Filling knitting machine

A technology of flat knitting machine and triangular carriage, which is used in textiles and papermaking, instruments, weft knitting, etc., can solve the problem of high machine body, and achieve the effects of improving weaving speed, reducing rigidity and easy setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

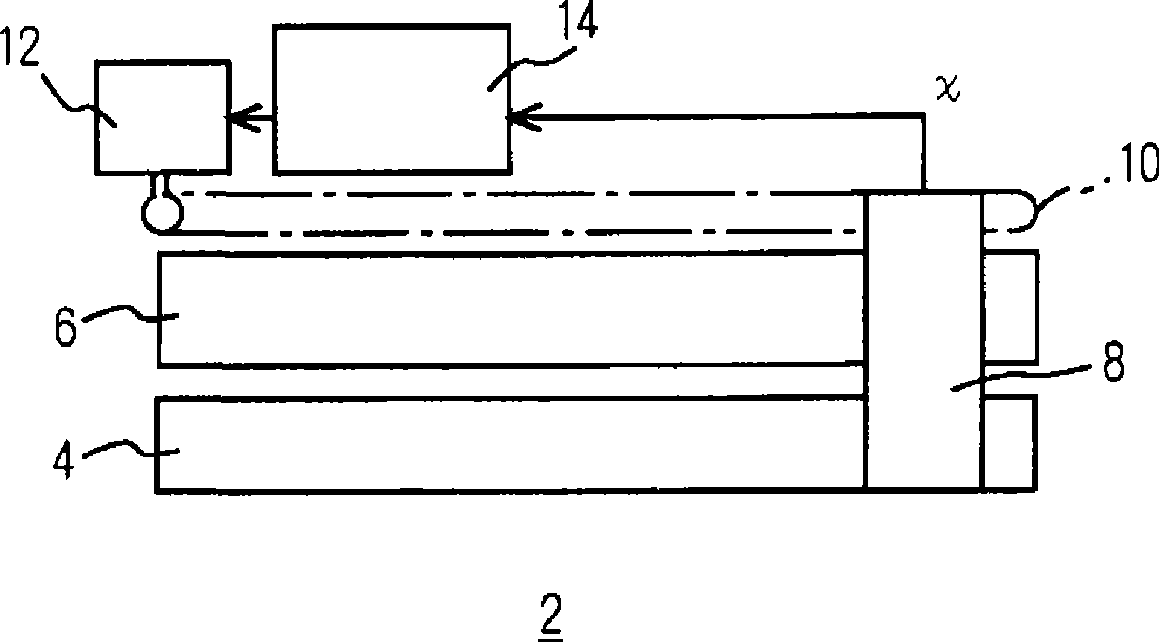

[0033] Figure 1 to Figure 5 The flat knitting machine 2 of the embodiment and its operation are shown. In each figure, 4 is a needle bed on the front side, 6 is a needle bed on the rear side, each may be one, or each may be two or each three, 8 is a carriage, and 8 is a carriage. The needle beds 4 , 6 are reciprocated, for example, by an endless belt 10 . 10 is a toothed belt, but it may also be a chain, and a pair may be provided at the front and back of the needle bed 4 . Furthermore, the carriage may be moved by a linear motor or the like. 12 is a travel motor, which drives the belt 10 to make the carriage 8 travel. 14 is the control part of the flat knitting machine 2.

