Patents

Literature

134results about How to "Improve weave quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

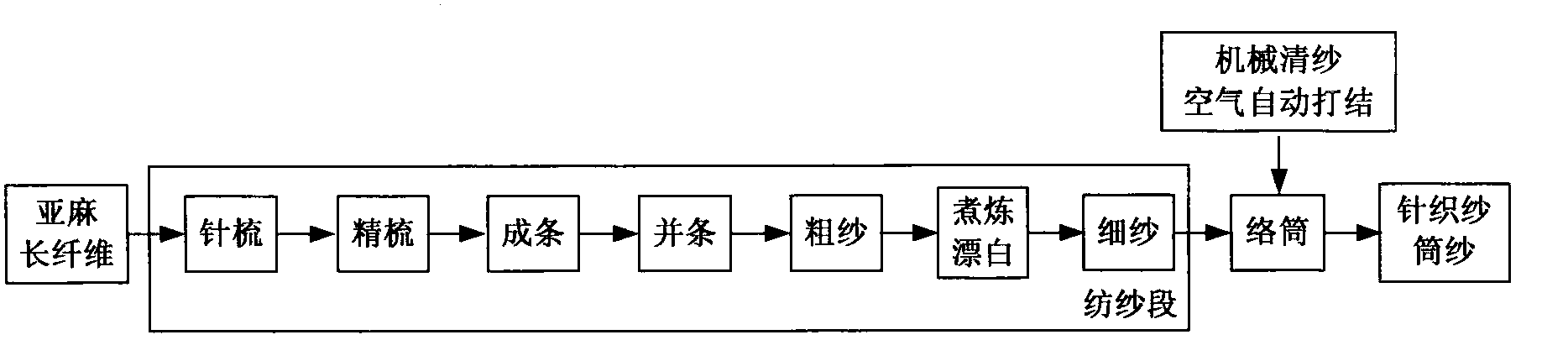

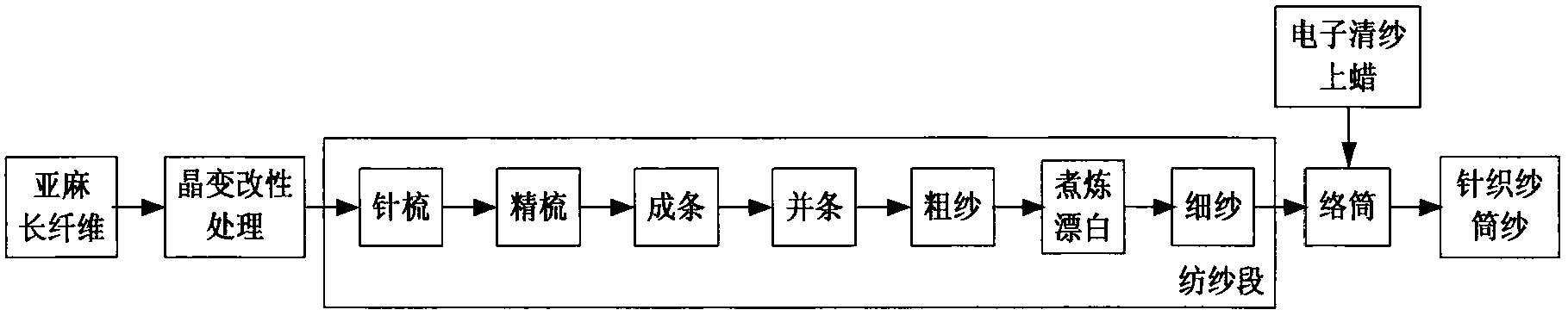

Method for spinning high-grade knitting yarns by using long flax fibers

InactiveCN102704095ASoft textureImproved drying uniformityFibre treatmentYarnYarnPulp and paper industry

The invention provides a method for spinning high-grade knitting yarns by using long flax fibers. The method comprises the steps of: carrying out crystallization modification treatment on the long flax fibers, carrying out gilling, combing, slivering, drawing, roving, boiling-off, bleaching and spinning operations sequentially, and carrying out electronic yarn clearing and waxing simultaneously in a spooling process, thereby forming the knitting yarns. According to the method provided by the invention, the crystallization modification treatment is carried out on the long flax fibers, so that the fibers are soft in texture and have an improved uniformity for dry adjustment, therefore a foundation for spinning the high-grade knitting yarns is laid; and electronic yarn clearing and waxing operations are simultaneously carried out in the spooling process owing to the facts that the fibers are soft in texture and have an improved uniformity for dry adjustment after the crystallization modification treatment is carried out on the long flax fibers, therefore the spinning efficiency is improved, and the knitting yarn quality is improved.

Owner:DONGHUA UNIV +1

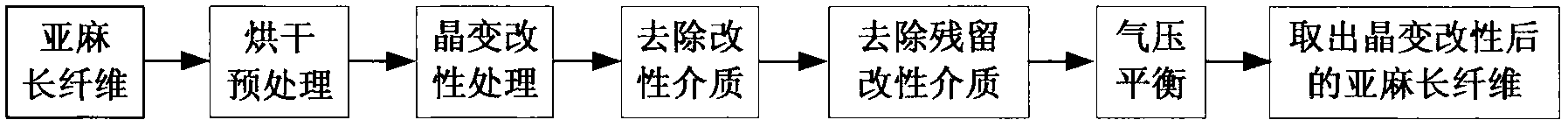

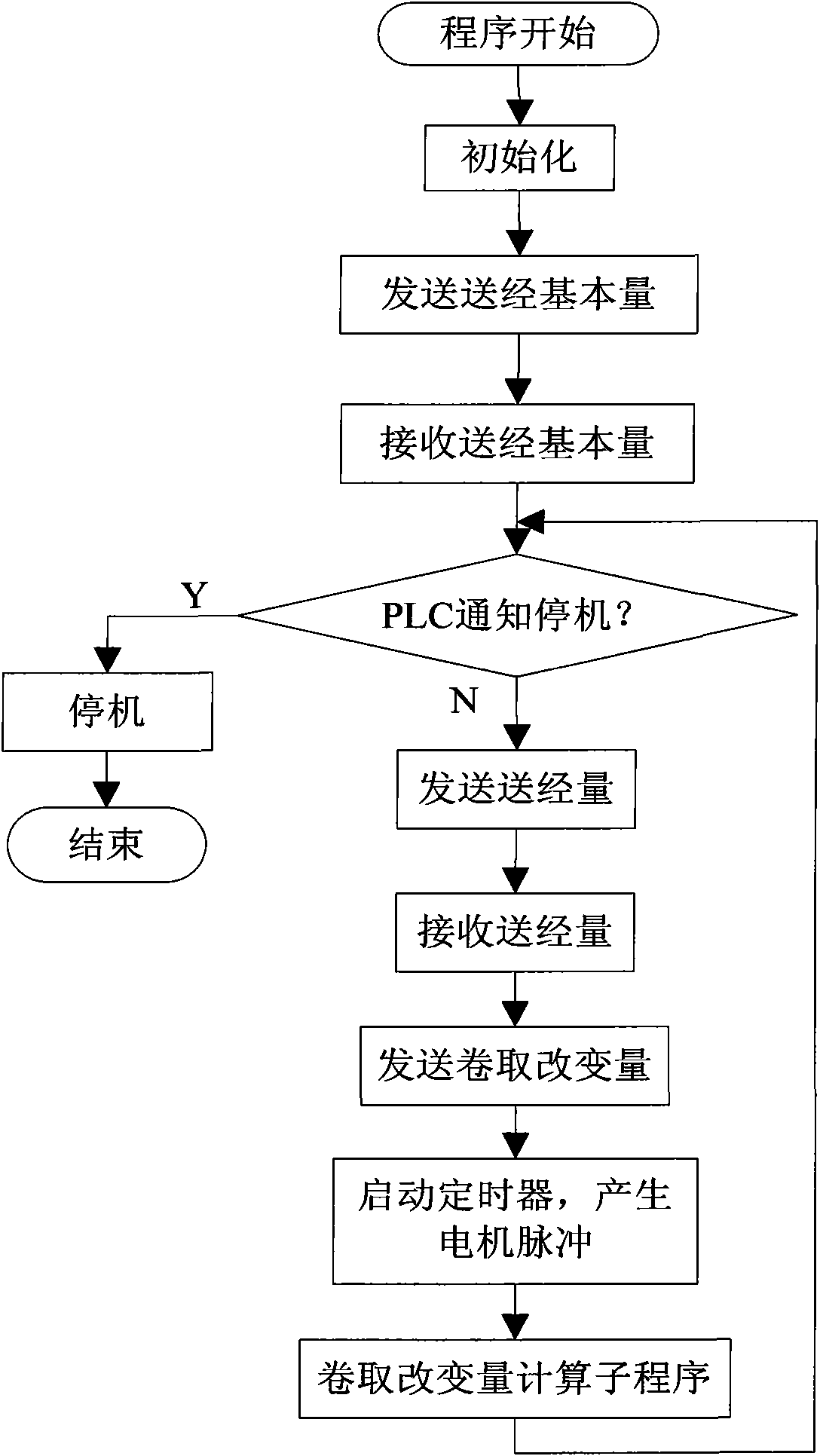

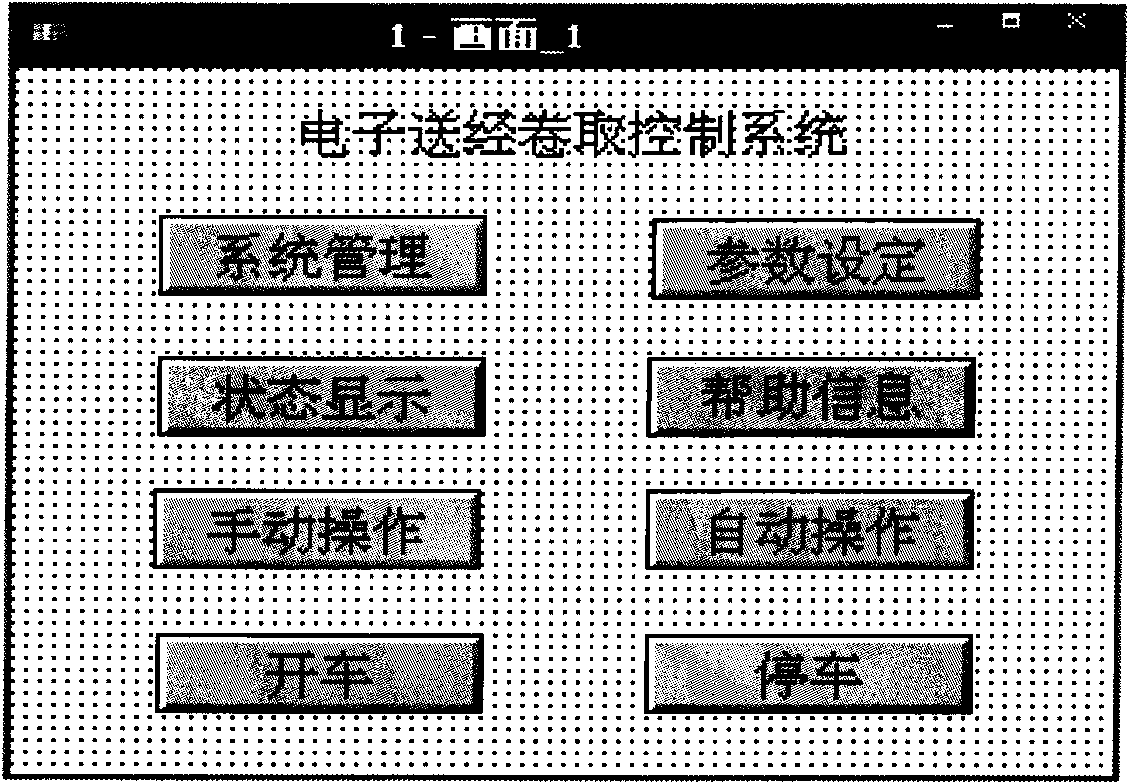

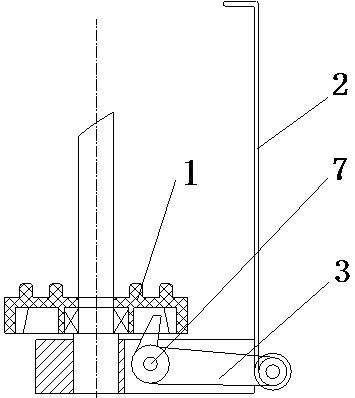

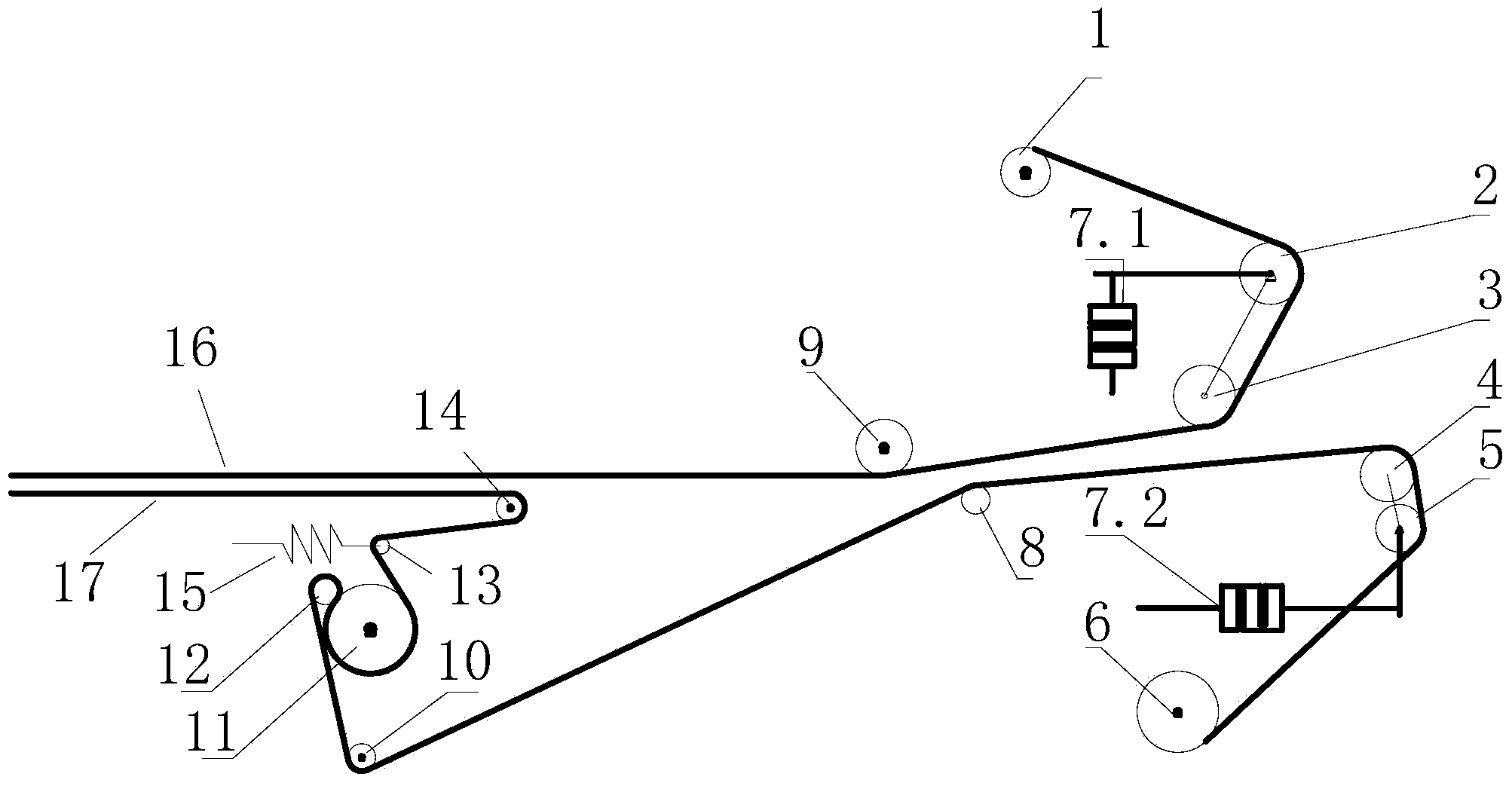

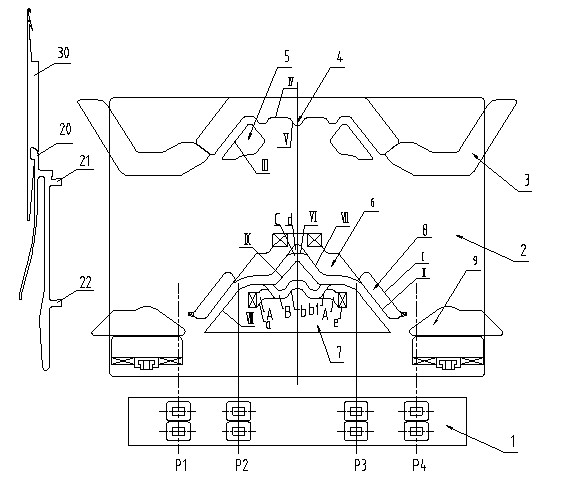

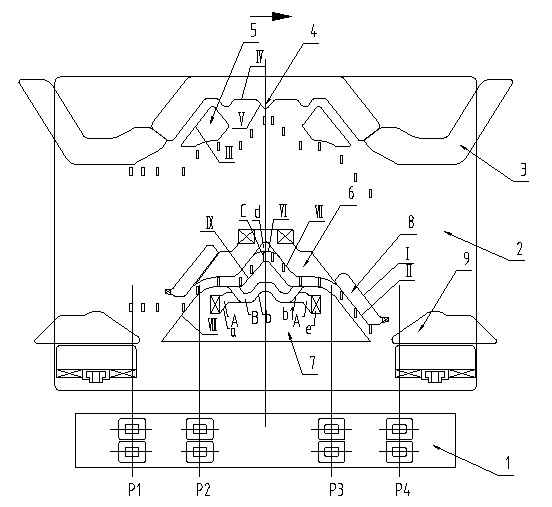

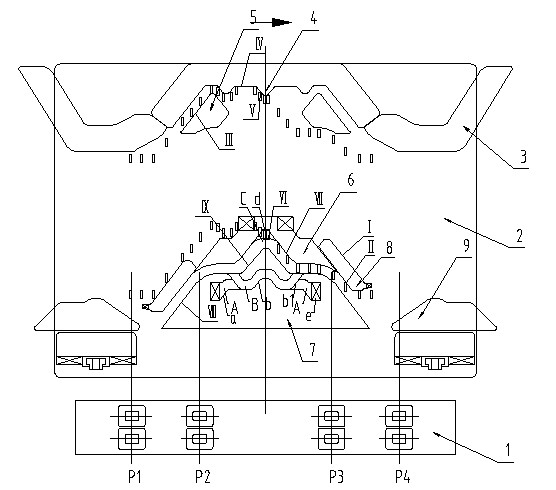

Method for controlling tension stability of wrap yarn during wrap feeding and rolling process of loom

InactiveCN101673119AShort response timeSmall overshootLoomsProgramme control in sequence/logic controllersYarnReduction drive

The invention relates to a method for controlling the tension stability of wrap yarn during the wrap feeding and rolling process of a loom, comprising two parts, namely, wrap feeding and rolling control system hardware and a software program of a core controller. The hardware part comprises a main controller PLC, a touch screen, a tension sensor, an encoder, a servo driver, a servo motor and a speed reducer; and the software part employs a novel control algorithm, namely, single nerve cell self-adaptive PID algorithm. The control system is tested on the SAURER400-type rapier loom and good control effect is achieved, the tension fluctuation of wrap yarn of the loom is obviously improved, and the end breakage rate of wrap yarn is greatly decreased; besides, the control method is universal and has certain practical value both in reconstruction of the old loom and in algorithm research of the new loom.

