Nano antibacterial vortex spinning yarns and production technology thereof

A vortex spinning and nano technology, applied in the field of nano antibacterial vortex spinning and its production technology, can solve the problems of poor moisture permeability, poor antibacterial effect, easy breeding of bacteria, etc., and achieve soft texture, good anti-wrinkle performance, and production technology Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

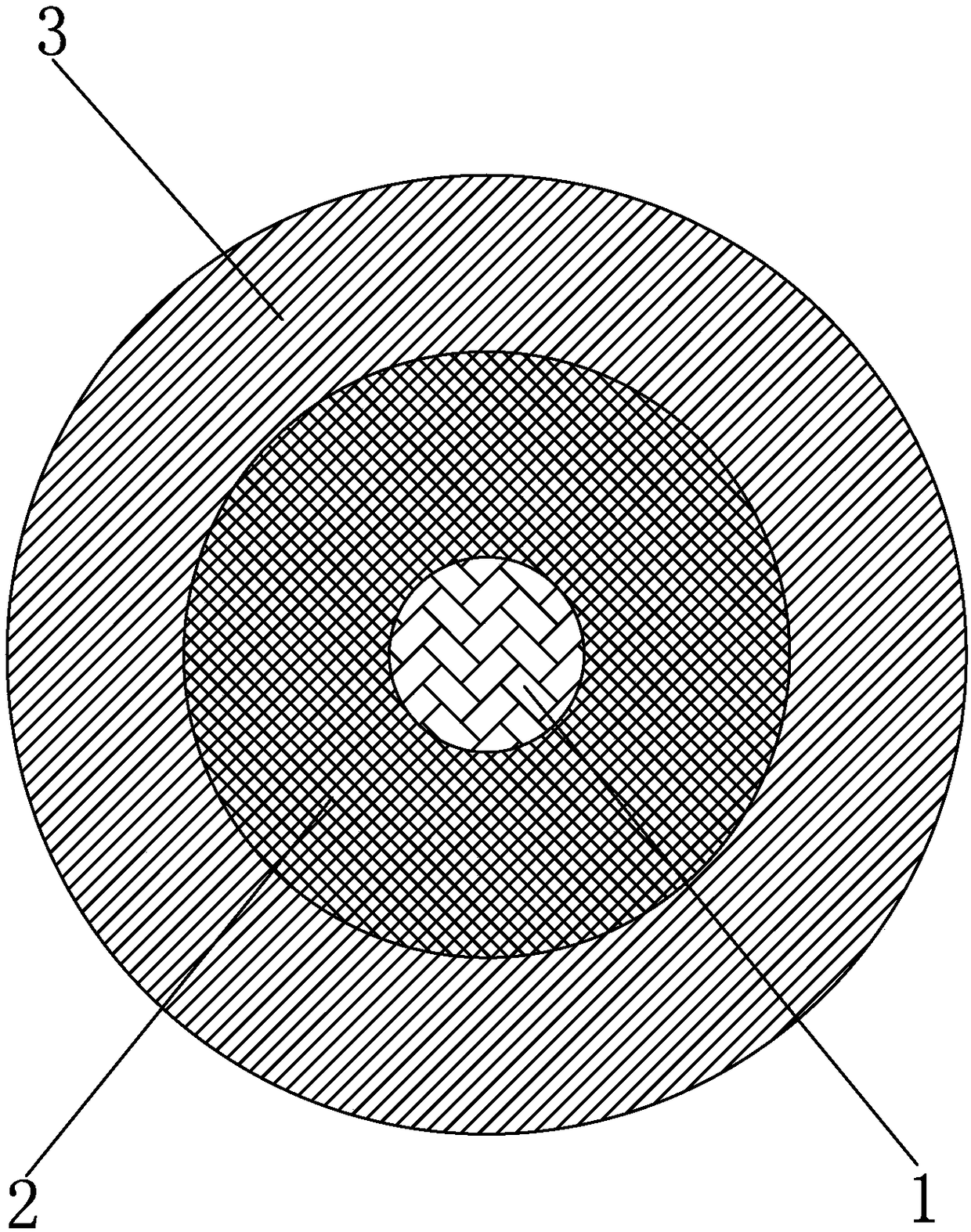

[0023] combine figure 1 , the invention discloses a nano antibacterial vortex spun yarn, which includes a yarn body; The wrapping yarn 3 is spirally wrapped around the core yarn 2 . The core yarn 2 includes polyester filaments 1 with special-shaped cross-sections, and tencel fibers and silver fibers located outside the polyester filaments 1 with special-shaped cross-sections. The polyester filament 1 with special-shaped cross-section is preferably 75D / 18F. The cross-section of the special-shaped cross-section polyester filament 1 is cross-shaped. Nano titanium dioxide photocatalyst is stained on the surface of polyester filament 1 with special-shaped cross section. Wrapped yarn 3 is made of natural plant fiber mixed with soybean protein fiber and bamboo fiber. The mixing ratio of soybean protein fiber and bamboo fiber is 1:1.

[0024] The special-shaped cross-section polyester filament 1 is located at the center of the core yarn 2, and the ratio of the quality of the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com