Patents

Literature

48results about How to "Fast pay-off speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

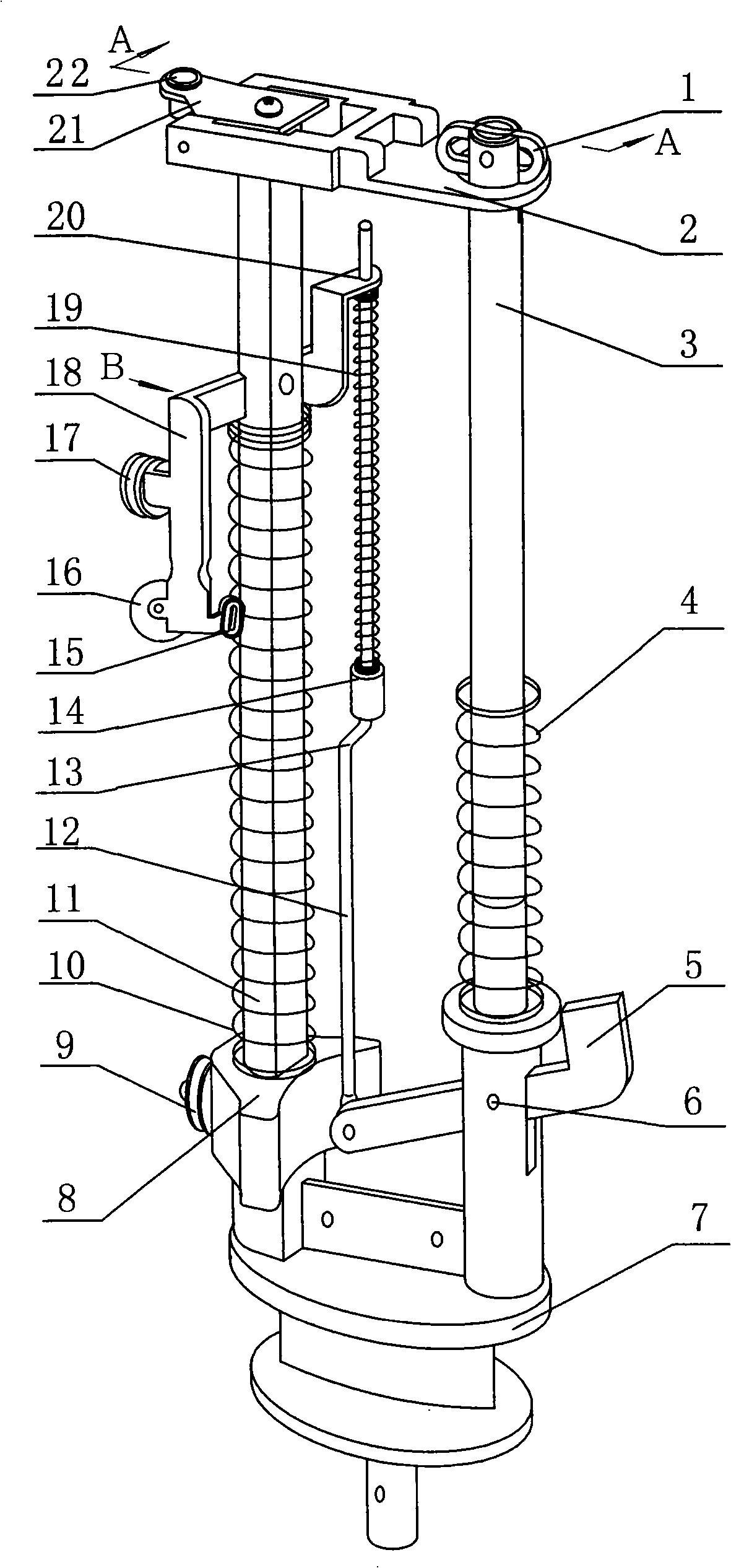

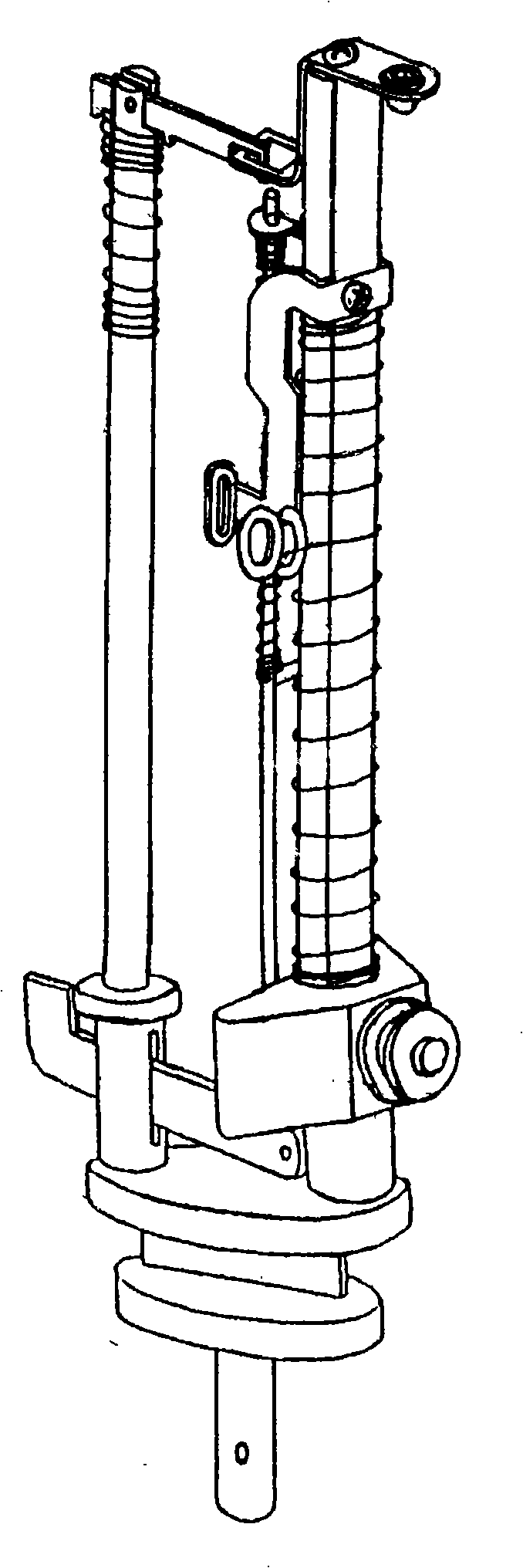

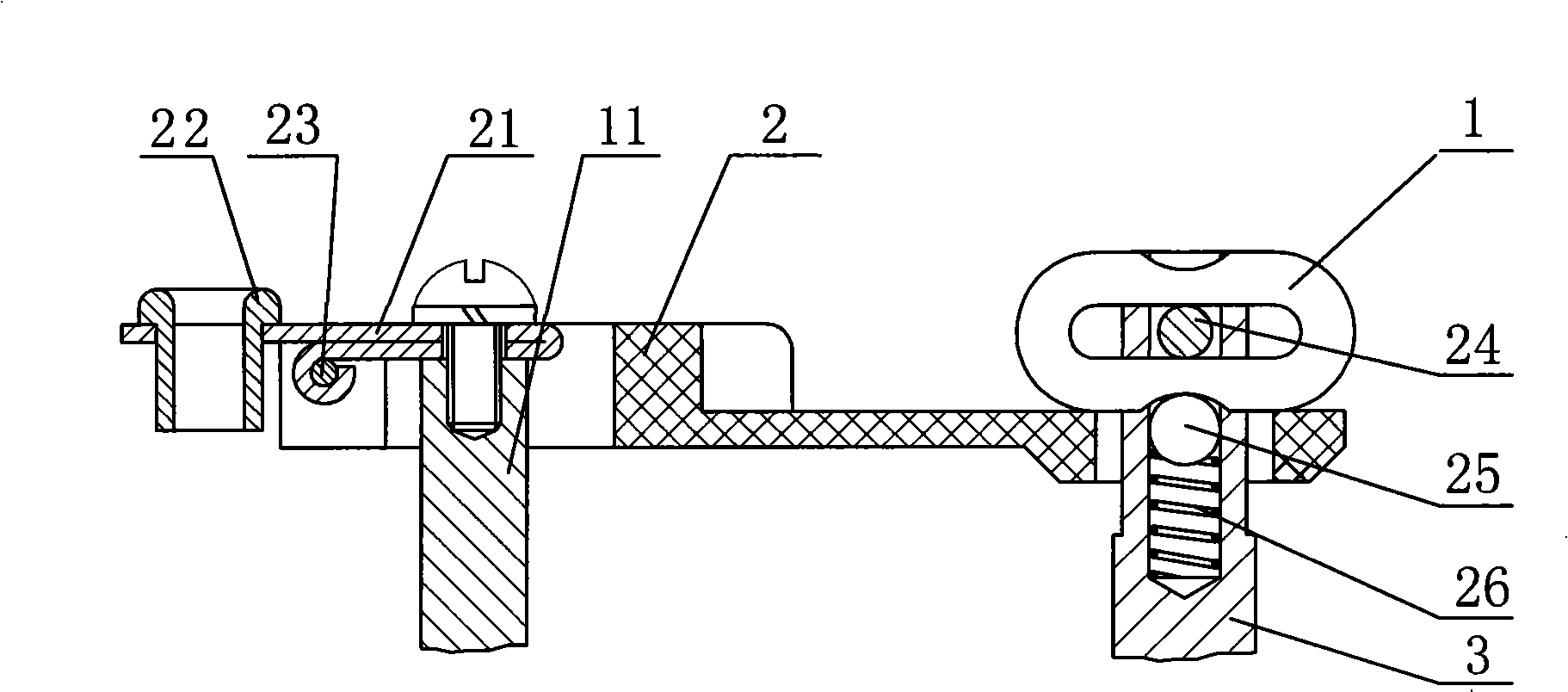

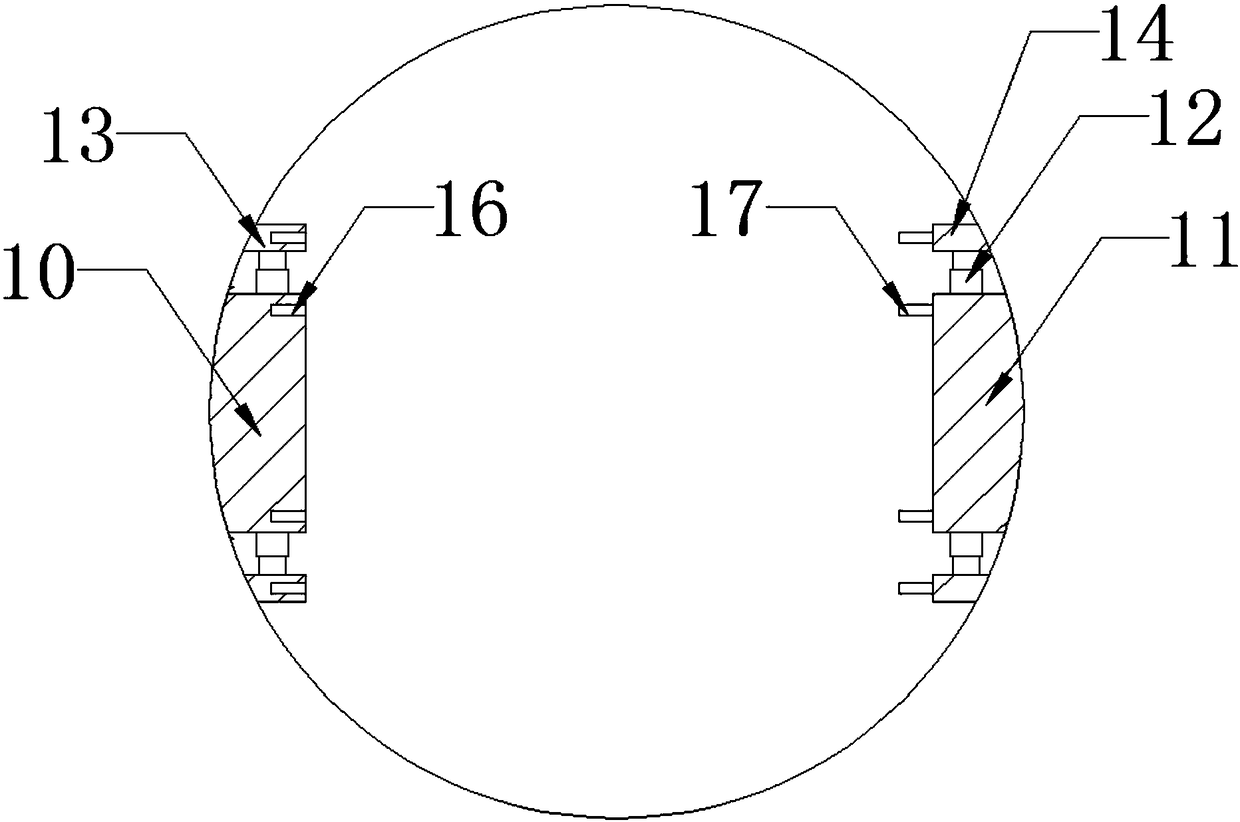

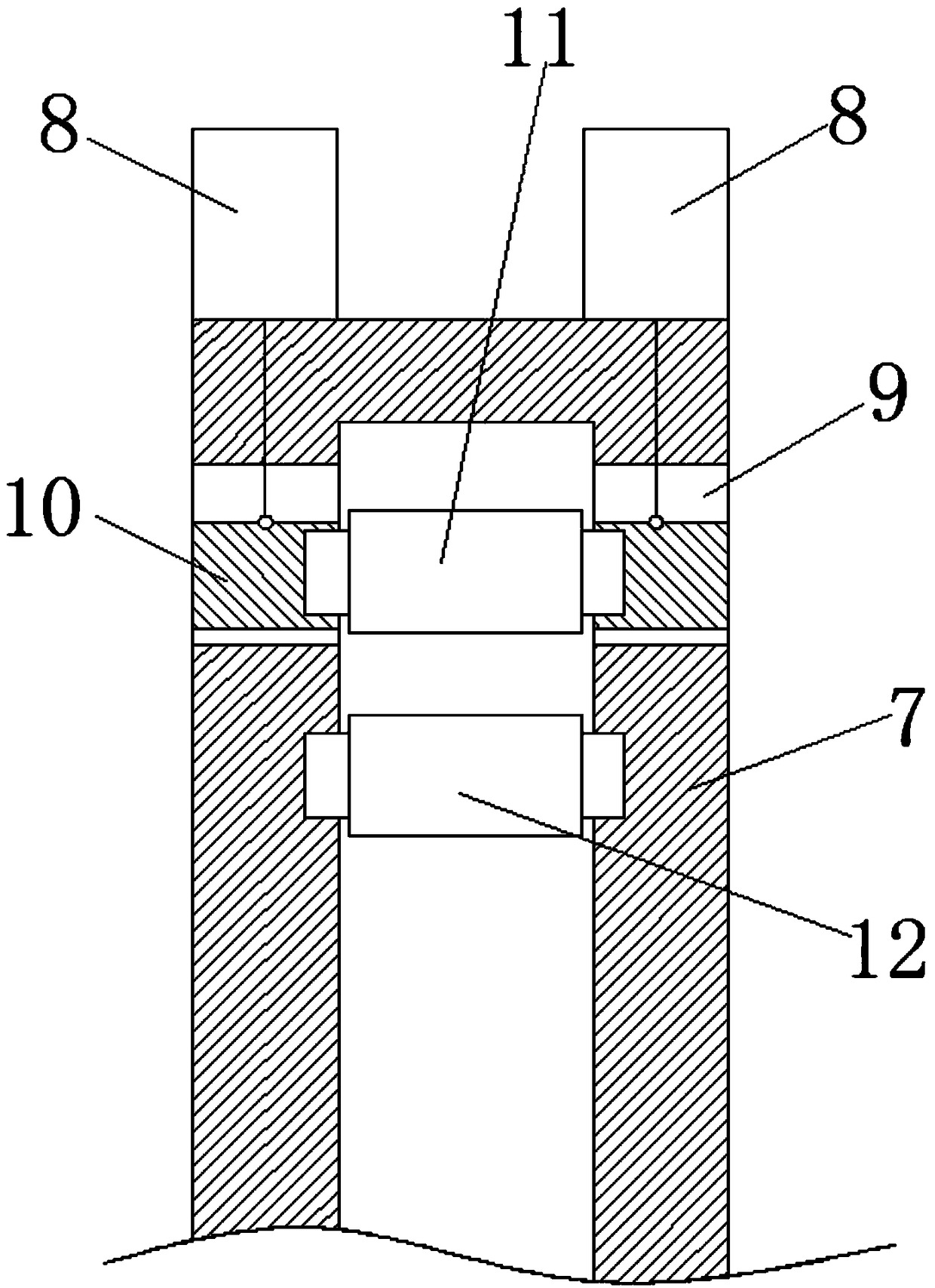

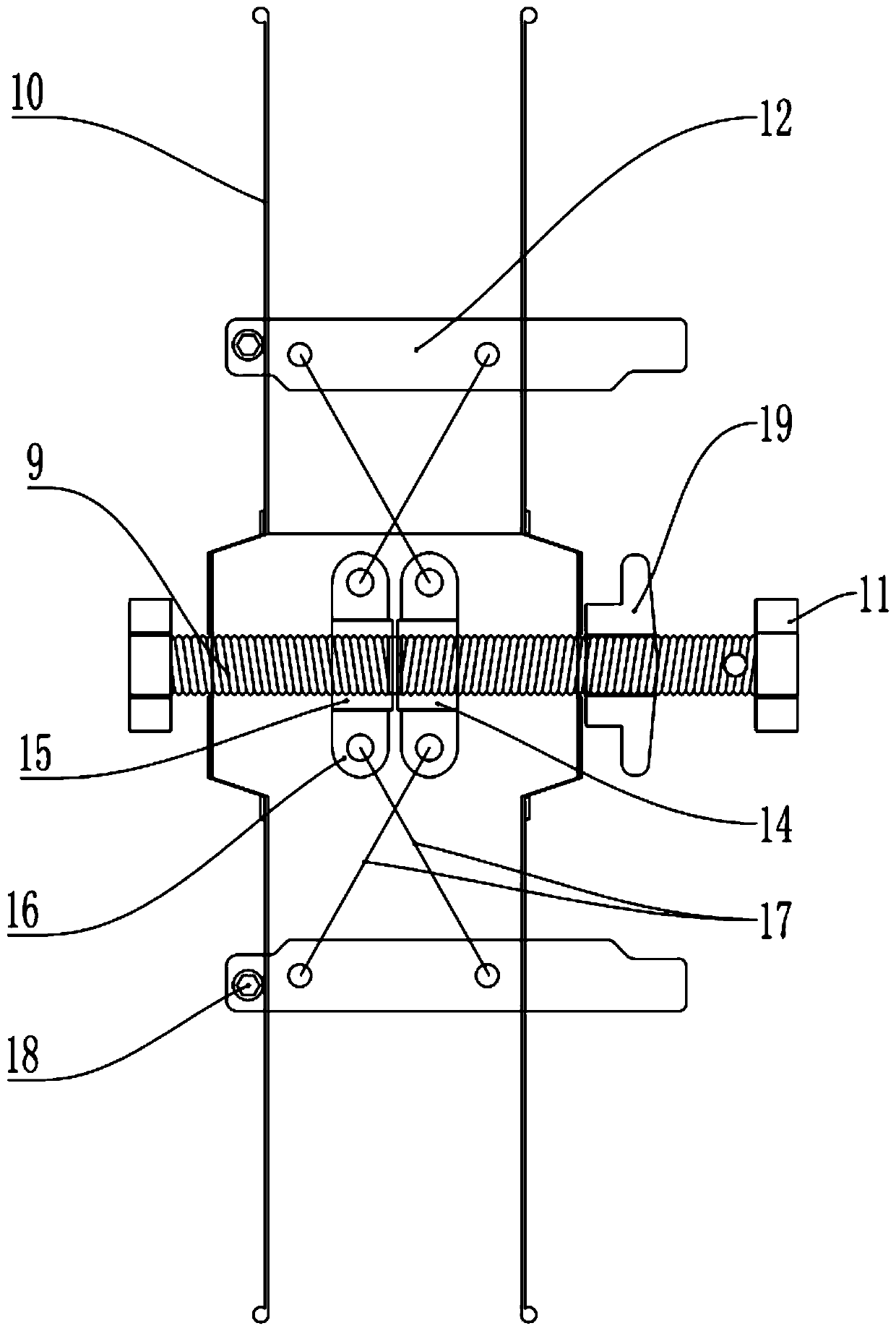

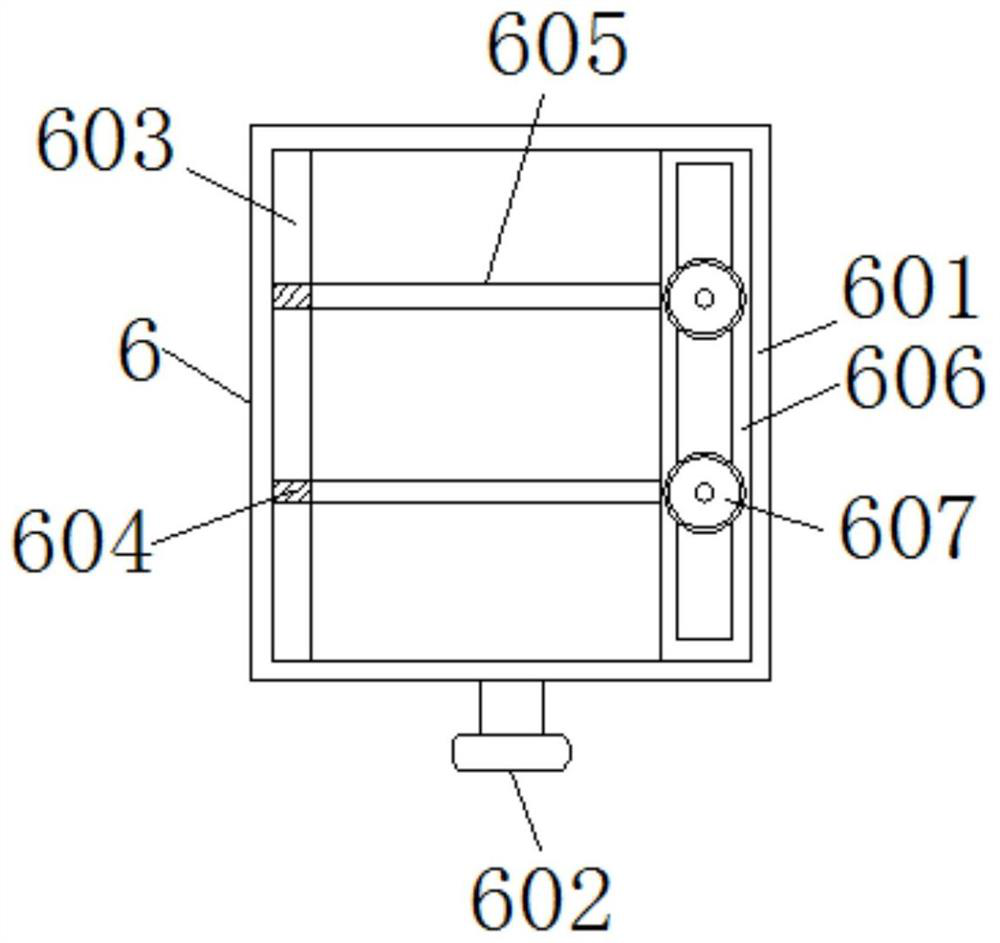

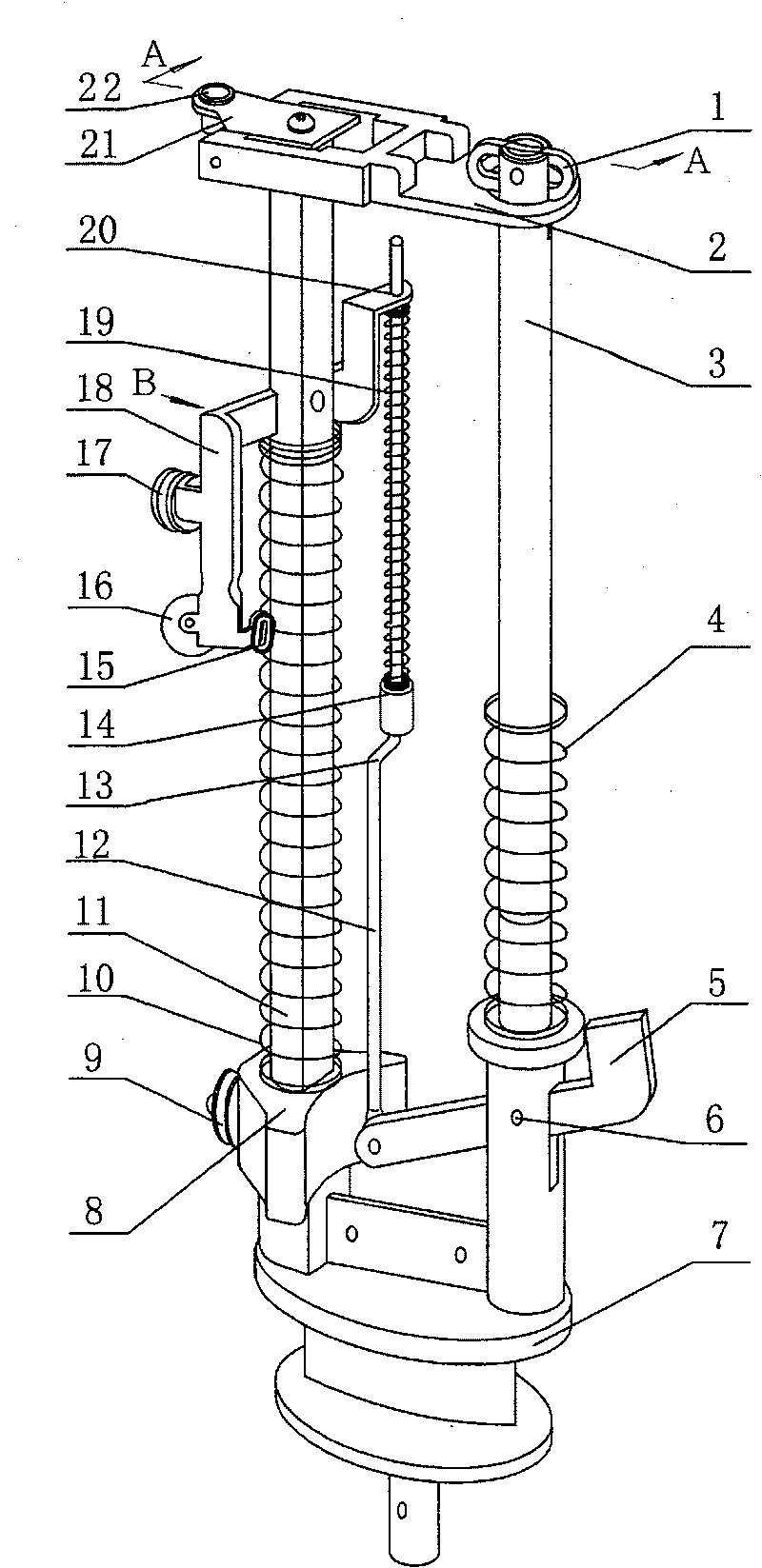

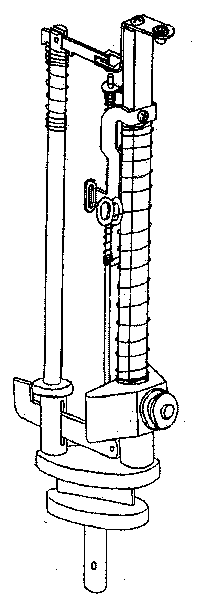

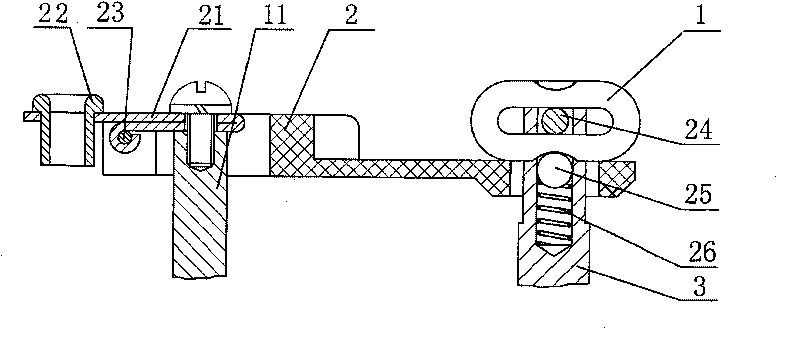

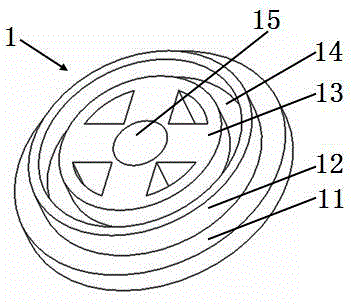

Spring spindle

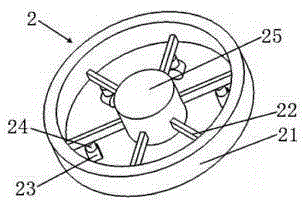

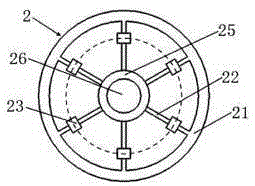

The invention relates to a spring spindle, wherein, a fixed piece is formed by fixing a right upright post which is fixed with a support and a connecting rod and a left upright post on a track rod, and the spring spindle is formed by connecting a weaving piece and the fixed piece into a whole through a pressure plate and a switch plate; the support is flanged; a pulley is divided into an upper pulley and an intermediate pulley; the upper pulley and the intermediate pulley which are connected to the support are arranged on the right of the right upright post; mounting axial lines of the upper pulley and the intermediate pulley are crossed and angulated at 57 to 63 DEG; a vertical and bended straight section on the middle of the connecting rod is provided with a limit rod; and the pressure plate is matched with a lock catch which is connected to the left upright post. The support is arranged on the right of the right upright post instead of being arranged on the left of the right upright post, thereby the angle between a leading-in porcelain eye and a thread-passing point is reduced to between 27 and 33 DEG; the angle is smaller, the pay-out resistance on bobbin is smaller, and then the pay-out speed is quick and the thread breakage time is greatly reduced; the connecting rod and the support are arranged on both sides of the right upright post so as to maintain routing balance, thereby the speed can be improved by 10 percent and the weaving quality and the production efficiency are greatly improved; and simultaneously the pressure plate has good strength and long service life, is convenient, quick and easy to operate, and is an updated product of the third generation.

