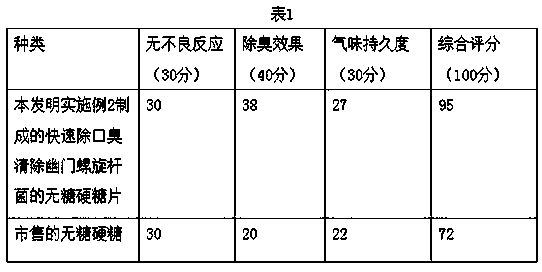

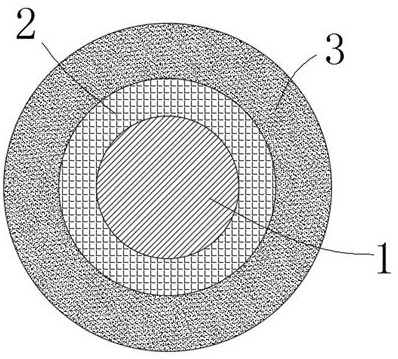

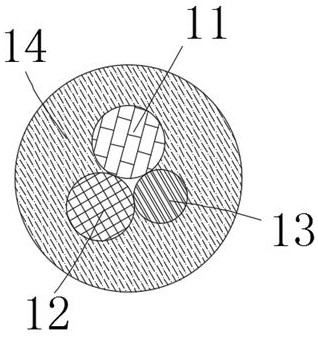

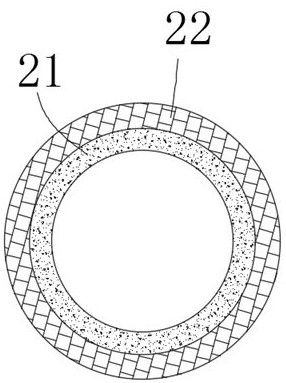

Sugar-free hard candy tablet for quickly removing halitosis and helicobacter pylori and preparation method thereof

InactiveCN109619248AEfficient killingChanges in oral hygieneConfectionerySweetmeatsOral ulcersBad mouth taste

The invention belongs to the technical field of food processing and manufacturing, in particular to a sugar-free hard candy tablet for quickly removing halitosis and helicobacter pylori and a preparation method thereof. The tablet comprises 55-65 parts of sorbitol; 5-10 parts of egg white lysozyme dry powder; 0.2-1.5 parts of papain; 5-10 parts of collagen; 5-10 parts of amino acid; 5-10 parts ofsmall molecular peptide powder; 0.05-0.07 part of vitamin A; 0.05-0.07 part of vitamin B and 0.05-0.07 part of vitamin E. The tablet can effectively kill helicobacter pylori in an oral cavity, thoroughly change the oral cavity cleanness, thereby achieving the effects of purifying the oral cavity, eliminating the halitosis and refreshing breath, the tablet has the functions of eating, nutrition, antibiosis, sterilization and anti-inflammation, and has obvious action and curative effect on prevention of oral ulcer, aphtha, gingivitis, halitosis, oral cavity diseases and the like, is a sugar-freefood, does not easily cause obesity, and is very favorable for being eaten by various people, middle-aged and old people and children.

Owner:唐婷

High-strength vortex spinning yarn and production method thereof

PendingCN111663218AGood moisture absorption and air permeabilityStretch, crisp and fluffy warmthContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention discloses a high-strength vortex spinning yarn. The high-strength vortex spinning yarn comprises a core yarn layer, a wrapping layer and a covering yarn layer. The wrapping layer is arranged on the outer surface of the core yarn layer, the covering yarn layer is arranged on the outer surface of the wrapping layer, and the core yarn layer comprises a first strand, a second strand, a third strand and a core fiber layer. The first strand, the second strand and the third strand are mutually wound, the core fiber layer is arranged on the outer side of the first strand, the outer sideof the second strand and the outer side of the third strand, and the wrapping layer comprises a first wrapping fiber layer and a second wrapping fiber layer. The second wrapping fiber layer is arranged on the outer surface of the first wrapping fiber layer, and the yarn wrapping layer comprises an acrylic fiber wrapping layer and a tencel fiber wrapping layer. The invention further provides a production method for the high-strength vortex spinning yarn. The yarn has less hairiness and is free of pilling, uniform in core yarn stress, good in structural strength, not prone to breakage and capable of being used as high-strength yarn.

Owner:江苏京正特种纤维有限公司

Quick-dry self-flow casting material for ladle permanent layer

The invention discloses a quick-dry self-flow casting material for a ladle permanent layer. The quick-dry self-flow casting material is prepared from the following raw materials in percentage by mass:56-75% of a pyrophyllite and fused mullite composite material of which the particle size is 1-9mm, 14-22% of a pyrophyllite and fused mullite composite material of which the particle size is 0-1mm, 2-8% of silicon nitride of which the particle size is less than or equal to 1mm, 0.5-1.5% of a water reduction agent, 0.8-1.5% of an anti-explosion agent, 1-3% of a combination agent, 1-3% of silicon dioxide micro powder of which the particle size is less than or equal to 60mu m, 1-4% of an active aluminum oxide micro powder of which the particle size is less than or equal to 60mu m, and 2-5% of asilica powder of which the particle size is less than or equal to 50mu m. By adopting the quick-dry self-flow casting material, the ladle permanent layer is good in thermal insulation, good in thermalshock resistance, good in peeling resistance and easy to construct, has the characteristics of excellent self flowing, spreading, filling and the like, can be rapidly baked without cracking, achievesthe purposes of self flowing and quick drying, in addition is free of iron slag adhesion, and is long in service life.

Owner:YANSHI ZHONGYUE REFRACTORY MATERIALS

Flavored oil chili and preparation method thereof

The invention relates to flavored oil chili and a preparation method thereof, and belongs to the technical field of food processing. The oil chili is prepared by decoction from the following raw foodmaterials: 10-15 kg of dried chilies, 8-12 kg of raw rapeseed oil, 0.5-1 kg of lard oil, 1-2 kg of thick broad-bean sauce, 1-2 kg of dried ginger, 1-2 kg of garlic, 3-4 kg of table salt, 1-2 kg of peanut kernels, 2-5 kg of Cuishao, 0.3-0.5 kg of fennel, 0.3-0.5 kg of lemons and 1-2 kg of dried fermented soya bean particles. The preparation method comprises the processes of preparing materials, performing soaking, performing primary decoction, performing secondary decoction, performing stewing and the like. The flavored oil chili provided by the invention is excellent in taste, mellow in taste,rich in nutrition and full in flavor.

Owner:尚伦艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com