Owner:TIANJIN POLYTECHNIC UNIV

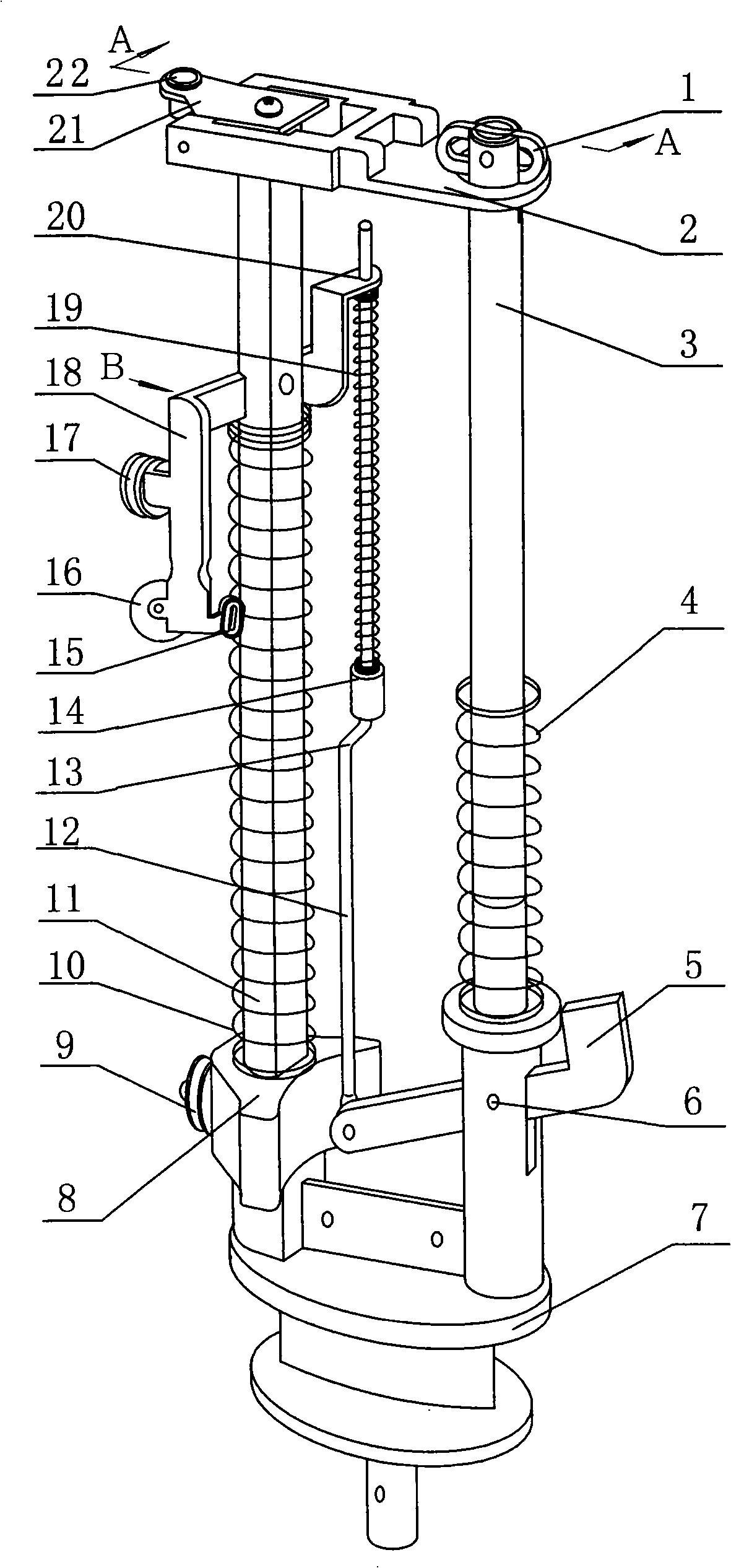

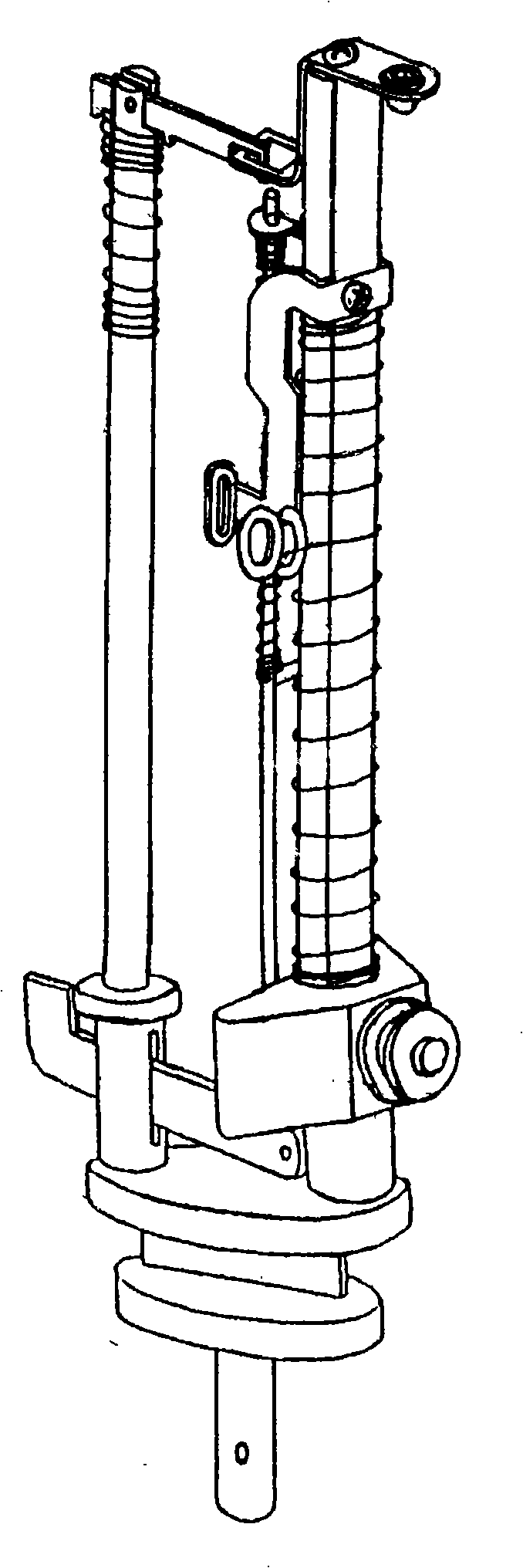

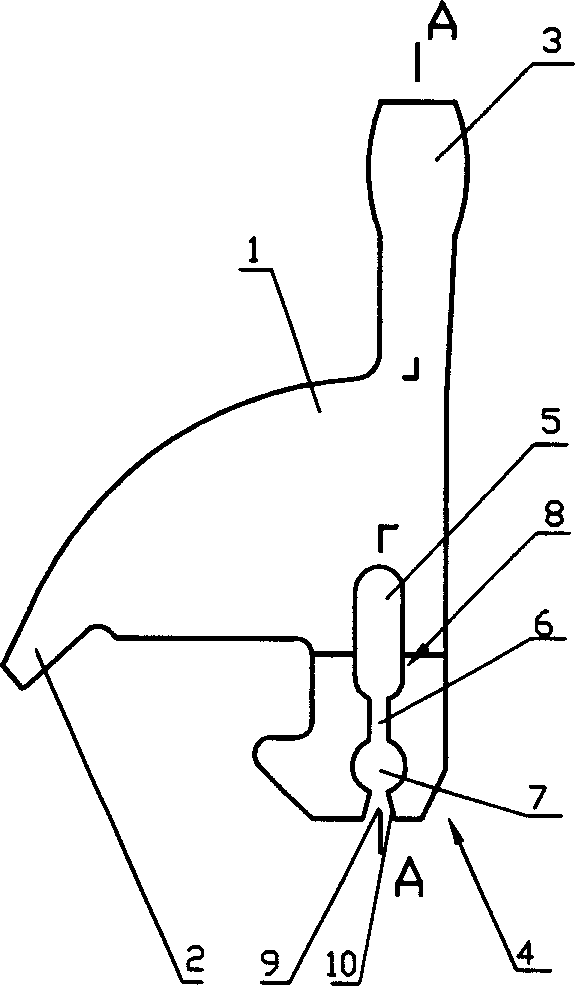

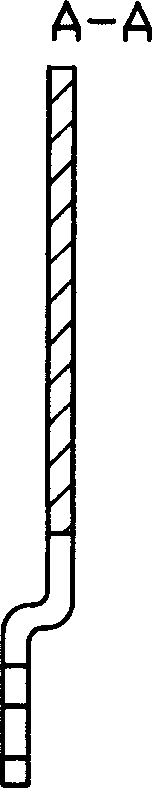

Spring spindle

The invention relates to a spring spindle, wherein, a fixed piece is formed by fixing a right upright post which is fixed with a support and a connecting rod and a left upright post on a track rod, and the spring spindle is formed by connecting a weaving piece and the fixed piece into a whole through a pressure plate and a switch plate; the support is flanged; a pulley is divided into an upper pulley and an intermediate pulley; the upper pulley and the intermediate pulley which are connected to the support are arranged on the right of the right upright post; mounting axial lines of the upper pulley and the intermediate pulley are crossed and angulated at 57 to 63 DEG; a vertical and bended straight section on the middle of the connecting rod is provided with a limit rod; and the pressure plate is matched with a lock catch which is connected to the left upright post. The support is arranged on the right of the right upright post instead of being arranged on the left of the right upright post, thereby the angle between a leading-in porcelain eye and a thread-passing point is reduced to between 27 and 33 DEG; the angle is smaller, the pay-out resistance on bobbin is smaller, and then the pay-out speed is quick and the thread breakage time is greatly reduced; the connecting rod and the support are arranged on both sides of the right upright post so as to maintain routing balance, thereby the speed can be improved by 10 percent and the weaving quality and the production efficiency are greatly improved; and simultaneously the pressure plate has good strength and long service life, is convenient, quick and easy to operate, and is an updated product of the third generation.

Owner:张宝香

Method for fabricating wovens

InactiveUS6918410B1Reduced set per beamReduce rejectionPile-fabric loomsPattern making devicesEngineeringAirbag

A method for weaving single-layered and / or multi-layered woven fabric, especially airbag fabric, includes interweaving warp threads delivered by at least two warp beams.