Owner:张宝香

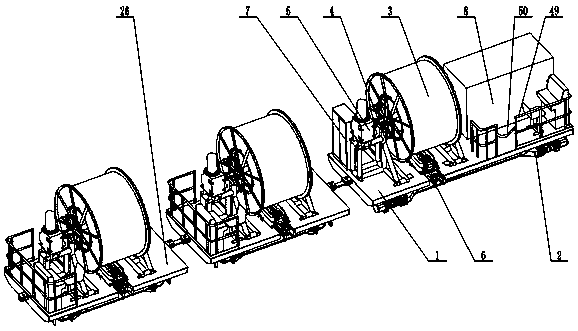

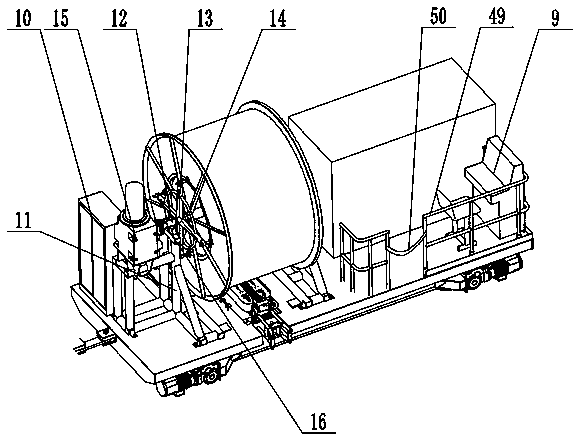

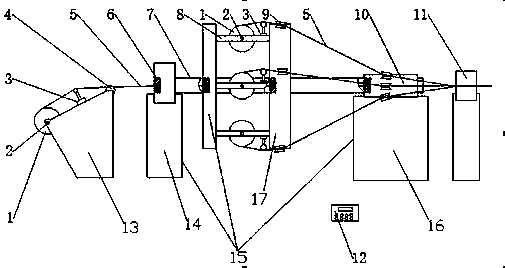

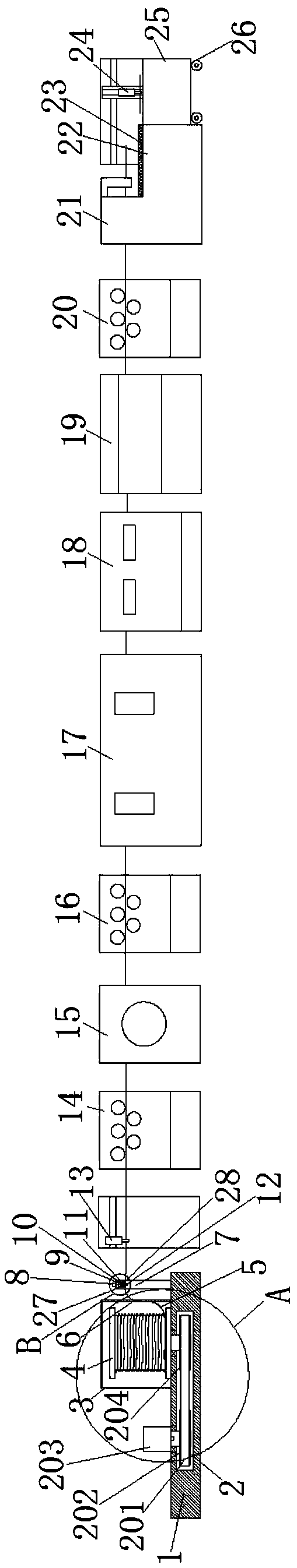

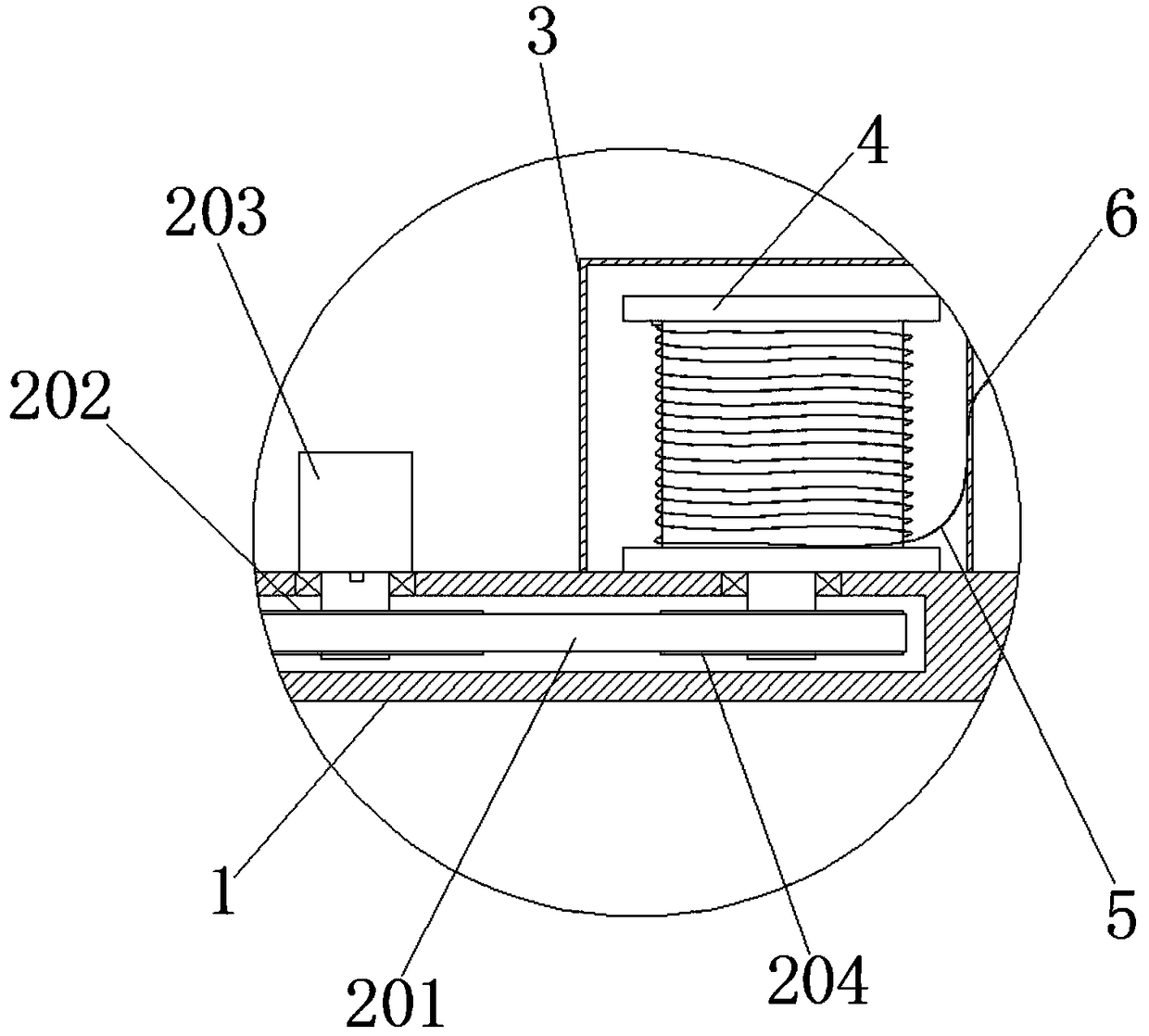

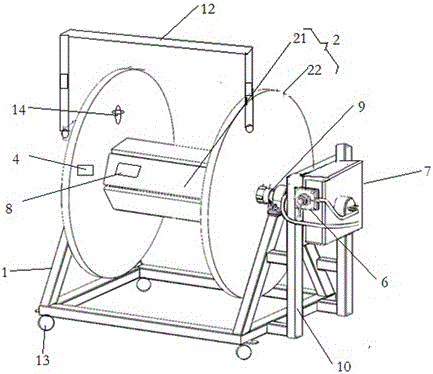

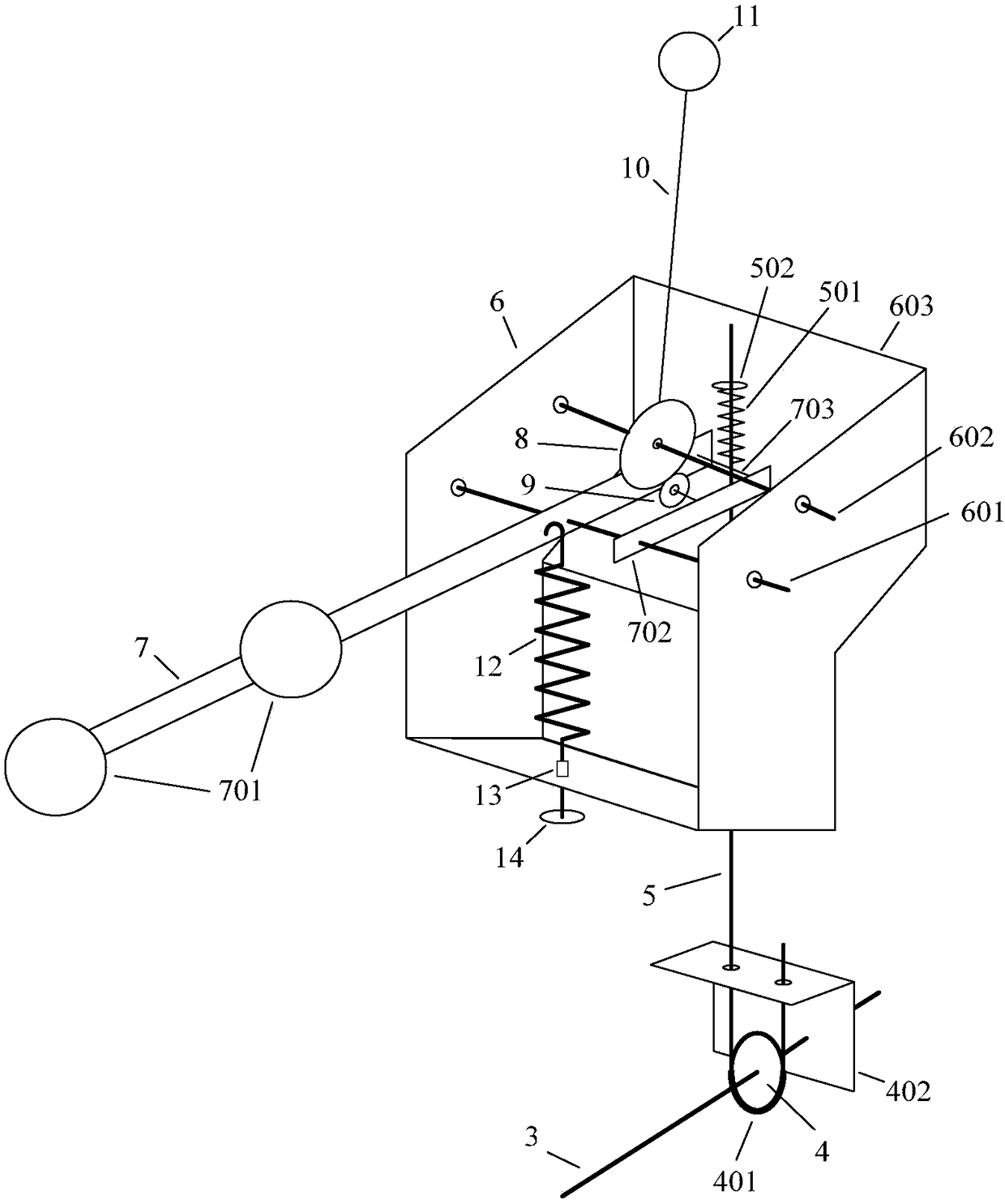

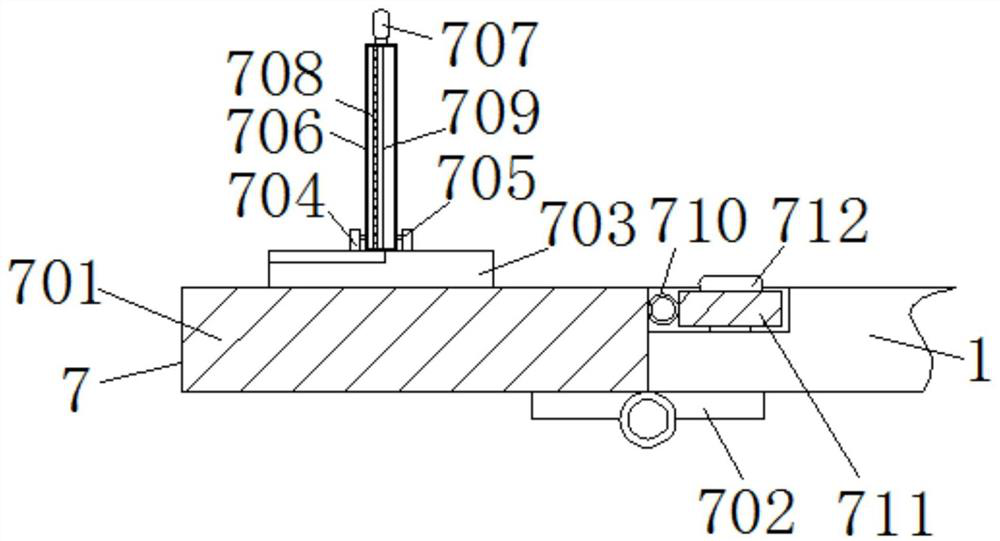

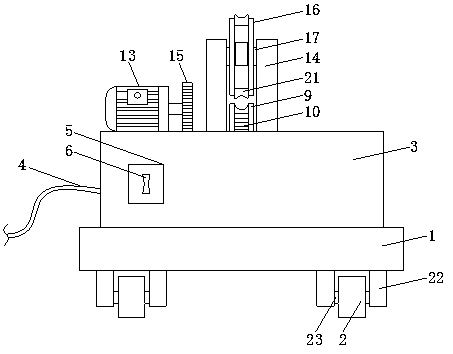

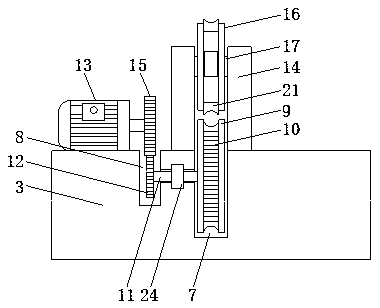

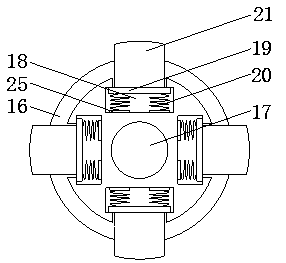

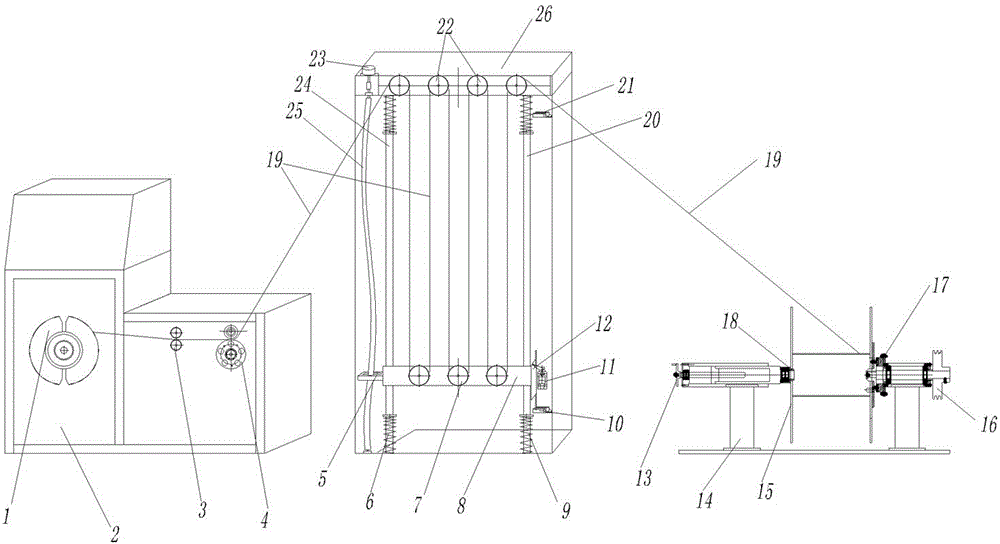

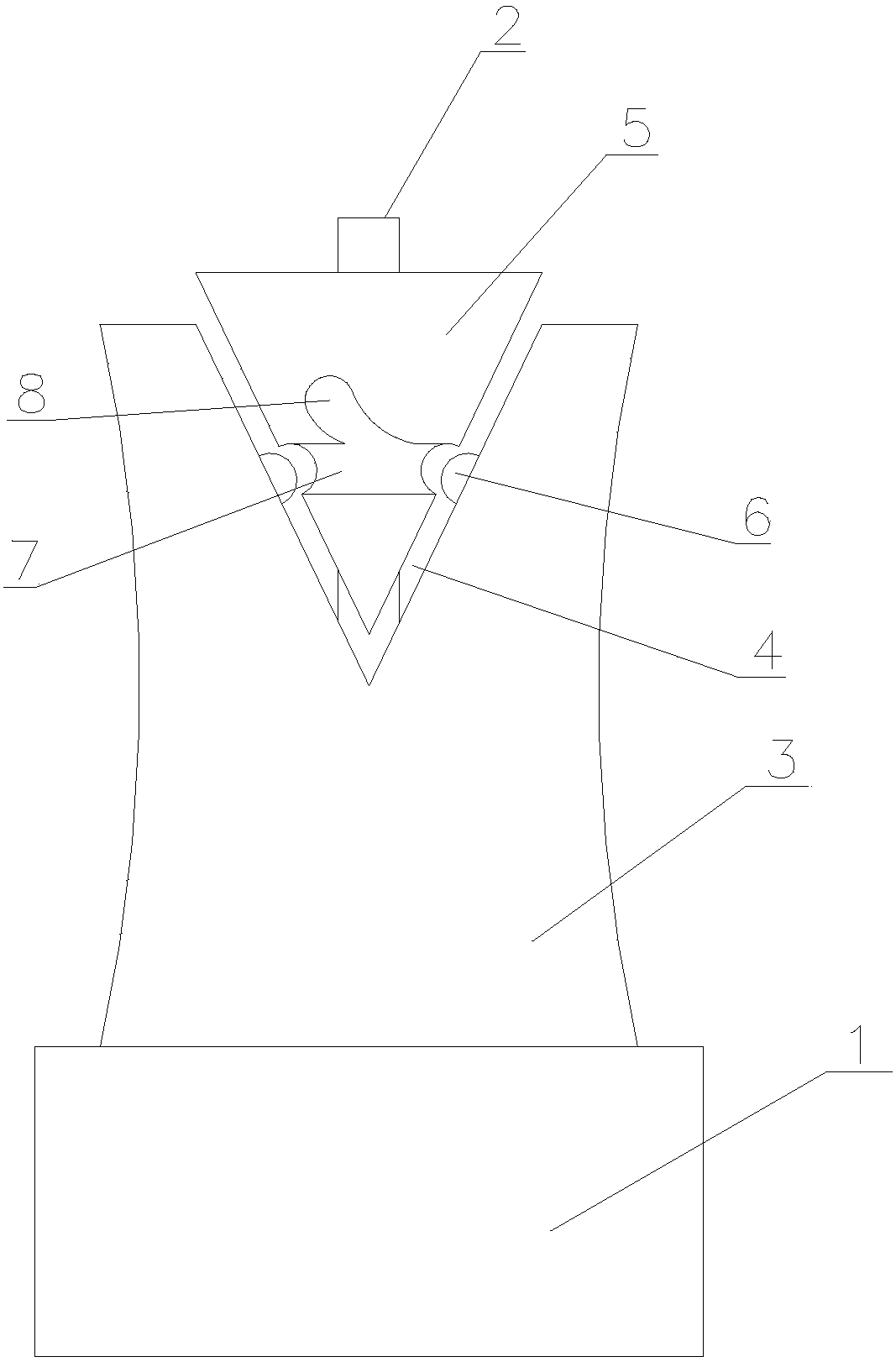

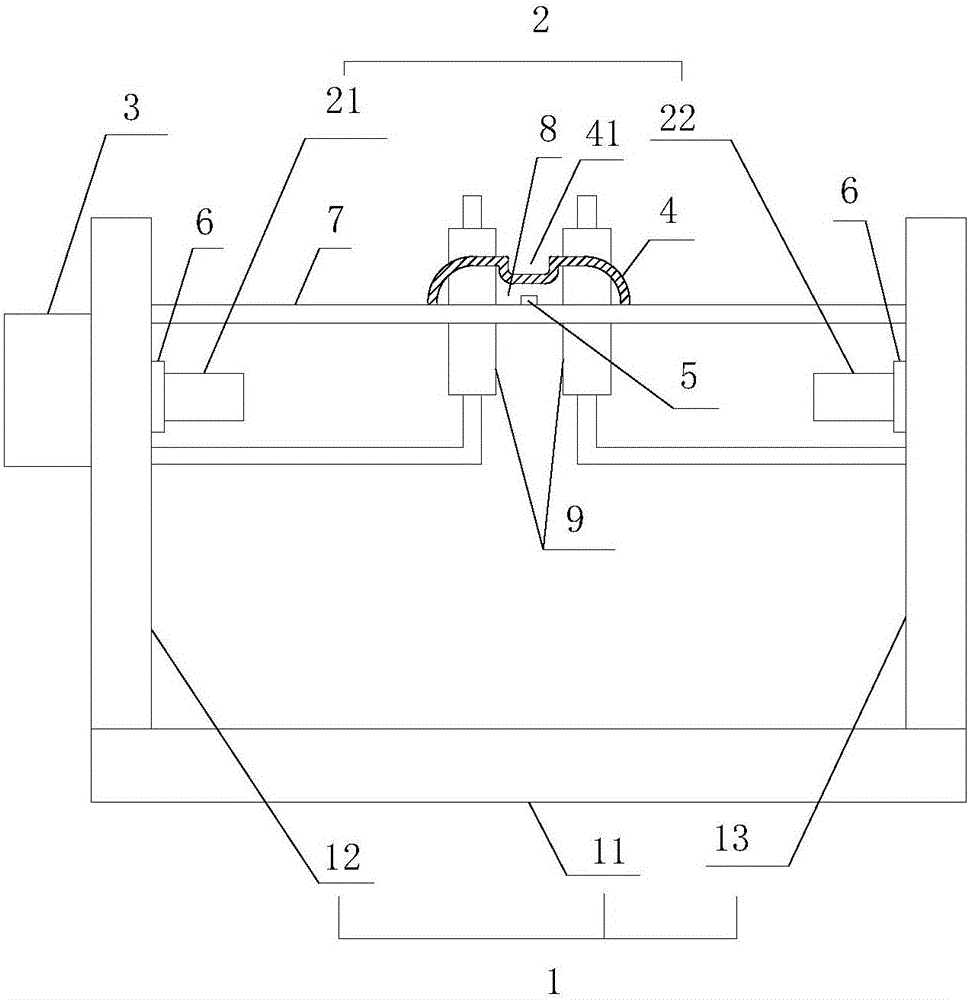

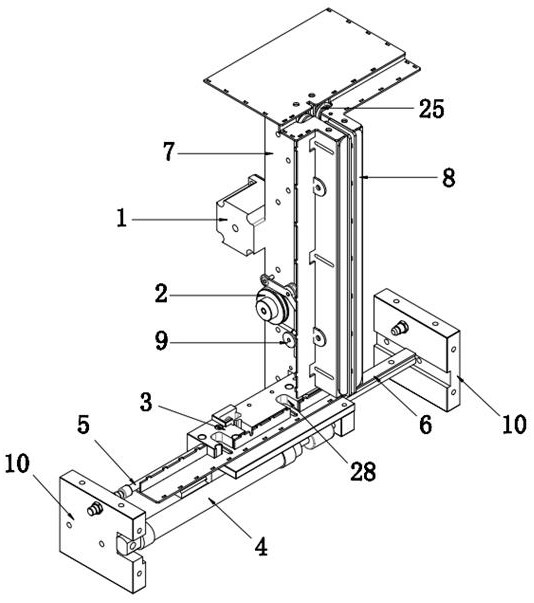

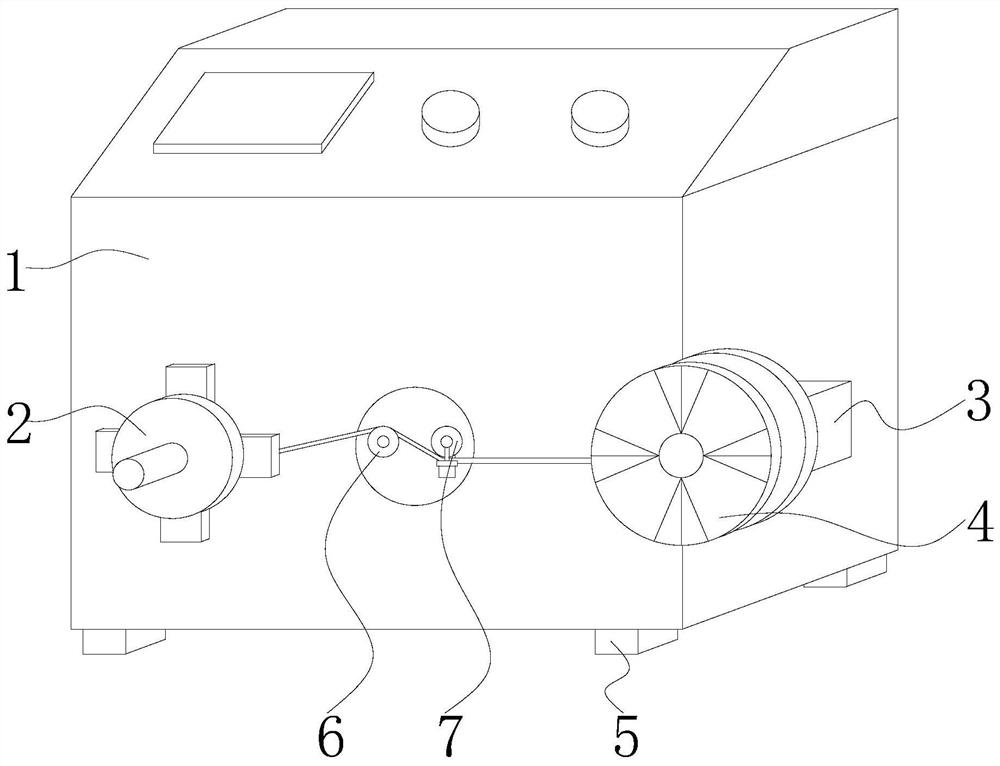

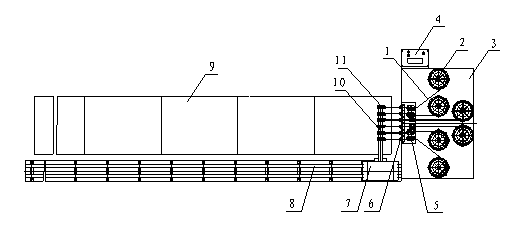

Cable laying equipment for urban rail transit

PendingCN111478230AAutomatic pay-offFast pay-off speedFilament handlingPropulsion using engine-driven generatorsElectric cablesRail transit

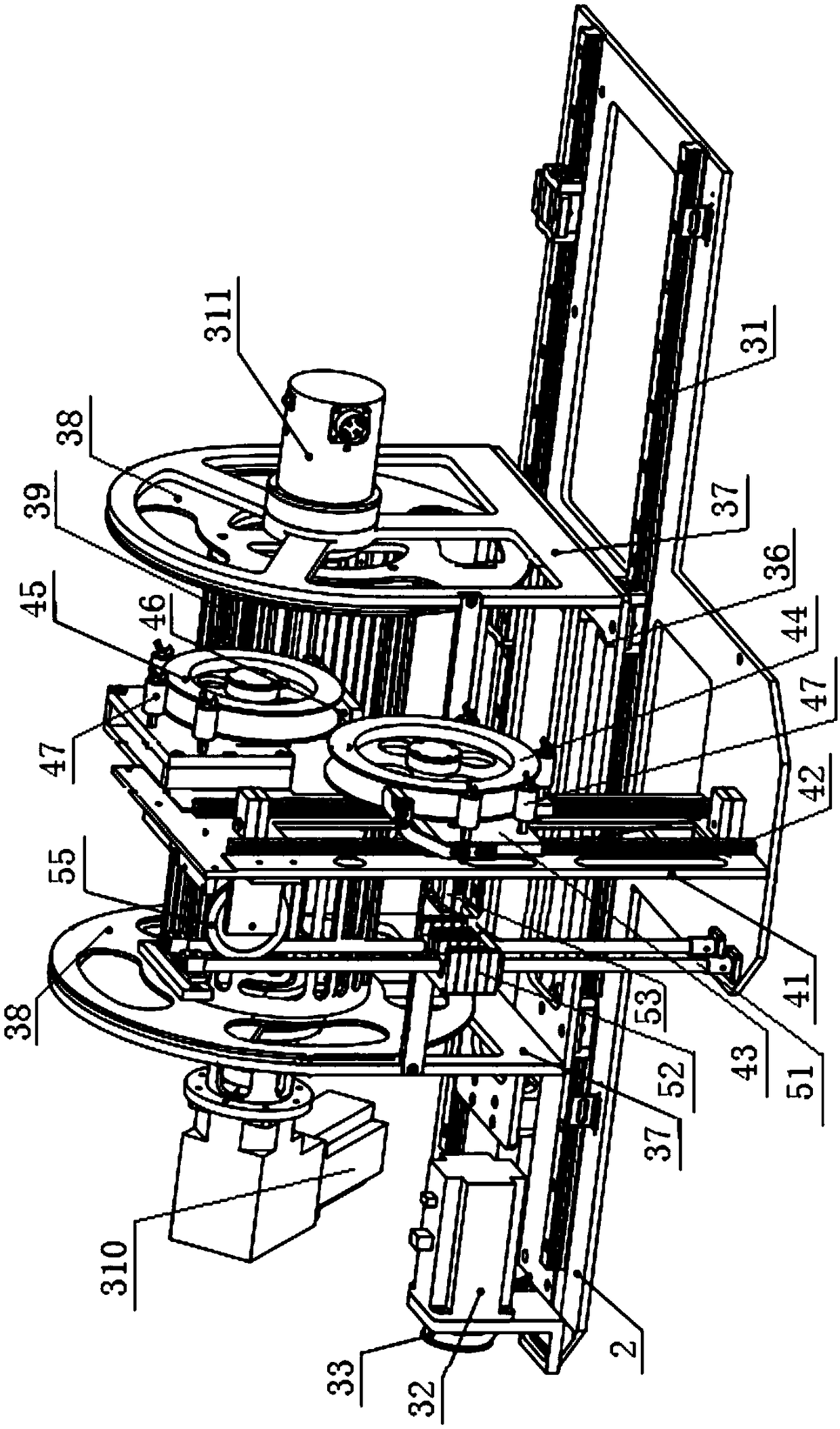

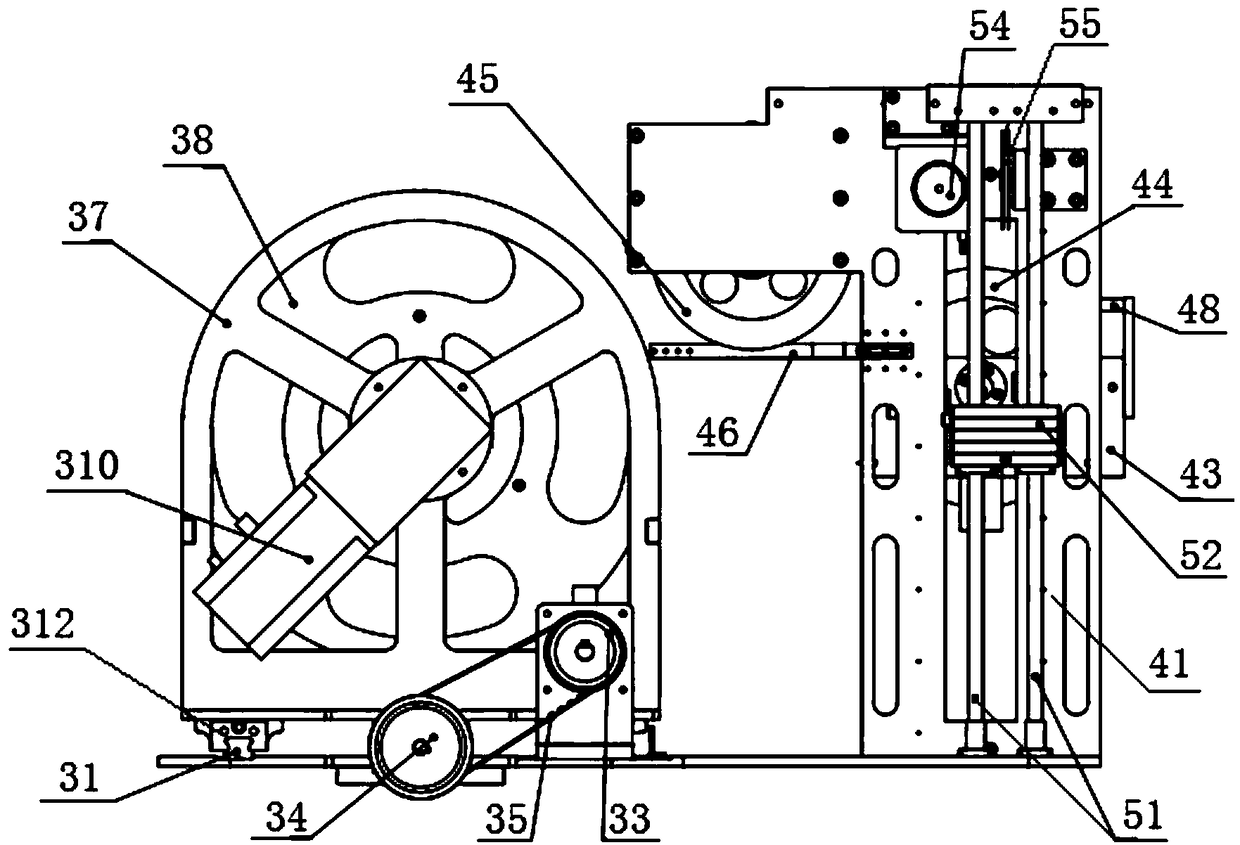

The invention discloses cable laying equipment for urban rail transit. The equipment includes a tractor, the tractor is provided with a driving device used for driving the tractor to move, a supporting device used for supporting a cable reel, a pay-off device used for driving the cable reel to rotate and a guide device used for guiding the direction of a cable. Wherein the guide device comprises afirst-stage guide mechanism and a second-stage guide mechanism which are sequentially arranged, and a cable sequentially penetrates through the first-stage guide mechanism and the second-stage guidemechanism and then extends out of the side portion of the tractor in the process that the pay-off device drives the cable reel to rotate. According to the cable laying equipment for urban rail transit, automatic paying-off can be achieved, the paying-off speed is higher, and a large amount of manpower is not needed.

