Patents

Literature

106results about How to "Increase weaving speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

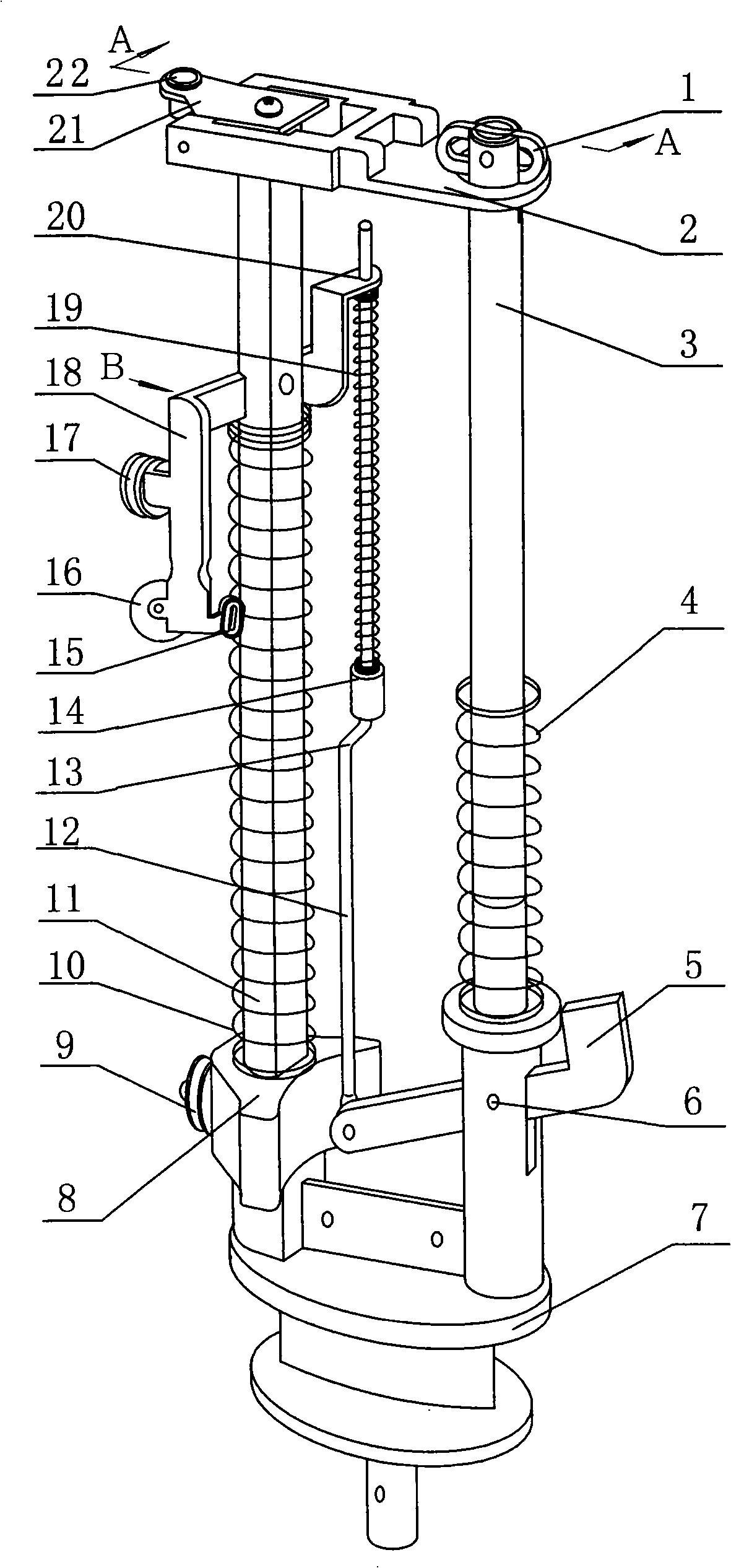

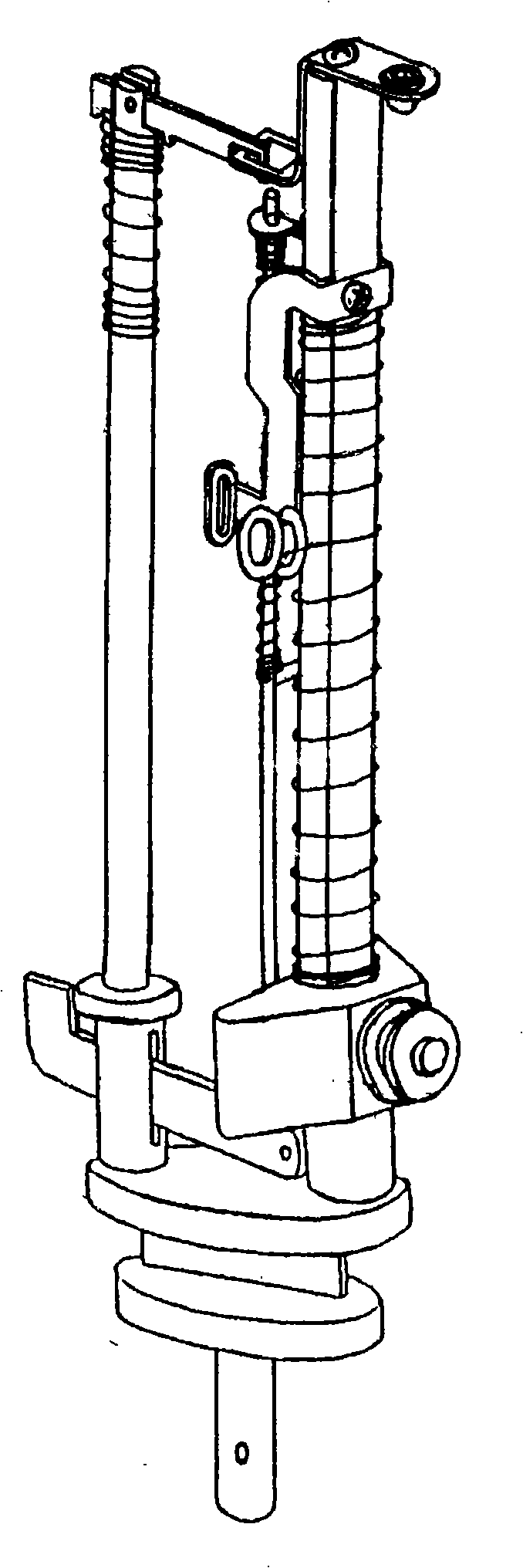

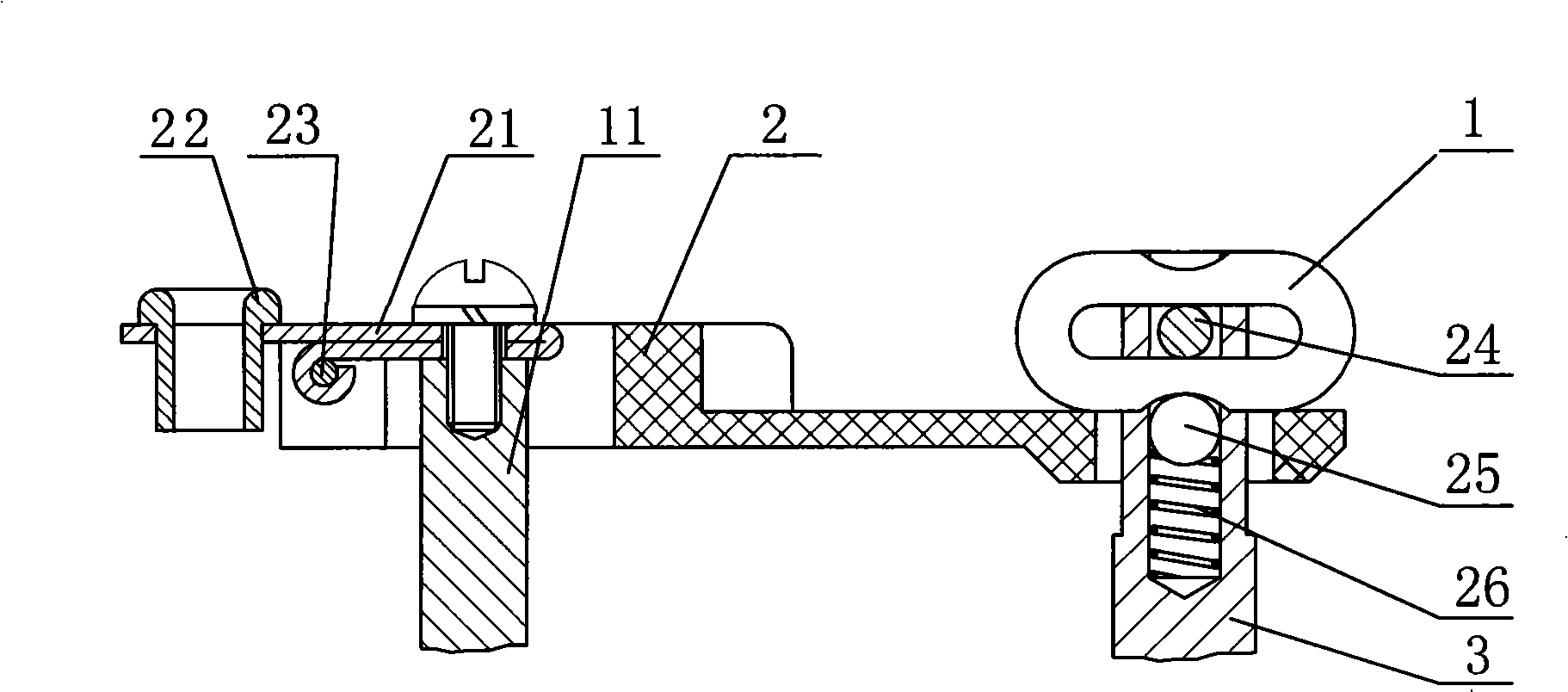

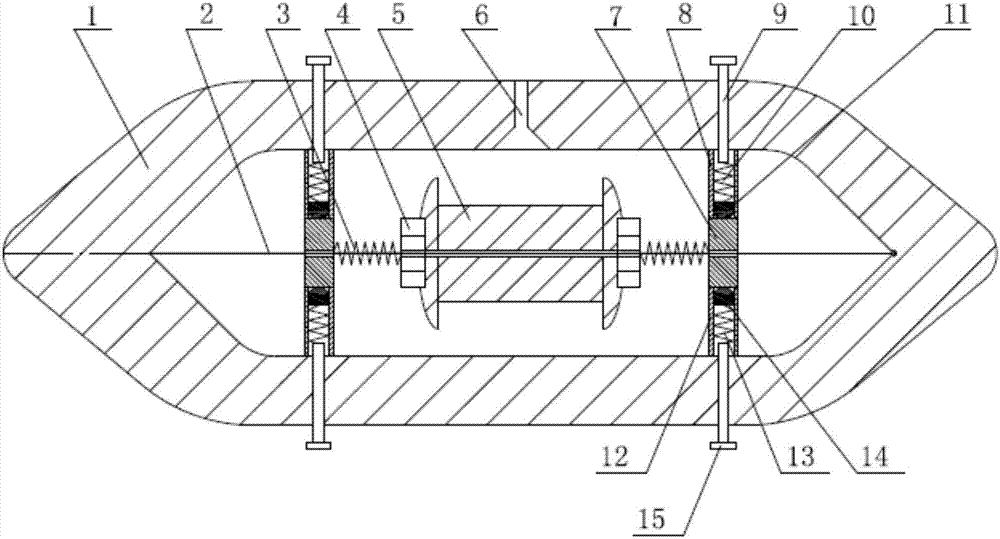

Spring spindle

The invention relates to a spring spindle, wherein, a fixed piece is formed by fixing a right upright post which is fixed with a support and a connecting rod and a left upright post on a track rod, and the spring spindle is formed by connecting a weaving piece and the fixed piece into a whole through a pressure plate and a switch plate; the support is flanged; a pulley is divided into an upper pulley and an intermediate pulley; the upper pulley and the intermediate pulley which are connected to the support are arranged on the right of the right upright post; mounting axial lines of the upper pulley and the intermediate pulley are crossed and angulated at 57 to 63 DEG; a vertical and bended straight section on the middle of the connecting rod is provided with a limit rod; and the pressure plate is matched with a lock catch which is connected to the left upright post. The support is arranged on the right of the right upright post instead of being arranged on the left of the right upright post, thereby the angle between a leading-in porcelain eye and a thread-passing point is reduced to between 27 and 33 DEG; the angle is smaller, the pay-out resistance on bobbin is smaller, and then the pay-out speed is quick and the thread breakage time is greatly reduced; the connecting rod and the support are arranged on both sides of the right upright post so as to maintain routing balance, thereby the speed can be improved by 10 percent and the weaving quality and the production efficiency are greatly improved; and simultaneously the pressure plate has good strength and long service life, is convenient, quick and easy to operate, and is an updated product of the third generation.

Owner:张宝香

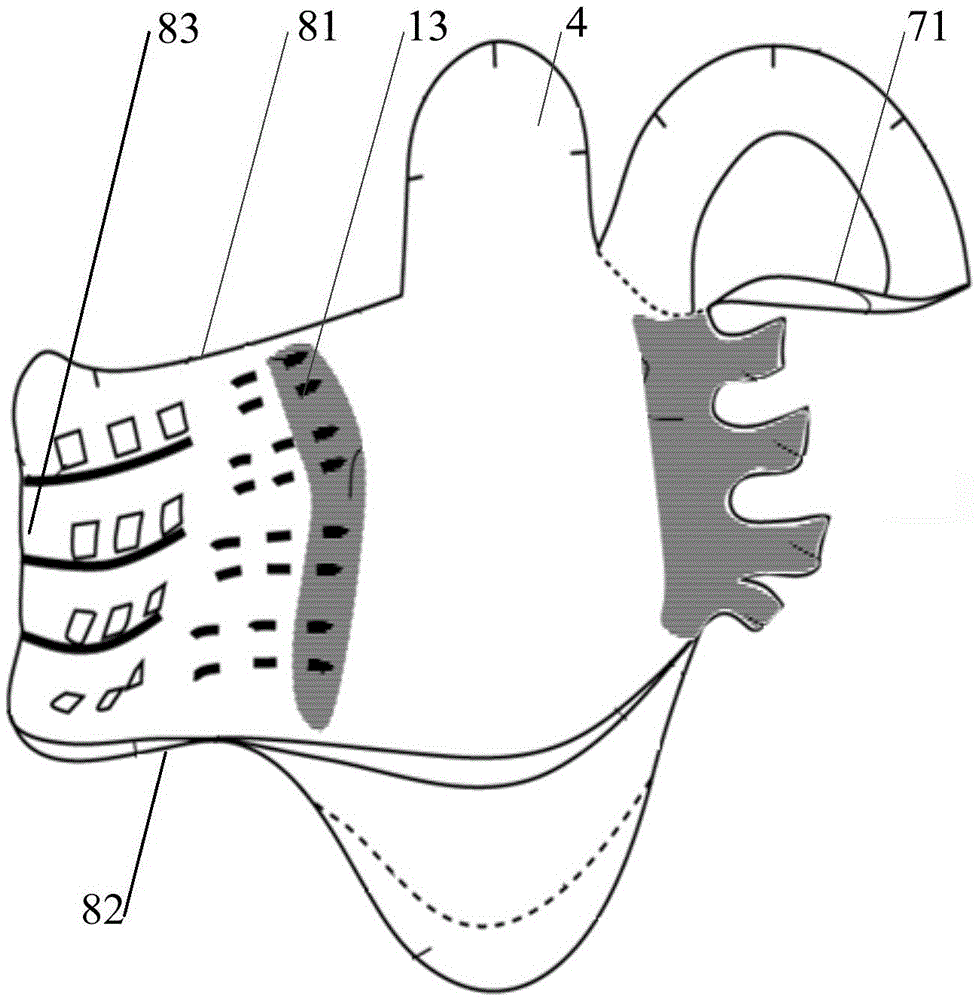

Formed knitted shoe cover, weaving method of formed knitted shoe cover and shoe body adopting formed knitted shoe cover

The invention discloses a formed knitted shoe cover, a weaving method of the formed knitted shoe cover and a shoe body adopting the formed knitted shoe cover. The weaving method comprises: by local weaving, obtaining a shoe rear waist and a shoe midsole, and extending to weave a shoe midsole middle part and a shoe midsole front part so as to form a heelpiece and the shoe midsole which are stereoscopically formed at a time; extending towards both sides of the shoe midsole middle part from the position of the shoe midsole middle part to form a shoe inner waist and a shoe outer waist; at one side of the shoe midsole front part and towards the direction far away from the shoe rear waist, forming a shoe endshield by local weaving; finally, carrying out point alignment and sewing on the edge of the shoe cover so as to obtain the knitted shoe cover stereoscopically formed at a time. In the weaving process, the shoe rear waist, a shoe midsole rear part, the shoe midsole middle part and the shoe midsole front part are formed and woven at a time, both the left and right sides of the shoe midsole middle part extend to be woven to obtain the shoe inner waist and the shoe outer waist, the shoe endshield is woven at the position of the shoe midsole front part, and finally, an alignment point at each position on the shoe cover is aligned and sewn so as to obtain the shoe cover stereoscopically formed at a time. The process of splicing each position of the shoe cover is simplified, so that the weaving process is optimized, and weaving efficiency is improved.

Owner:NEW TECH KNITTING CO LTD

Aging method of cattail

InactiveCN105965646AImprove smoothnessGood flexibilityRadiation/waves wood treatmentWood treatment detailsAge methodMicrowave

The invention discloses an aging method of cattail. The aging method particularly comprises the steps of arrangement, fermentation, aging and drying. The aging method of cattail is simple, and is low in cost; the cost is saved by 13.4%; cattail is subjected to yeast fermentation treatment, so that a fiber structure is softened, a smoothness sense of cattail is improved, the soaking of an aging treatment agent is accelerated, and the weaving speed is increased; the aging treatment agent is extracted from all natural raw material, two times of extraction are conducted after lactobacillus fermentation, and the aging treatment agent is safe and nontoxic, so that the mildewproof and mothproof effects are improved significantly, the color and luster of the aged cattail are pure and natural, and an extraction yield is increased by 8.4%; the aging treatment is conducted through microwave ultrasound, so that the painting is quick and uniform, the flexibility of cattail is improved, the grade of a woven product is raised, the drying is facilitated, and the working efficiency is improved.