Owner:GLOBAL SAFETY TEXTILES

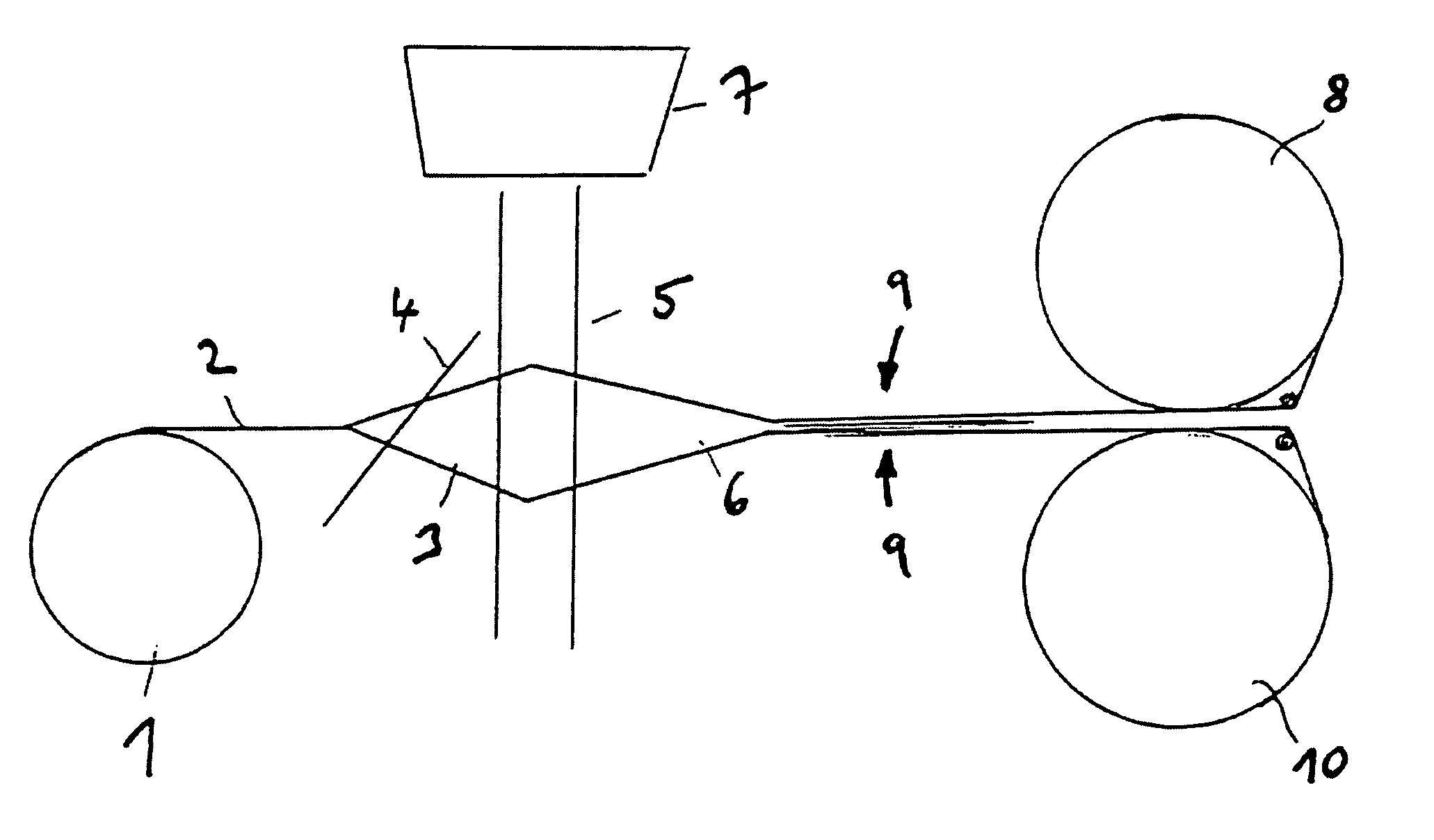

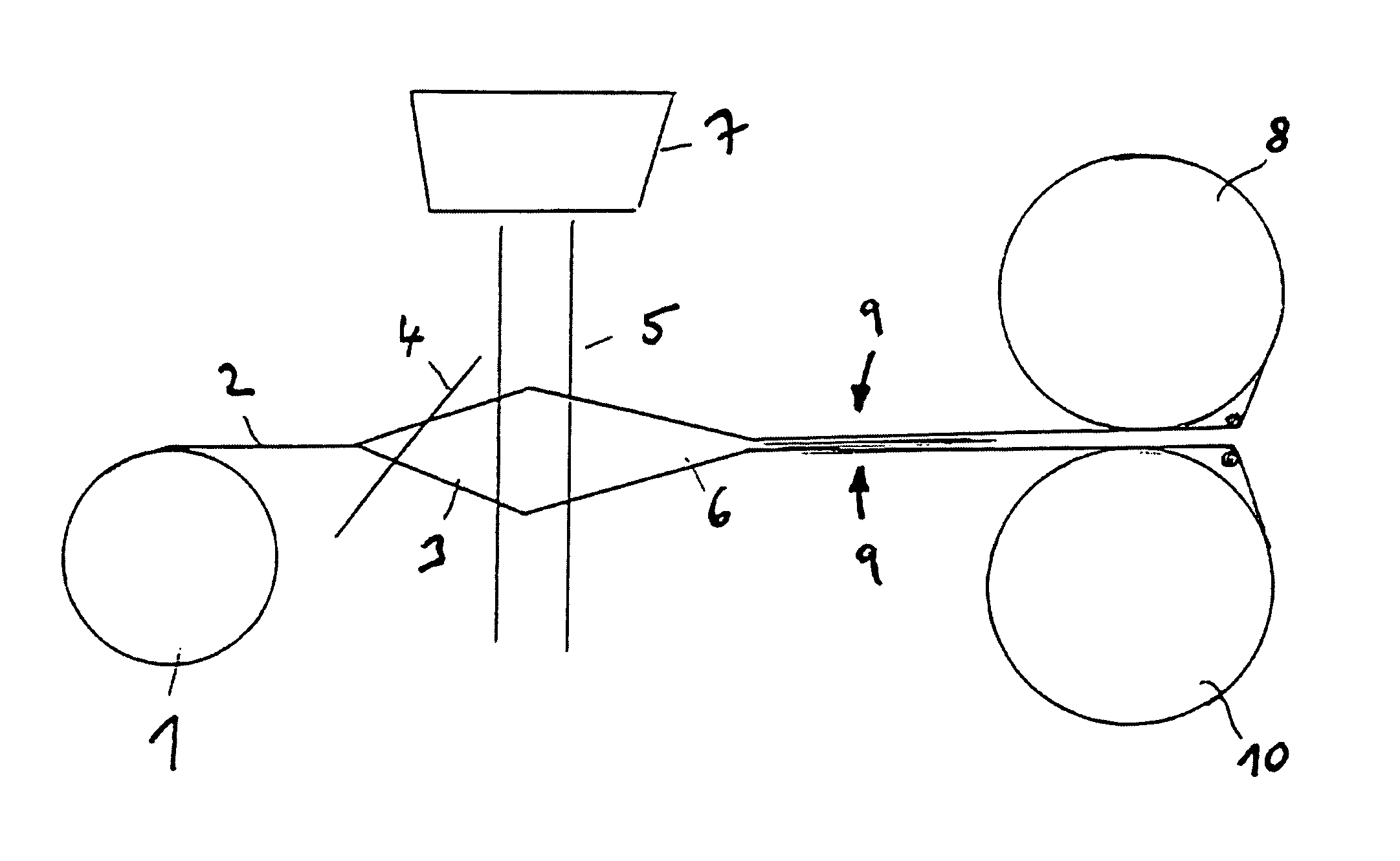

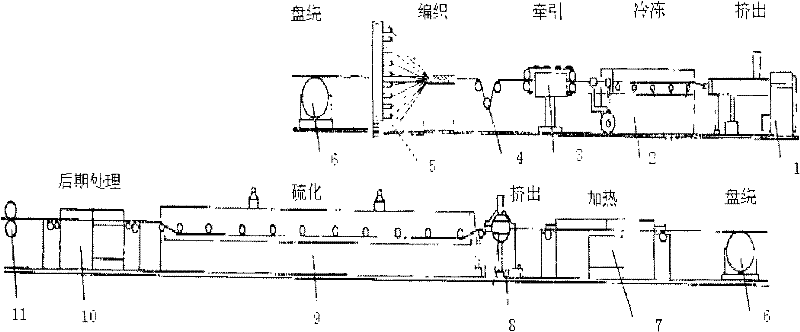

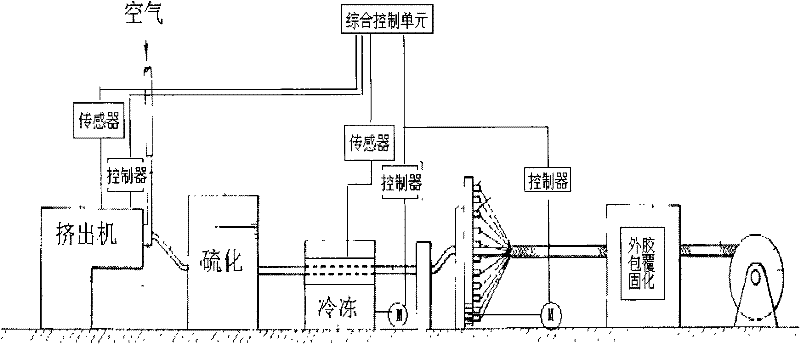

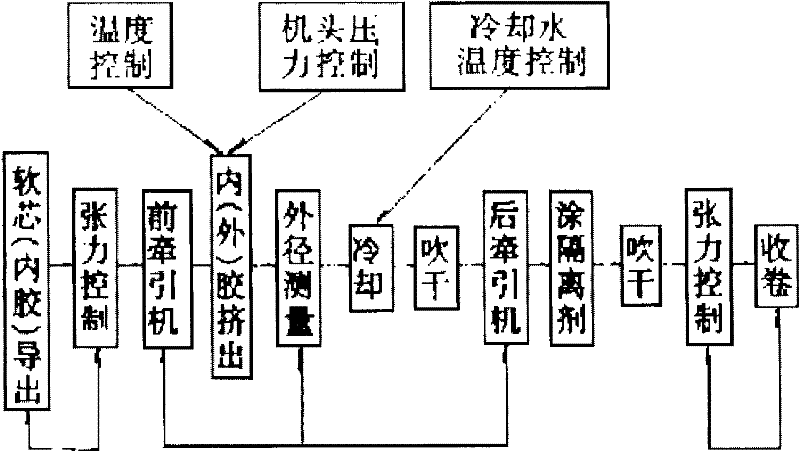

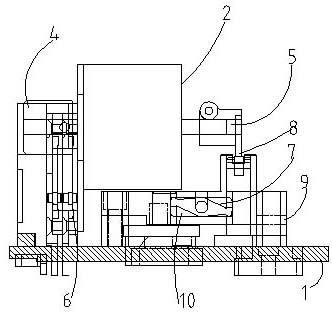

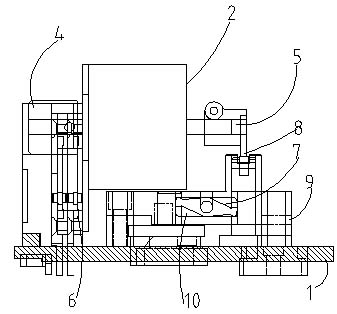

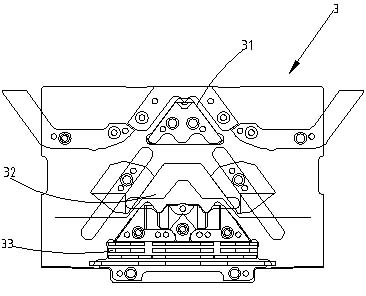

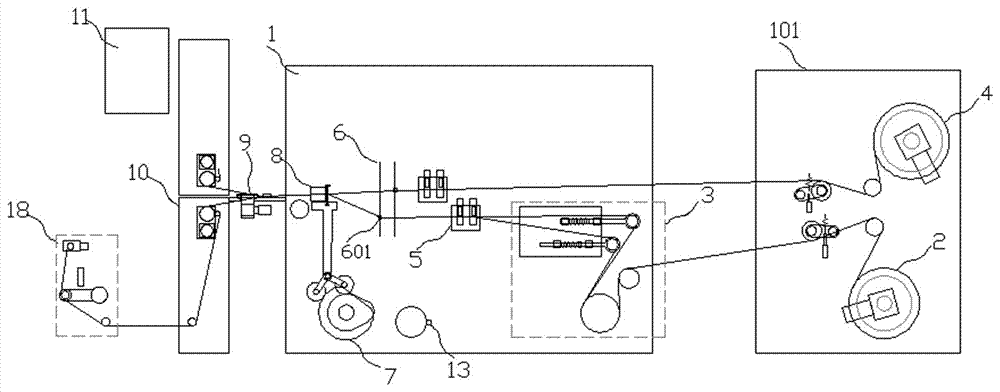

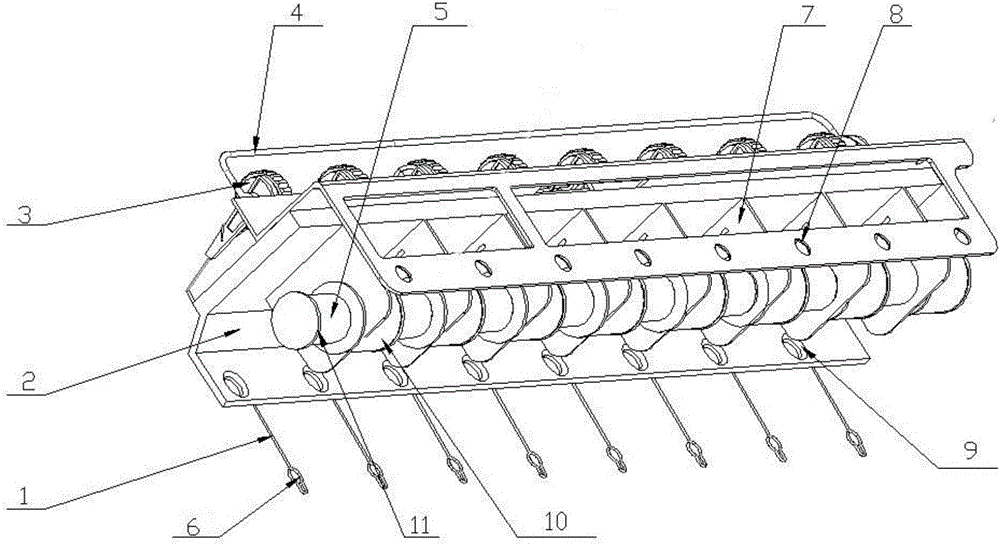

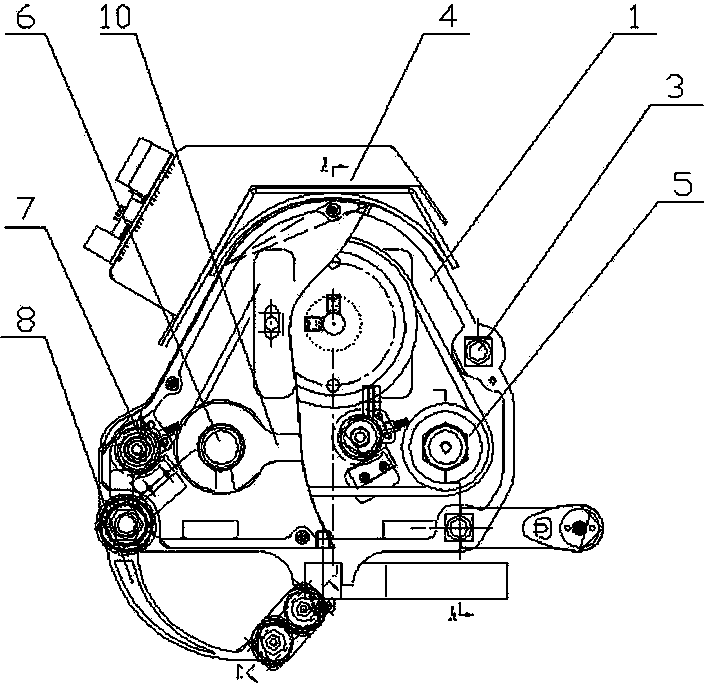

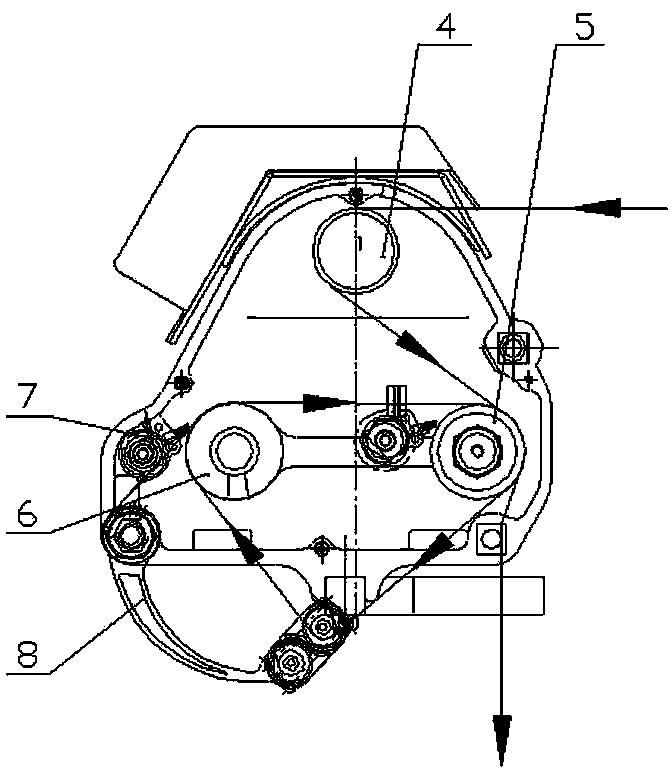

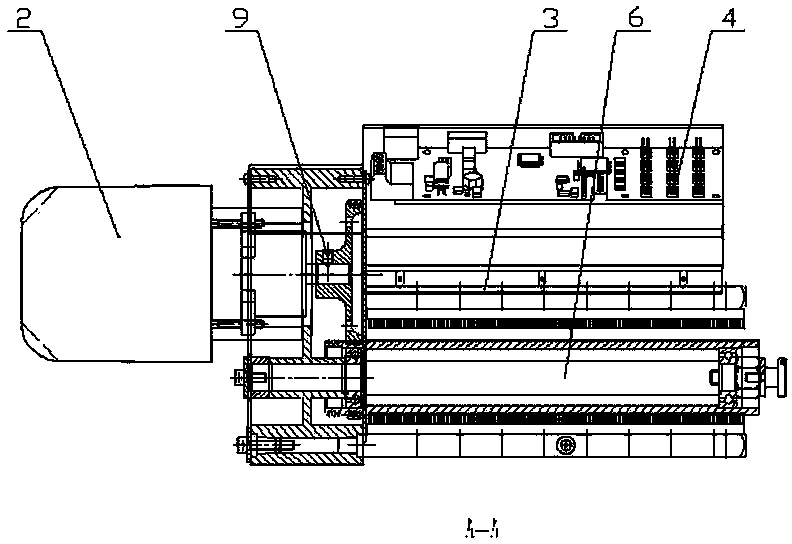

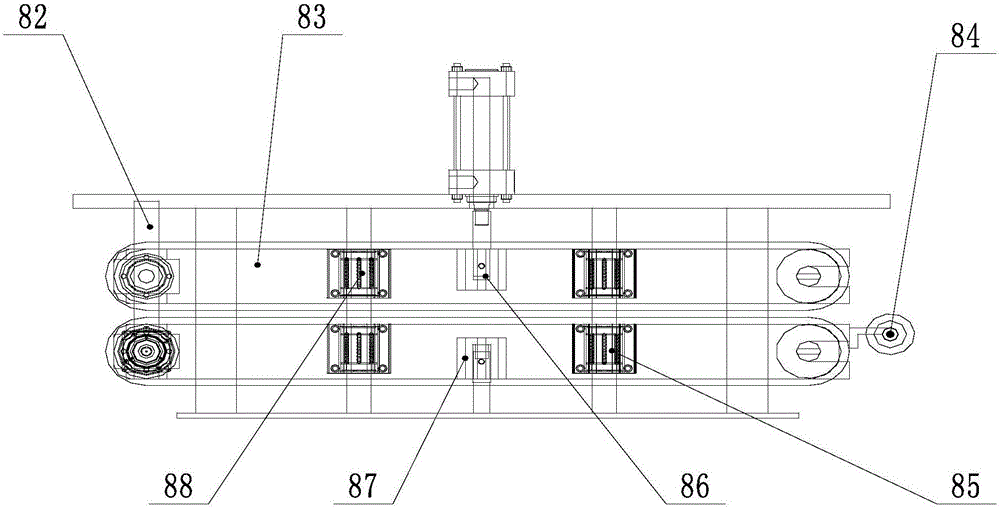

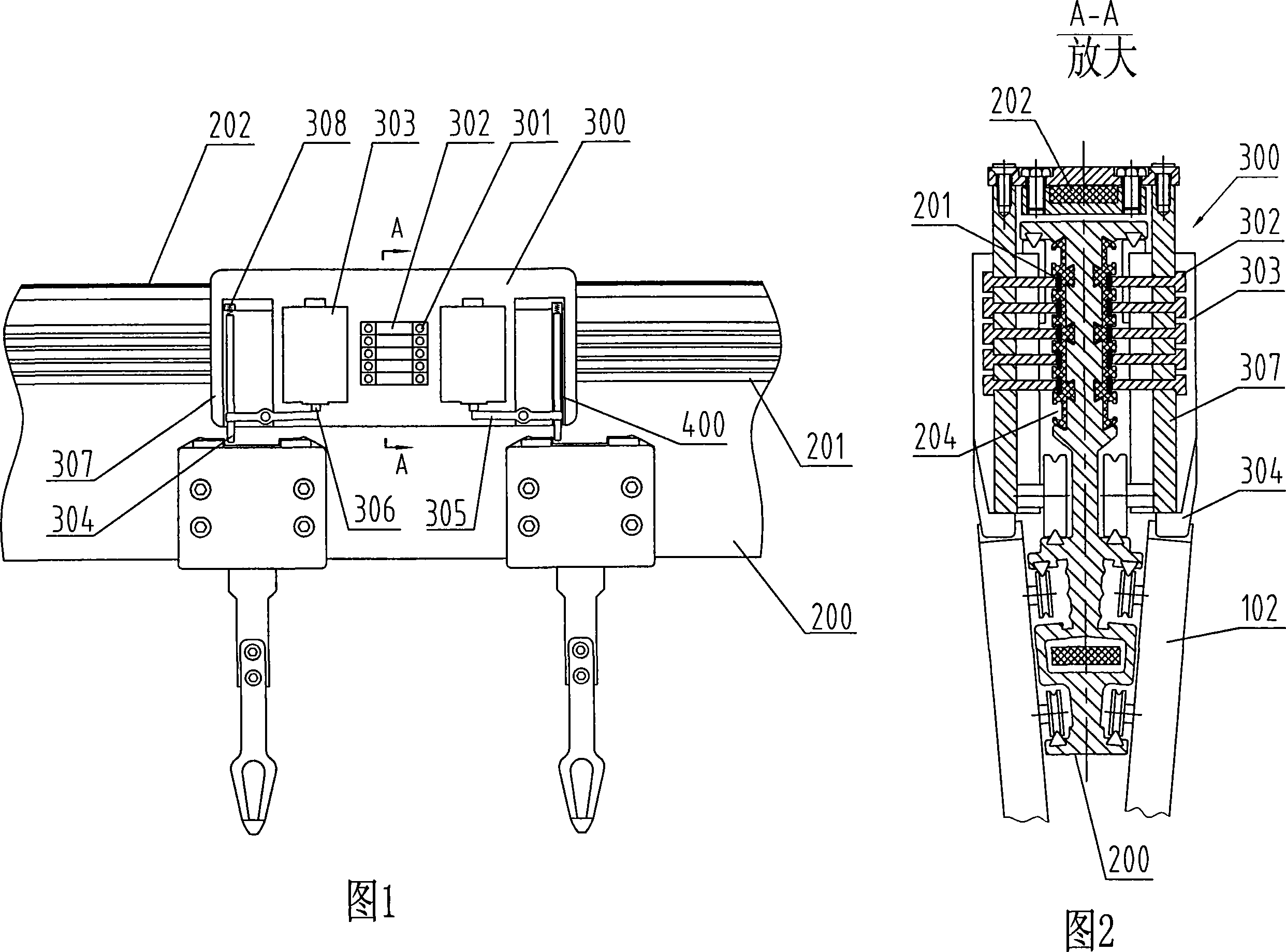

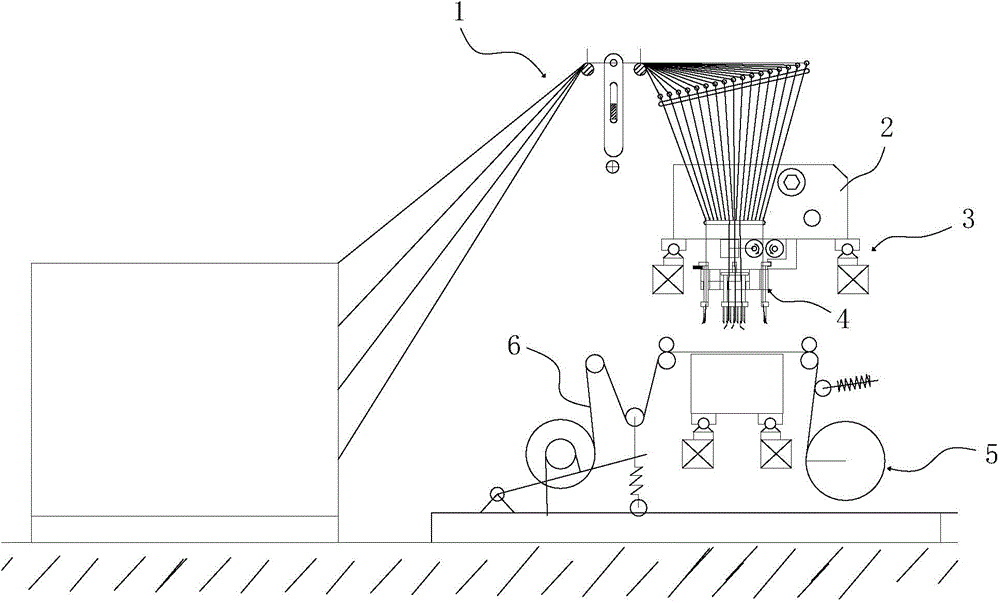

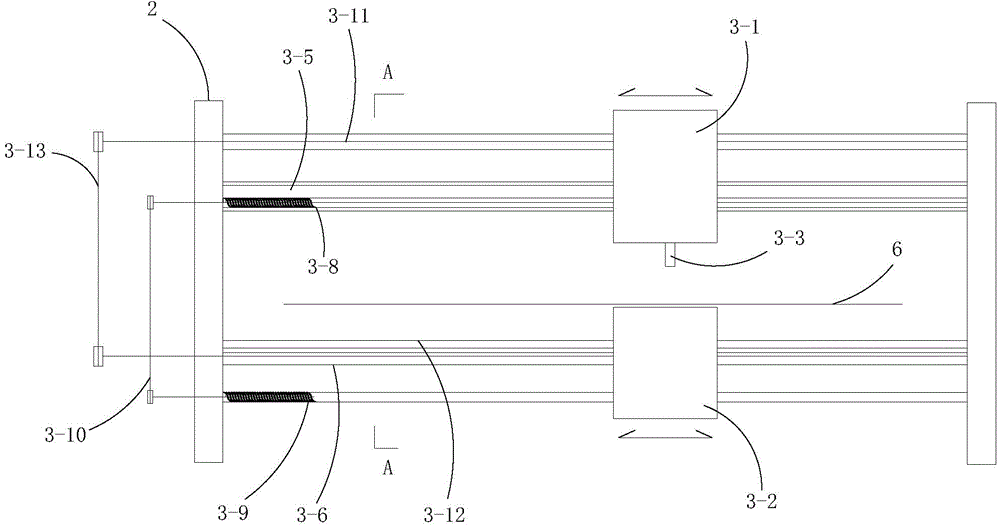

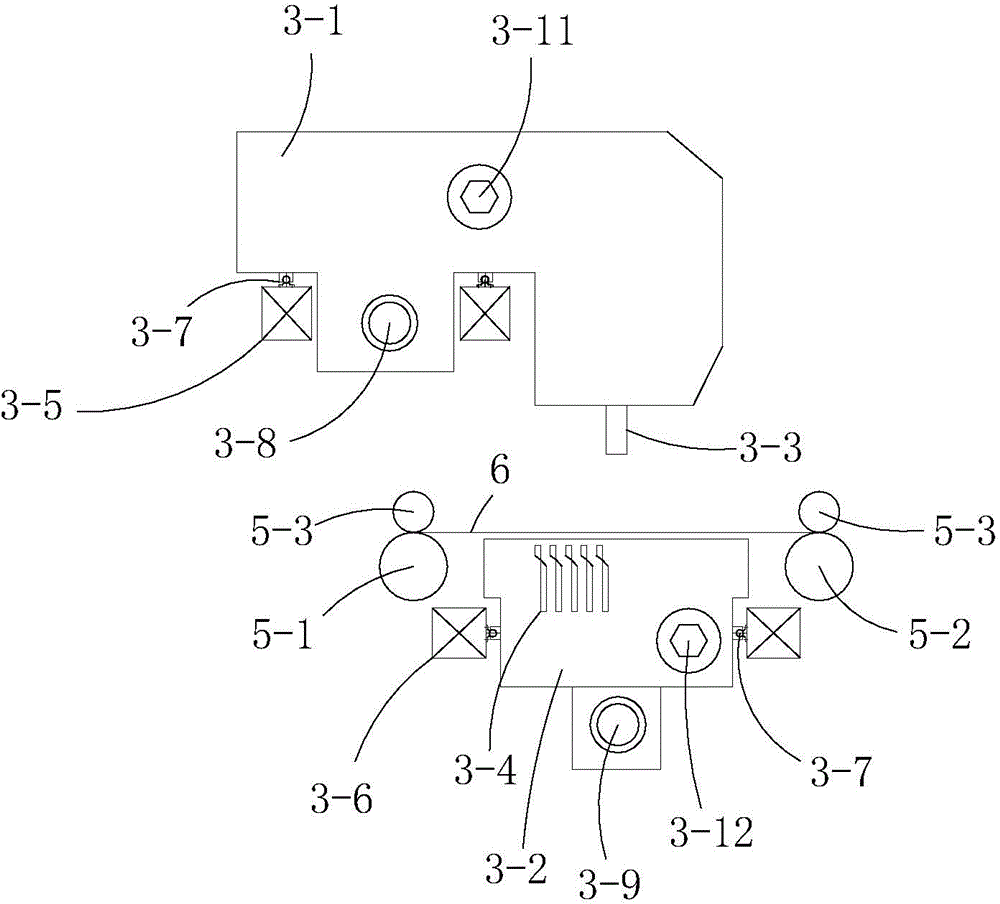

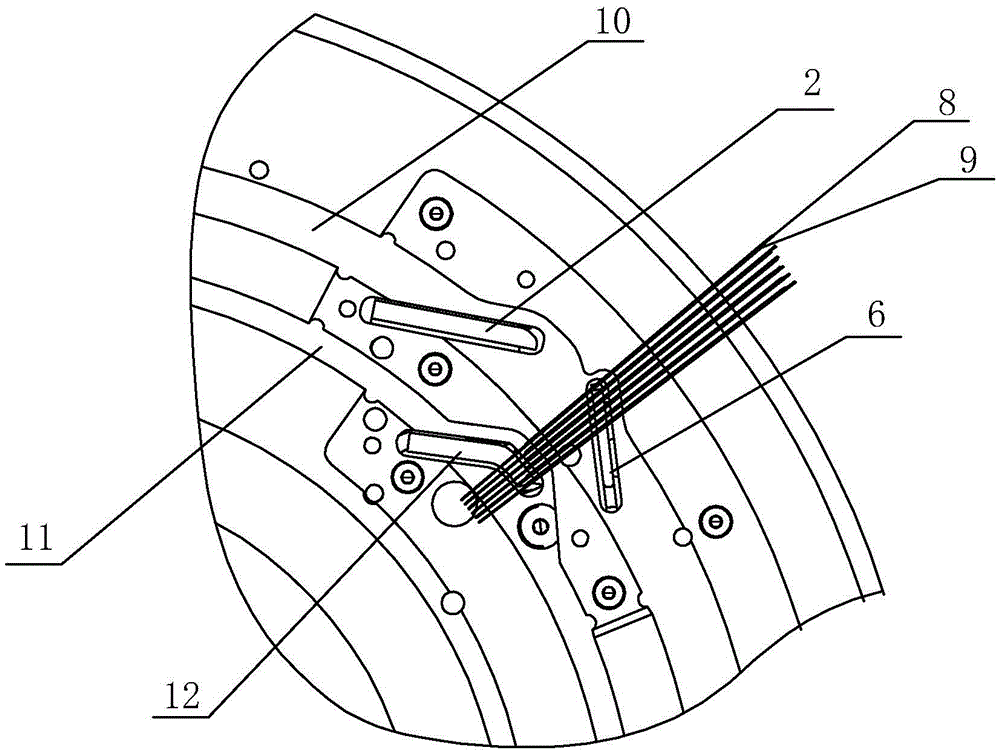

Braided rubber tube automatic-controlled linkage-production method and apparatus thereof

InactiveCN102452177AReduce noiseImprove weave qualityTubular articlesAutomatic controlControl function

The invention relates to a braided rubber tube automation control linkage production method and an apparatus thereof. The apparatus comprises rubber tube extruders, a rubber tube freezer, a steel wire braiding machine, a sulfurization device, traction machines, and other related equipment. The apparatus further comprises an automatic adjustment and detection system for tube-tire wall thickness uniformity, a waterless cooling system used in a tube-tire and mandrel extruding process, a tube-tire winding and unwinding device with automatic detection and control function, an energy-saving type primary winding braiding machine, a secondary winding braiding machine, a traction mechanism, an automatic controlled system for linkage control and detection, a steel wire braiding machine noise inhibition device, a braiding steel wire breaking detection and control system, a braided rubber tube freezer energy saving application technology and temperature measurement and automatic temperature control refrigeration control system, an automatic dehumidify and drying device during a rubber tube freezing and braiding process, a system for linkage detection and control, an automatic winding detection and control device. In addition, a whole traction drive system and an integrated intelligent monitoring system are designed.

Owner:王东奎

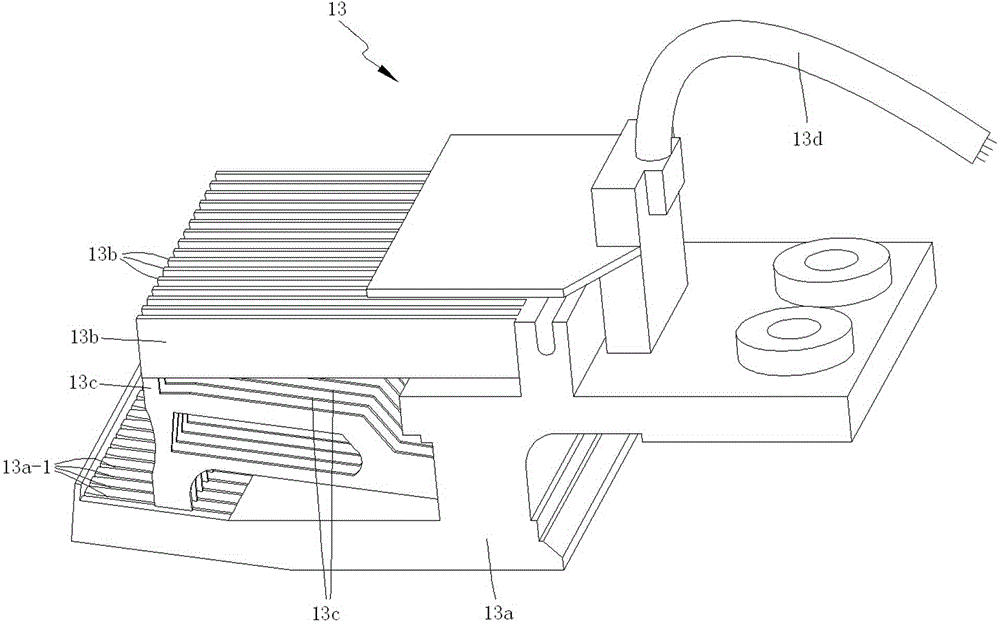

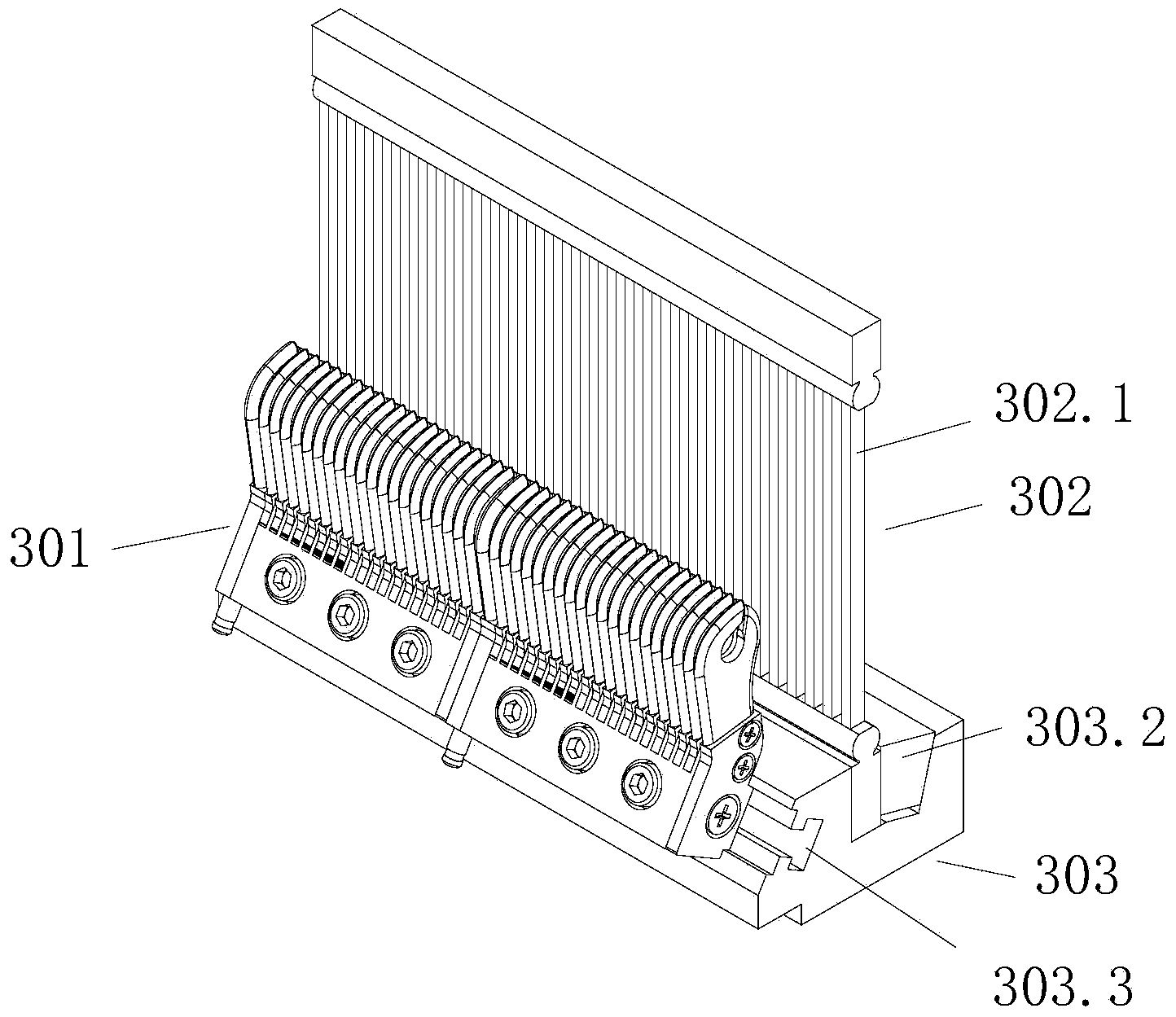

Numerical control fly reed mechanism of towel machine

The invention relates to a numerical control fly reed mechanism of a towel machine, comprising an electric control box, a numerical control motor, an origin signal acquisition mechanism, a main signal acquisition mechanism and a fly reed, wherein the origin signal acquisition mechanism is arranged on a shaft or a gear which is synchronous with a rotating shaft of the fly reed; the main signal acquisition mechanism is arranged on a shaft or a gear which is synchronous with a main shaft of the towel machine; the main signal acquisition mechanism generates an electric signal and sends the electric signal to the electric control box to control the numerical control motor to rotate forwardly or reversely so as to drive the fly reed to be opened or closed; and the origin signal acquisition mechanism generates an electric signal and controls the numerical control motor to stop working by the electric control box. The numerical control fly reed mechanism adopts the main signal acquisition mechanism to control the opening and closing of the fly reed and adopts the origin signal acquisition mechanism to control the closing and stationary of the fly reed; and the numerical control motor adjusts a rotating angle of a reed seat, thus being capable of realizing fast or slow weaving of various fur-type or special-type furs, and the wool yarn has good weaving quality. The numerical control fly reed mechanism has simple structure, convenient operation, stable running, low energy consumption, low noise and long service life.

Owner:王勇

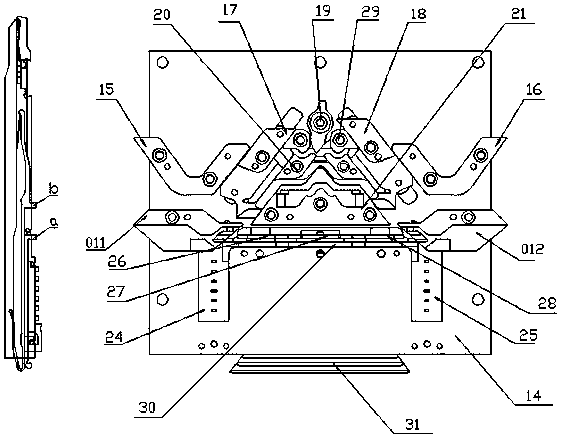

Full-automatic computerized flat knitting machine

The invention discloses a full-automatic computerized flat knitting machine, which comprises a hill-shaped plate, a fixed seat arranged above the hill-shaped plate, a triangle mechanism arranged on the fixed seat, and a step motor arranged above the fixed seat, wherein the triangle mechanism comprises a turning-needle triangle moving up and down, a pressing-needle triangle, and a knitting triangle moving in a direction opposite to the moving direction of the turning-needle triangle; two ends of the output shaft of the step motor are respectively provided with a gear and a cam; the gear is in transmission connection with the pressing-needle triangle through a rack; and the cam drives the turning-needle triangle and the knitting triangle to move up and down through a lever rotationally arranged on the fixed seat. The full-automatic computerized flat knitting machine is reasonable in design and simple in structure; a plurality of actions of the triangle mechanism are controlled by one step motor; the transmission connection lines are concise and the combined drive is carried out according to movement relations of the triangles; the movement stability is high; the lifting speed of the triangle mechanism is greatly improved; and the positioning accuracy of various triangles is improved, so that the work efficiency and the knitting accuracy of the flat knitting machine are improved, and the fabric knitting quality is improved further.