Owner:THE 1ST ENG CO LTD OF CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP

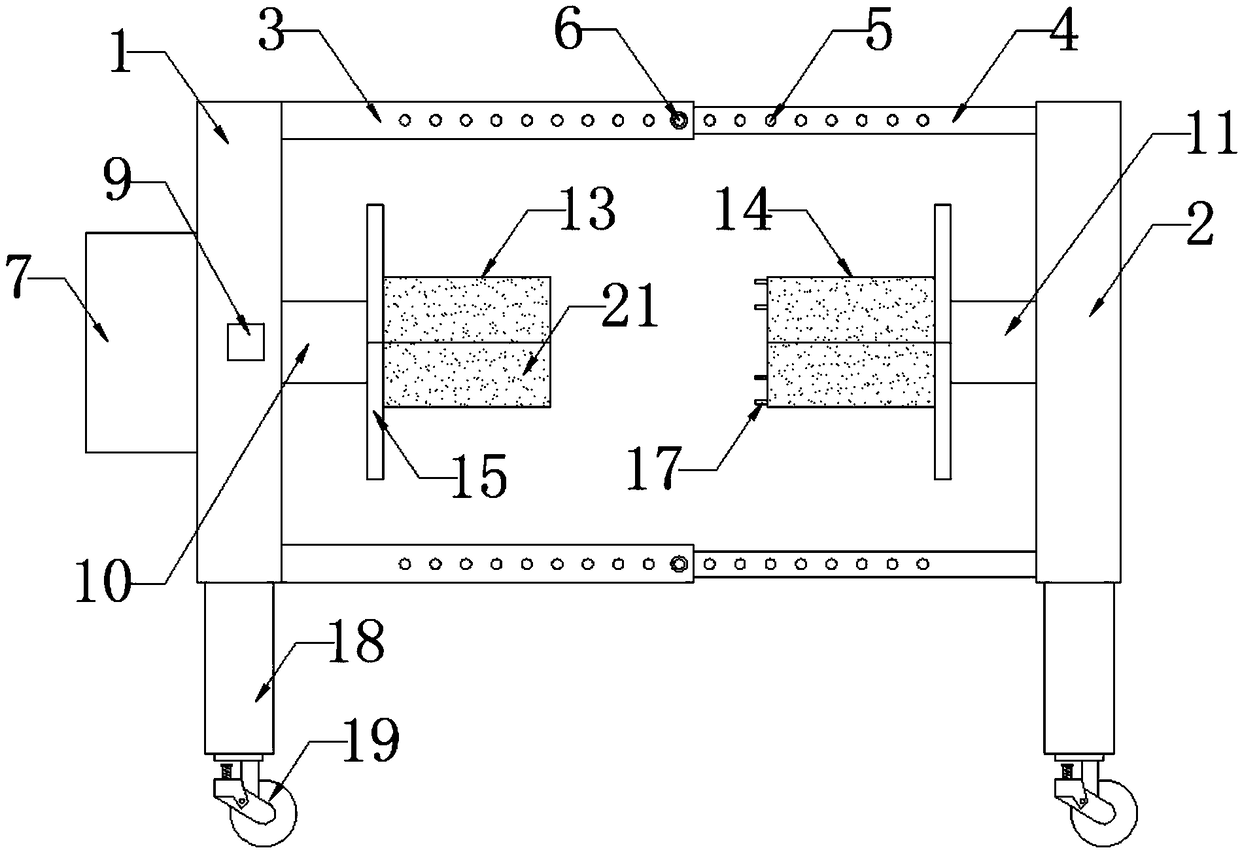

Electric wire pay-off device for architectural decoration and finishing

The invention discloses an electric wire pay-off device for architectural decoration and finishing. The electric wire pay-off device comprises a first fixed plate and a second fixed plate, wherein each of four corners at the side of the first fixed plate is fixedly connected with one end of a corresponding outer pipe, and each of four corners at the side of the second fixed plate is fixedly connected with one end of a corresponding inner pipe; the other end of each outer pipe is fixedly connected with the other end of the corresponding inner pipe by enabling a hinge pin to penetrate through ahinge pin hole, the middle portion of one side of the first fixed plate is rotationally connected with one end of a first rotating shaft through a bearing pedestal, and the middle portion of one sideof the second fixed plate is rotationally connected with one end of a second rotating shaft through a bearing pedestal; and the outer portion of the first rotating shaft is fixedly connected with theinner sides of two first arc-shaped plates through four electric telescopic rods, and the outer portion of the second rotating shaft is fixedly connected with the inner sides of two second arc-shapedplates through four electric telescopic rods. According to the electric wire pay-off device for architectural decoration and finishing, the distance between the two first arc-shaped plates and the distance between the two second arc-shaped plates can be adjusted by adjusting lengths of the electric telescopic rods, and therefore the electric wire pay-off device can be applied to electric wire coils with different sizes and inner diameters.