Owner:阜南县大喜柳编工艺品有限公司

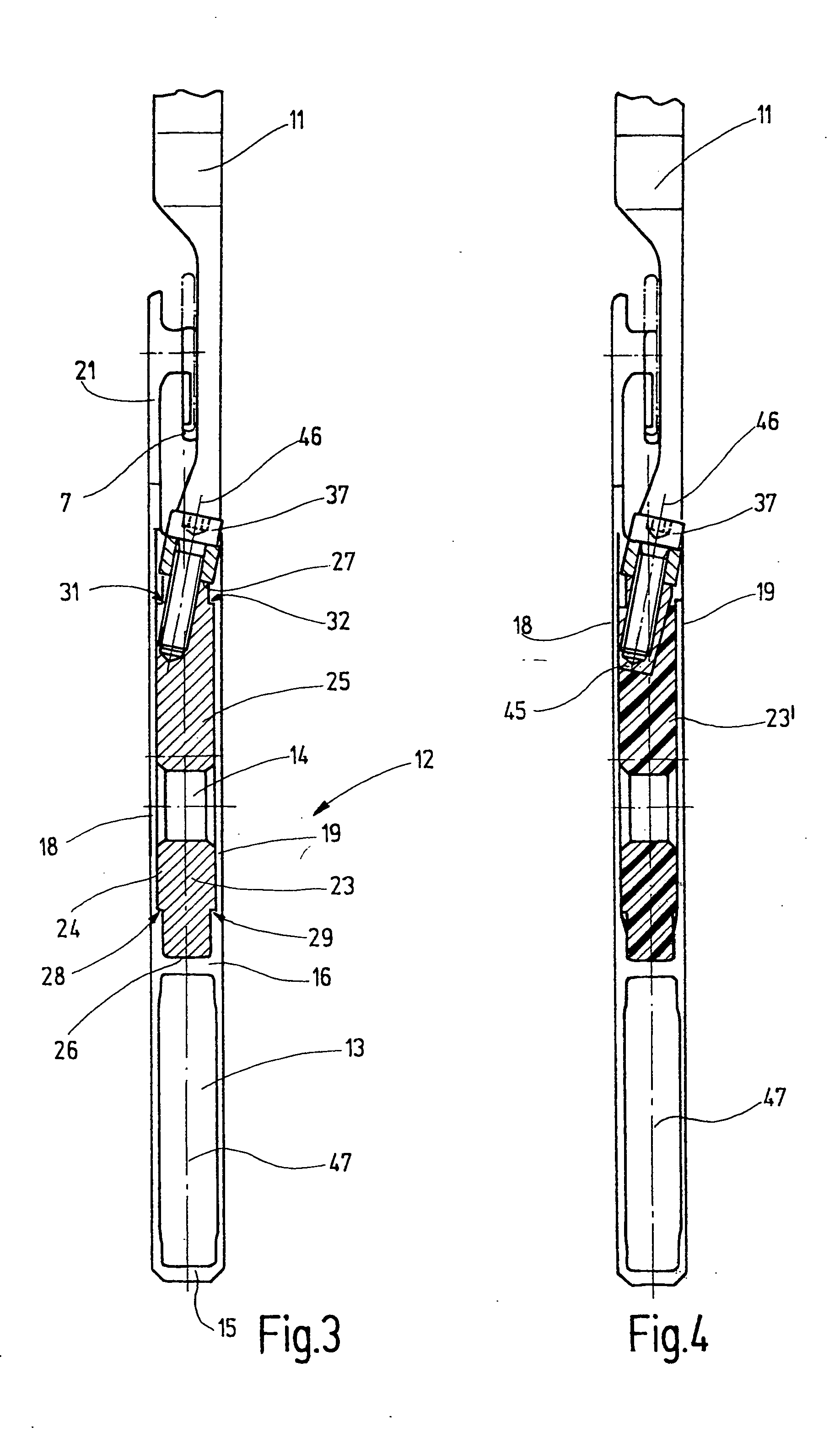

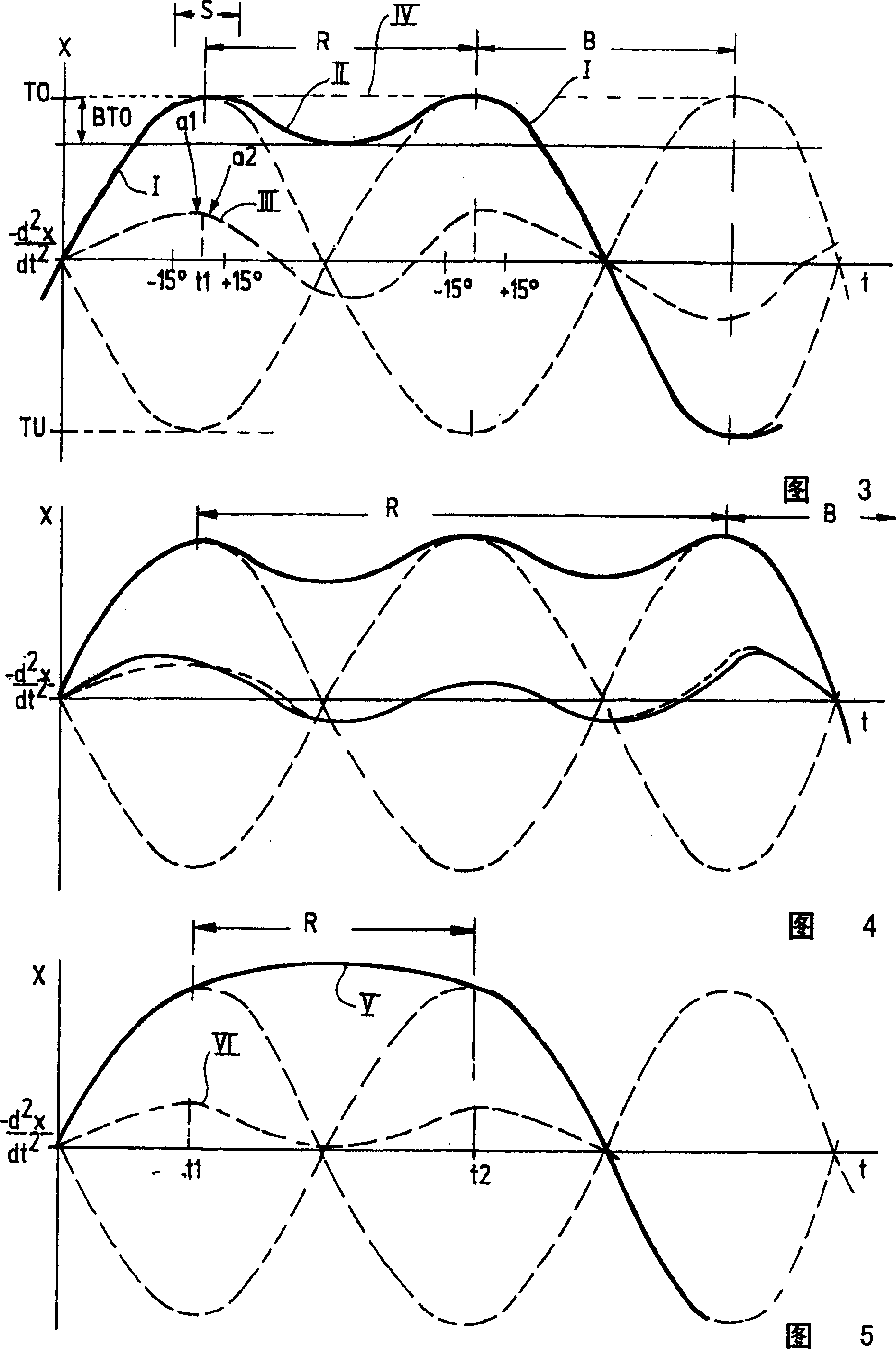

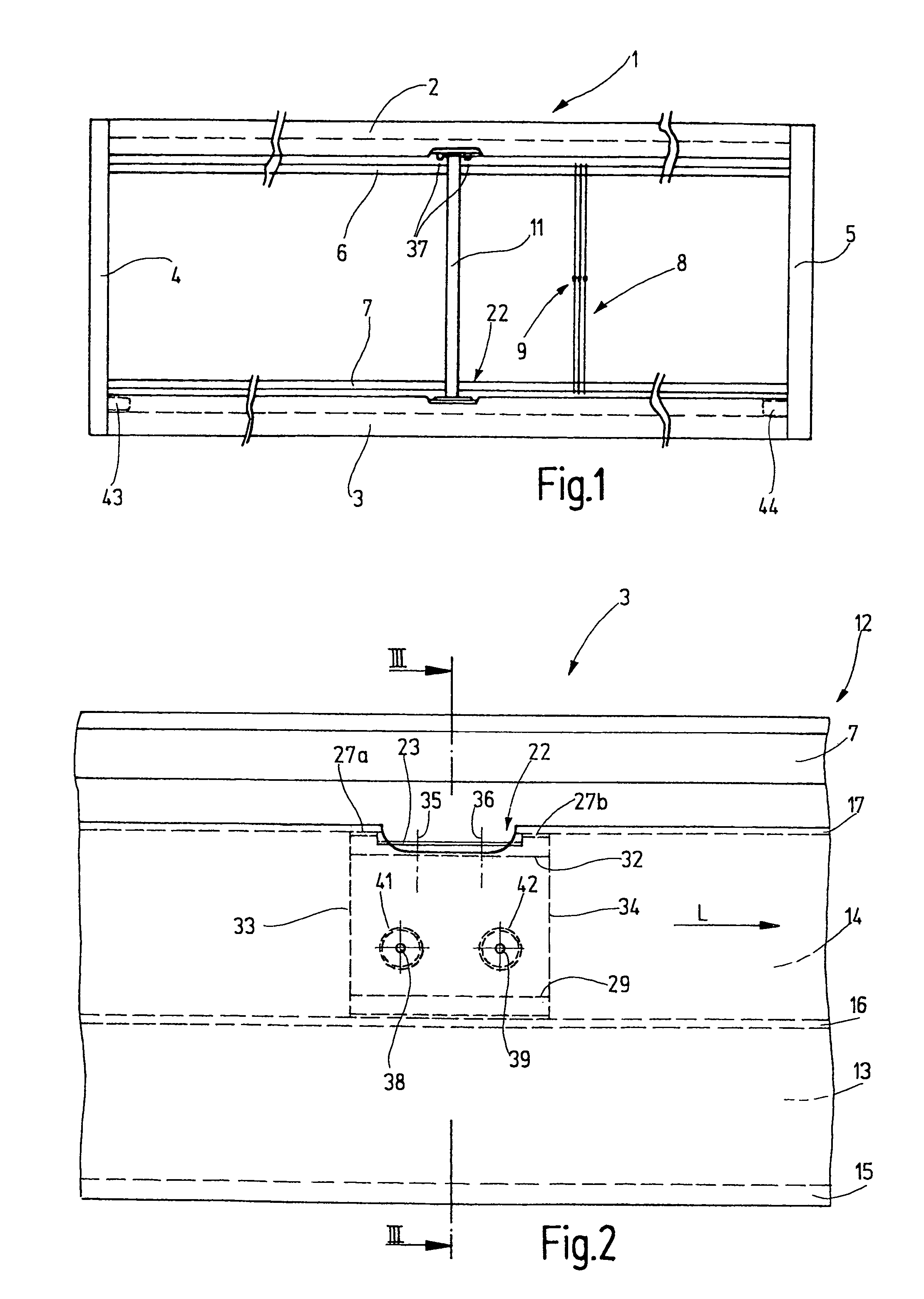

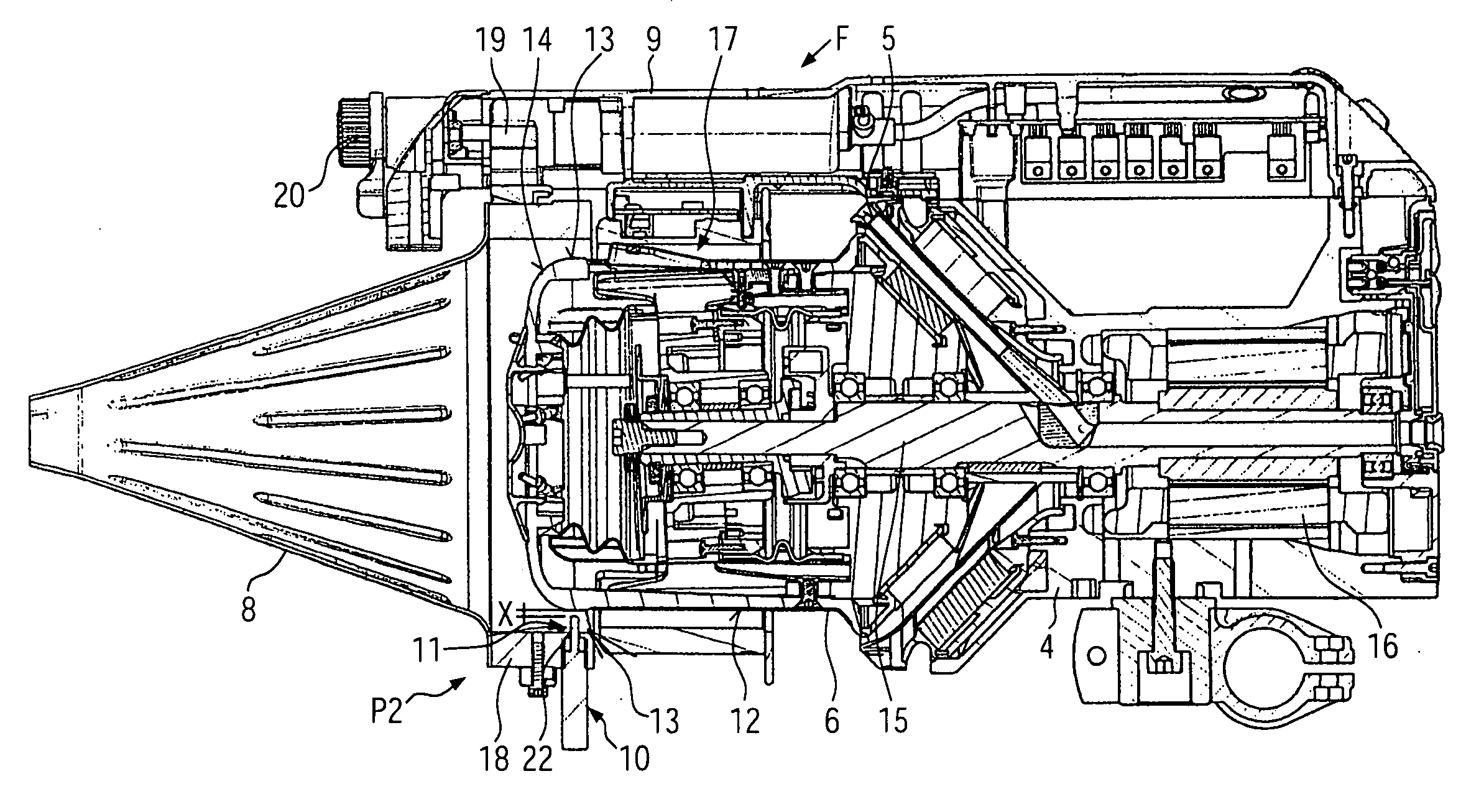

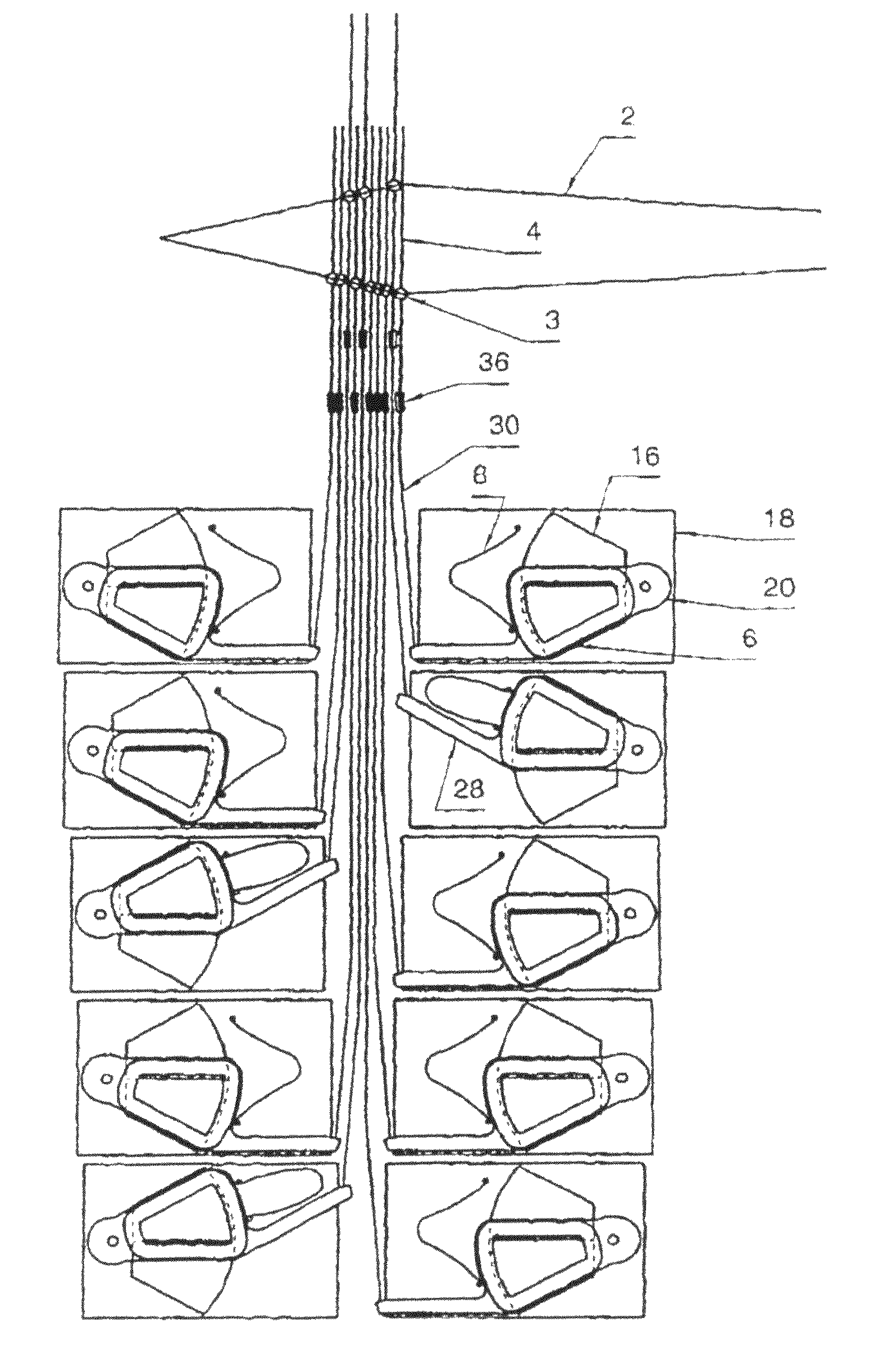

Shaft drive system for power loom shafts

A novel shaft gear for harmonious engagement and disengagement of individual heddle shafts and for deriving their motion from the rotary motion of a single input shaft has a coupling system with two input elements. While one of the input elements serves to drive the output element of the coupling system permanently, the other input element serves solely to synchronize the output element briefly with the first input element. The switchover takes place in the brief synchronous phases, in selected angular regions that correspond to the top or bottom reversal point of the heddle shaft. For the switchover, such novel shaft drive mechanisms do not require any stoppage of motion for the input shaft or the shaft drive mechanism.

Owner:GROZ BECKERT KG

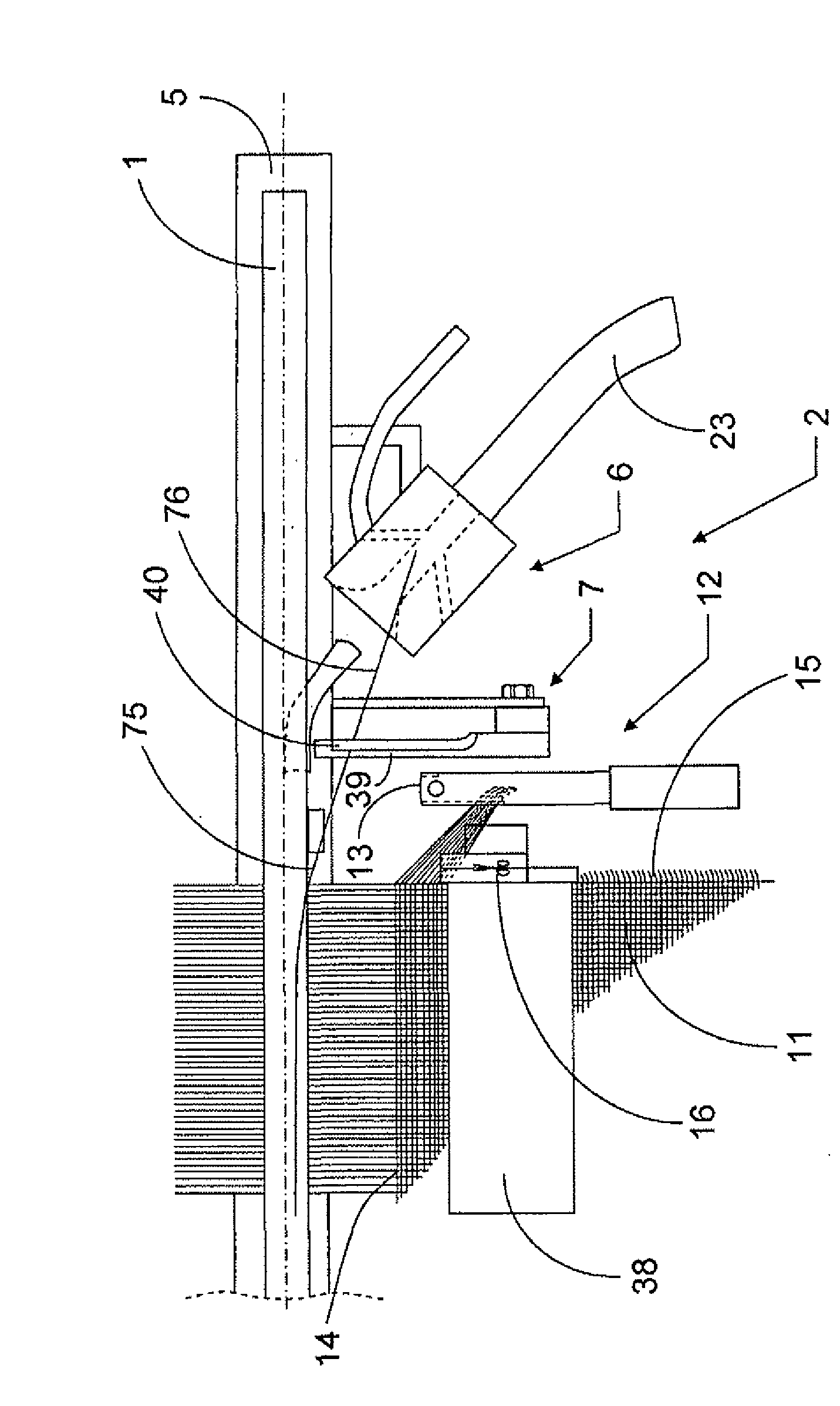

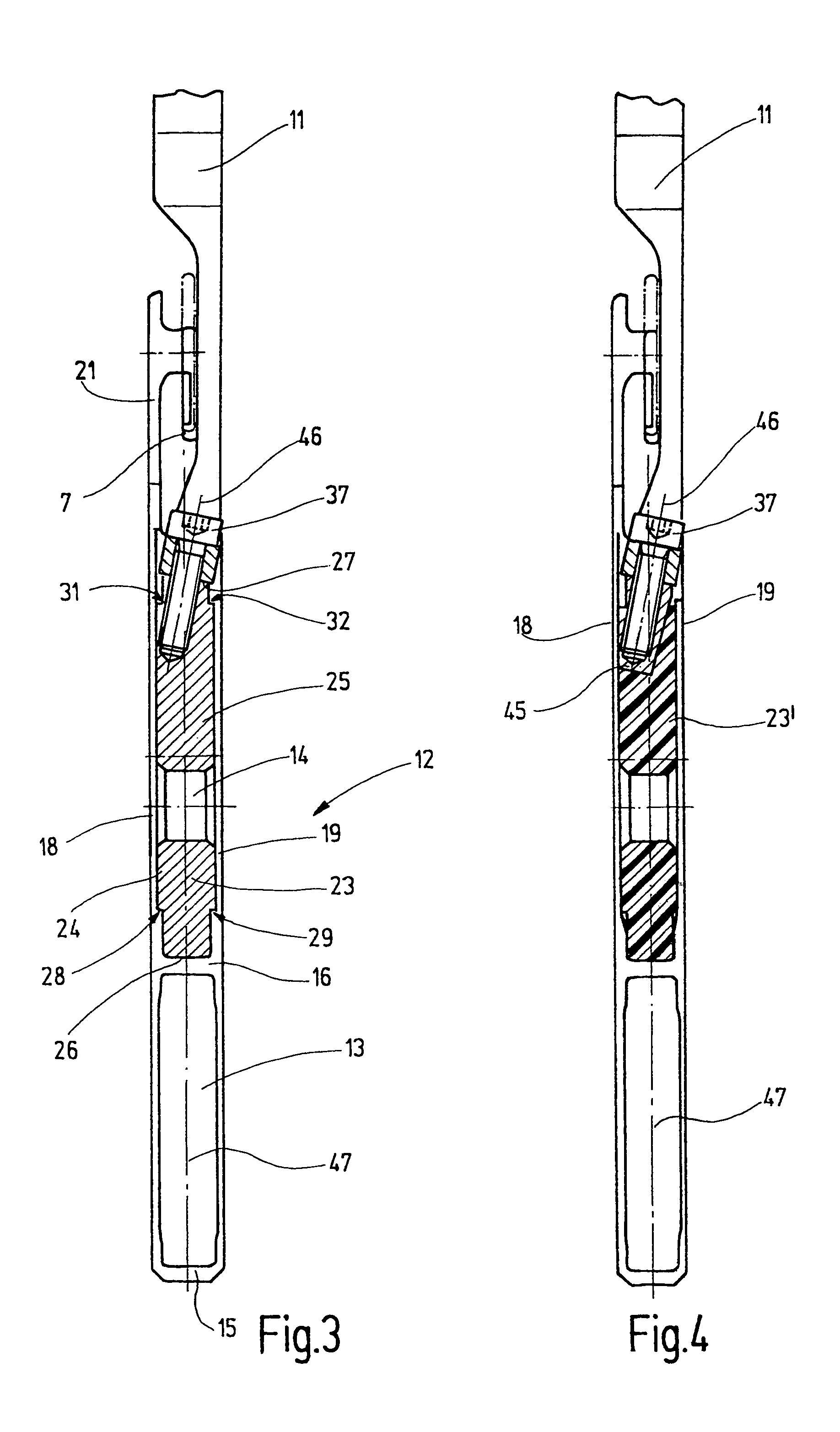

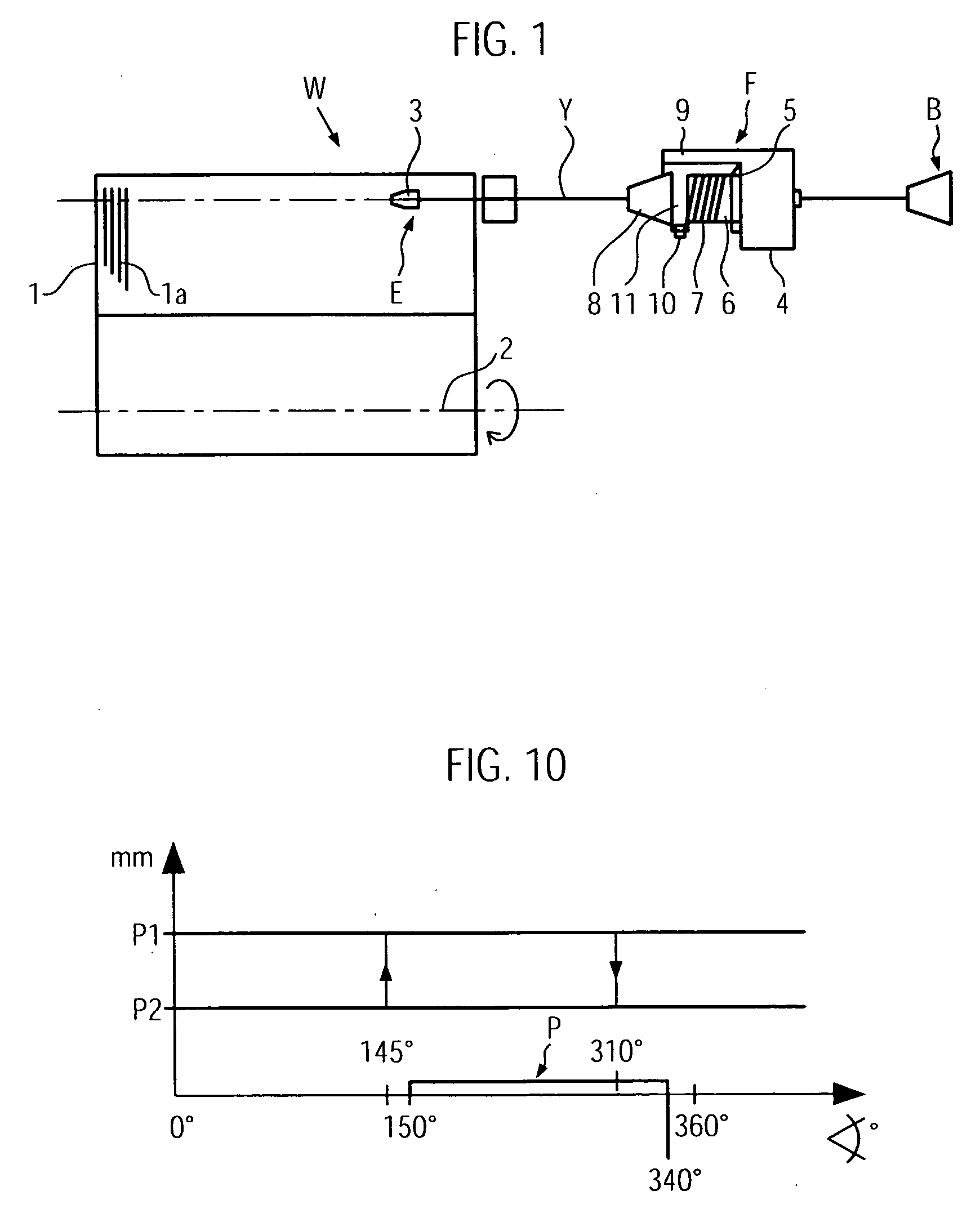

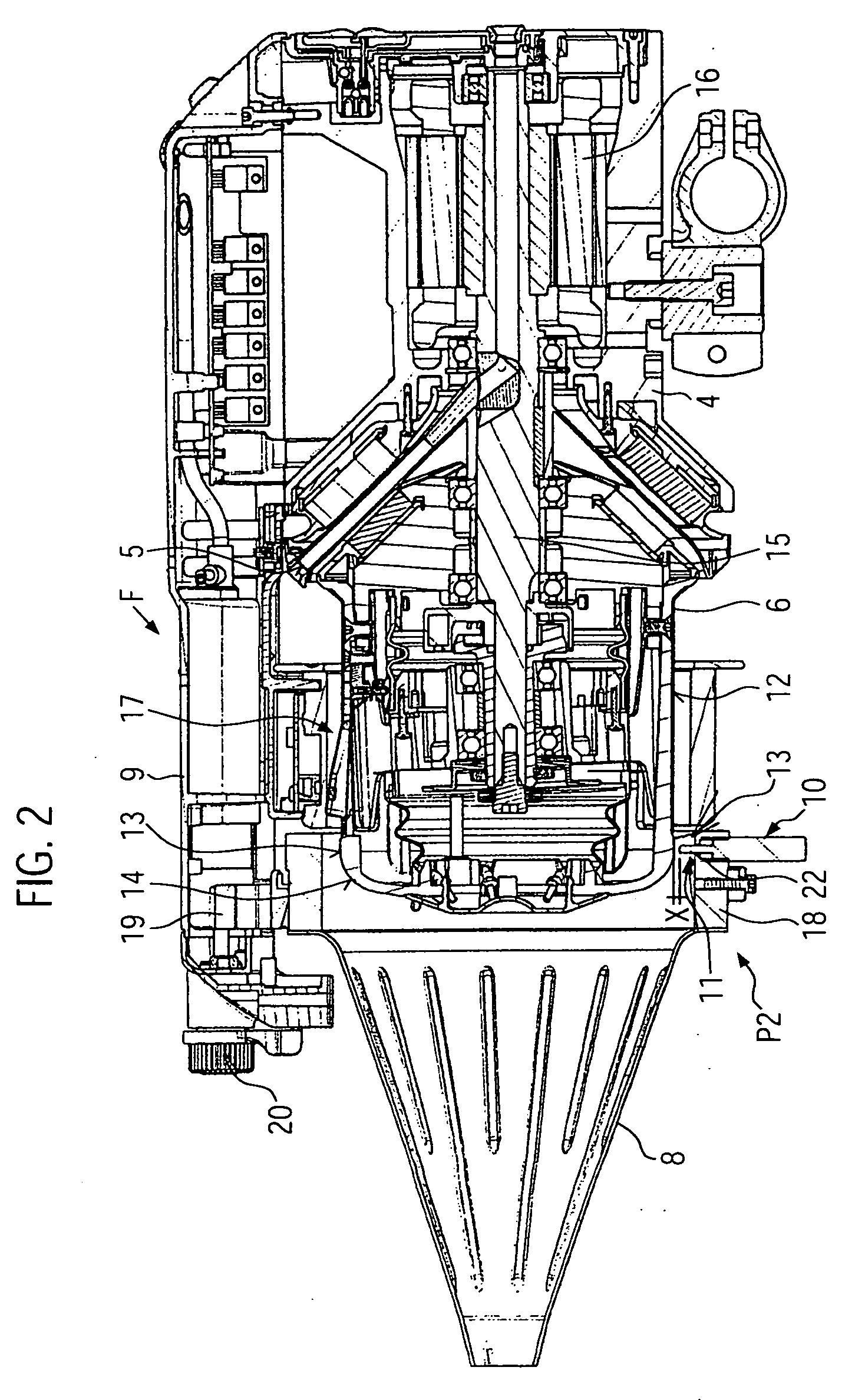

Device and method for catching and stretching weft threads in weaving machine

Device and method for catching and stretching a weft thread (75) inserted through a guide channel (4) into a shed (69) of a weaving machine with a pneumatic suction nozzle (6), a thread clamp (7) and a guide element (8) for guiding the weft thread (75), wherein the guide element (8) is attached in order to deflect the weft thread (75) over a limited angle (A) with respect to the direction of insertion (B) and wherein the suction nozzle (6) is attached in order to catch the weft thread (75) at this angle (A). Weaving machine comprising a device of this type.