Owner:JIANGSU ZOJE MACHINERY TECH

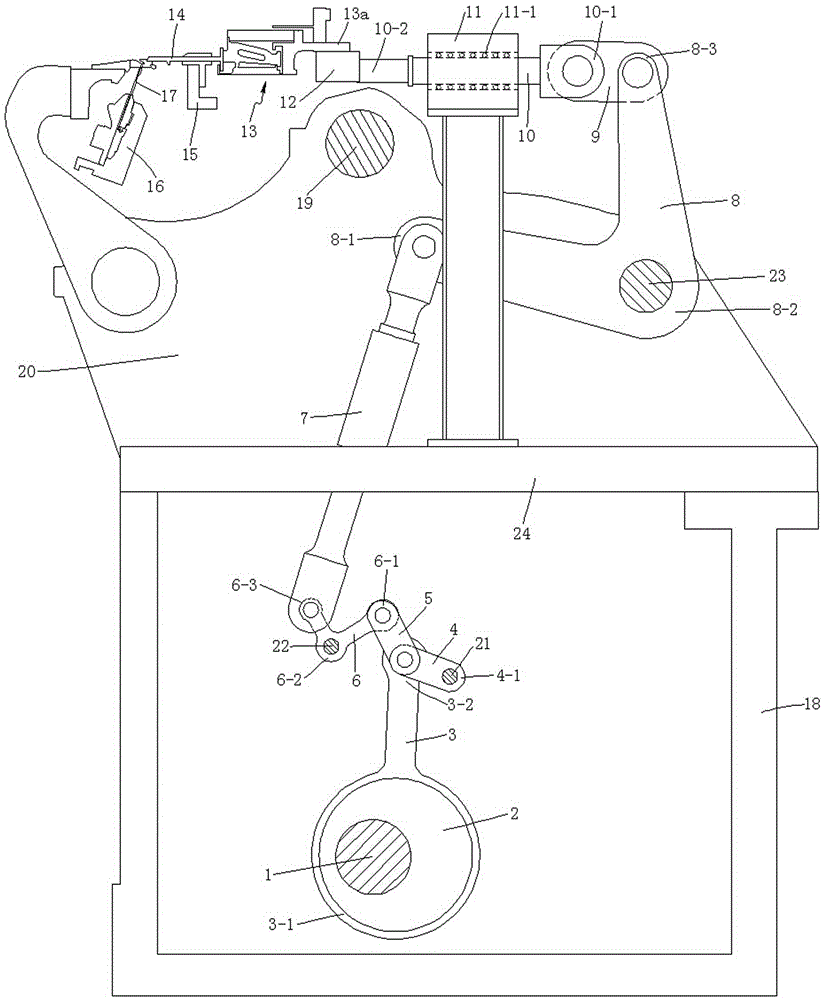

Needle-pressing mechanism for warp-knitting machine

InactiveCN104963079AReduce wear and tearExtended service lifeWarp knittingReciprocating motionEngineering

The invention discloses a needle-pressing mechanism for a warp-knitting machine. The needle-pressing mechanism comprises a transmission main shaft, a jacquard needle bed, a jacquard needle-pressing assembly, a push needle, a push need guide block and a bearded needle. The transmission main shaft drives the push needle to perform reciprocating motion by means of a push needle movement mechanism in order to open and close the bearded needle so that knitting in loops is finished. The push needle movement mechanism comprises an eccentric wheel, an eccentric sleeve connecting rod, a first connecting rod, a second connecting rod, a first triangular connecting rod, an oil tank output rod, a second triangular connecting rod, a third connecting rod, a push needle shaft and a guide seat. The left end of the second connecting rod is rotatably connected with the right upper end of the first triangular connecting rod. The left upper end of the first triangular connecting rod is rotatably connected with the lower end of the oil tank output rod. The upper end of the oil tank output rod is rotatably connected with the left upper end of the second triangular connecting rod. The push needle shaft is arranged along a horizontal direction. The right end of the push needle shaft is rotatably connected with the left end of the third connecting rod. A shaft body of the push needle shaft penetrates through the guide seat and is slidably connected with the guide seat. The needle-pressing mechanism for the warp-knitting machine helps to improve looping quality and prolongs service lifetime of the jacquard needle-pressing assembly.

Owner:江苏润源控股集团有限公司

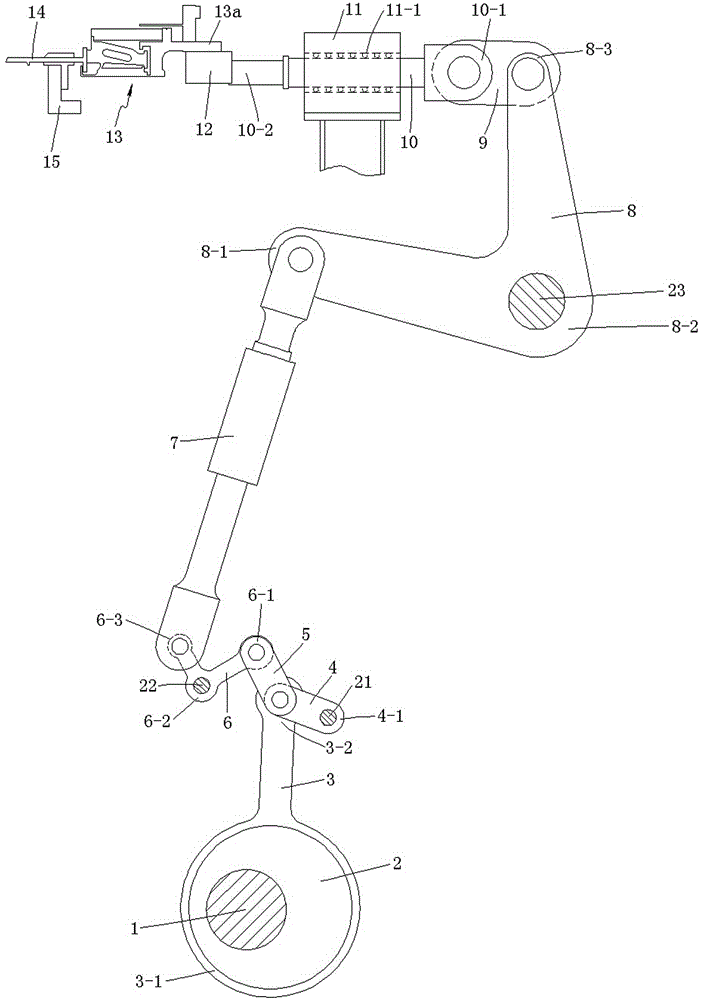

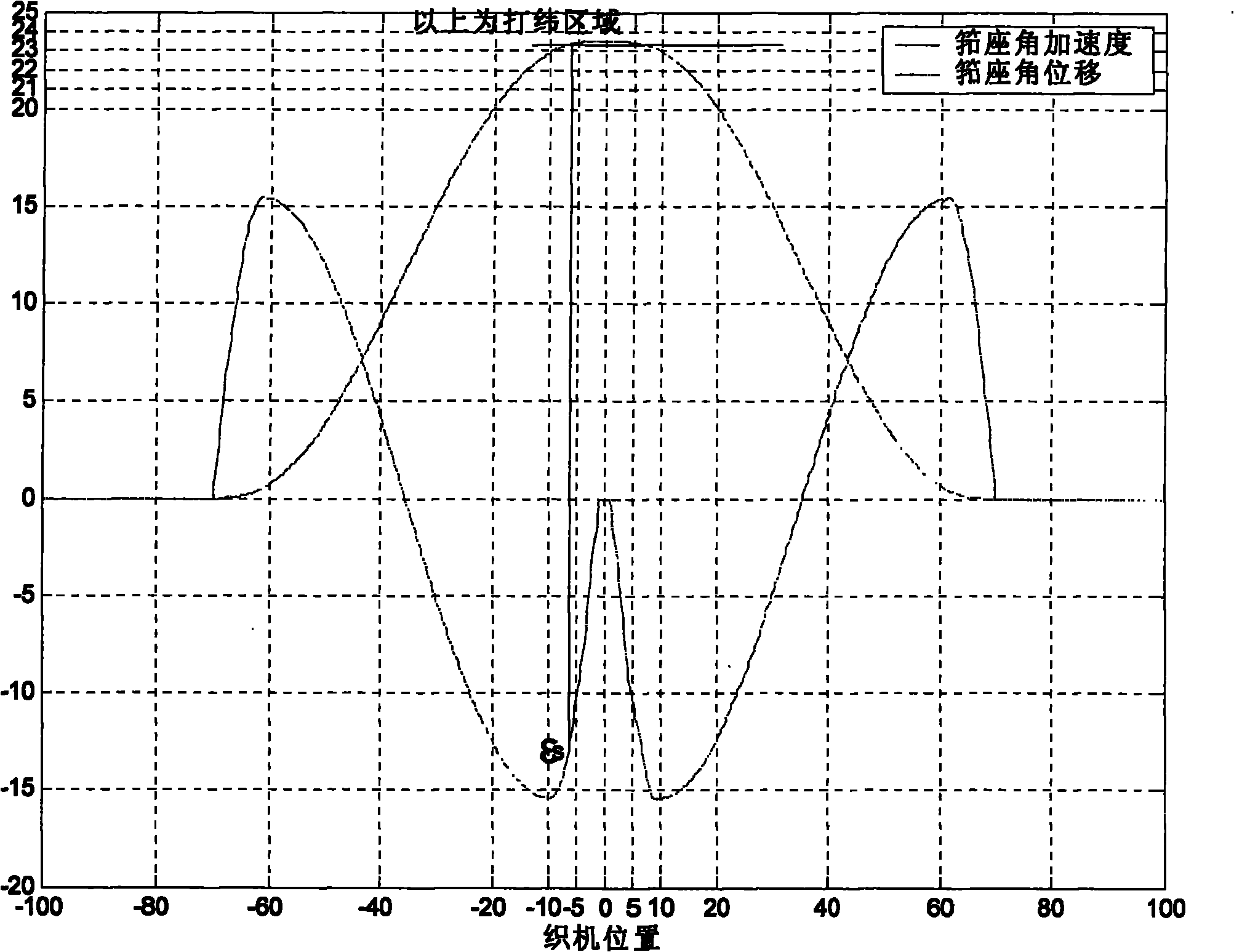

Non-inertial beating-up mechanism of weaving machine and sley motion method for implementing non-inertial beating-up

InactiveCN101831752ASatisfy angular acceleration requirementsOvercoming rare filesLoomsEngineeringCam

The invention relates to a non-inertial beating-up mechanism of a weaving machine and a sley motion method for implementing non-inertial beating-up. The beating-up mechanism mainly comprises a geometrically-closed conjugate cam and a swing arm, wherein a roller which is arranged on the swing arm is conjugate with the cam, the rotational motion of the cam enables the swing arm to obtain a rotation angle through the roller, the swing arm is fixedly connected with a beating-up shaft through a beating-up support arm, and an aluminum sley and a steel reed are fixedly arranged on the beating-up support arm; the warp face of fabric passes through the steel reed and forms a cloth fell at a cloth support plate, and the throughout S area of the cloth fell is a non-inertial beating-up area. In the method for implementing the non-inertial beating-up, in the beating-up area, the angular acceleration speed of the sley is in a smaller value of negative acceleration and has reverse direction with the motion of the sley, and the inertia force of the sley at the beating-up area also points to the cloth fell, that is to say, when the sley moves at high speed, the inertia force that points to the cloth fell is smaller than the beating-up resistance once the sley enters into the beating-up area and before the sley reaches the front of the limited beating-up position. The invention has the characteristics of simple structure, convenient and reliable use, improved weaving quality, stable performance, simple and reliable implementation method, and the like.

Owner:杭州天马纺织机械有限公司

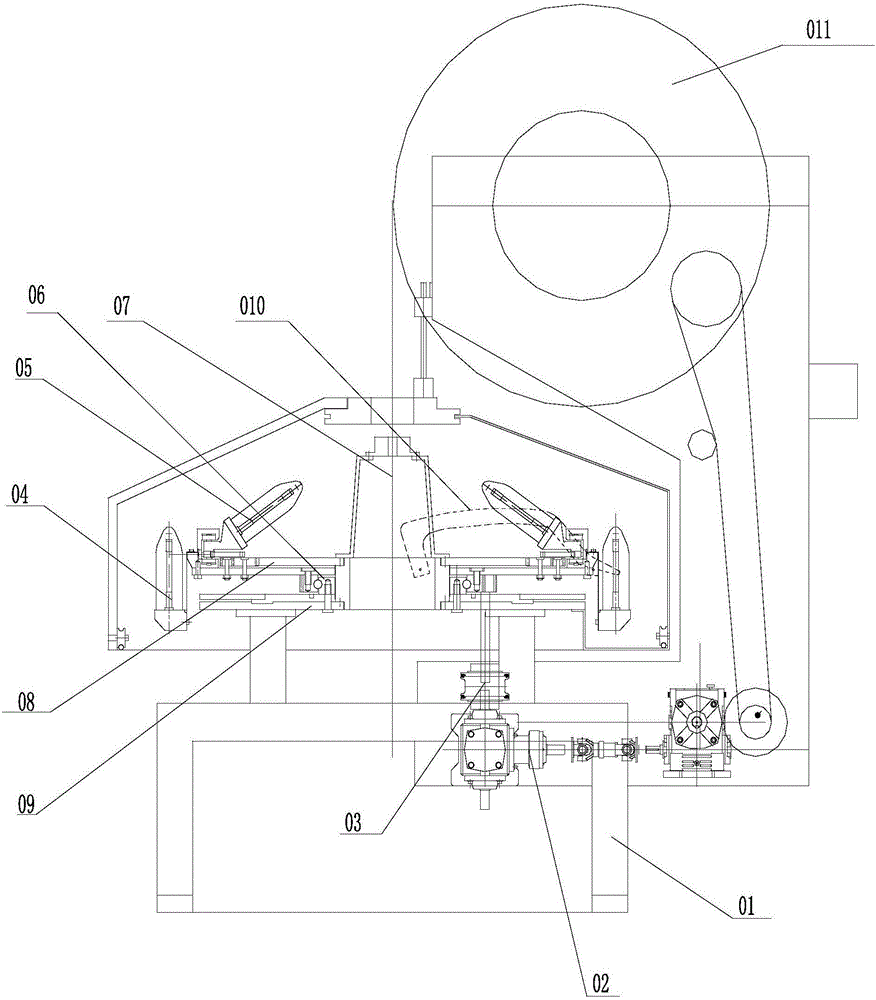

Velveteen air jet loom

PendingCN106987981AStable tension controlWeaving speed is fastCam shedding mechanismPile-fabric loomsNumerical controlAir-jet loom

The invention relates to a velveteen air jet loom. The velveteen air jet loom comprises a machine frame, a numerical control velveteen let-off mechanism, a velveteen shaft let-off mechanism, a bottom shaft let-off mechanism, a warp stop mechanism, an opening mechanism, a beating-up mechanism, an air jet weft insertion mechanism, a reeling mechanism, a batching mechanism and an electric control box. The velveteen shaft let-off mechanism lets pile warp off through the numerical control velveteen let-off mechanism, lets ground warp off through the bottom shaft let-off mechanism, the warp are conveyed into the air jet weft insertion mechanism from the opening mechanism through the warp stop mechanism, the air jet weft insertion mechanism is driven by the beating-up mechanism to complete weaving of double-layer velveteen, and then the double-layer velveteen is conveyed to a double-layer cutting mechanism, cut apart, and reeled through the reeling mechanism so as to be conveyed to the batching mechanism for collection.