Owner:浙江富海建筑装饰工程股份有限公司

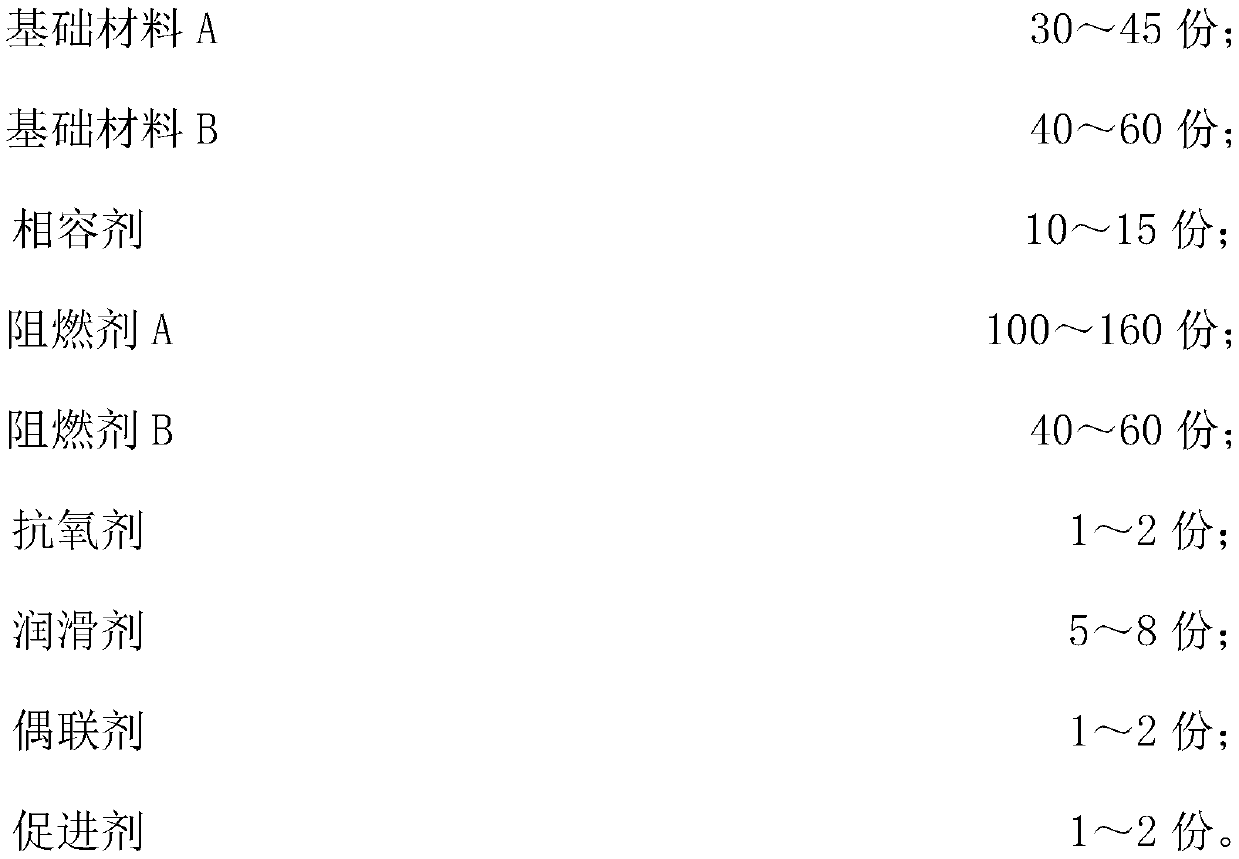

B1-grade flame-retardant 105-DEG C irradiation crosslinking halogen-free low-smoke insulated cable material and preparation method thereof

PendingCN111378222AImprove flame retardant performanceLow smoke productionPlastic/resin/waxes insulatorsTemperature controlPolymer science

The invention relates to the technical field of chemical engineering, in particular to a B1-grade flame-retardant 105-DEG C irradiation crosslinking halogen-free low-smoke insulated cable material, which comprises the following components in parts by weight: 30-45 parts of a base material A; 40-60 parts of a base material B; 10 to 15 parts of a compatilizer; 100 to 160 parts of a flame retardant A; 40 to 60 parts of a flame retardant B; 1-2 parts of an antioxidant; 5-8 parts of a lubricant; 1-2 parts of a coupling agent; and 1-2 parts of an accelerant. The preparation method of the cable material comprises the following steps: firstly, preparing the components in parts by weight; then adding the components into a high-speed mixer, stirring for 8-12 minutes at a high speed, and controllingthe temperature to be 50+ / -2 DEG C; and then adding the stirred materials into an internal mixer for internal mixing, discharging the materials when the temperature of the internal mixed materials reaches 150-155 DEG C, and performing double-cone forced feeding and granulation by a 75 / 180 double-stage extruder to obtain the B1-grade flame-retardant 105-DEG C irradiation crosslinking halogen-free low-smoke insulated cable material.

Owner:杭州美临新材料科技有限公司

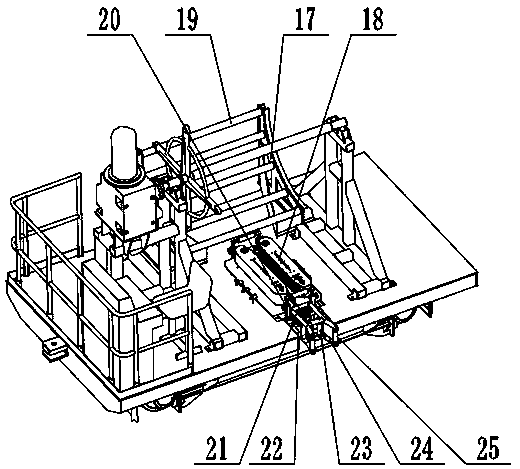

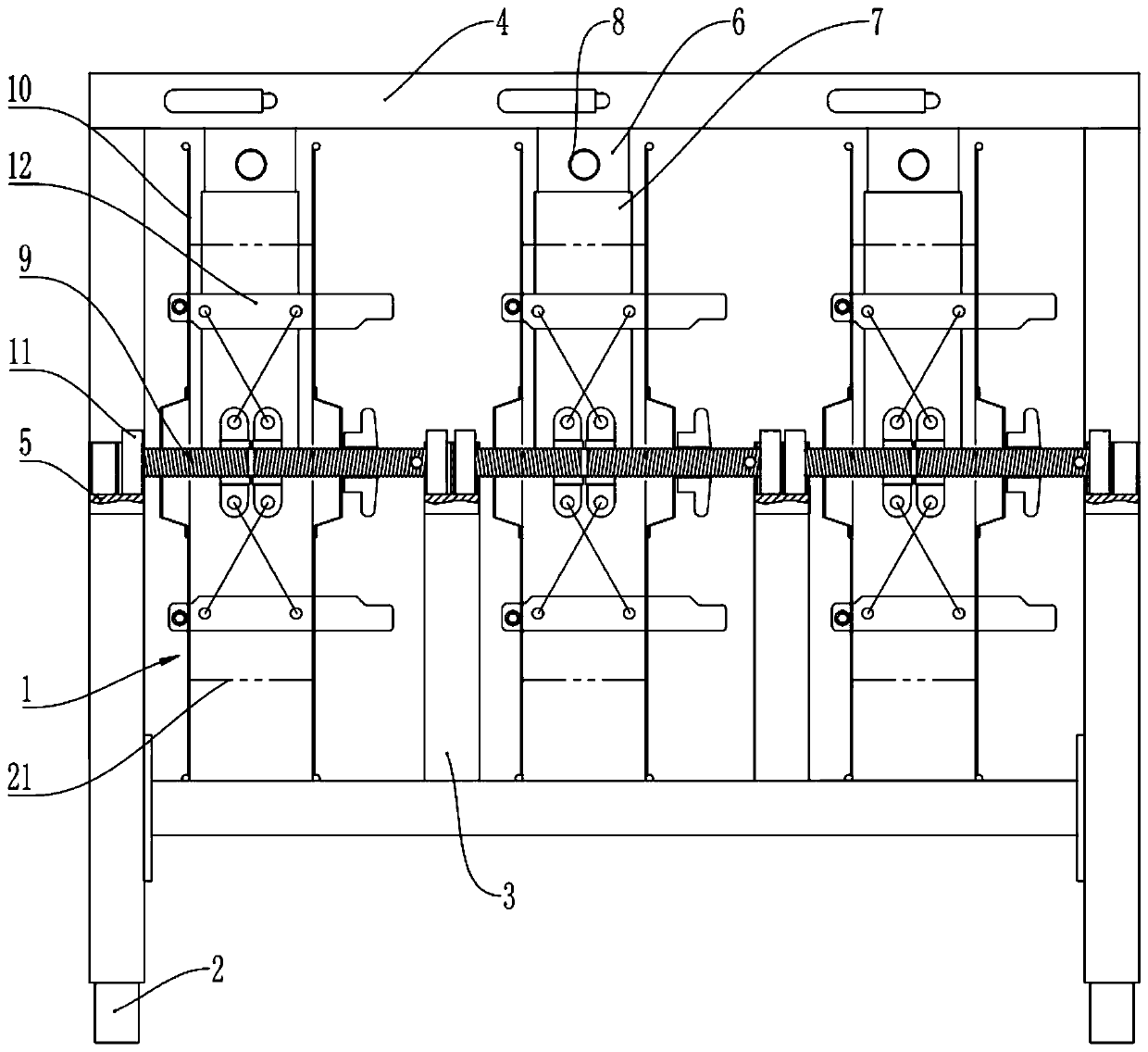

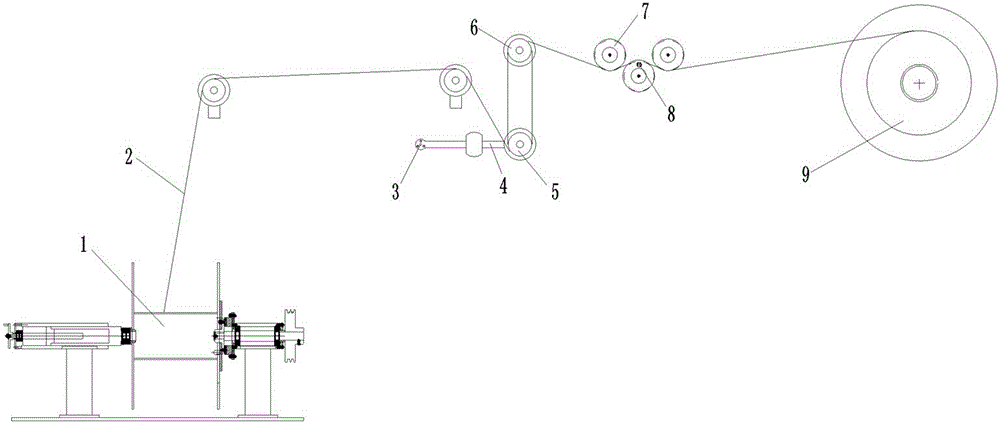

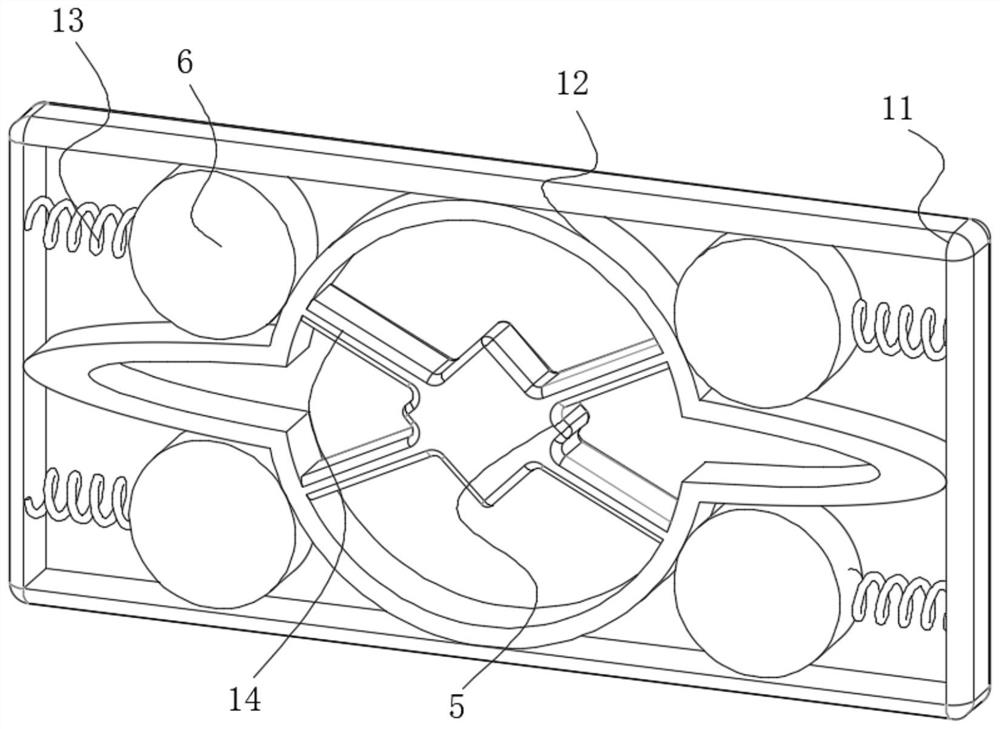

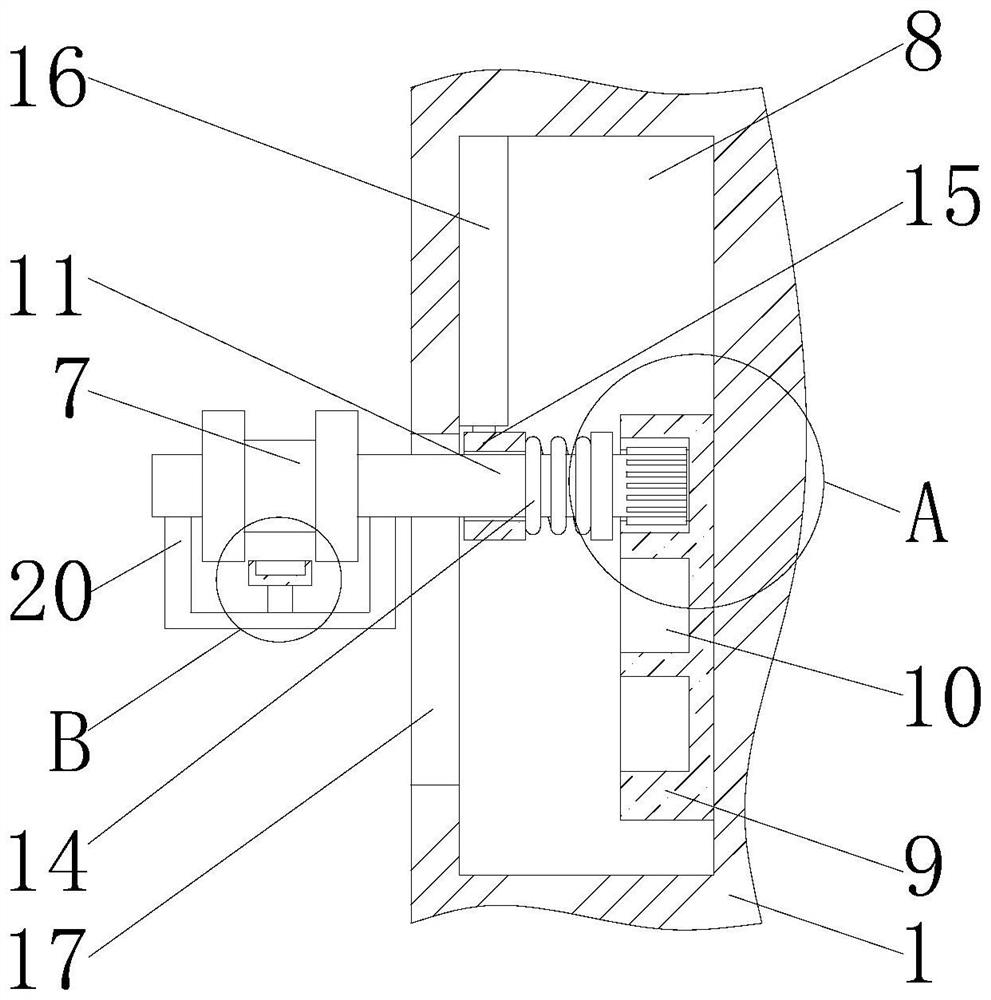

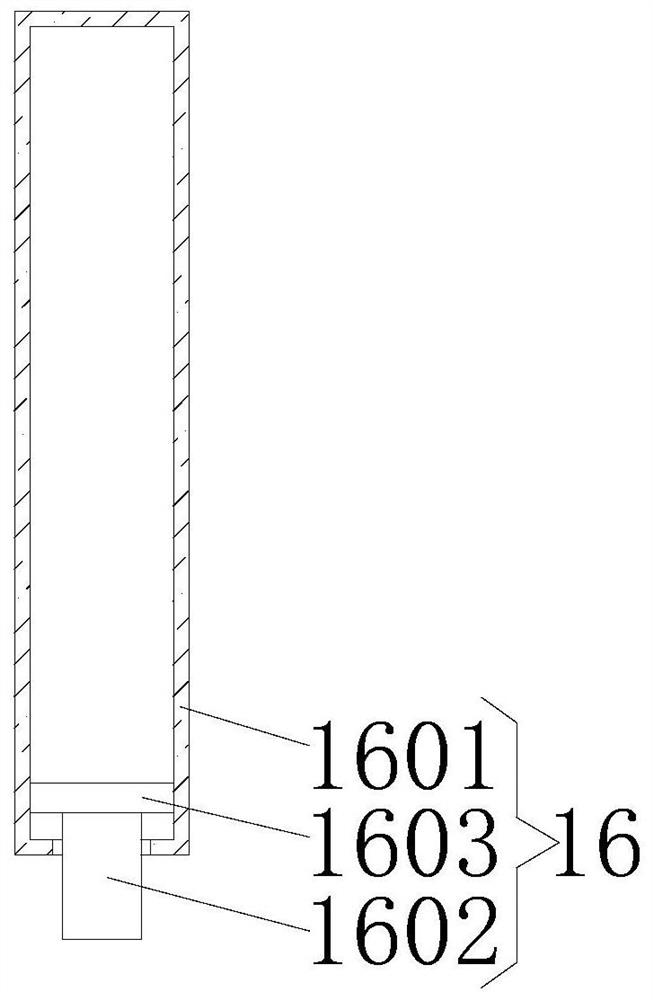

Automatic adjustment control device capable of controlling tension and preventing breakage line for cabling equipment of communication cable

PendingCN108597689AAvoid quality lossFast pay-off speedFilament handlingCable/conductor manufactureControl systemMechanical engineering

The invention discloses an automatic adjustment control device capable of controlling tension and preventing breakage line for cabling equipment of a communication cable. The automatic adjustment control device comprises a stranded wire core, a pay-off rack, a twisting cage, a line die holder and a master control system, wherein the pay-off rack, the twisting cage, the line die holder and the master control system are sequentially connected, the master control system is used for controlling the whole device, a pay-off disc is arranged on the pay-off rack, a brake is arranged on a side surfaceof the pay-off disc, a support roller is arranged on the pay-off rack, the twisting cage comprises a twisting cage rear seat, a twisting core and a twisting cage front seat which are sequentially connected, an annular support is arranged on the twisting cage rear seat and the twisting cage front seat, a rotatable twisting core is arranged on the annular support, the twisting core comprises a linedisc rack and the pay-off disc on the line disc rack, the brake is arranged on the side surface of the pay-off disc, a support wheel is arranged at a right side of the line disc rack and is used for guiding the twisting line core, a support wheel is arranged at the twisting cage front seat, a branch machine is arranged at a right side of the support wheel, and breakage line-prevention device is arranged on the pay-off rack, the twisting cage and the line die holder. The tension of a cable is monitored by the breakage line-prevention device, and the cable is prevented from being damaged by pulling or broken due to abrupt tension.

