Cable or optical cable releasing device

A technology of pay-off device and optical cable, applied in the directions of optical fiber/cable installation, cable laying equipment, etc., can solve the problems of labor-intensive pay-off, affecting the construction progress, etc., and achieve the effect of labor-saving, cost reduction and simple structure of pay-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

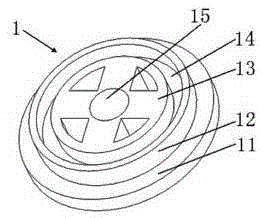

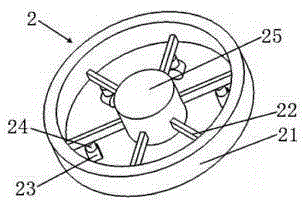

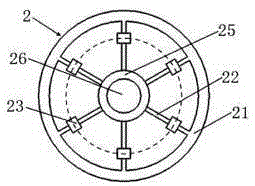

[0028] please see Figure 1 to Figure 5 ; A cable or optical cable pay-off device is characterized in that it includes a fixing device 1, a movable device 2 and a rotating support body 3; Limiting part 12, protruding from the base and fixing seat 13 whose outer diameter is less than the diameter of the inner edge of the limiting part, the limiting part is located outside the fixing seat, a cylindrical annular channel 14 is formed between the limiting part and the fixing seat, and the center of the fixing seat has a The first groove 15 that is sunken in the direction; the movable device has a cylindrical ring bracket 21 located on the outer layer, a shaft hole positioning column 25 located in the center, six bearing rods 22 connecting the cylindrical ring bracket and the shaft hole positioning column, and each bearing rod is below Connecting rods 24 are installed, and a sliding device 23 is installed below each connecting rod. The center of the bottom of the shaft hole position...

Embodiment 2

[0037] please see Figure 6 , and refer to Figure 1 to Figure 5 , a cable or optical cable pay-off device, basically the same as the implementation example 1, the difference is that: the base 11 of the fixing device also has a plurality of fixing holes 16.

[0038] Further, the above-mentioned fixing holes are symmetrically distributed on the fixing device.

[0039] The existence of the fixing hole can make the fixing device be fixed on a horizontal surface, such as a mud floor, etc., so that the wiring and the cable are more stable.

Embodiment 3

[0041] please see Figure 7 , and refer to Figure 1 to Figure 5, a cable or optical cable pay-off device, basically the same as the implementation example 1, the difference is that: the inner side of the sliding device is equipped with an inner limiting device 27, the outer side of the sliding device is equipped with an outer limiting device 28, and the inner and outer limiting The device is not in contact with the sliding device, but it limits the direction of the sliding device. It does not make the sliding device rotate 360 degrees around the connecting rod, but the direction is relatively stable. In this way, when the movable device starts, it is more labor-saving to put the cable , since all sliders move in one direction.

[0042] Implementation example 3

[0043] please see Figure 7 , and refer to Figure 1 to Figure 5 , a cable or optical cable pay-off device, basically the same as the implementation example 1, the difference is that: the inner side of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com