Owner:PICANOL SUZHOU IND PARK TEXTILE MACHINERY

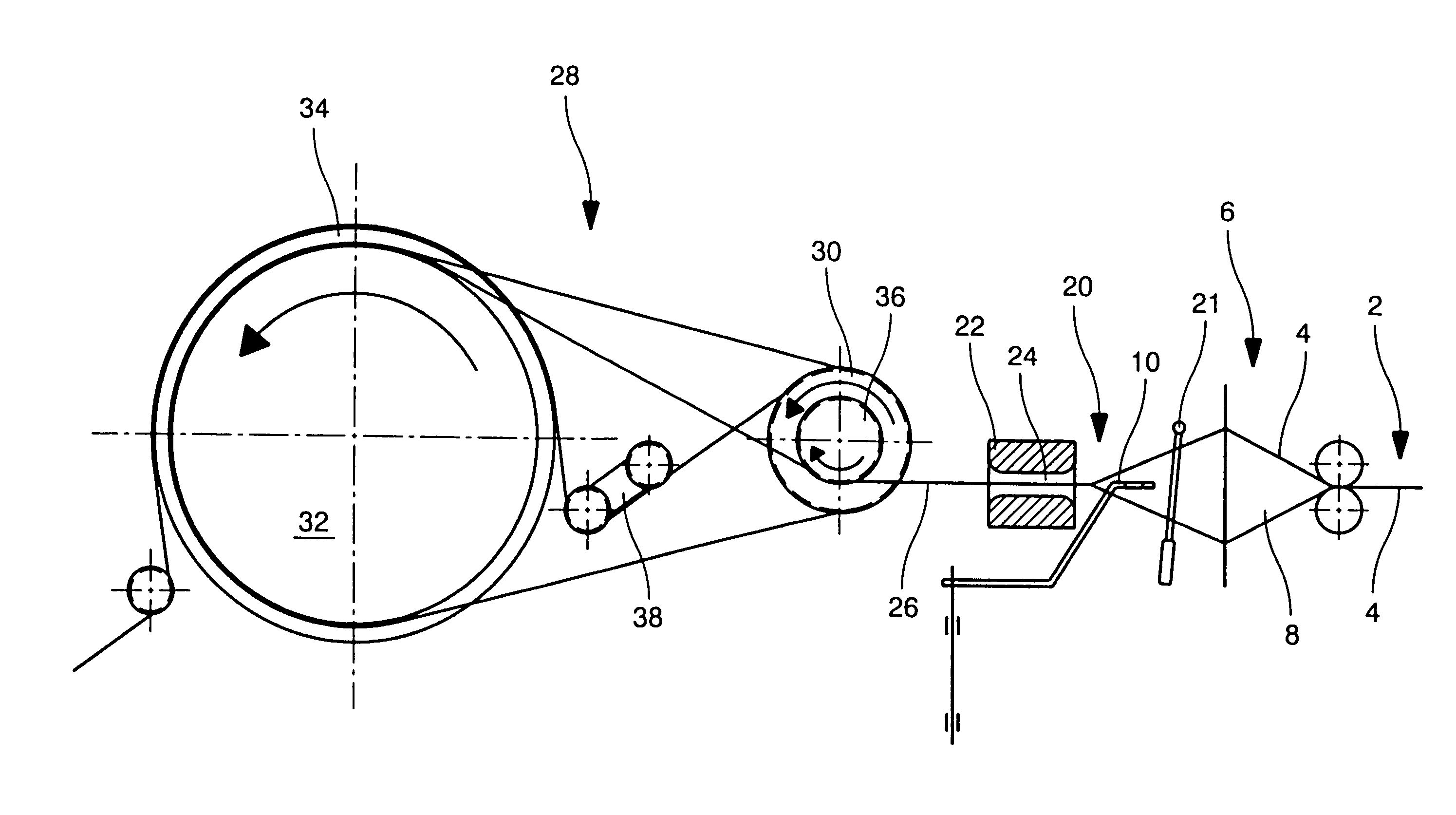

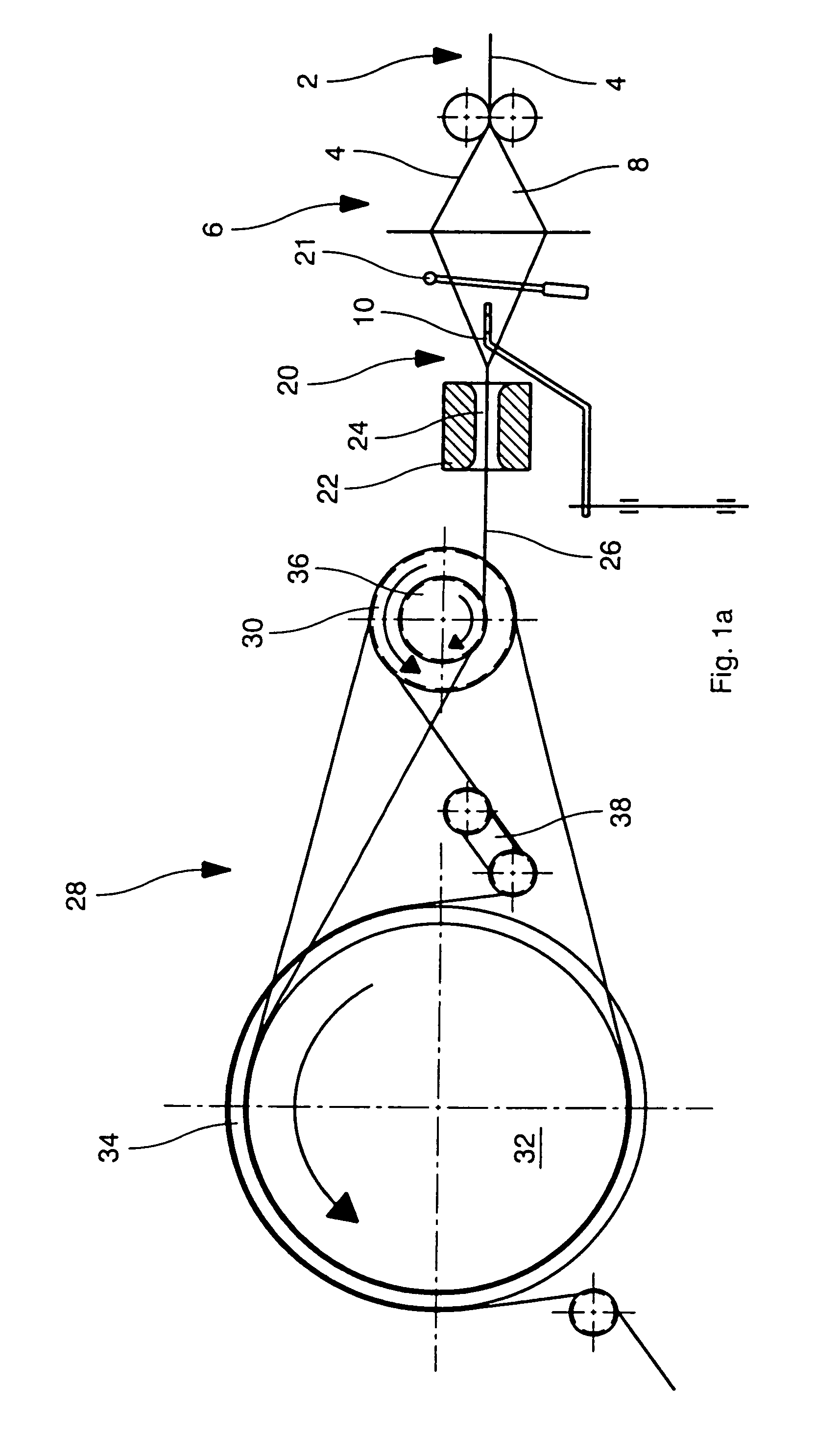

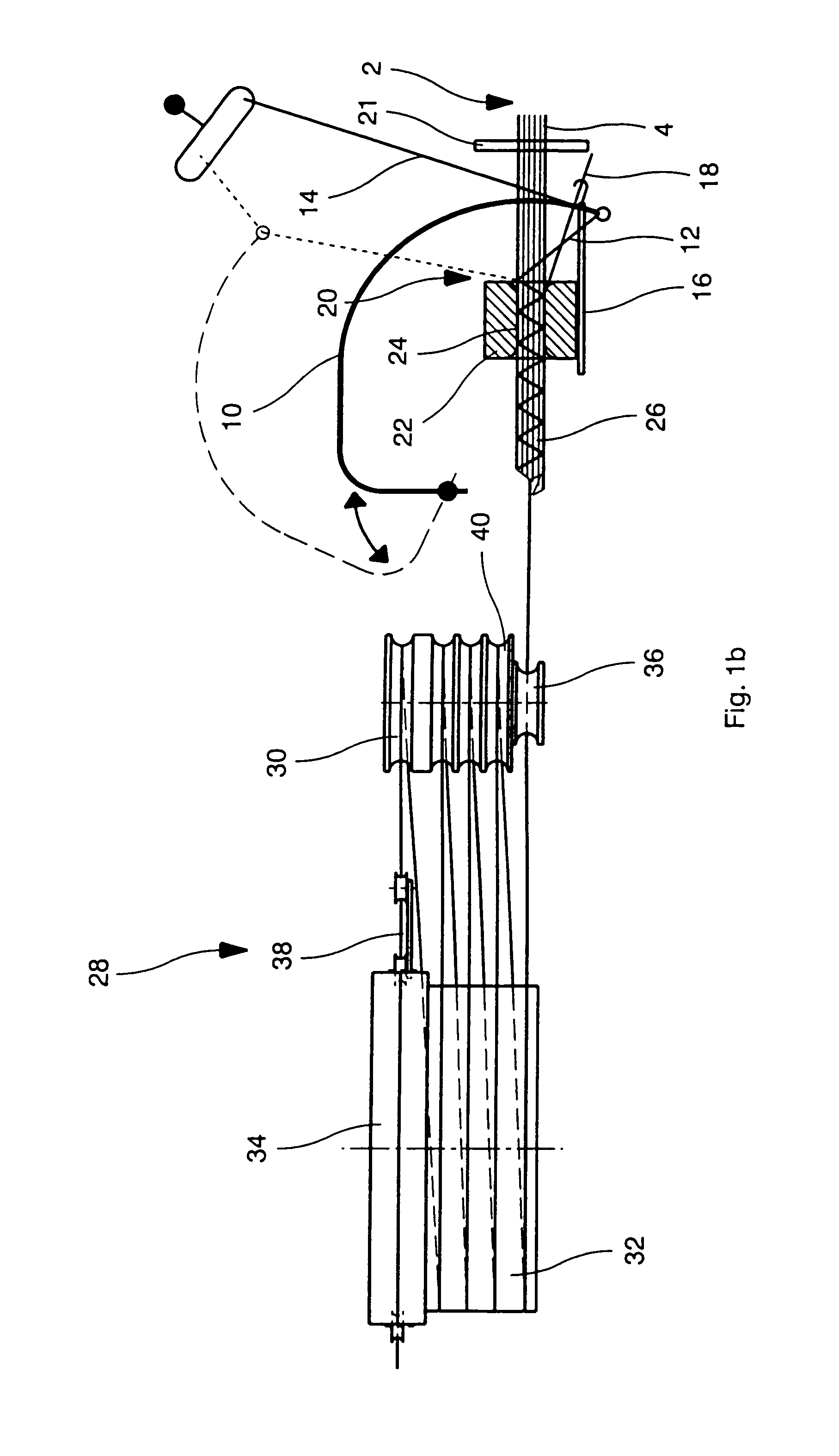

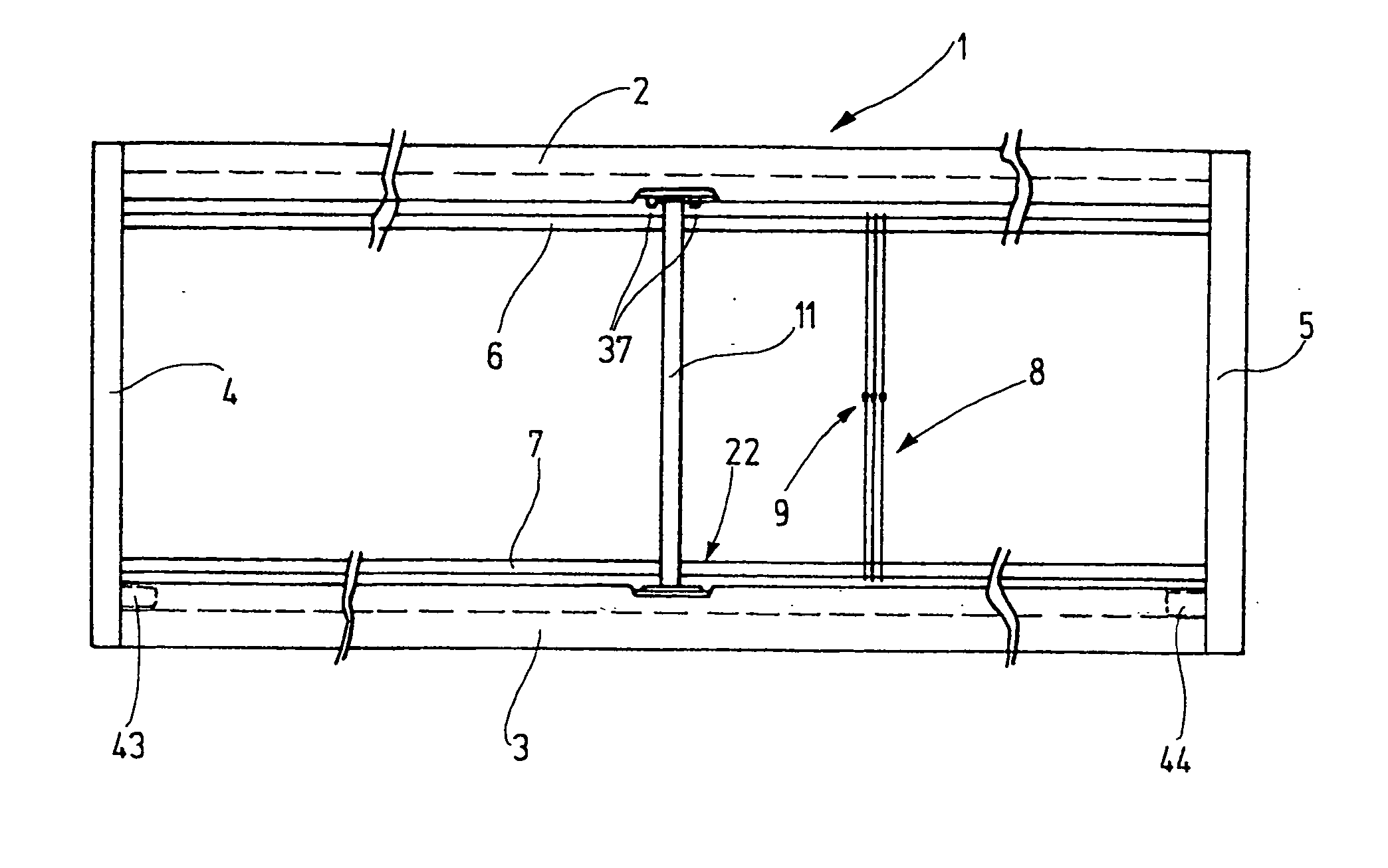

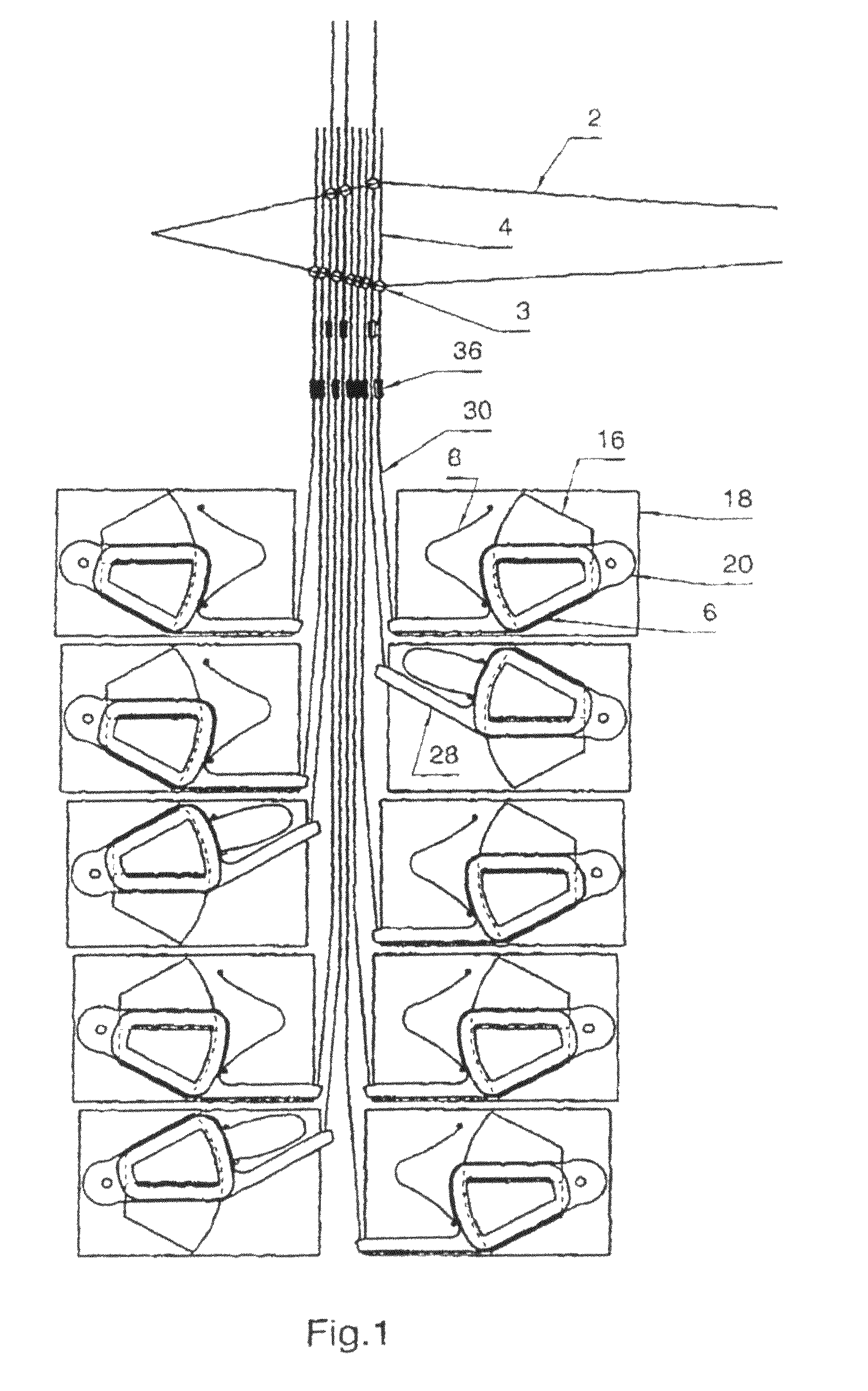

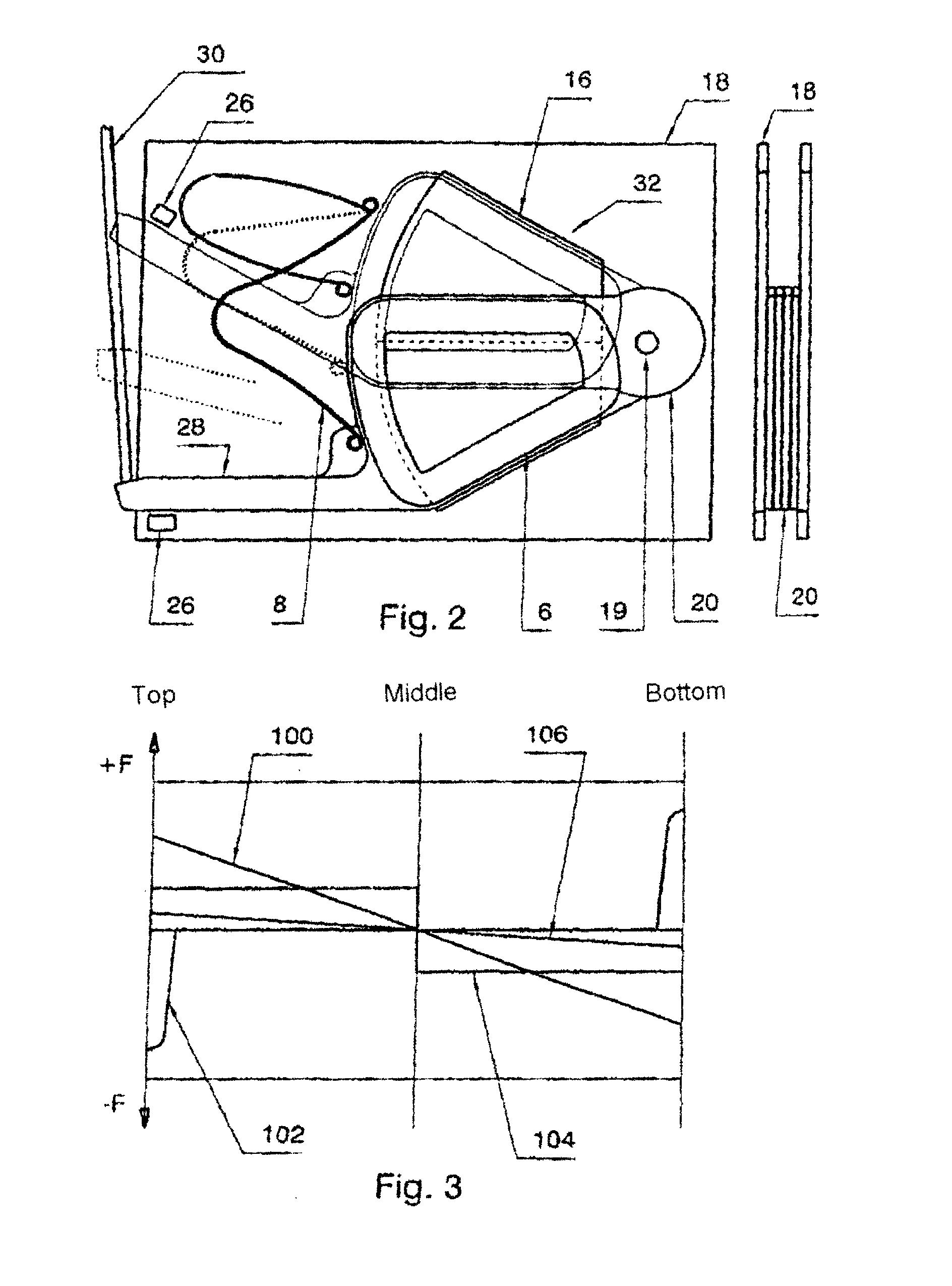

Loom for producing a woven article with a profiled cross section, in particular a rope

InactiveUS20110155276A1Relieve pressureAvoid analysisSmallware loomsAuxillary apparatusYarnWoven fabric

The loom contains a weaving station, at which warp yarns can be interwoven by means of at least one weft yarn, a device for supplying the warp yams, and a device for supplying the at least one weft yam. A shedding device for forming a shed from the warp yarns, and a weft insertion needle for inserting a weft yarn loop into the shed, are also present. The weft yam loop is tied off with a knitting needle and beaten with a reed. A take-down device serves to draw off the woven fabric that is produced. In order to produce a profiled woven article, the weaving station is assigned a fabric holder with a shaping aperture whose opening cross section corresponds substantially to the cross section of the profiled woven article that is to be produced with a round or polygonal cross section.

Owner:TEXTILMA AG

Loop-pile cutting circular machine

ActiveCN103938357ASolve the problem of uneven hair surface and hair end hookIncrease weaving speedCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

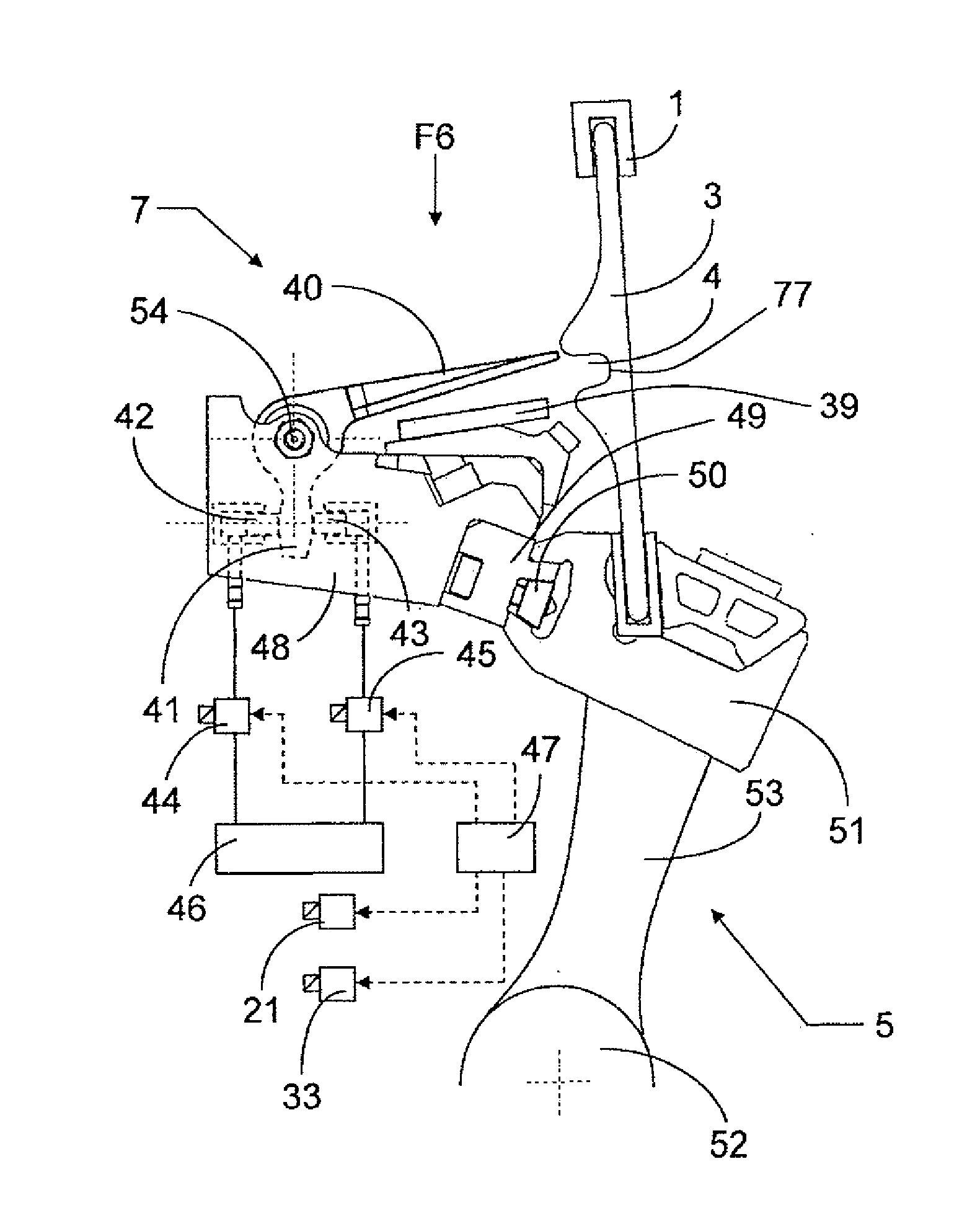

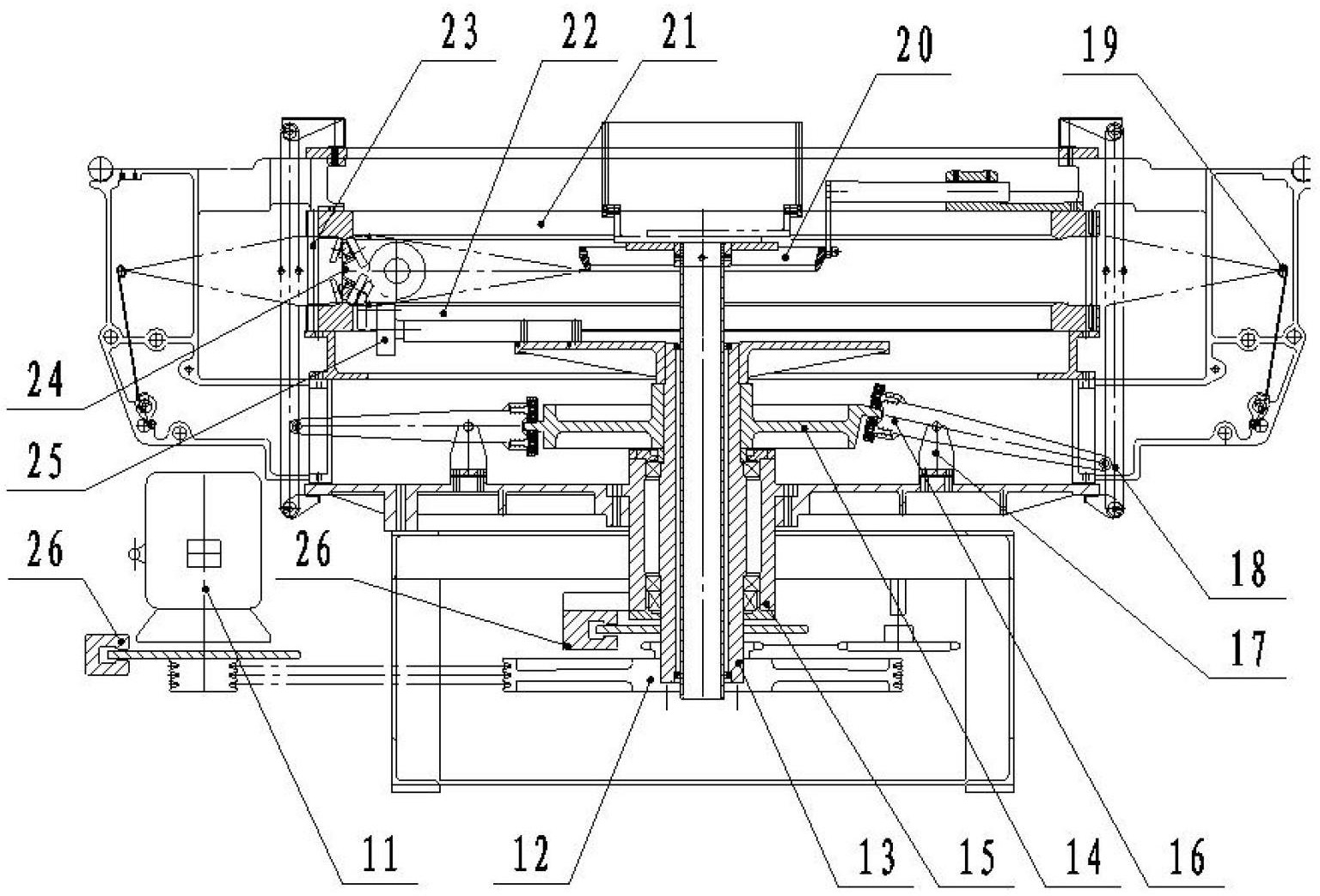

Glove weaving device

ActiveCN107354567AIncrease weaving speedVariety of colorsCircular knitting machinesElectric machineryEngineering

The invention discloses a glove weaving device. The glove weaving device comprises a device frame, an automatic density adjustment mechanism, an ejector rod control mechanism, a glove length detecting mechanism, a scissor driving mechanism, a fork knife driving mechanism, a cam driving mechanism, a device head driving mechanism, a needle selecting mechanism and a control unit, wherein the automatic density adjustment mechanism is installed on a device head, the ejector rod control mechanism, the scissor driving mechanism and the fork knife driving mechanism are installed on sharp corner wall boards of the device frame and used for controlling movement of ejector rods, scissors and a fork knife respectively, the glove length detecting mechanism and the cam driving mechanism are installed on a rear wall board of the device frame, and the needle selecting mechanism is installed below a needle plate and used for selecting needles; the device head driving mechanism is installed on a box of the device frame and used for controlling movement of the device head. With the glove weaving device, gloves can be woven and measured in a full-automatic mode; through a motor, all the mechanisms are driven to act, the structure is concise and reliable, assembling is convenient, operation is stable, and the maintenance rate is low.