Owner:JIANGSU TRIGIANT TECH

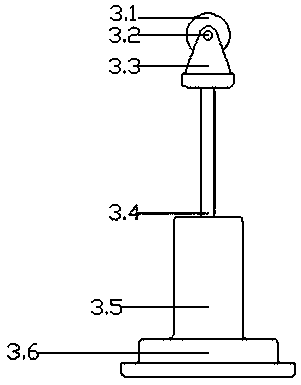

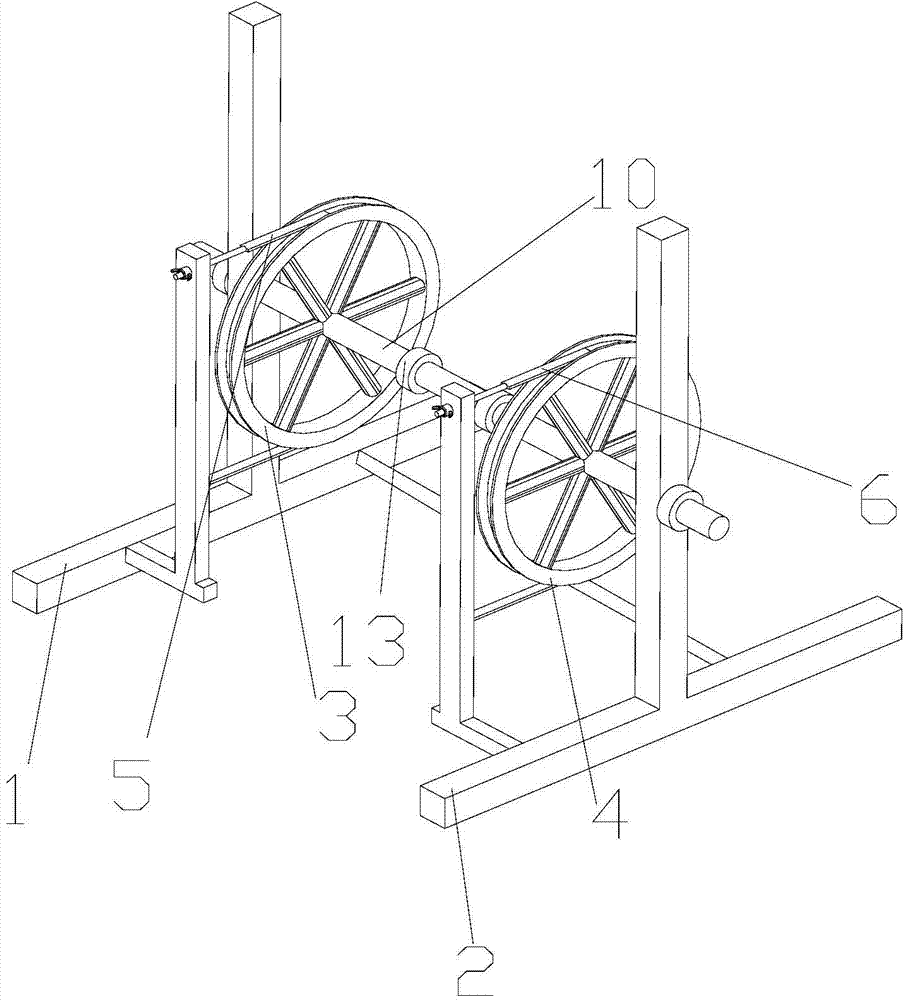

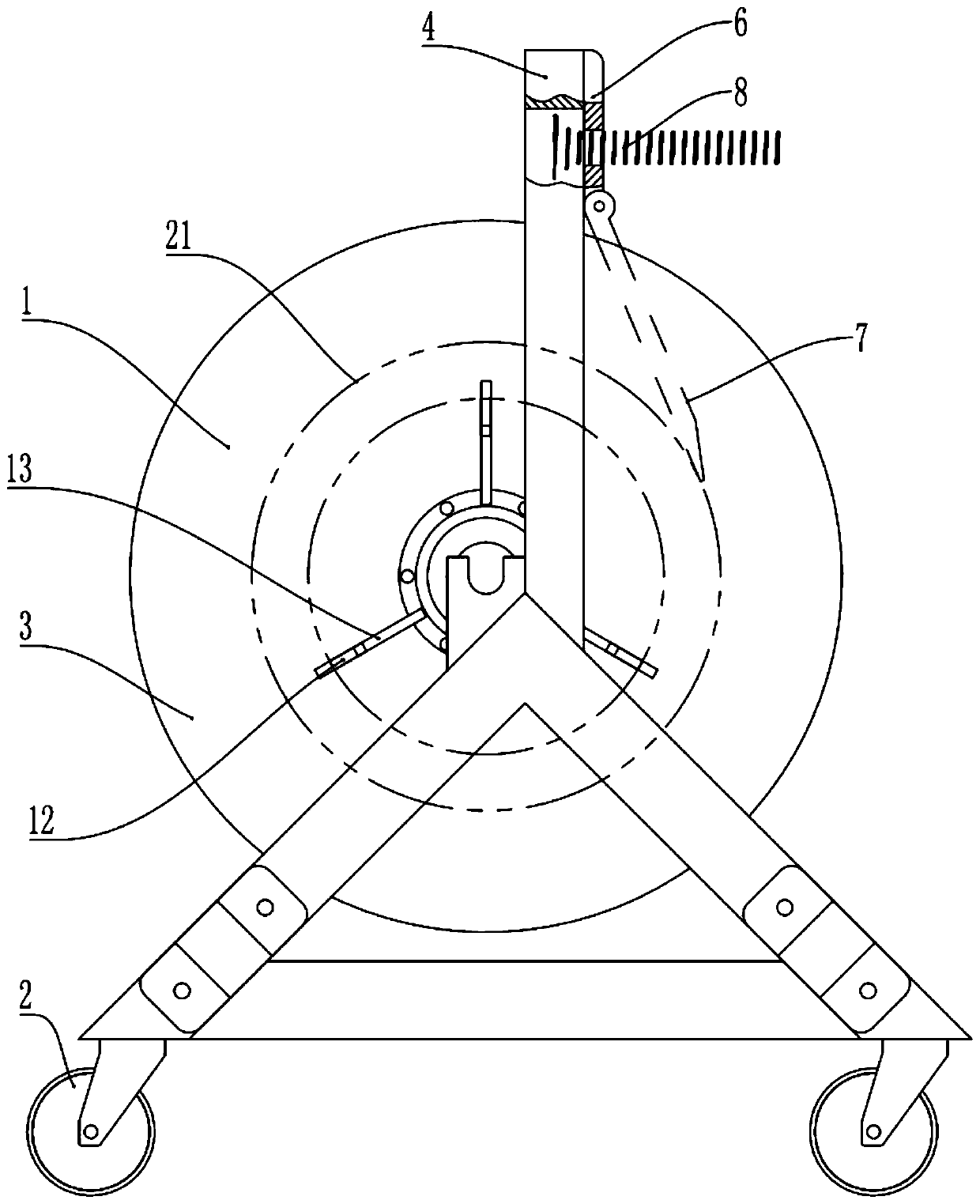

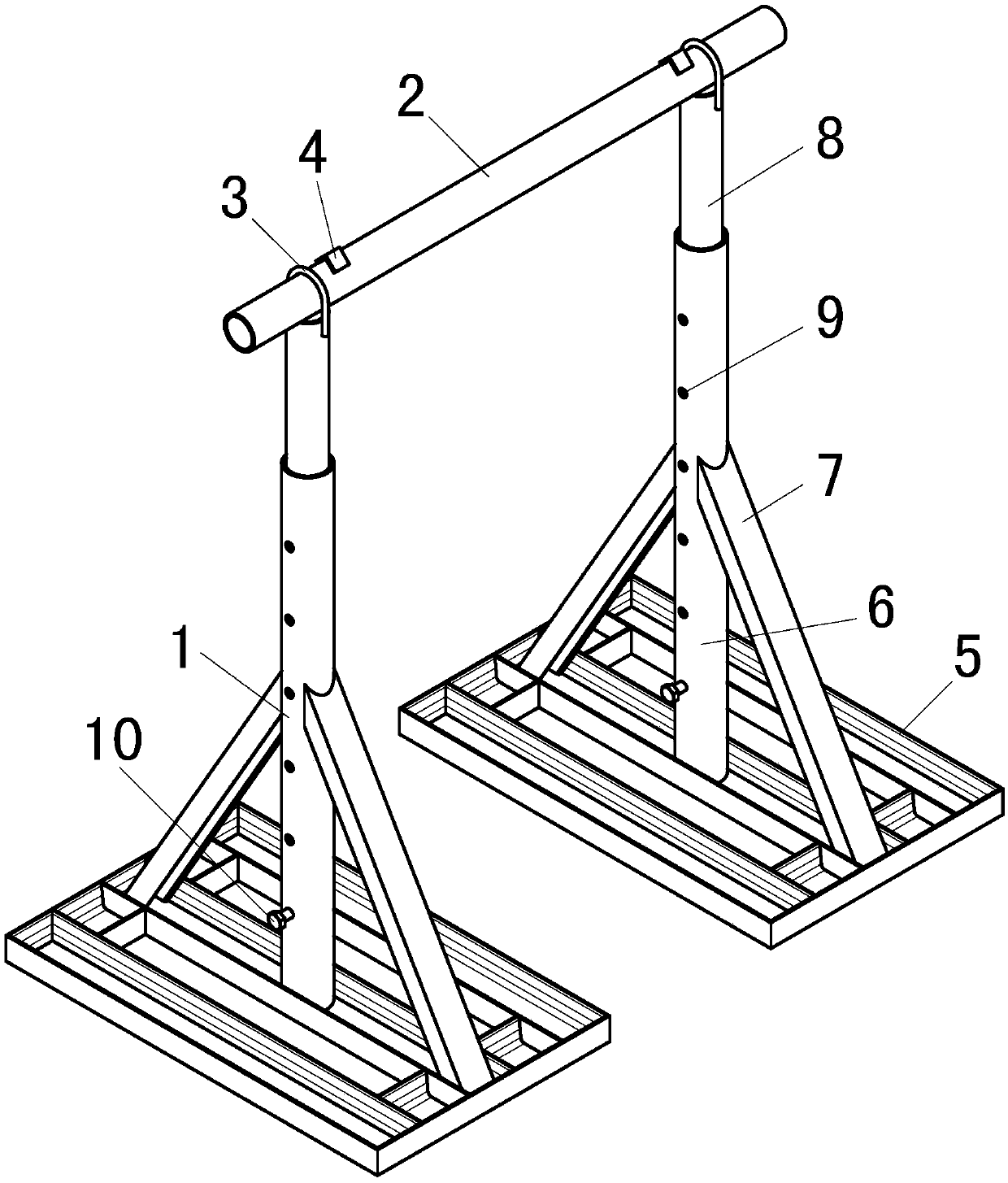

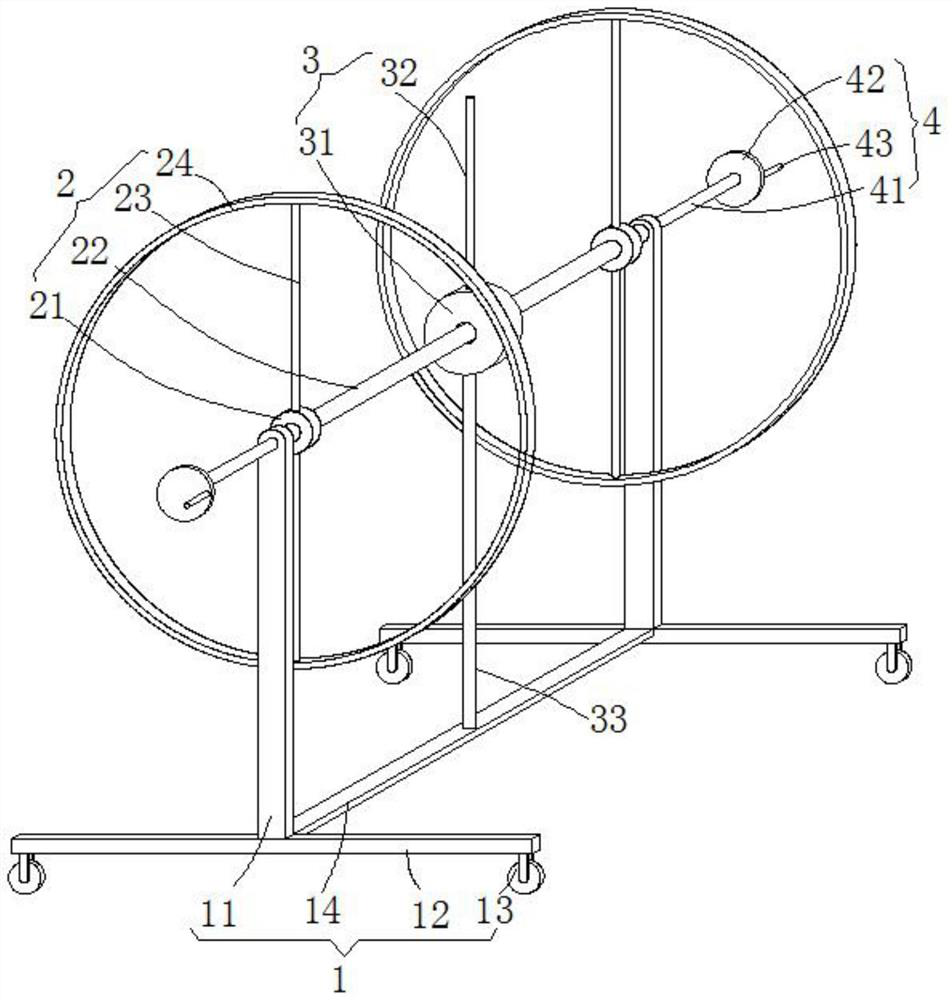

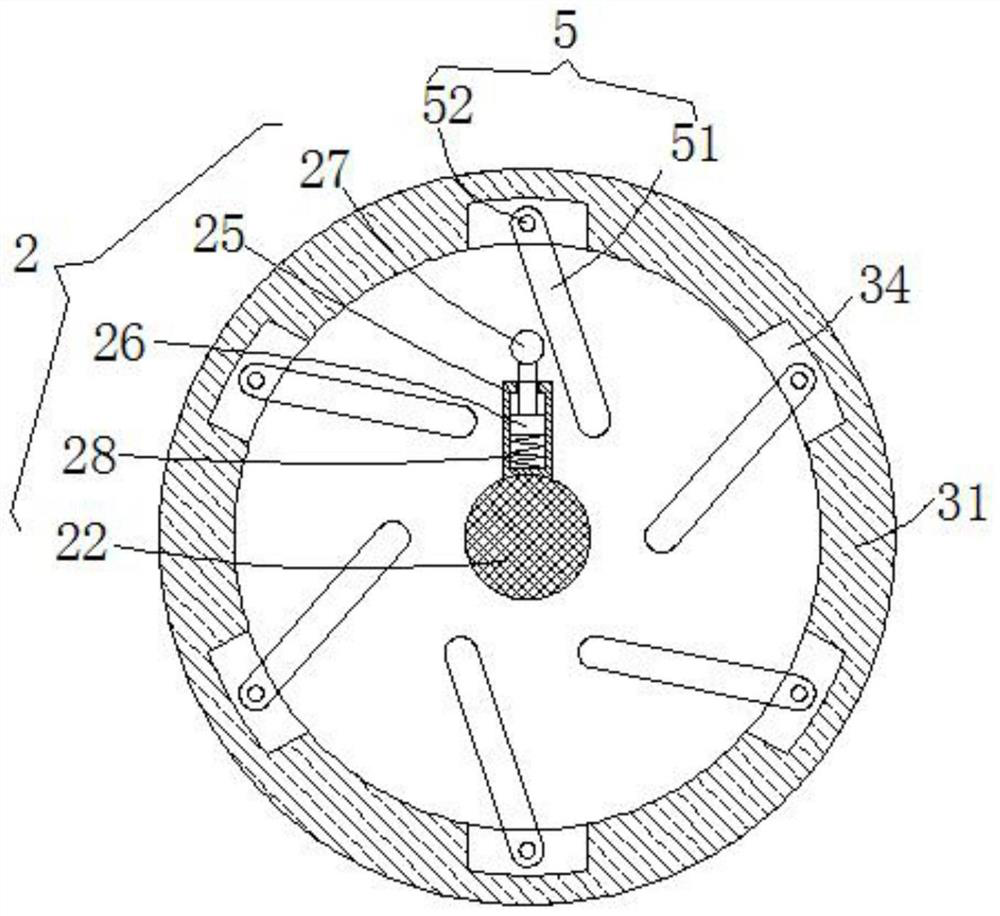

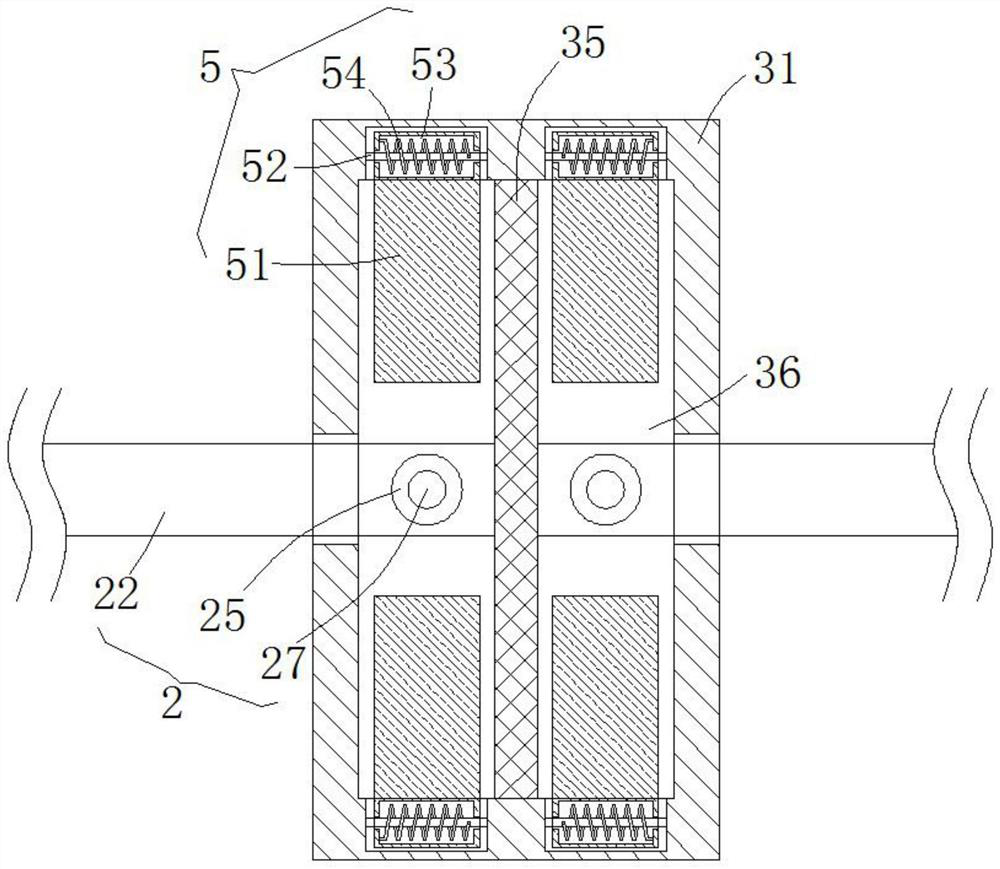

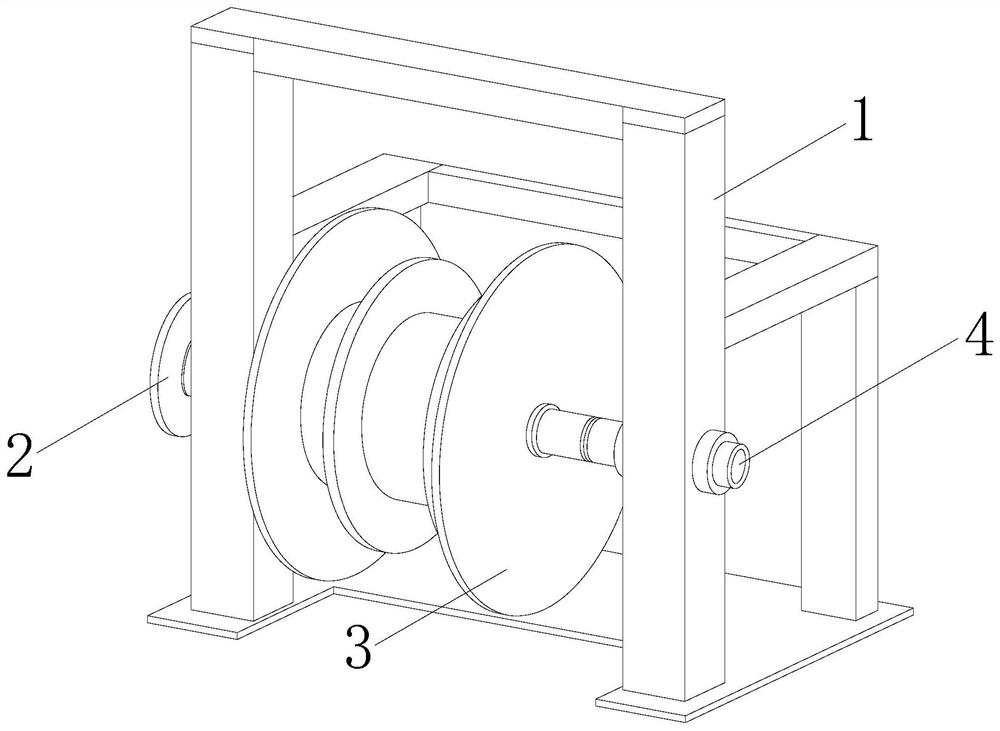

Cable or optical cable releasing device

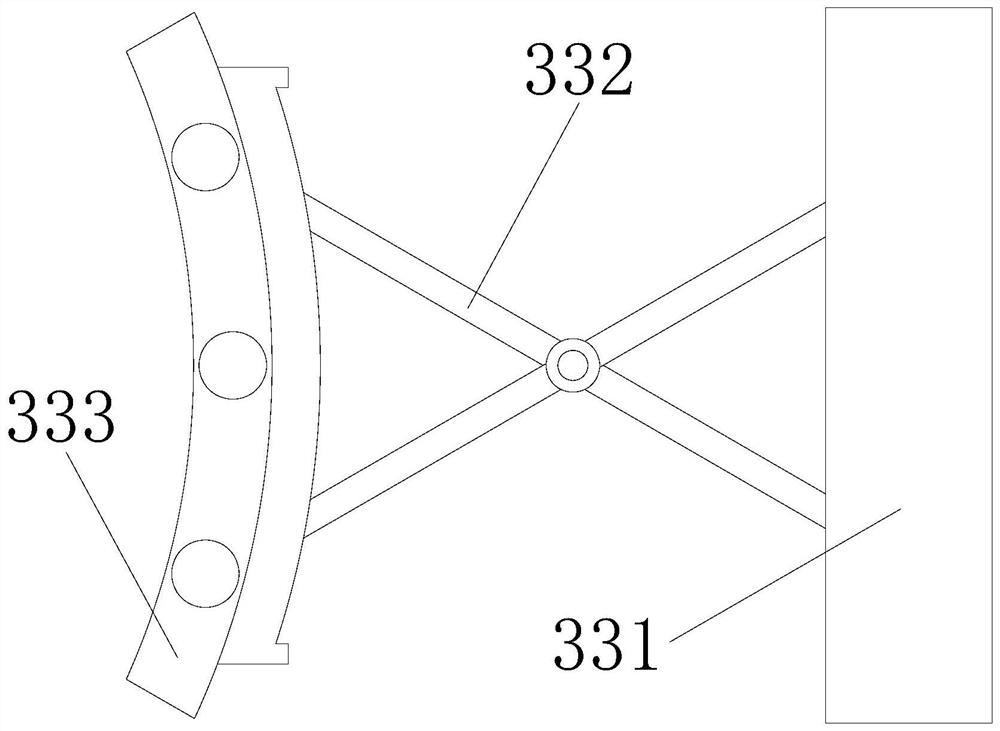

ActiveCN105390995ALow costEffort-saving tractionOptical fibre/cable installationApparatus for laying cablesEngineeringMechanical engineering

The invention belongs to the technical field of power construction and cables, and in particular relates to a cable or optical cable releasing device, which is characterized by comprising a fixing device (1), a moving device (2) and a rotary supporting body (3); during a mounting state, the fixing device is placed on the horizontal plane, the moving device is placed above the fixing device, and the rotary supporting body is arranged between the moving device and the fixing device. The cable or optical cable releasing device mainly has the following beneficial effects: the cable or optical cable releasing device is simple in structure, easy to mount, more labor-saving during releasing and fast in releasing speed.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY +1

Paying-off method of paying-off device

ActiveCN104709760AIncrease frictionLine optimizationFilament handlingEngineeringMechanical engineering

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Automatic profile steel production line

InactiveCN108889790AFast pay-off speedIncrease productivityWire straightening devicesExtrusion cleaning devicesManipulatorEngineering

The invention discloses an automatic profile steel production line in the technical field of profile steel machining. The automatic profile steel production line comprises a feeding device, a pre-straightening machine, a sandblast derusting machine, a first fine straightening machine, a steel brush derusting machine, a cold drawing machine, a profile steel polishing machine, a second fine straightening machine, a profile steel cutting machine and a discharging device, wherein the feeding device comprises a base, a rotating disc and a first mechanical arm, the rotating disc is rotatably mountedon the base and is used for reeling steel bars, and the first mechanical arm is used for dragging the steel bars to the pre-straightening machine; the rotating disc is provided with a driving assembly for driving the rotating disc to rotate, a guiding assembly for guiding the steel bars is arranged on one side, close to the rotation disc, of the base and comprises a bracket, the bracket is arranged on the base, an upper guiding wheel and a lower guiding wheel are mounted on the bracket, the lower guiding wheel is rotatably mounted on the bracket, and a first gap convenient for the steel barsto pass through is formed between the upper guiding wheel and the lower guiding wheel. The automatic profile steel production line has the advantages that the paying off of the steel bars is facilitated, the materials are conveniently conveyed, and meanwhile, the safety is improved.

Owner:扬州八方冷拉型钢有限公司

Rapid fixing type paying-off construction process

ActiveCN110203755AScattered situations will not occurRealize the needs of coiling and unwindingFilament handlingApparatus for laying cablesEngineeringElectric power

The invention relates to the technical field of electric power paying-off, and particularly discloses a rapid fixing type paying-off construction process. The rapid fixing type paying-off constructionprocess comprises the following steps that S1, a rapid fixing type paying-off device is taken, wherein the rapid fixing type paying-off device comprises a support and a cable installing disc, the cable installing disc is rotationally connected to the support, and the cable installing disc comprises a supporting shaft and two baffle discs which are distributed in the axial direction of the supporting shaft; S2, a cable coil is installed, wherein the cable installing disc is taken down from the support, the baffle discs are taken down from the cable installing disc, the cable coil which needs to be installed sleeves expanding rods, then the taken-down baffle discs are installed back, stretching and retracting units are adjusted, so that the inner ring of the cable coil is tightened throughthe expanding rods, the baffle discs are adjusted, so that the baffle discs tightly press against the two sides of the cable coil, and the cable installing disc are installed on the support; and S3, paying-off is prepared, wherein a cable head of the outer ring of the cable coil is sorted out, and a section of cable is pulled out for later use. According to the scheme, the problems that the cablecoil is scattered, the paying-off speed of the cable is low and the manual labor intensity is large in the prior art are solved through the cable installing disc, the stretching and retracting units and the expanding rods.