Owner:JIANGSU YOUCHENG CNC TECH CO LTD

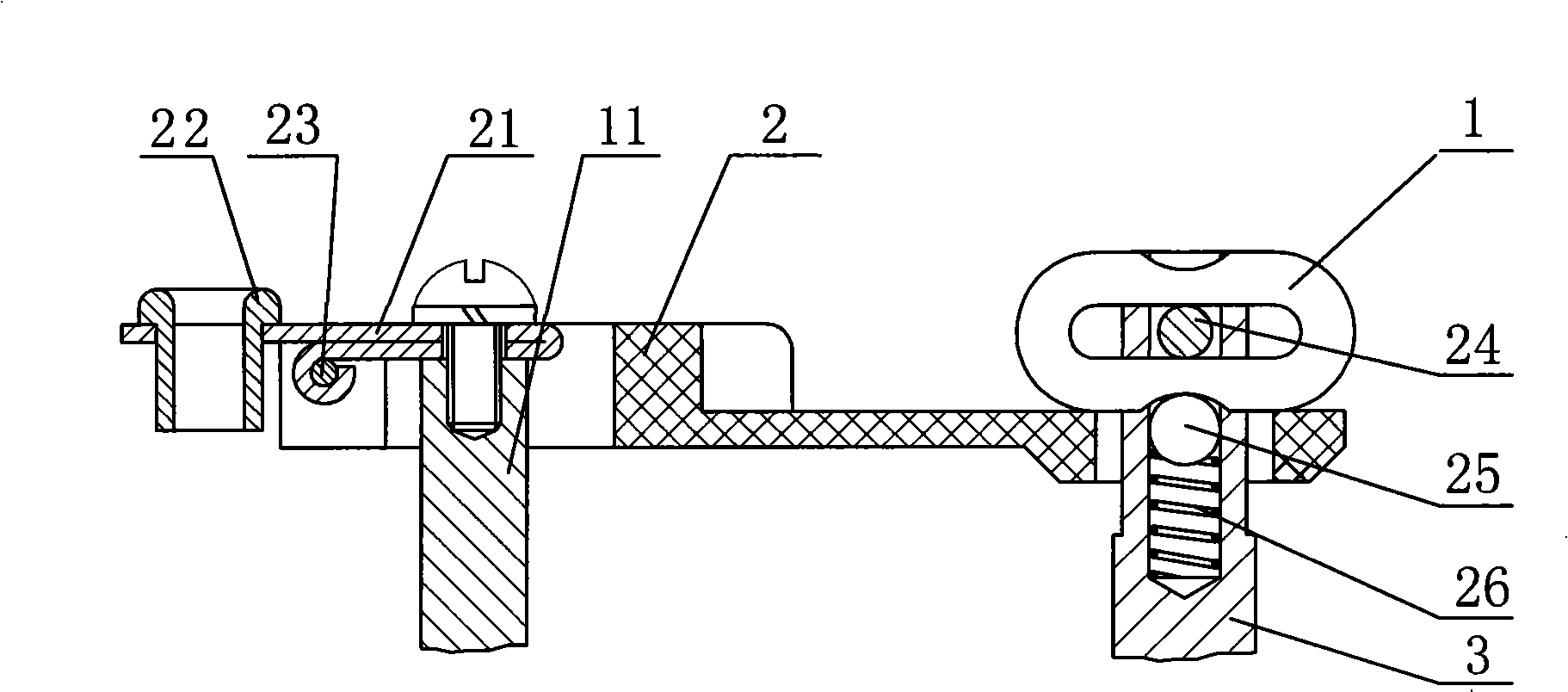

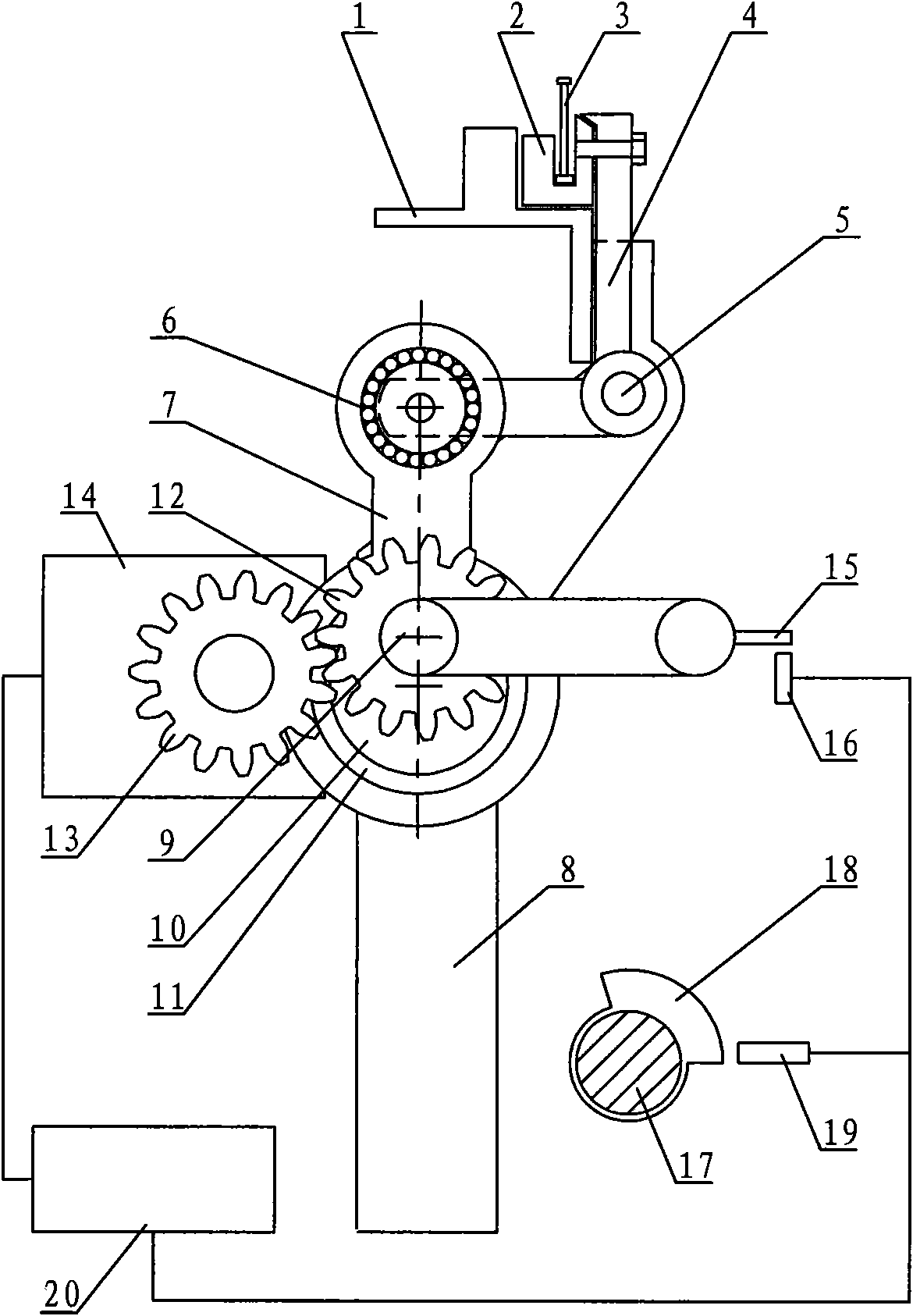

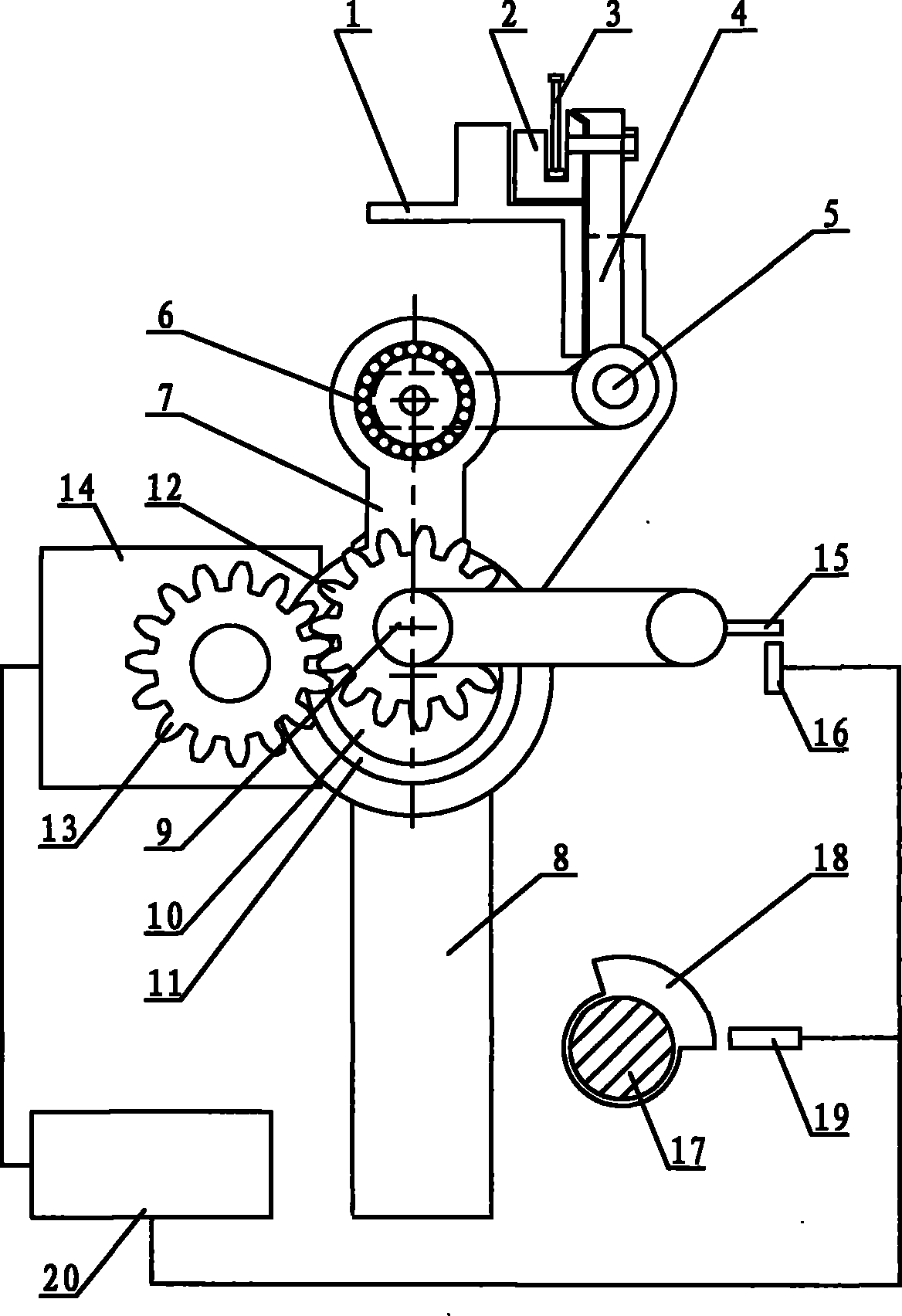

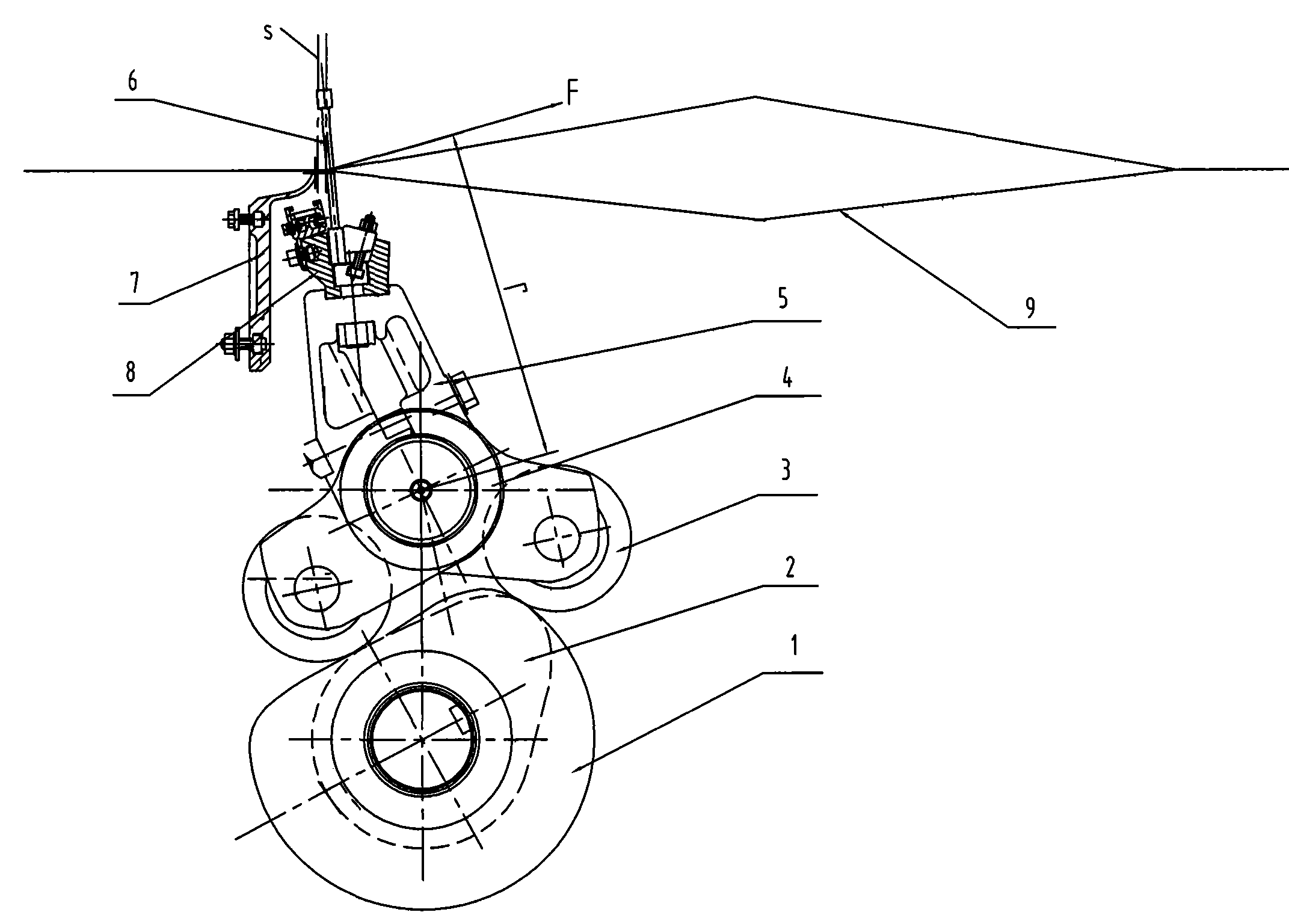

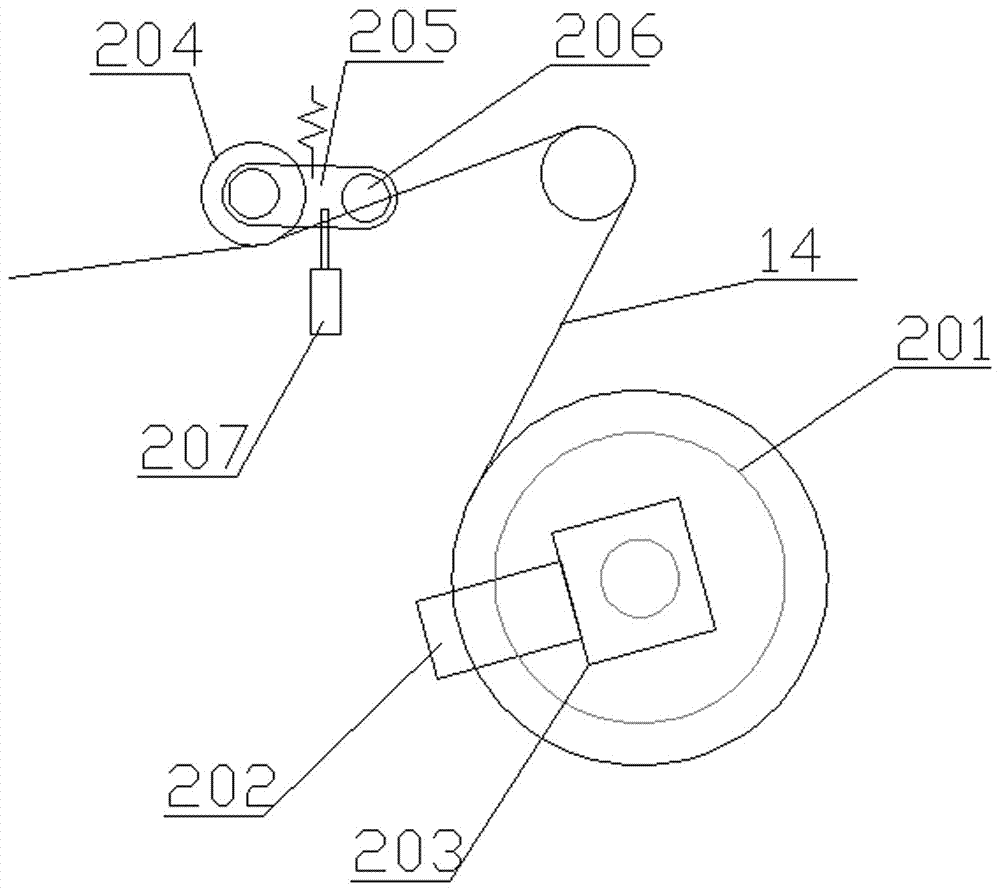

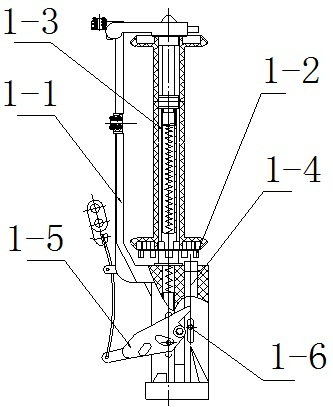

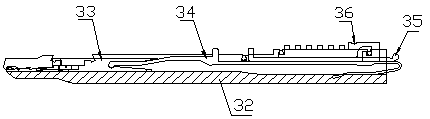

Pay-off braking device for spindle of high-speed braiding machine

InactiveCN102644159ALight and sensitive pay-offLine brakes are light and sensitiveBraidCircular discYarn

The invention relates to a pay-off braking device for a spindle of a high-speed braiding machine and belongs to a spindle braking structure of a braiding machine. The pay-off braking device comprises a spool base, a braking claw and a connecting rod, wherein one end of the braking claw is pressed on a side wall of an inner circular groove under the spool base; the other end of the braking claw is connected with the connecting rod; the spool base has a shape of a disc; a hole is formed in the middle of the disc; cylinders are uniformly distributed on the circumference of the same circle center as the hole; the inner circular groove is arranged under the disc; raised platforms are arrayed on an inner wall of the inner circular groove; the braking claw is L-shaped; the front end of the braking claw is pawl-shaped and moves in the inner circular groove under the spool base; a small hole is formed at a bent part of the braking claw and is sleeved on a pivot shaft; and the rear end of the braking claw is in sliding connection with the connecting rod. The pay-off braking device has the advantages that: a pay-off line is controlled by the pay-off braking device in a point contact way; the spindle pay-off is easy and flexible; the abrasion is small; the braking is accurate and gapless; a transmission part is simple in structure, low in cost, high in flexibility and long in service life; a rough yarn and a spun yarn are compatible; the yarn is free from being broken; and the braiding is uniform.

Owner:韩百峰

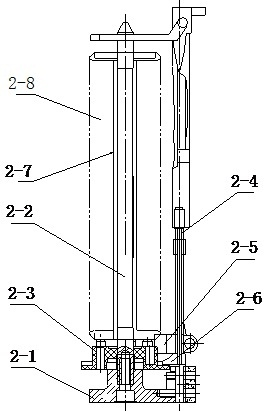

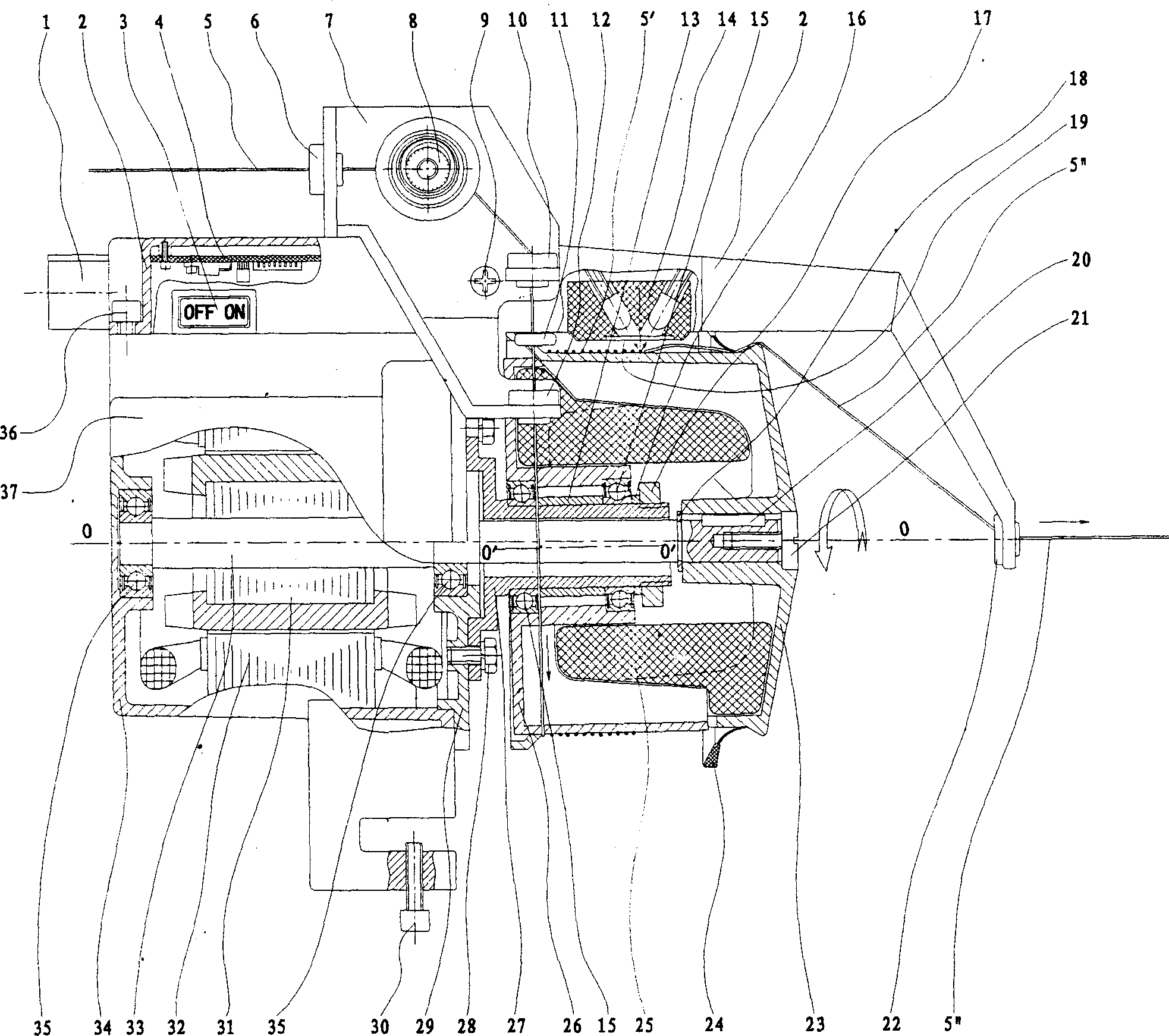

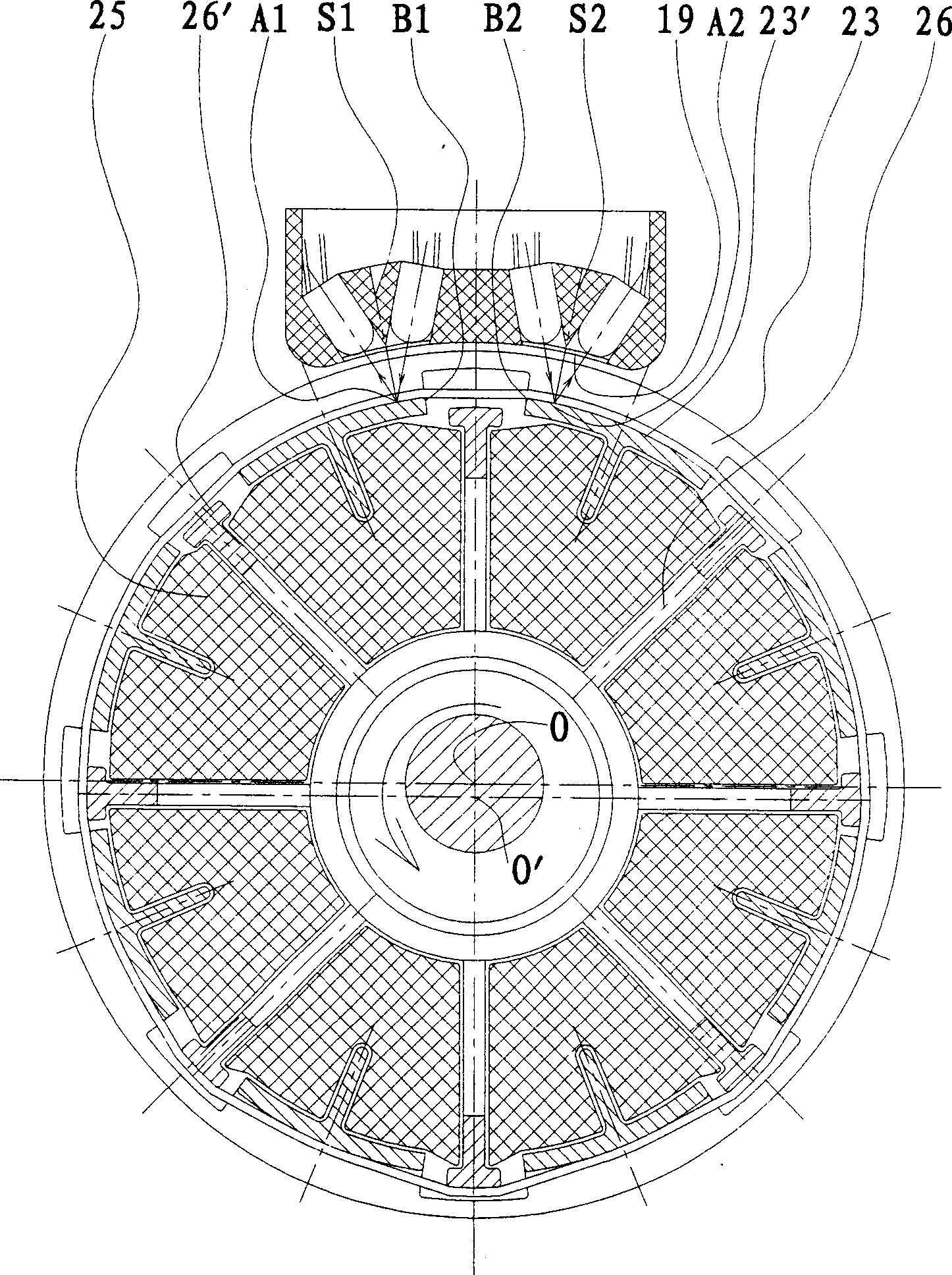

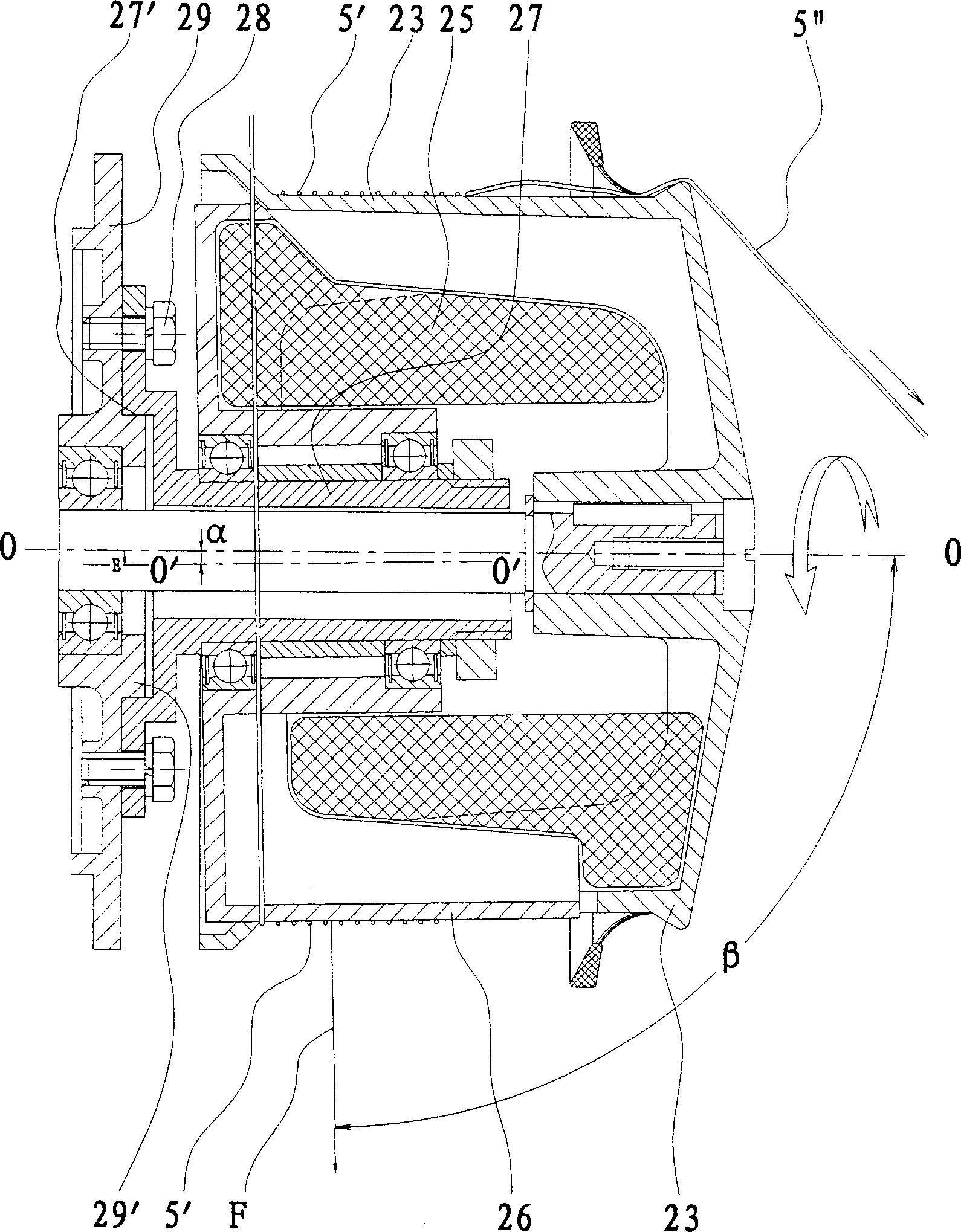

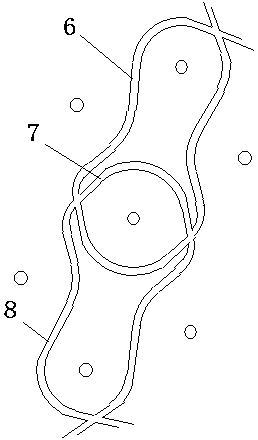

Rotating-drum yarn storing device for intermittent yarn storage and its manufacture

There is a device that stores thread for non-shuttle spinning machine, composed by electronic motor, inner-spinning drum, outer-spinning drum, hollow oblique axis, up-cover board, spinning tension machine, breaking spinning switch, electrical machinery controlling circuit board and spinning sensor and so on. The spinning cover of the outer-spinning drum is identical with the outside diameter of the inner-spinning drum. But each has different resolving axis. The resolving axis (O'-O') has a specified deviation distance to the outer-spinning axis and also has a specified angle of inclination, beta. So it can make the thread twined on the storing spinning cylinder, composed by outer-spinning drum and inner-spinning drum, move forward in a specified interval an ensure not overlapping spinning.

Owner:绍兴市联创电器有限公司

Safety alarm device for flat knitting machine

ActiveCN101260594AImprove weave qualityExtended service lifeKnittingEngineeringElectrical and Electronics engineering

The invention relates to the flat knitting machine technical field, in particular to a safety alarm device for a flat knitting machine, which is positioned on one end of a handpiece near to a neilsbed. The safety alarm device comprises a probe, a probe seat and a microswitch, wherein the probe connected on the probe seat matches the microswitch fixed on the probe seat. The safety alarm device is characterized in that: the safety alarm device also comprises a probe carriage, the probe is in transmission connection with the front of the probe carriage through a shaft pin, the side of the probe carriage is in transmission connection with the probe seat through a rotating shaft, and the axial direction of the rotating shaft is mutually vertical to the axial direction of the shaft pin. The lower end of the probe carriage is provided with a grooving; the rotating shaft horizontally drills through the grooving and is in transmission connection on the probe seat, a torsional spring is sleeved on the rotating shaft, the main body of the torsional spring is positioned in the grooving, and two ends of the torsional spring are fixed on the probe seat. The safety alarm device for the flat knitting machine provides multi-position safe warning for the flat knitting machine, and has better protection to fabrics and the machine.