Owner:Zhejiang Baixiang Technology Co Ltd

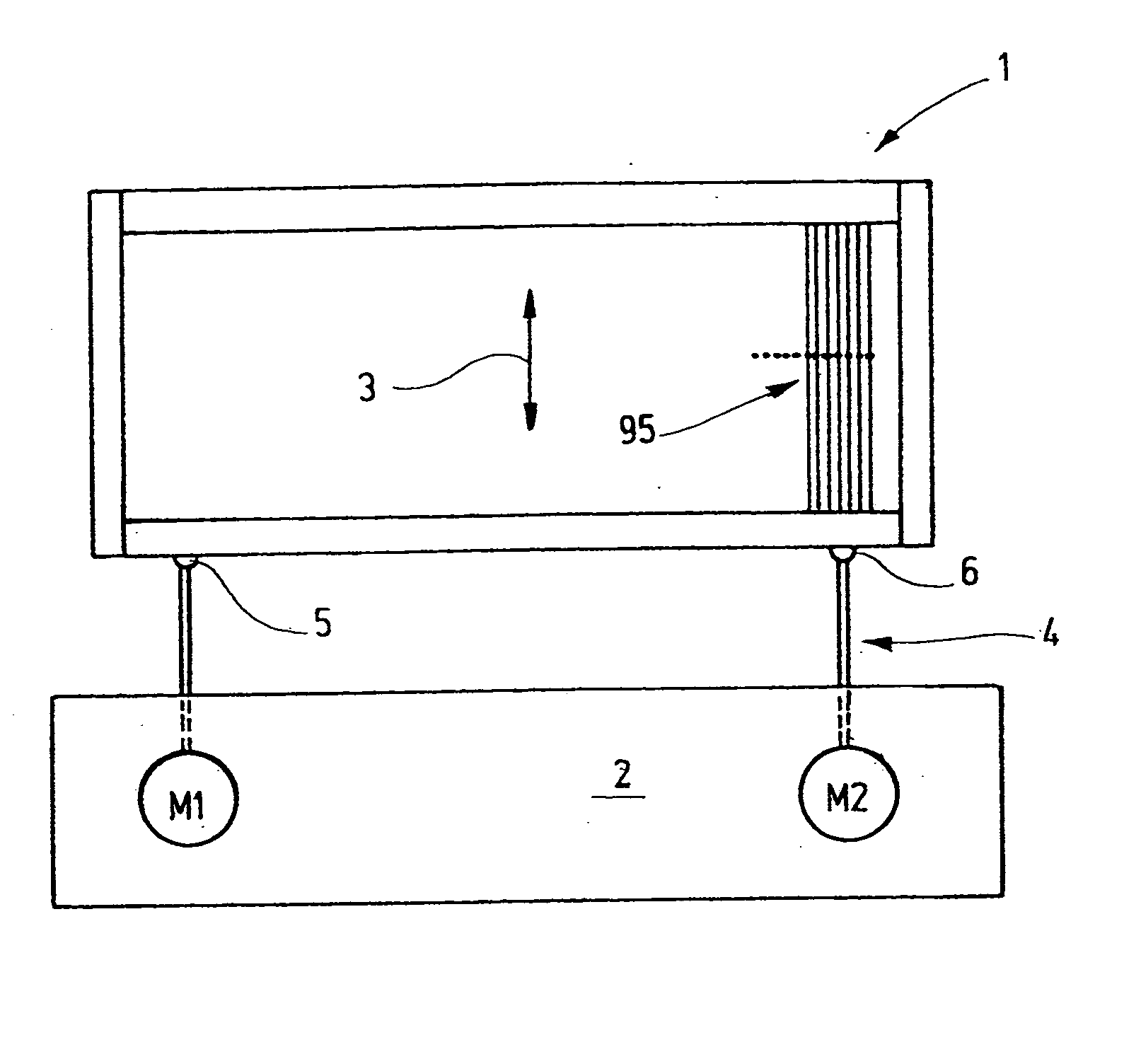

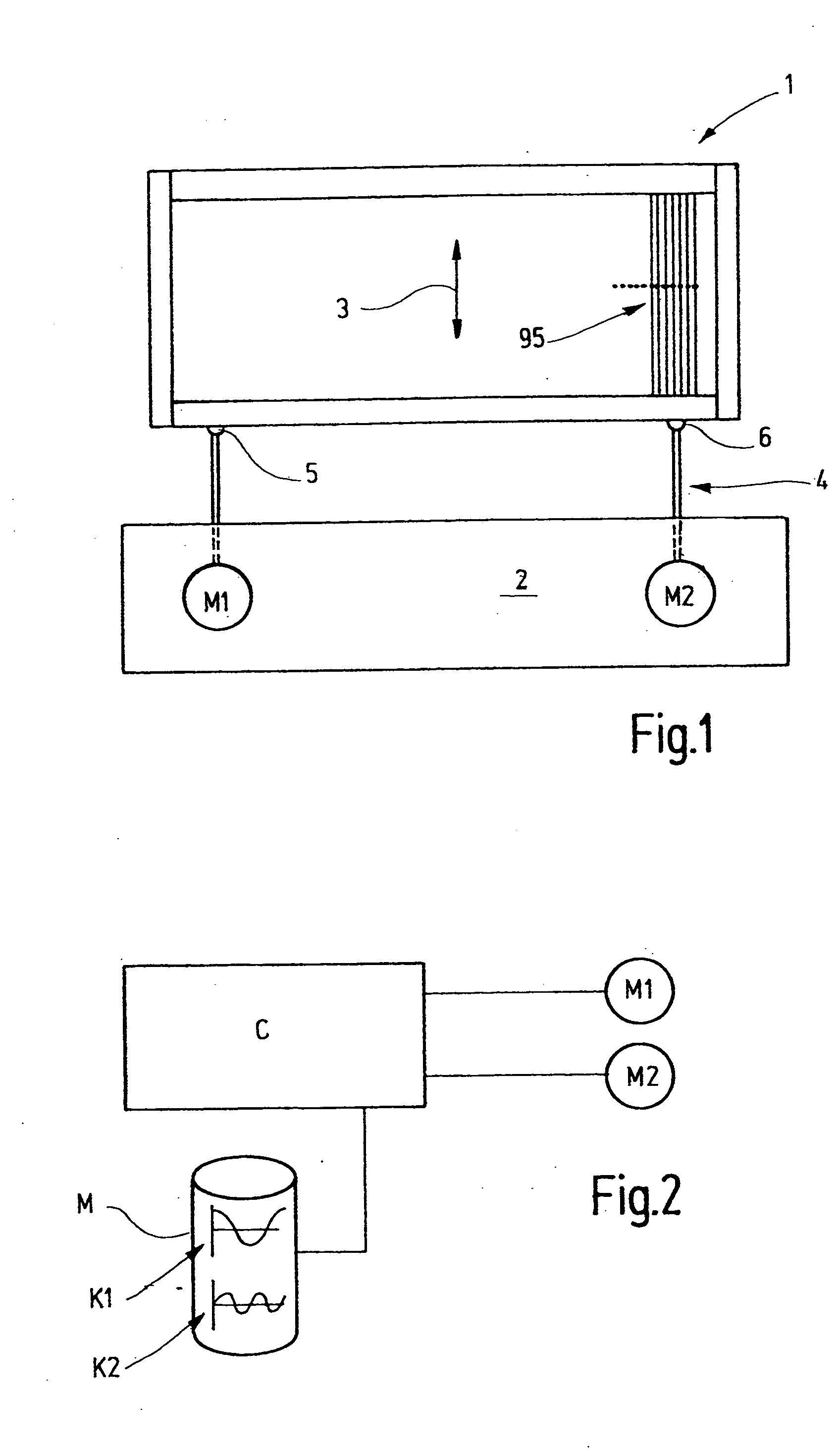

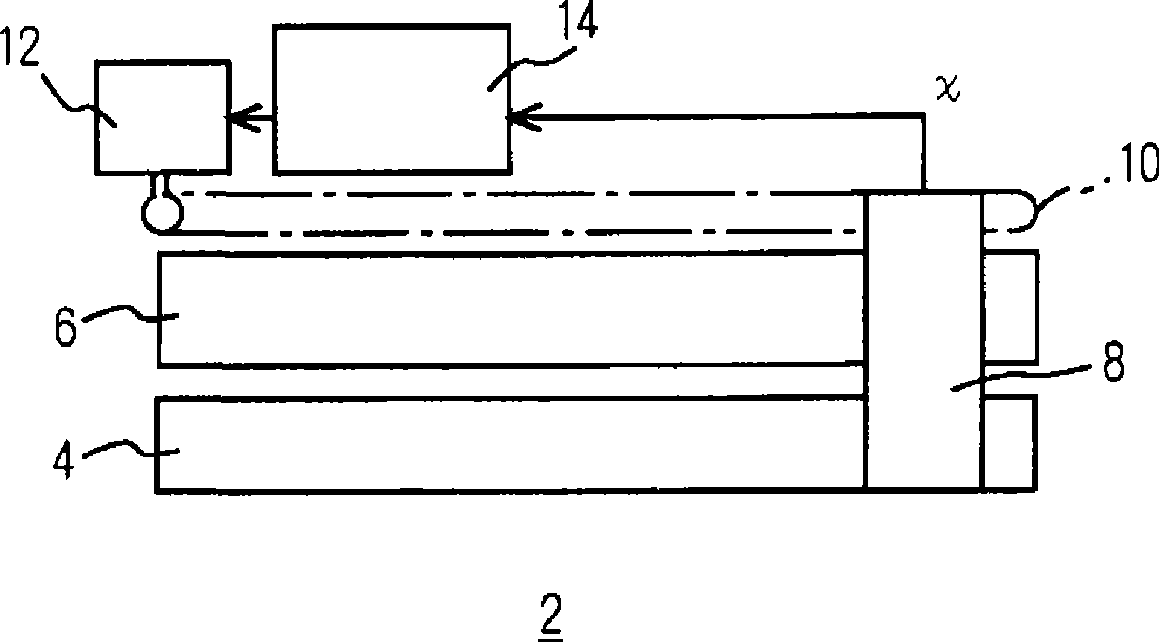

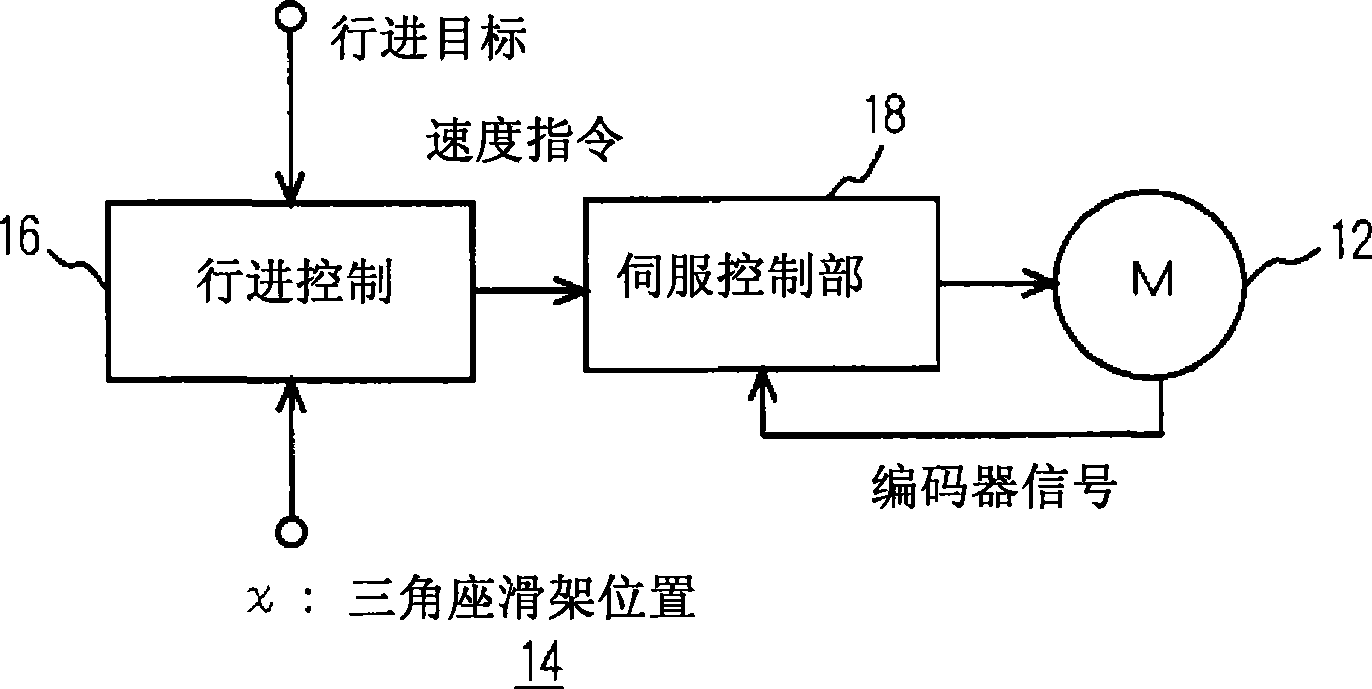

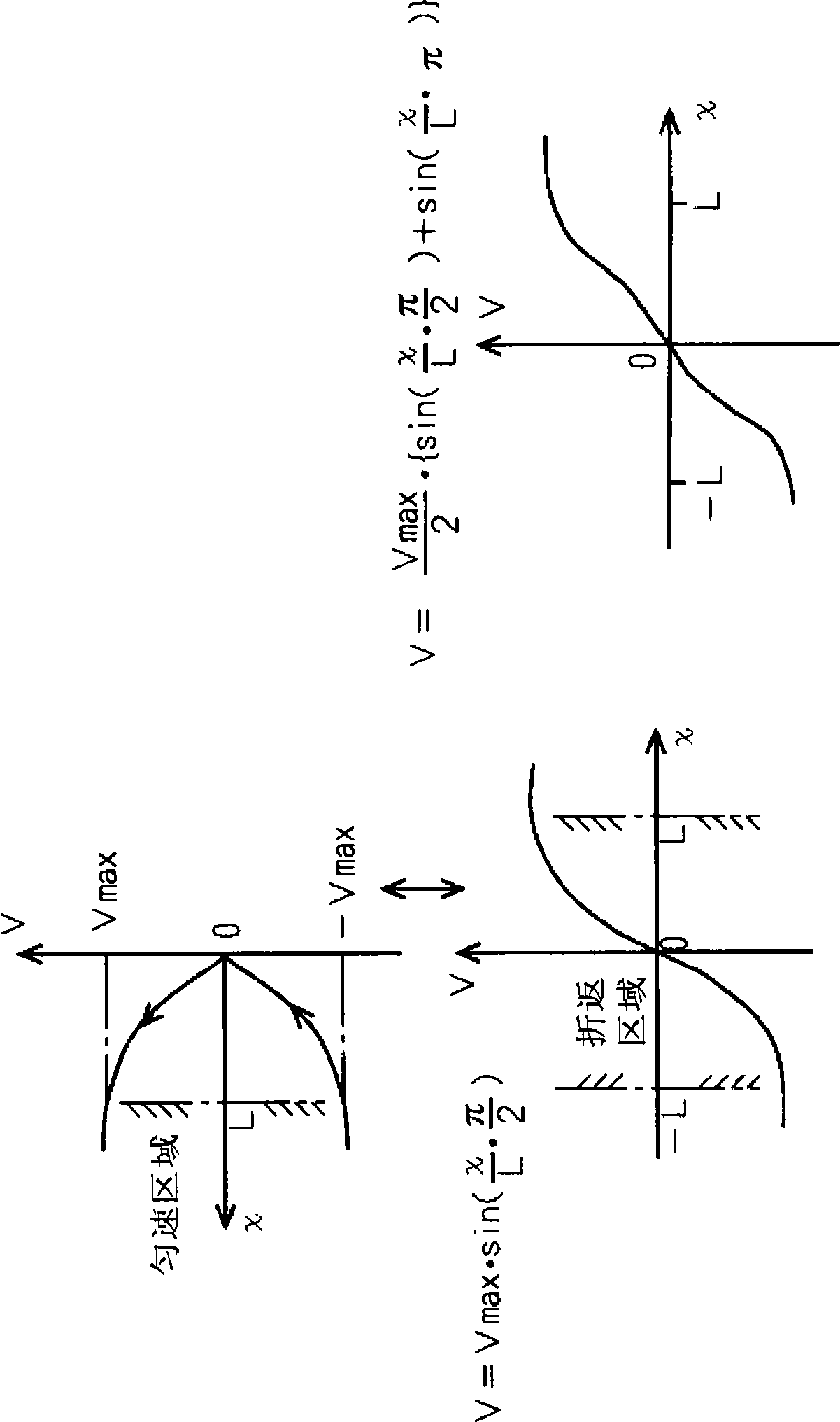

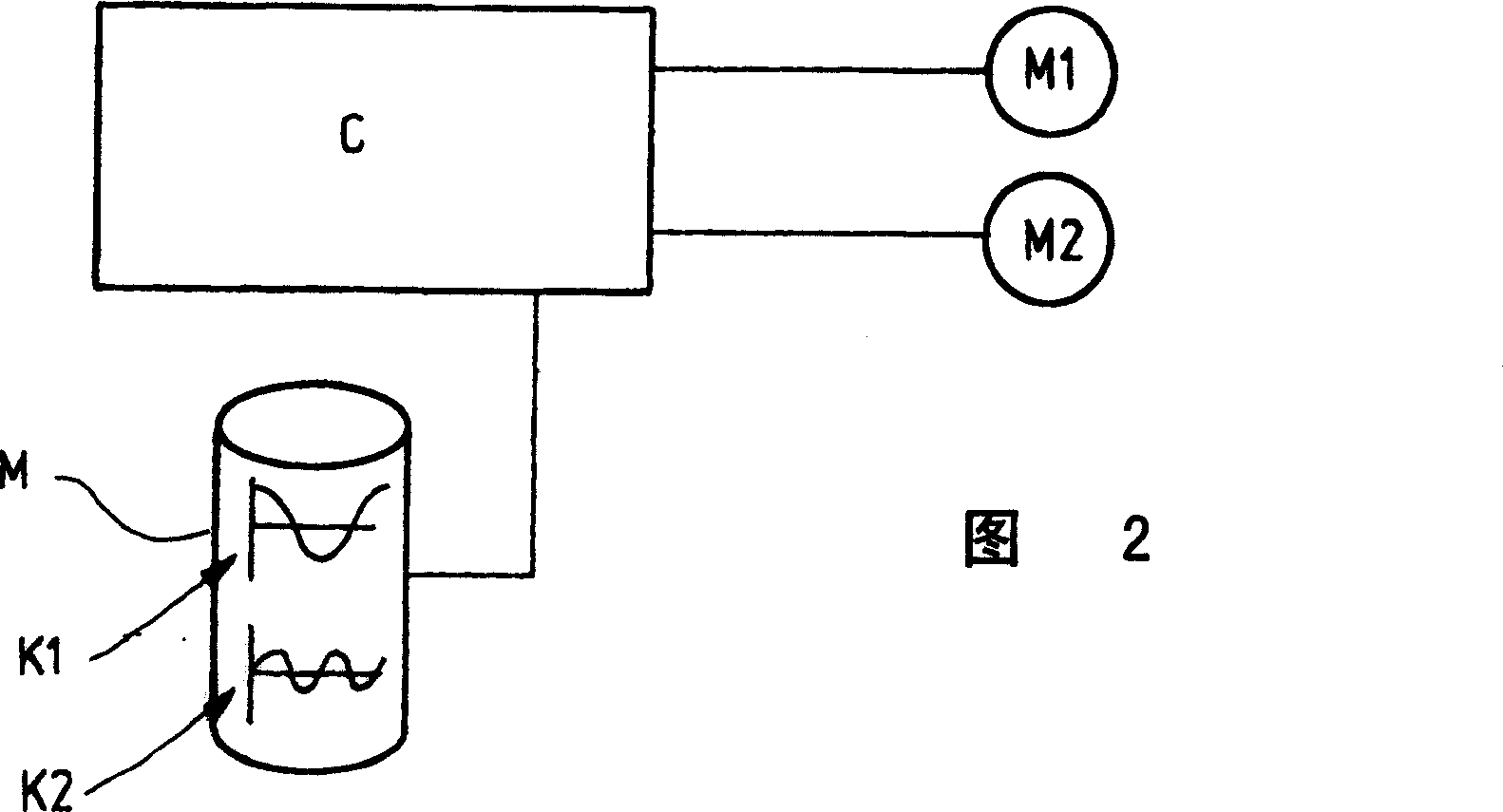

Filling knitting machine

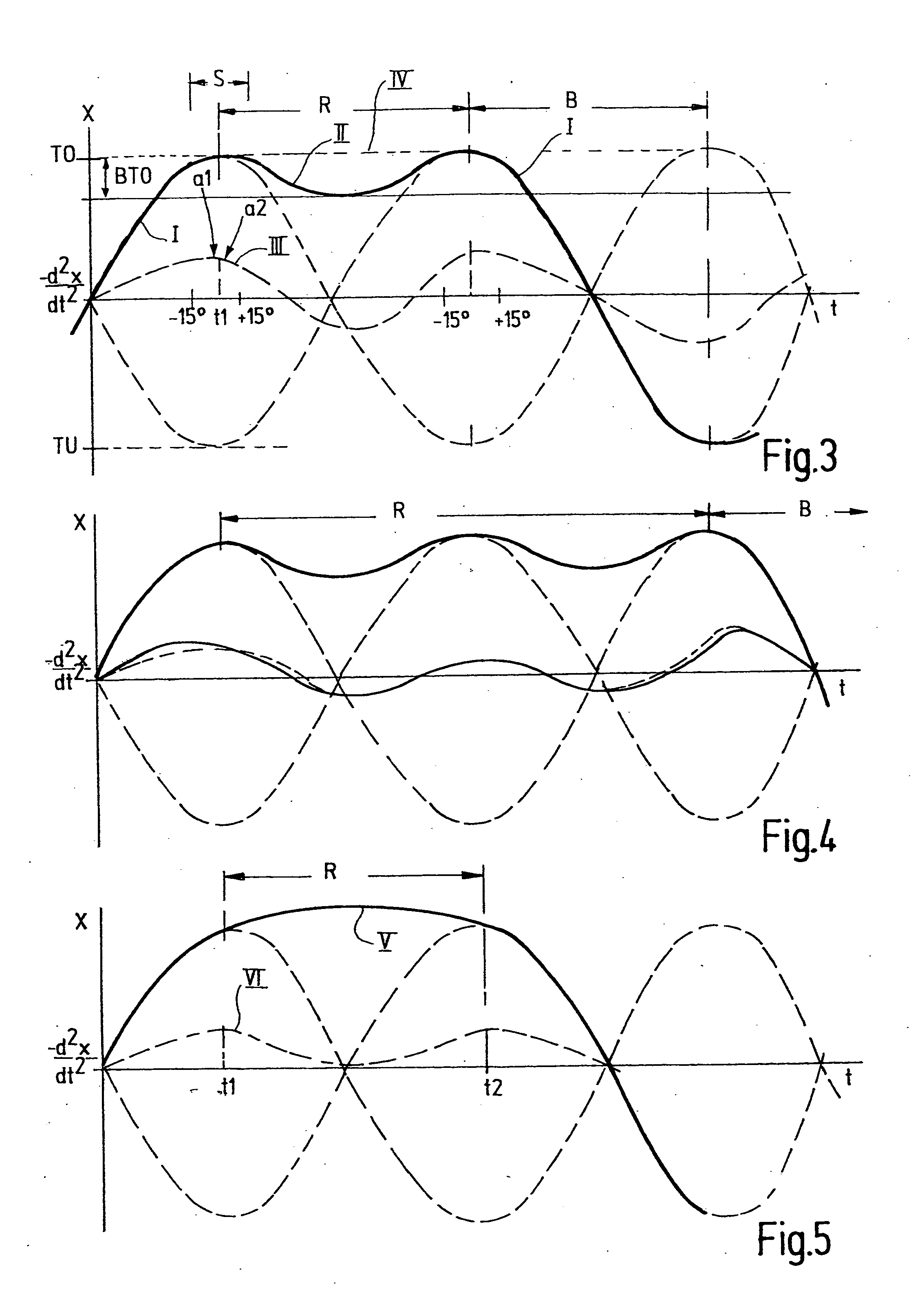

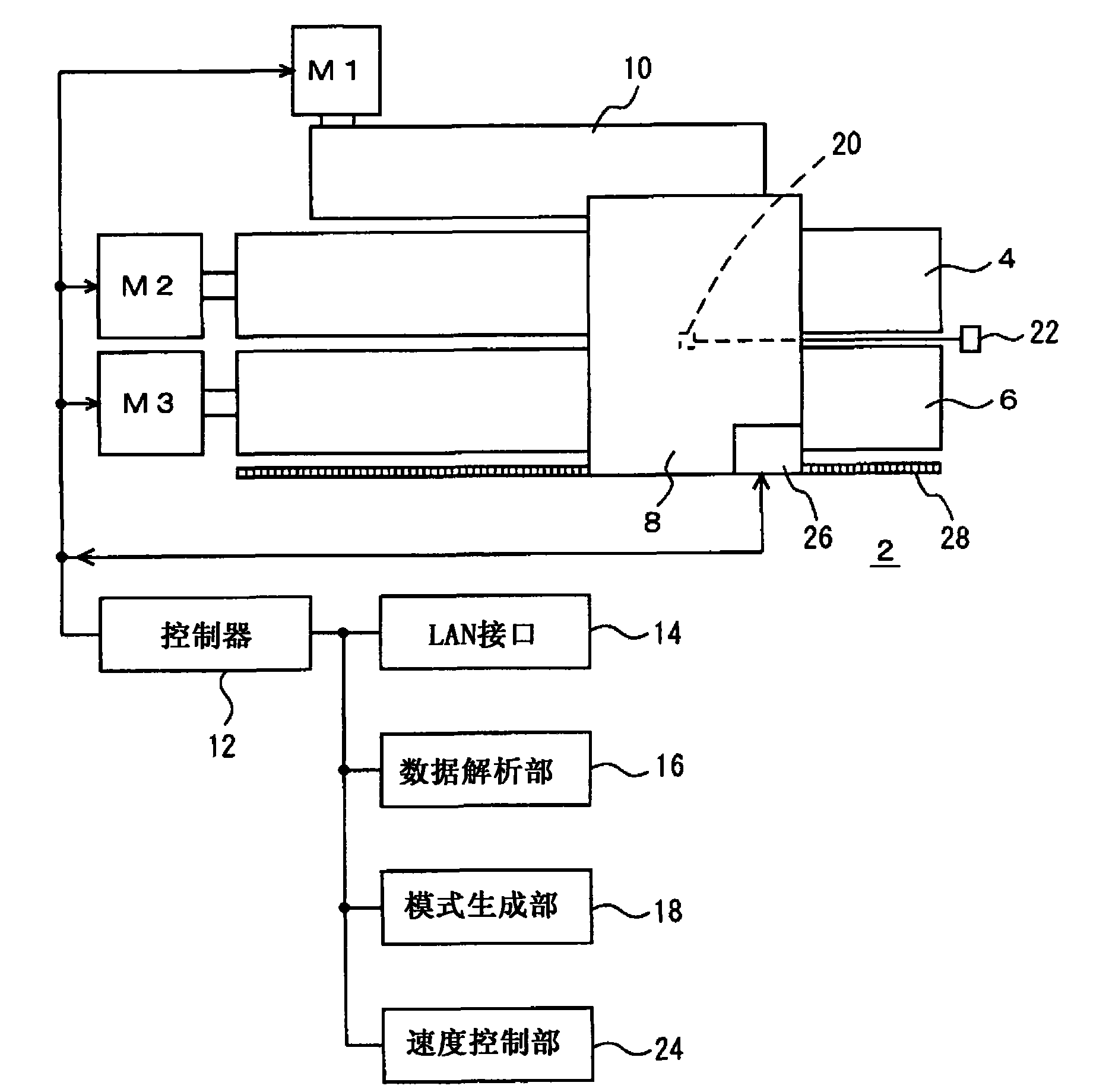

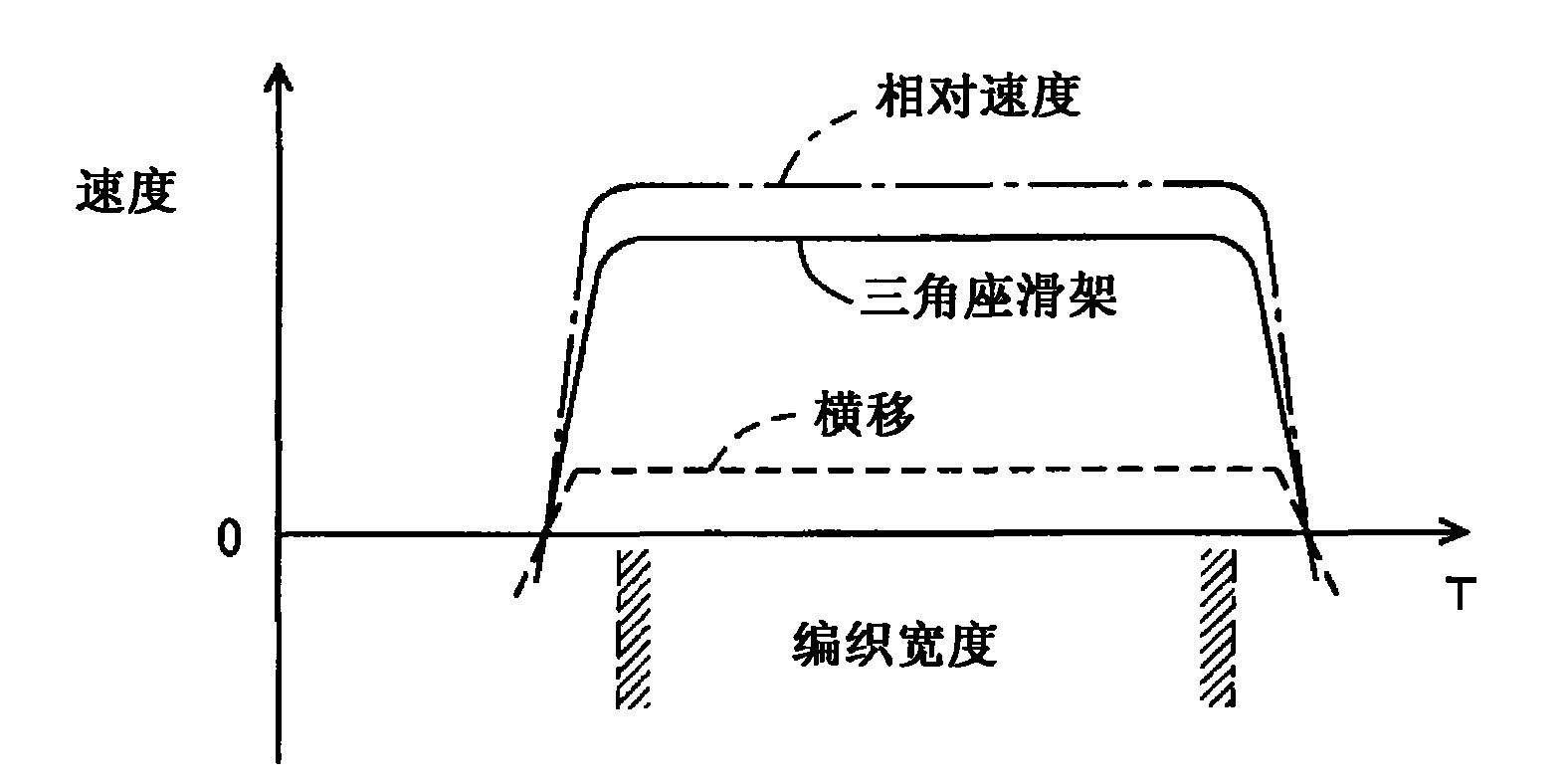

ActiveCN101479417AReduce vibrationReduce noiseWeft knittingNumerical controlMechanical engineeringAcceleration Unit

A flat knitting machine in which the speed of a carriage is set such that the acceleration thereof is maximized in the vicinity of a return point and the speed and the acceleration are smoothly changed between a fixed speed area and the return point. Accordingly, the vibration of the flat knitting machine can be reduced.

Owner:SHIMA SEIKI MFG LTD

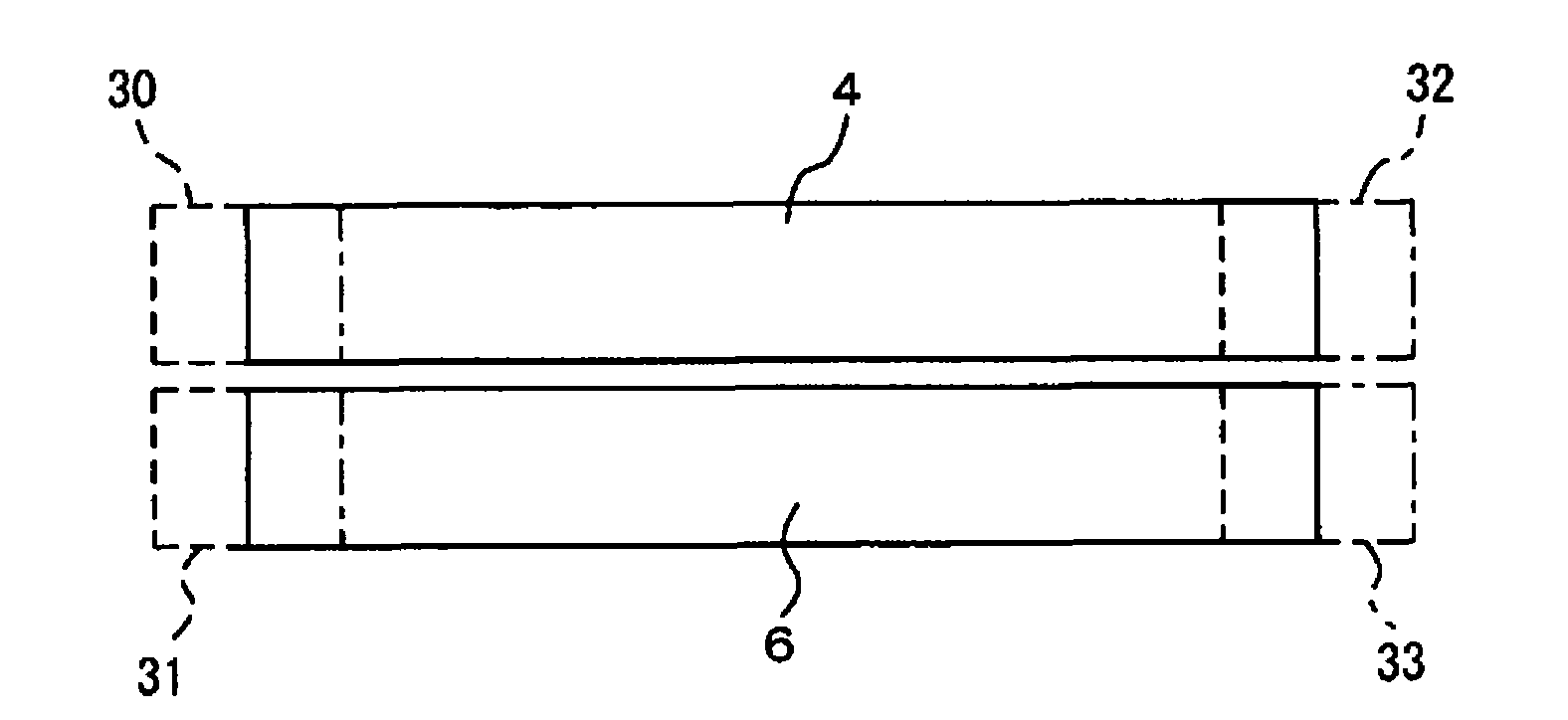

Weft knitting machine and method of knitting using racking of weft knitting machine

A knitting fabric is knitted by a weft knitting machine comprising a needle bed, a carriage, and a controller. To perform the knitting, the needle bed is moved in the direction reverse to the moving direction of the carriage while the carriage moves so as to move the needle of the needle bed forward and backward. A knitting speed can be improved by increasing the speed of the carriage relative to the needle.

Owner:SHIMA SEIKI MFG LTD

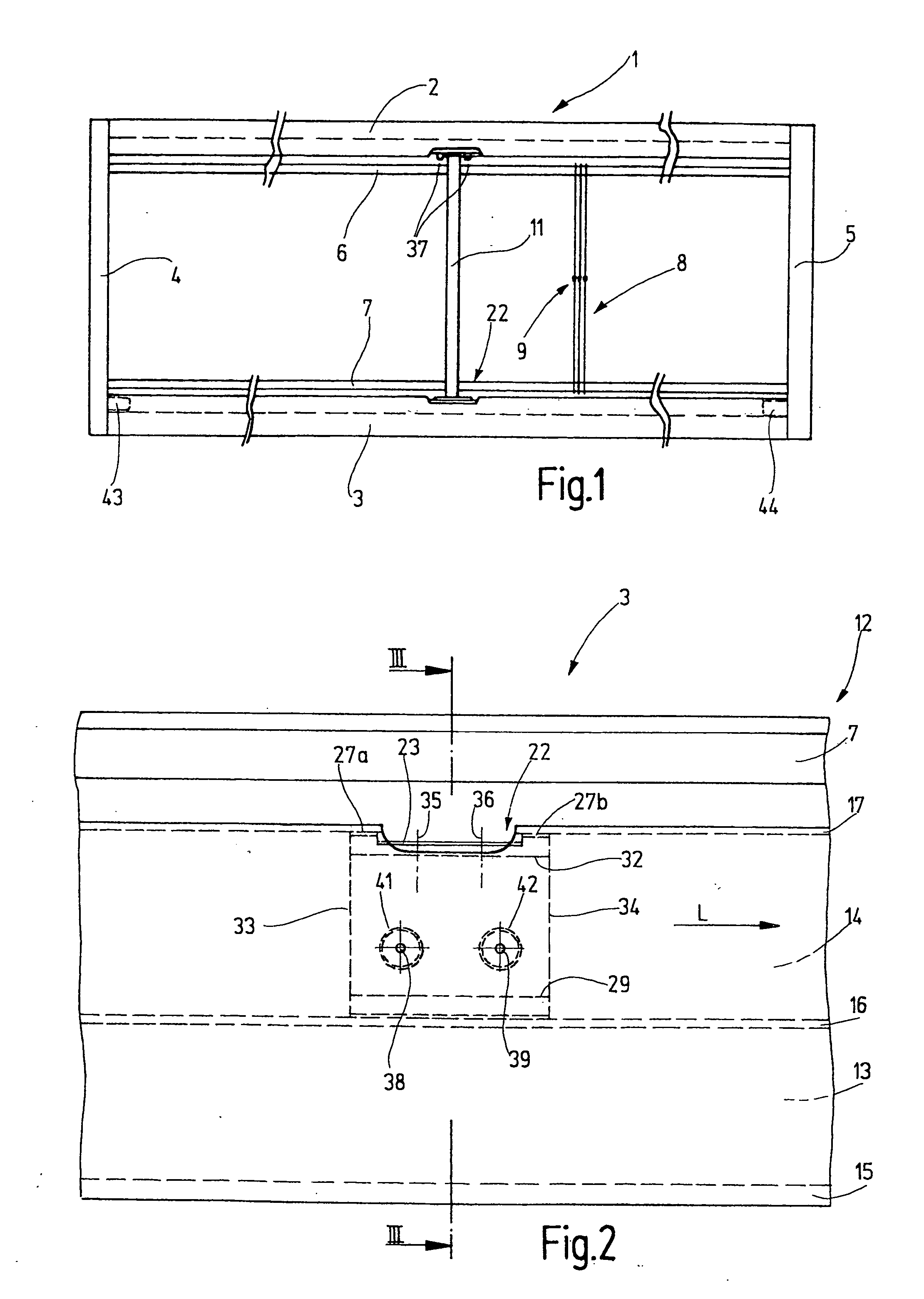

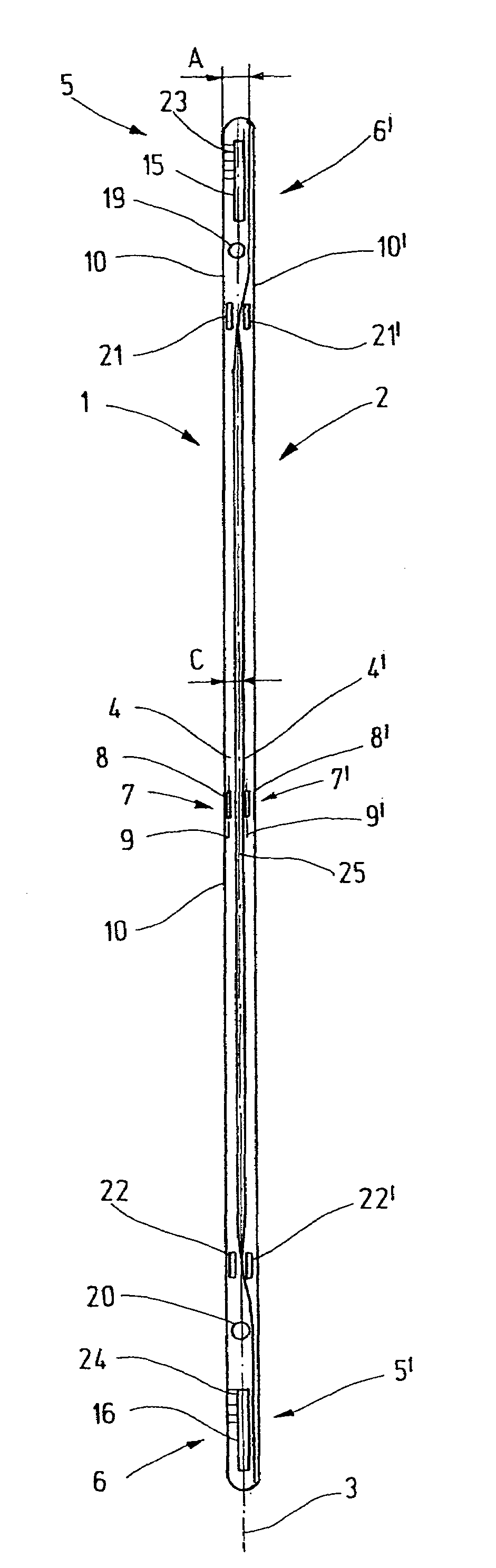

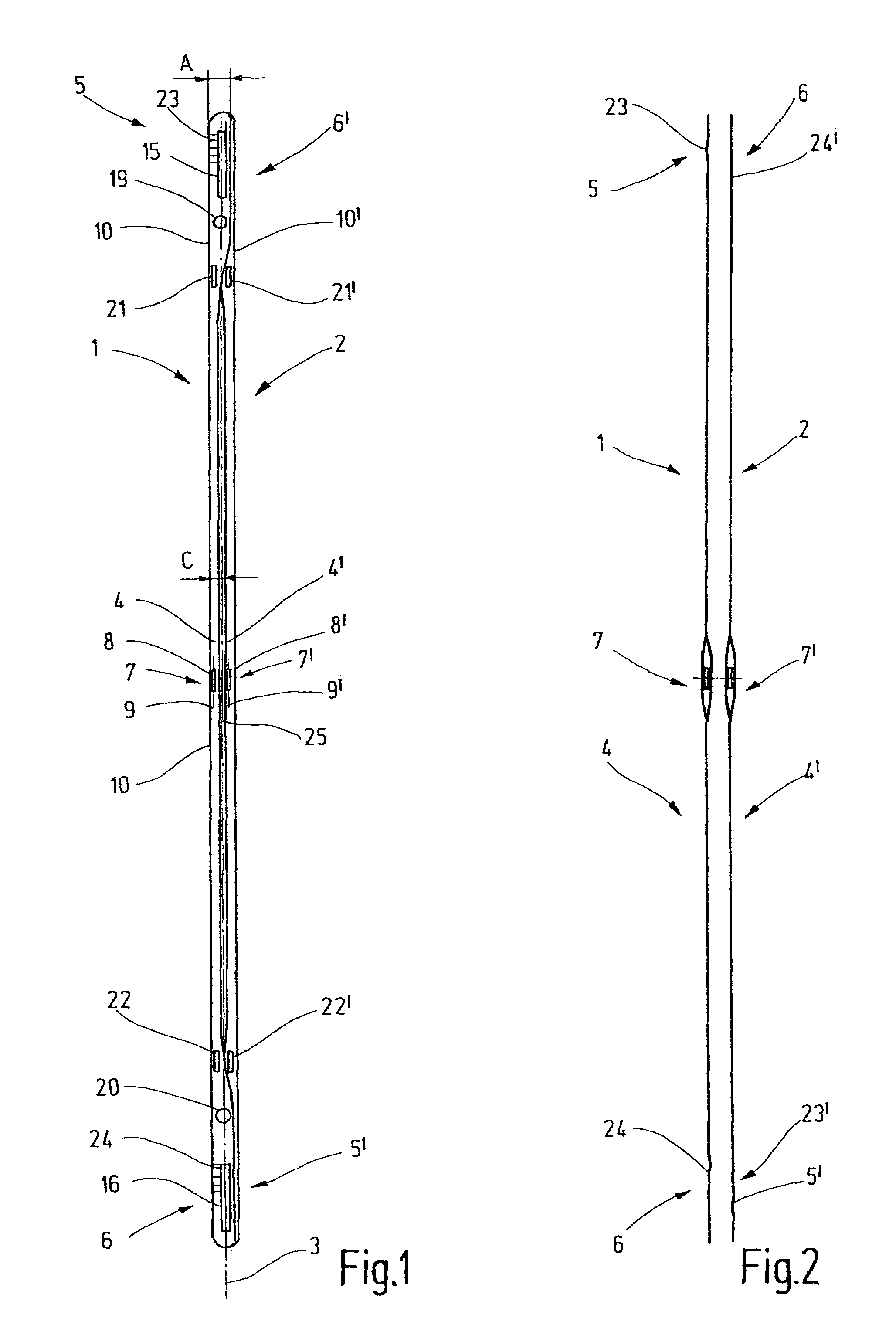

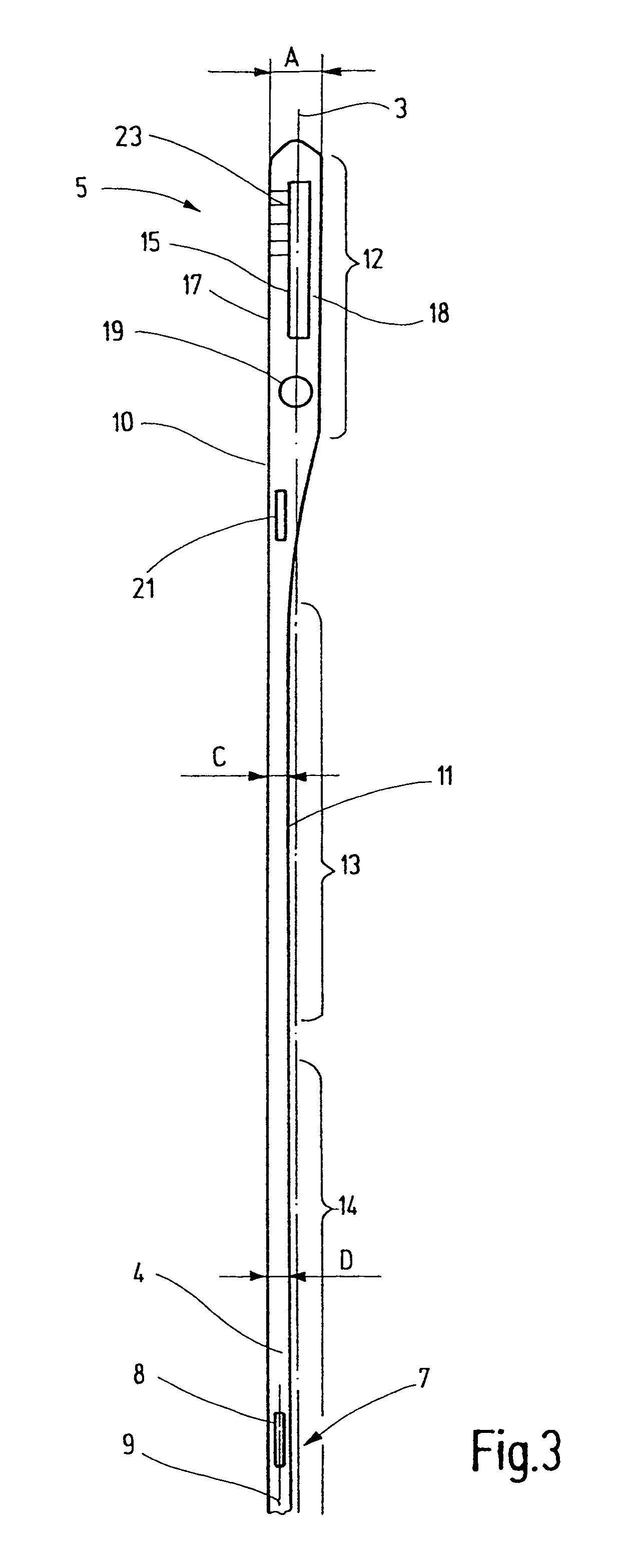

Heddle shaft with center connector