Owner:CHONGQING CONSTR NINTH ENG

Movable-type electric cable machine with electric leakage protection function

InactiveCN106099823ASimple structureReasonable designArrangements using take-up reel/drumMotor driveMovable type

The invention discloses a mobile electric cable machine with a leakage protection function, which includes a cable support, a winding reel, an explosion-proof plug, a leakage protector, a leakage protection switch, a motor, and a storage battery. The winding reel includes a reinforcing roller and The reinforced guard plate is located at both ends of the reinforced drum, the explosion-proof plug is set outside the reinforced guard plate, the leakage protector is fixed on the inner side of the reinforced guard plate, the junction box is set on the reinforced drum, and the junction box is equipped with a terminal, and one end of the leakage protector is connected to the wiring Terminal connection, the other end of the leakage protector is connected with the leakage protection switch, a rolling shaft is set on the cable support, the winding reel is set on the rolling shaft through a reinforcing roller, a mounting frame is provided at the right end of the cable support, and the rolling shaft is connected to the motor , the motor is connected to the battery. The invention is simple in structure and reasonable in design. The motor drives the rolling shaft to rotate, and the rolling shaft drives the winding reel to run, which reduces the work intensity of construction personnel dragging the cable, increases the speed of unwinding, and reduces the friction between the cable and the ground.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

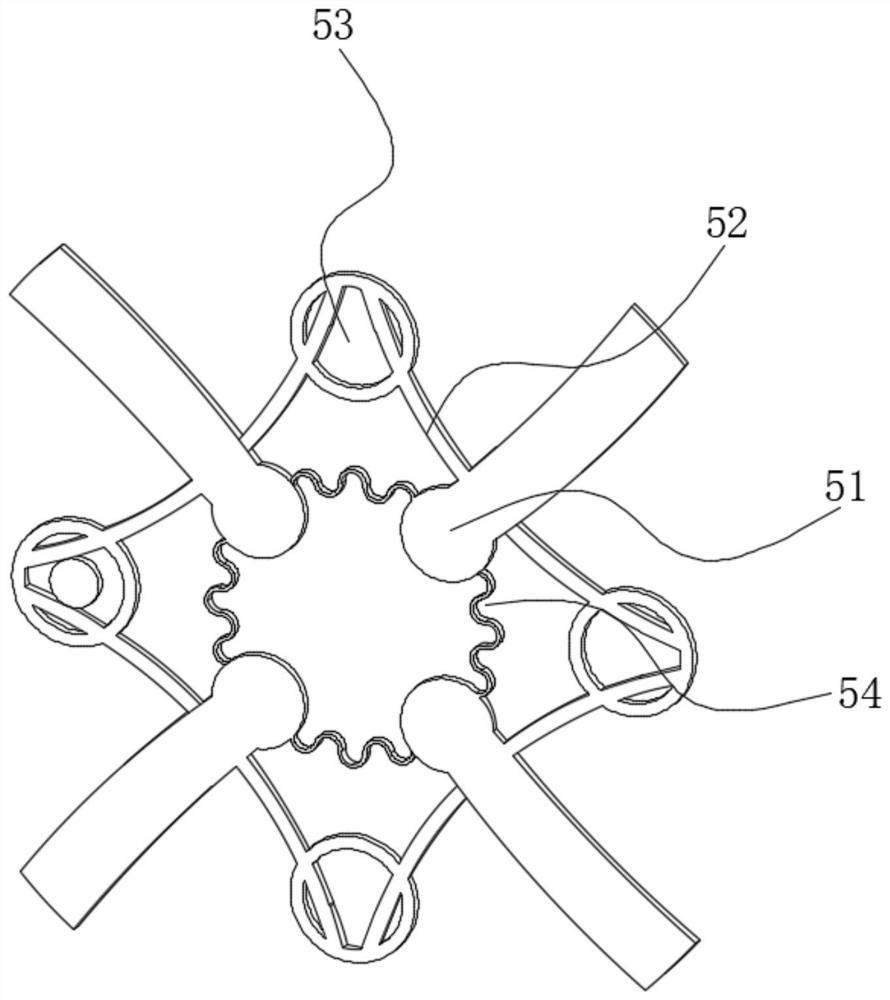

Passive pay-off rack

PendingCN109230865ASolve the technical problems of inconvenient tension adjustment and unstable pay-offPay-off tension automatic adjustmentFilament handlingEngineeringCycloid gear

The invention relates to a passive pay-off rack. The technical problem that for a traditional passive pay-off rack, tension adjustment is inconvenient, and paying off is unstable can be solved. The passive pay-off rack comprises a pay-off rack main body which comprises a bearing frame, a bearing rod and a tension adapter, and a pay-off shaft is arranged under the tension adapter; the tension adapter comprises a transversely arranged threading plate and a longitudinally arranged swing rod, a cycloid gear is arranged on the top of the swing rod, the bottom of the swing rod is fixed to an elliptic bearing which is fixed in a shell, a circular bearing is fixed to the threading plate, the elliptic bearing and the circular bearing are tangently arranged, and the elliptic bearing is arranged above the circular bearing; the passive pay-off rack further comprises a vertical screw rod which is fixedly connected with the threading plate, the bottom of the vertical screw rod is fixedly connected with one end of a brake strap, the other end of the brake strap is fixed to the bearing rod, and a brake wheel is arranged on the upper portion of the brake strap and connected with the pay-off shaft.The passive pay-off rack is firm in structure, very small in abrasion loss and stable in pay-off tension.

Owner:安徽光纤光缆传输技术研究所

Simple electrical paying-off device

PendingCN109534037AReduce construction costsFast pay-off speedWebs handlingWaste materialPosition angle

Owner:CHINA CONSTR FOURTH ENG DIV INSTALLATION ENG

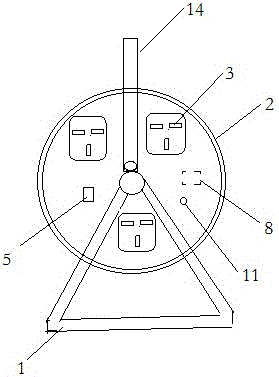

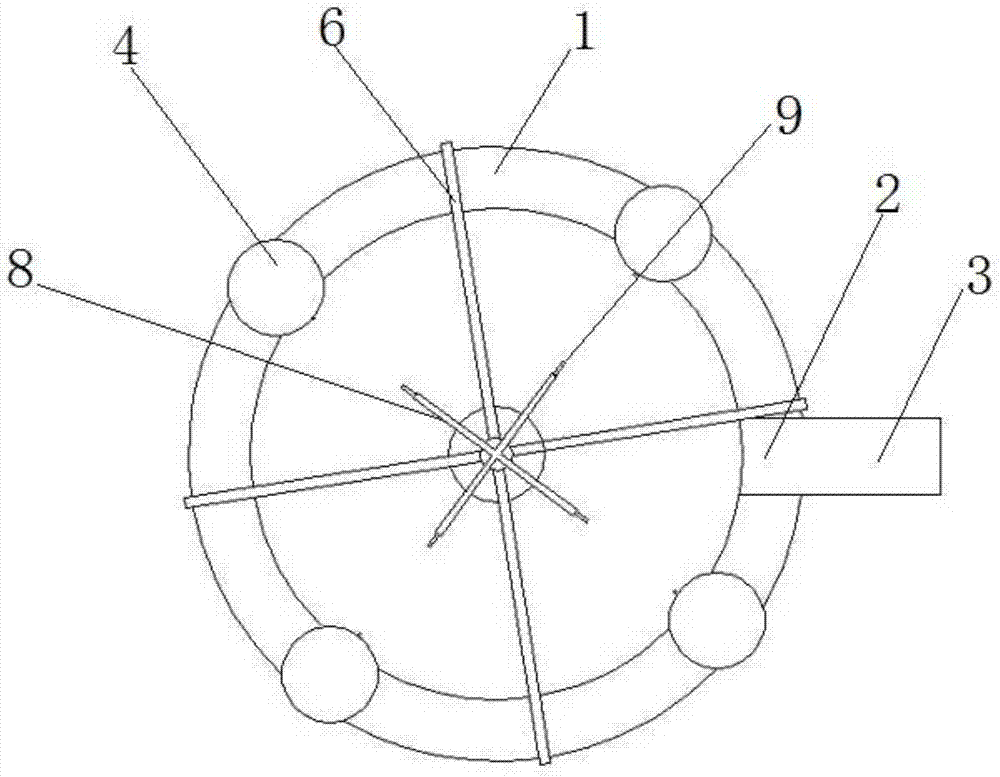

Copper wire releasing device capable of quickly replacing wire barrels

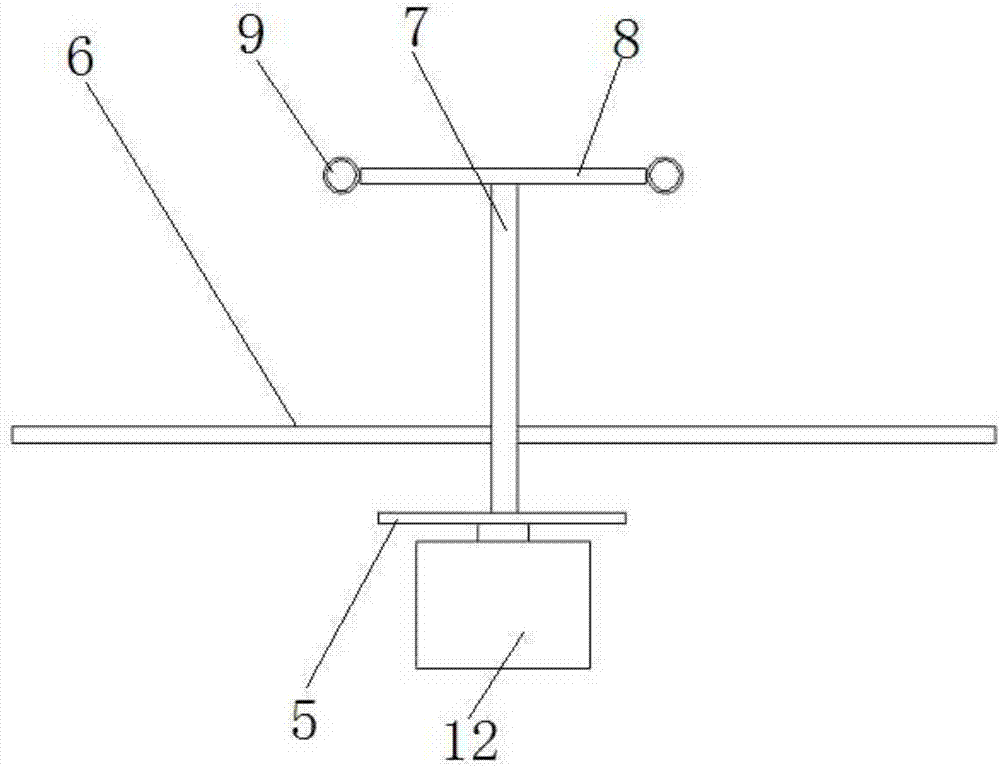

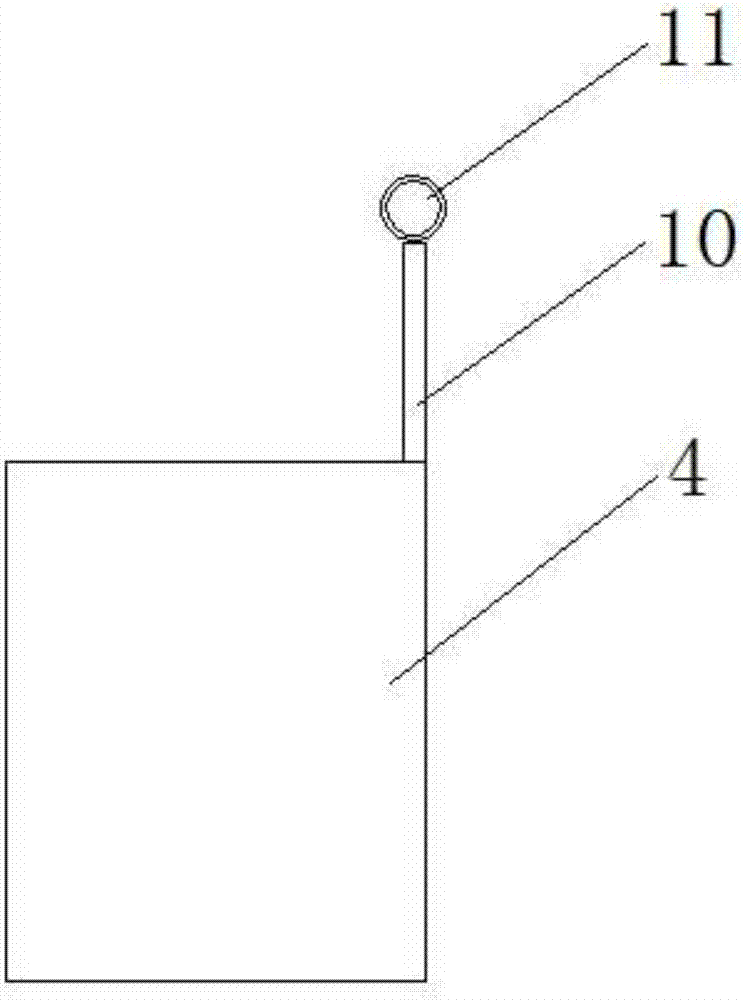

The invention discloses a copper wire pay-off device capable of quickly replacing a wire barrel, which comprises an annular slide rail, a gap, an inlet track, a wire barrel, a turntable, a lever, a first support rod, a horizontal bar, and a first wire passing collar , the second pole and the second wire passing collar, the annular slide rail is provided with a plurality of wire barrels, the edge of the annular slide rail is provided with a gap, the gap is provided with an inlet track, and the annular slide rail A turntable is arranged in the center of the rail, and a first vertical support rod is arranged on the turntable, at least one cross bar is arranged at the top of the first support rod, and first wire passing collars are provided at both ends of the cross bar , the side wall of the first pole is provided with at least one driving rod, the length of the driving rod is greater than the radius of the circular slide rail, and the top of the edge of the line barrel is provided with a vertical second pole, the second The top of the pole is provided with a second wire passing collar. The invention has the advantages of simple structure, convenient use, fast pay-off speed, smooth pay-off and convenient replacement of the wire barrel.

Owner:蒙玛特(天津)铜业有限公司

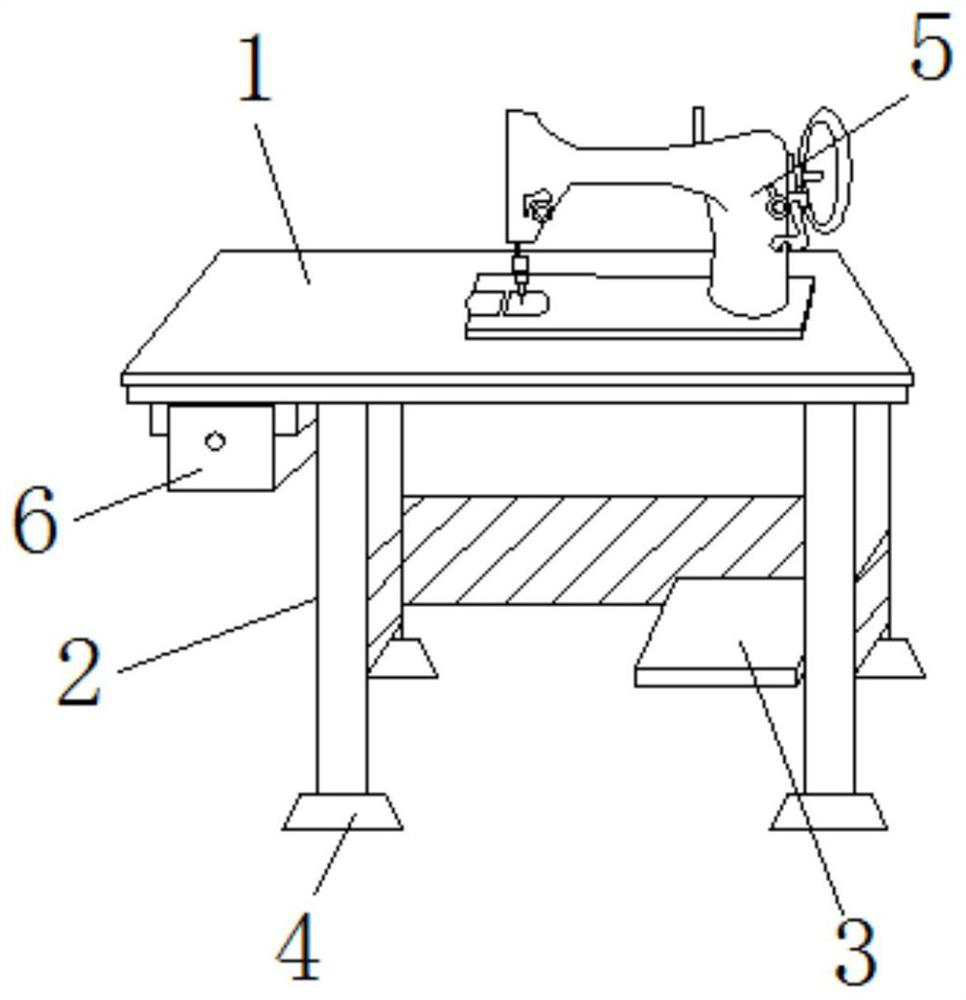

Sewing and trimming device for clothing manufacturing and using method

PendingCN111962219AGuaranteed stabilityImprove the quality of workWorkpiece carriersSevering textilesManufacturing engineeringWorkbench

The invention discloses a sewing and trimming device for clothing manufacturing. The sewing and trimming device comprises a workbench, wherein a supporting frame is fixedly mounted at the bottom end of the workbench, a pedal plate is fixedly connected to the interior of the supporting frame, a stabilizing mechanism is mounted at the bottom end of the supporting frame, the top end of the workbenchis fixedly connected with a sewing device, the top end of the sewing device is provided with a pay-off positioning mechanism, and a trimming mechanism is mounted on the surface of the left end of theworkbench. According to the device, aiming at the situation that some tools are needed to assist during sewing, partition plates are installed in a placement box, the positions of the partition platescan be adjusted through a guide block and guide grooves, first hand screw bolts can be tightened after the adjustment is completed, the positions of the partition plates can be fixed, in this way, aworker can classify and place wire barrels according to requirements, and taking is facilitated; and placement bags are installed on the inner wall of the placement box, and the placement bags are provided with different calibers, the different tools can be conveniently stored, the use of a user is facilitated, and the working efficiency is improved.

Owner:浙江天驰服饰有限公司

Mobile electronic projection device for measuring paying off

PendingCN110657791ANot easy to shakeEasy to adjust directionReference line/planes/sectorsLaser transmitterEngineering

The invention discloses a mobile electronic projection device for measuring paying off. The device comprises a base body, a supporting rod, an inner sleeve and an outer sleeve. Supporting legs are arranged at the bottom of the circular-truncated-cone-shaped base body; a vertical supporting rod is arranged in the center of the upper surface of the base body; the inner sleeve sleeves the periphery of the supporting rod; through holes are evenly distributed in the pipe wall where the inner sleeve is located; and the through holes are filled with balls. The outer sleeve is connected to the outer wall of the inner sleeve in a sleeving mode and rotates on the outer wall of the inner sleeve; and a protruding edge protruding outwards is arranged at the bottom of the outer sleeve and is sleeved inan annular groove of the base body. A laser receiver is arranged at the top where the outer sleeve is located; and an annular laser transmitter is connected to the outer wall of the outer sleeve in asleeving mode. An accurate pay-off point position is accurately and rapidly located according to the mutual synergistic effect of the annular laser transmitter and the laser receiver. Moreover, the device is used conveniently; the labor cost is lowered; the pay-off time is saved; the pay-off speed is increased; the high pay-off point precision is ensured; and the engineering quality is guaranteedindirectly.

Owner:THE FOURTH ENG CO LTD OF CCCC FIRST HIGHWAY ENG

Automatic conveying device for electric wires and cables

The invention provides an automatic conveying device for electric wires and cables; and the device comprises a base plate, and relates to the field of electric equipment installation. The automatic conveying device for the electric wires and the cables comprises the base plate; two rollers are movably mounted at the bottom of the base plate; a support plate is fixedly connected to the top of the base plate; a power supply connecting wire is fixedly mounted on the left side of the support plate; the front surface of the support plate is fixedly connected with a mounting plate; a motor switch isfixedly mounted on the front surface of the mounting plate; a rotating groove and a gear groove are formed in the top of the support plate; the gear groove is positioned on the left side of the rotating groove; a conveying main wheel is arranged in the rotating groove; and an antiskid groove is formed in the surface of the conveying main wheel. The automatic conveying device for the electric wires and the cables is simple in structure, convenient to operate and convenient to convey unwound electric wires and cables, saves physical strength in manual conveying, accelerates the unwinding speed,and improves the working efficiency.

Owner:ZHENJIANG CHANGHE ELECTRIC POWER TECH

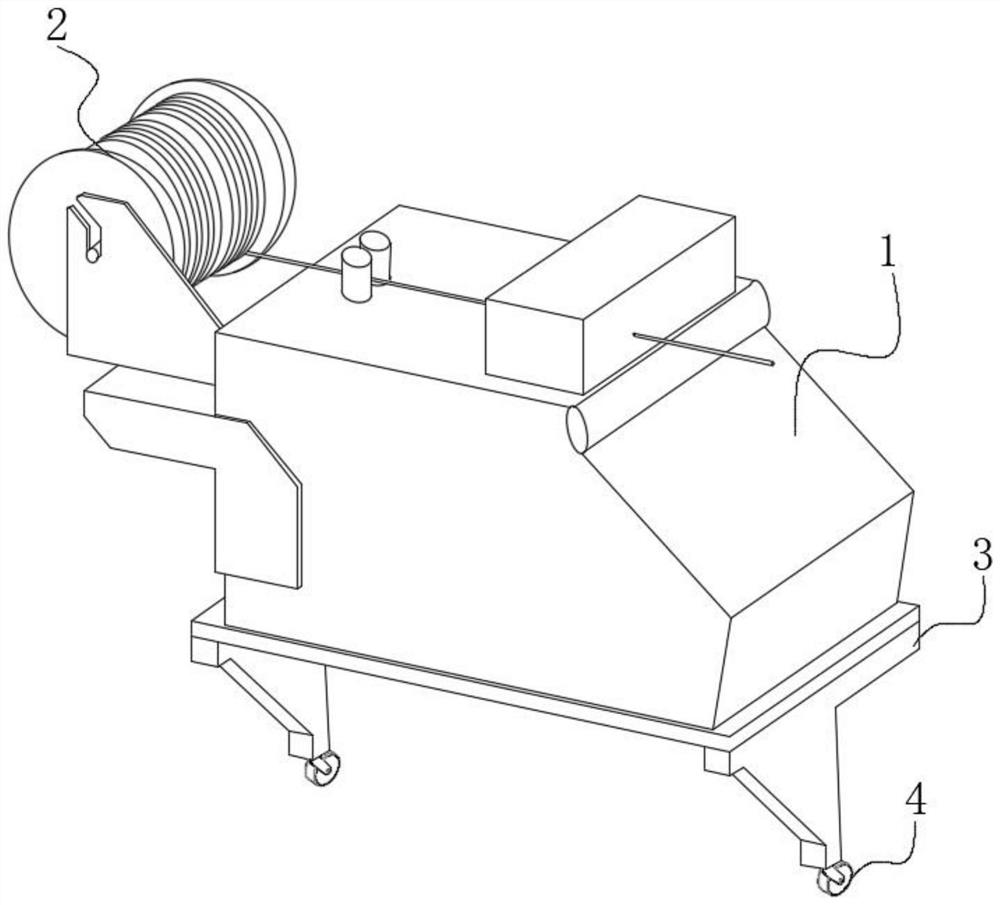

Cable manufacturing equipment

InactiveCN104464960AFast pay-off speedImprove cable manufacturing efficiencyCable/conductor manufactureEngineeringMechanical engineering

Owner:HENAN COMM CABLE

Water-soluble enameled wire surface lubricating oil and production method and application thereof

InactiveCN109679745AWon't burn easilyImprove securityLubricant compositionInsulating conductors/cablesAlcoholWater soluble

The invention provides water-soluble enameled wire surface lubricating oil. The water-soluble enameled wire surface lubricating oil comprises the following components in percent by mass: 0.5-30% of stearic alcohol ester, 0.5-20% of block silicone oil, 0.5-20% of isopropanol and the balance of water. The invention further provides a production method and application of the water-soluble enameled wire surface lubricating oil. The obtained enameled wire lubricating oil does not burn easily in the case of electronic sparks and an open fire, so that the safety is very high; the friction coefficientis low, so that the wire breaking rate is small, the wire unreeling speed during production can be increased, and the yield is greatly increased; an obtained enameled wire has a smoother and brightersurface, and the insulating performance of the enameled wire is also guaranteed better; the cost is low.