Owner:NINGBO CIXING

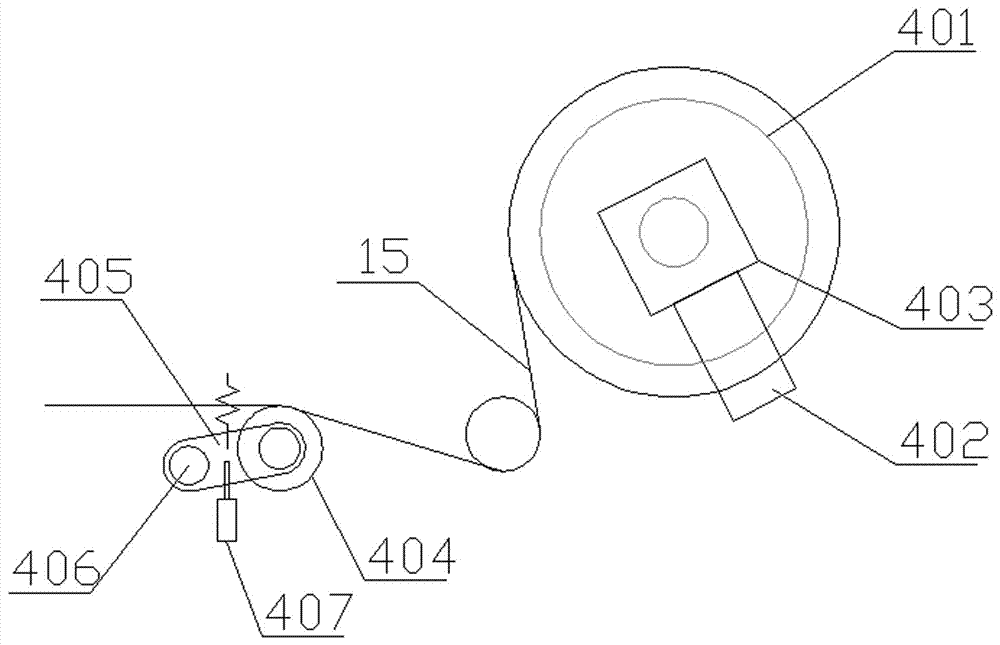

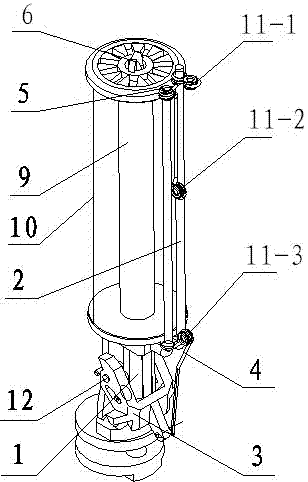

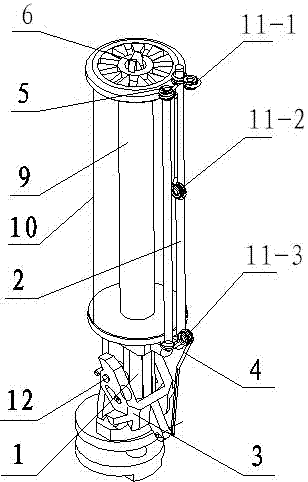

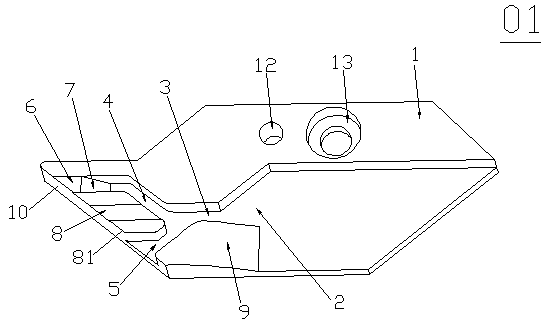

Large-capacity super-spun-yarn cursory spindle of high speed machine

The invention provides a large-capacity super-spun-yarn cursory spindle of a high speed machine, belonging to the cursory spindle of a braiding machine. A brake pin is arranged in a spindle seat of the cursory spindle; the bottom part of the brake pin is provided with a short compressed spring; a line weight is connected with the spindle seat through a pin and one end of the line weight is connected with a connecting rod; one side of the spindle seat is connected with a guide column and the guide column is sleeved with the connecting rod; the upper end of the spindle seat is connected with a bobbin shaft and the upper end of the bobbin shaft is provided with a clamping cap; a long compressed spring is arranged in the bobbin shaft and a bobbin is sleeved on the bobbin shaft; the upper end of the guide column is connected with a fixed frame and the fixed frame is connected with an upper threading device; and the middle part of the guide column is connected with a guide column threading device and a lower threading device is connected with the lower part of the guide column. The large-capacity super-spun-yarn cursory spindle of the high speed machine, disclosed by the invention, has the advantages of large bobbin capacity, small spindle friction resistance, light paying-off, smoothness in yarn discharging and no yarn breakage in paying-off and braiding processes of super spun yarns, can run at a high speed without yarn breakage, so that raw materials are saved; the clamping cap is in a 'Y' shape, the bobbin is convenient to load and unload and the yarn exchanging time is saved; and therefore, the braiding quality and the production quality are improved.

Owner:韩百峰

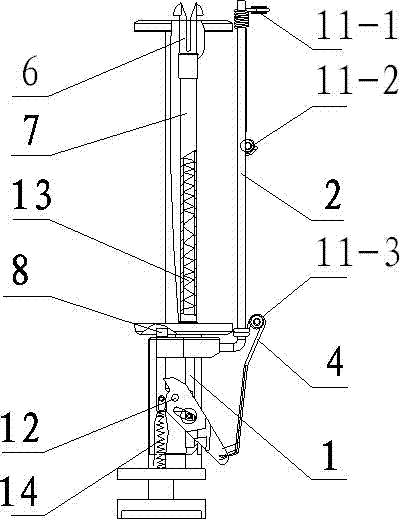

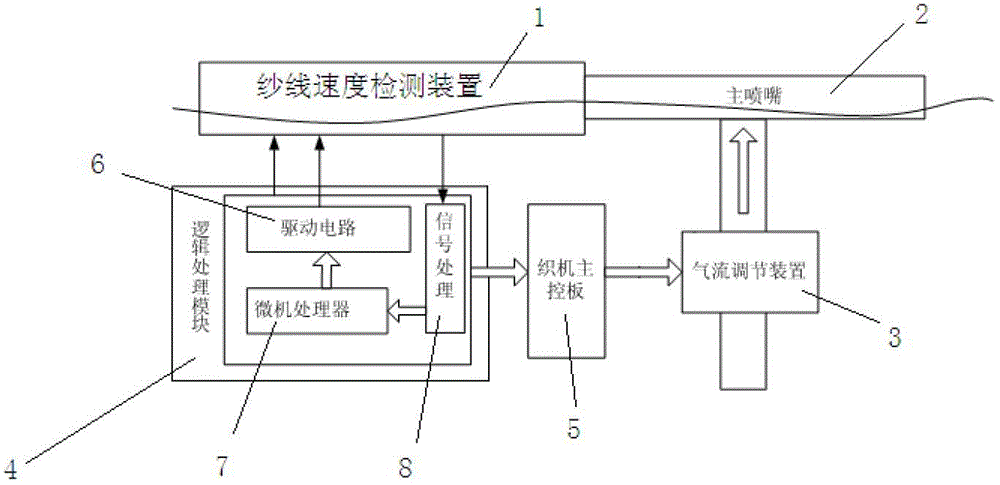

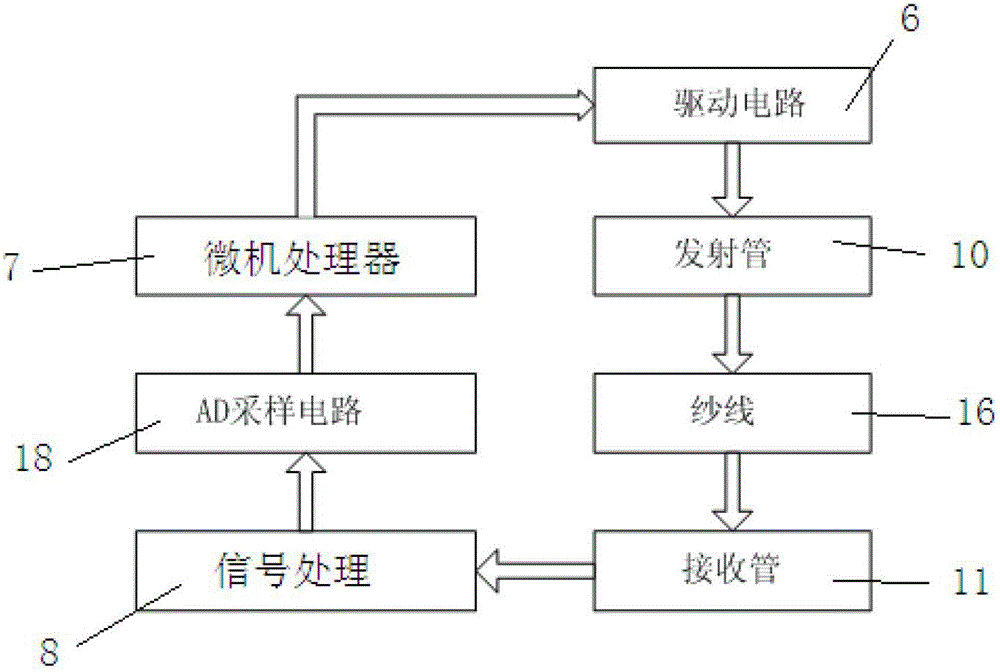

Automatic weft insertion rate control system for air-jet loom and regulation method of control system

The invention discloses an automatic weft insertion rate control system for an air-jet loom and a regulation method of the control system. The system comprises a yarn speed detection module, a main jet, an air flow regulation device and a logical processing module, wherein the yarn speed detection module and the main jet are fixedly mounted by a first groove screw and a second groove screw; the yarn speed detection module is connected with the logical processing module by a circuit; the logical processing module is connected with a loom master control board by a circuit; the loom master control board is connected with the air flow regulation device by a circuit; and the air flow regulation device is connected with the main jet by a pipeline. During a production course, the air-jet loom provided with the system can automatically control the air flow regulation device after different yarns are replaced, so that the yarns can reach the set weft insertion rate, the yarns can accurately pass through a fell within specified shedding time, a stoppage rate is reduced, the weaving efficiency is improved, and the weaving quality is improved.

Owner:ZHEJIANG LIMA YUNSHAN TEXTILE

Yarn tension control device

InactiveCN106637643ATension size real-time controlImprove weaving efficiencyWeft knittingYarn tensionControl theory

The invention discloses a yarn tension control device. The device comprises a fixing support and a control unit, the control unit comprises a broken yarn jumper spring, a jumper spring rotary knob, a jumper spring limit, a frosted roll and a motor. A motor support is arranged on the fixing support, yarn guide inlet holes and yarn guide outlet holes are formed in the fixing support, a motor is arranged on the motor support, the motor is connected to the frosted roll, the jumper spring limit is arranged at the upper part of the fixing support, the lower side of the jumper spring limit is provided with the jumper spring rotary knob, the jumper spring rotary knob is connected to the broken yarn jumper spring, the lower end of the broken yarn jumper spring is provided with broken yarn jumper spring yarn guide holes, a stopper is arranged on the jumper spring limit, the stopper is electrically connected to a controller, and the controller is electrically connected to the motor. According to the yarn tension control device, multiple control units are utilized to achieve independent control over every yarn, and the computer flat knitting machine weaving efficiency and weaving quality can be well improved.

Owner:FLYING TIGER TEXTILE MACHINERY +1

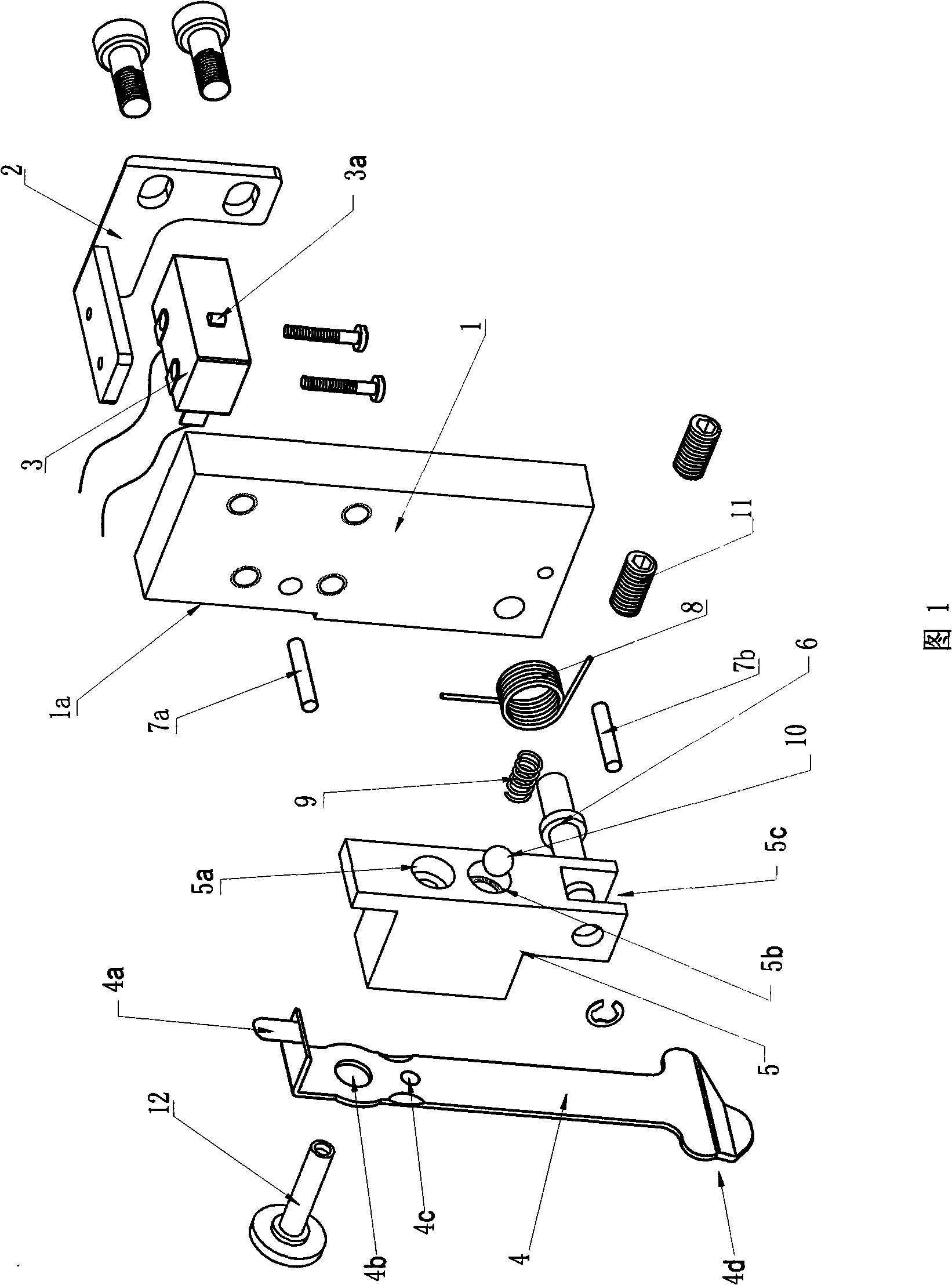

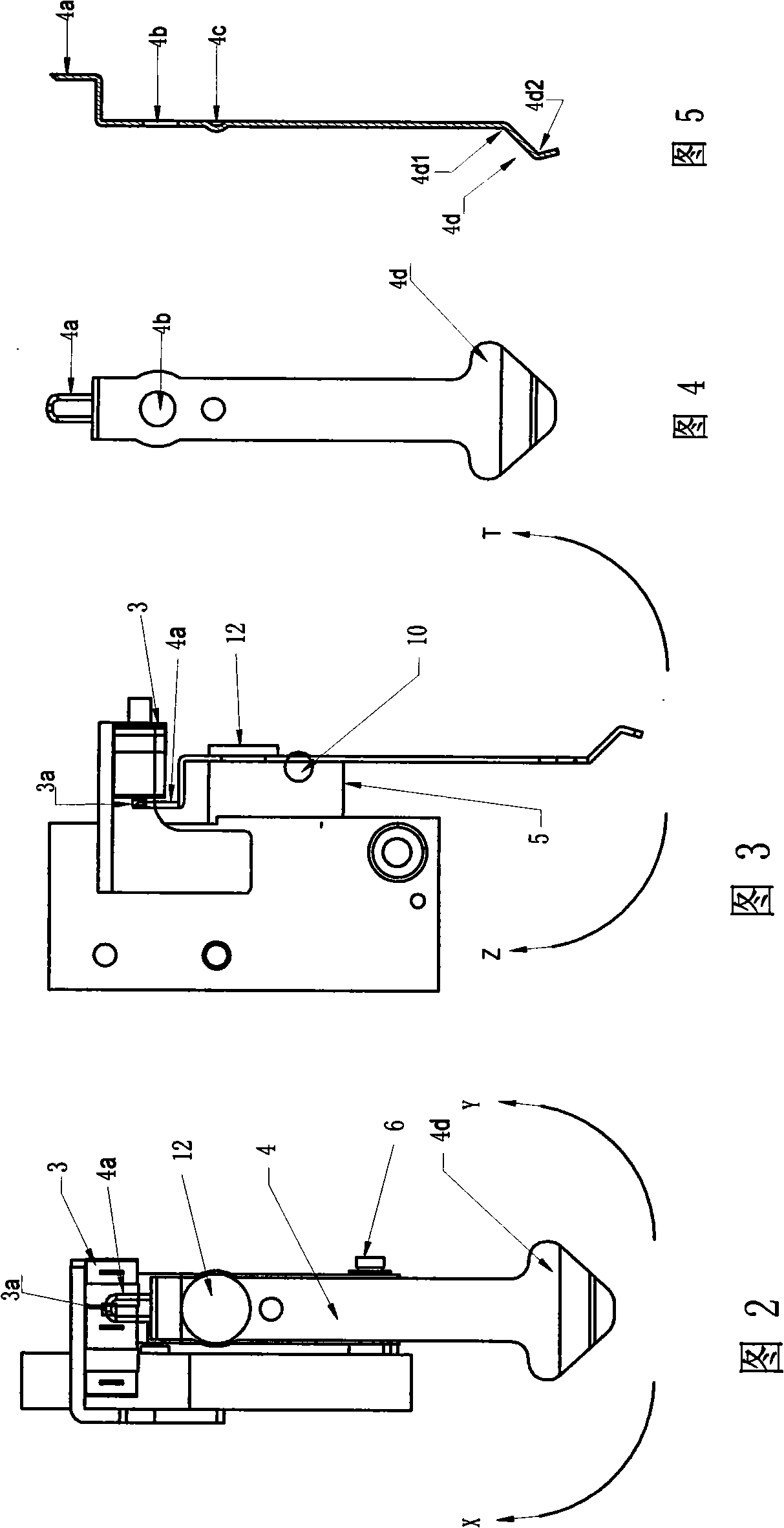

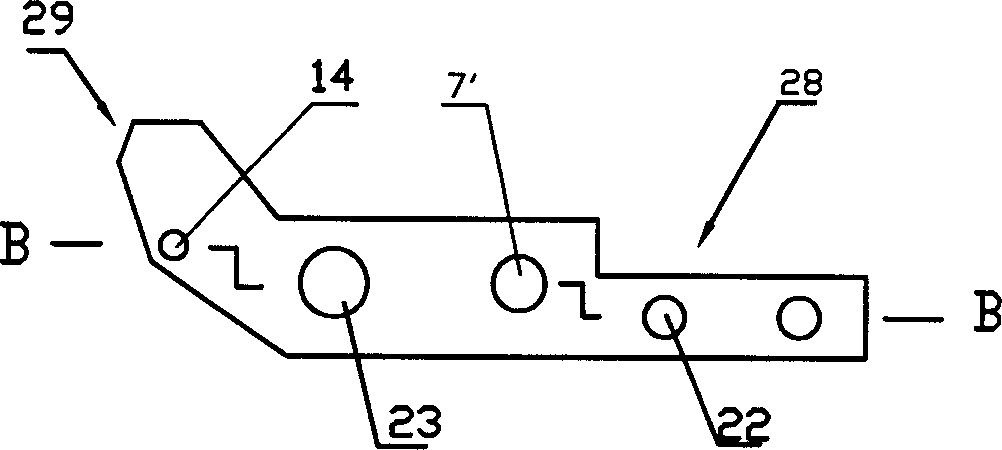

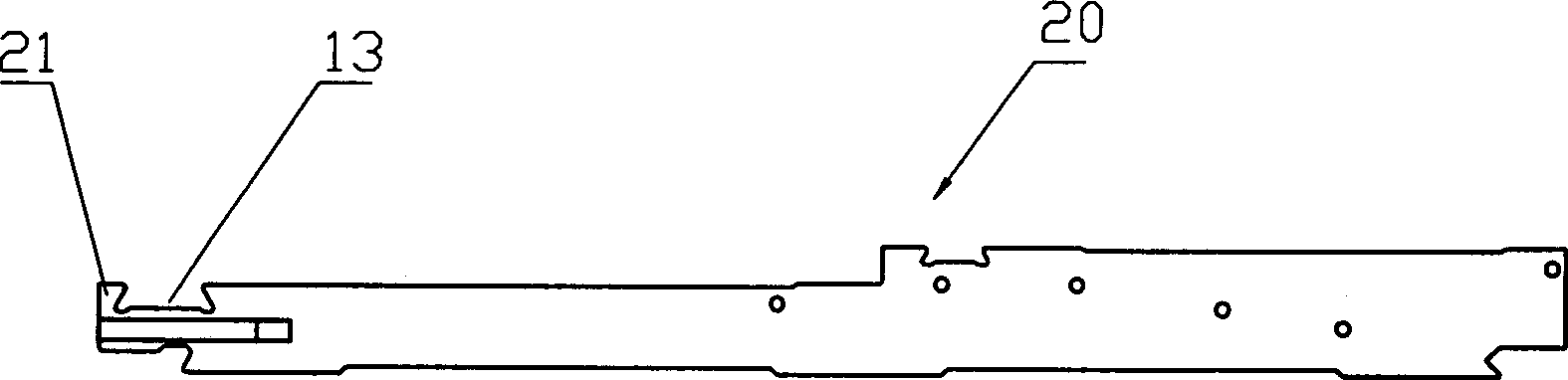

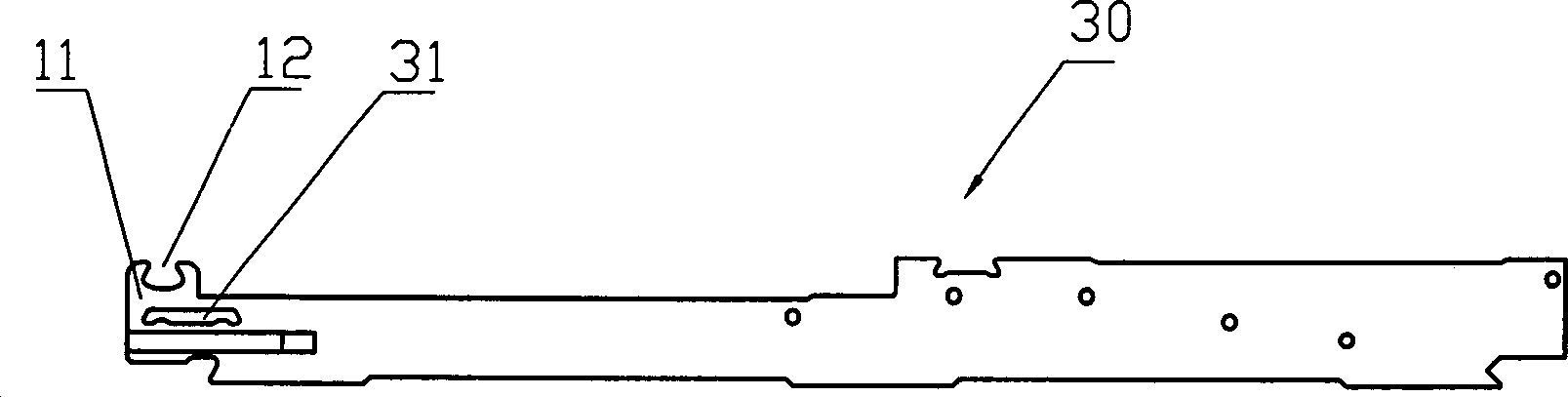

Thread-clamping and thread-loosing apparatus for straight-bar machines

InactiveCN1544738AImprove weave qualityImprove quality reliabilityWeft knittingEngineeringPlane parallel

The invention relates to a line-pressing and-stripping device for flat knitting machine, and its technical project: it includes depositing piece, de-circle piece, inserted piece, needle plate groove and steel wire rotating shaft, where the depositing piece and the de-circle piece are connected with the rotating shaft, the bottom of the de-circle piece is inserted in the needle groove and one side of the de-circle piece is tightly set with the inserted piece, the bottom end of the depositing piece extends downwards a plane parallel with the original plane in the direction of one side surface at two continuous basic 90 deg. bending angles; the top of the locating hole is set with a long groove hole and there is a gap on the edge of the bottom end of the locating hole and the locating hole connects the long groove hole and the gap, the depositing piece is connected with the rotating shaft in socketing mode; one side surface of the de-circle piece is set with several bosses. Its advantages: (1) good weaving quality and the reliability is largely enhanced; (2) accurate locating, largely saving time and labour and the product cost is reduced; (3) simple and easy to make and low cost.

Owner:冯加林

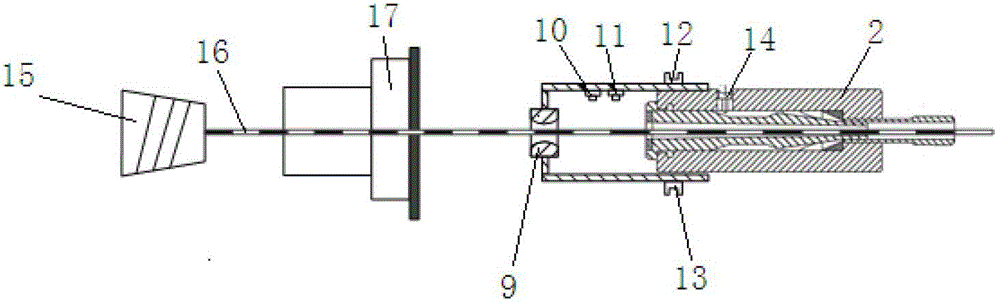

Computerized flat knitting machine yarn feeder and yarn detection control system thereof

The invention discloses a computerized flat knitting machine yarn feeder and a yarn detection control system of the computerized flat knitting machine yarn feeder. The computerized flat knitting machine yarn feeder comprises a box, a driving motor, a yarn guide rod, an encoder, a first yarn feeding roller, a second yarn feeding roller, paraffin removal devices and an adjusting device, wherein the driving motor is installed outside the box. The driving motor drives the first yarn feeding roller and the second yarn feeding roller to rotate through a yarn feeding belt wheel, the first yarn feeding roller and the second yarn feeding roller are connected in parallel through a connecting plate, the side face of the first yarn feeding roller and the side face of the second yarn feeding roller are provided with the paraffin removal devices respectively, the paraffin removal devices are composed of anti-caking rods and brushes, the brushes fixedly adhere to the corresponding anti-caking rods, and the adjusting device forms a swing arm type adjusting structure through a rotatable fixing supporting point, ceramic wheel carriers and two movable ceramic wheel sets installed on fixing blocks. The computerized flat knitting machine yarn feeder is provided with the encoder, the speed and the length of yarn can be measured, stitches can be adjusted, yarn feeding is uniform and stable, the paraffin removal devices and the adjusting device are arranged, paraffin on the surfaces of the yarn feeding rollers is removed in time, service life is prolonged, and knitting efficiency and knitting quality are effectively improved.