InactiveUS20050081943A1Little playImprove rigidityHealdsOther shedding mechanismEngineeringMechanical engineering

Owner:GROZ BECKERT KG

Method for supporting a weft guide element

Owner:SULTEX AG

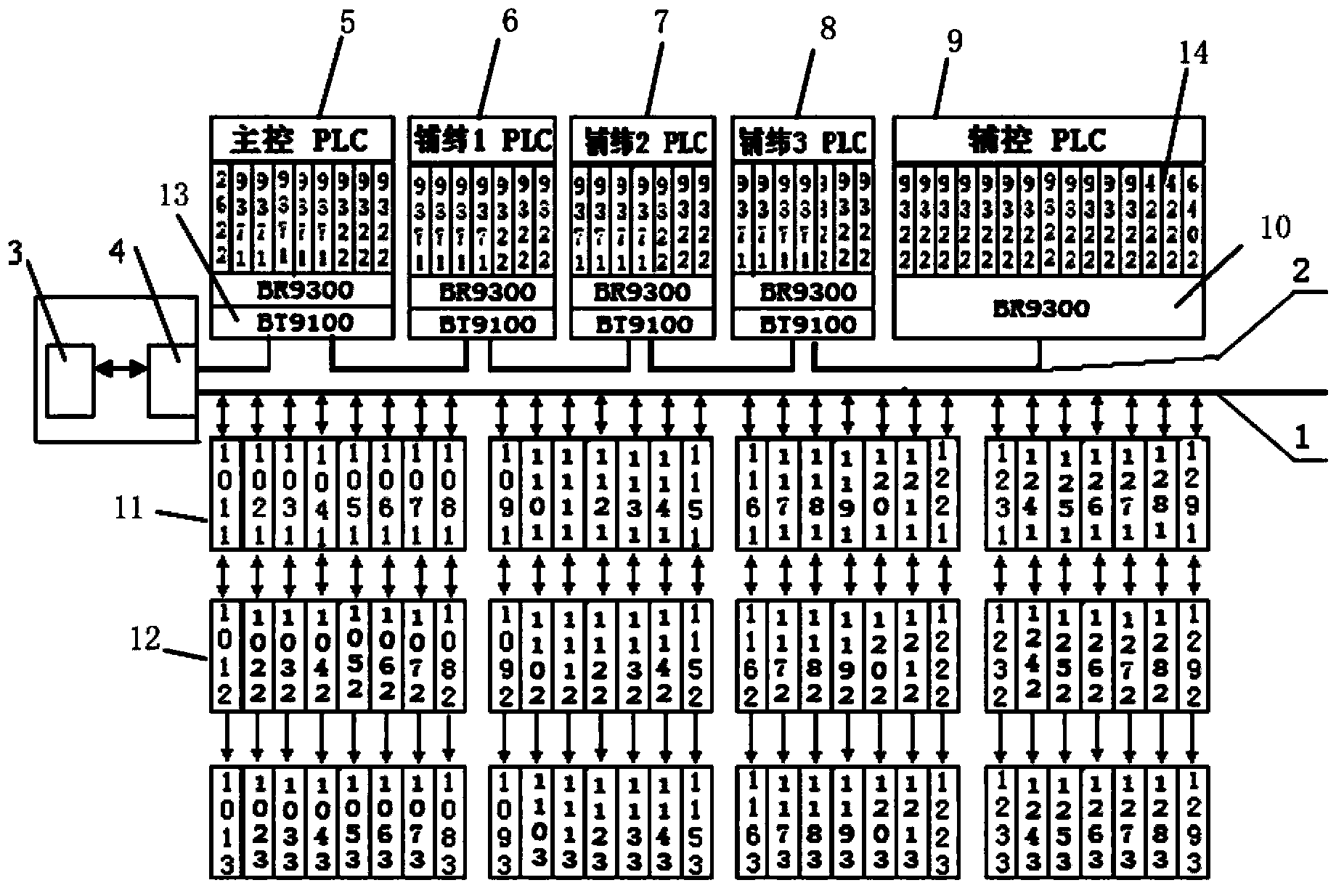

Real-time high and low speed communication control system of carbon fiber multiaxial warp knitting machine

InactiveCN103353745AIncrease weaving speedImprove performanceEnergy efficient ICTWarp knittingFiberLow speed

The invention relates to the technical field of textile warp knitting, and specifically relates to a real-time high and low speed communication control system of a carbon fiber multiaxial warp knitting machine. The system comprises a real-time high-speed PowerLink bus, low-speed X2X communication buses, and a man-machine operating device connecting the real-time high-speed PowerLink bus and the low-speed X2X communication buses through a signal converter. The low-speed X2X communication buses are connected with a master controller in a communication manner, a first weft thread controller connected with the master controller in a communication manner, a second weft thread controller connected with the first weft thread controller in a communication manner, a third weft thread controller connected with the second weft thread controller in a communication manner, and an assistant controller connected with the third weft thread controller in a communication manner. The system manages in a centralized manner, and controls in a distributed manner, and coordinates and manages each control unit, thereby greatly improving operation stability and efficiency of the system.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