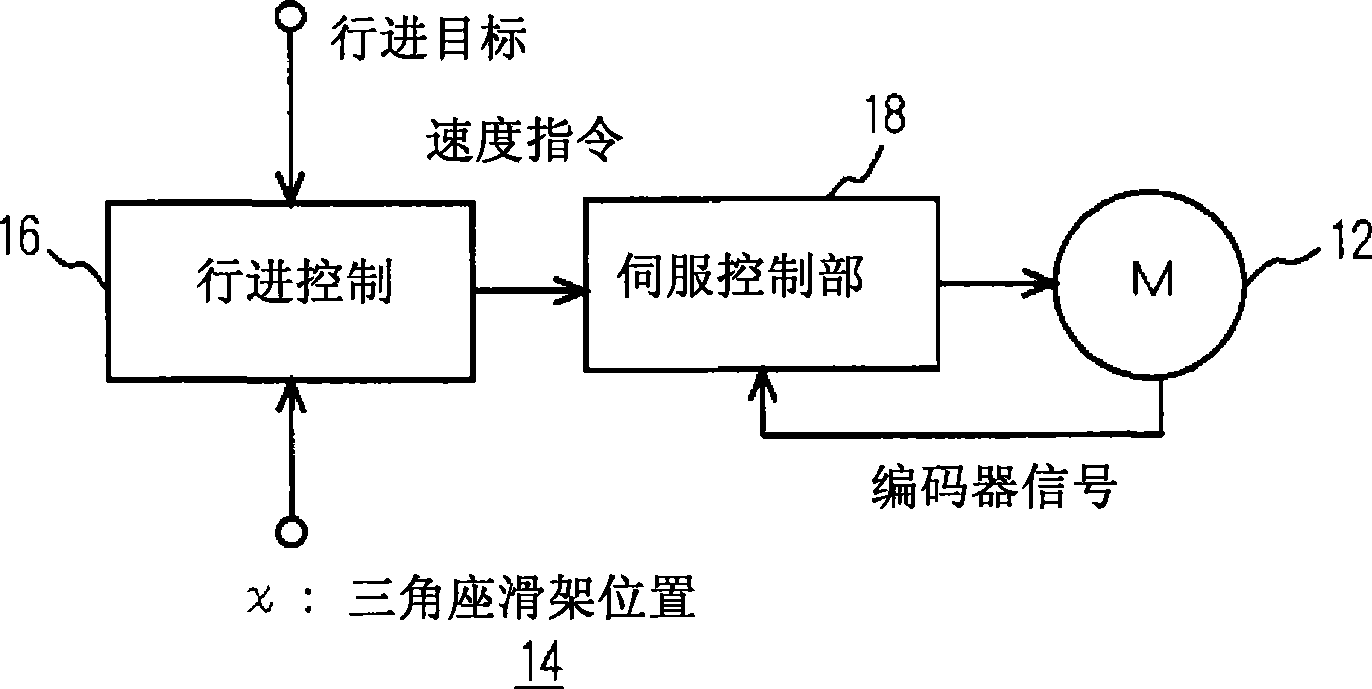

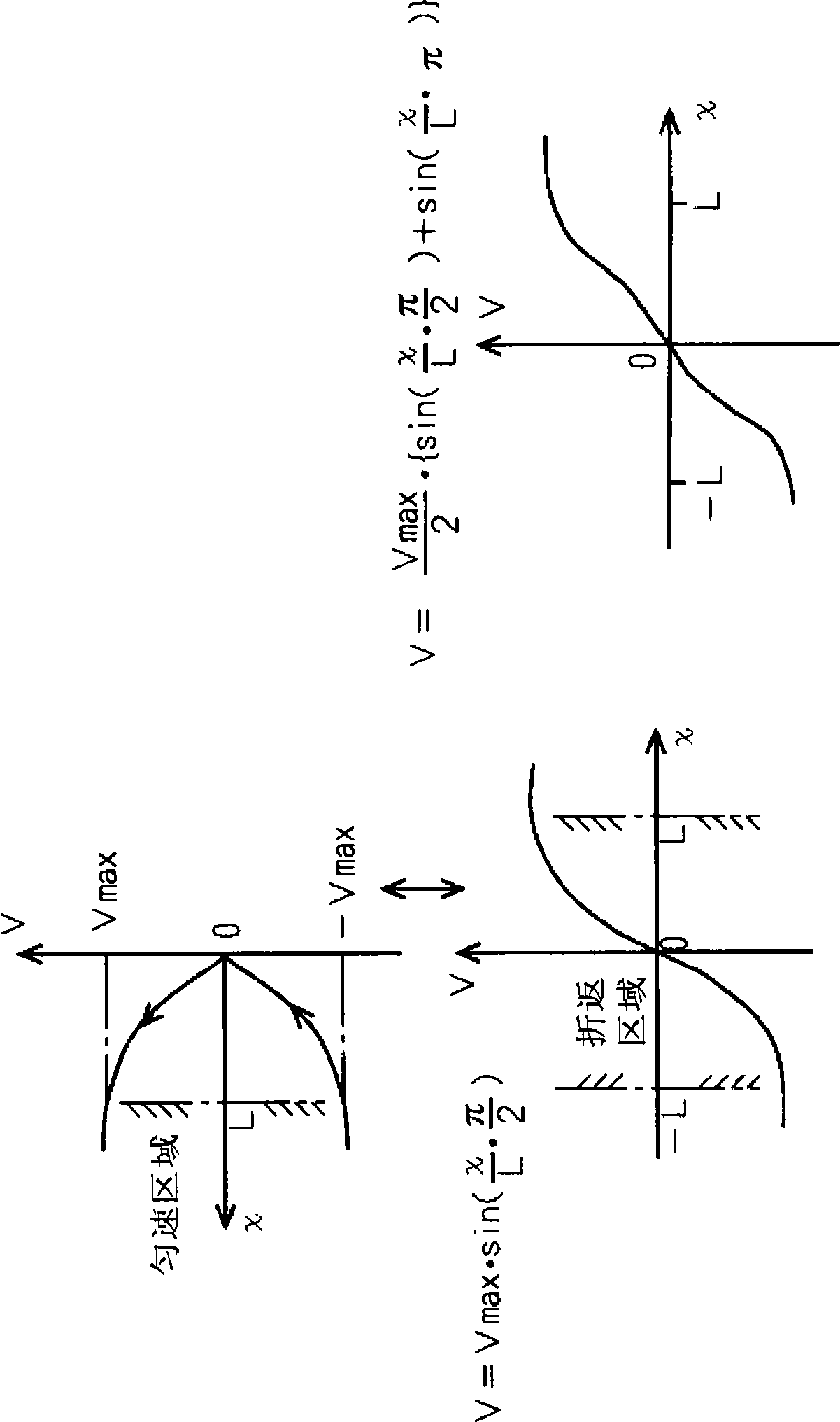

[0034] Such as figure 2 As shown, the travel control unit 16 inputs a travel target such as the position of a turning point from a not-shown upper-level control unit, and inputs a position x of the carriage 8 from a not-shown sensor. The travel control unit 16 generates a speed command based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com