Owner:QUANZHOU JINGZHUN MACHINERY

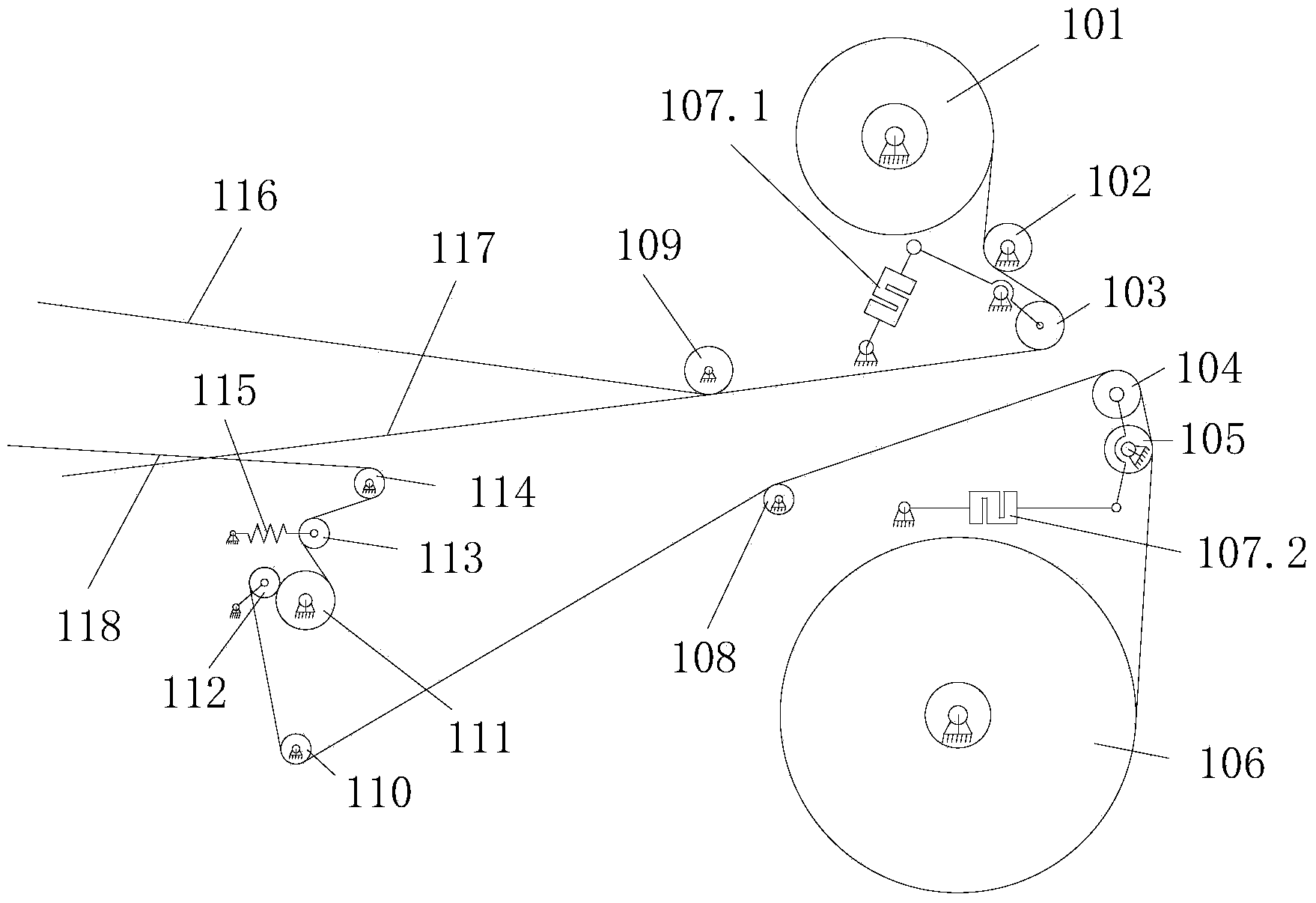

Air jet loom for weaving lint

ActiveCN104018279AAuto resizeAvoid high and low fleece phenomenonPile-fabric loomsControl systemAir-jet loom

The invention discloses an air jet loom for weaving lint. The air jet loom comprises a frame and a control system, wherein the frame is provided with a warp feeding device, an opening device, a weft guiding device and a coiling device in sequence in a lint weaving direction; the warp feeding device comprises a ground warp feeding mechanism and a pile warp feeding mechanism; the weft guiding device comprises a plurality of pipe piece weft guiding units connected in sequence, and flat reed structures positioned behind the pipe piece weft guiding units; all the pipe piece weft guiding units and the flat reed structures are mounted on a reed base; and a lint edge supporting and ironing device is arranged between the coiling device and the weft guiding device. The air jet loom preferably solves such problems as warp feeding tension control, easy wear of abnormal reeds in a weft guiding process and lint edge shearing encountered in the lint weaving.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

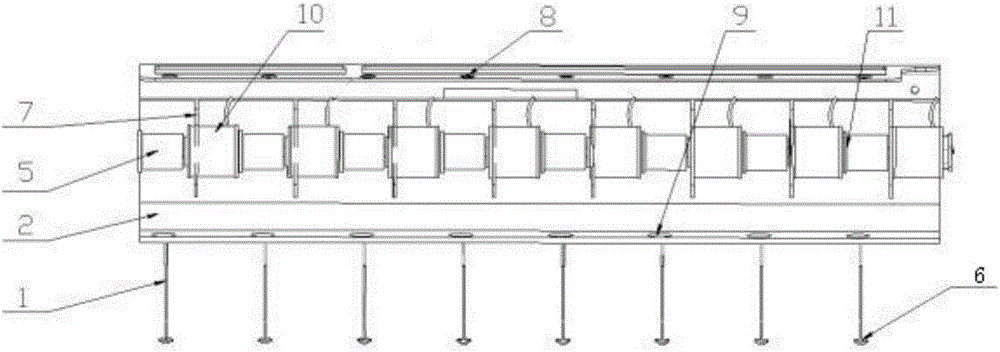

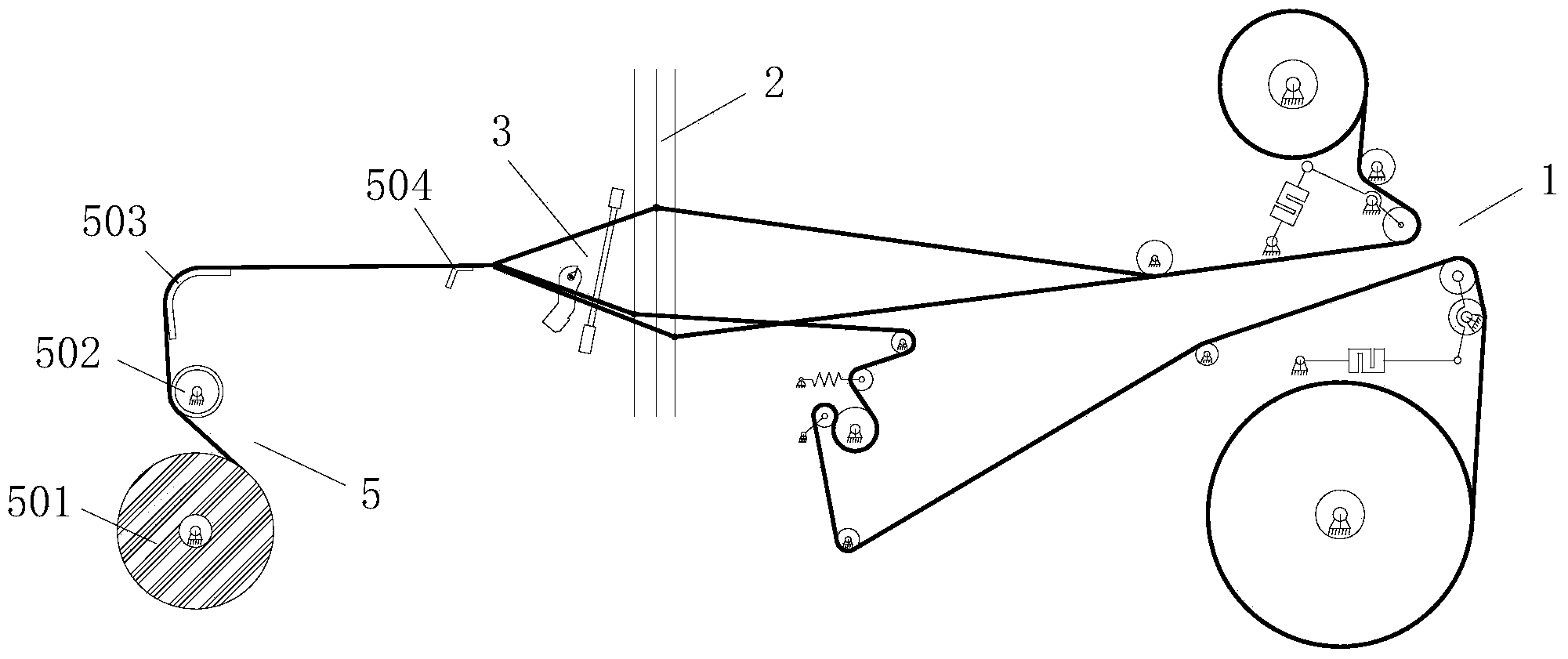

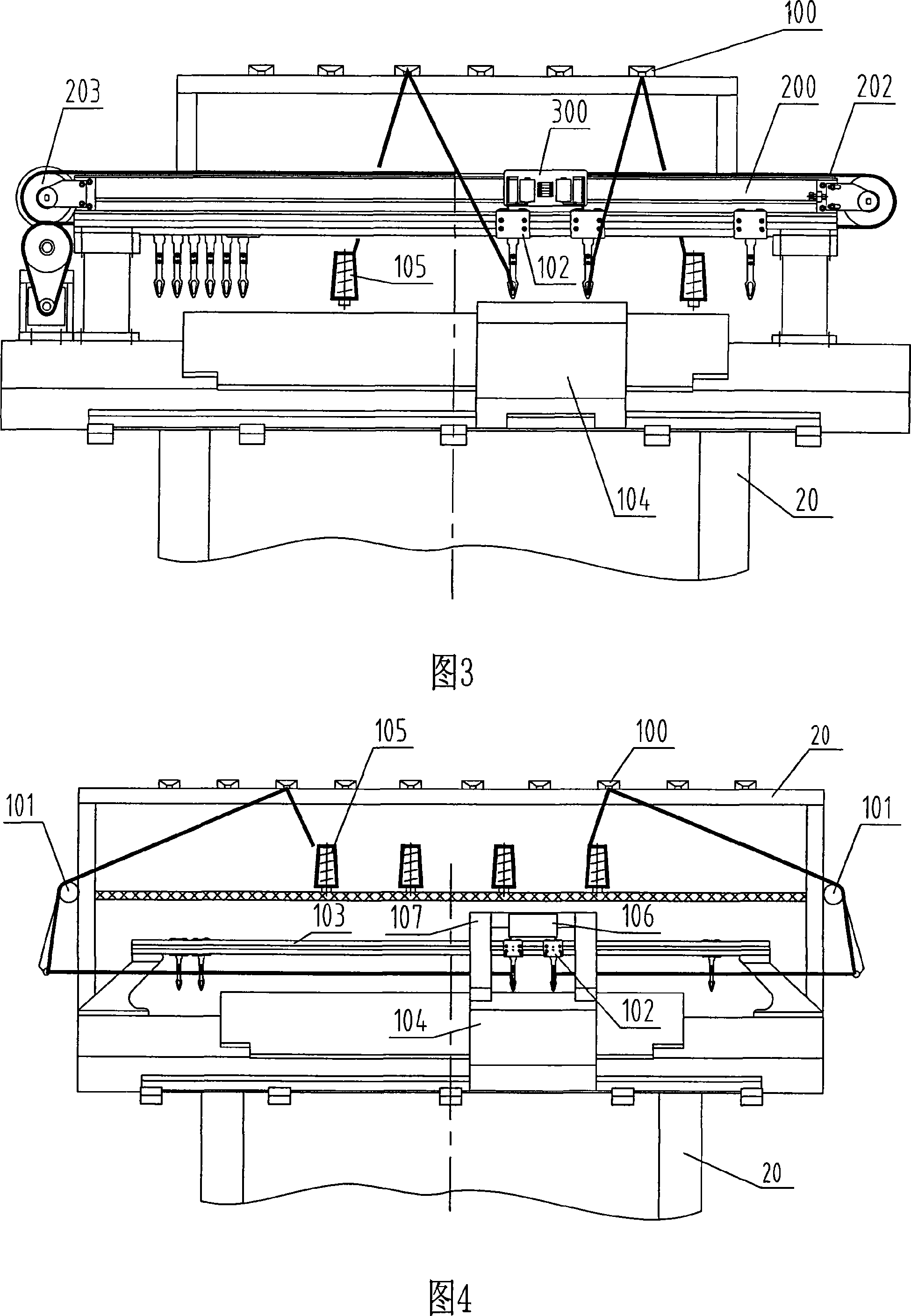

Warp feeding device of lint air jet loom

The invention discloses a warp feeding device of a lint air jet loom. The warp feeding device comprises a frame and a servo control system, wherein a ground warp feeding mechanism is arranged at the upper part of the frame, and a pile warp feeding mechanism is arranged at the lower part of the frame; the ground warp feeding mechanism is provided with a ground warp weaving shaft and a ground warp feeding tension roller in sequence in a ground warp conveying direction; the ground warp weaving shaft is driven by a ground warp servo motor; the ground warp feeding tension roller is connected with a ground warp tension sensor; the pile warp feeding mechanism is provided with a pile warp shaft disk, a pile warp feeding tension roller, a yarn guide roller, a velvet raising control roller and a velvet raising tension roller in sequence in a pile warp conveying direction; the pile warp shaft disk is driven by a pile warp servo motor; the pile warp feeding tension roller is connected with a pile warp tension sensor; the velvet raising tension roller is connected with a tension spring; and the servo control system comprises a servo controller. The warp feeding device is precise in tension control, can adjust the positions of ground warps and pile warps and the heights of velvets, prevents the generation of high-low velvet phenomenon, and improves the weaving quality.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY +1

Novel knitting machine

The invention discloses a novel knitting machine. The novel knitting machine comprises a frame, a driving device, an internal knitting support, an internal knitting center, a rotary support, an internal ingot combination, a traction device, a control system, a slide way combination, an external ingot combination, a thread passing device and the like, wherein the traction device finishes traction through two belts which run synchronously in order to ensure stable traction speed and freeness from sliding and injury; matching between the traction speed and a knitting speed is realized through the control system; the thread passing device is a semi-oval curved thread passing plate, so that an internal ingot thread and an external ingot thread constantly keep a maximum distance in a running process, and thread breakage is reduced. The knitting machine is simple in structural design, is skillful and reasonable in concept, and has breakthrough significance to practical production; compared with the conventional way, the novel knitting machine has the advantages that the production efficiency is increased by over 35 percent, and meanwhile the knitting quality is improved; the novel knitting machine can be widely applied.

Owner:青岛事旺达智能科技有限公司

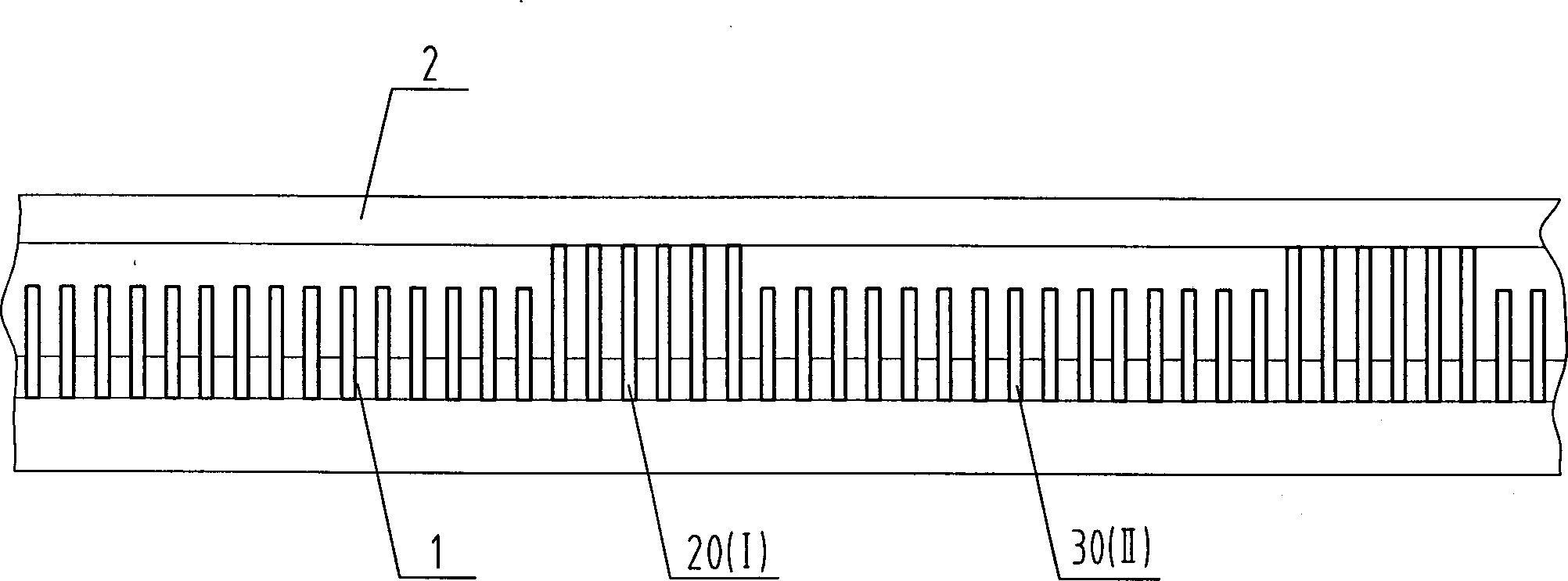

Knitting mechanism for flat knitting machine and method

ActiveCN109023688ASimple structureSimple structural designWeft knittingTextile/flexible product manufactureCamDISC assembly

The invention relates to a knitting mechanism for a flat knitting machine and a method. The knitting mechanism comprises a triangular bottom plate and a knitting needle assembly. At least one knittingunit is arranged on the triangular bottom plate, the knitting unit and the knitting assembly cooperate to carry out knitting, the knitting unit comprises an upper left protection plate, a swing cam,a needle turnover cam, an upper right protection plate, a left stitch cam, a right stitch cam, a knitting cam, a disc assembly, a guide assembly corner, a non-woven pressing sheet and a needle selecting cam. A needle groove is formed in a needle plate body, combined knitting needles are arranged in the needle groove, and the combined knitting needles comprise a retreating needle, a long stitch, ashort stitch and a needle selecting stitch. The needle selecting triangular structure design is simple, processing is easy, and the needle selecting position is accurate. Compared with an existing bottom plate device, the bottom plate structure is more simplified, the weight is reduced, the long stitch is only provided with a needling butt, the structure is simple, five basic actions of knitting,ring gathering and needle turnover and non-weaving can be carried out, and a specific needling knitting method is provided.

Owner:桐乡市强隆机械有限公司

Cam knitting mechanism with electromagnetic needle selecting function of computerized flat knitting machine

A cam knitting mechanism with an electromagnetic needle selecting function of a computerized flat knitting machine comprises an electromagnetic needle selector, a cam bottom plate and a knitting cam. The knitting cam comprises a loop transfer needle retaining cam, a loop transfer ordering cam, an eyebrow cam, a looping cam and needle pressing cams, the loop transfer needle retaining cam, the loop transfer ordering cam and the eyebrow cam are disposed on the upper portion of a knitting unit, the looping cam is arranged below the eyebrow cam, the needle pressing cams are arranged on two symmetric sides of the eyebrow cam, the eyebrow cam, the looping cam and the needle pressing cams form a looping needle way, an A needle way and a B needle way arranged at the upper end of the A needle way are arranged in the looping cam symmetrically, the B needle way is communicated with the A needle way and the looping needle way, the looping needle way is deeper than the B needle way, the B needle way is deeper than the A needle way, and the A needle way, the B needle way and the looping needle way form a loop collecting and integrating needle way. The size of the cam bottom plate is reduced by the electromagnetic needle selecting mode, material consumption and cost are reduced, all cams are fixed knitting cams, so that a knitting needle of the head of the computerized flat knitting machine is stable in running and knitting quality is improved.