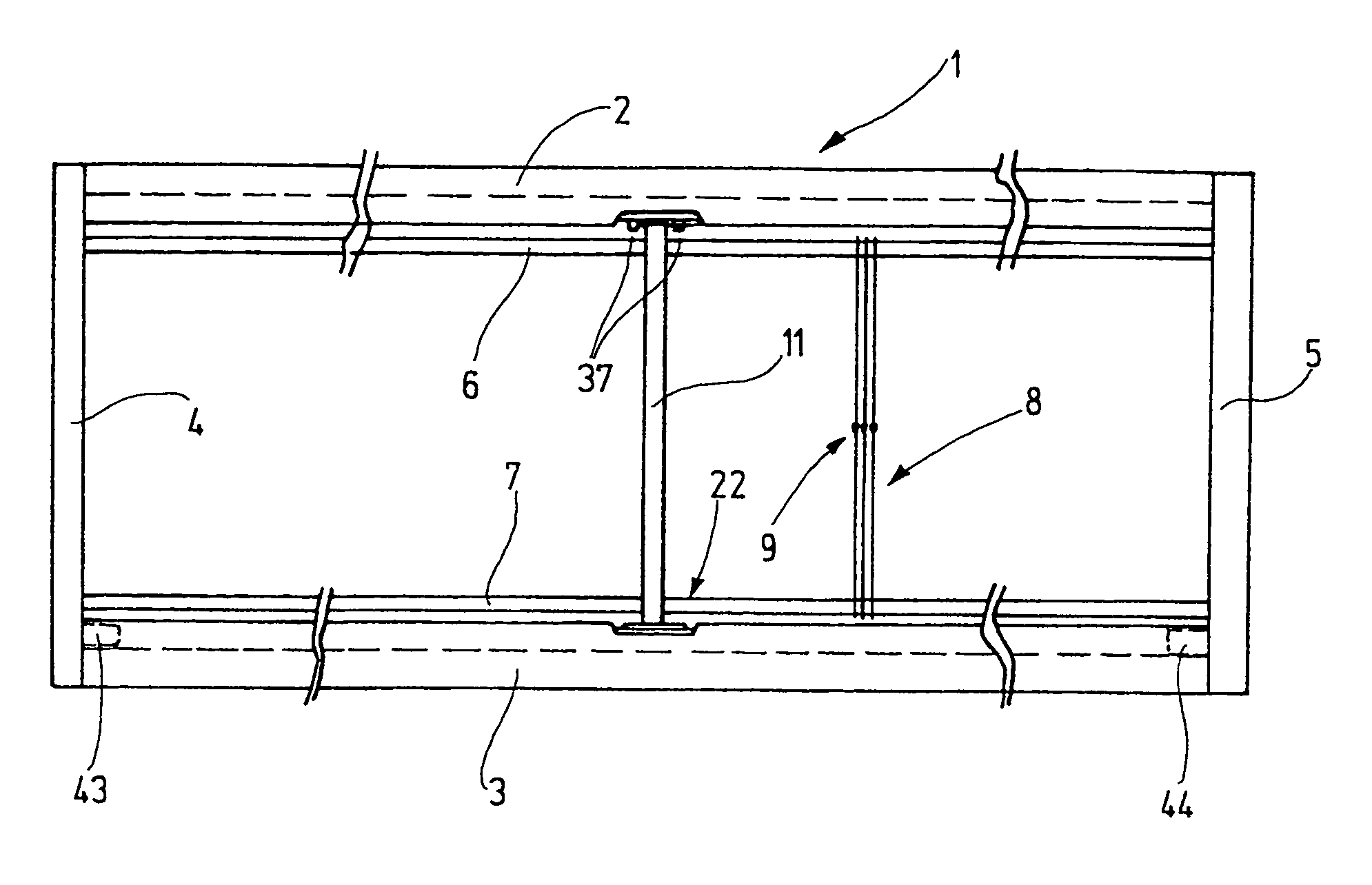

Circular weaving machine and method for producing a hollow profile-like fabric

Owner:INNOTEC LIGHTWEIGHT ENG & POLYMER TECH

Air-jet loom weaving method with polyester cotton wrap yarn fabric

InactiveCN101418489AOvercoming the Disadvantages of DeformationReduce untwisting phenomenonLoomsWoven fabricsInsertion timeAir-jet loom

The invention discloses an air jet loom weaving method for a polyester cotton core-spun yarn fabric with a polyester filament as a core and cotton fiber wrapped outside polyester, which orderly comprises working procedures such as doubling, twist stabilization after twisting, warping and rebeaming, reeding, loom beam on-hook, adjustment of process parameters and so on. In the working procedure of batch warping, the rebeaming is performed on a sizing machine, and the sizing is not performed; during the reeding after the rebeaming, 50 to 100 percent of harness frame numbers are increased than the prior species according to the warp density; the weft-insertion time is adjusted to ensure that the weft-insertion time of previous group of auxiliary nozzles is longer than that of next group of the auxiliary nozzles and the weft-insertion time is orderly shortened in a step shape, and the entire auxiliary nozzles are synchronously closed at the same angle position. The working procedures after the adjustment effectively solve the problem that the dyeing of the polyester cotton core-spun yarn fabric has color difference after the polyester cotton core-spun yarn fabric is woven on an air jet loom, and ensure that the polyester cotton core-spun yarn fabric can be fully and normally woven on the air jet loom. The weaving efficiency can reach 96 percent, the rate of first-grade products when getting off the loom can reach more than 93 percent, woven cloth has qualified various indicators and fully satisfies the normal production of the dyeing and finishing, and no quality problem exists after the dyeing.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Loop-pile cutting circular machine

ActiveCN103938357BIncrease weaving speedHigh densityCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

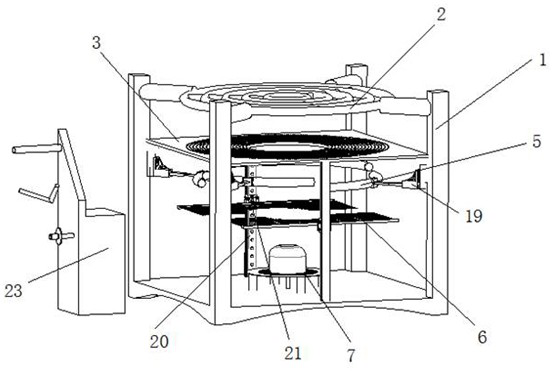

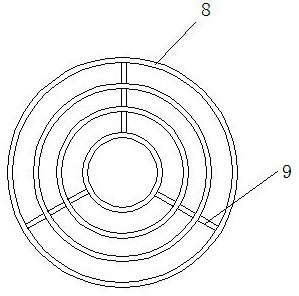

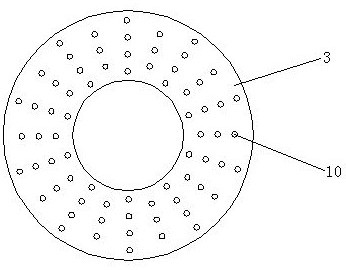

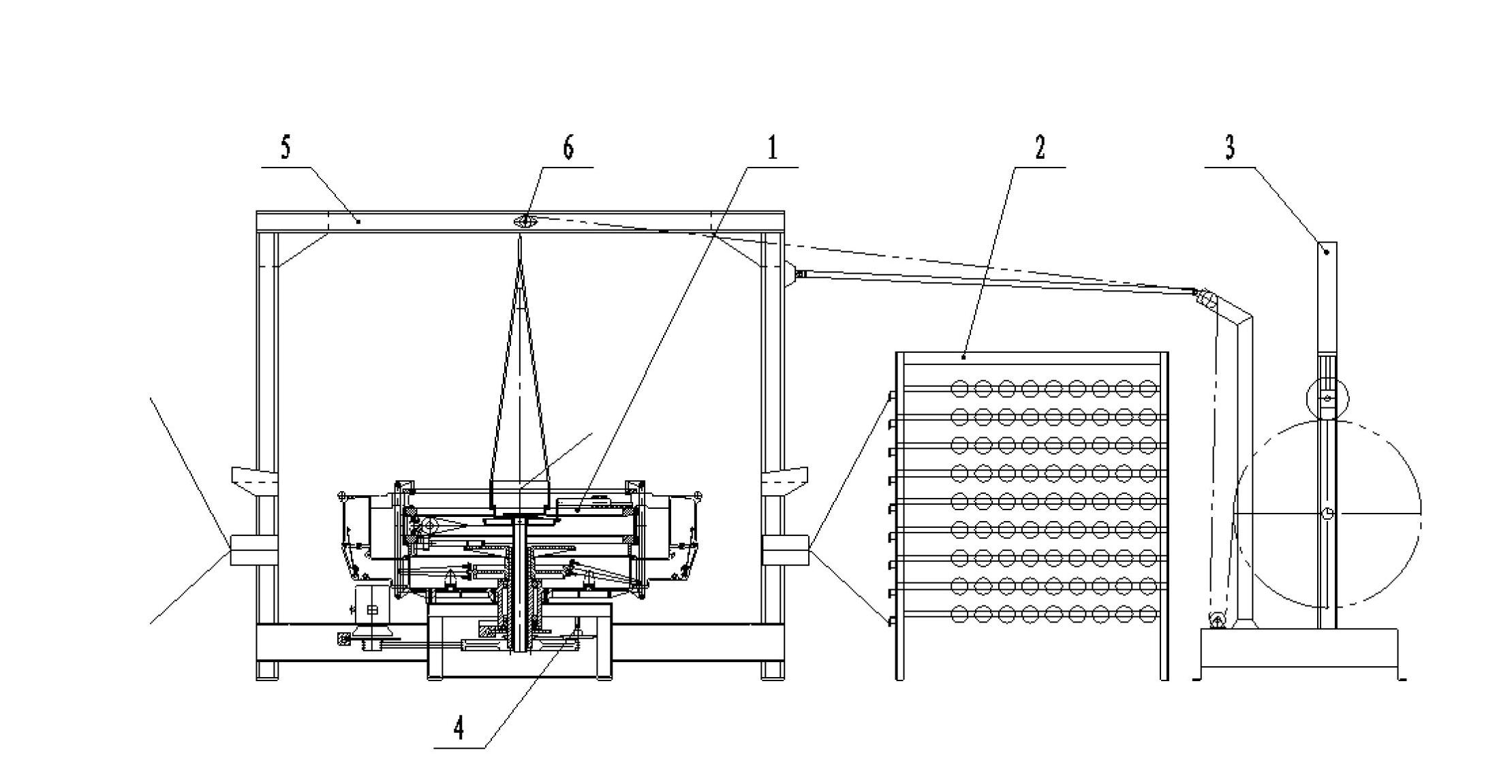

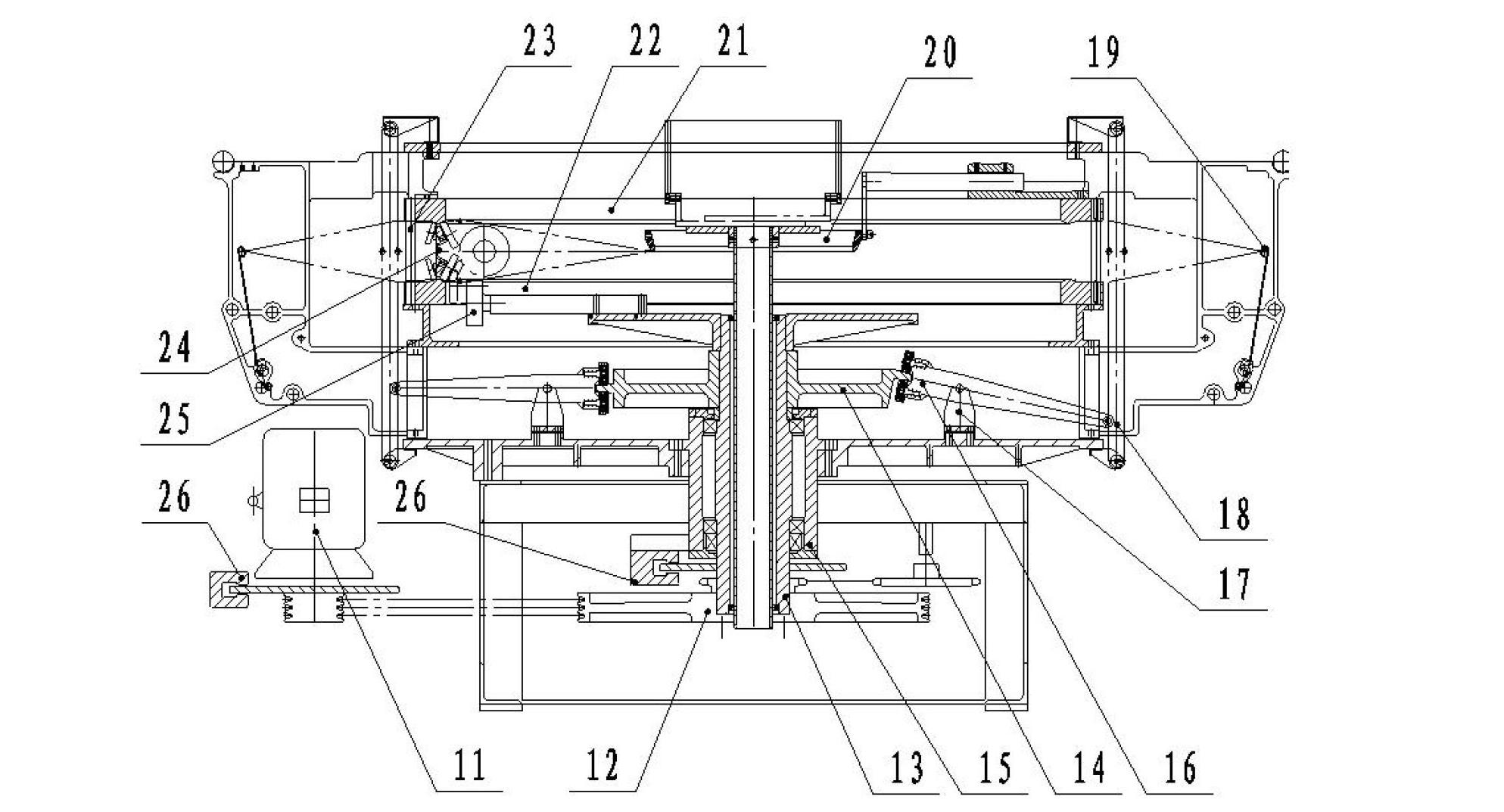

Three-dimensional knitting machine for carbon fiber preforms

The invention discloses a three-dimensional knitting machine for carbon fiber preforms. The three-dimensional knitting machine comprises a rack. An annular disperser, a track disc, an automatic driving yarn carrying device, a shaping device, a pre-forming carding device and a pre-forming device are sequentially arranged on the rack from top to bottom. A plurality of circles of threading holes areformed in the track disc. A plurality of circles of wave-shaped track grooves are formed in the bottom face of the track disc. Every two adjacent circles of threading holes are connected through one circle of wave-shaped track groove. The wave trough of each wave-shaped track groove bypasses the threading holes in the inner circle in every two adjacent circles of threading holes. The wave crest ofeach wave-shaped track groove bypasses the threading holes in the outer circle in every two adjacent circles of threading holes. The wave crests and the wave troughs of every two adjacent circles ofwave-shaped track grooves intersect with each other. The automatic driving yarn carrying device comprises an upper sliding box, a middle control box and a lower yarn clamping assembly. The productionof the carbon fiber preforms by the equipment is convenient and fast, and the production cycle is greatly shortened.

Owner:宜兴市易问信息科技有限公司

Moldproof method for maize peels used for weaving

InactiveCN106182261ALight colorDarken the colorRadiation/waves wood treatmentWood treatment detailsSnow moldVitamin C

The invention discloses a moldproof method for maize peels used for weaving. The moldproof method is simple, high-efficient, safe, non-poisonous and environment-friendly, and cost is reduced by 17.3%; the maize peels are soaked in a strong salt solution, so that mold on the surfaces of the maize peels can be effectively killed; the maize peels are soaked in a vitamin C solution, so that an antimicrobial and moldproof effect is realized; the color of the maize peels is lighter, and the maize peels turn naturally white, so that the maize peels are prevented from turning yellow latterly; the maize peels are soaked in a Chinese medicine mold preventive solution which is environment-friendly and harmless to human bodies, does not darkening the color of the maize peels, can improve the antibacterial property of the maize peels and can prevent drug-resistance, so that the bacteriostasis rate can reach up to 86.3%, and the maize peels can be prevented from molding in 9 years after vacuum packing; and after the maize peels are dried through low-temperature ozone, the flexibility of the maize peels is improved, and the color of the maize peels is white and natural, so that the weaving speed is improved by 13.7%.

Owner:阜南县东奥工艺品有限公司

Production method of elastic fine-denier polyester and elastane composite filament fabric

InactiveCN107700030AIncrease jet pressureIncrease weaving speedLoomsWoven fabricsColor differenceWeft yarn

The invention discloses a production method of elastic fine-denier polyester and elastane composite filament fabric. Weaving is conducted with an air-jet loom, the weaving means of double nozzles or multiple nozzles is adopted, and used weft yarns are air textured composite filaments composed of polyester multifilaments and elastane filaments; the air textured composite filaments are provided withentanglement points, so that the polyester multifilaments and the elastane filaments are broken apart by gas flow at the entanglement points, and the polyester multifilaments are entangled with the elastane filaments. According to the production method of the fine-denier polyester and elastane composite filament fabric, a traditional twisting composite means is replaced with an air textured composite means, so that the fine-denier polyester and elastane composite filaments are not broken apart to form a woven defect and color difference in the weaving process; single filaments composing polyester are unlikely to be blown off by the nozzles, and the air-jet pressure of the air-jet loom during weft insertion can be increased, so that the weaving speed is improved.

Owner:董坚强

Shaft drive system for power loom shafts

ActiveCN1598106AWork fasterNo sudden changes in acceleration force ratingsDobbiesHealdsCoupling systemControl theory

A novel shaft gear for harmonious engagement and disengagement of individual heddle shafts and for deriving their motion from the rotary motion of a single input shaft has a coupling system with two input elements. While one of the input elements serves to drive the output element of the coupling system permanently, the other input element serves solely to synchronize the output element briefly with the first input element. The switchover takes place in the brief synchronous phases, in selected angular regions that correspond to the top or bottom reversal point of the heddle shaft. For the switchover, such novel shaft drive mechanisms do not require any stoppage of motion for the input shaft or the shaft drive mechanism.

