Method for spinning high-grade knitting yarns by using long flax fibers

A long-fiber and knitting yarn technology, which is applied in fiber processing, textiles, papermaking, yarn, etc., can solve the problems of low-grade knitting yarn, large yarn loss, and low efficiency, and achieve improved spinning efficiency, quality, and adjustment. The effect of dry uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

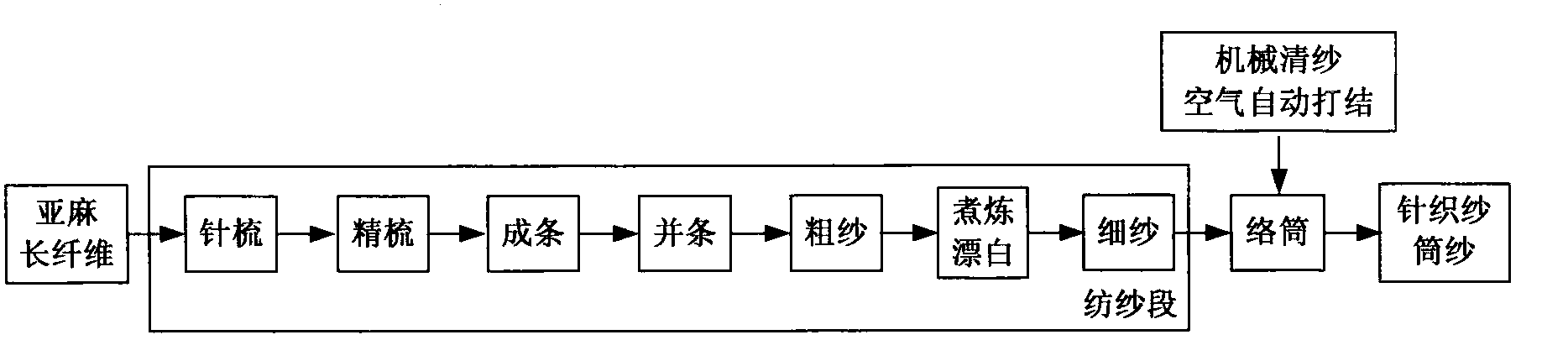

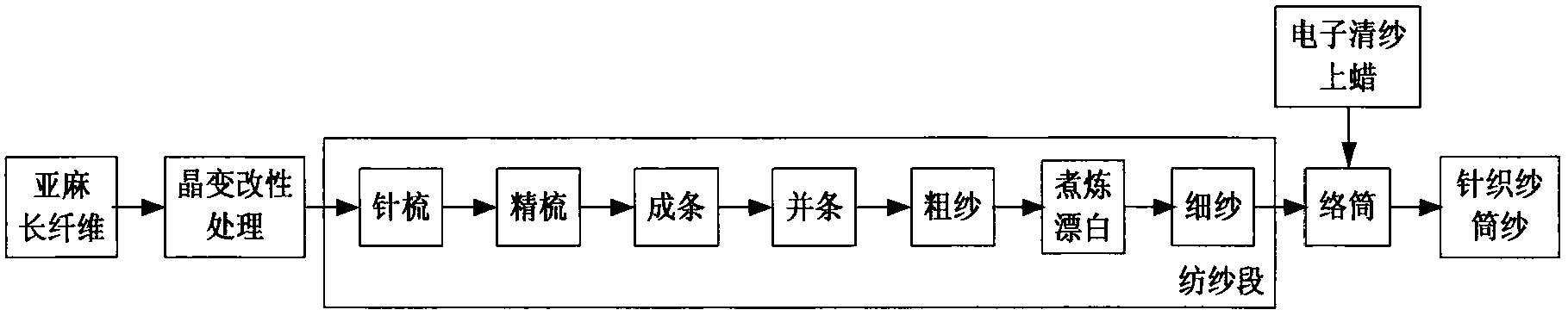

[0019] Such as figure 2 As shown, the method of spinning high-grade knitting yarn with flax long fiber is as follows:

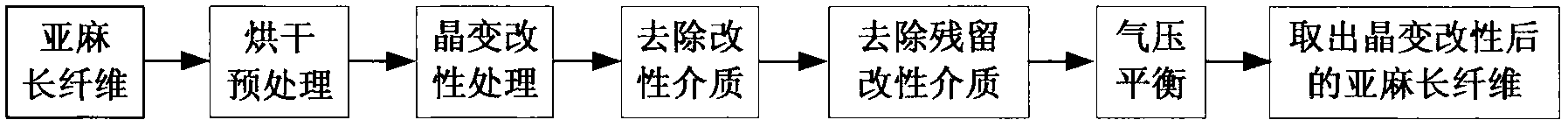

[0020] (1) if image 3 As shown, after the commercially available flax long fiber is dried and pretreated at 135°C, it is dried and the water content is less than 1%, and the dried flax long fiber is put into a closed modified processor, After evacuating the modified processor, fill it with gaseous ammonia, so that the internal pressure of the modified processor is 3MPa, and then fill it with liquid ammonia, so that the liquid ammonia is immersed in all the long flax fibers and the internal pressure of the modified processor is 5Mpa, hold the pressure for 4 minutes Finally, liquid ammonia is removed, and then heating and vacuuming are carried out alternately to remove residual gaseous ammonia and liquid ammonia. When the pressure in the modified processor is heated until the pressure does not increase basically, the air pressure is balanced. Open the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com