Owner:冯加林 +2

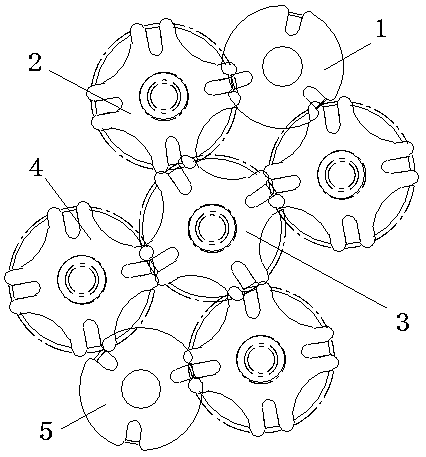

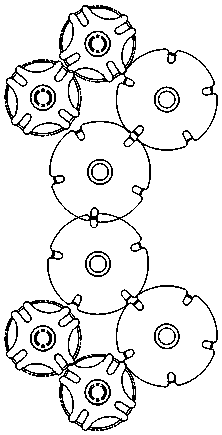

Entwined drive-cross system for national costume decoration belt knitting machine

The invention relates to an entwined drive-cross system for a national costume decoration belt knitting machine, and belongs to the national costume decoration belt knitting machine. The number of front-transition gear driving plates and rear-transition gear driving plates of the entwined drive-cross system is separate two; front-rotation gear driving plates and rear-rotation gear driving plates are separately meshed with the two front-transition gear drivings and the two rear-transition gear driving plates to form a front transmission system and a rear transmission system, an entwined weavingsystem is formed between the front transmission system and the rear transmission system through common gear driving plates meshed with each other, and adjacent drive-cross slots are aligned synchronously during operation; the rear part of a front guide rail overlaps the front part of a rear guide rail to form a common guide rail; the intersection of the front guide rail and the rear guide rail islocated on one side of the rear guide rail; and the diameter of the front guide rail at the common guide rail is larger than that of the rear guide rail. The entwined drive-cross system for the national costume decoration belt knitting machine has the advantages that the guide rail of the knitting machine has no spindle interference phenomenon, the shape of the machine is reduced, and the space is saved; the reduction of the number of teeth of a drive-cross gear increases the rotation speed of the machine, and the production volume increases with the improvement of the rotation speed of the machine; and a spindle is woven evenly smoothly, and the weaving quality is improved.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

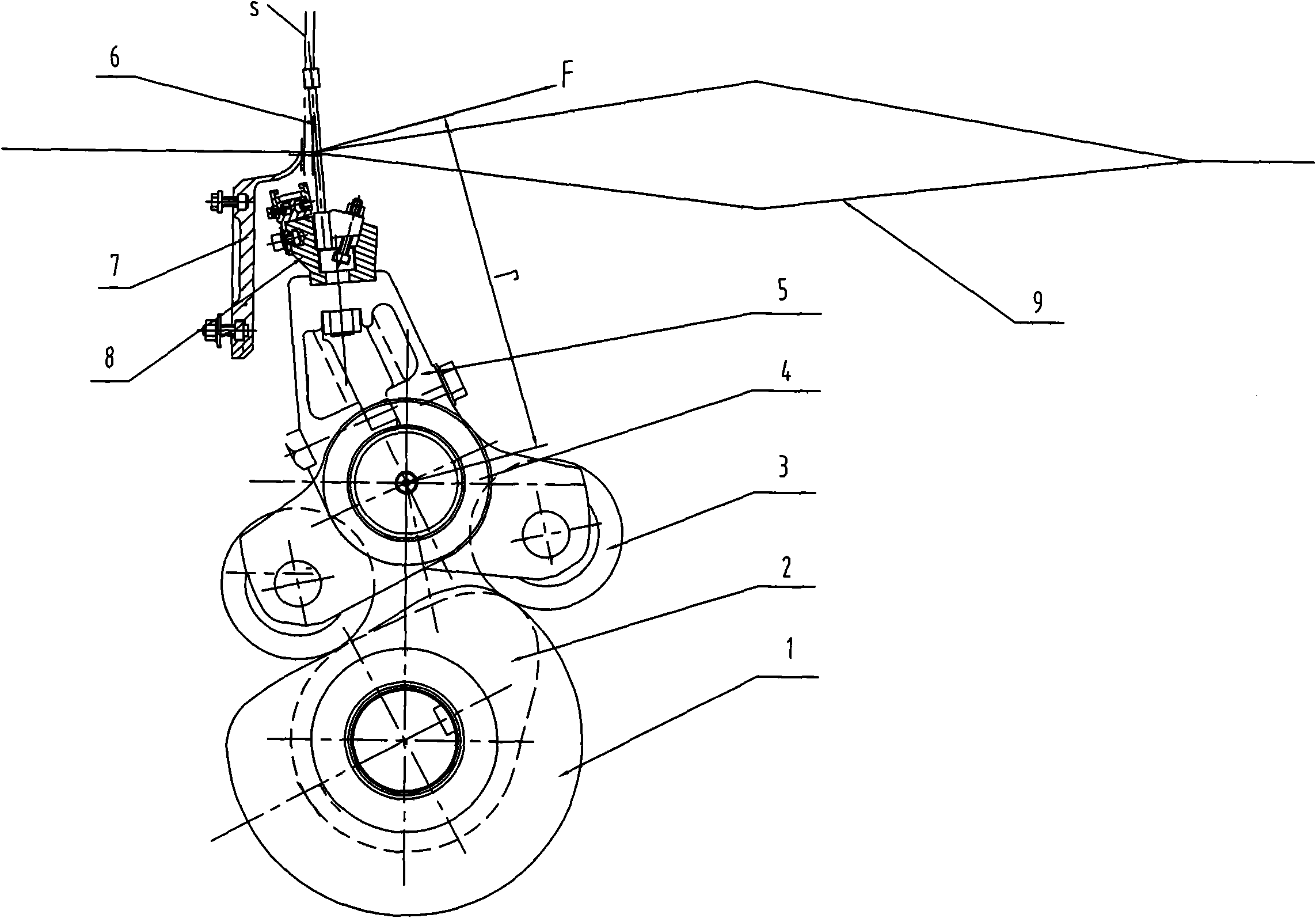

Yarn feeding device for computer flat machine

The present invention relates to a yarn feeding device of a computerized knitting machine and has the technical proposal that the present invention comprises a shuttle bar, a shuttle box and a shuttle box controlling mechanism, wherein, the shuttle box controlling mechanism is arranged on two sides of the upper part of the shuttle bar, the shuttle box is arranged on two sides of the lower part of the shuttle bar, and the shuttle box controlling mechanism is connected with the shuttle box in a rotary way through a clip flap on the controlling mechanism to drive the shuttle box to move together along the shuttle bar. The present invention has the advantages that the shuttle box controlling mechanism formerly arranged on the nose connecting frame is arranged on the shuttle bar, on one hand, the weaving wire on a wire frame is directly guided on the shuttle box, and the weaving wire is not required to be bended, thereby, the mutual entanglement and whipping together cannot be caused, the suffered pulling force is small and the force distribution is uniform, thus being favorable to the improvement of the quality of weaving; on the other hand, the controlling of the shuttle box on the shuttle bar is executed by the shuttle box controlling mechanism through a computer order, thereby, the driving structure is simple, and the occupied space is small, but the operation is accurate and effective, more shuttle boxes can be arranged on the shuttle bar to meet the needs of more weaving patterns and more complex weaving patterns, so as to provide superior knitting performance for the computerized knitting machine, and to greatly increase the performance-to-price ratio.

Owner:冯加林 +1

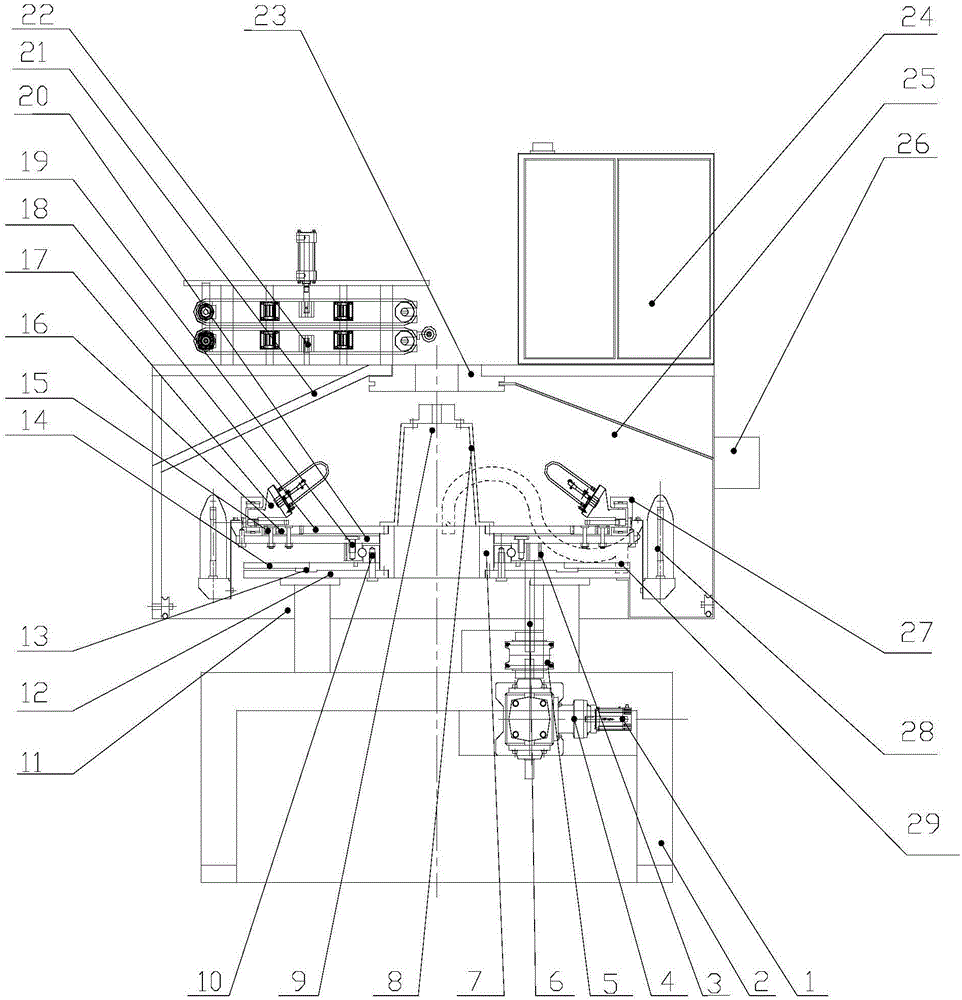

Carpet weaving machine

InactiveCN105297303AImprove weaving efficiencyImprove weave qualityTufting apparatusYarnControl system

The invention discloses a carpet weaving machine which comprises a yarn placing and synchronous conveying mechanism, an electrical control system and a rack, and is characterized by further comprising a machine head transverse moving mechanism, a yarn color selecting mechanism and a base fabric feeding mechanism. The weaving machine has the advantages that the weaving accuracy is high, the weaving machine is suitable for weaving of large-breadth carpets, the automation degree is high, the weaving machine has more tufting styles, the processing efficiency is high, the stability is high, and the weaving quality is high.

Owner:TIANJIN HAIYAN TECH

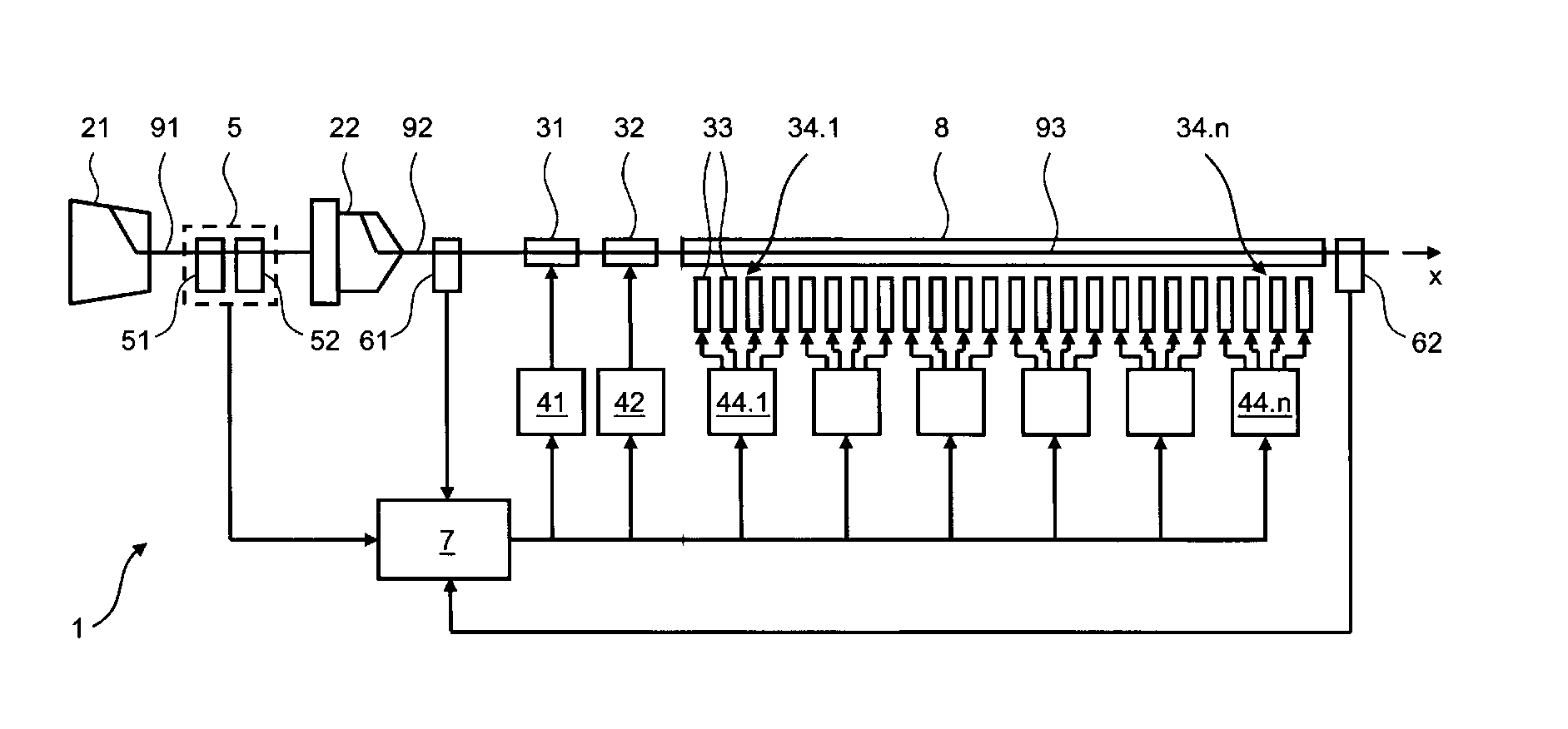

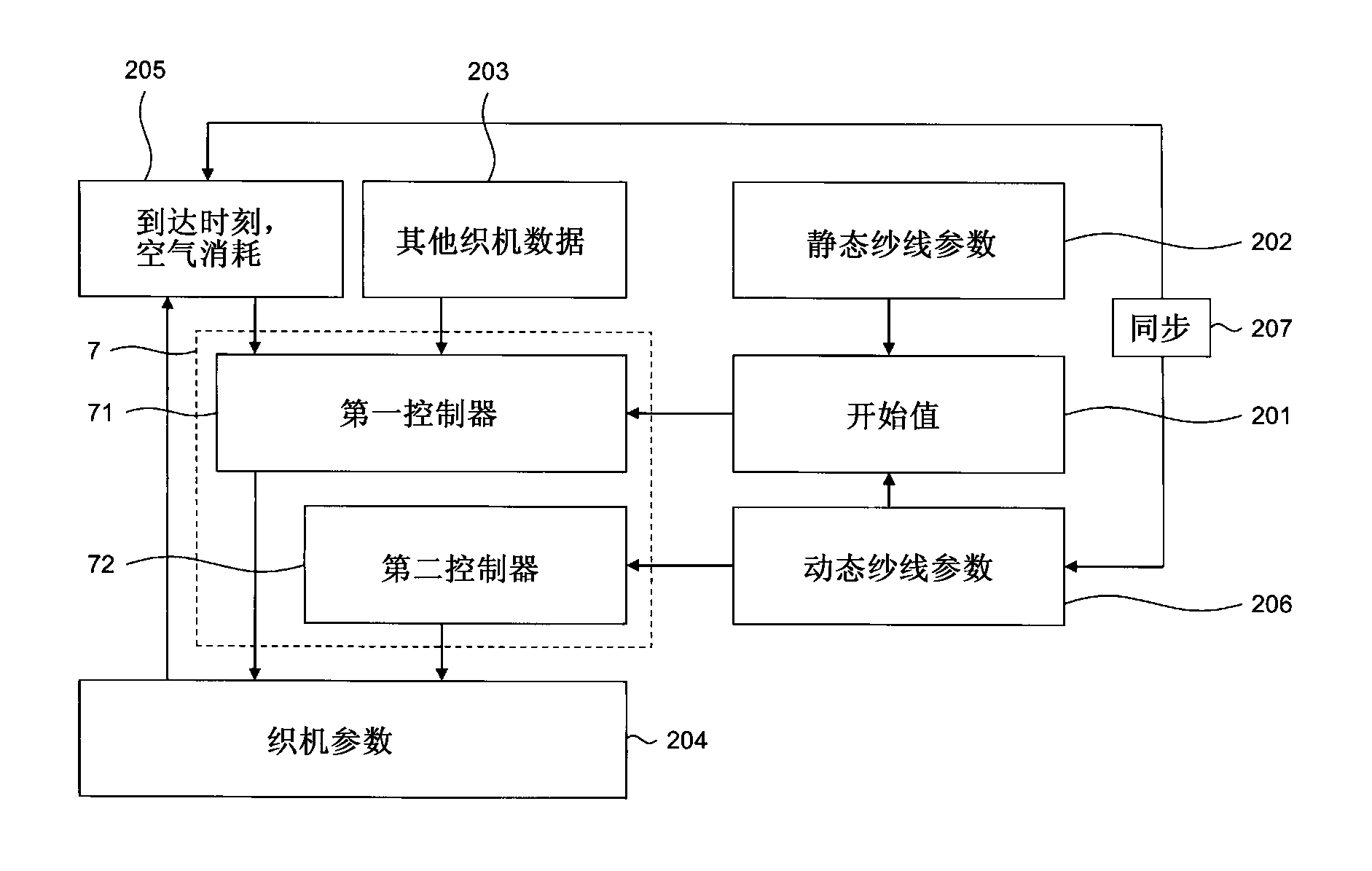

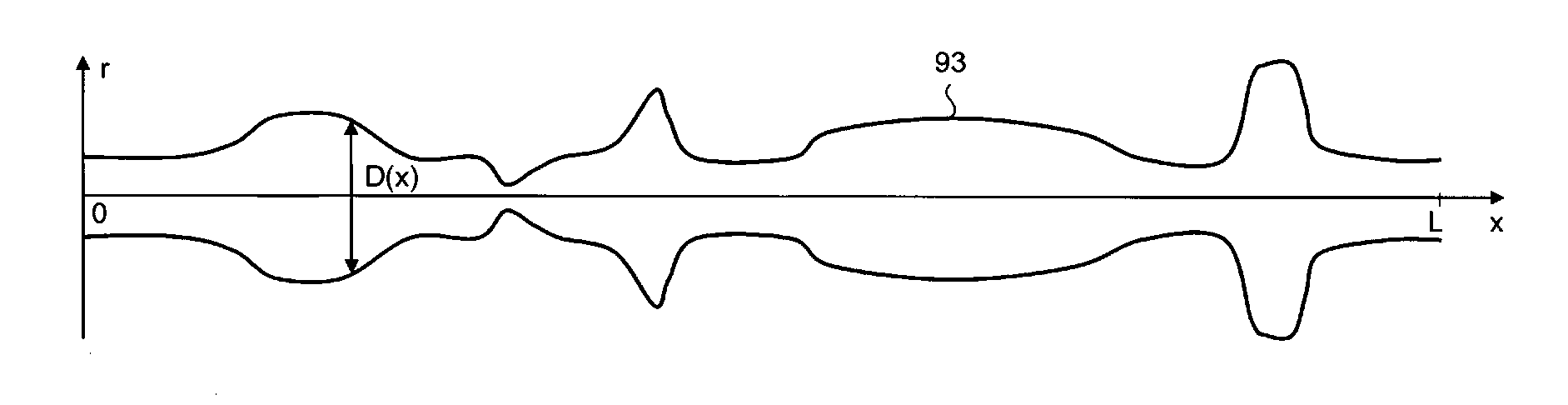

A method and apparatus for controlling a jet loom

A method for controlling a jet loom (1) is proposed. The jet loom (1) contains a plurality of relay nozzles (33) arranged along a fluid feed conduit (8). A weft yarn (93) is introduced into the fluid feed conduit (8), the relay nozzles (33) are actuated so as to eject time- staggered fluid pulses which produce a fluid flow in the fluid feed conduit (8), and the weft yarn (93) is conveyed by the fluid flow through the fluid feed conduit (8). The relay nozzles (33) are actuated based on a local distribution of characteristics within the respectively conveyed weft yarn section (93). Thus, the energy and air consumption of the jet loom (1) are reduced and the productivity of the jet loom (1) is increased

Owner:USTER TECHNOLOGIES +1

Auxiliary device for removing tying line

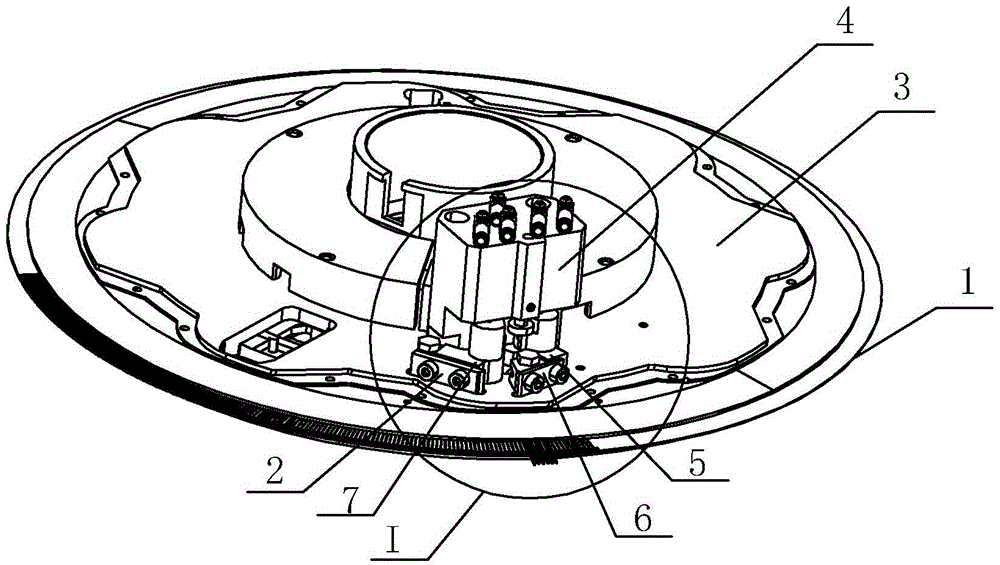

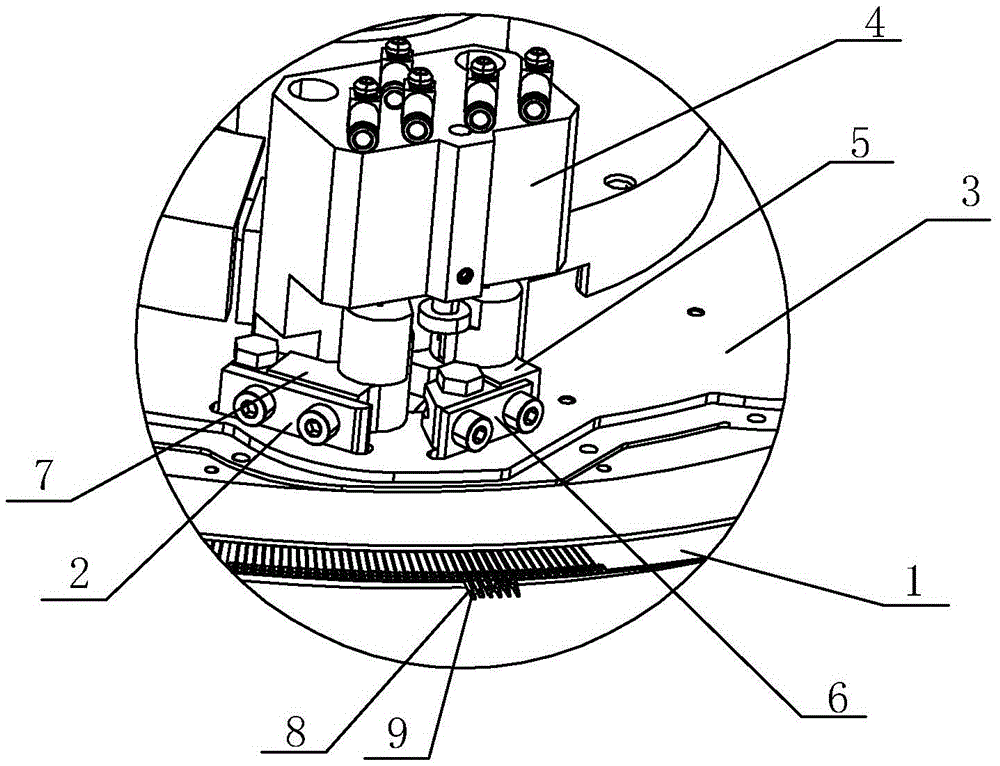

ActiveCN105463681APrevent "hanging Luokou" phenomenonImprove weaving efficiencyWeft knittingBiomedical engineeringNeedle track

An auxiliary device for removing a tying line belongs to the field of weaving machinery and comprises a Hough plate, Hough needles, a Hough needle triangular assembly, a pneumatic device, an installation disc, auxiliary Hough needles, an auxiliary Hough needle triangle and an auxiliary Hough needle triangular seat, wherein the Hough needles are embedded into needle grooves in the Hough plate; the installation disc is placed over the Hough plate; the lower side end surface of the installation disc is provided with a Hough needle track; a needle-starting triangular base seat and a tying triangular base seat of the Hough needle triangular assembly are both connected with the pneumatic device; the auxiliary Hough needles are embedded into the needle grooves, so Hough needles and auxiliary Hough needles in the same direction are embedded into a part of the needle grooves side by side; the front end of each auxiliary Hough needle is provided with an opening; the auxiliary Hough needle triangle is fixed on the auxiliary Hough needle triangular seat; the lower side end surface of the installation disc is provided with an auxiliary Hough needle track; a second through hole corresponding to the auxiliary Hough needle triangle is formed in the auxiliary Hough needle track; and the auxiliary Hough needle triangular seat is connected with the pneumatic device. A problem that a tying line on the Hough needle cannot be automatically removed during the tying work of a circular machine can be solved.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

Combined insertion piece

InactiveCN1793466AChange structureDoes not affect interspersedWeft knittingEngineeringMechanical engineering

Owner:冯加林

Method for detecting insulation weaving quality of superconducting wire by weight of woven layer

ActiveCN110608966AEasy to operateSolve the surveyorCable/conductor manufactureMaterial weighingInstabilityEngineering

The invention provides a method for detecting the insulation weaving quality of a superconducting wire by the weight of a woven layer. The method comprises the following steps that wire splitting is completed to ensure that tension is stable; weaving is started after a strand of wire is marked, a weaving pitch h is measured after to-be-marked parts are all woven, and the number of grids N is calculated; a sample wire is fixed to a wire density sampling device after the weaving is completed, the sample wire is cut off after being straightened to obtain a 1m sample with the woven layer, and thewoven layer falls off and is weighed to obtain the weight G of the 1m sample with the woven layer; a parameter C can be calculated by substituting N and G into a formula; and a 1.5m sample wire withthe woven layer is taken at the outer end of the to-be-detected wire, the sample wire is straightened and cut off, the woven layer falls off and is weighed to obtain G', and a change ratio P of the number of grids is calculated. The effects of the method are that detection work can be quantified, operation is simplified, a process is standardized, human instable factors caused by different measuring personnel and measuring methods are eliminated, the weaving quality can be greatly improved, and invisible weaving irregularities caused by tension change and the like can be reduced.

Owner:西部超导材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com