Owner:GROZ BECKERT KG

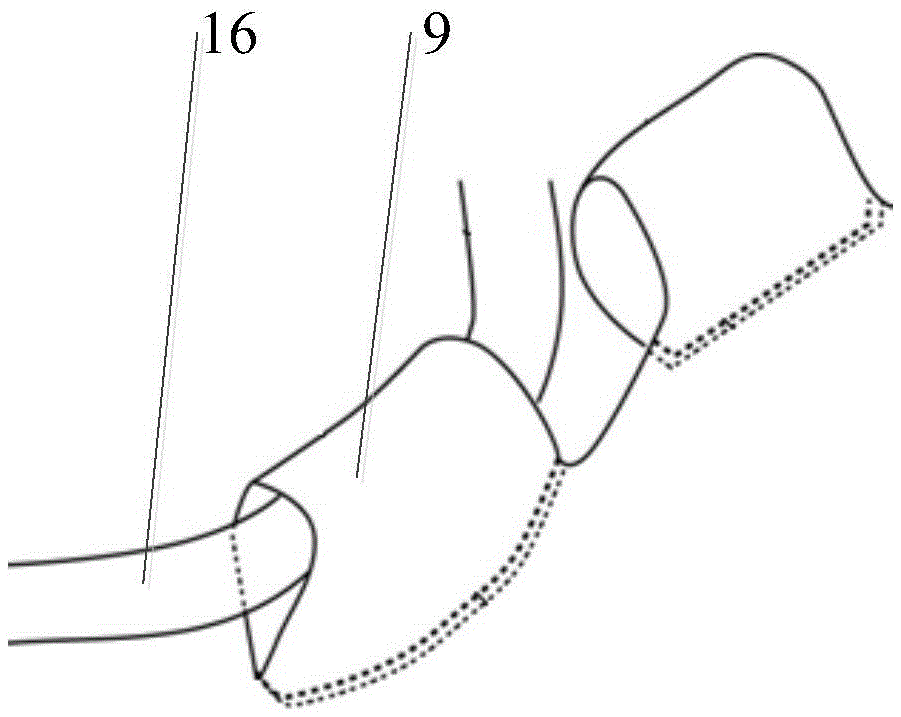

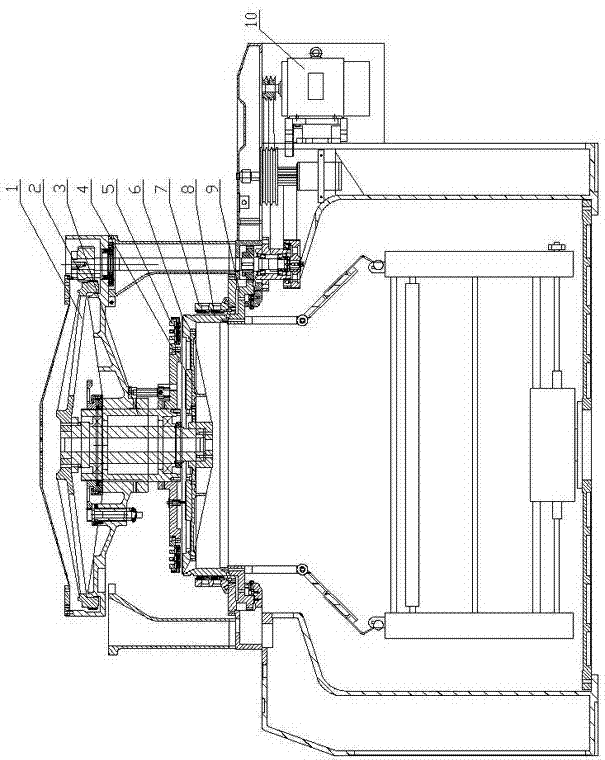

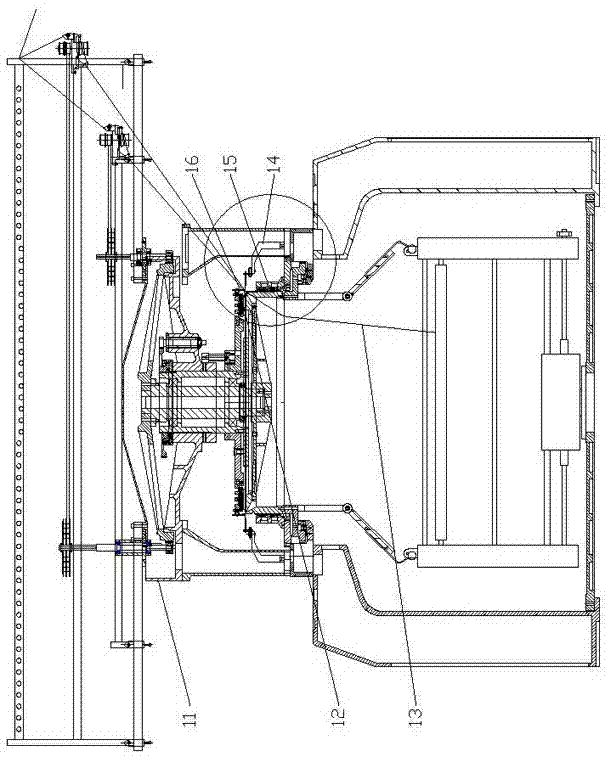

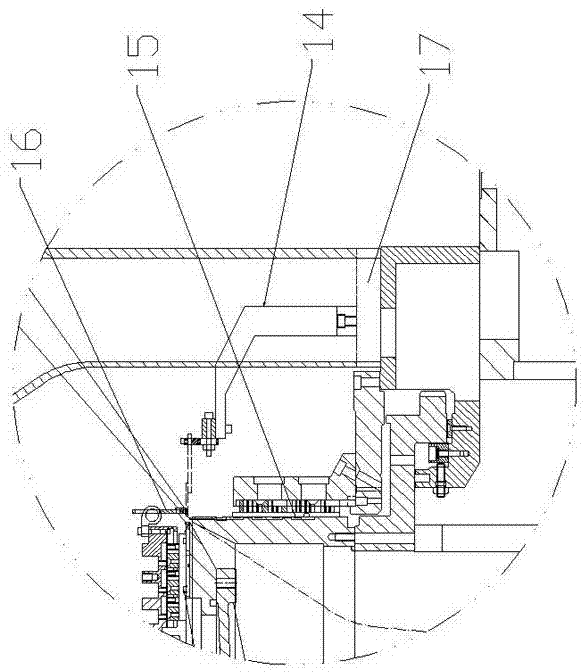

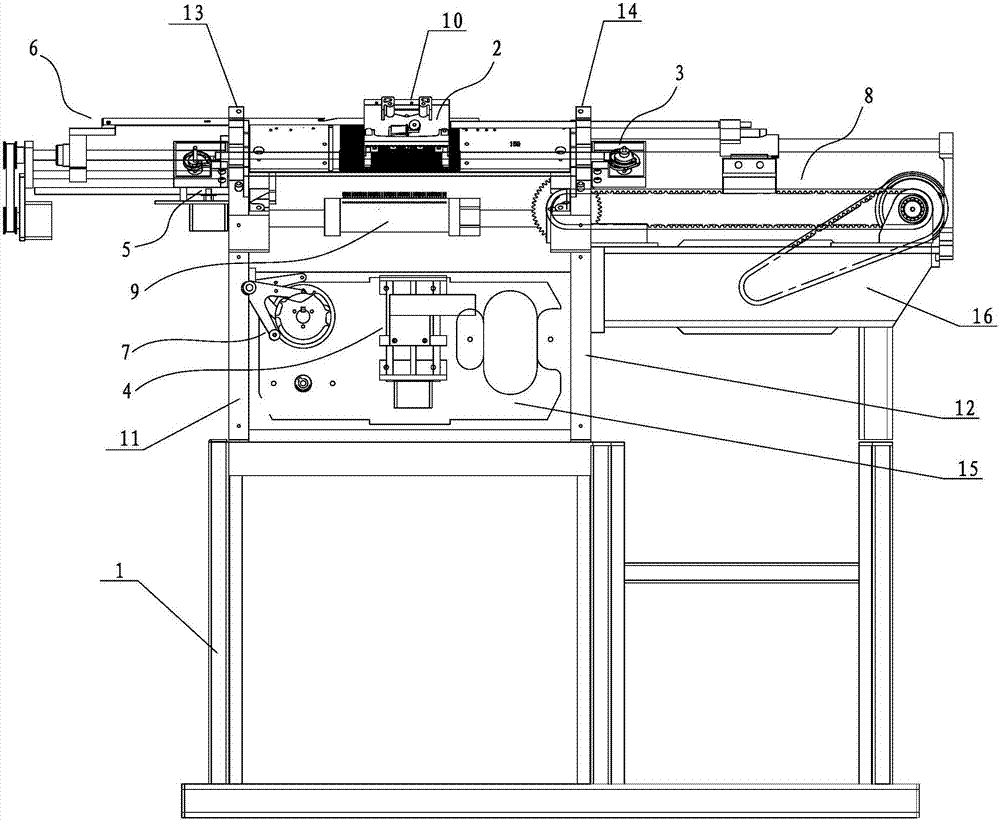

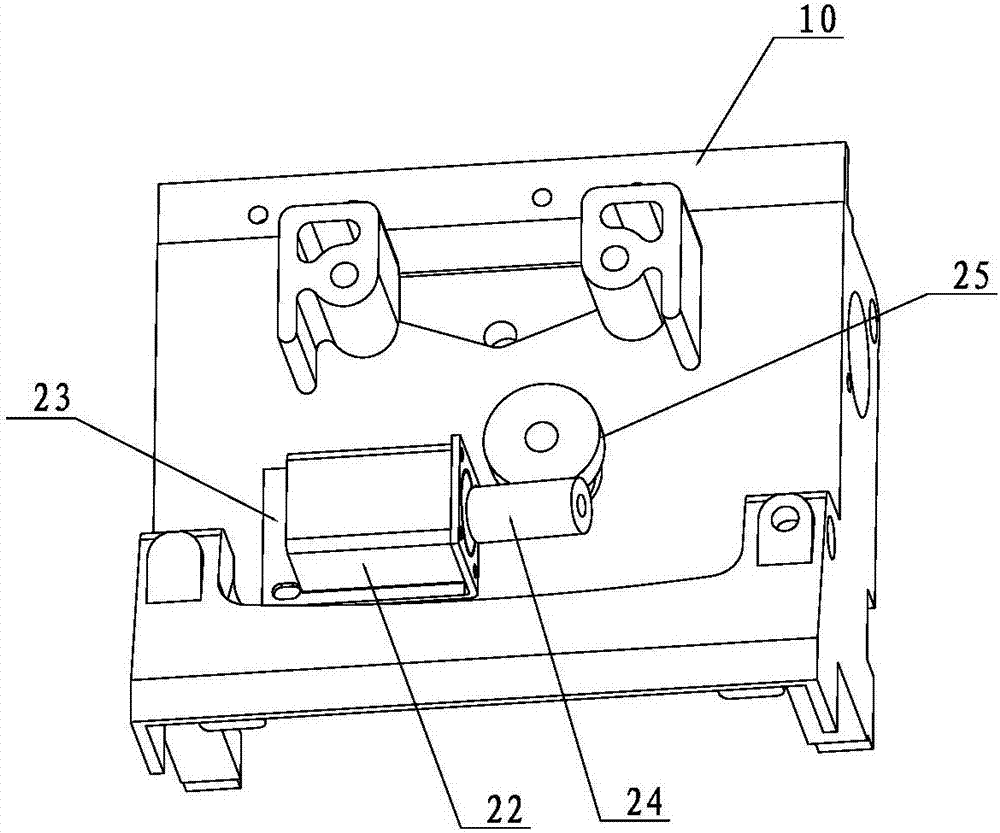

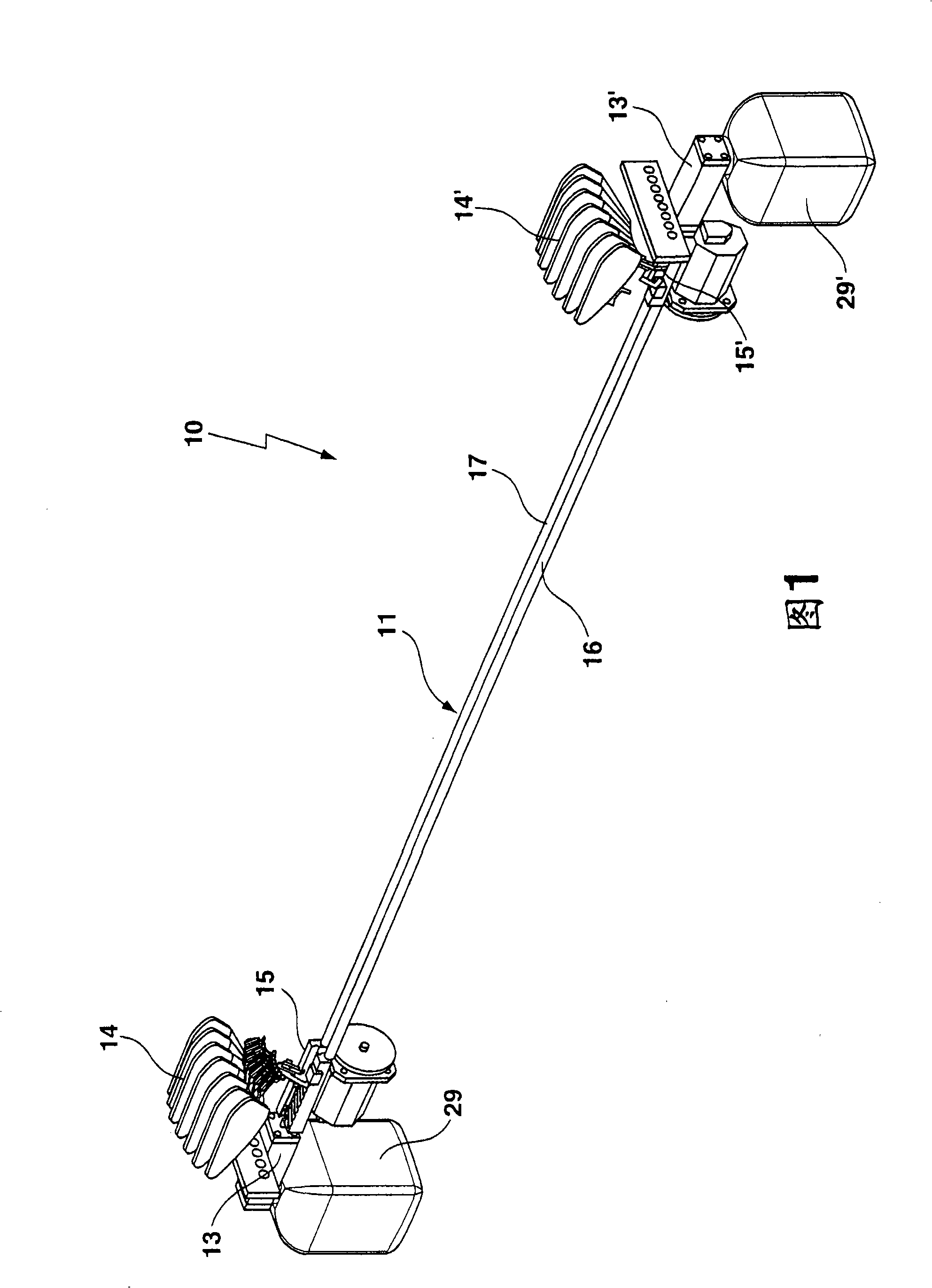

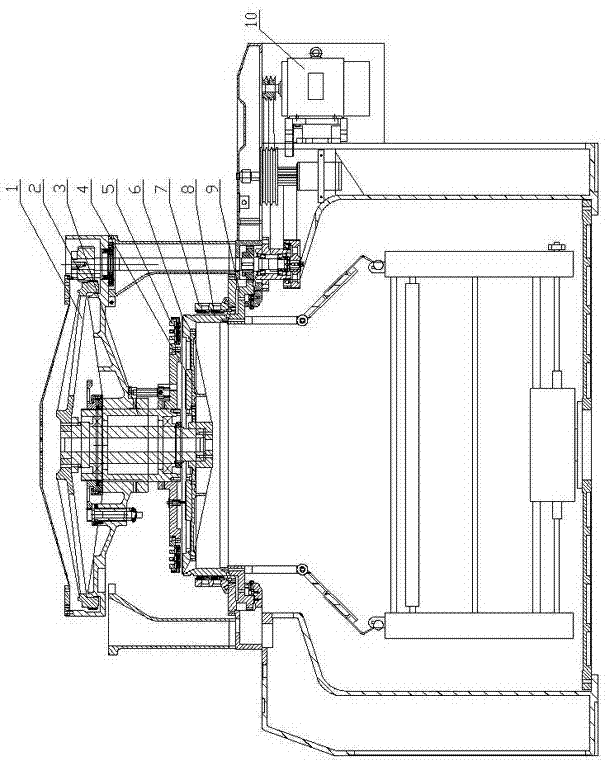

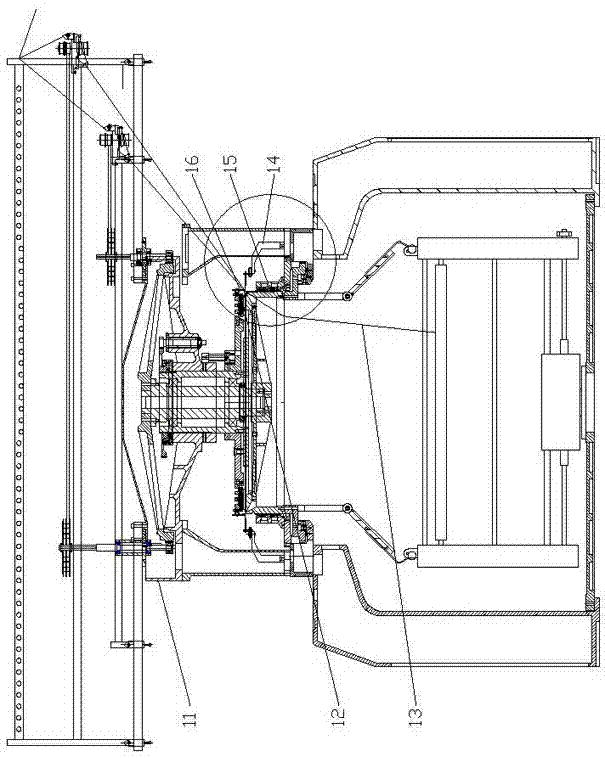

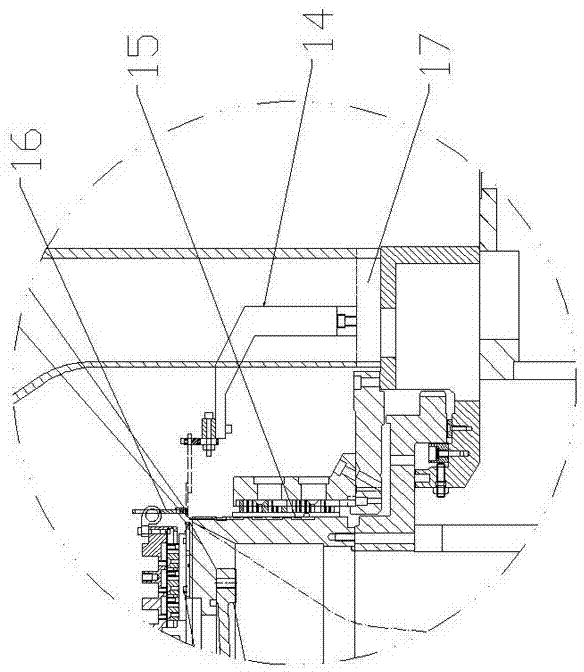

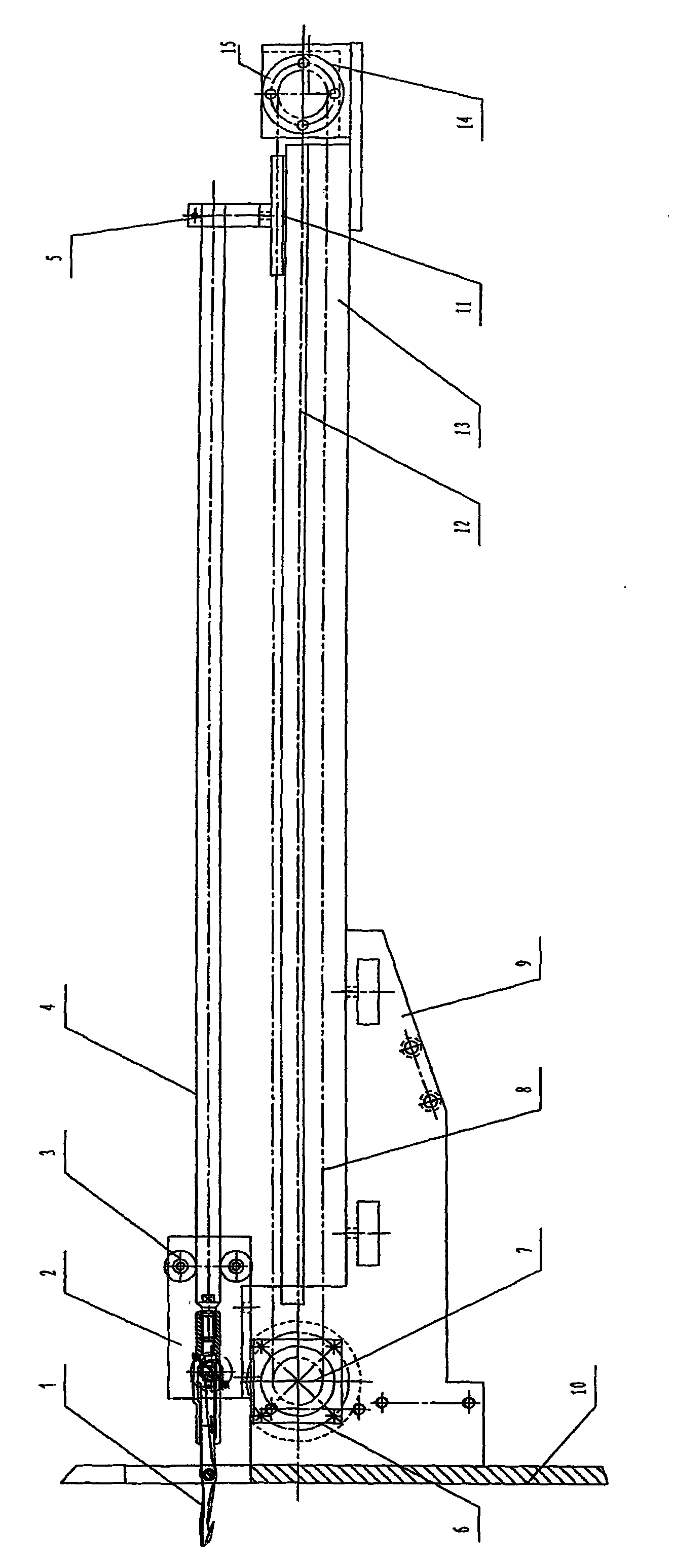

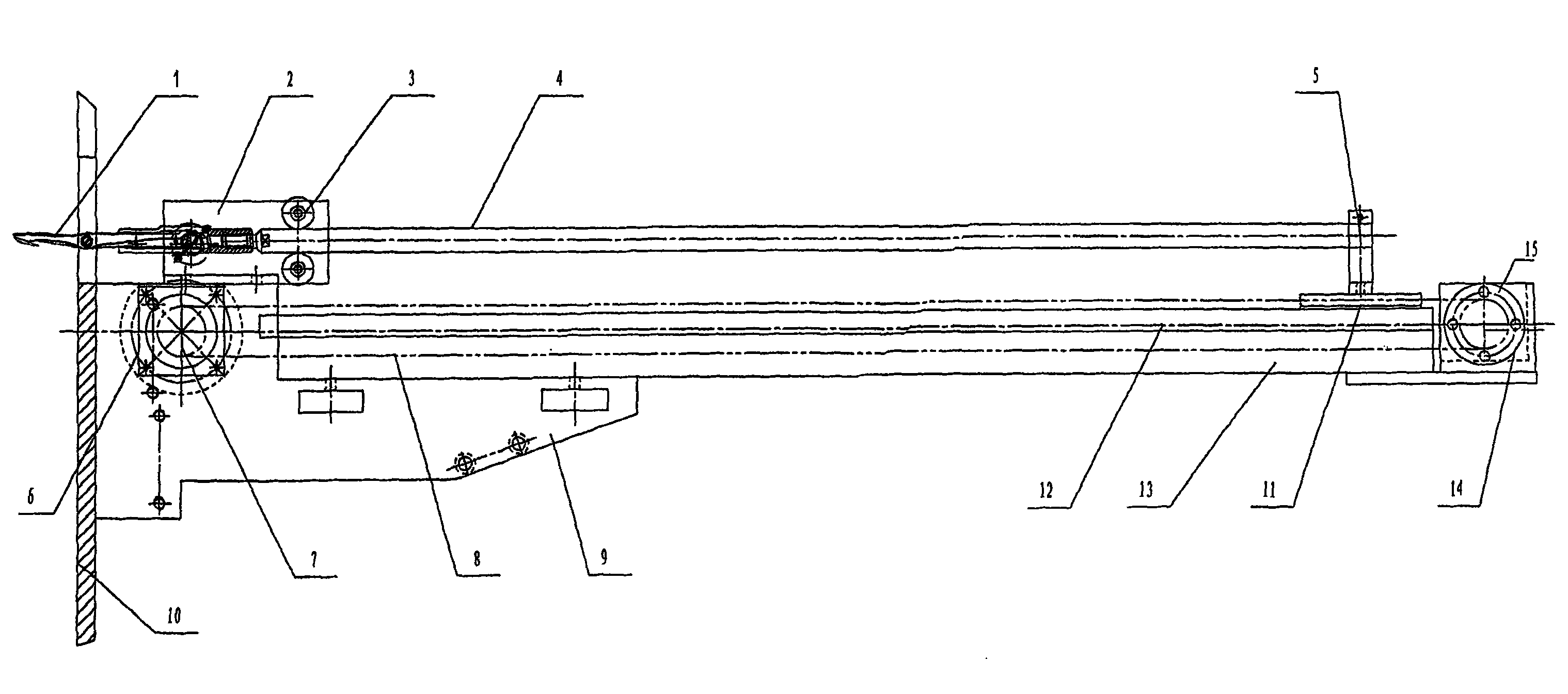

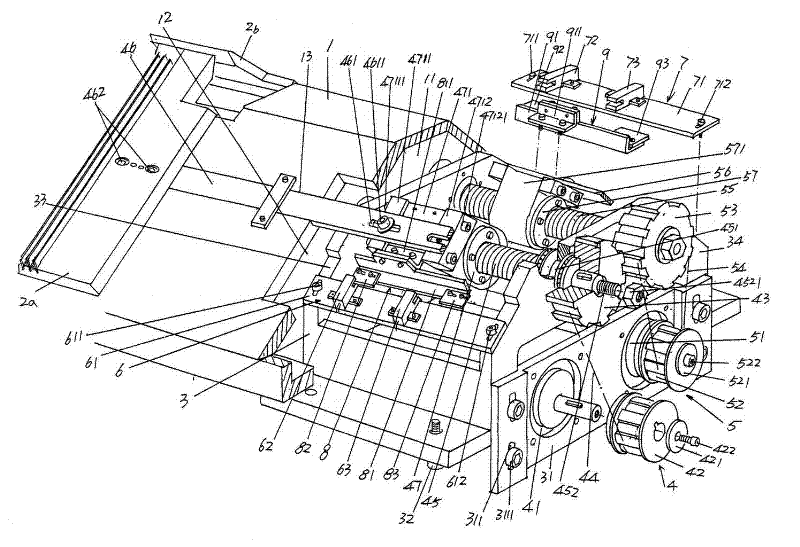

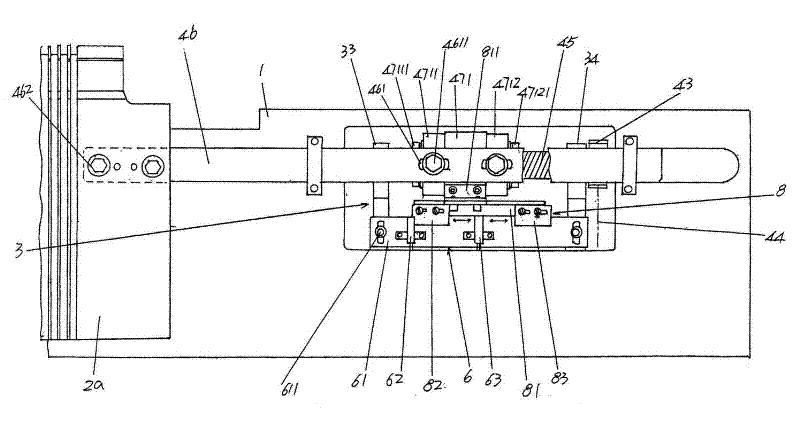

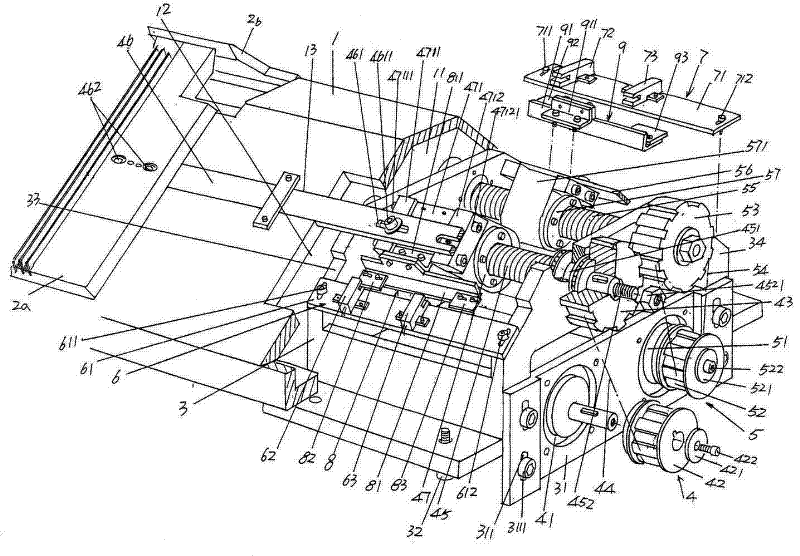

Weft inserting mechanism of sample loom

The invention relates to a weft inserting mechanism of a sample loom, which is used for introducing weft yarn into a warp yarn weaving port for filling warp blends to form a cloth sample. The weft inserting mechanism comprises a rapier head (1), a rapier (4), a guide wheel (3), a rapier seat (5), a guide wheel support seat (2), a rigid support seat (9), a linear bearing sliding block (11), a linear guide rail (12), a cantilever bracket (13), a right wall board (10), a servo motor (6), a synchronous belt pulley I (7), a synchronous belt pulley support seat (14), a synchronous belt pulley II (15) and a synchronous belt (8), wherein two ends of the rapier (4) are fixed to the rapier seat (5) by the guide wheel (3); the rapier seat (5) is arranged on the linear bearing sliding block (11); the linear guide rail (12) is arranged on the cantilever bracket (13); one end of the cantilever bracket (13) is arranged on the rigid support seat (9); the synchronous belt pulley I (7) is arranged on an output shaft of the servo motor (6); the synchronous belt pulley support seat (14) and the synchronous belt pulley II (15) are arranged at the other end of the cantilever bracket (13); and the synchronous belt (8) is connected with the rapier seat (5). The invention improves the weaving speed, simultaneously avoids the use of compressed air and solves the problems that an air cylinder is easy to damage and the cloth cover is polluted.

Owner:JIANGYIN TONGYUAN TEXTILE MACHINERY

Softening treatment method of wheat straws

InactiveCN106182292AEasy knittingKeep natural colorRadiation/waves wood treatmentWood treatment detailsCelluloseLiquid waste

The invention discloses a softening treatment method of wheat straws. The method is simple and feasible, is high in working efficiency, is low in cost, can perform large-batch treatment, is safe and nontoxic, is free of environmental pollution, and saves the cost of 11.8%; the wheat straws are ultrasonically treated for the first time to quickly increase the structure water content for primarily softening cellulose; softening liquid contains multiple plant extracting agents, is safe, nontoxic and low in cost, and can be recycled; finally, waste liquid can serve as a fertilizer to be directly applied to soil, so that the effects of safety and environmental protection are achieved, and the planting cost is saved; the softening liquid enables the wheat straws to become soft, tough and smooth and to be easily woven, so that the working efficiency is improved, the weaving fracture rate is reduced by 7%, the weaving speed is accelerated by 10.2%, the wheat straws prevent mould and moth, resist storage, and generate no mould and moth for seven months under normal environment, and the storage cost is reduced; and the wheat straws are ultrasonically treated for the second time to remove a treatment agent therein, so that no treatment trace after drying is guaranteed, and the natural color and fragrance of the wheat straws are kept.