Owner:博罗县润达线缆材料科技有限公司

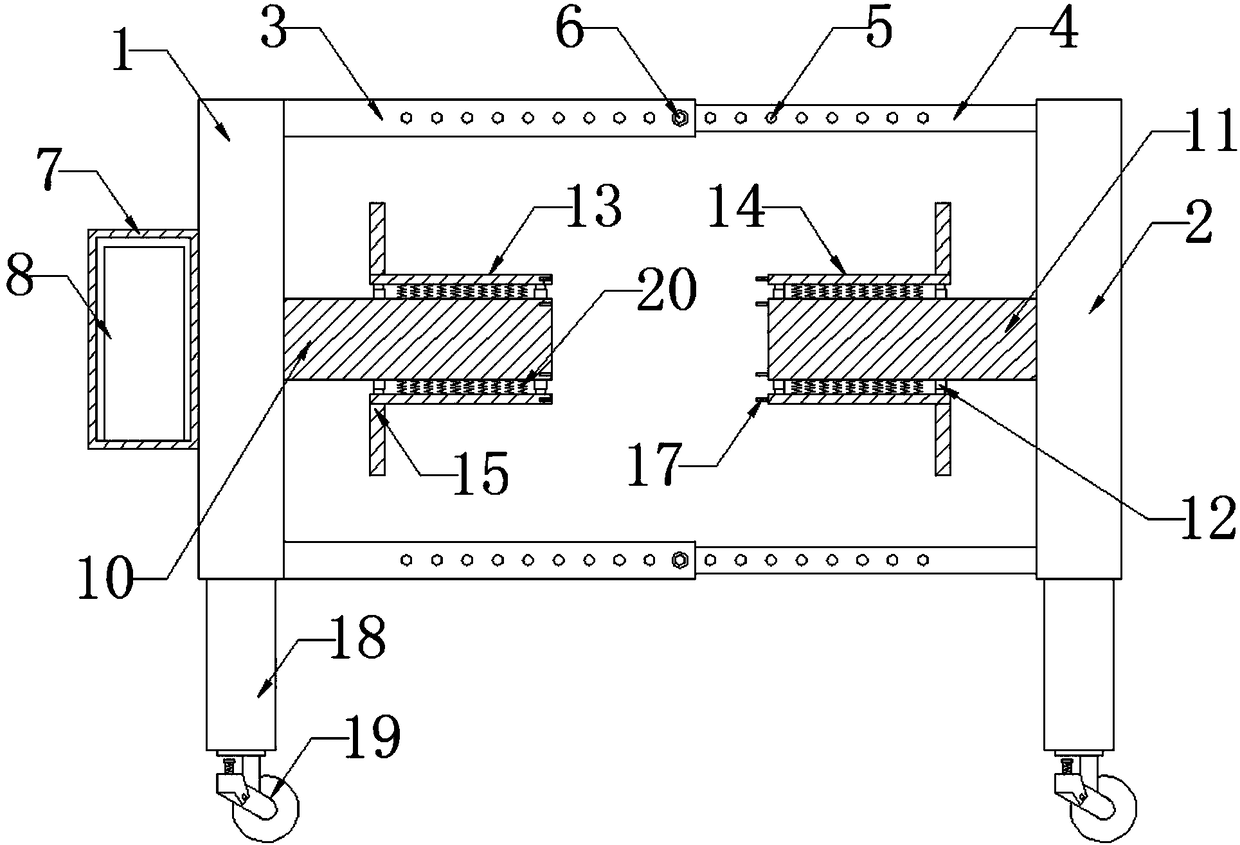

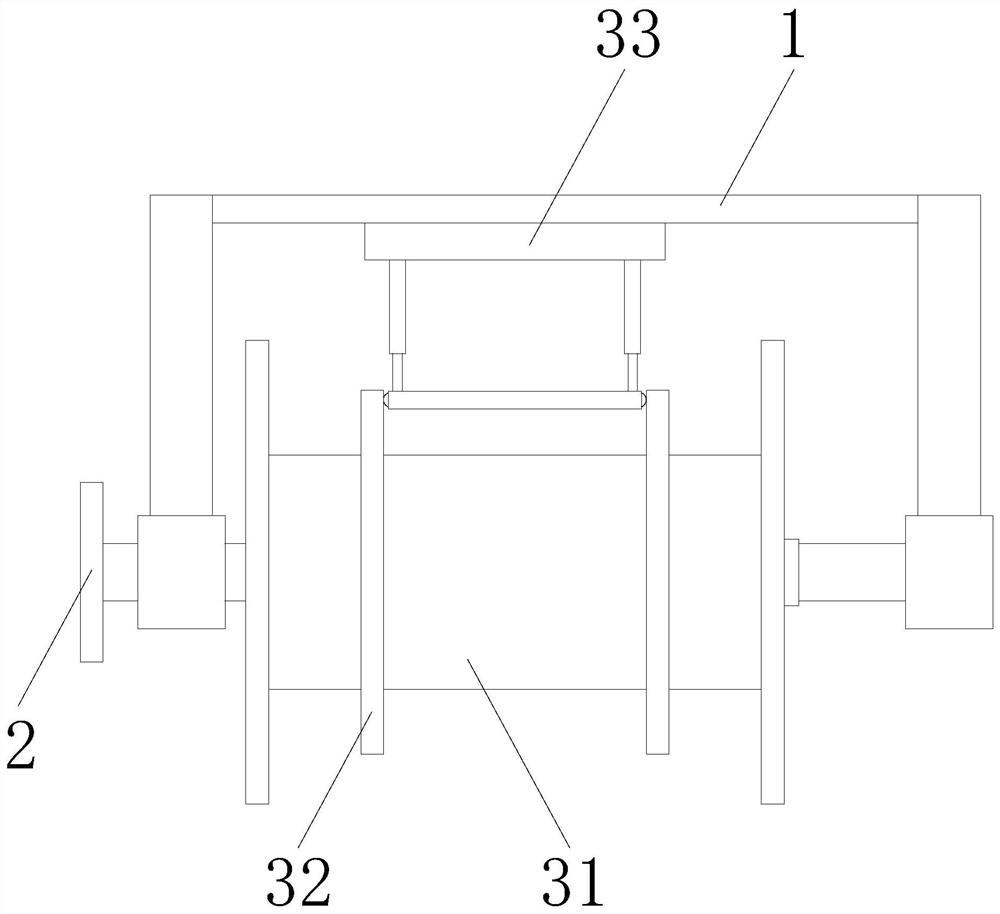

Electrical engineering pay-off positioning device

ActiveCN113003294AMeet the layout needsFast pay-off speedFilament handlingElectronic waste recyclingElectrical engineering technologyProcess engineering

The invention discloses an electrical engineering pay-off positioning device, and relates to the technical field of electrical engineering. The electrical engineering pay-off positioning device comprises a supporting mechanism, two wrapping connection mechanisms and a reversing mechanism, the two wrapping connection mechanisms are symmetrically distributed and arranged at the positions of the two sides of the upper end of the supporting mechanism correspondingly, and the two wrapping connection mechanisms are connected through the reversing mechanism. According to the electric engineering pay-off positioning device, pay-off operation can be carried out in two directions at the same time, the pay-off speed is increased, the cable laying requirement is met, and manpower is saved. In addition, after pay-off is finished, redundant cables which are paid off under the inertia effect in a rotating mode can be tightened by reversely stirring the wrapping connection mechanisms through the reversing mechanism, and meanwhile, the situation that due to random rotation pay-off of the wrapping connection mechanisms, excessive pay-off is caused, and waste is caused accordingly can be avoided.

Owner:安徽祥源科技股份有限公司

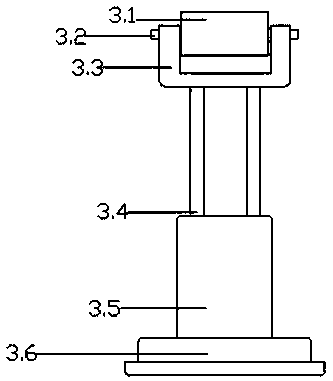

Spring spindle

The invention relates to a spring spindle, wherein, a fixed piece is formed by fixing a right upright post which is fixed with a support and a connecting rod and a left upright post on a track rod, and the spring spindle is formed by connecting a weaving piece and the fixed piece into a whole through a pressure plate and a switch plate; the support is flanged; a pulley is divided into an upper pulley and an intermediate pulley; the upper pulley and the intermediate pulley which are connected to the support are arranged on the right of the right upright post; mounting axial lines of the upper pulley and the intermediate pulley are crossed and angulated at 57 to 63 DEG; a vertical and bended straight section on the middle of the connecting rod is provided with a limit rod; and the pressure plate is matched with a lock catch which is connected to the left upright post. The support is arranged on the right of the right upright post instead of being arranged on the left of the right uprightpost, thereby the angle between a leading-in porcelain eye and a thread-passing point is reduced to between 27 and 33 DEG; the angle is smaller, the pay-out resistance on bobbin is smaller, and thenthe pay-out speed is quick and the thread breakage time is greatly reduced; the connecting rod and the support are arranged on both sides of the right upright post so as to maintain routing balance, thereby the speed can be improved by 10 percent and the weaving quality and the production efficiency are greatly improved; and simultaneously the pressure plate has good strength and long service life, is convenient, quick and easy to operate, and is an updated product of the third generation.

Owner:张宝香

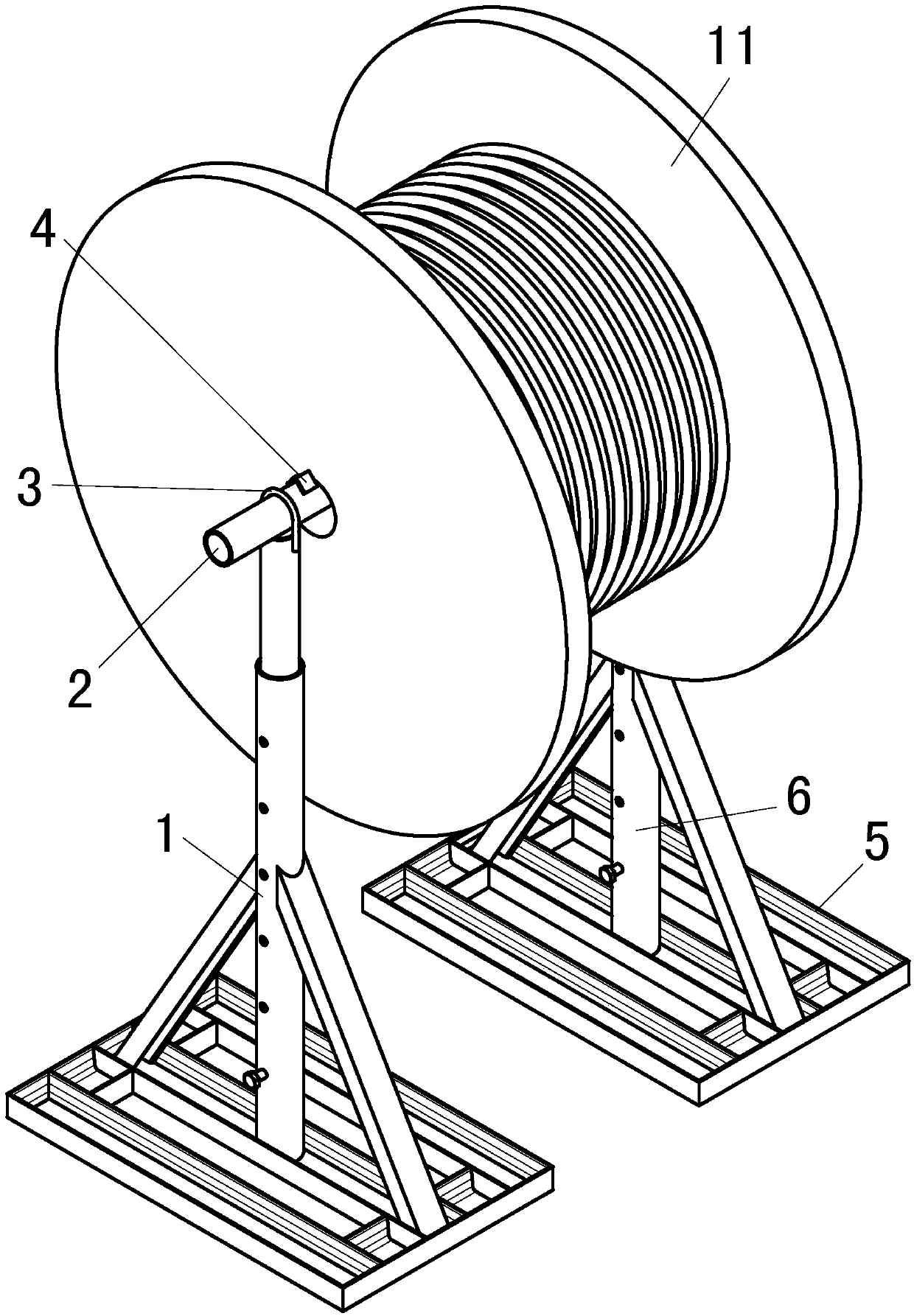

Low voltage home line pay-off stand

A low-voltage user line pay-off rack comprises a base frame, wherein a vertical column is arranged on the base frame and is sleeved with a rotor, the rotor is a waist-shaped cylinder, a conical groove is formed in the upper end face of the waist-shaped cylinder, the vertical column is further sleeved with a conical press block, and the conical press is inversely arranged in the clamped in the conical groove. The low-voltage user line pay-off rack has the advantages that the low-voltage user line pay-off rack for rapid pay-off construction is safe, reliable and convenient to use, a line is pulled during paying off, a hemispherical convex block slides from a spherical groove to a slide way and is clamped into the annular groove, and the rotor rotates and the hemispherical convex block stably slides in the annular groove during paying off. When paying off is stopped, the hemispherical convex block slides from the slide way to the spherical groove to play a positioning effect, meanwhile excessive and messy paying off caused by slight pulling can be avoided, taking up can be achieved by taking out the conical press block, the paying-off speed is high, guide lines are not messy, construction movement is convenient, and the working efficiency is improved.

Owner:ANHUI ELECTRIC POWER FUYANG POWER SUPPLY

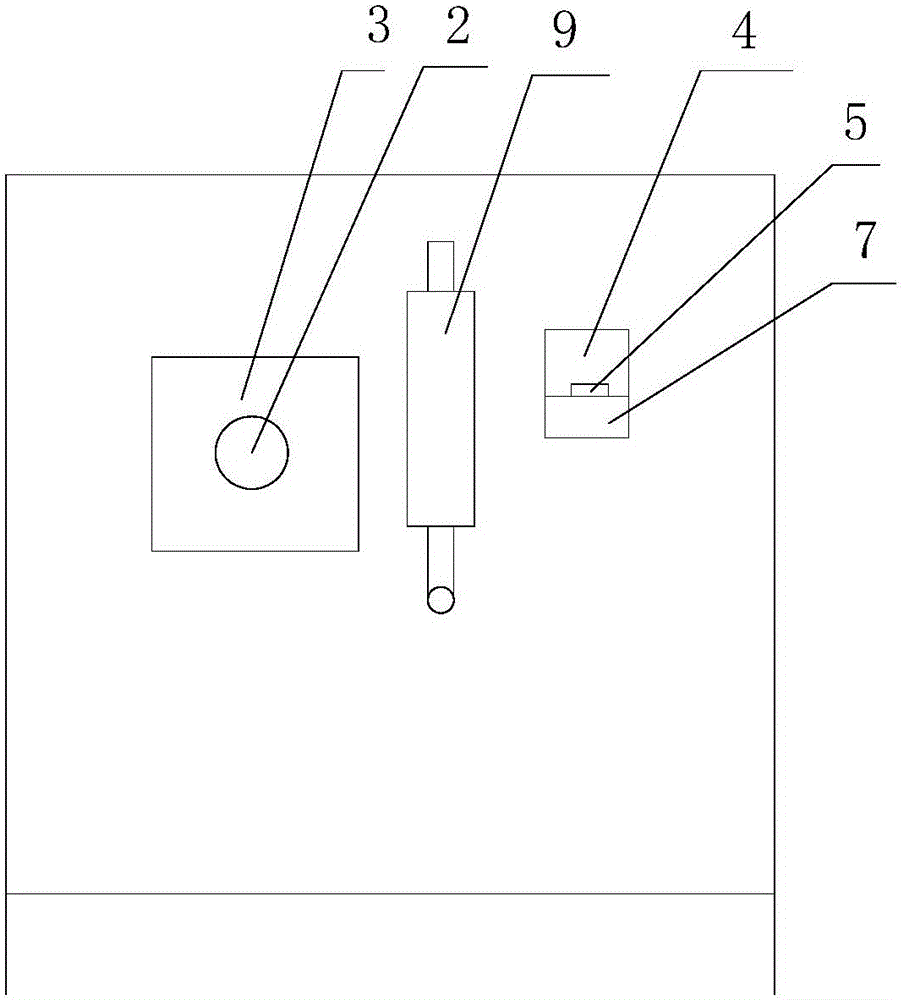

Wire winch device

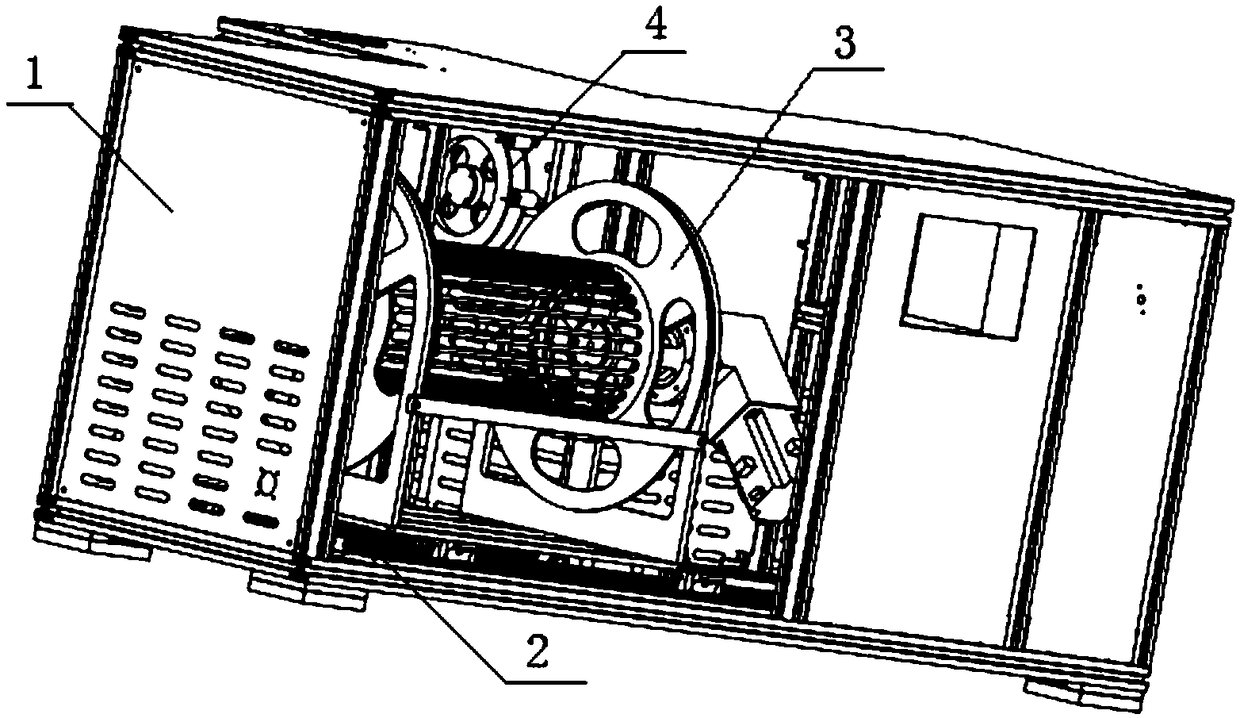

The invention discloses a wire winch device. The wire winch device comprises a box body, a large bottom plate, a winding mechanism, a wire passing mechanism and an automatic control mechanism, whereinthe large bottom plate is fixed to the inner bottom plate of the box body, and the winding mechanism, the wire passing mechanism and the automatic control mechanism are located in the box body. According to the wire winch device, the automatic control mechanism is matched with the wire passing mechanism to automatically judge whether the cable winding and unwinding speed is matched with the winding mechanism; and when the winding mechanism is not matched with the cable winding and unwinding speed, the winding speed of the winding mechanism is automatically controlled, and the translation speed of the winding mechanism is automatically controlled to be matched with the winding speed of the winding mechanism.