Owner:阜南县大喜柳编工艺品有限公司

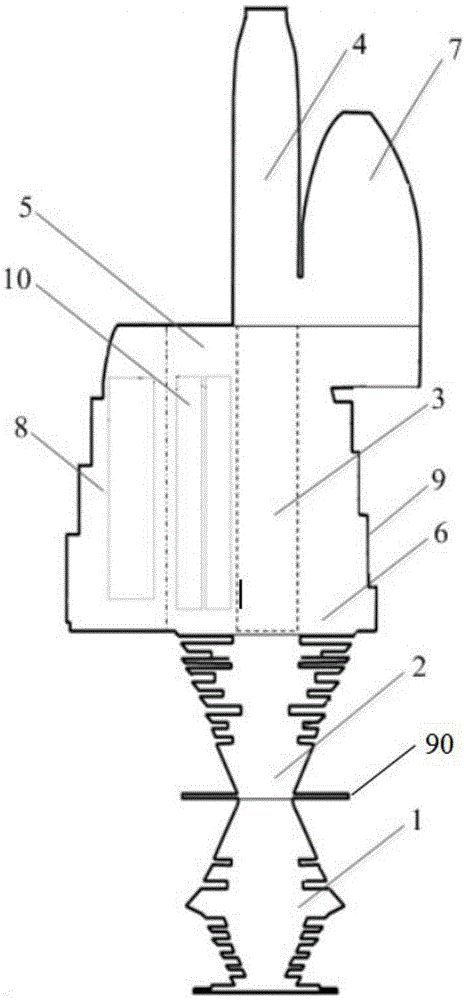

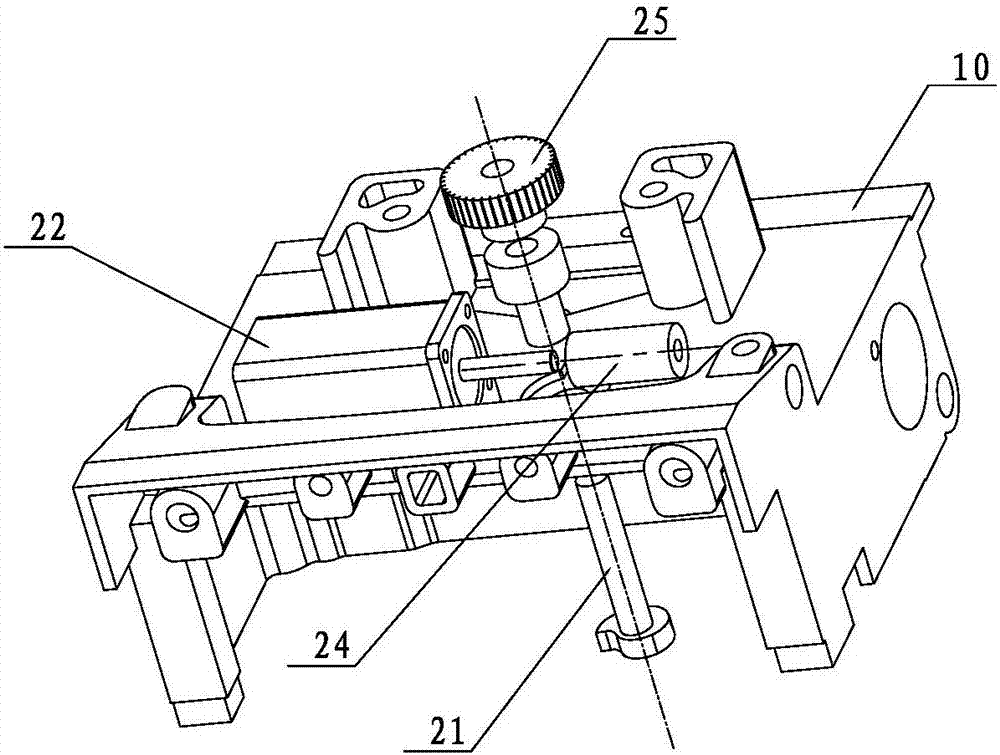

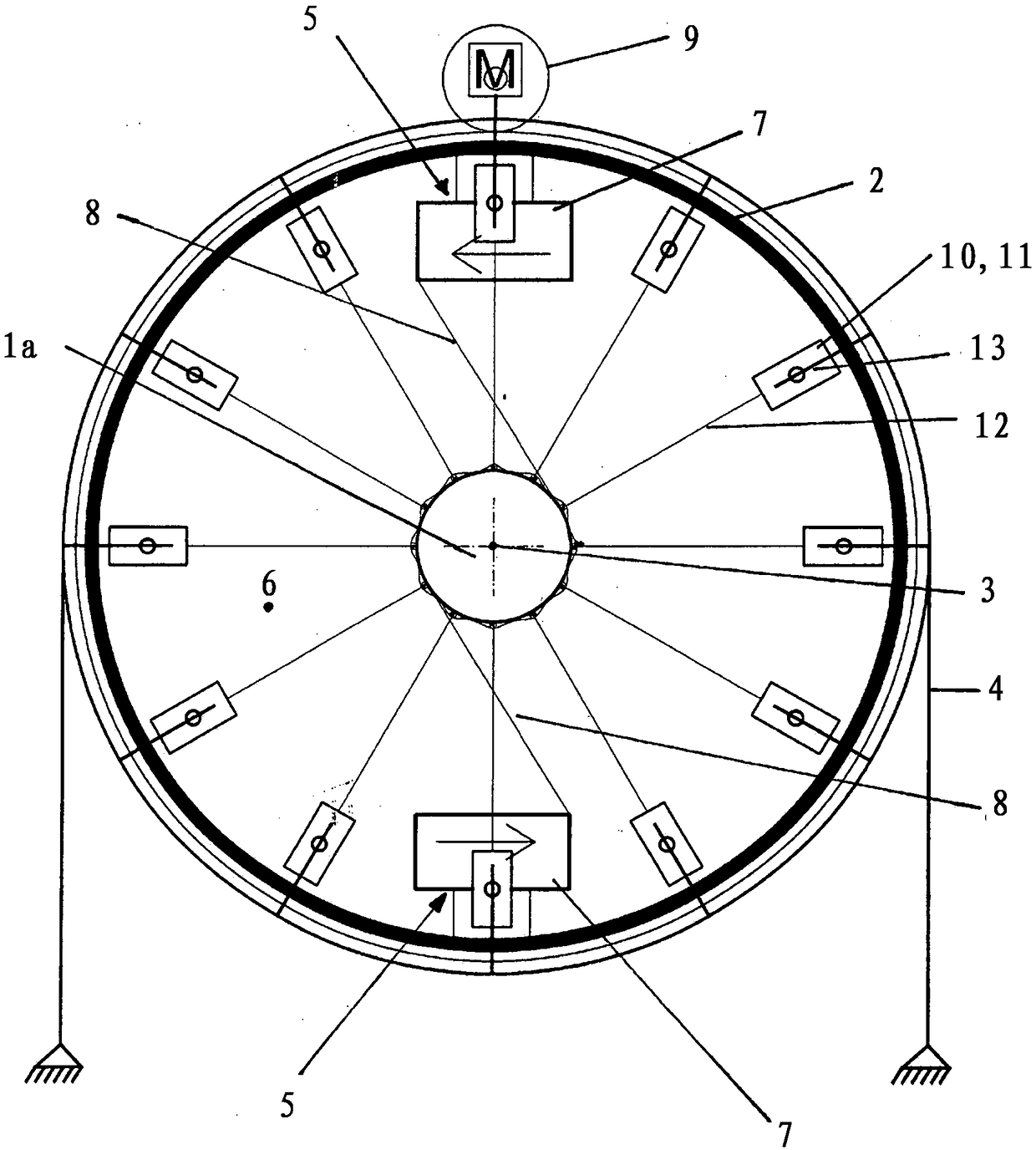

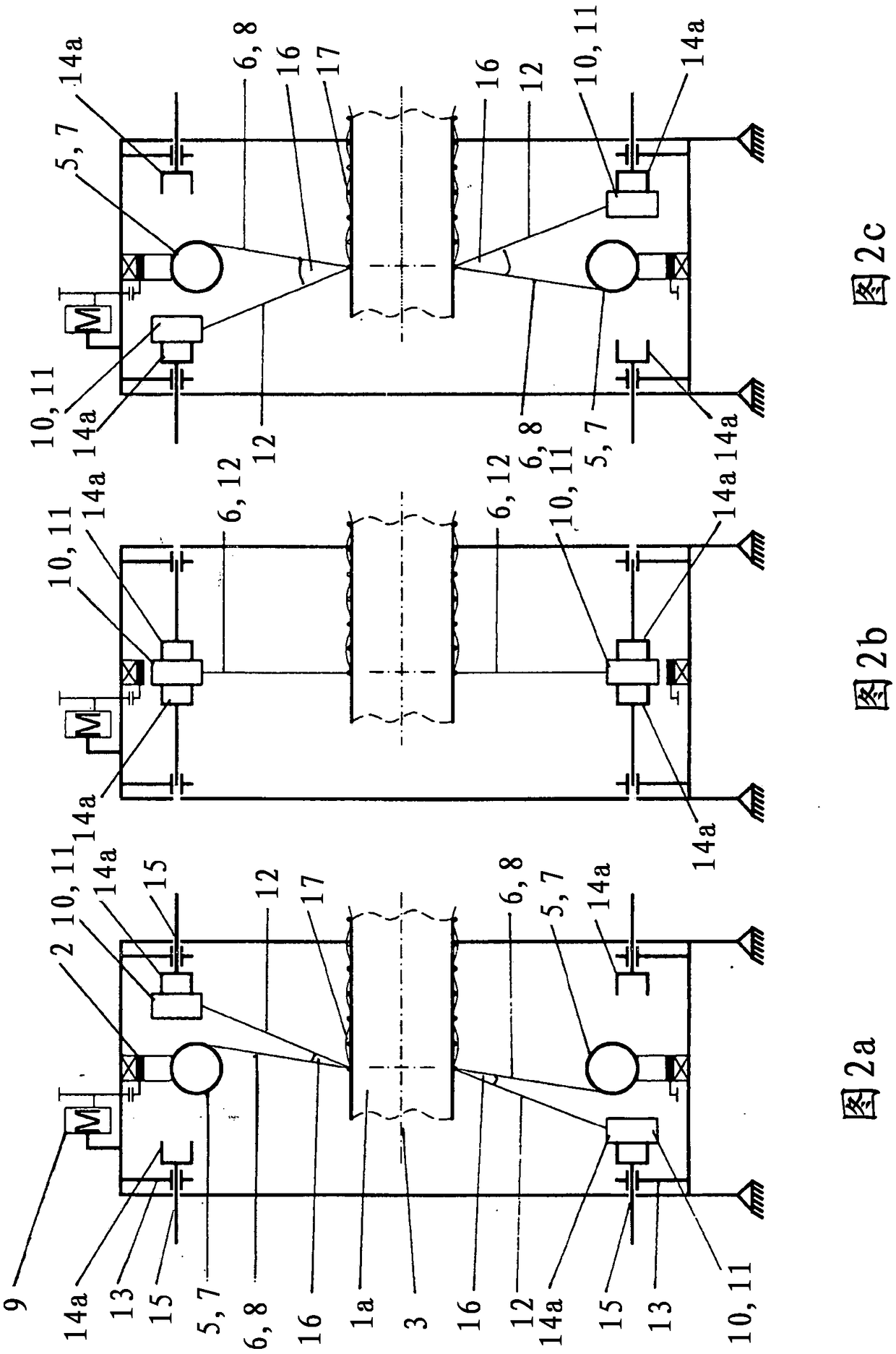

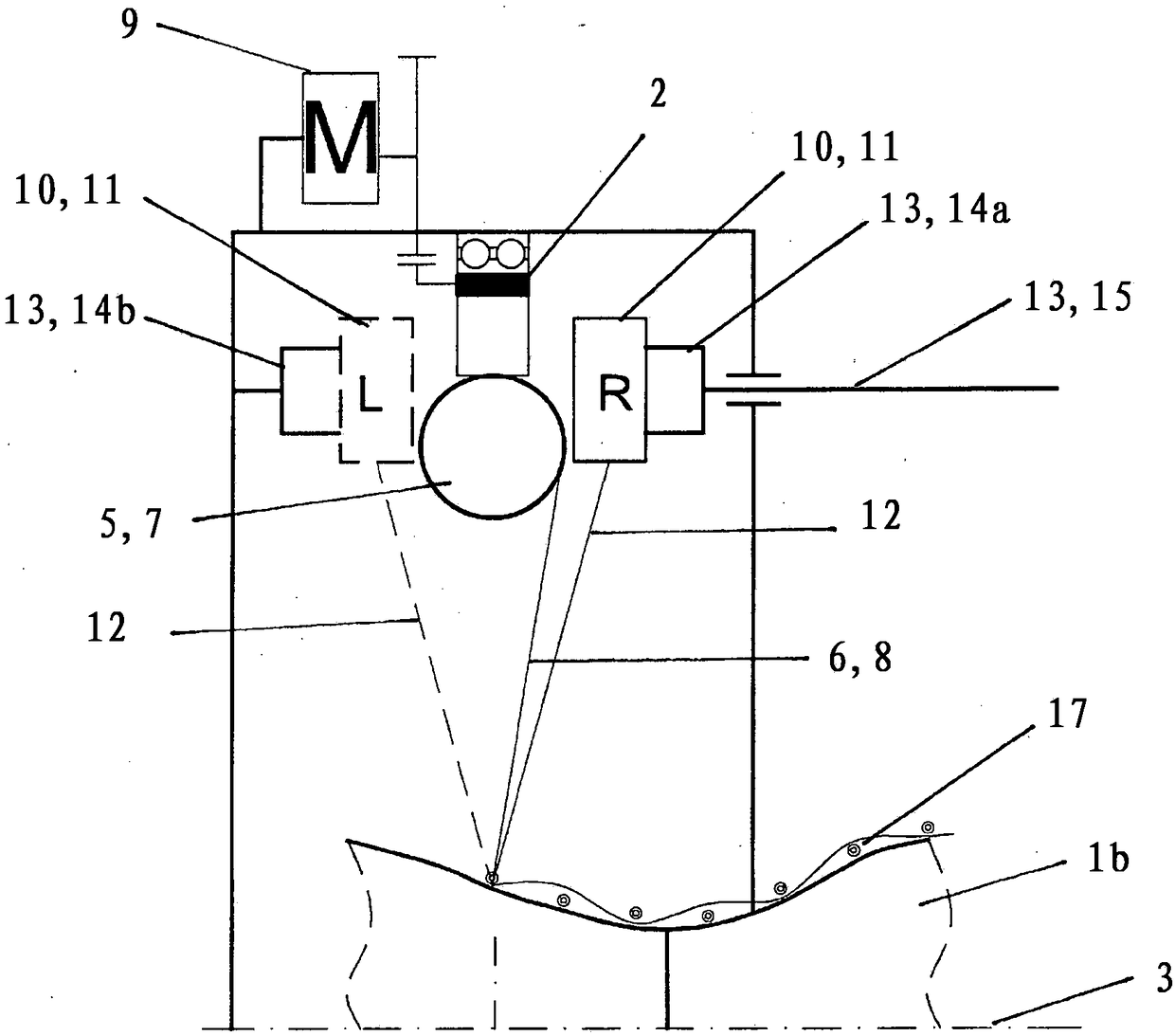

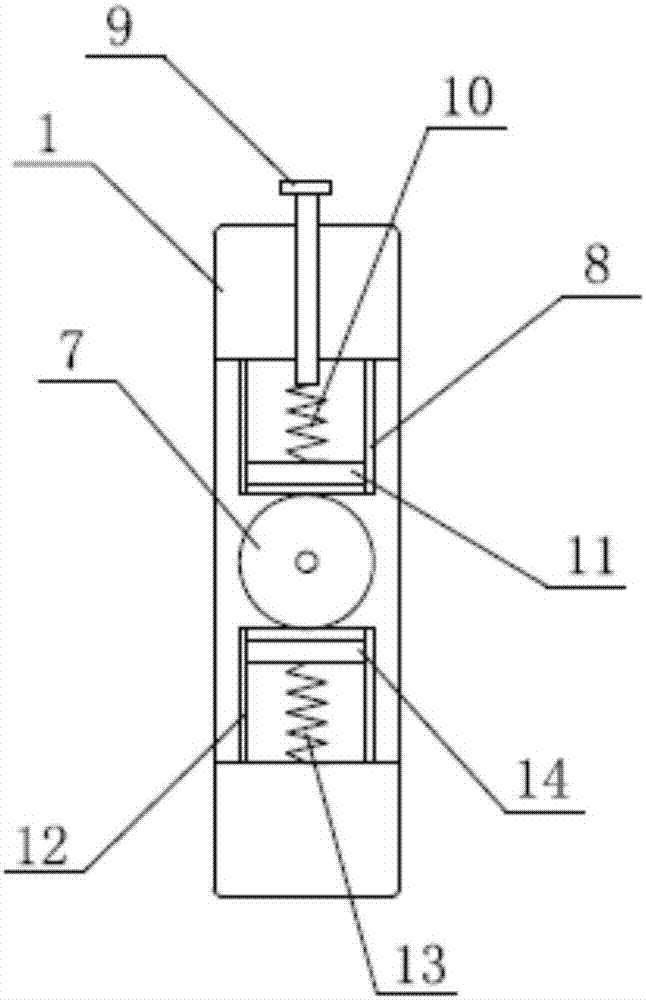

Plastic circular weaving machine

InactiveCN102677369AIncrease weaving speedReduce power consumptionCircular loomsElectric machineryPropeller

The invention discloses a plastic circular weaving machine comprising a main machine (1), a let-off system (2), a wrap-up device (3) and a stand (5), wherein the main machine comprises a main motor (11), a transmission system, a warp opening and crossing mechanism and a weft guiding mechanism; the weft guiding mechanism comprises an upper door ring (21), a lower door ring (22), a connection column (23), eight shuttles (24) and eight propellers (25); the transmission system comprises a belt wheel (12), a main shaft (13) and a support (14); and the length of each shuttle (24) is equal to or less than 300mm. According to the technical scheme of the invention, the weaving speed of the plastic circular weaving machine is improved, the power consumption as well as the failure rate and flawed cloth rate of the plastic circular weaving machine is reduced, the service lives of a shuttle wheel and a balance wheel are prolonged, and the structure of the circular weaving machine is simplified.

Owner:HENGYI PLASTIC EQUIP MFG

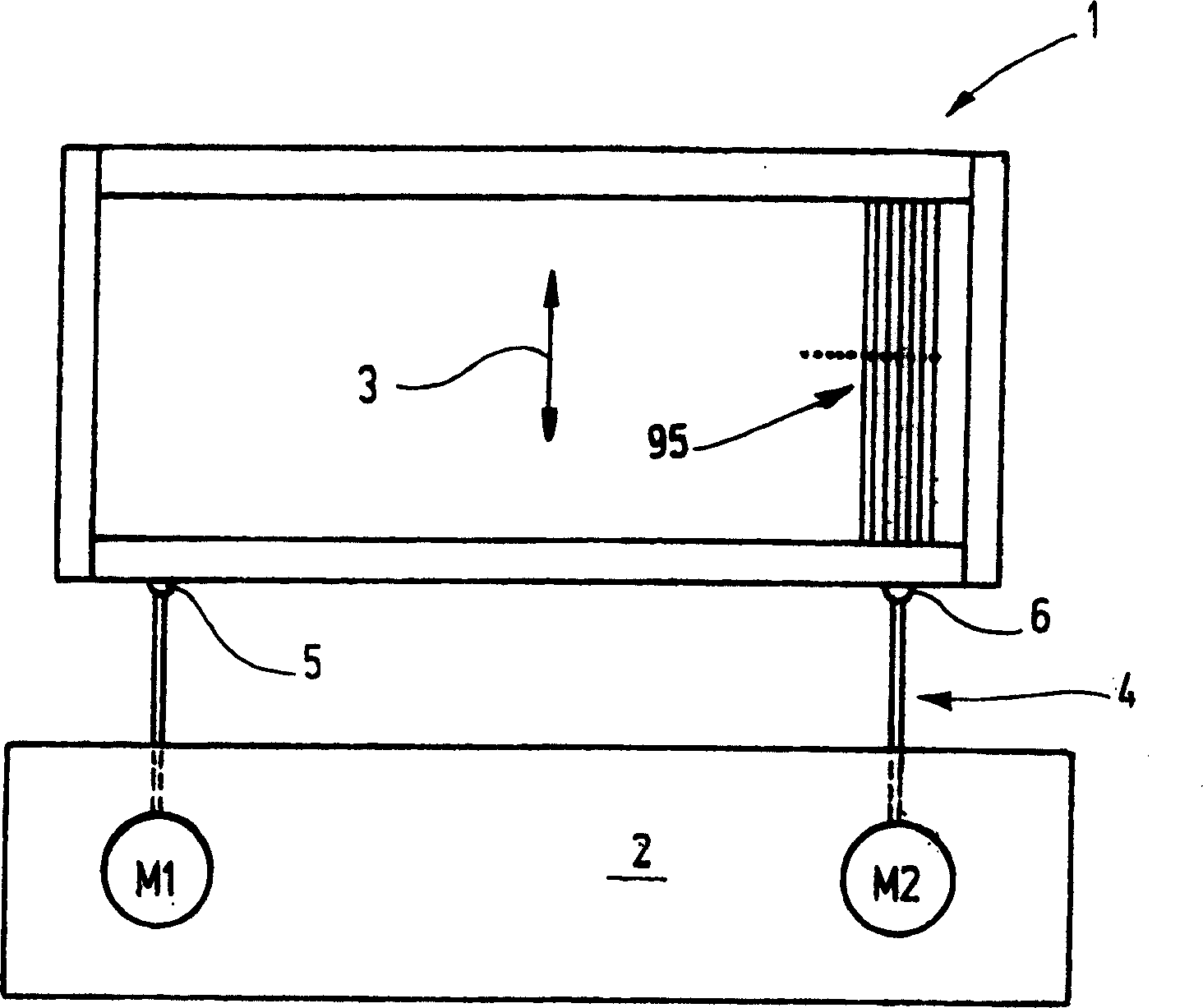

Horizontal moving mechanism for needle bed of computer flat knitting machine

InactiveCN102534985AMove quicklyIncrease weaving speedWeft knittingElectric machineryElectrical and Electronics engineering

The invention relates to a horizontal moving mechanism for a needle bed of a computer flat knitting machine, which belongs to the technical field of knitting mechanisms. The computer flat knitting machine comprises a rack, a front needle bed and a rear needle bed, wherein a rack cavity is formed on the bottom part of the rack; the front needle bed is arranged on the front side of the rack; and the rear needle bed is arranged on the rear side of the rack and is corresponding to the front needle bed. The horizontal moving mechanism for the needle bed comprises a screw bracket, a front needle bed driving device, a rear needle bed driving device, a front needle bed position signal collecting device, a rear needle bed position signal collecting device, a first signal sensing device and a second signal sensing device, wherein the screw bracket is arranged in the rack cavity and is fixed with the rack; a motor base is arranged on one end of the screw bracket; the front needle bed driving device is arranged on the screw bracket; the rear needle bed driving device is arranged on the screw bracket; the front needle bed position signal collecting device is fixedly arranged on the upper part on one side of the screw bracket; the rear needle bed position signal collecting device is fixedly arranged on the upper part on the other side of the screw bracket; the first signal sensing device is fixed with the front needle bed driving device; and the second signal sensing device is fixed with the rear needle bed driving device. The horizontal moving mechanism for the needle bed of the computer flat knitting machine has the advantages of wide application range, high production efficiency and simple overall structure, and the computer flat knitting machine in the prior art can be configured as well.

Owner:江苏雪亮电器机械有限公司

Heald, particularly for rapidly running weaving machines

Owner:GROZ BECKERT KG

Heddle shaft with center connector

InactiveUS7137415B2Increase weaving speedLittle playHealdsOther shedding mechanismEngineeringMechanical engineering

Owner:GROZ BECKERT KG

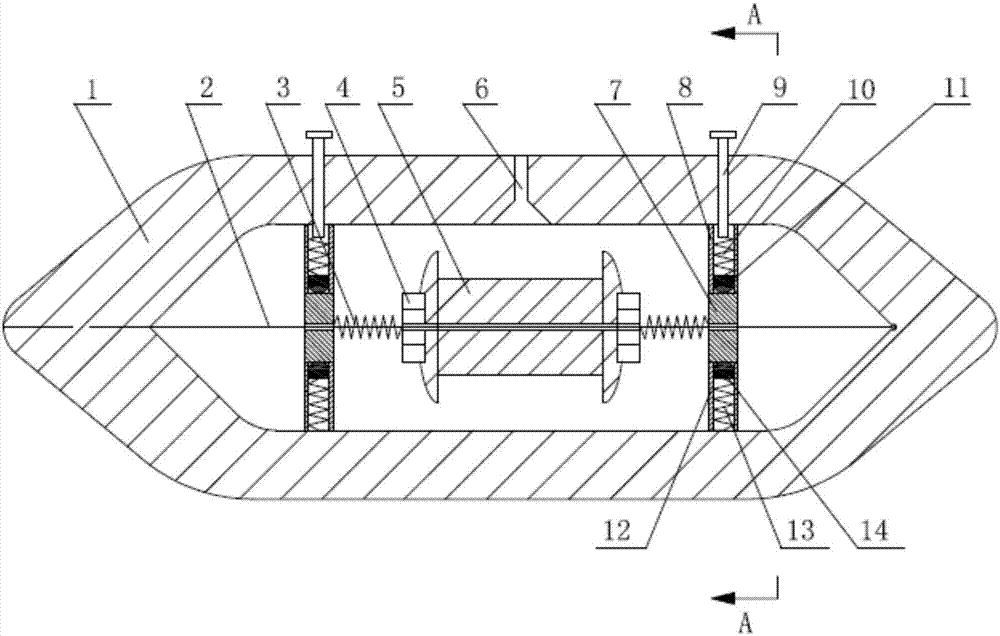

A loom shuttle with a weft tension controller

The invention discloses a loom shuttle with weft yarn tension controllers. The loom shuttle comprises a shell, the two weft yarn tension controllers and rotary springs. A cavity is arranged in the middle of the shell, a yarn guide opening is formed in the shell, a spool for storing weft yarns is arranged in the shell and sleeves an axial fixing steel wire in the shell, and the two symmetrical weft yarn tension controllers are arranged on two sides of the spool and comprise rotary discs, lower sleeves and upper sleeves; lower half cylinders and lower springs are arranged in the lower sleeves, the lower half cylinders upper half cylinders are in contact with the rotary discs, upper half cylinders, upper springs and upper adjusting screws are arranged in the upper sleeves, the upper half cylinders are in contact with the rotary discs, and the upper adjusting screws are in contact with the upper springs; the rotary springs are connected with the rotary discs and the spool. The loom shuttle has the advantages that the problem of fringe of fabrics due to loose weft yarns in weaving procedures of looms can be effectively solved by the aid of the loom shuttle, and accordingly the quality level of woven products can be upgraded; tension of weft yarns can be uniformly controlled, accordingly, weft yarn breakage phenomena can be prevented, and the weaving efficiency can be improved; the weaving speeds can be increased, and the production cost can be reduced; the loom shuttle is simple in structure and low in repair and maintenance cost.

Owner:SUZHOU UNIV

Drying anti-craking method of rattans

InactiveCN107263646AReduce breakageAvoid breakingWood treatment detailsReed/straw treatmentEngineeringBreakage rate

The invention mainly relates to the technical field of weaving handicrafts, and discloses a method for drying and preventing cracking of rattan, comprising: rattan fermentation, primary drying, and secondary drying; the method is simple, easy to operate, and reduces the fracture rate of rattan weaving by 8.5% %, drying and anti-cracking are treated at the same time, the treatment time is shortened to 17-18 days, the utilization rate of the rattan is improved, and the production cost is saved; after the fresh rattan bark is stacked, the fermentation liquid is sprayed and covered with a black plastic film, Promote the proliferation of Lactobacillus plantarum and yeast in the fermentation broth, slowly ferment the rattan, gradually reduce the pH to 4.6~4.8, and produce extracellular metabolites rich in polypeptides, polysaccharides and fats, which gradually penetrate into the rattan tissue and soften the rattan bark And the fiber structure of the rattan core, so that both the rattan bark and the rattan core can be used for weaving, which improves the weaving performance of the rattan and reduces breakage.

Owner:安徽宏润工艺品有限公司

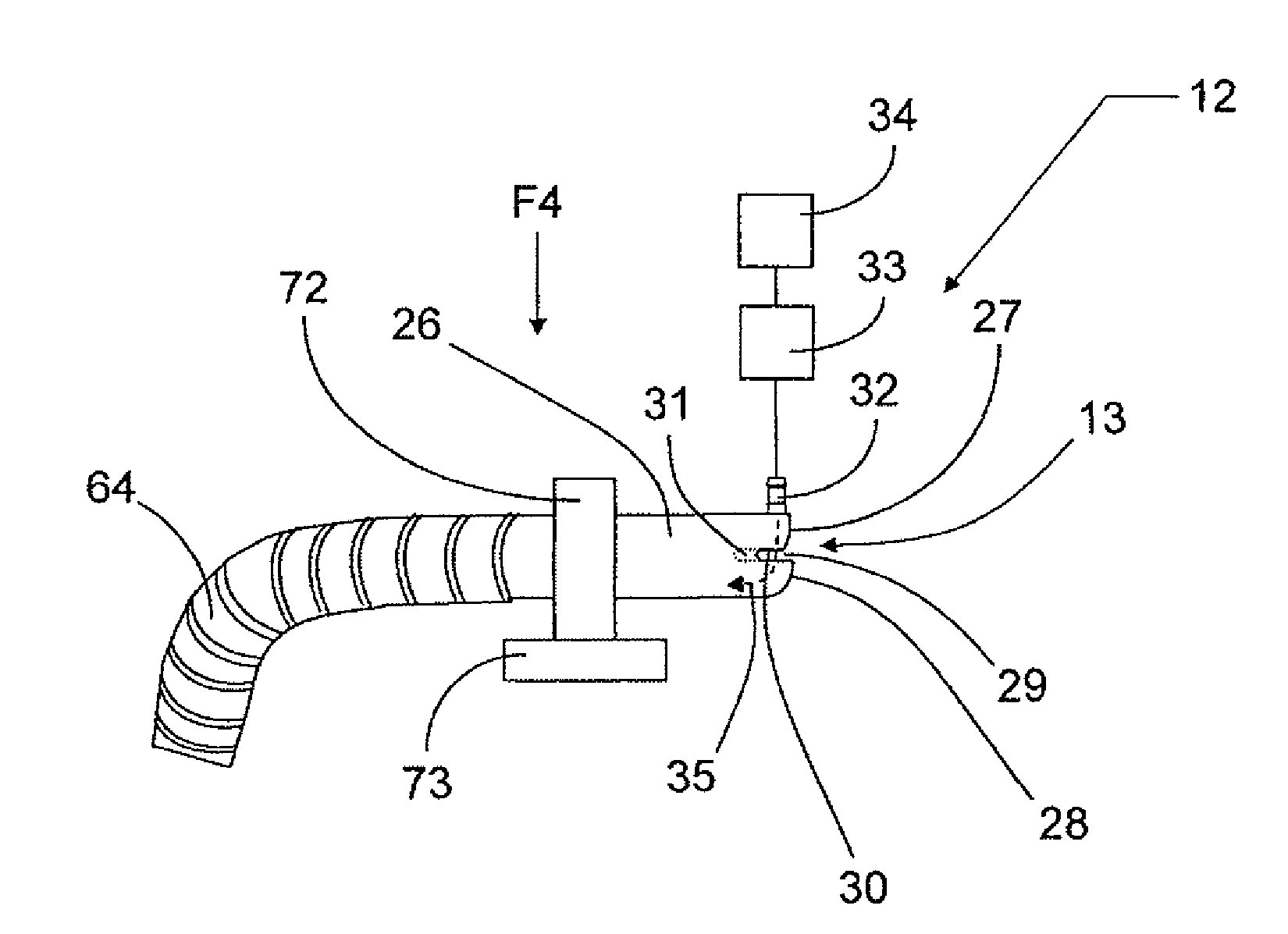

Weaving machine, yarn feeder and method for inserting a weft yarn

A projectile-weaving machine is equipped with a weft yarn feeder having a stationary storage body for intermediately storing a yarn store consisting of windings, the weft feeder comprising a passive hollow balloon breaker functionally associated to a withdrawal rim of the storage body. In addition to the passive balloon breaker, several yarn control elements are separated in circumferential direction for being actively moved by a drive from an outer rest position into an inner operative position which without totally stopping withdrawn weft yarn are brought into a mechanical engagement on the weft yarn upstream from the withdrawal rim and starting with an end phase of an insertion on the weft yarn while the weft yarn is taken off from the yarn store over the withdrawal rim.

Owner:IRO AB

Device for controlling the transverse movement of the warp threads of a textile weaving machine

InactiveUS7806146B2Small space requirementIncrease weaving speedJacquardsDobbiesProcessor registerSingle strand

In order to solve the problem of not having enough space available for a large number of components and keeping the deflection of the electric motor small in a device for controlling the transverse movement of the warp threads of a textile weaving machine, particularly a textile weaving machine with single strand movements, the invention proposes to operatively connect the strands via power transmission elements having different lengths in a staggered or register-like way to an electric motor and to provide the electric motors with a ratio in relation to the strands such that the movement of the electric motors brings about a greater movement of the strands.

Owner:TEXTILMA AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com