Owner:合肥正阳光电科技有限责任公司

Cable paying-off device

ActiveCN103956703ALow costLabor-saving cable pullOptical fibre/cable installationArrangements using take-up reel/drumStructural engineeringElectric cables

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY +1

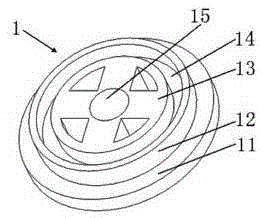

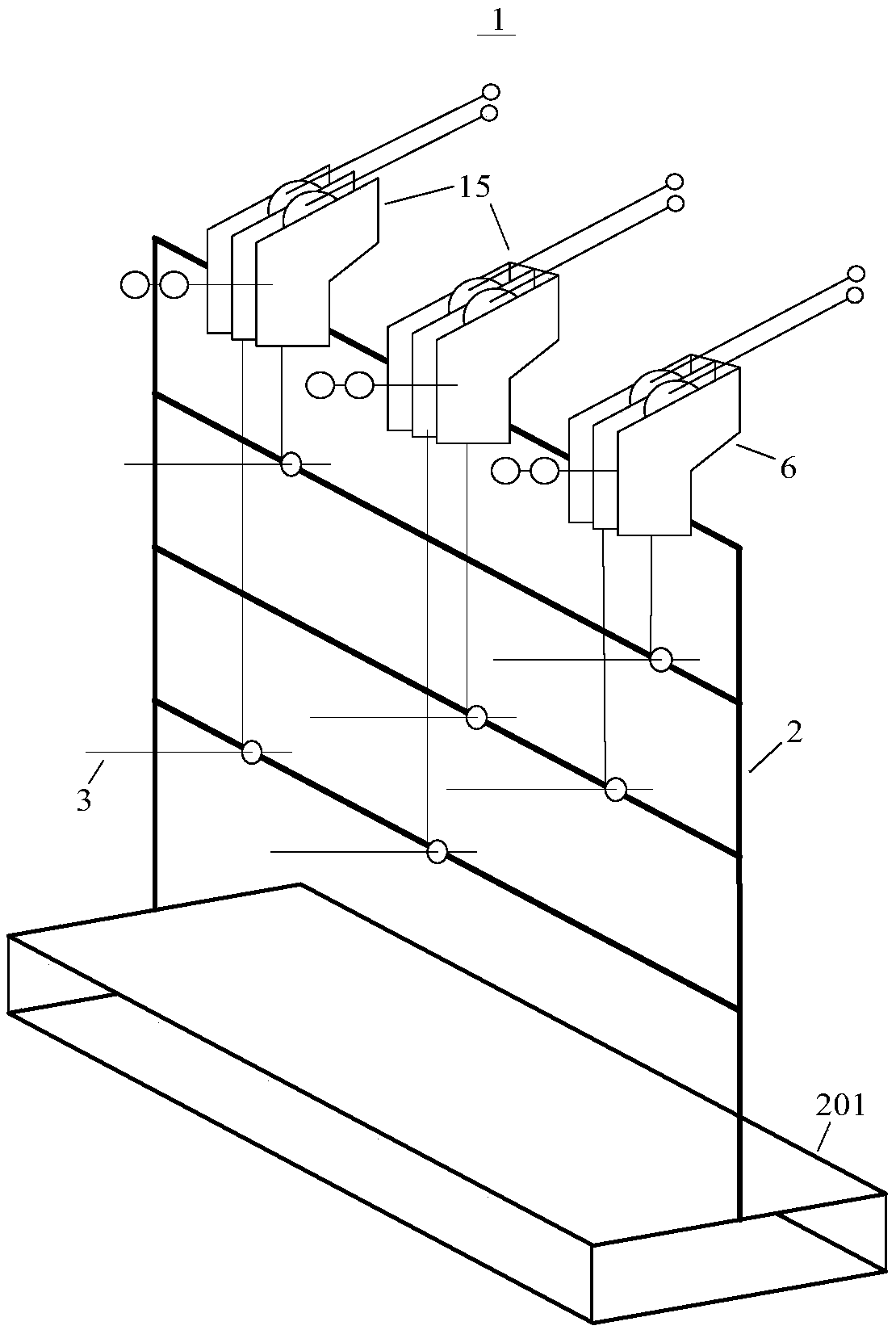

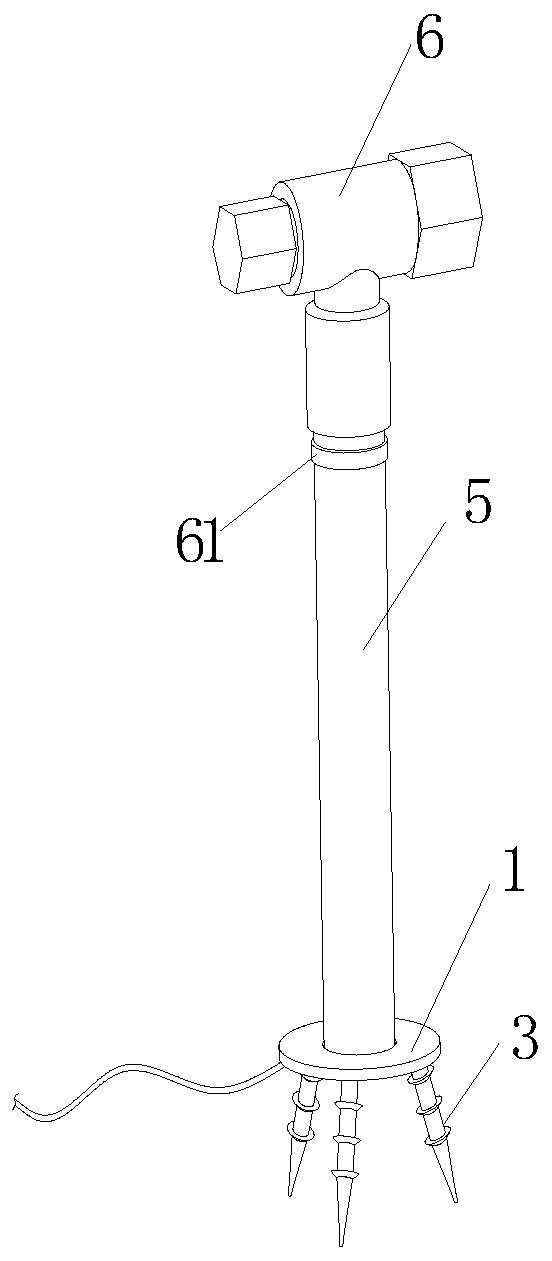

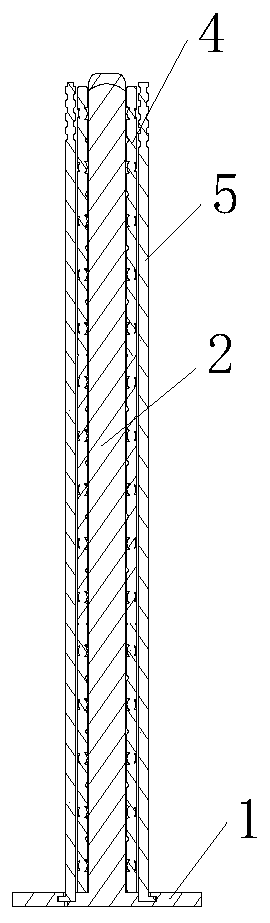

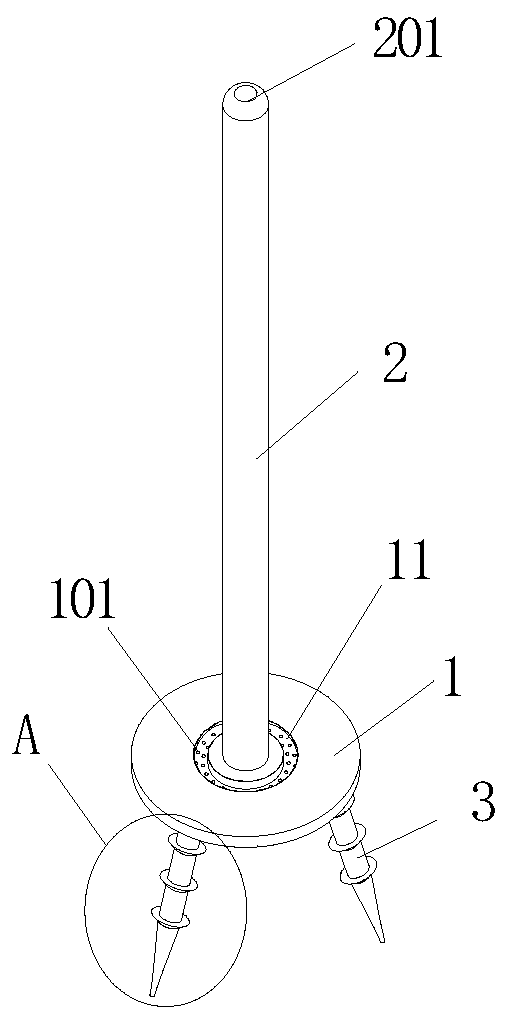

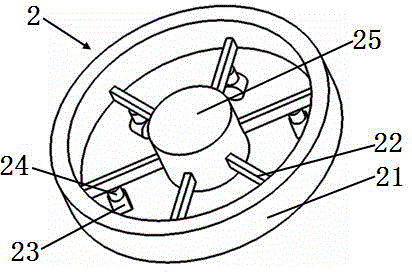

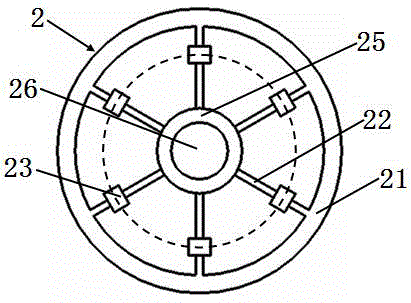

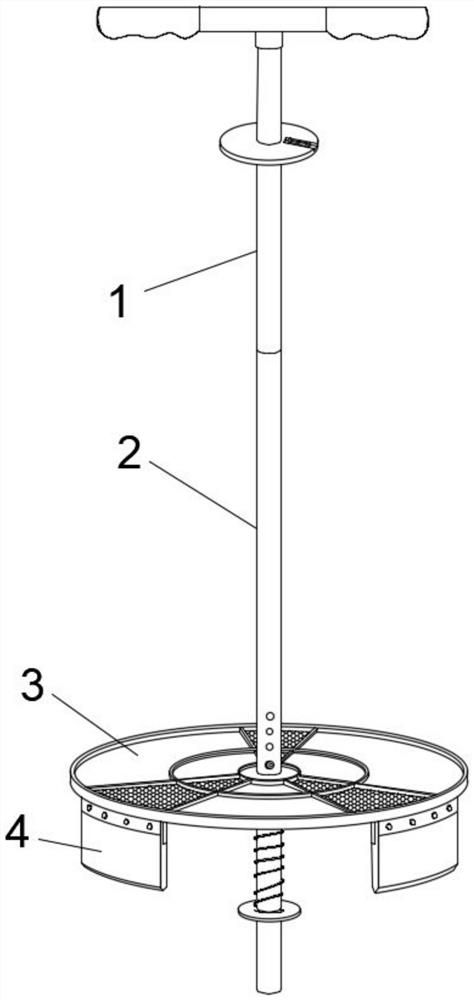

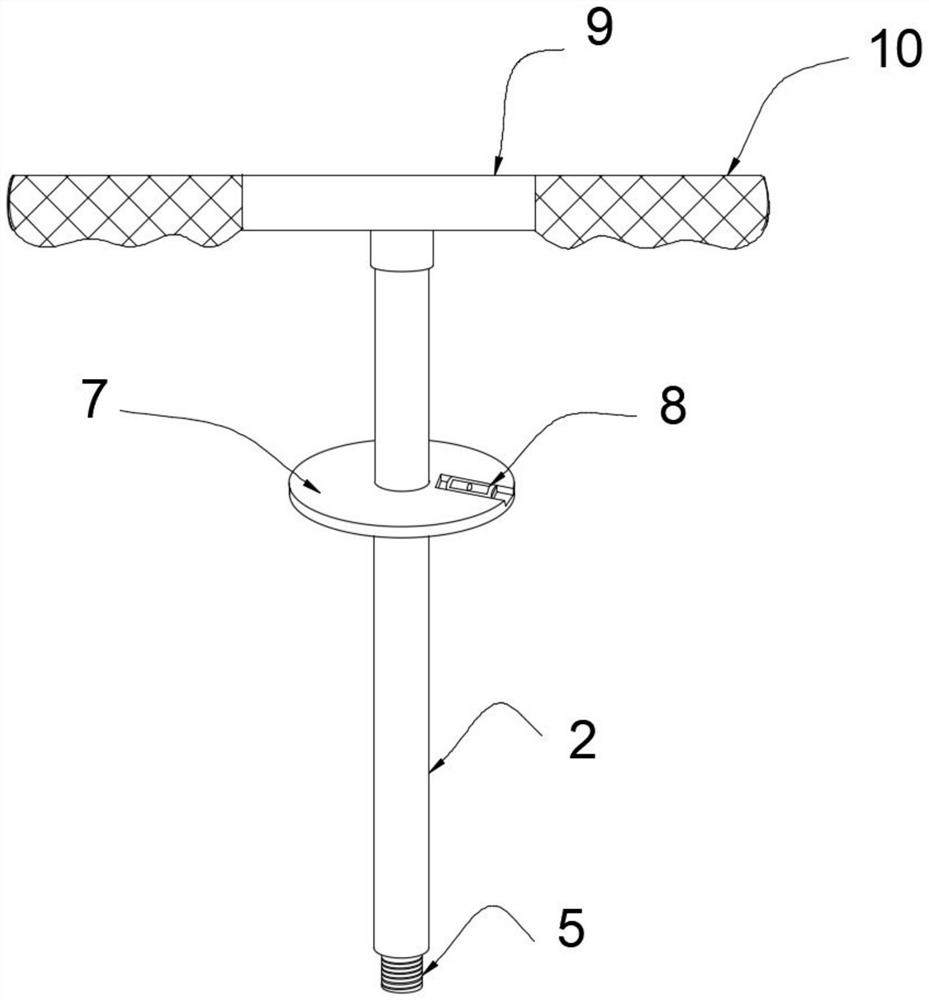

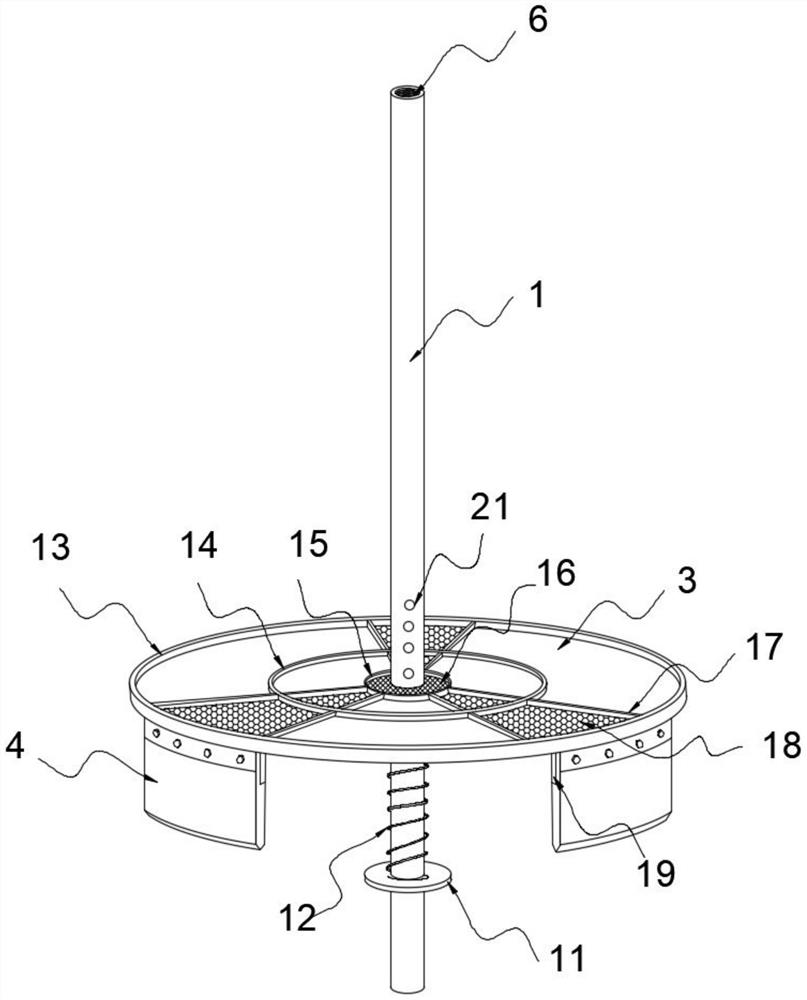

Positioning and paying-off device for pipe pile construction and construction method

ActiveCN113882379AEasy constructionImprove efficiencyGeothermal energy generationFoundation testingArchitectural engineeringStructural engineering

The invention discloses a positioning and paying-off device for pipe pile construction and a construction method, and belongs to the field of pipe pile construction. The positioning and paying-off device comprises a lower main rod and an upper main rod, wherein the upper main rod is detachably connected with the lower main rod; a measuring piece is arranged on the upper main rod; the measuring piece is detachably connected with the upper main rod; a pedal disc is mounted on the lower main rod; the outer diameter of the pedal disc is matched with the outer diameter of a pipe pile; the pedal disc sleeves the lower main rod; an elastic supporting piece is mounted below the pedal disc; the elastic supporting piece is suitable for supporting the pedal disc to be positioned on the lower main rod and move up and down along the lower main rod; a side plate is mounted below the pedal disc; the side plate is detachably connected with the pedal disc; and during working, the bottom end of the side plate is suitable for being inserted into the ground. The positioning and paying-off device solves the technical problems that the pipe pile is accurately positioned at a relatively low cost, deviation caused by inclination of the pipe pile is reduced, and later remediation cost is affected.

Owner:CHINA MCC17 GRP

Pay-off rack capable of automatically regulating speed

The invention discloses a pay-off rack capable of automatically regulating a speed. The pay-off rack comprises a support, a pay-off shaft, a motor, an elastic diaphragm and a sensor, wherein the pay-off shaft is fixed on the support through a bearing, and one end of the pay-off shaft is connected with an output shaft of the motor; a cross beam is arranged on the support and at one side of the pay-off direction of the pay-off shaft; a wiring groove for penetration of a wire body is pre-formed in the elastic diaphragm, the two sides of the elastic diaphragm are fixed on the cross beam respectively, and a gap is reserved between the inner circumferential surface of the elastic diaphragm and the cross beam to form a buffer cavity; and the sensor is arranged in the buffer cavity, located below the wiring groove, and connected with the motor. According to the pay-off rack disclosed by the invention, the problem of wire breakage or sliding-off of the wire body due to a too high or too low tensioning force is solved through adjustment of the motor for a pay-off speed, thus effectively increasing the processing efficiency of a cable.

Owner:ANHUI HUANENG CABLE GRP

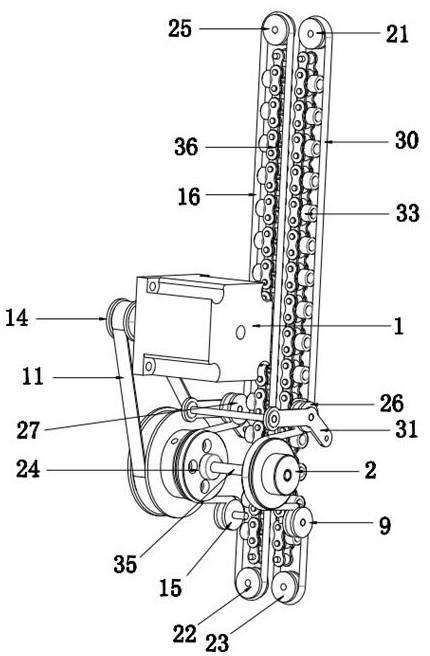

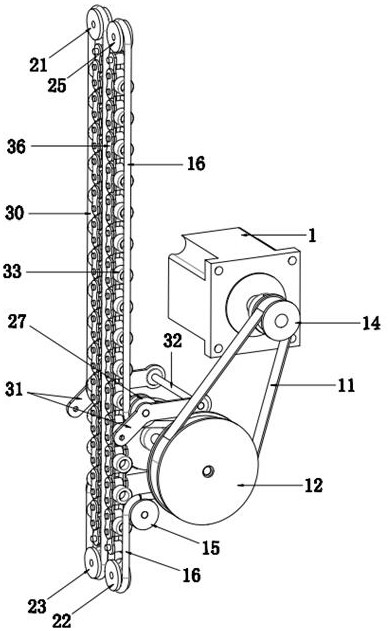

Automatic USB wire harness feeding device

ActiveCN112061863AImprove online efficiencyFast pay-off speedFilament handlingDrive wheelStructural engineering

The invention discloses an automatic USB wire harness feeding device. The device comprises a bottom stainless steel case, wherein plug steel and an upper stainless steel case are sequentially arrangedat the upper end of the bottom stainless steel case from left to right; a transverse moving mechanism used for horizontally moving a USB wire harness is arranged in the bottom stainless steel case; the transverse moving mechanism comprises fixing plates on the left side and the right side of the interior of the bottom stainless steel case, a linear sliding rail between the two fixing plates and amoving base connected to the linear sliding rail in a sliding mode; a discharging mechanism and a driving mechanism used for driving the discharging mechanism are arranged in the upper stainless steel case; the driving mechanism comprises a belt driving wheel and a left driving wheel; the left end of the belt driving wheel is connected to a right driving wheel; and the right driving wheel is connected to the left driving wheel through a connecting shaft. The automatic USB wire harness feeding device is high in wire setting-out speed, about 30 USB wire harnesses can be stacked, a single personcan operate 2-3 automatic USB wire harness feeding devices, and the USB wire harness feeding efficiency is greatly improved.

Owner:东莞市钢成自动化设备科技有限公司

Pay-off device for power construction

The invention belongs to the field of power construction, and particularly relates to a pay-off device for power construction. The pay-off device comprises a vehicle body, the left side of the vehicle body is rotatably connected with a winding coil through a connecting plate, the lower part of the winding coil is fixedly connected with a push handle, the upper surface of the vehicle body is rotatably connected with the winding coil through an electric wire, the lower surface of the vehicle body is fixedly connected with a vehicle frame, and the bottom end of the vehicle frame is rotationally connected with wheels. In the process, mechanical paying-off is adopted, compared with traditional manual paying-off, the device is high in paying-off speed and higher in efficiency, the rolling coil can fasten the cable through friction force to prevent the cable from loosening during paying-off, the problem that the taken-up coil is not tight is effectively solved, and the machine paying-off precision is higher than that of manual operation, and when paying-off is stopped, the rolling coil prevents the electric wire from continuous pay-off ; and in the actual use process, the device can solve the problem that due to inertia, paying-off is too long, and the accuracy of data is affected to a certain extent.

Owner:覃刚

A wire drawing and unwinding device for surface treatment of metal products

ActiveCN110370126BPlace stablePrevent disengagementGrinding drivesGrinding machinesIndustrial engineeringMetal

The invention discloses a wire drawing and unwinding device for surface treatment of metal products. In the present invention, the joint use of the first clamping strip, the limiting groove, the spring, the protective block and the telescopic mechanism is used, and the first clamping strip and the second clamping strip in the inner cavity of the limiting groove are clamped and limited, so that the movable rod can be stabilized. Placement, easy to adjust, through the use of the spring, the spring can drive the movable rod to move backward automatically, preventing the movable rod from breaking away from the limit slot, and the line is limited by the protective block, which effectively prevents the line from breaking away from the bottom of the second pulley. The use of the telescopic mechanism achieves the purpose that the spring can move up and down while being limited by the movable block, and solves the problem that the existing wire drawing and unwinding device cannot adjust the tightening degree of the wire during use, which may easily cause the wire to fall off the pulley, and the protection effect is low The problem.

Owner:ANHUI QIMING SURFACE TECH

Control line pay-off machine

The invention discloses a control line pay-off machine, and relates to a pay-off machine capable of paying off a plurality of control lines at one step. The control line pay-off machine mainly solves problems that an internal combustion locomotive is provided with more than 600 control lines, the control lines are mainly paid off manually traditionally, only one control line can be paid off by one person at a time, the speed and the efficiency are low, the labor intensity is high, and the pay-off lengths are inaccurate. The control line pay-off machine comprises at least six pay-off racks and control lines arranged on turntables of the pay-off racks, and is characterized in that the pay-off racks are arranged on a workbench, line tensioners are arranged on a side surface of the workbench, the quantity of the line tensioners corresponds to that of the pay-off racks, line clippers are arranged on the outer side surface of the workbench, and line clamps are arranged on a trolley which is arranged on tracks. The control line pay-off machine has the advantages that the lines are pulled and paid off by the electric trolley, accordingly, the control line pay-off machine is high in speed and efficiency and low in labor intensity and is controlled by a computer, and the pay-off quantity and the pay-off lengths are quite accurate.

Owner:CRRC LUOYANG CO LTD

Pay-off rack for electric power construction

The invention discloses a pay-off rack for electric power construction. The pay-off rack structurally comprises a supporting frame, a driving disc, an unwinding device and a connecting shaft. The driving disc is arranged on the outer side of the left end of the supporting frame, and the driving disc and the unwinding device rotate synchronously. In the cable pay-off process, the thickness of a cable on a pay-off disc is gradually reduced, at the moment, a sliding block slides on a guide polish rod through the elastic force of a spring, a pushing plate pushes an abutting device in the sliding process, the thickness of the cable on the pay-off disc is gradually reduced, and the abutting device gradually gets close to and abuts against the outer side of the cable on the pay-off disc. It is ensured that the traction force of the whole cable during pay-off is kept consistent, accumulation and winding of later paid-off cables after pay-off are avoided, the cables on the pay-off disc are pushed into buckling strips in order through separation rods, the abutting force with the cables is improved, the cable pay-off speed is prevented from being too high, and the cables can be paid off in order through the buckling strips, so that the orderly laying effect of the cables is improved.

Owner:陈培安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com